1. Introduction

In various industrial fields, control and instrumentation (C&I) cables assure the stability and reliability of system operations through controlling systems, transmitting signals, and monitoring networks. Likewise, in nuclear power plants (NPP), ensuring the integrity of electrical cables, which is highly relevant with the coolant system, safety injection system, and the containment spray system, is essential for plant operation [

1]. The multi-core C&I cables in NPPs are generally installed to minimize both space and cost as well as prevent wiring labor in limited areas. Moreover, C&I cables are often installed in containment areas under the conditions of high temperature and high radiation, thus exposing their polymeric insulation materials to chemical/physical changes. Consequently, faults resulting from various external stresses inflict errors in the C&I signals, signal leakages, and interference noises in the multi-core cables, which pose serious threats to the operation of the NPP. Therefore, it is of paramount importance to accurately distinguish the faulty line among others and to instantaneously detect the fault upon its occurrence to prevent any accidents which may lead to severe health problems and economic losses.

Safety measures should also be established for multi-wires inside automotive electronics of vehicles. In automotive electronics, cables and connectors are usually installed near vibration motors and wheels. Thus, the wires subjected to vibration and heat damage are highly susceptible of causing failures during operation [

2,

3]. Wiring failures causing the detrimental situations of uncontrollable vehicles or sudden breakdowns endanger both the driver and the pedestrians, leading to secondary damages.

The reflectometry technique, a non-invasive electrical cable diagnosis method, possesses the capacity of detecting faults and assessing cable conditions [

4]. When an impedance change is caused by a fault or degradation due to operations in a C&I cable, a propagated signal is reflected and transmitted at the local impedance discontinuity point depending on the reflection coefficient [

5]. Reflectometry can be divided into two categories depending on its domain of analysis: the time domain reflectometry (TDR) and frequency domain reflectometry (FDR) [

6,

7]. Both methods are easy to implement and need not require high voltages. Unfortunately, the diagnostic results of both the TDR and FDR method are highly susceptible to electric noise and crosstalk [

8,

9]. Moreover, signal attenuation, distortion, and dispersion, which are all likely to occur in the measured reflected signal during signal propagation, diminish the accuracy and reliability of the diagnostic results. Conversely, the time-frequency domain reflectometry (TFDR) method simultaneously analyzes the reflected signal in both the time and frequency domains, which compensates for the drawbacks of the conventional methods [

9]. Herein, the incident signal can be designed in the time and frequency domains according to the characteristics of the cable, and the impedance discontinuity points in the cable can be detected using the time-frequency distribution similarities between the incident signal and the reflected signal. Therefore, reflected signals are less likely to be affected by the cable propagation characteristics or external noises. However, existing reflectometry methods focus on diagnosing a single or pair core cable and is thereby unsuitable for multi-core cables or wired networks. When reflectometry is applied to a multi-core cable, the reflected signal generated at an actual fault point of a defective line is introduced to a normal line and can be measured due to crosstalk [

10].

This paper presents a multi-core cable diagnosis method which detects faults and distinguishes faulty lines using the machine learning-based TFDR. First, the location and type of cable fault are detected using a regression-based artificial neural network (ANN) of the TFDR results [

11,

12]. Then, the data clustering is used to differentiate the faulty lines. Various existing clustering algorithms are selectively used based on crisp [

13], fuzzy [

14], and possibility methods [

15,

16]. The hierarchy clustering algorithm is an unsupervised machine learning algorithm which builds a hierarchy of clusters based on group similarities without any knowledge about the pre-defined groups [

17,

18]. The main advantage of the hierarchical clustering over partial clustering is that a hierarchy dendrogram can be drawn to find the appropriate number of clusters in a dataset.

This paper extends the contribution of [

19] in terms of the theoretical algorithm of fault detection and differentiation. In [

19], we investigated the faulty line detection in a multi-core cable by using K-means clustering-based TFDR. When a fault occurred, results showed that other normal lines were affected at similar points in the multi-core cable. However, only the identification of the faulty line within the multi-core cable had been considered in the study. Moreover, classifying the impedance discontinuity points from the TFDR results in the multi-core cable have not been considered in [

19] which is important for applications to the multi-core cable diagnosis. On the other hand, the applicability of the proposed algorithm in this paper is verified through additional experiments using various types of multi-core cables. To achieve this goal, we extracted input features of the TFDR results and learned each machine learning algorithm for diagnostic purposes. The detection and clustering results obtained from the experimental fault scenarios reveal that clustering TFDR results can be used for fault locating faulty line identification among a pool of normal lines in a multi-core cable. The following sections describe the TFDR, ANNs, and clustering algorithms that are used to detect and analyze the fault in multi-core cables. In

Section 3, we present cable fault scenarios and our experimental setup, and, in

Section 4, we discuss the obtained experimental results. Finally, we conclude the paper in

Section 5.

2. Theoretical Background

2.1. Time-Frequency Domain Reflectometry

The TFDR process consists of three steps: (1) First, we designed the optimal incident signal, which is applied to the cable, and (2) the reflected signal is then measured. (3) Then, we calculated the time-frequency cross-correlation (TFCC) between the reference signal and the reflected signal [

9].

The TFDR uses a Gaussian envelope with a linear chirp signal as a reference signal, which can be expressed as follows [

9]:

where

is the effective time duration,

is the center time,

is the center frequency of the chirp signal, and

is the frequency increment by time.

The reflected signals are attenuated and distorted over the entire frequency band during propagation. Therefore, the attenuation and distortion of the signal vary depending on cable length and insulation. Alternatively, through designing adequate time and frequency ranges of the reference signal according to the frequency characteristics of the cable, a less distorted and attenuated reflected signal can be obtained, which improves the accuracy and resolution of the results. In addition, reducing overlapping reflections by designing the reference signal leads to an improved diagnostic performance. The designing process of the optimal reference signal is described in [

20].

Then, the time-frequency distribution similarity between the incident signal and the reflected signal was calculated via the normalized TFCC [

9]. Consequently, the impedance discontinuity points in the cable was detected and localized according to the TFCC value.

Therefore, this allows the specific detection of the reflected signal which has the same time-frequency signature as the incident signal. The normalized TFCC is expressed as follows:

where

and

are the RID-Rihaczek distributions of the incident signal and the reflected signal, respectively [

21,

22]. The TFCC are normalized by the energy of the incident signal and the reflected signal in the time-frequency domain. The TFCC results are focused on the detection of all possible impedance discontinuity points which results from various causes including the fault, damaged equipment, loose connectors, and unterminated cables.

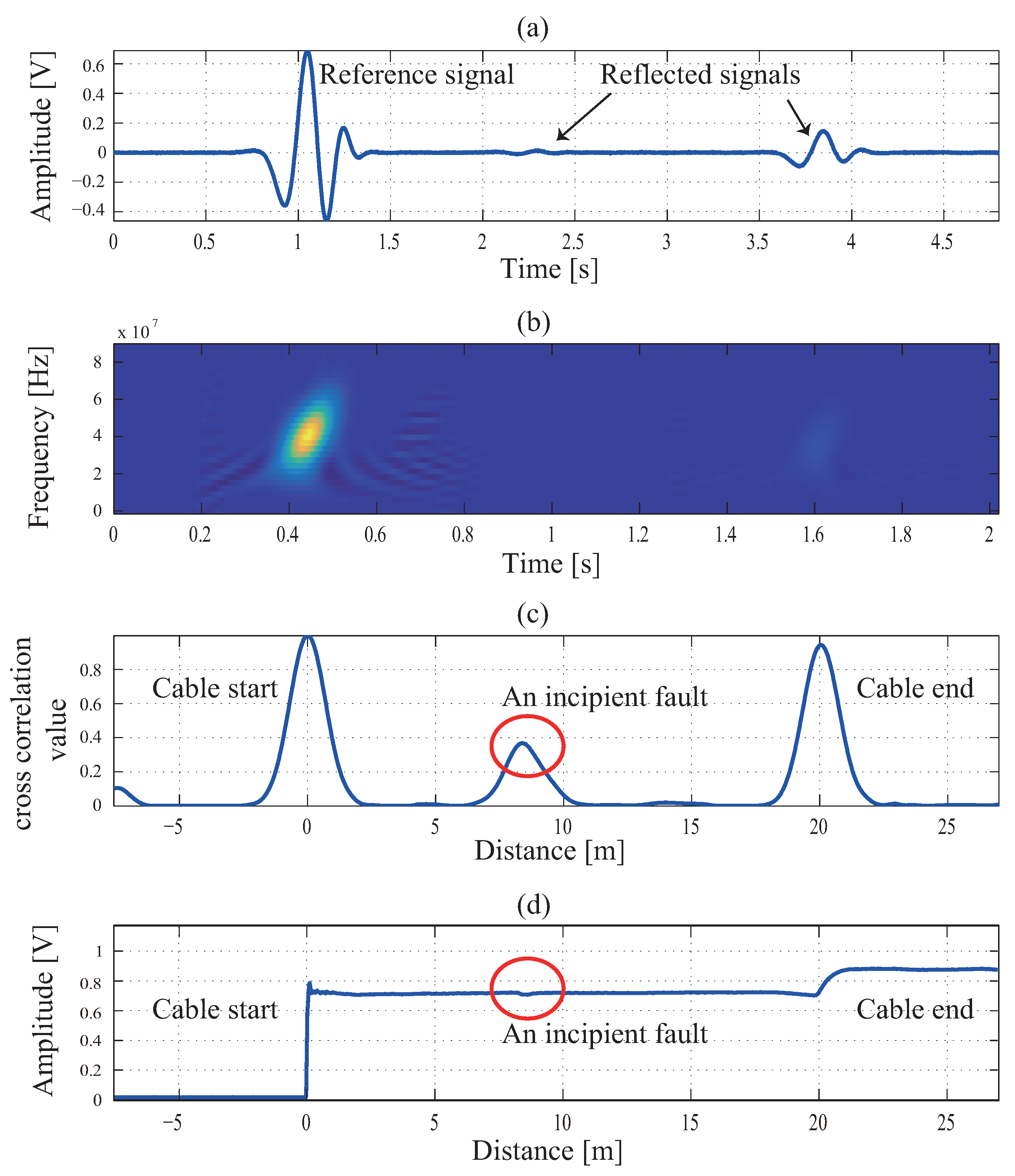

Figure 1 shows examples of the TFDR and step-pulse TDR measurement signals, respectively. The cable length is 20 m, and an incipient fault (insulation fray) is located at 8.5 m of the cable. In

Figure 1a,d, the cable start and end points can be easily detected, however, the incipient fault at 8.5 m is indistinguishable from noise when using the TDR. On the other hand, the TFDR calculates the cross-correlation between the reference signal and the reflected signal. Therefore, the fault was successfully detected through using the time-frequency similarity of the signal despite its low energy as shown in

Figure 1c. Hence, compared to the TDR method, the TFDR is more adequate for detecting fine signals of the fault as shown in

Figure 1c,d.

2.2. Fault Detection Using an Artificial Neural Network for Regression

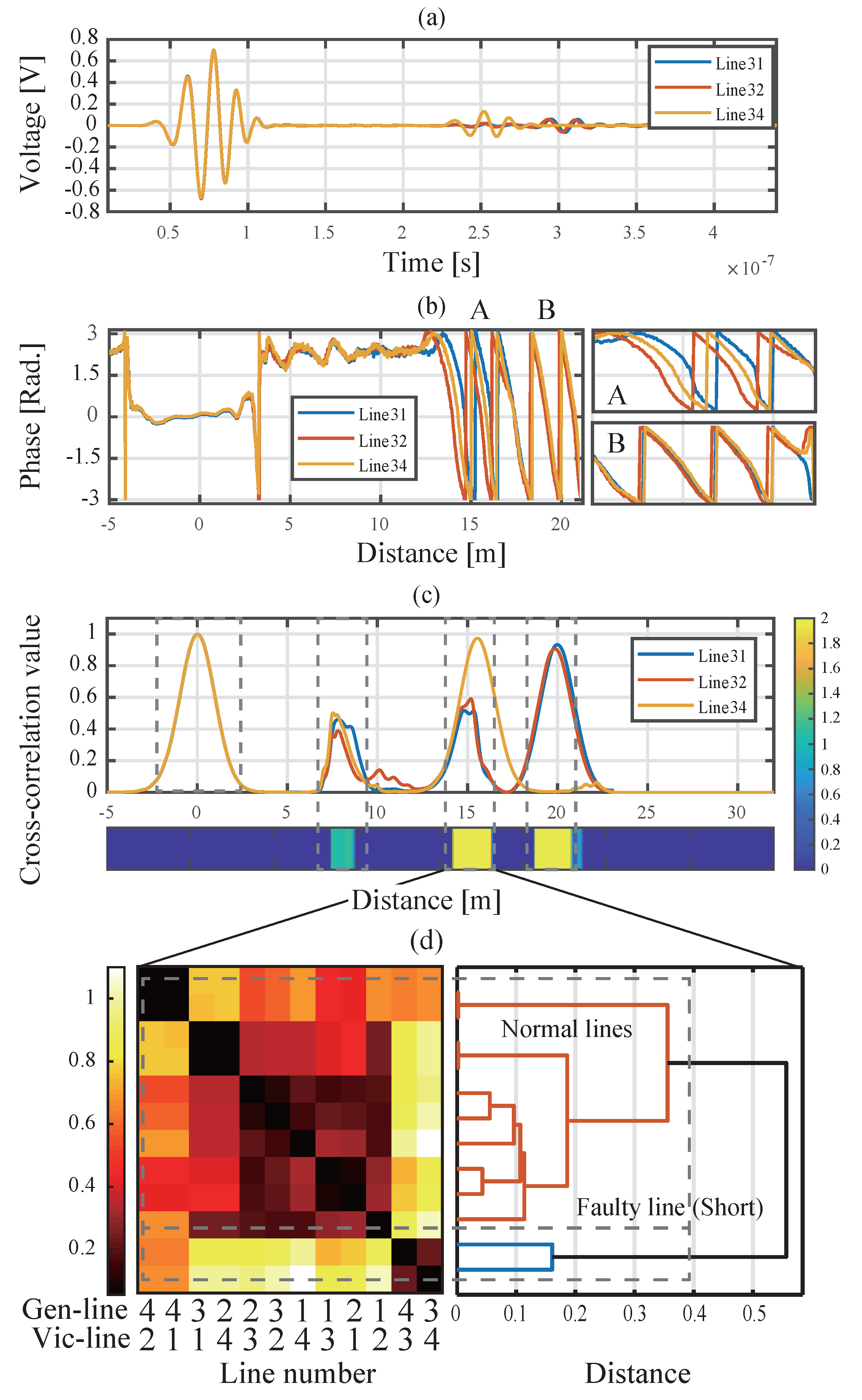

When an incident signal is applied through one of the lines of a cable that has N cores (generator line), reflected signals are obtained from the other lines (victim lines) in the TFDR. Consequently, the total of generator-victim reflected signals are obtained from the N-core cable. Since the features of the reflected signals depend on the connected generation-victim line pairs, the fault location and the faulty line can be identified by analyzing the total big data measured from the cable.

The ANN, a statistical learning algorithm inspired from neural networks in a biological nervous system is widely utilized in machine learning and cognitive sciences. Specifically, the ANNs are applied in function approximation, recognition, classification and pattern recognition. We used a multi-layer perceptron (MLP) which is a class of the feed-forward ANN to detect the fault location and to distinguish the cable connection points in a multi-core cable. The topological structure of the MLP used in this study is illustrated in

Figure 2. The MLP consists of one input layer with three neurons, one hidden layer with 25 neurons, and one output layer with two neurons [

23]. Since the number of hidden layers determines the performance of the data fitting process, an appropriate number of hidden layers is requisite.

In this study, the optimal hidden layer of the MLP is determined by the split-sample method. For the split-sample method, 50% of the data samples have been used for training and the remaining half has been used for testing. The activation function for the hidden layer was the hyperbolic tangent sigmoid function as follows:

where

x and

are the input and output of the hidden neuron, respectively.

First, we set the thresholds of the average TFCC () and the normalized variance (), respectively and classified the TFDR reflected signal cases in a multi-core cable as follows: (1) a normal cable junction, (2) a balanced fault, or faults in all lines, and (3) the unbalanced fault, or a partial line fault resulting in reflected signals due to both the fault and cross-talk. The threshold value of each input parameter was set with preliminary test results considering noise, signal interference, and cross-terms.

Next, the input features of the TFDR results for the MLP were set as time domains: average of the TFCC, the normalized energy variance of the reflected signals, and the time delay between the reference signal and the reflected signal. The time delay and the average of the TFCC are strongly relevant with the fault existence and location of the reflected data, respectively. In addition, the normalized energy variance of the reflected signals contain information on the presence of an incipient partial line fault. Partial line faults require the detection of faulty lines through classification before all lines become defective leading to devastating errors in the multi-core cable. The input features can be expressed as follows:

where

i and

j refer to the connected generation and victim line number, respectively.

is the reflected signal with i-th generation/j-th victim line.

is the center time of

and

is the center time of the reference signal

which are expressed as follows:

The output parameters were the fault determination index (

) and the unbalanced signal index (

). The fault determination index estimates the fault location, and the unbalanced signal index estimates the type of the fault. The dataset to train the MLP according to the averages of TFCC, normalized energy variance, and time delay were obtained by the simulated measured data considering the thresholds for each cable sample. The dataset was randomly divided into two separate sets, each for training (85%) and testing (15%). We employed a scaled conjugate gradient (SGC) back-propagation algorithm with a cross-entropy performance function [

24]. Furthermore, the training process was ceased under the following conditions: (1) the maximum number of iterations (1000) is reached; (2) the maximum amount of time is exceeded; (3) the performance is minimized to the goal; or (4) the performance gradient falls below the target.

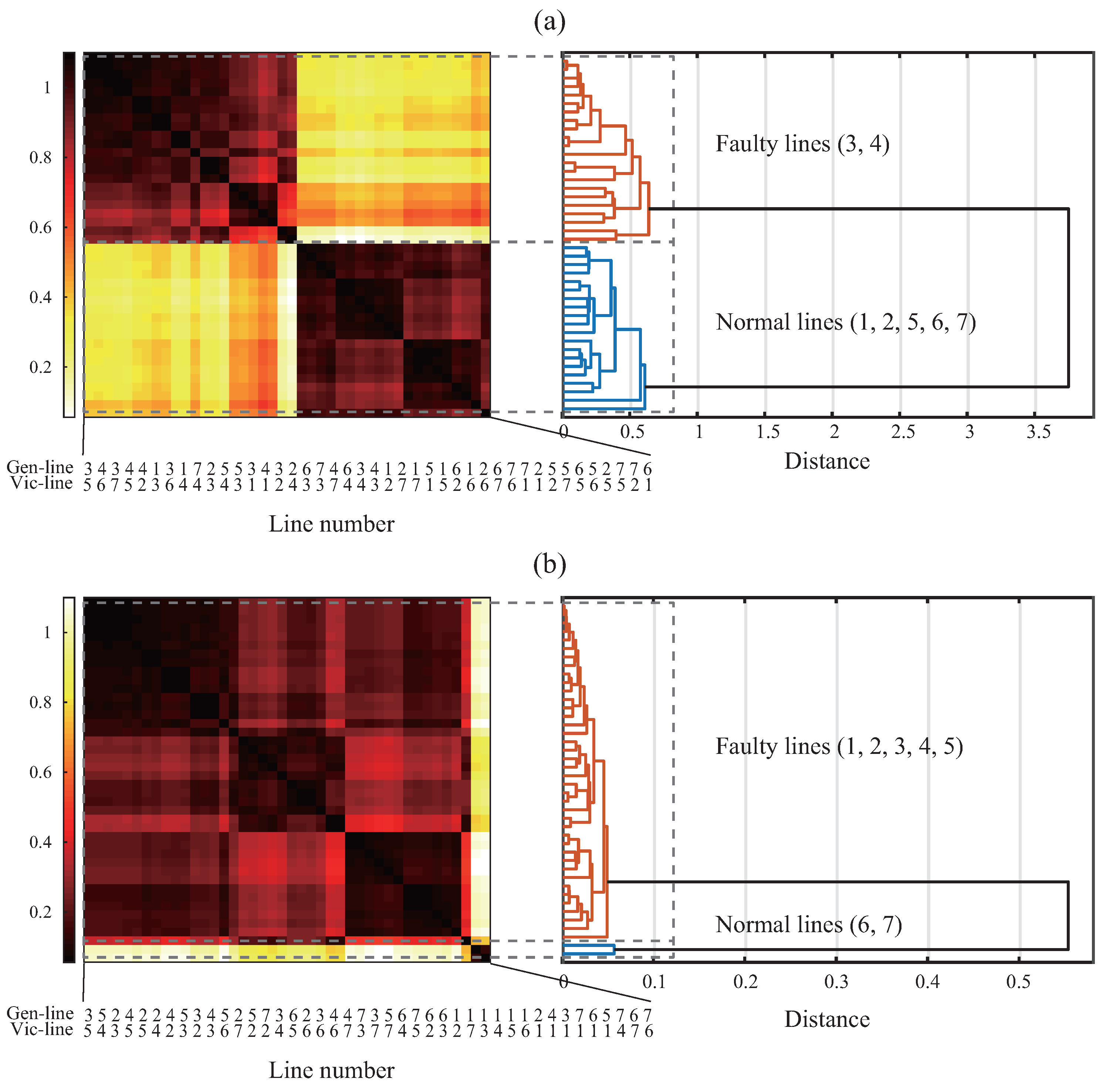

2.3. Line Classification Using Clustering Analysis

Following the detection and classification of the impedance discontinuity points, the clustering algorithm was used for differentiating faulty lines in the multi-core cable. The input features for clustering were the TFCC results and the phase synchrony index of each reflected data, which estimates the phase difference between the incident signal and the reflected signal to distinguish the characteristics of the fault. The phase synchrony between the incident and the reflected signal was estimated using the reduced interference Rihaczek time-frequency distribution, which provides a better localization for the phase-modulated signals and time-varying phases [

25]. The phase difference between the incident signal and the reflected signal is computed as follows:

The TFCC and the phase synchrony of the real impedance discontinuity point differ with the crosstalk signals. While, the TFCC values are related with the degree of the impedance discontinuity, phase difference is relevant to the type of impedance discontinuity. When at least one generation-victim line pair is defective, a reflected signal with a faulty line pair at the real impedance discontinuity point shows a high TFCC value. Estimated phase values are either the same (open) or the opposite (short) with those of the cable endpoints. Conversely, reflected signals caused by crosstalk have relatively lower TFCC values and show a different phase from actual defective lines. Therefore, a clustering analysis using the energy and phase properties of the reflected signal can be utilized to differentiate the faulty line.

We used the hierarchy agglomerative clustering algorithm which allows each data to fit into multiple clusters with varying degrees of similarities. Hierarchy clustering is used for maximizing both the similarity within the cluster and the dissimilarities among clusters. First, the starting point for each data is in its own cluster, and the cluster pair merges as it rises above the hierarchy which continues until only a final cluster remains. Let be the data set. The hierarchy clustering process was done as follows:

- (1)

Create the similarity matrix

, where

is the distance between data samples using the following formula:

where

K is dimension of the data;

- (2)

Find the closest pair of clusters and merge them into a single cluster;

- (3)

Compute similarities between the new cluster and each of the old clusters;

- (4)

Repeat steps (2) and (3) until all data are clustered into a single cluster of size N.

In the clustering process, the similarities among clusters are defined as the shortest distance between two points in each cluster which is expressed as follows:

where

X and

Y indicate separate clusters.

In addition, the silhouette index was calculated for each data cluster in order to validate its accuracy and internal consistency. The silhouette of a cluster measures the similarity of its own data and compares it with other clusters. The silhouette index for data

l,

can be expressed as follows: [

26]

where

is the average dissimilarity of l with all the other data within the same cluster,

is the lowest average dissimilarity of data

l with the data in the other clusters, (of which data

l is not a member).

indicates how well data

l is assigned to its cluster and

indicates how similar data

l is to the data in neighboring clusters. The silhouette index ranges from −1 to 1; a higher silhouette value indicates clustering results of higher quality. An average silhouette index greater than 0.5 indicates reasonable partitioning of the data [

27].

Figure 3 shows the overall fault detection and classification process for a multi-core cable, including the fault detection and faulty line classification steps.

3. Experimental Setup

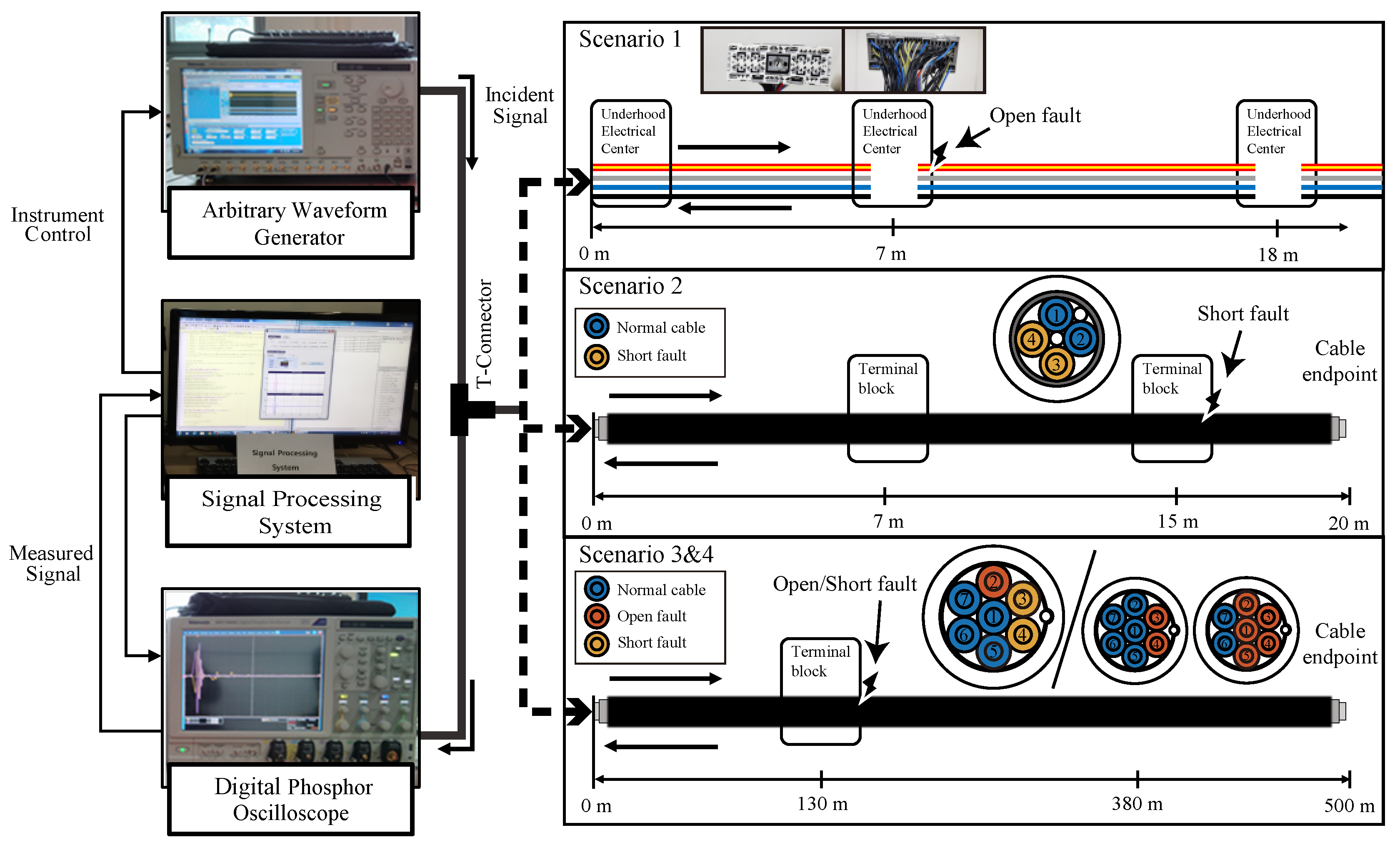

Figure 4 shows a schematic diagram of the proposed TFDR system. It consists of an incident signal generation part, a signal measurement part, and a signal processing part. After designing the optimal reference signal, the arbitrary waveform generator (AWG) creates the designed incident signal, and this signal is applied to the cable. Then, the digital storage oscilloscope (DSO) measures the reflected signal from the cable. Finally, the signal processing system receives the measured signal and performs a time-frequency analysis on it.

To verify the performance of the proposed algorithm for multi-core cable fault diagnosis, we simulated four fault scenarios using multi-core cables of varying types and lengths. The cable sample used for the first scenario consisted of four different wires of an automotive multi-wire with UEC connectors. Automotive wires possess the characteristics of lacking a jacket and having a single insulation layer for each core. The total length of the cable was 18 m, and the cable end was connected to another UEC connector. In the scenario, we emulated an open fault in the red line at 7 m of the UEC connector. We conducted the fault location detection and the differentiation of the actual faulty line among automotive wires. In the second scenario, a short fault at one of two terminal blocks (15 m) was emulated in a four-core 20 m length C&I cable of an NPP. In other words, both a normal and faulty cable junction coexist in the same cable. In the third scenario, a combination of an open and short fault was emulated in a seven-core C&I cable. In specific, one line was opened, and two lines were shorted at the terminal block (130 m). In the final scenario, an open fault due to physical stress from one external direction was emulated in the same seven-core C&I cable used in a previous scenario. Here, we detected the faulty lines of the cable and additionally estimated the direction of the external physical stress at the terminal block. The total lengths of the C&I cable samples for scenarios 3 and 4 were both 500 m with a Class 1E. The cable cross sections of the experiments are illustrated in

Figure 5. The algorithm was initially applied in long cables when using multi-core C&I cables. However, acknowledging that wires in automotive vehicles are generally installed in limited spaces, the proposed algorithm was targeted at short-length cables for experiments using automotive wires.