Qualification of a Ni–Cu Alloy for the Laser Powder Bed Fusion Process (LPBF): Its Microstructure and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

3. Results

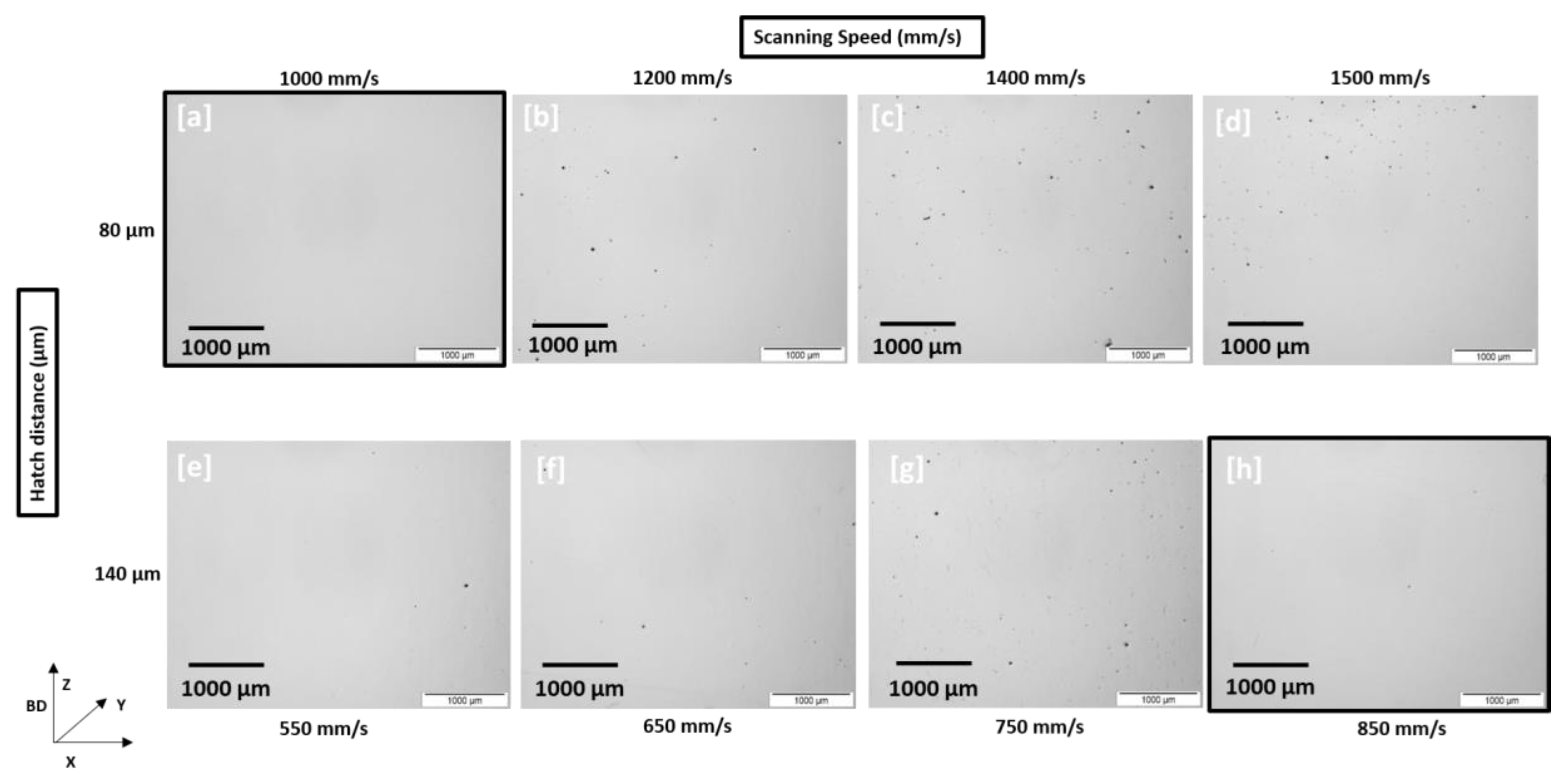

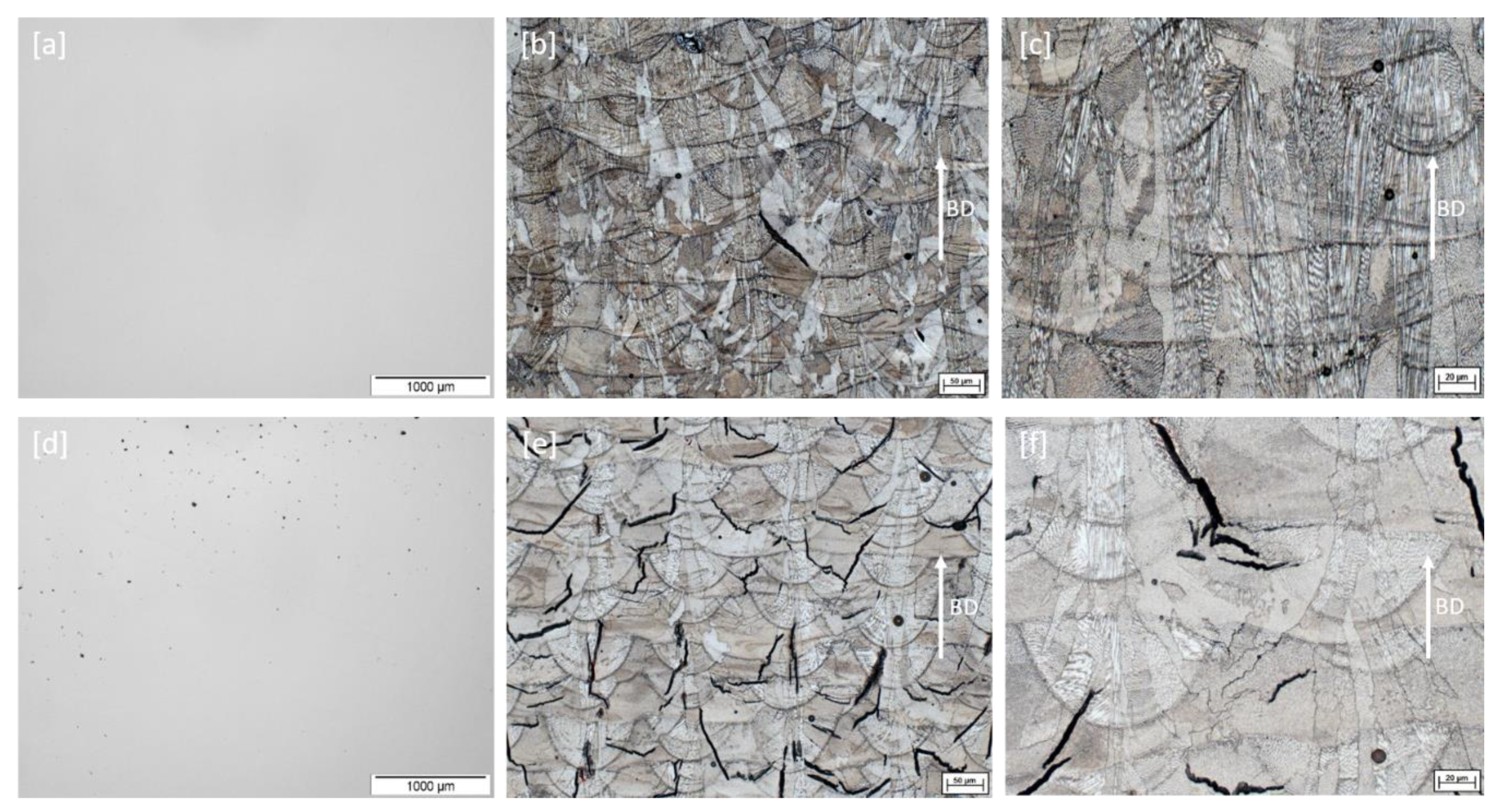

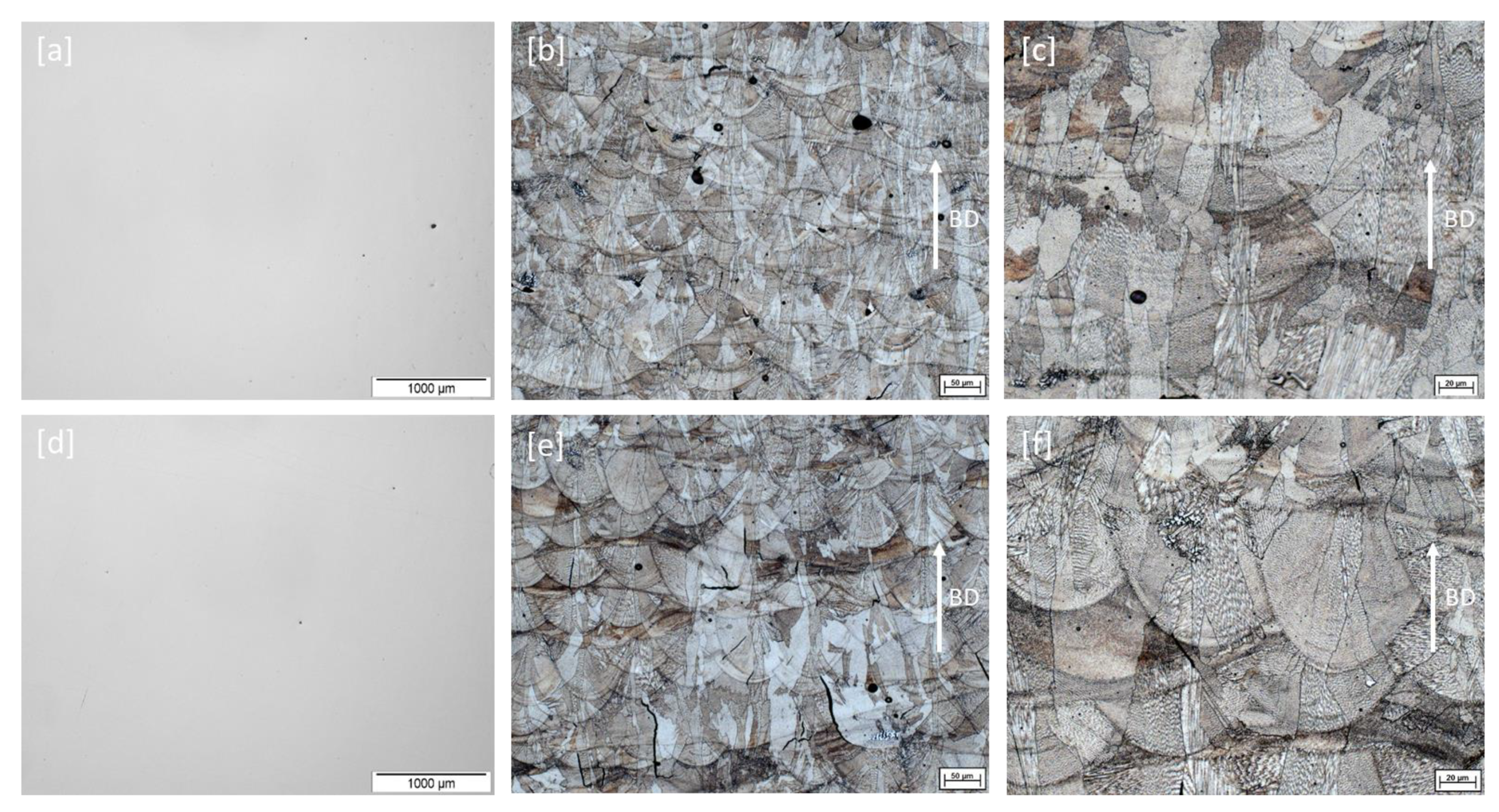

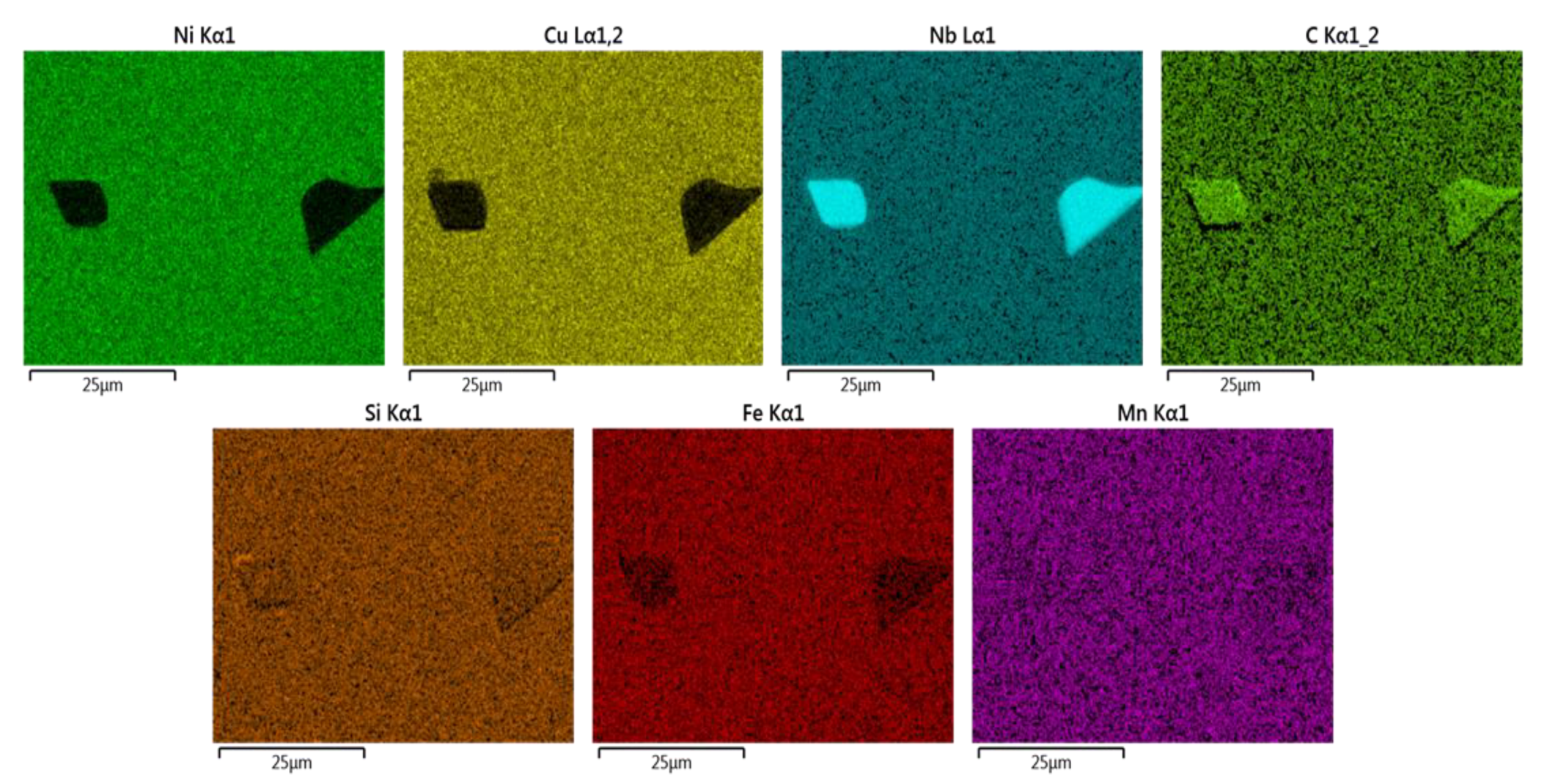

3.1. As-Built LPBF Micrographs

3.2. As-Cast Micrographs

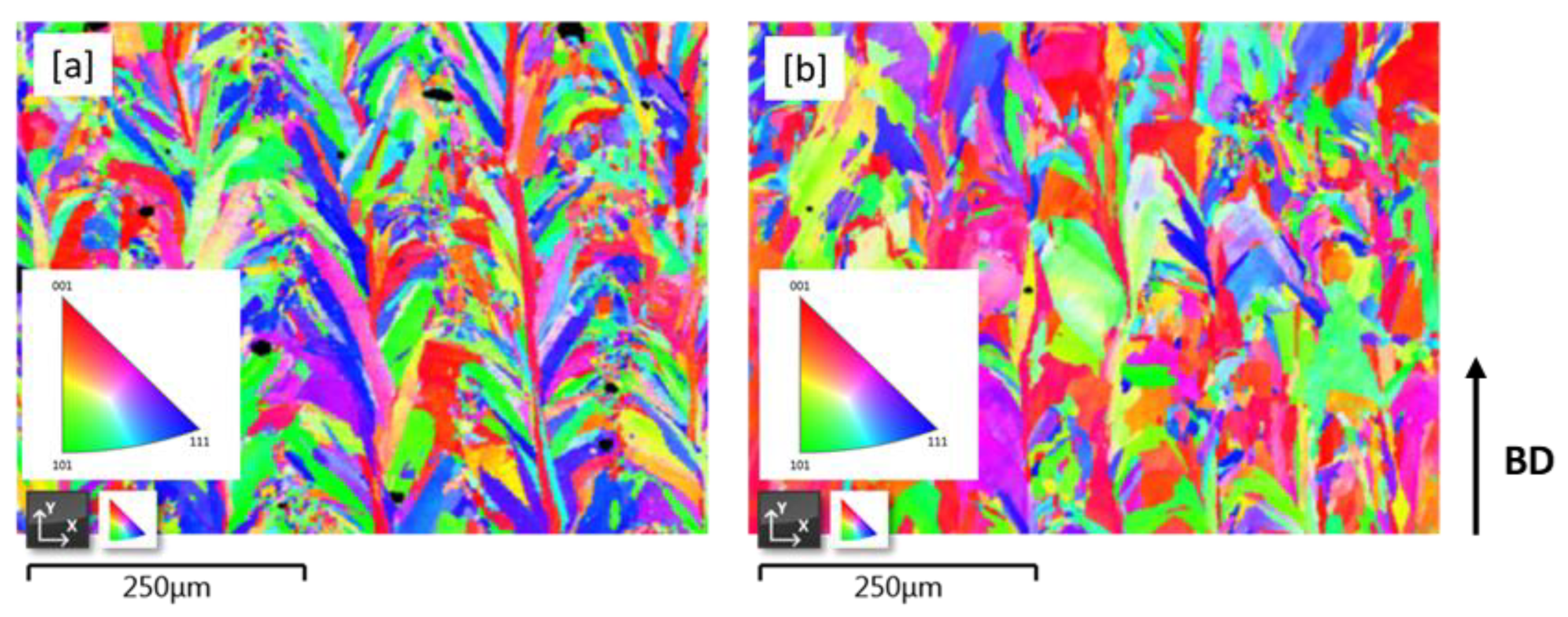

3.3. EBSD Measurement of As-Built Samples

3.4. Mechanical Properties

3.4.1. Microhardness

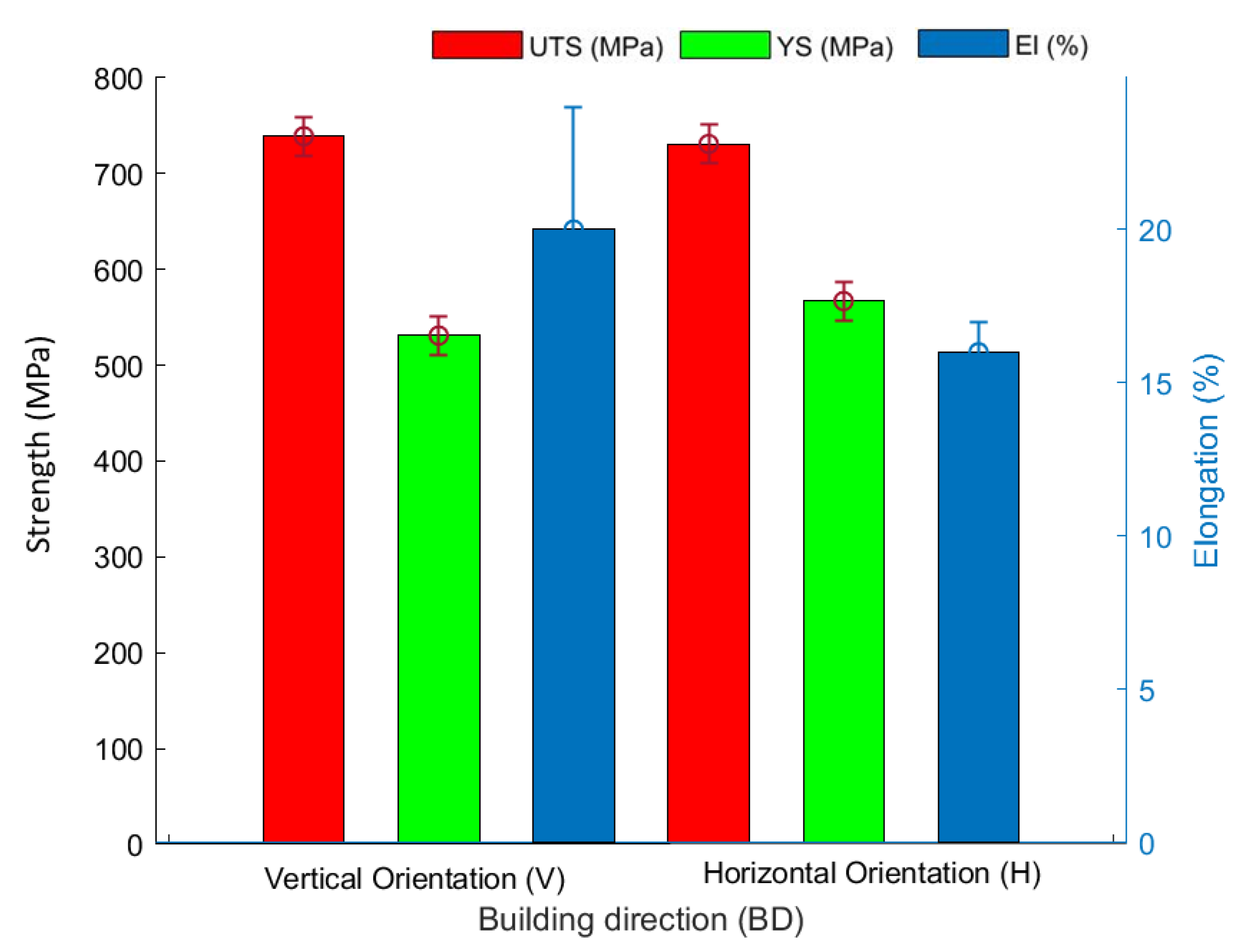

3.4.2. Tensile Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lippold, J.C.; Kisser, S.D.; Dupont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2011; p. 456. [Google Scholar]

- Esgin, U.; Özyürek, D.; Kaya, H. An investigation of wear behaviors of different Monel alloys produced by powder metallurgy. AIP Conf. Proc. 2016, 1727. [Google Scholar] [CrossRef] [Green Version]

- Xiaoping, Z.; Wenzhang, C. Experimental Research on Heating Performance of Monel K-500 Alloy. Adv. Mater. Res. 2012, 572, 273–277. [Google Scholar] [CrossRef]

- Kutz, M. Handbook of Materials Selection; John Wiley & Sons, Inc.: New York, NY, USA, 2002; pp. 237–241. [Google Scholar]

- Barsanescu, P.-D.; Leitoiu, B.; Goanta, V.; Cantemir, D.; Gherasim, S. Reduction of Residual Stresses Induced by Welding in Monel Alloy, Using Parallel Heat Welding. Int. J. Acad. 2011, 3, 335–339. [Google Scholar]

- Neenu, J.; Jobil, V. Study on Behavior of Steel, Monel and Inconel at Elevated Temperature. IJEDR 2015, 3, 327–331. [Google Scholar]

- Devendranath, R.K.; Arivazhagan, N.; Narayanan, S. Effect of filler materials on the performance of gas tungsten arc welded AISI 304 and Monel 400. Mater. Des. 2012, 40, 70–79. [Google Scholar] [CrossRef]

- Devendranath, R.K.; Arivazhagan, V.; Narayanan, S.; Mukund, N.; Arjun, M.; Raunak, K. Development of defect free Monel 400 welds for marine application. Adv. Mater. Res. 2012, 383–390, 4695. [Google Scholar] [CrossRef]

- Ventrella, V.A.; Berretta, J.R.; De-Rossi, W. Micro Welding of Ni-based Alloy Monel 400 Thin Foil by Pulsed Nd:YAG laser. Phys. Procedia 2011, 12, 347–354. [Google Scholar] [CrossRef] [Green Version]

- Kukliński, M.; Bartkowska, A.; Przestacki, D. Microstructure and selected properties of Monel 400 alloy after laser heat treatment and laser boriding using diode laser. Int. J. Adv. Manuf. Tech. 2018, 98, 3005–3017. [Google Scholar] [CrossRef] [Green Version]

- Bopp, C.; Santhanam, K. Corrosion Protection of Monel Alloy Coated with Graphene Quantum Dots Starts with a Surge. ChemEngineering 2019, 3, 80. [Google Scholar] [CrossRef] [Green Version]

- Himanshu, B.S. Surface roughness modeling of Ni -Co based alloy using RSM. Int. J. Emerg. Trends Res. 2016, 1, 29–39. [Google Scholar]

- Davis, J.R. Nickel, Cobalt, and Their Alloys, 1st ed.; ASM International: Novelty, OH, USA, 2000; pp. 294–295. [Google Scholar]

- Zils, R. Werkstoffe im Pumpenbau. Chem. Ing. Tech. 2008, 80. [Google Scholar] [CrossRef]

- Lee, F.T.; Major, J.F.; Samuel, F.H. Fracture Behaviour Of A112wt.%Si0.35wt.%Mg(O-O.O2)wt.%Sr Casting Alloys Under Fatigue Testing. Fatigue Fract. Eng. Mater. Struct. 1995, 18, 385–396. [Google Scholar] [CrossRef]

- Röhrig, K.E. Guss aus Hochkorrosionsbeständigen Nickel-Basislegirerungen. Available online: https://www.kug.bdguss.de/fileadmin/content/Publikationen-NormenRichtlinien/Guss_aus_hoch_korr.best._Nickelleg.pdf (accessed on 10 March 2020).

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of Materials Qualification Needs for Metal Additive Manufacturing. JOM 2016, 68. [Google Scholar] [CrossRef] [Green Version]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Marenych, O.; Kostryzhev, A.; Shen, C.; Pan, Z.; Li, H.; Van Duin, S. Precipitation Strengthening in Ni–Cu Alloys Fabricated Using Wire Arc Additive Manufacturing Technology. Metals 2019, 9, 105. [Google Scholar] [CrossRef] [Green Version]

- Labudovic, M.; Hu, D.; Kovacevic, R. A three dimensional model for direct laser metal powder deposition and rapid prototyping. J. Mater. Sci. 2003, 38, 35–49. [Google Scholar] [CrossRef]

- Anderson, R.; Terrell, J.; Schneider, J.; Thompson, S.; Gradl, P. Characteristics of Bi-metallic Interfaces Formed during Direct Energy Deposition Additive Manufacturing Processing. Metall. Mater. Trans. B 2019, 50, 1921–1930. [Google Scholar] [CrossRef]

- Raffeis, I.; Adjei-Kyeremeh, F.; Vroomen, U.; Suwampinij, P.; Ewald, S.; Bührig-Polaczek, A. Investigation of the Lithium-Containing Aluminum Copper Alloy (AA2099) for the Laser Powder Bed Fusion Process [L-PBF]: Effects of Process Parameters on Cracks, Porosity, and Microhardness. JOM 2019, 71, 1543–1553. [Google Scholar] [CrossRef]

- Mugwagwa, L.; Yadroitsev, I.; Matope, S. Effect of Process Parameters on Residual Stresses, Distortions, and Porosity in Selective Laser Melting of Maraging Steel 300. Metals 2019, 9, 1042. [Google Scholar] [CrossRef] [Green Version]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. 2006, 12, 265. [Google Scholar] [CrossRef]

- Nguejioa, J.; Szmytkaa, F.; Hallaisb, S.; Tanguyb, A.; Nardonec, S.; Godino Martinezc, M. Comparison of microstructure features and mechanical properties for additive manufactured and wrought nickel alloys 625. Mater. Sci. Eng. A 2019, 764, 138214. [Google Scholar] [CrossRef]

- Pourbabak, S.; Montero-Sistiaga, M.L.; Schryvers, V.; Van Humbeeck, J.; Vanmeensel, K. Microscopic investigation of as built and hot isostatic pressed Hastelloy X processed by Selective Laser Melting. Mater. Charact. 2019, 153. [Google Scholar] [CrossRef]

- Raghavana, S.; Baicheng, Z.; Pei, W.; Chen-Nan, S.; Mui, L.S.N.; Tao, L.; Jun, W. Effect of different heat treatments on the microstructure and mechanical properties in selective laser melted INCONEL 718 alloy. Mater. Manuf. Process. 2016. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.Y.; Weaver, M.Y.; Guo, B. Microstructure Evolution Characteristics of Inconel 625 Alloy from Selective Laser Melting to Heat Treatment. Mater. Sci. Eng. A 2017. [Google Scholar] [CrossRef]

- Kulkarni, A. Additive Manufacturing of Nickel Based Superalloys. arXiv 2018, arXiv:1805.11664. [Google Scholar]

- Aminipour, N.; Derakhshandeh-Haghighi, R. The Effect of Weld Metal Composition on Microstructural and Mechanical Properties of Dissimilar Welds between Monel 400 and Inconel 600. J. Mater. Eng. Perform. 2019, 28, 6111. [Google Scholar] [CrossRef]

- Debidutta, M.; Vignesh, M.K.; Ganesh, R.B.; Pruthvi, S.; Devendranath, K.R.; Arivazhagan, N.; Narayanan, S. Mechanical Characterization of Monel 400 and 316 Stainless Steel Weldments. Procedia Eng. 2014, 75, 24–28. [Google Scholar]

- Chlebus, E.; Grubern, K.; Kuźnicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

- McLouth, T.D.; Witkin, D.B.; Bean, G.E.; Sitzman, S.D.; Adams, P.M.; Lohser, J.R.; Yang, J.-M.; Zaldivar, R.J. Variations in ambient and elevated temperature mechanical behavior of IN718 manufactured by selective laser melting via process parameter control. Mater. Sci. Eng. A 2020, 780, 139–184. [Google Scholar] [CrossRef]

- Marchese, G.; Garmendia, X.C.; Calignano, F.; Lorusso, M.; Biamino, S.; Minetola, P.; Manfredi, D. Characterization and Comparison of Inconel 625 Processed by Selective Laser Melting and Laser Metal Deposition. Adv. Eng. Mater. 2017, 19. [Google Scholar] [CrossRef]

- Yan, F.; Xiong, W.; Faierson, E.J. Grain Structure Control of Additively Manufactured Metallic Materials. Materials 2017, 10, 1260. [Google Scholar] [CrossRef] [Green Version]

- Seede, R.; Mostafa, A.; Brailovski, V.; Jahazi, M.; Medraj, M. Microstructural and Microhardness Evolution from Homogenization and Hot Isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases. J. Manuf. Mater. Process. 2018, 2, 30. [Google Scholar] [CrossRef] [Green Version]

- Brandt, M.; Sun, S.; Leary, M.; Feih, S.; Elambasseril, J.; Liu, Q. High-Value SLM Aerospace Components: From Design to Manufacture. Adv. Mater. Res. 2013, 147, 633. [Google Scholar] [CrossRef]

- Shifeng, W.; Shuai, L.; Qingsong, W.; Yan, C.; Sheng, Z.; Yusheng, S. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 214, 2660–2667. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of Hatch Spacing on Melt Pool and As-built Quality During Selective Laser Melting of Stainless Steel: Modeling and Experimental Approaches. Materials 2019, 12, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, S.; Brandt, M.; Easton, M. Powder Bed Fusion Processes: An Overview, Laser Additive Manufacturing-Materials, Design, Technologies, and Applications; Centre for Additive Manufacturing: Melbourne, Australia, 2017; pp. 55–77. [Google Scholar]

- Hanzl, P.; Zetek, M.; Bakša, T.; Kroupa, T. The Influence of Processing Parameters on the Mechanical Properties of SLM. Parts Procedia Eng. 2015, 100, 1405–1413. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef] [Green Version]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and Control of Powder Properties for Additive Manufacturing. JOM 2015, 67. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Kunze, K.; Etter, T.; Grässlinc, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical propertiesof IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2014, 620, 213–222. [Google Scholar] [CrossRef]

- Deev, A.A.; Kuznetcov, P.A.; Petrov, S.N. Anisotropy of Mechanical properties and its correlation with the structure of the stainless steel 316L produced by SLM Method. Phys. Procedia 2016, 83, 789–796. [Google Scholar] [CrossRef] [Green Version]

- Etter, T.; Kunze, K.; Geiger, F.; Meidani, H. Reduction in mechanical anisotropy through high temperature heat treatment of Hastelloy Xprocessed by Selective Laser Melting (SLM). IOP Conf. Ser. Mater. Sci. Eng. 2015, 82, 012097. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. 2018, 92, 112–224. [Google Scholar] [CrossRef]

| Material: G-NiCu30Nb | Nominal Composition (wt.%) | ||||||

|---|---|---|---|---|---|---|---|

| Ni | Cu | Nb | Fe | Mn | Si | Al | |

| Cast | 60.25 | 31.28 | 2.87 | 3.28 | 1.00 | 1.38 | 0.10 |

| Gas atomized powder | 59.39 | 29.89 | 3.87 | 3.68 | 0.99 | 1.65 | 0.53 |

| Sample | Laser Power (W) | Layer Thickness (µm) | Scanning Speed (mm/s) | Hatch Distance (µm) | Relative Density (%) |

|---|---|---|---|---|---|

| 2a | 200 | 30 | 1000 | 80 | 99.80 |

| 2b | 200 | 30 | 1200 | 80 | 99.72 |

| 2c | 200 | 30 | 1400 | 80 | 99.63 |

| 2d | 200 | 30 | 1500 | 80 | 99.70 |

| 2e | 200 | 30 | 550 | 140 | 99.78 |

| 2f | 200 | 30 | 650 | 140 | 99.77 |

| 2g | 200 | 30 | 750 | 140 | 99.71 |

| 2h | 200 | 30 | 850 | 140 | 99.80 |

| Material: G-NiCu30Nb | HV0.2 |

|---|---|

| As-Cast | 179 |

| LPBF as-built cube (ys =80 µm) | 247 |

| LPBF as-built + PHT (ys = 80 µm) | 221 |

| LPBF as-built cube (ys = 140 µm) | 244 |

| LPBF as-built + PHT (ys = 140 µm) | 210 |

| Material: G-NiCu30Nb | |||

|---|---|---|---|

| UTS (MPa) | YS (MPa) | El (%) | |

| As-Cast [16] | 450 | 170 | 25 |

| LPBF as-built (V) at r.t.p | 739 | 531 | 20 |

| LPBF as-built (H) at r.t.p | 731 | 567 | 16 |

| LPBF as-built + PHT (V) | 674 | 408 | 31 |

| LPBF as-built + PHT (H) | 665 | 417 | 25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raffeis, I.; Adjei-Kyeremeh, F.; Vroomen, U.; Westhoff, E.; Bremen, S.; Hohoi, A.; Bührig-Polaczek, A. Qualification of a Ni–Cu Alloy for the Laser Powder Bed Fusion Process (LPBF): Its Microstructure and Mechanical Properties. Appl. Sci. 2020, 10, 3401. https://doi.org/10.3390/app10103401

Raffeis I, Adjei-Kyeremeh F, Vroomen U, Westhoff E, Bremen S, Hohoi A, Bührig-Polaczek A. Qualification of a Ni–Cu Alloy for the Laser Powder Bed Fusion Process (LPBF): Its Microstructure and Mechanical Properties. Applied Sciences. 2020; 10(10):3401. https://doi.org/10.3390/app10103401

Chicago/Turabian StyleRaffeis, Iris, Frank Adjei-Kyeremeh, Uwe Vroomen, Elmar Westhoff, Sebastian Bremen, Alexandru Hohoi, and Andreas Bührig-Polaczek. 2020. "Qualification of a Ni–Cu Alloy for the Laser Powder Bed Fusion Process (LPBF): Its Microstructure and Mechanical Properties" Applied Sciences 10, no. 10: 3401. https://doi.org/10.3390/app10103401

APA StyleRaffeis, I., Adjei-Kyeremeh, F., Vroomen, U., Westhoff, E., Bremen, S., Hohoi, A., & Bührig-Polaczek, A. (2020). Qualification of a Ni–Cu Alloy for the Laser Powder Bed Fusion Process (LPBF): Its Microstructure and Mechanical Properties. Applied Sciences, 10(10), 3401. https://doi.org/10.3390/app10103401