Effect of Thickness Ratio Coefficient on the Mixture Transportation Characteristics of Helical–Axial Multiphase Pumps

Abstract

1. Introduction

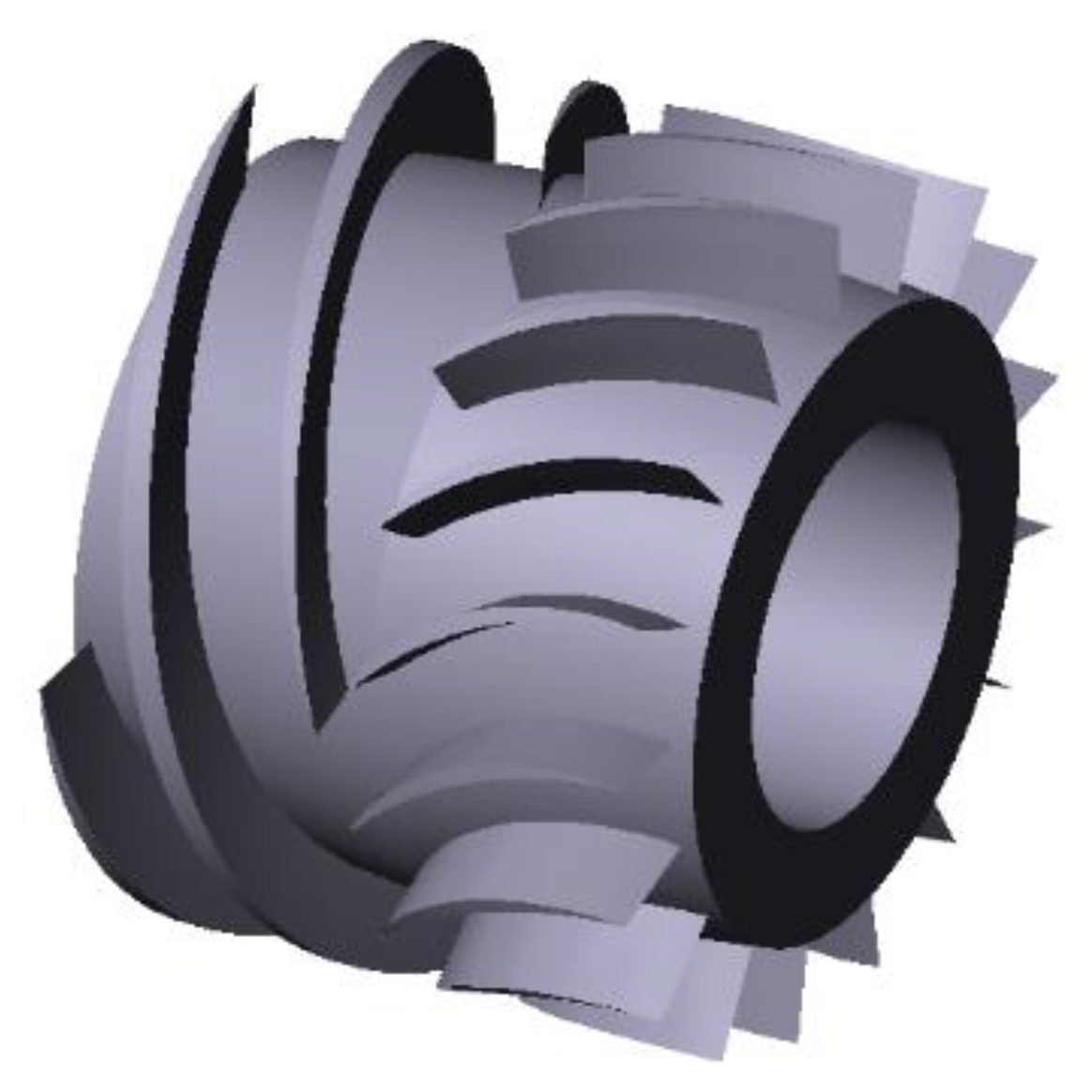

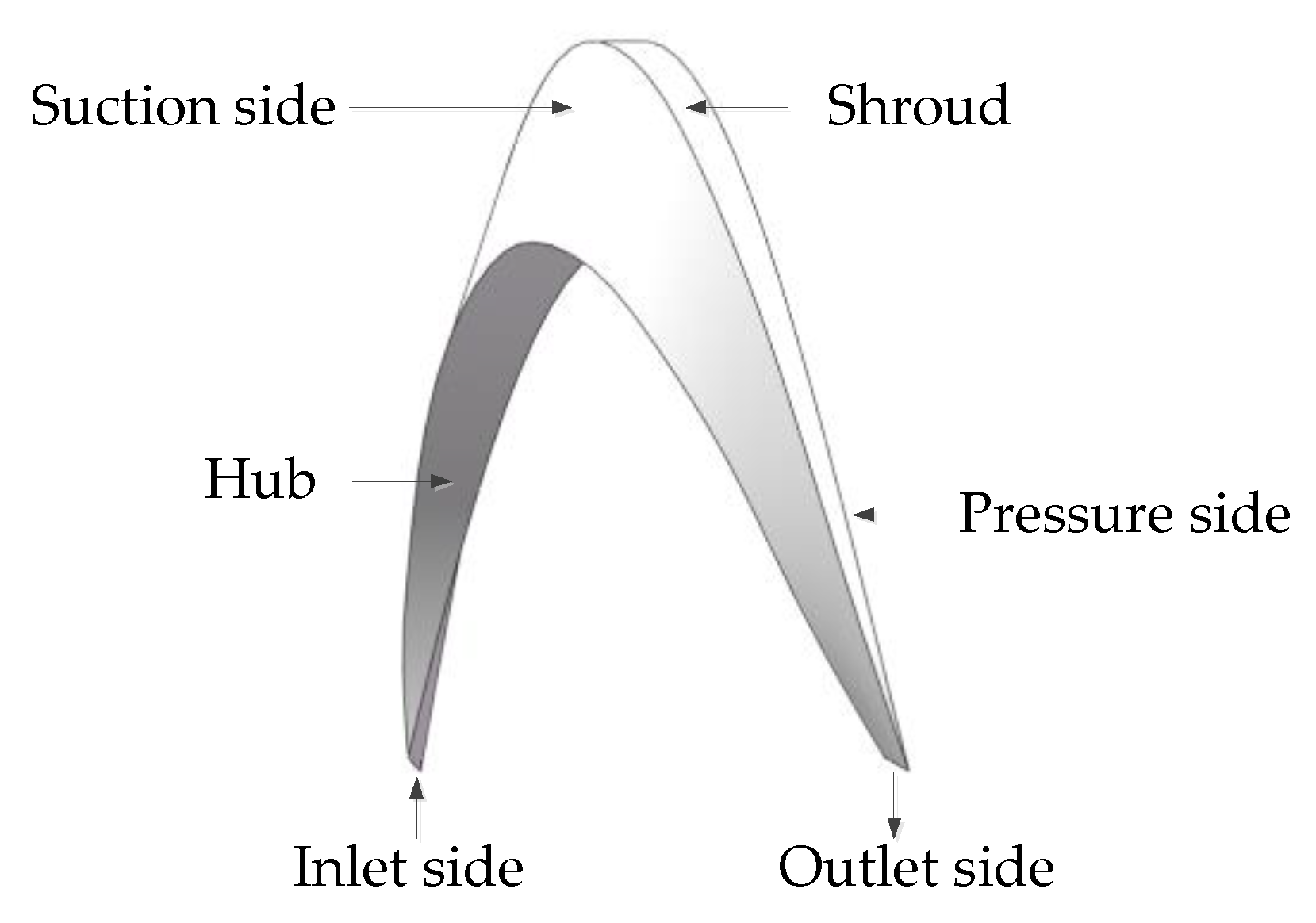

2. Design and Modeling of Helical–Axial Multiphase Pump

2.1. Parameter Determination

2.2. Model Establishment

2.3. Mesh Generation

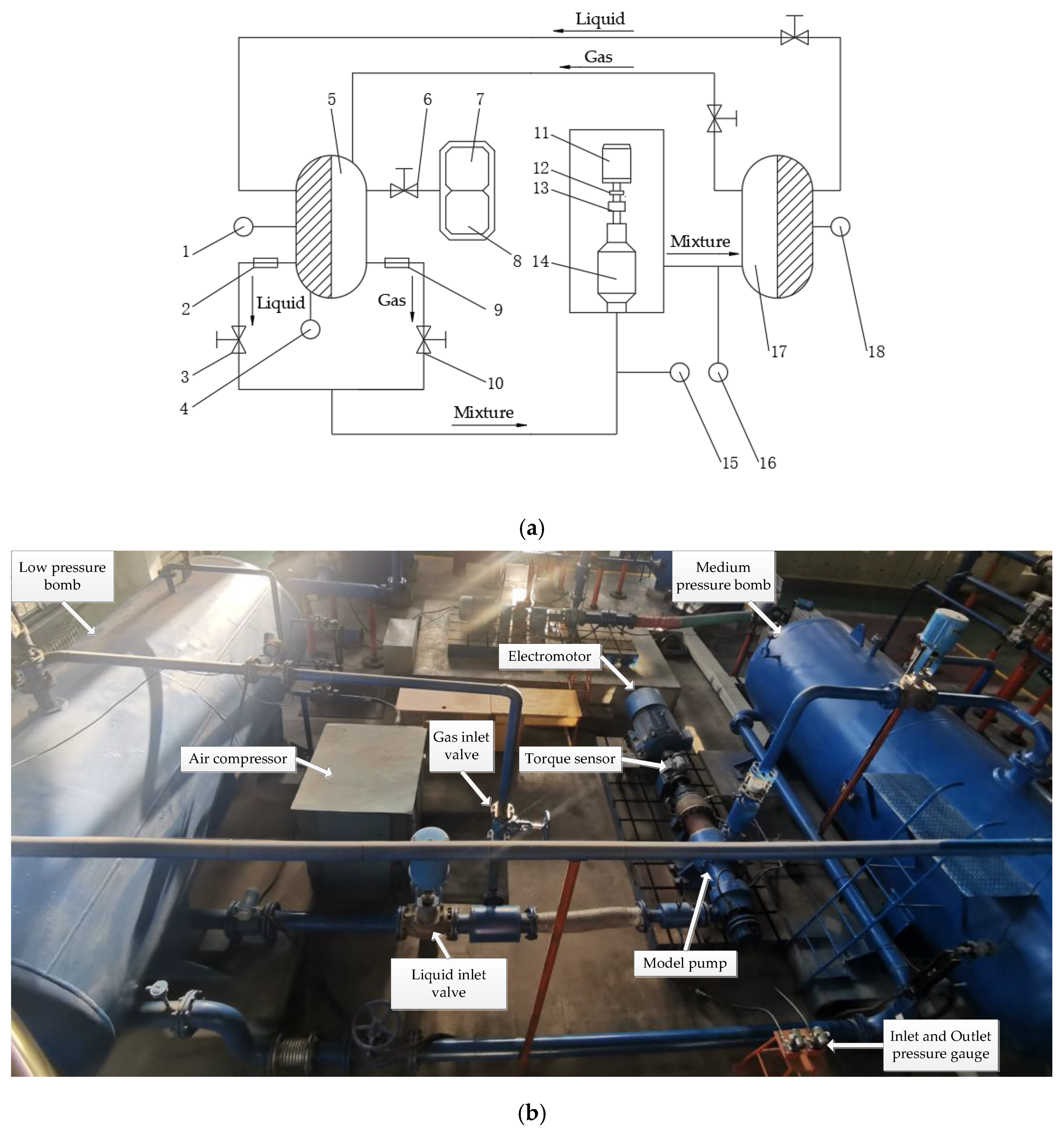

3. Numerical Simulation and Results Analysis

3.1. Numerical Method

3.2. Boundary Condition

3.3. Setting of the Numerical Calculation

3.4. Governing Equations

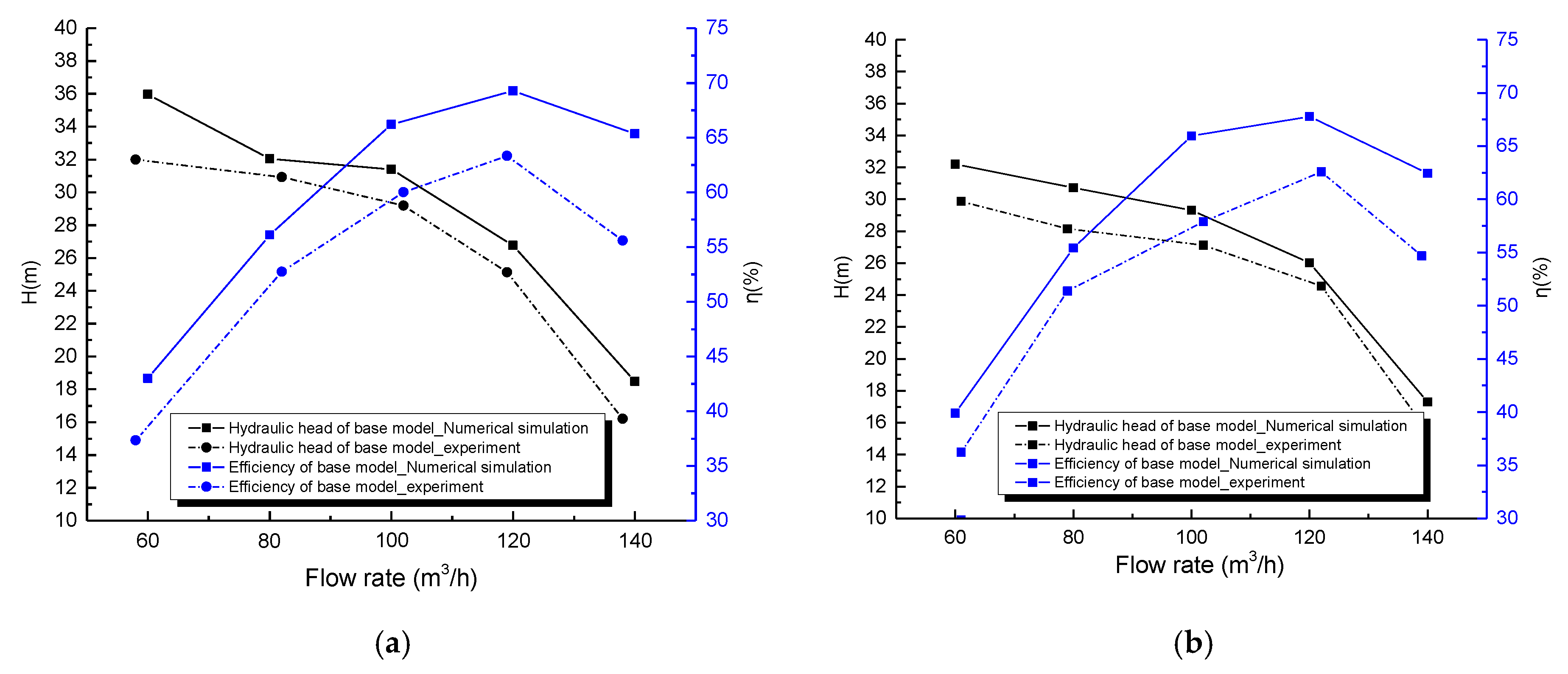

3.5. Analysis of Simulation and Experimental Results

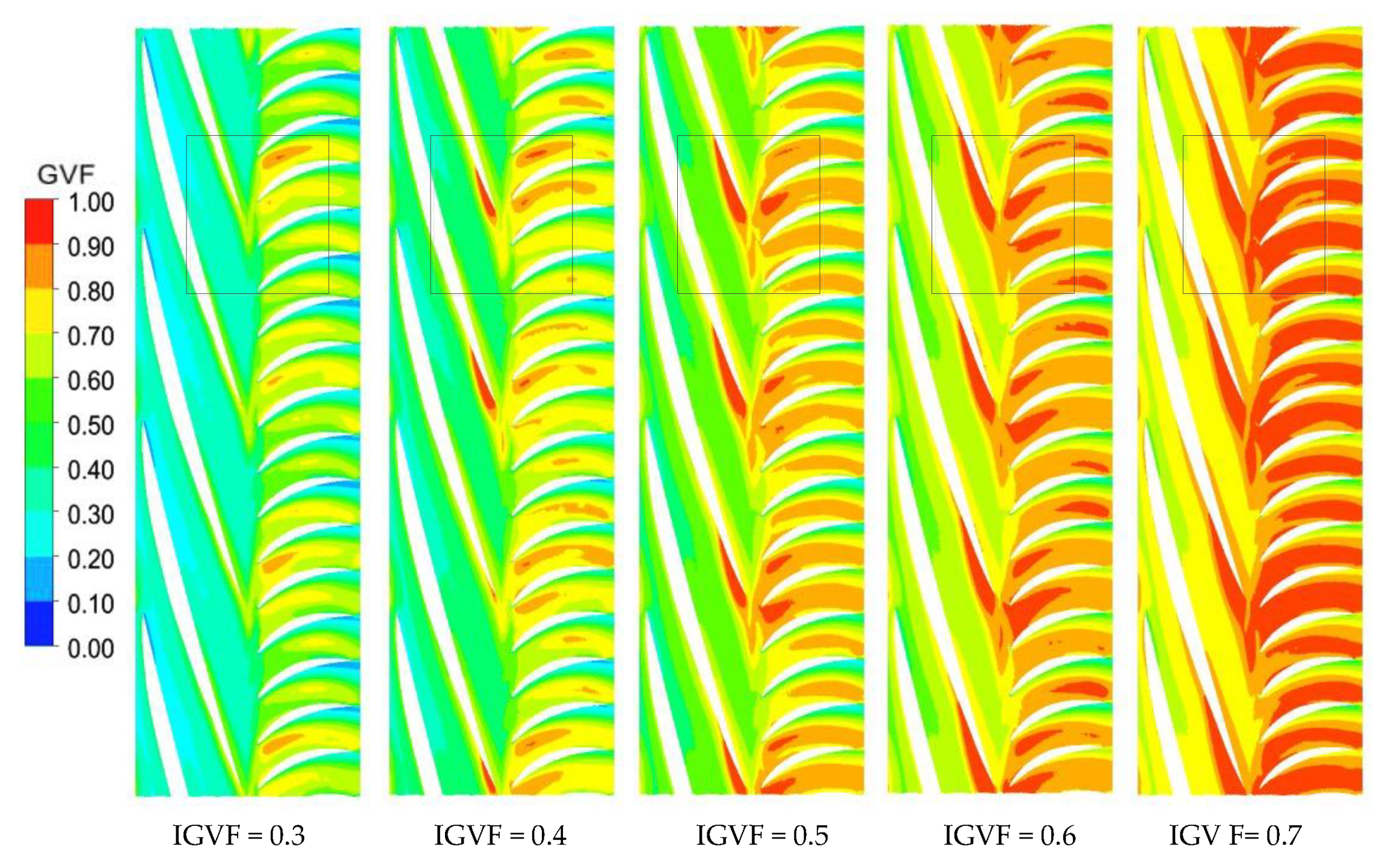

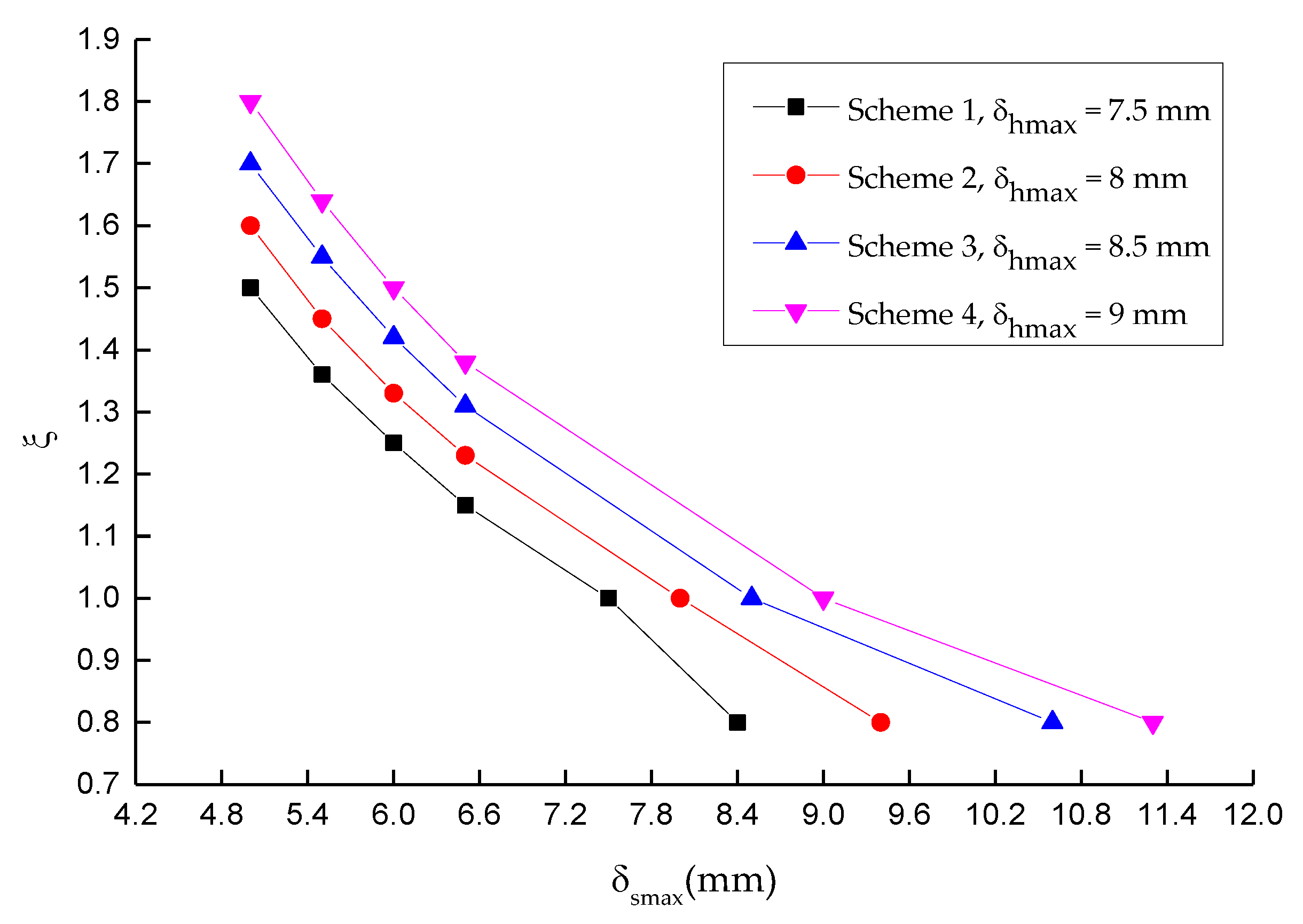

4. Optimization Design Scheme and Results Analysis

4.1. Optimization Design Scheme

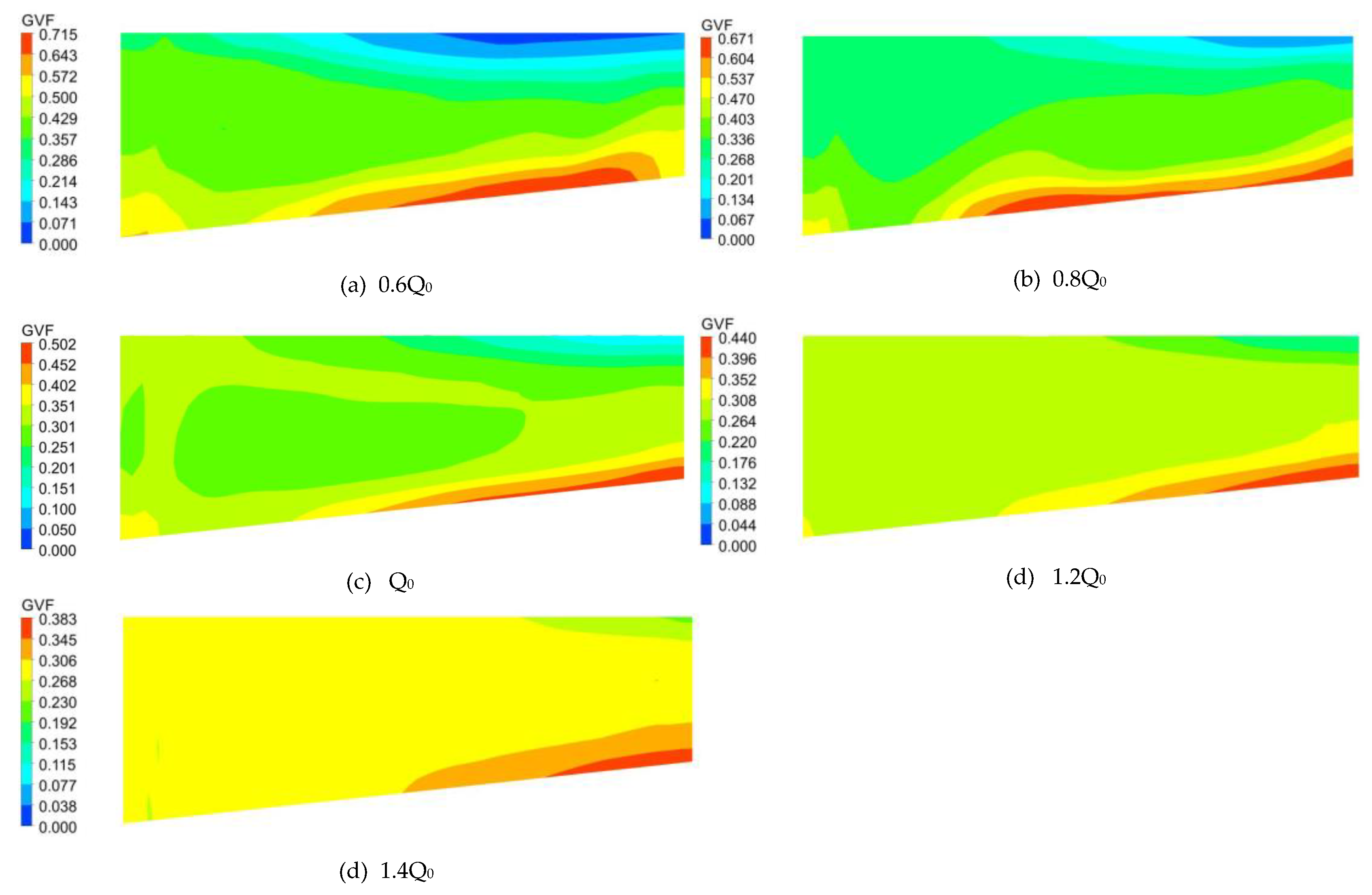

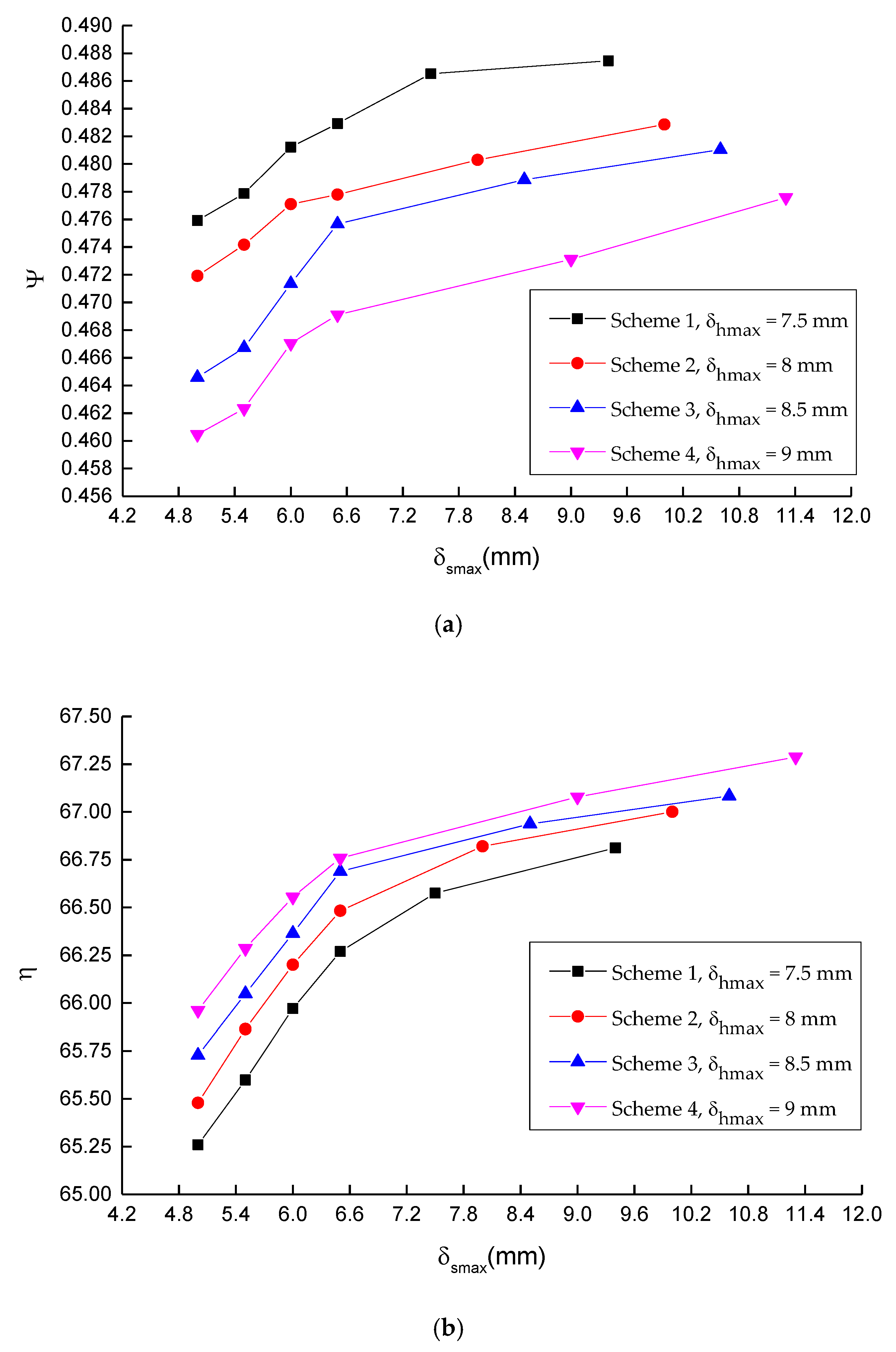

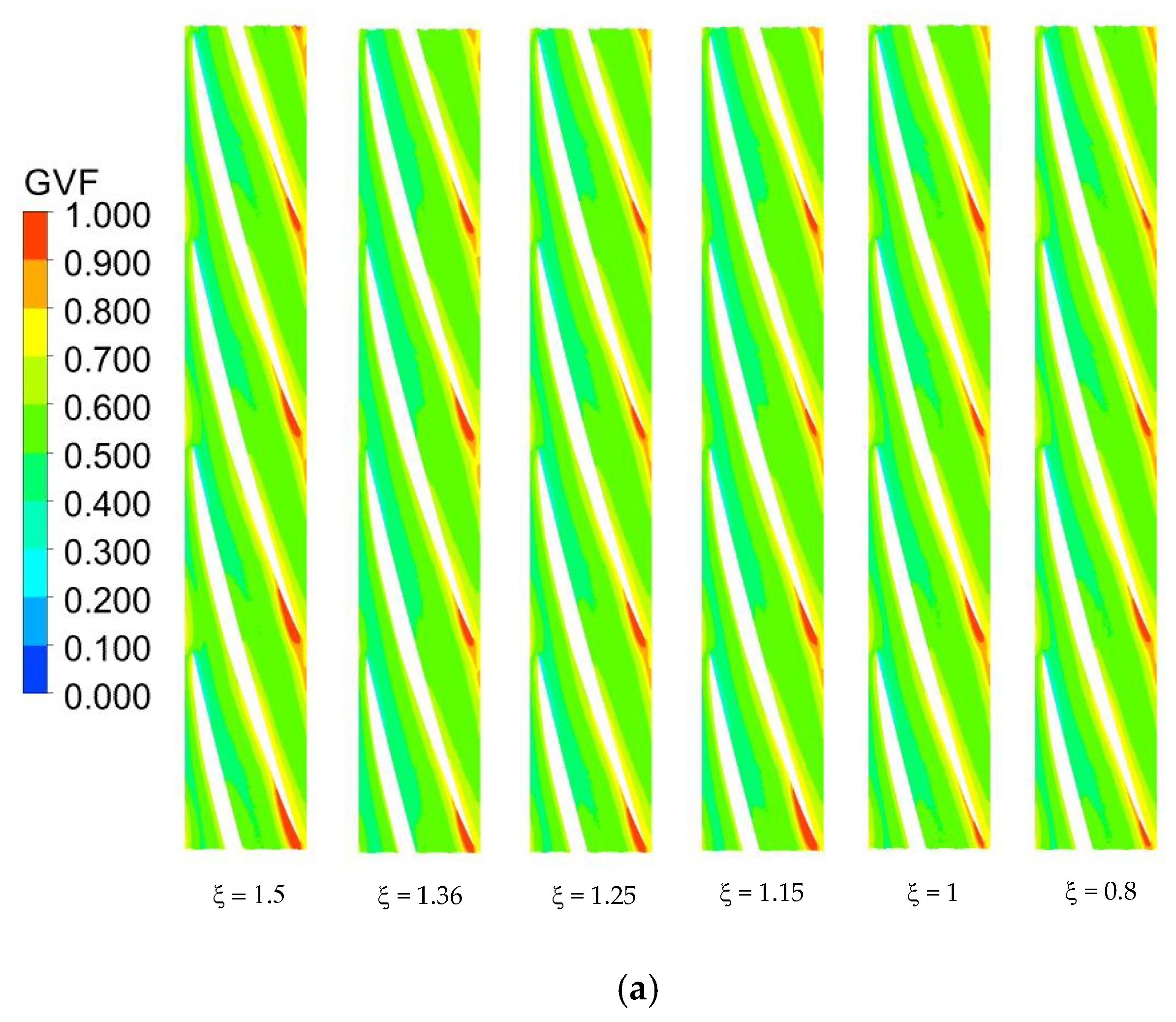

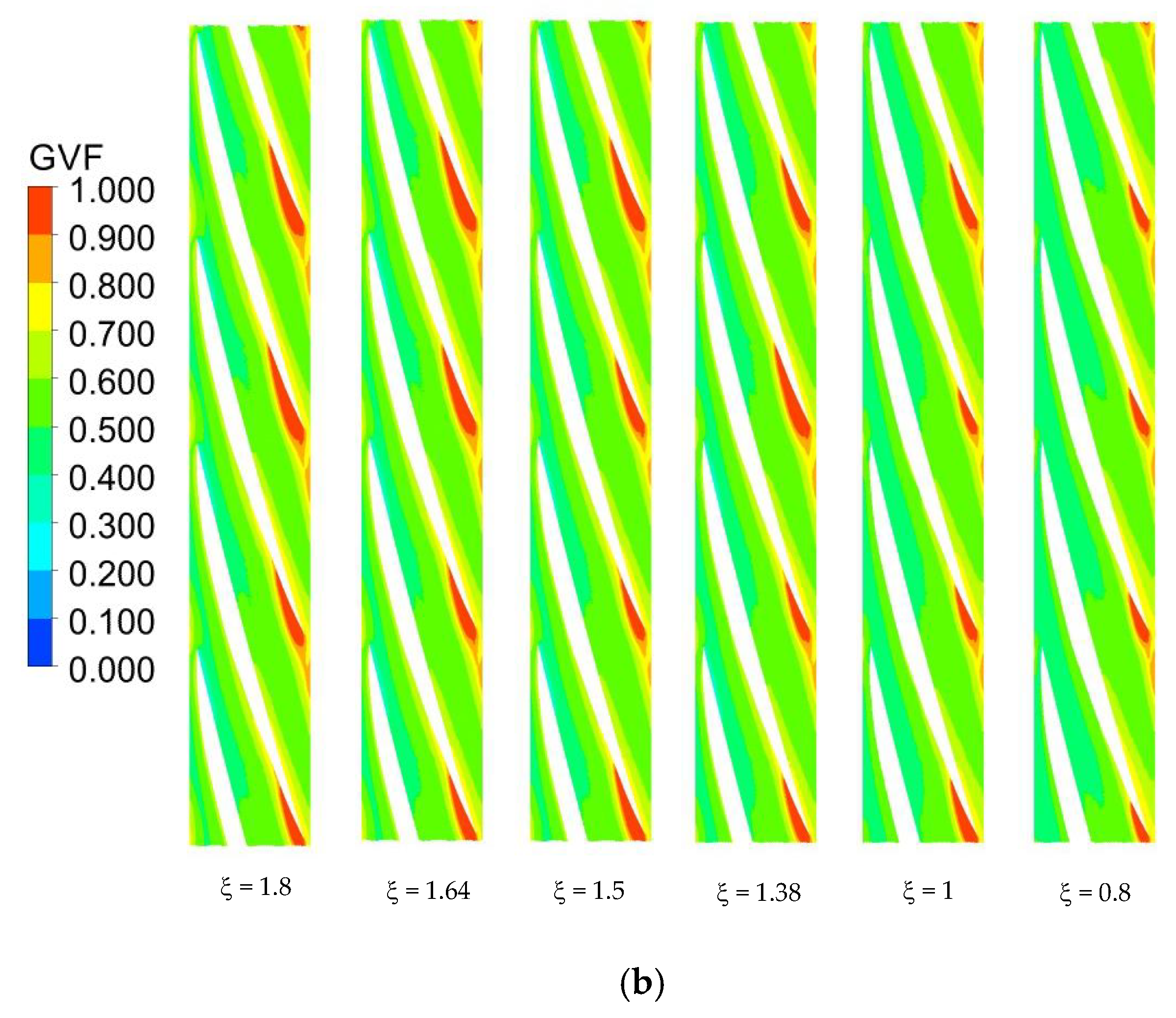

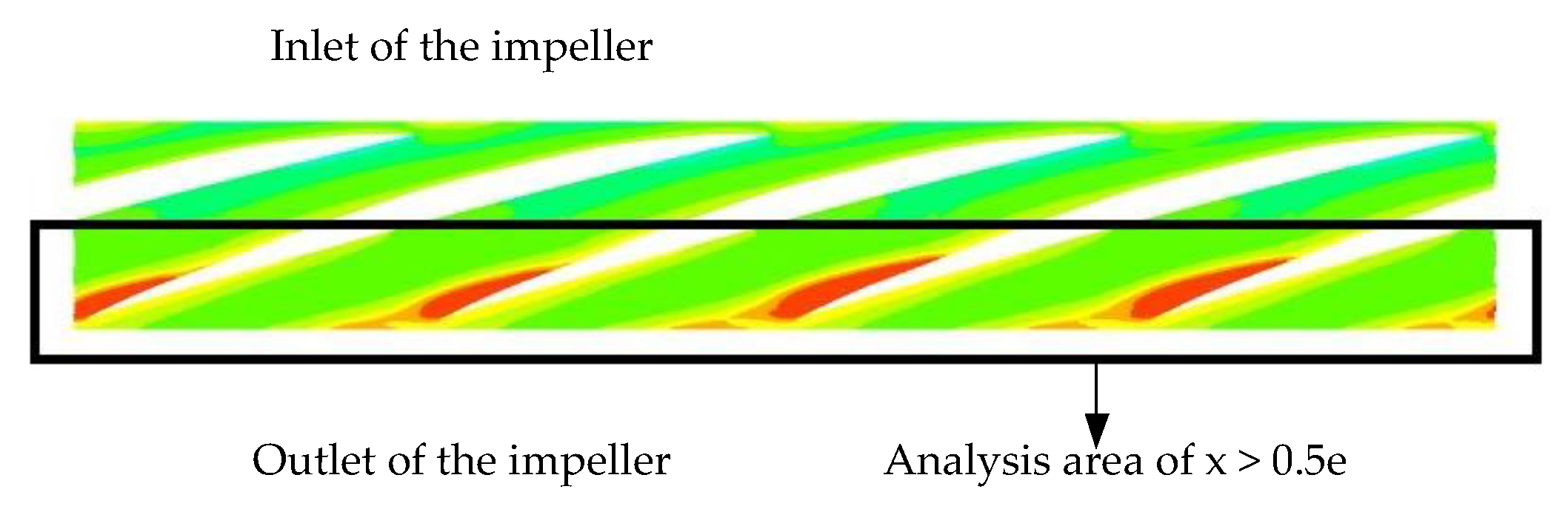

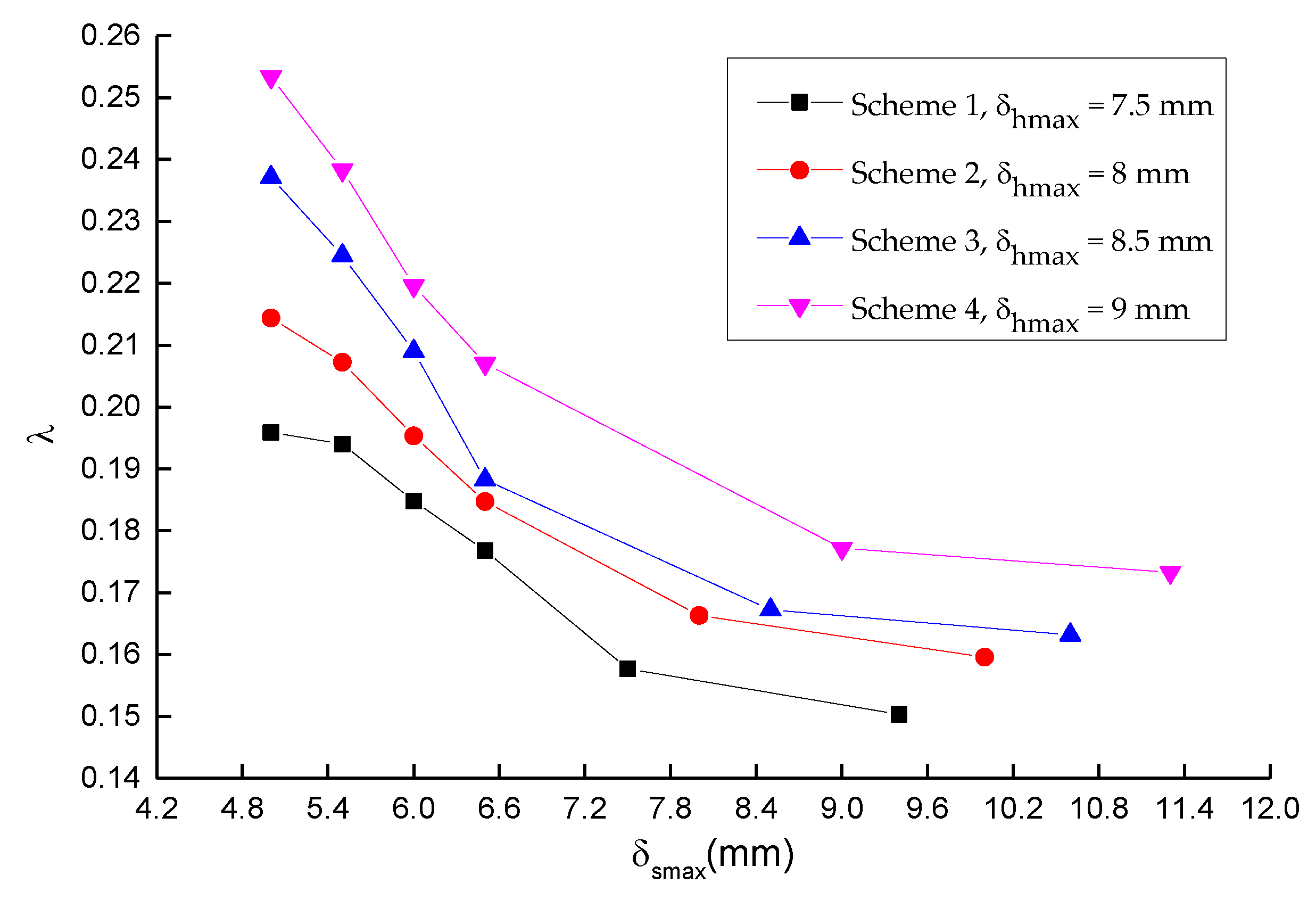

4.2. Results Analysis

5. Conclusions

- (1)

- As the head coefficient Ψ and efficiency η increase, the aggregation degree of gas λ decreased with the decreasing of the thickness ratio coefficient ξ while the hub thickness was maintained. The head coefficient of the modification multiphase pump was 5.8% higher in comparison to the base pump, while the efficiency was 3.1% higher than that of the base pump; the optimal model in the research was the model of scheme 1 with ξ = 0.8.

- (2)

- When the maximum thickness of the hub was unchanged, the reduction of the thickness ratio coefficient ξ decreased some of the separation inductive force of the gas–liquid two-phase flow, which is conducive to inhibiting the separation of the gas–liquid two-phase, thus improving the gas–liquid two-phase transportation performance of multiphase pumps.

- (3)

- A super-separated airfoil was defined and found to be ξ = 0.8 in scheme 1, which was able to delay the separation area of the gas and liquid two-phase flow beyond the region with a chord length greater than 90%. The aggregation degree of this model was the lowest, which was 30.3% lower in comparison with the base pump.

- (4)

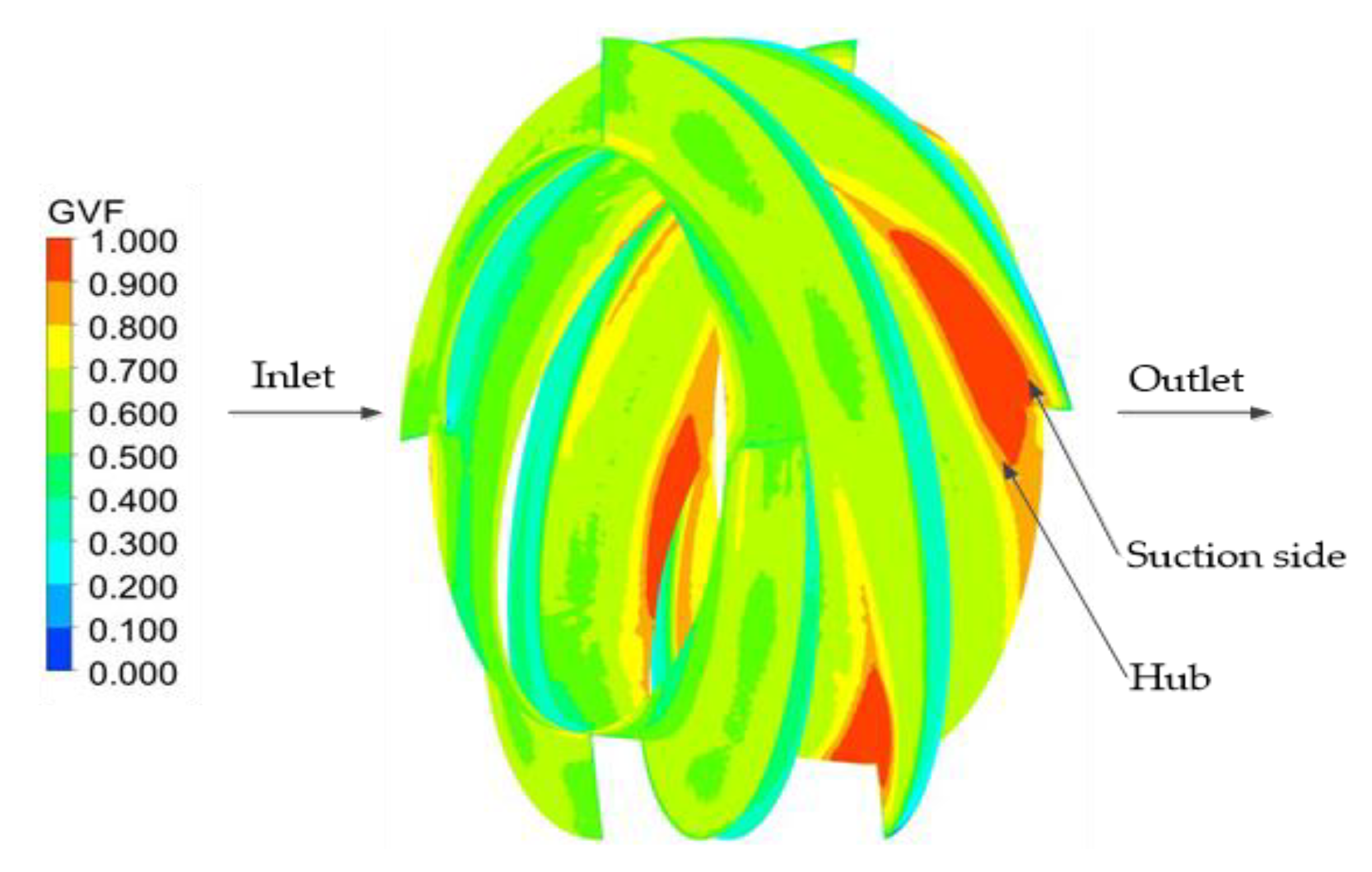

- The change trend in the gradient of turbulent kinetic energy in the flow passage of the impeller was related to the distribution of gas. The gas accumulation region was similar to the area where the gradient of turbulent kinetic energy was large, and so the energy loss could be interpreted. The accumulation phenomenon of gas phase became more and more obvious along the hub side from the inlet to the outlet, especially at the outlet area.

- (5)

- The research on the influence of the thickness ratio coefficient on the multiphase pump provided some reference value for the modification design of impellers. In future work, visual observation techniques of the internal flow field can be adopted to provide visual evidence for the modification of the multiphase pump.

Author Contributions

Funding

Conflicts of Interest

References

- Hua, G.; Falcone, G.; Teodoriu, C. Comparison of multiphase pumping technologies for subsea and downhole applications. Oil Gas Facil. 2012, 1, 36–46. [Google Scholar] [CrossRef]

- Cao, F.; Shu, P.C. Technology and research progress of twin-screw type multiphase pump. China Petrol. Mach. 1999, 3, 49–52. [Google Scholar]

- Shao, C.L.; Li, C.Q.; Zhou, J.F. Experimental investigation of flow patterns and external performance of a centrifugal pump that transports gas-liquid two-phase mixtures. Int. J. Heat Fluid Flow 2018, 71, 460–469. [Google Scholar] [CrossRef]

- Salis, J.D.; Marolles, C.D.; Falcimaigne, J. Multiphase pumping-operation and control. In Proceedings of the SPE Annual Technical Conference and Exhibition 1996, Denver, CO, USA, 6–9 October 1996. [Google Scholar]

- Li, Q.P.; Xue, D.S.; Zhu, H.W.; Li, Z.F. Research on hydraulic design concept of an helical-multiphase pump and its experimental studies on performances. J. Eng. Therm. 2005, 26, 84–87. [Google Scholar]

- Dal Porto, D.F. Multiphase-pump trails demonstrate practical applications for the technology. SPE Prod. Facil. 1997, 12, 159–164. [Google Scholar] [CrossRef]

- Samsudin, Z.B.; Ajmi, S.M.; Qudaihy, D.S. Production enhancement using a multiphase helico-axial pump in a remote hilly-terrain oil field in Saudi Arabia. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition 2012, Al-Kahobar, Saudi Arabia, 8–11 April 2012. [Google Scholar]

- Saadwi, H. An overview of multiphase pumping technology and its potential application for oil fields in the gulf region. In Proceedings of the International Petroleum Technology Conference 2007, Dubai, UAE, 4–6 December 2007. [Google Scholar]

- Gruehagen, H.; Lim, D. Subsea separation and boosting–An overview of ongoing projects. In Proceedings of the 2009 SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 4–6 August 2009. [Google Scholar]

- Davis, B.E.; Kelly, C.; Kierulf, K. BP King-Deep multiphase boosting made possible. In Proceedings of the 2009 Offshore Technology Conference, Houston, TX, USA, 4–7 May 2009. [Google Scholar]

- Magrini, K.L.; Sarica, C.; Al-Sarkhi, A. Liquid entrainment in annular gas/liquid flow in inclined pipes. SPE J. 2012, 17, 617–630. [Google Scholar] [CrossRef]

- Cioncolini, A.; Thome, J.R. Entrained liquid fraction prediction in adiabatic and evaporating annular two-phase flow. Nucl. Eng. Des. 2012, 243, 200–213. [Google Scholar] [CrossRef]

- Abelsson, C.; Busland, H.; Henden, R. Development and testing of a hybrid boosting pump. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011. [Google Scholar]

- Ma, X.J.; Qu, X.; Xiao, X.J. Three-dimensional modeling of lamina on axial gas-oil multiphase pump. Drain. Irrig. Mach. 2008, 26, 15–17. [Google Scholar]

- Ma, X.J.; Wang, Z.; Zhang, M.Z. Numerical simulation and flow analysis on compression stage of oil-gas mixture pump based on CFX software. Oil Field Equip. 2011, 40, 32–36. [Google Scholar]

- Yu, Z.Y.; Cao, S.L.; Wang, G.Y. CFD analysis of the air-water bubbly flow in a multiphase rotodynamic pump impeller. J. Eng. Thermophys. 2007, 28, 46–48. [Google Scholar]

- Li, Q.P.; Xue, D.W.; Li, Z.F. Optimize of the helico-axial multiphase pump prototype and its experimental studies on performances. J. Eng. Thermophys. 2004, 25, 962–964. [Google Scholar]

- Cao, S.L.; Peng, G.Y.; Yu, Z.Y. Hydrodynamic design of rotodynamic pump impeller for multiphase pumping by combined approach of inverse design and CFD analysis. J. Fluids Eng. 2005, 127, 330–338. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Zhu, H.W. Numerical simulation of gas-liquid two-phase with blade-type multiphase pump. Pump Technol. 2010, 5, 32–39. [Google Scholar]

- Kong, X.L.; Lv, Y.; Gao, J.W. Research on multi-stage compressible simulation of helico-axial multiphase pump. China Petrol. Mach. 2016, 44, 77–81. [Google Scholar]

- Zhang, J.Y.; Zhu, H.W.; Xu, B.G. Methods for improving gas and liquid phases mixing in impeller with high gas void fraction. J. Drain. Irrig. Mach. Eng. 2012, 30, 641–645. [Google Scholar]

- Kim, J.D.; Lee, H.C. Reliability verification of the performance evaluation of multiphase pump. Eng. Technol. Int. J. Mech. Mechatron. Eng. 2014, 8, 1985–1989. [Google Scholar]

- Suh, J.W.; Kim, J.H.; Choi, Y.S. A study on numerical optimization and performance verification of multiphase pump for offshore plant. J. Power Energy 2017, 231, 382–397. [Google Scholar] [CrossRef]

- Ma, X.J.; Li, X.K.; Han, W.; Wang, N. Optimization design of multiphase pump using combined orthogonal design and neural network. J. Lanzhou Univ. Technol. 2011, 37, 37–41. [Google Scholar]

- Shi, Y.; Zhu, H.W.; Yin, B.B. Numerical investigation of two-phase flow characteristics in multiphase pump with split vane impellers. J. Mech. Sci. Technol. 2019, 33, 1–11. [Google Scholar] [CrossRef]

- Lee, H.C.; Kim, Y.H. Performance Improvement of Multiphase Pump for Offshore Plants through Optimization Technique. In Proceedings of the 6th International Symposium on Fluid Machinery and Fluids Engineering, Wuhan, China, 22–25 October 2014. [Google Scholar]

- Shi, G.T.; Wang, Z.W. Pressurization performance of different areas within multiphase pump impeller. J. Drain. Irrig. Mach. Eng. 2019, 37, 13–17. [Google Scholar]

- Shi, G.T.; Luo, K.; Wang, Z.W. Study on load distribution characteristics of axial flow multiphase pump. Water Resour. Power 2018, 36, 175–178. [Google Scholar]

- Liu, M.; Cao, S.; Cao, S.L. Numerical analysis for interphase forces of gas-liquid flow in a multiphase pump. Eng. Comput. 2018, 35, 2386–2402. [Google Scholar] [CrossRef]

- Sher, F.; Sajid, Z.; Tokay, B.; Khzouz, M.; Sadiq, H. Study of gas–liquid mixing in stirred vessel using electrical resistance tomography. Asia Pac. J. Chem. Eng. 2016, 11, 855–865. [Google Scholar] [CrossRef]

- Zhang, L.P.; Chang, X.H. Mesh Generation Techniques in Computational Fluid Dynamics; Science Press: Beijing, China, 2017; pp. 10–12. [Google Scholar]

- Dong, L.; Liu, H.L. Detailed CFD Numerical Calculation Example of Vane Pump; China Machine Press: Beijing, China, 2015; p. 120. [Google Scholar]

- Yuan, S.F. The Characteristics of Gas-Liquid Mixed Transportation in Helical Axial-Flow Multiphase Pump. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, May 2019. [Google Scholar]

- Ge, Z.G. Numerical simulation of internal flow characteristics of centrifugal pump under the condition of bubble inflow. In Proceedings of the 11th National Conference on Hydraulic Machinery and Its Systems, Beijing, China, 19–22 October 2018. [Google Scholar]

- Wang, G.Y.; Huo, Y.; Zhang, B. Evaluation of Turbulence Models for Predicting the Performance of an Axial-Flow Pump. Trans. Beijing Inst. Technol. 2009, 29, 309–313. [Google Scholar]

- Yu, Z.Y.; Zhang, Q.Z. Numerical analysis of gas-liquid mixed transport process in a multiphase rotodynamic pump. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 2062. [Google Scholar] [CrossRef]

- Yi, S.; Zhu, H.W.; Zhang, J.Y. Experiment and numerical study of a new generation three-stage multiphase pump. J. Pet. Sci. Eng. 2018, 169, 471–484. [Google Scholar]

- Liu, M.; Tan, L.; Cao, S.L. Design Method of Controllable Blade Angle and Orthogonal Optimization of Pressure Rise for a Multiphase Pump. Energies 2018, 11, 1048. [Google Scholar] [CrossRef]

- Zhang, J.S.; Tan, L. Energy Performance and Pressure Fluctuation of a Multiphase Pump with Different Gas Volume Fractions. Energies 2018, 11, 1216. [Google Scholar] [CrossRef]

- Hu, K.; Li, Z.B. Detailed Explanation of ANSYS ICEM CFD Engineering Example; The People’s Posts and Telecommunications Press: Beijing, China, 2014; pp. 207–212, 313–319. [Google Scholar]

- Liu, X.R. Research on the Characteristics in Flow Path Tapered Axial-flow Multiphase Pump; Lanzhou University of Technology: Lanzhou, China, 2019. [Google Scholar]

- Zhang, T.; Zhu, X.J.; Peng, F.; Min, S.S. Analysis of effect of near-wall treatments on numerical computation of turbulent flow. J. Nav. Univ. Eng. 2013, 25, 108–112. [Google Scholar]

- Menter, F.R. Two-Equation Eddy-Viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Guan, X.F. Modern Pumps Theory and Design; China Aerospace Publishing House: Beijing, China, 2011; 845p. [Google Scholar]

- Ma, X.J.; Zhao, J.; Shao, L. Influence of airfoil selection on performance of oil-gas multiphase pump. Oil Gas. Storage Transp. 2009, 37, 17–19. [Google Scholar]

- Kim, J.H.; Lee, H.C. Improvement of Hydrodynamic Performance of a Multiphase Pump Using Design of Experiment Techniques. J. Fluids Eng. 2015, 137, 081301. [Google Scholar] [CrossRef]

- Wang, F.J. Computational Fluid Dynamics Analysis: Principles and Applications of CFD Software; Tsinghua University Press: Beijing, China, 2004; pp. 24–29. [Google Scholar]

| Type of Pump | Advantage | Disadvantage |

|---|---|---|

| Twin-screw multiphase pump | Stable operation; the performance is not sensitive to gas volume fraction | Short lifespan; inconvenient maintenance |

| Helical–axial multiphase pump | Large conveying flow; higher gas-liquid two-phase transportation capacity with the high inlet gas volume fraction; | Performance degrades with the increasing of inlet gas volume fraction |

| Centrifugal pump | Simple structure and easy to manufacture | Low gas volume fraction; the efficiency will drop sharply when the gas volume fraction is above 10% |

| Design Flow Rate (Q0, m3 h−1) | Hydraulic Head (H, m) | Rotational Speed (n, rpm) | Efficiency (η, %) |

|---|---|---|---|

| 100 | 30 | 4500 | 62 |

| Hydraulic Parts | Main Structural Parameter | Value |

|---|---|---|

| Impeller | Diameter D (mm) | 150 |

| Number of blades Z | 4 | |

| Half cone angle of the hub γ (°) | 6 | |

| Axial length e (mm) | 55 | |

| Inlet angle of the blade β1 | 10 | |

| Outlet angle of the blade β2 | 14 | |

| Diffuser | Diameter Dd (m) | 150 |

| Number of blades Zd | 17 | |

| Half cone angle of the hub γd (°) | 6 | |

| Axial length ed (mm) | 55 | |

| Inlet angle of the blade βd1 | 38 | |

| Outlet angle of the bladeβd2 | 90 |

| Mesh Scheme | |||||

|---|---|---|---|---|---|

| Components | 1 | 2 | 3 | 4 | 5 |

| Inlet domain | 1,522,500 | 1,522,500 | 1,522,500 | 1,522,500 | 1,522,500 |

| Impeller | 625,907 | 1,193,245 | 2,761,281 | 3,618,690 | 4,780,106 |

| Diffuser | 772,633 | 1,417,004 | 1,735,270 | 2,458,466 | 3,177,553 |

| Outlet domain | 1,522,500 | 1,522,500 | 1,522,500 | 1,522,500 | 1,522,500 |

| Total meshes | 4,443,540 | 5,655,249 | 7,541,551 | 9,122,156 | 11,002,659 |

| Hydraulic head | 32.61 | 31.86 | 31.4 | 31.36 | 31.33 |

| Efficiency | 68.1% | 67.3% | 66.2% | 66.17% | 66.13% |

| Multiphase Models | Applicability |

|---|---|

| Mixture | A simplified multiphase model, which is suitable for gas–liquid two-phase flow with low gas phase fraction. There is only one set of momentum equations, and the continuity equation can be solved for gas–liquid two-phase flow. |

| Eulerian | The model establishes the momentum equation and continuity equation for each phase, which can describe the two-phase flow well and has a high accuracy of calculation. |

| VOF | The model is suitable for two-phase flow with obvious stratification and is used to deal with the problem of multiphase flow without interpenetration. |

| Turbulence Models | Applicability |

|---|---|

| Standard k-ε model | A simplified multiphase model, which is suitable for gas–liquid two-phase flow with low gas phase fraction. There is only one set of momentum equations, and the continuity equation can be solved for gas–liquid two-phase flow. |

| RNG k-ε model | The model can deal with the turbulent flow problem with a low Reynolds number. The influence of the vortex in the turbulent flow is considered in the RNG κ-ε model, it has higher accuracy than the standard k-e model. |

| SST k-w | The model considers the effect of shear stress on turbulent flow, can deal with free flow in the near-wall region and is often used for flows with large eddies. It has high accuracy and reliability. |

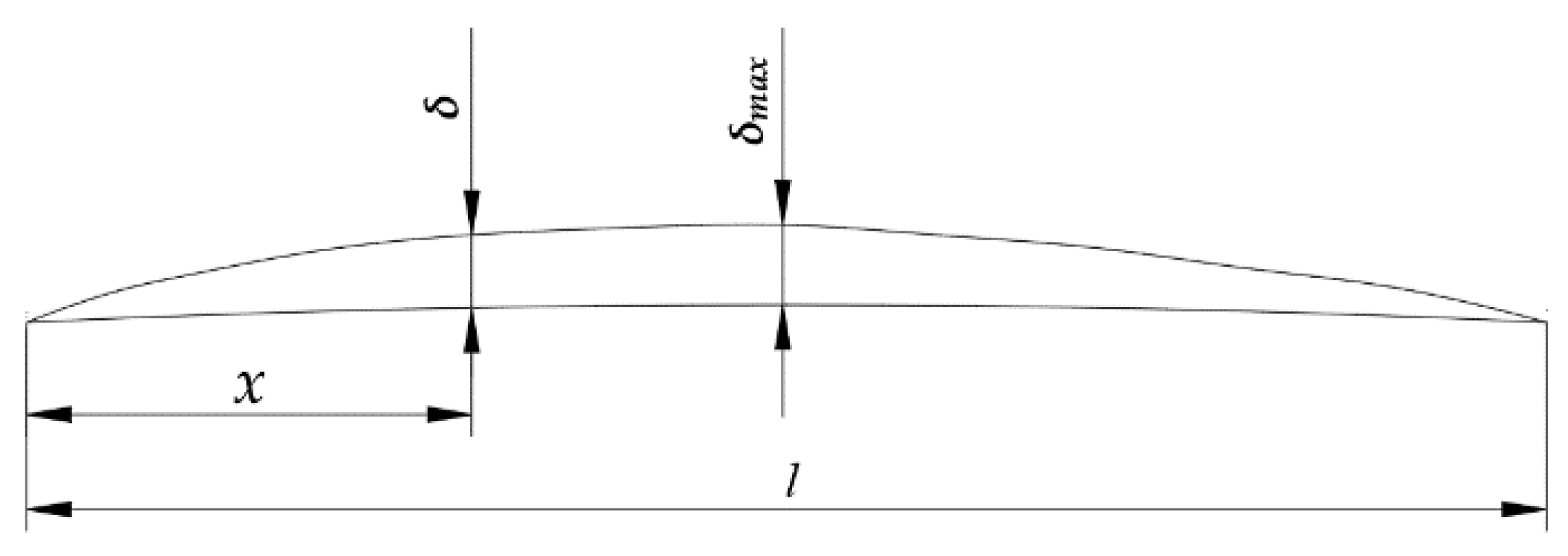

| x/l | 0 | 0.05 | 0.075 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 0.95 | 1 |

| δ/δmax | 0 | 0.296 | 0.405 | 0.489 | 0.778 | 0.92 | 0.978 | 1 | 0.883 | 0.756 | 0.544 | 0.356 | 0.2 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, W.; Li, X.; Su, Y.; Su, M.; Li, R.; Zhao, Y. Effect of Thickness Ratio Coefficient on the Mixture Transportation Characteristics of Helical–Axial Multiphase Pumps. Appl. Sci. 2020, 10, 345. https://doi.org/10.3390/app10010345

Han W, Li X, Su Y, Su M, Li R, Zhao Y. Effect of Thickness Ratio Coefficient on the Mixture Transportation Characteristics of Helical–Axial Multiphase Pumps. Applied Sciences. 2020; 10(1):345. https://doi.org/10.3390/app10010345

Chicago/Turabian StyleHan, Wei, Xing Li, Youliang Su, Min Su, Rennian Li, and Yu Zhao. 2020. "Effect of Thickness Ratio Coefficient on the Mixture Transportation Characteristics of Helical–Axial Multiphase Pumps" Applied Sciences 10, no. 1: 345. https://doi.org/10.3390/app10010345

APA StyleHan, W., Li, X., Su, Y., Su, M., Li, R., & Zhao, Y. (2020). Effect of Thickness Ratio Coefficient on the Mixture Transportation Characteristics of Helical–Axial Multiphase Pumps. Applied Sciences, 10(1), 345. https://doi.org/10.3390/app10010345