1. Introduction

When forming electronic elements by printing with nanoparticles (NP), an important process that ensures the electronic properties of these elements is the sintering of NP arrays deposited on the substrate. In recent years, studies and applications of local laser sintering of NP arrays on substrates have been developing, which significantly expands the possibilities of micron-size printing methods in the areas of heat-sensitive plastic substrates and a variety of NP materials used [

1,

2]. In particular, the method of laser sintering of micron-size conductors from silver NPs and organic thin-film transistors on polyethylene naphthalate (PEN) substrates was studied in [

3,

4]. Most metals used for the synthesis of NPs, e.g., copper or aluminum, have a high oxidation reactivity in ambient conditions. It results in the formation of oxide insulating film 1–3 nm thick on a surface, preventing the high conductivity between particles. To minimize the oxygen flow to the surface of NPs a layer of noble metal or other inert coating substance (thiol, polymer) may be applied [

5,

6]. Also, to prevent oxidation processes, it is possible to form samples in a high vacuum or in an inert gas environment [

7].

The use of laser sintering for micron-size elements formed by the developing aerosol printing technology, which is based on selective deposition of aerodynamically focused NP streams onto the substrate is promising. In the first implementation of the technology samples were being formed by microdrops from the dispersion of NPs (inks) [

8]. Aerosol printing allows to form functional elements on the substrates with a minimum line width of around 10 μm, which is much lower than while using inkjet and screen printing technologies [

9]. However, when NPs are delivered to the substrate as a part of the ink, solvent and other organic additives must be removed before sintering. This makes the sintering process of NP array dependent on the composition of the ink used.

In the last decade, many studies have been done in the field of conductive lines formation by selective laser sintering of NP arrays formed by ink printing, mainly on heat-sensitive substrates (PET, PEN, polyamide), e.g., [

10,

11,

12,

13]. Sintering processes were studied using continuous (CW) and pulsed nanosecond and picosecond laser sources operating at 248, 532 and 1064 nm. The processes of laser radiation absorption by silver NPs and energy transfer to the substrate were studied experimentally and by computer simulation. The high specific conductivity of sintered silver NP arrays, 4–6 times smaller than for bulk silver, was demonstrated in studies using inks of silver NPs of less than 50 nm in size and a mass fraction of 34–75 wt% and with the use of nanosecond pulsed laser sources with a wavelength 532 nm [

10,

12].

Special attention was paid to the process of removing solvents and other additives from the ink deposited on the substrate, as this procedure improves the laser sintering efficiency of the silver NP arrays. In recent articles the time spent on drying of deposited inks at 60–80 °C has been reduced from 24 hours to 30–60 min. The use of ink with a high mass fraction of silver NPs (70–75 wt%) was a fundamentally new step in this direction. It allowed to evaporate the solvent and the volatile additives from the ink at room temperature, by leaving the ink to dry for 1 h [

12]. However, the problem of drying the ink deposited on the substrate remains.

Recently [

14,

15,

16] a new approach in aerosol printing has been proposed with no ink used. In this approach, NPs just before being used are synthesized in the processes of a spark discharge in a flowing gas between electrodes of the material desired [

17]. The aerosol stream of NPs is focused and delivered to the treated surface, the particles are deposited in a dry form without a solvent. Recent studies have shown a high efficiency and productivity of dry aerosol printing in comparison with the other additive technologies [

15,

18,

19,

20]. Electrode materials used as sources of NPs in the process of dry aerosol printing are not limited by storage conditions and expiry date. Synthesized in an inert gas stream aerosol NPs are characterized by a high purity of the material, which allows to form structures free from impurities and surfactants [

21]. This allows one to sinter NP arrays with laser radiation immediately after their deposition, which is of interest for mass production of microelectronic and photonic elements, including manufacturing on curved and heat-sensitive substrates [

10,

22,

23].

In this regard, an urgent scientific interest arises to study the efficiency of laser radiation absorption by a NP array. It is well-known that the absorption ability of NPs depends both on the wavelength of incident laser radiation and their shape and size due to plasmon effects [

24,

25]. It is expected that in the process of the powder structure monolithization caused by laser sintering, its optical absorption coefficient decreases due to consolidation and enlargement of the particles comprising the structure, whereas the reflection coefficient increases. The efficiency of laser energy absorption consequently drops. Thus, the process of laser radiation absorption during the sintering of NP arrays appears to be essentially nonlinear and requires experimental research to be done.

During the study of laser sintering of metal NP arrays, it is convenient to characterize the efficiency of the process by specific electrical values—conductivity and/or resistance, in comparison with bulk material [

11,

22,

26]. In this paper, the influence of laser radiation energy parameters in sintering processes on the electrical conductivity and microstructure of silver NP arrays is investigated. It is silver that is attractive for the purposes of conductive microstructure formation due to the high parameter values of electrical conductivity and plasticity and low melting point, which essentially decreases for NPs together with their size diminishing. Sintering processes were done for continuous and pulsed laser sources with wavelengths 527, 980 and 1054 nm. Conductivity and morphology of microstructures were studied for the samples obtained.

2. Materials and Methods

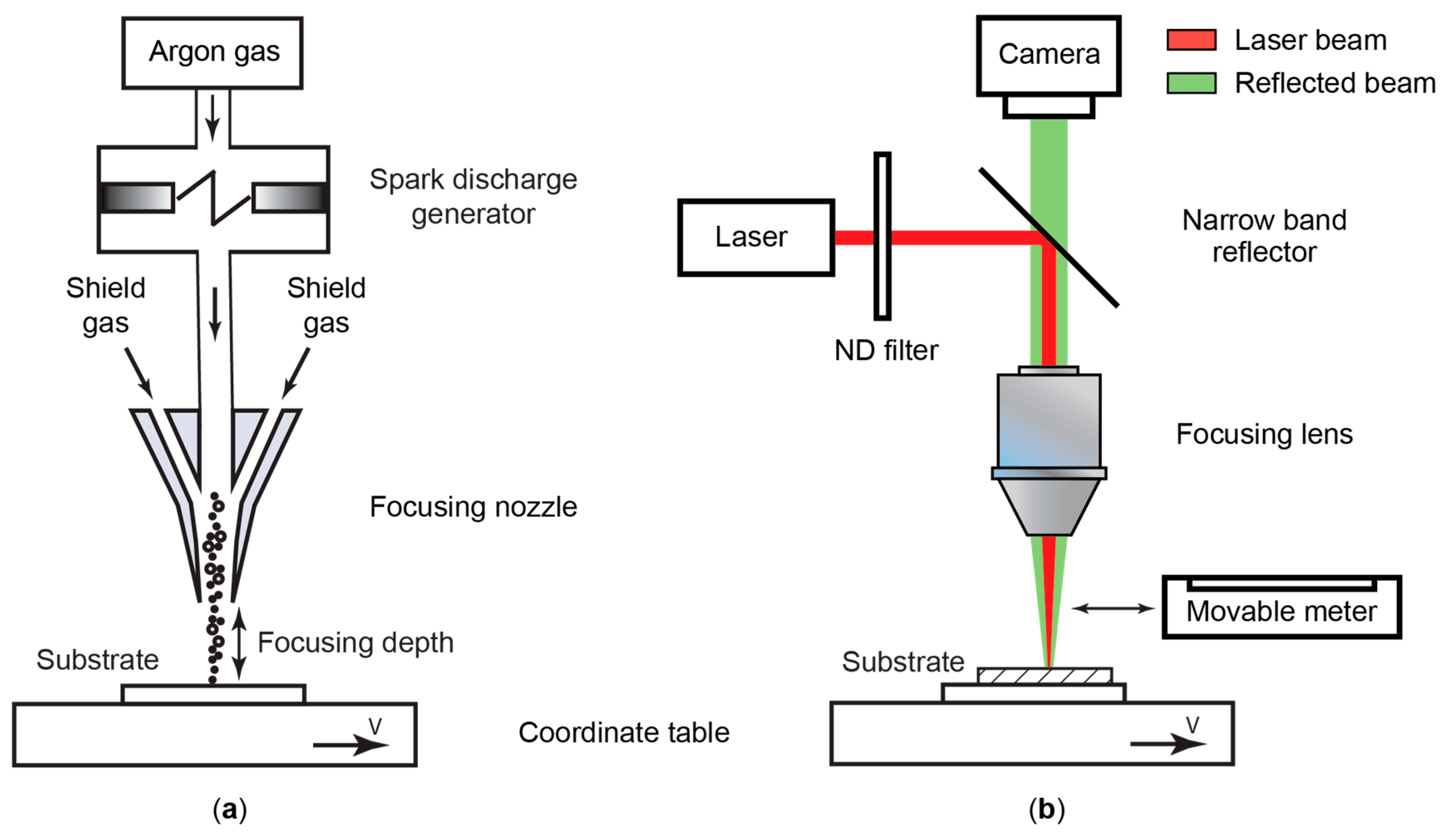

This research is aimed to investigate the laser sintering processes of silver NP arrays synthesized by electrical erosion in a spark discharge between silver electrodes in an argon flow atmosphere and deposited on a substrate. The setup for the micron-sized elements formation from such NPs is schematically presented in

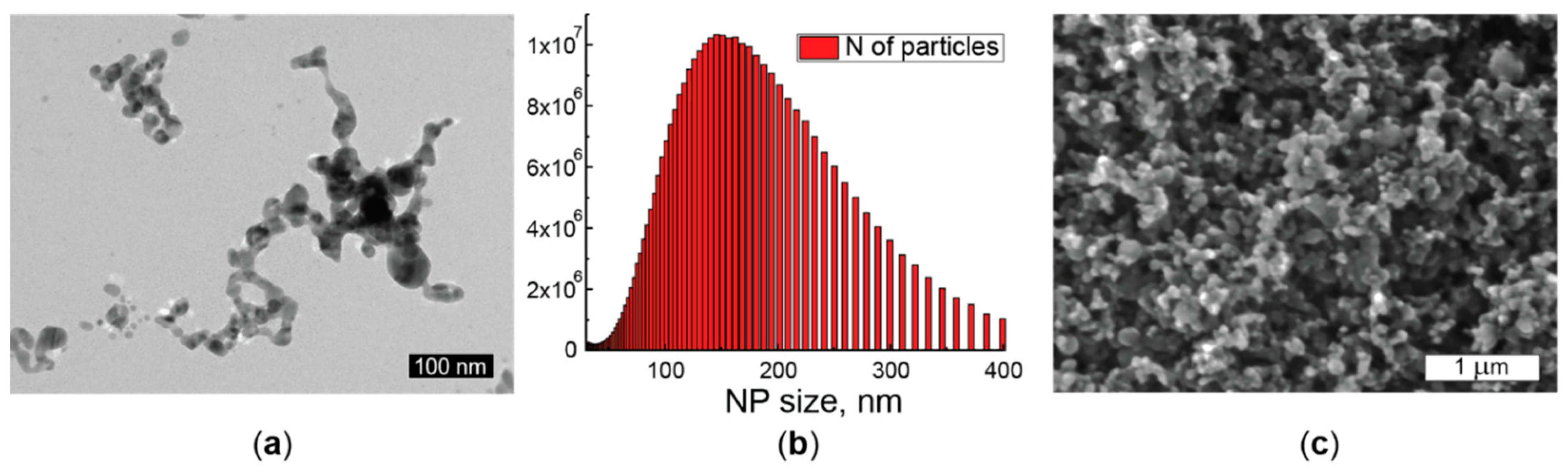

Figure 1a. NPs with an average size of around 10 nm were synthesized in a spark discharge chamber. Further an aerosol of those particles with the high-purity argon flow entered the focusing aerodynamic system in the form of the nozzle, described earlier in [

14,

27]. The design of the nozzle provides an additional external compressing gas stream, which allows to control the cross-section of the aerosol stream by adjusting its parameters [

28,

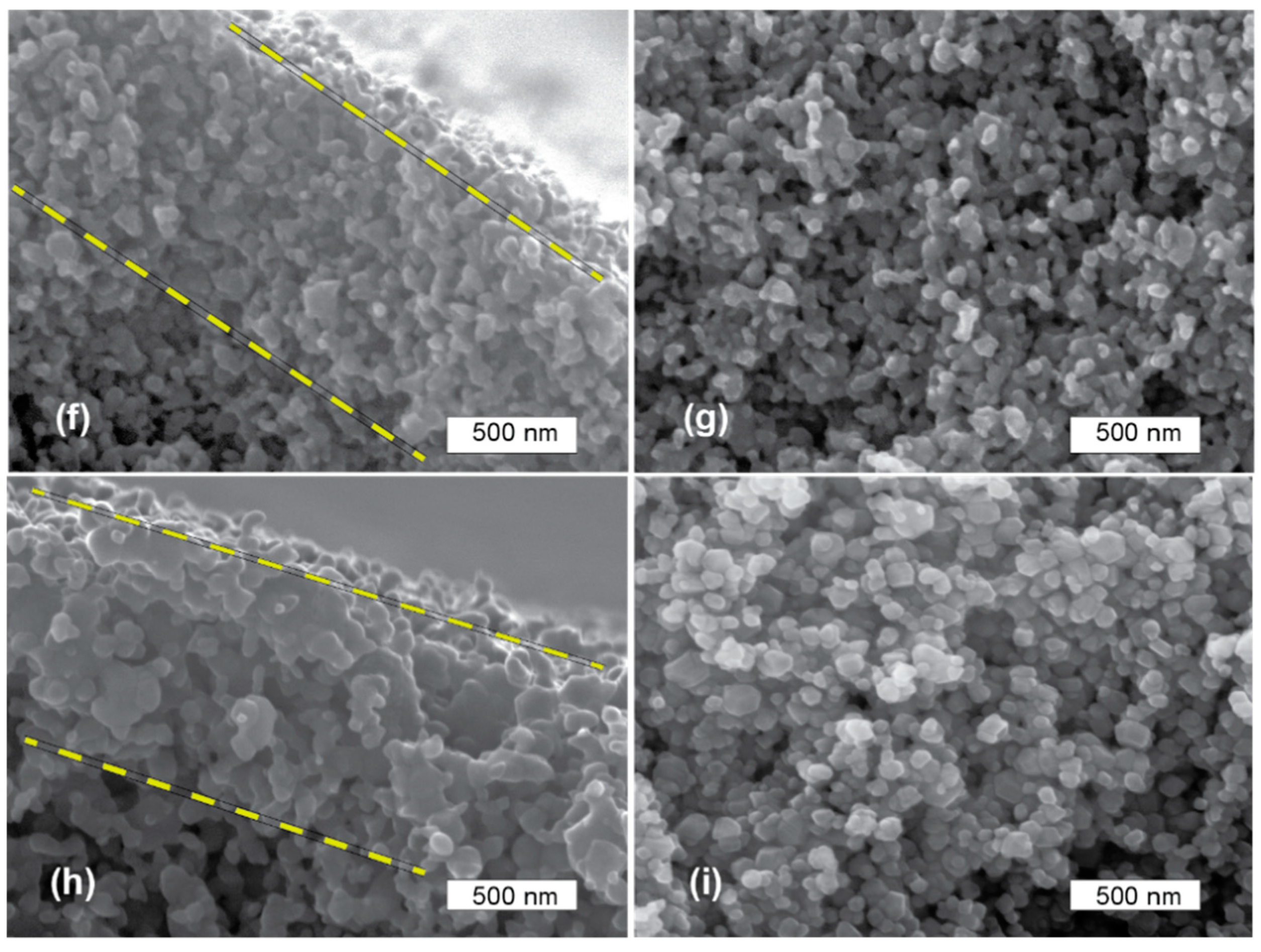

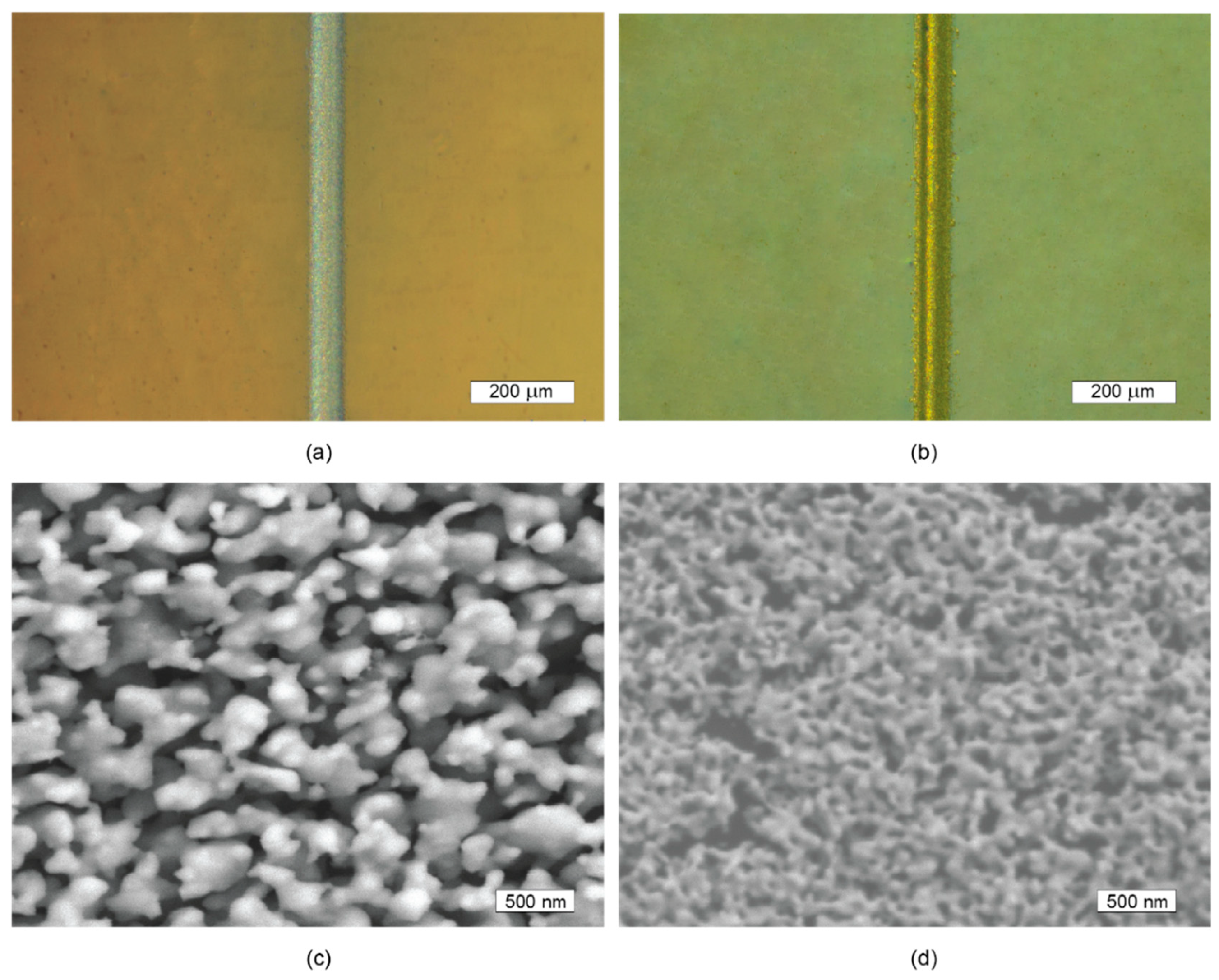

29]. In addition, the experimental setup enables to control the distance between the nozzle and the substrate within its change up to 4 mm, which makes printing on a curved surface possible. Silver NP arrays in the form of lines were deposited on polished silicon substrates 540 μm thick placed on a precision movable coordinate table. To demonstrate the applicability of the proposed approach for the formation of silver NP arrays on heat-sensitive substrates, we conducted similar experiments on the deposition of silver NP arrays by dry aerosol printing and their subsequent sintering by pulsed laser radiation on the polyamide substrates 140 μm thick. These lines had cross-sections in the form of a Gaussian distribution with the FWHM parameter in the range of 40–80 μm and a height parameter of 10–20 μm (

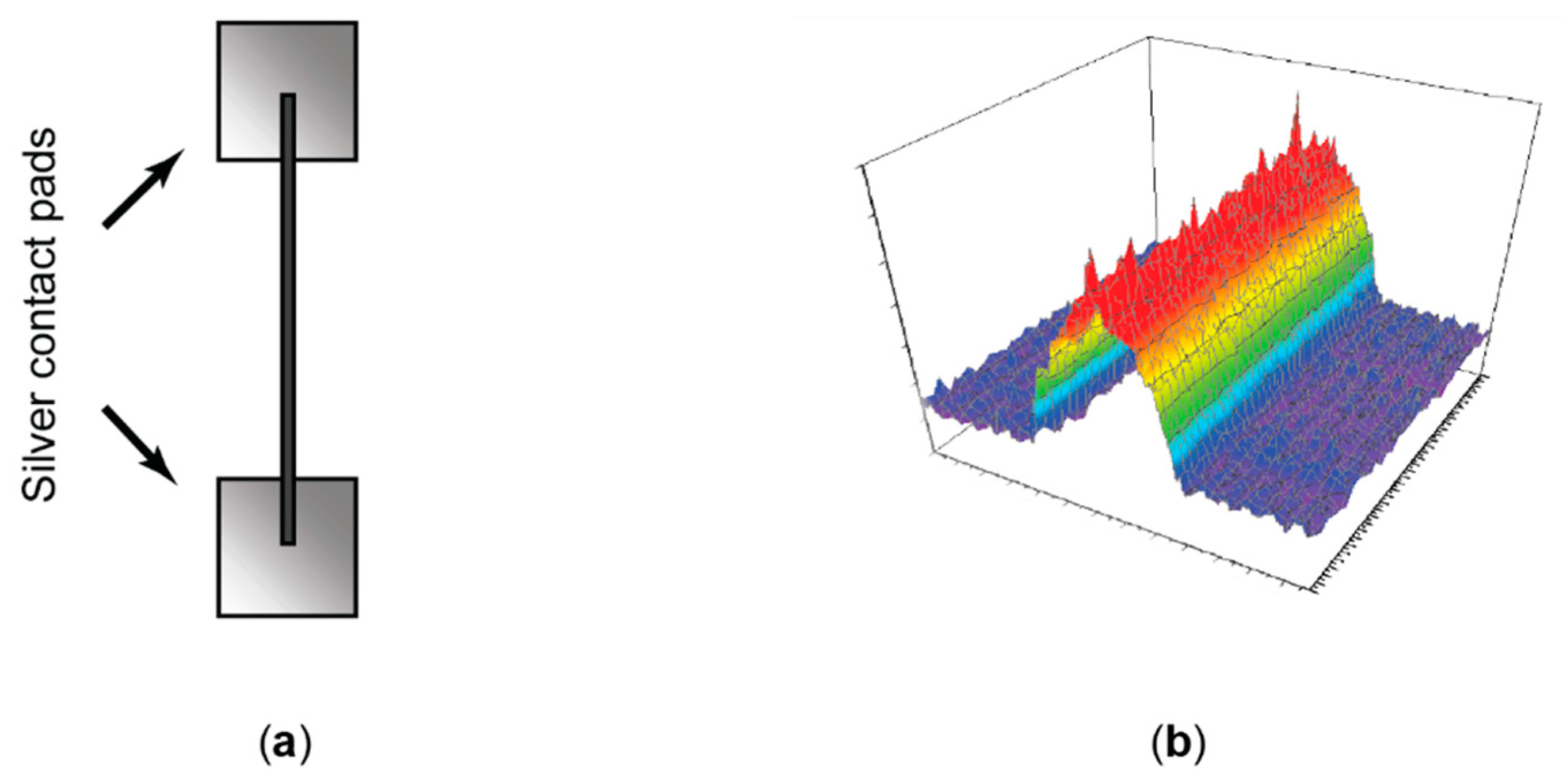

Figure 2b). The lines were formed between two prefabricated silver contact pads about 5 μm thick spaced 5 mm apart (

Figure 2a).

Contact pads were used to measure the conductivity of the sintered lines by a two-contact method. They were formed by an AMT AJ 15XE aerosol printer (Neotech, Nuremberg, Germany) by depositing microdrops of silver NP ink and then sintered in a conventional resistive furnace at 250 °C for 20 min. The ink used for printing was a mixture of PG-007 MOP и PG007-EG (PARU Co., Ltd., Sunchon, Republic of Korea) in a volume ratio of 3:1, with a mass concentration and an average nanoparticle size 46% and 18 nm, respectively. The method described provides a high conductivity of the material for the contact pads, equal to the half of the specific conductivity for bulk silver [

30]. This peculiarity is important for voltage drop minimization on contact pads while measuring the conductivity of the studied lines.

The sintering process of the resulting silver NP arrays in the form of lines was done under the influence of a laser radiation with wavelengths 527, 980 and 1054 nm. The characteristics of the lasers used are given in

Table 1. Four types of CW and pulsed laser sources were installed alternately on the laser position into optical stand being combined with the aerosol printing setup. The optical setup is schematically presented in

Figure 1b. The use of the same coordinate table in the time-spaced processes of printing and subsequent sintering made it possible to continuously form and sinter NP lines. Sintering processes under the influence of laser radiation were controlled by adjusting the power and diameter of the laser beam, and the speed of movement both of the substrate and the sample. Pulsed laser sources were additionally characterized by a pulse repetition rate, chosen equal to 4 kHz for the research, and a pulse duration equal to 20 ns. Measurements for laser radiation parameters were taken by the following devices: BeamOn HR (Duma Optronics, Nesher, Israel) for measurements of the laser beam diameter in the plane of the sample, F150A-BB-26 (Ophir, North Logan, UT, USA) for measurements of the radiation power incident on the sample and 0D-08A (Avesta, Ltd., Troitsk, Russia) with an oscilloscope for pulse repetition rate measurements.

To obtain data on the average electrical conductivity σ over cross-section of the sintered silver lines, the absolute resistance of the lines, their cross-section profile and length were measured by a 287 multimeter (Fluke, Everett, WA, USA) DCM 3D optical profiler (Leica, Wetzlar, Germany) and VHX-1000 optical microscope (Keyence, Itasca, IL, USA) respectively.

The shapes and sizes of the deposited NP and their agglomerates were studied by transmission electron microscope (TEM) JEM-2100 (JEOL, Ltd., Tokyo, Japan). Additionally, the statistical size distribution of silver NP agglomerates in the aerosol stream after the focusing nozzle was measured by the aerosol NP analyzer SMPS 3936 (TSI Inc., Shoreview, MN, USA).

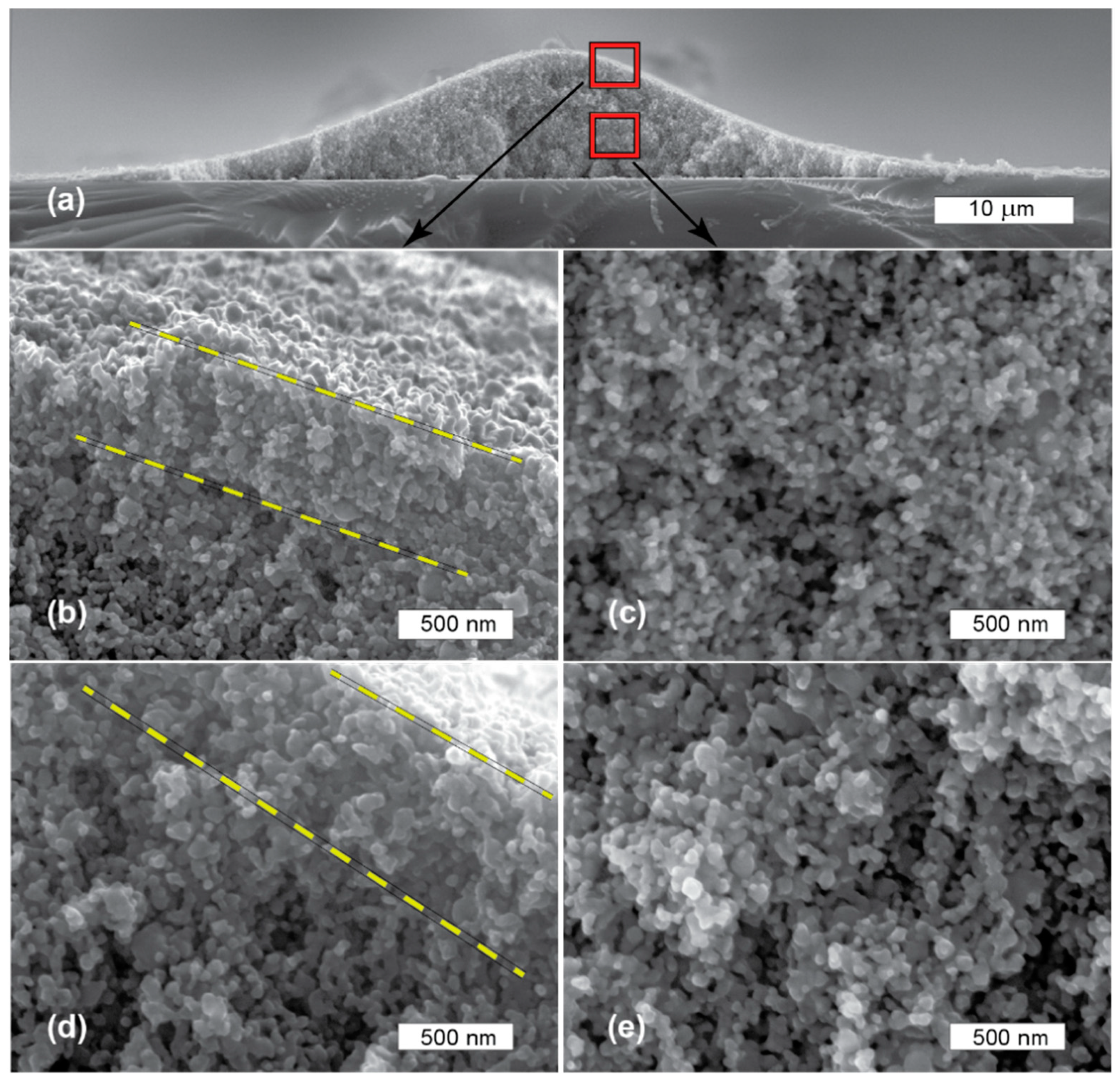

To study the microstructure of sintered samples in the form of lines along the cross-section, their fractures were prepared. To obtain a brittle fracture and minimize the effects of silver crystallites plastic deformation, the samples were cooled in liquid nitrogen, after which a transverse brittle fracture of the line was made together with the substrate. The transverse line fractures obtained in this way were studied by scanning electron microscope (SEM) JSM 7001F (JEOL, Ltd., Tokyo, Japan). The porosity pattern and its boundaries were determined from the images of fractures, the average crystallites statistical sizes were estimated for processing of over 400 particles, approximating them with a sphere. Crystallite sizes were compared for a pore-free layer near the array outer surface and for a porous microstructure in the central part of the line fracture. The samples surface roughness was studied by atomic force microscopy (AFM) using a Solver PRO-M system (NT-MDT, Zelenograd, Russia).

4. Discussion

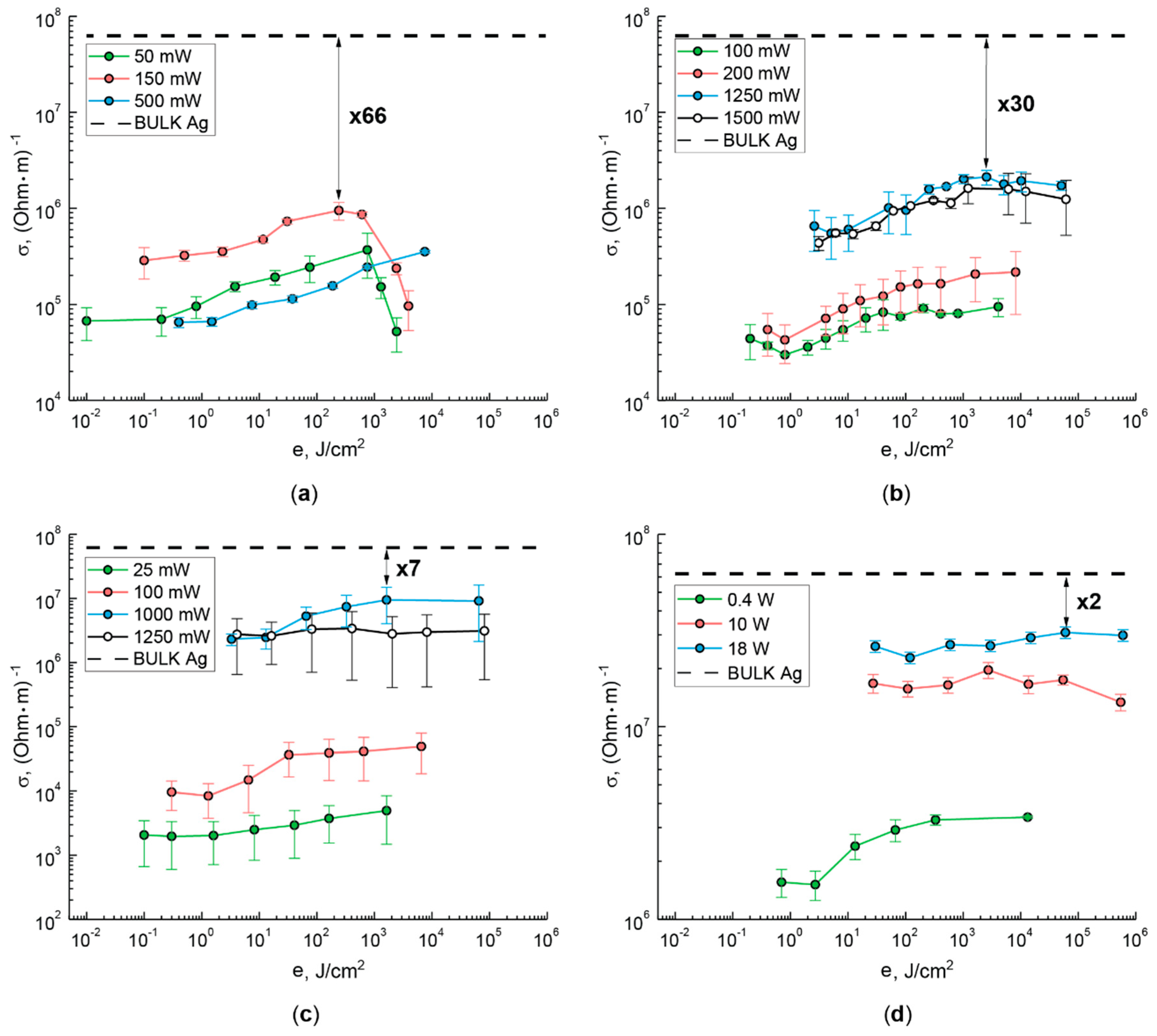

Comparing the data on average specific conductivity σ(e) (

Figure 4) and on microstructure (

Figure 5,

Table 2) of silver NP arrays sintered by four types of laser radiation, we assume that the best conductivity areas in all cases are non-porous external layers with thickness in the range 0.5–1 μm. The formed contacts between crystallites and their large size values indicate the better conductivity of pore-free external layers in comparison with porous zones. In contrast, in porous zones, silver crystallites are connected in agglomerates with conductive contacts inside, between which there are many submicron pores, potentially reducing conductivity. Particularly this occurs in porous zones of samples sintered by pulsed laser radiation (

Figure 5c,e). Assuming that the specific conductivities in the porous and pore-free zones of the sample are significantly different and homogeneous, the average specific conductivity for the entire sample is expressed by the following equation:

where S

np, S

p, S

0—the cross-sectional areas for the pore-free and porous zones and the cross-section for the whole line, respectively, σ

np, σ

p—unknown specific conductivities for the pore-free and porous zones, respectively. So, while sintering by pulsed radiation with wavelengths 527 and 1054 nm in optimal regimes, the maximum achieved values of the average specific conductivity are less than the specific conductivity of bulk silver by 66 and 30 times, respectively. Since the cross-sectional area of the pore-free layers S

np in the experiments is approximately 10% of the cross-sectional area for the entire line fracture S

0, the local specific conductivities for these layers

according to (1) may approach to values, around 6.6 and 3 times less than for bulk silver if the conductivities in the porous zones are greatly less and may be neglected. In similar experiments with CW laser radiation the average conductivity of the samples was found to be 7 and 2 times larger than the specific conductivity of bulk silver for wavelengths 527 and 980 nm, respectively. In these samples, the cross-sectional area of the non-porous layers is approximately 16% of the cross-sectional area for the entire line fracture. Based on the high values of the lines average conductivity and Equation (1), we may conclude that in both cases the specific conductivity of pore-free layers approach the specific conductivity of bulk silver. With longwave CW laser sintering, an additional significant contribution to the conductivity is made due to the porous microstructure. The microstructure of surface pore-free layers with well-formed inter-granular boundaries (

Figure 5f,h) indicates their high conductivity. Despite the many submicron pores in the inner cross-sectional area of the sample sintered by CW radiation with a wavelength 980 nm (

Figure 5i), well-formed inter-crystalline contacts providing significant conductivity are observed. In contrast, for a sample sintered by CW radiation with a wavelength 527 nm (

Figure 5g), the inner porous cross-sectional area of the sample is characterized by poorly formed contacts between crystallites, which cannot provide significant conductivity.

The interaction of laser radiation with the sample surface is characterized by scattering and absorption processes on NP agglomerates [

24]. Considering the agglomerate array consisting of individual NPs [

31], a Rayleigh scattering model may be applied to each NP [

32,

33,

34]. It explains the significant back propagation of radiation. For an array of NP agglomerates, the processes of backscattering and absorption on individual NPs limit the radiation penetration into the array to a certain thickness, at which NPs acquire energy through direct radiation heating. Further, the energy from the zone of radiation direct heating is transmitted deeper via thermal conductivity process. And then we may assume that the thickness of the zone directly heating by radiation is close to the experimentally observed thickness of the sintered pore-free layer in the range 0.5–1 μm. Previously the idea of two mechanisms of laser radiation energy input to silver NPs at different depths of the array was discussed in the literature. In particular, in [

11] authors use significantly different optical penetration depth for radiation with wavelengths 532 and 1064 nm for sintering processes modeling.

Since the radiation absorption by NP as a function of incident radiation wavelength is resonant due to plasmon oscillations, the sintering processes of NP arrays should significantly depend on the wavelength of laser radiation. It was previously established [

35,

36] that silver NP of spherical shape with an average size of 15 nm effectively absorb radiation with a wavelength 400 nm, and when the wavelength increases, for example, to 527 nm, the absorption efficiency of such particles sharply decreases. However, with the particles enlargement, the resonance wavelength of the absorbed radiation redshifts. In particular, at a particle diameter of around 100 nm, the radiation absorption with a wavelength 527 nm reaches its maximum, but for a wavelength 980 nm, the absorption is still small. It is this resonant effect that explains the need to use more energy for laser sintering with increasing the wavelength of the radiation in order to obtain close results of the average conductivity of microstructures. Thus, from the comparison of the optimal regimes for laser sintering of silver NP arrays by pulsed radiation at wavelengths 527 and 1054 nm and by CW radiation at wavelengths 527 and 980 nm, we see (

Figure 4) that in both cases the energy used is almost of an order of magnitude greater for longwave radiation. This effect may be explained by the significantly different absorption efficiency of laser radiation with different wavelengths as follows. In the laser sintering processes, crystallites increase in the average sizes from 15 to 70–120 nm and at the final stage combine into a solid body. It means the energy of laser radiation enters the NP array through absorption by increasing in size individual NP and at the final stage the radiation interacts with a monolithic polycrystalline metal. We may expect a significant increase in the efficiency of the laser radiation energy absorption and sintering if the particle size, corresponding to the resonant absorption of the radiation used, gets in the range of particle size caused by growth during sintering process. It occurred in our experiments with laser sintering of silver NP arrays with a wavelength 527 nm. Previously this effect of strong absorption of laser radiation with a close wavelength (532 nm) by silver NPs was discussed and demonstrated, in particular, in the articles [

11,

12] contributed to laser sintering of silver NP ink with initial particle sizes of 30–50 nm.

The natural result is that the values of the average specific conductivity of silver lines obtained by pulsed laser sintering with wavelengths 527 and 1054 nm in optimal regimes on silicon substrates (

Figure 4a,b) were about three times less than for similar values of the lines conductivity on polyamide substrates (

Table 3). Since the radiation energy transmitted to the NP array at a given wavelength was the same for both types of substrates, we assume that the energy supplied to the sample is more efficiently spent on NPs sintering on polyamide substrates than on silicon substrates. A similar effect was previously observed in [

10] where authors compared the laser sintering processes of NP inks on glass and PET substrates at radiation wavelength 532 nm. In recent articles [

11,

12] the computer modelling of laser radiation energy transfer to the silver ink NP array on PEN substrates has shown that the energy transfer from the NP array to the substrate is limited because of the low thermal conductivity of the plastic substrate. The positive effect of the polyamide substrate low thermal conductivity probably takes place in our experiments as the thermal conductivity of polyamide (0.21 W/(m·K)) is almost three orders of magnitude lower than the thermal conductivity of silicon (149 W/(m·K)). Sufficiently high values of specific conductivity of sintered silver NP lines on polyamide substrates indicate the feasibility of further research on laser sintering of silver NP arrays formed by dry aerosol printing on plastic substrates.

5. Conclusions

In conclusion, it is important to emphasize the basic regularities of local laser sintering by pulsed and CW radiation of silver NP arrays formed by dry aerosol printing. While sintering lines of silver NPs with initial dimensions about 15 nm on polished silicon substrates in the near-surface zone of the samples a pore-free conductive layer was formed. The thickness of the layer was about 0.5 μm and about 1.0 μm while sintering by pulsed laser radiation with pulse duration in the nanosecond range and wavelengths 527 and 1054 nm and CW laser radiation with wavelengths 527 and 980 nm, respectively. The highest values of the average specific conductivity, 7 and 2 times lower than the specific conductivity of bulk silver, were achieved in optimal sintering regimes by CW laser radiation with wavelengths 527 and 980 nm, respectively. Another important regularity is that if the conditions for radiation absorption induced by plasmon resonance are realized in the range of particle size growth during sintering, the efficiency of the NP sintering by laser radiation increases by of an order of magnitude. In our experiments, it is achieved by sintering silver NP arrays with pulsed and CW laser radiation with a wavelength 527 nm. In this case, samples with higher conductivity were characterized by a microstructure with well-formed contacts between silver crystallites and lower porosity.

Additional experiments on laser sintering of silver NP lines on heat-sensitive polyamide substrates by pulsed laser radiation with wavelengths 527 and 1054 nm with sintering process parameters close to the optimal regimes showed three times higher values of average specific conductivity compared to lines sintered on silicon substrates. This makes the proposed method promising for the development of research on the use of laser sintering of silver NP arrays formed by dry aerosol printing on heat-sensitive substrates.