1. Introduction

The environment has become part of the technical-economic, strategic, and managerial decision-making of companies only in recent decades. In the past, issues related to the choice of resources and energy, reduction of waste, and emissions into the environment were usually introduced by sector, following regulatory actions laid down by various national and international public bodies. The current perspective, instead, considers the reduction of the environmental impacts of production activities a positive factor, transforming it from an “obligation” (and an additional cost) into a market opportunity and a source of internal efficiency [

1]. New production strategies must be, therefore, conceived to combine efficiency and eco-efficiency, that is, “create more value with less impact” [

2]. Promoting eco-efficiency improves eco-compatibility and competitiveness of the production system, enabling the achievement of apparently incompatible objectives, such as those of economic and productive excellence and environmental excellence.

The delay in achieving this goal is often attributed to market barriers, such as economies of scale related to the use of proven technologies and materials, and including cultural and economic factors, such as the difficulty of institutions in grasping the benefits and opportunities of developing sustainable production process [

3]. A positive contribution to the reduction of this gap can be given by the search for potential synergies between environmental disciplines and approaches and the management ones, starting from the common themes of investigation and the context of application: the manufacturing. In this regard, approaches that have great potential are those included, respectively, in the field of Industrial Ecology (IE) [

4] and those based on Lean Manufacturing (LM). IE has been recognized as a wide research field, focused on environmental improvements in production and consumption activities; conceived as the science of sustainability, IE uses an interdisciplinary approach to the design and operation of economic systems in an interdependent way with the natural system, in analogy with biological ecosystems [

5,

6]. It involves products and processes design and technology, organization, and management solutions [

7]. In IE, issues, such as biodiversity, carrying capacity, life cycle, metabolism, are analyzed to learn and try to implement “nature lessons” in economic systems [

8]. In these systems, each process is part of a large cycle involving various interdependent and interacting organisms; waste produced by an organism represents a resource for others and is, thus, cost-effective because it reduces waste to a minimum. The application of IE principles can support a sustainable industrial development or redevelopment; the efficient use and flows of materials and energy in products, processes, industrial sectors, and economies are investigated to highlight the potential role of industry in reducing environmental burdens [

9,

10,

11].

LM (or Lean Production) is a management approach that considers wasteful the resources used to any other purpose other than the creation of value for the customer. It provides a set of tools to detect and remove/reduce such waste [

12]. The common concept of “waste” (

Muda, or non-value) in LM and “waste” (scraps/rubbish/garbage) in IE, can be considered the basis of their integration. This article presents an overview on the development of the main production paradigms of the twentieth century and the variables at the basis of competitiveness in this era; it, therefore, proposes an analysis of the potential for integration between the IE and LM approaches in contemporary production systems, in order to promote the application and dissemination of strategies and tools that combine competitiveness and sustainability. In the first part, the main key performance indicators of manufacturing will be identified and the guiding principles and operational tools of approaches “Lean” to the production activity are introduced, especially for their ability to pursue efficiency through the reduction of Muda. The environment as new variable will be then introduced, including the perspective proposed by the IE. To conclude, on the basis of the value/waste relationship and the concept of eco-efficiency, contributions in the literature on the possible links between LM and IE approaches and tools will be highlighted; as a result, integrating sustainable strategies in the Lean models is suggested by considering the environmental load as an additional kind of

Muda.

2. Principles and Paradigms of Manufacturing

Dating back to the last century, two main phases prevailed in the development of manufacturing, namely “Fordism” and “post-Fordism”. The former represents the key features of an industrial paradigm, while the latter represents a set of alternative production models, alternatively focused on a technological, organizational, and managerial basis. This path of evolution includes the emergence and consolidation of the most important management variables and performance indicators.

2.1. Fordism: the Rationality

The origin of Fordism traditionally dates back to 1913, the year in which Henry Ford established the mechanization of the assembly line at a plant in Dearborn, Michigan [

13]; but the introduction and consolidation of Fordism were actually far more complex processes. Fordism is typically based on a technical and production model,

i.e., the mass production, to obtain the maximum value of standard products, which points to the maximum quantities of uniform products, by means of the rigid sequence of the flow of production, guaranteed by the assembly line and a business organization with long-term planning of production, strongly hierarchical, with strict division between planning and execution. Over time, it has gradually transformed into an economic paradigm, in which large-scale production, aimed at containing

costs (C) and making low-price products, available for an emerging new social class (the factory workers), ensuring profit for companies and growth to the whole economic and social system. A unifying feature of Fordism is the

rationalization of products, processes, resources, and labor, as well as the whole society.

2.2. Post-Fordism: the Flexibility

The overcoming of the Fordist paradigm does not take place by the application of a new conceptual model, but, rather, as the result of an independent series of changes adopted in response to an emerging new economic and production phase. The large factory ceases to be the referential model, giving way to smaller production units characterized by a greater specialization. Functional hierarchy is then surpassed: all companies involved in the supply chain become autonomous units of a unique production process; this new model has been defined as

flexible specialization [

14]. Affordability and differentiation are opposite features that current technologies cannot reconcile: companies are, thus, faced with the so-called

productivity dilemma [

15], which focuses on flexibility (F), while maintaining high productivity levels. Companies move from the relentless pursuit of economies of scale towards the search for “economies of scope” or “variety”, not referring to reductions in the average cost per unit but associated with lowering the average cost in producing a wide range of products. Thus, setting up competitive advantages arises largely within the production system: innovation in manufacturing then becomes a significant competitive lever [

16].

2.3. The “Toyota Production System”: The Effectiveness

The most effective alternative to Fordism is named for the company, which firstly invented and implemented it: the

Toyota Motor Company [

17]. The Japanese model of the Toyota Production System (TPS) is probably the most comprehensive expression of the post-Fordism phase, which is reached not so much with technological innovation as with organizational and management innovations. The TPS view of the supply chain and logistics activities, named Just-in-Time (JIT), required perfect timing between the production line and suppliers to ensure that purchased materials are delivered only when needed [

18]. The implementation of JIT has led to increased levels of productivity and quality in production and has enhanced the responsibility and commitment of workers in Japanese industries. One of the basic conditions of the TPS, is making differentiated productions for ever changing and increasingly demanding markets; it is a production system designed in a general economic context of low or zero growth [

19]. The crucial issue for each company’s management became increasingly to survive; as a result, costs were constantly reduced without increasing production, but reducing and differentiating it, thus, transforming the relation between production and the market.

2.4. The Role of Quality

A crucial role in manufacturing can be attributed to the variable

quality (Q). The concept of Q has always been present in economic issues, since the beginning of trade; however, in the first post-world war period, the technological development and the renewed market expectations triggered the need to design methods and systems to set Q targets, as compliance with design specifications. In 1959, the U.S. Department of Defense issued the first regulation to solve Q problems in manufacturing, in particular in the nuclear and aerospace industries. The groundwork was then laid for a “quality system”. In the United States, the development of Q concept led to the Total Quality System (TQS) view, based on the Total Quality Control developed by Feigenbaum, a “management methodology essential for the company and for customer satisfaction, an effective system to integrate the efforts of developing, maintaining, and improving the quality of the various organization groups so that marketing, engineering, production, and assistance are performed at the highest levels of economy, in line with customer satisfaction” [

20]. Simultaneously, in Japan, a different approach was developed, known as Company Wide Quality Control (CWQC), inspired by the TQS, but based on a completely different concept. The CWQC is a real management strategy that aims to achieve maximum customer satisfaction through an involvement of all employees, from management to operational staff, towards excellence, to be pursued through a process of continuous improvement, so-called Kaizen [

21,

22]. Recently, the concept of manufacturing has progressively assumed a wider perspective, which includes, not only technical issues, but also social and ethical aspects [

23].

2.5. The Timeliness and the Relevance of Processes

At the end of the twentieth century, a referential variable in assessing business production performance is represented by

time (T). In the 1980s, in fact, new management models that attempted to counter the growing complexity of context, by focusing on the processes and how to respond to the dynamics and variability of the markets were established. The objective of the joint improvement of performance, traditionally considered antithetical, oriented companies to the so-called Time-based competition [

24], in which the benefits of reducing the overall time of the new products development (

time-to-market) and operational processes (

lead-time of production, logistics, and administrative processes) are highlighted. The ability to develop and introduce new products faster than competitors, implies significant benefits in terms of profitability and market share, while reducing production and logistics cycles determines benefits in terms of improved joint performance, previously considered incompatible. Thus, key objectives do not affect obtaining the maximum efficiency and saturation of each single resource or activity, but, the overall performance of the production system (e.g., product quality, throughput time, flexibility of response) [

25].

2.6. Value in Production Dynamics

The most popular formalization of the

value analysis (V) in manufacturing, as a measure of the operating effectiveness of companies, has been provided by Porter [

26]; he uses the value chain (VC) concept to quantify the contribution of each business activity for the production of the total value and the ability to transfer it to their customers. The ultimate goal is to maximize the margin, or added value, as the difference between the product/service (P/S) price and all costs generated by the various business activities, known as

value-adding activities. Porter identifies the cost leadership and the differentiation as two strategic alternatives in achieving the so-called Competitive Advantage, in order to maximize internal efficiency, and, thus, reduce overall Cs, or try to raise the sales

price (P) acting on customer expectations. Subsequently, the VC concept tends to take on a broader meaning, considering also the external relations and the connections/relationship along the supply chain.

The analysis of the links among the activities carried out by external stakeholders focuses the analysis on the entire “value system” [

27], made up of the value chains of competitors, suppliers, distribution channels, and final customers. The emphasis on connections allows overcoming of some limitations of the VC model. In fact, it has been observed that the economic actors are not related to each other according to the most simple, unidirectional, and sequential model described by the VC, but in far more complex modes [

28,

29].

3. Value and Wastes: The “Lean Manufacturing”

As illustrated so far, the relevance of the different variables to define the “rules of the game” in manufacturing is continuously changing. Technological, socio-political, and market pressures have revealed the most important pillars on which competitiveness is based, at different times and in different ways: reduce Cs, reduce T, and enhance Q to maximize V. The organization model that perhaps best embodies this

modus operandi, was theorized in the early 1990s by Womack and Jones and is known as Lean Production (LP). The two researchers define it as a production practice that considers the expenditure of resources for any goal other than the creation of value for the end customer to be wasteful, and thus a target for elimination [

12]. This is an approach that has incorporated the JIT and TQC principles, extending them to production processes, to logistics and finally to the supply chain system.

The Lean approach introduces another key variable in manufacturing: the concept of “waste” (W),

i.e., any activity performed by a company, which absorbs resources and does not create “value” for the end customer. This concept derives from the Ohno analysis [

30] in the TPS, who used the term

Muda for the first time indicating non-value activities. The seven most common types of waste or Muda are related to:

Transport—this activity is associated to the transport of materials; it does not create value, but is often indispensable. It must however be highlighted that the more a product is transported, it is more likely to have higher Cs or delays (T), or an increase of damage and loss Q.

Waiting—the waiting waste happens when operators are stopped waiting for parts, machines, or other colleagues. The possible causes are generally the lack of material in warehouses or failure of machinery for processing. Waiting negatively affects C and T.

Motion—people or equipment moving or walking more than is required to perform processing. Moving more than is required has negative effects on C and T and may cause damage and injury to the operator.

Inventory—this Muda is referred to raw materials, work in process, or finished goods that spread all over the shop-floor and warehouse. The presence of minimum inventory is positive, because it allows the guaranteeing of the continuity of the production process, if the production is discontinuous or characterized by a high number of types of product. However, the period of storage of products and components is a time that does not add any kind of value, and it generates costs (lighting, handling, immobilization, air-conditioning of the premises) and risk of damage.

Over-processing—occurs when more work is done on a process than is necessary. This also includes using components that are more complex or expensive than absolutely required.

Overproduction—it occurs when product is produced more than demand. This Muda is related to the waste of stock of finished products. Producing in excess, in fact, needs to use, in advance, some corporate resources and the above needs to have the finished products’ warehouses in which to store the materials awaiting sale.

Defects—one of the most obvious forms of waste is represented by defective products. Defects slow down production and increase lead time (T). Defects represent a threat to companies because they may occur in various ways. If there are no systematic and valid control methods in the production system, the defect may not be identified and the product may unnecessarily be processed, causing a high financial burden for the company (C) or even delivered to the customer (Q).

Subsequently, Womack and Jones [

12] introduced an eighth Muda:

Manufacturing products that do not meet customer demand, based on a fundamental concept of “customer value”,

i.e., Q characteristics of the product that meets customer demand at a given price and time. It is based on the concept of utility [

31], intended as the capacity to bring practical advantages to users.

The perception of quality (performance) of the product purchased, in relation to competition and to the total price paid, contributes in determining its “value”. Any activity that consumes resources but creates no value to the customer is Muda and could be either saved (reduce price and maximize margins) or reinvested to produce performances that meet customer demand (with the ability to raise selling price). An “

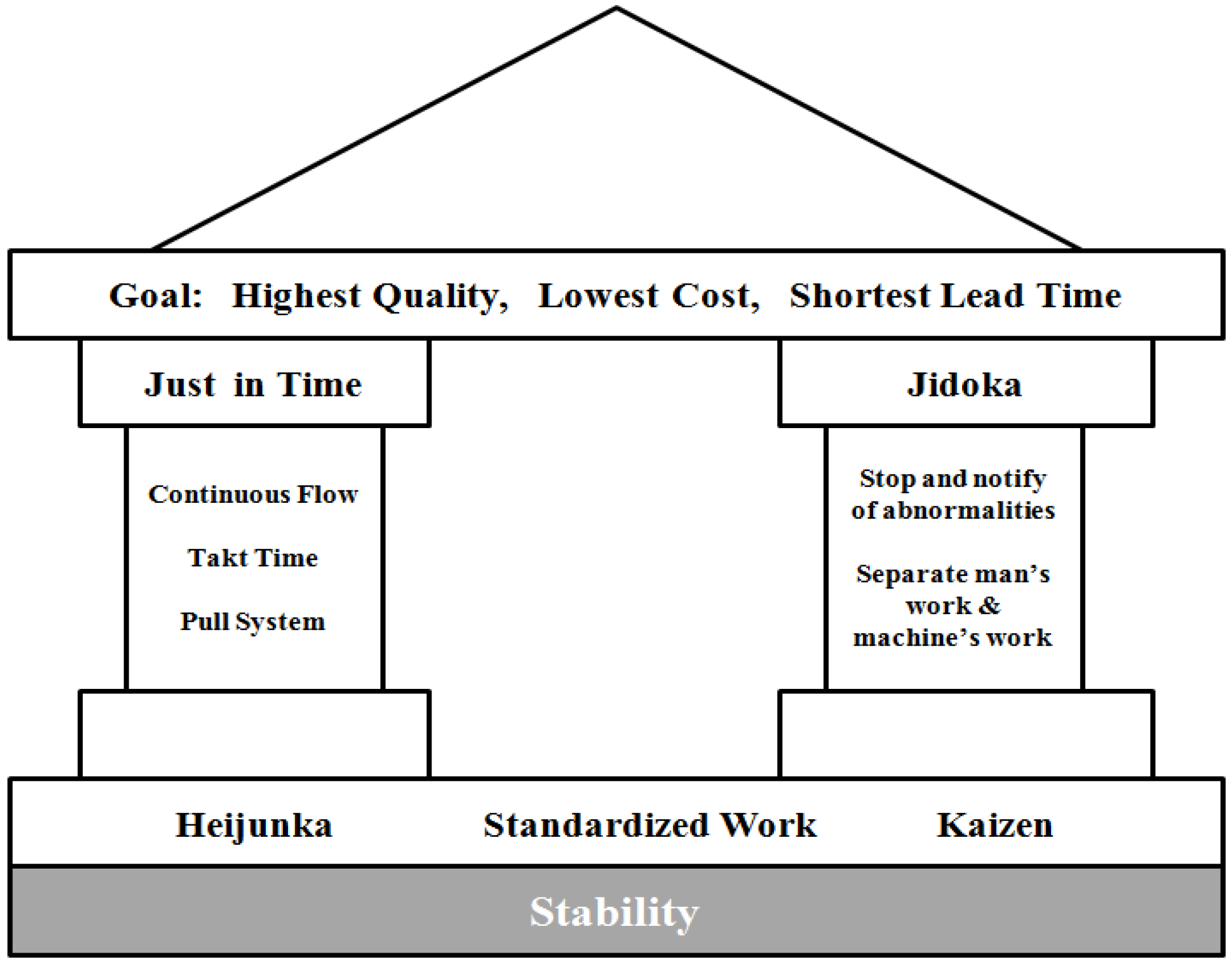

ad hoc” tool for each form of Muda removal and containment is developed in the Lean approach. These tools and their relationships are typically depicted in a scheme recognized as “Lean Manufacturing House” or “Toyota Production System House” (

Figure 1).

Figure 1.

Toyota Production System House (Adapted from [

32]).

Figure 1.

Toyota Production System House (Adapted from [

32]).

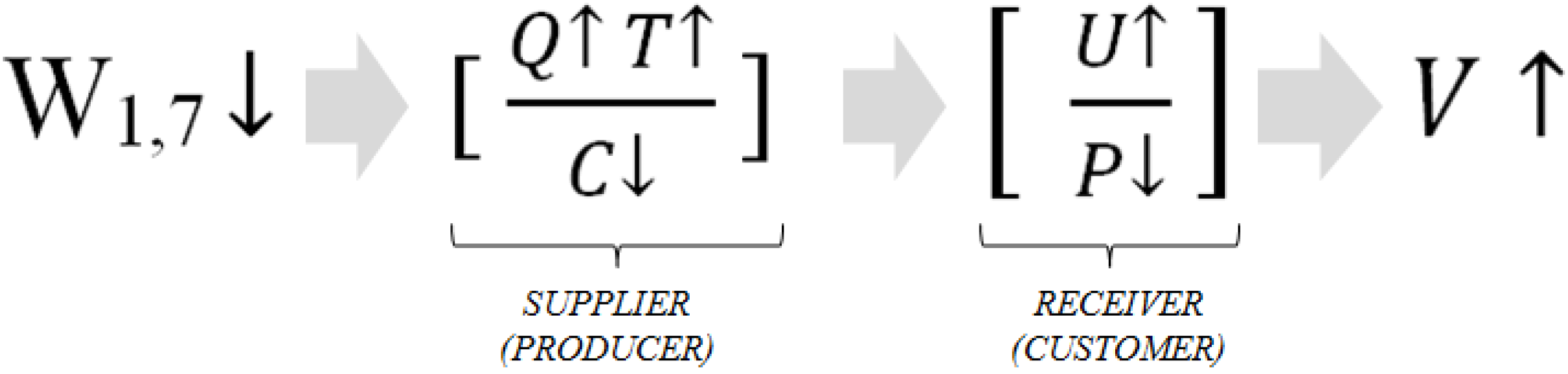

The major contribution of the “Lean” manufacturing lies in being able to integrate into a single, consistent view based on the value, the more important variables up to that point identified and recognized in manufacturing, and have identified in Muda the operational issues on which to take measures to improve the efficiency and, therefore, the overall performance. The importance of removing Muda is based on the direct connection of such variables; by intervening on a Muda, a synergistic and positive effect on the competitiveness of the entire system is enhanced. It is clear that, improving internal efficiency by operating on transportation, handling and inventory implies improving Q, T, or reducing Cs, and, thus, be able to manage prices, or provide a higher level of performance to the customer and then to increase value. The following scheme (

Figure 2) summarizes how a reduction of the seven Muda listed above may reflect in a positive effect on the major performance indicators of the Lean approaches (C, T, Q) and how this would enable the supplier/producer to increase the satisfaction (perceived usefulness) of the receiver/customer or lower selling prices (margins), that is, increase the value produced and transferred.

Figure 2.

Manufacturing variables in the “Lean” perspective.

Figure 2.

Manufacturing variables in the “Lean” perspective.

Customer loyalty determines for a company a steady stream of positive results over time and promotes the ability to maintain leadership, thus enhancing and consolidating its position [

33].

4. Environmental Issues in Manufacturing: The Clean(er) Production

In the past, the relation manufacturing/environment was based on the assumption that the environment was able to absorb a certain pollutant load without significant imbalances; therefore, environmental damage could be avoided by controlling the way, the time, and rate at which pollutants were released.

Against this background, the uncontrolled release of many harmful substances, led to a costly repair to remedy the damage of the past and to isolate pollutants through the end-of-pipe system. These actions settled pollution problems at local level, but created new problems. In fact, the end-of-pipe systems often simply transfer pollution from upstream to downstream of the production chain, i.e., from an environmental receptor to another without, therefore, resolving the problem. In addition, the end-of-pipe measures, although not as costly as the repair of damage to the environment, contribute to an increase in production costs and require a regulatory control that have proven to be ineffective due to high costs and the amount of work needed.

Awareness of these limits has gradually shifted the focus from reactive actions (

pollution control) to preventive actions. While reactive actions focus on measures to reduce risks and damage caused by waste and harmful substances after being produced, preventive actions focus on the conditions and circumstances to avoid damage before it occurs. The preventive strategy includes product reformulation/redesign, modifying consumer models, reducing the use of harmful substances and waste minimization; “prevention is better than cure” is the basis of environmental policies aimed at encouraging the implementation of so-called

cleaner technologies. The Organisation for Economic Co-operation and Development (OECD), has adopted a more process-oriented production strategy and defines cleaner technologies as “

Technologies that extract and use natural resources as efficiently as possible in all stages of their lives; that generate products with reduced or no potentially harmful components; that minimise releases to air, water and soil during fabrication and use of the product; and that produce durable products which can be recovered or recycled as far as possible; output is achieved with as little energy input as is possible” [

34]. Cleaner technologies can be adopted through substantial change in production processes, or integrating partial changes in current processes to recover and boost by-products otherwise unused. Adopting cleaner technologies to improve functional performance and redefining commodity markets, implies changing production processes to improve overall environmental conditions. It, thus, represents stepping up restructuring systems and an important opportunity to retrieve efficiency.

Process and product innovation is an essential tool to achieve positive results in managing the environmental variable. This requires, for companies, introducing new organizational solutions that enhance environmental compatibility of products and business processes and improve business competitivity. Companies are now required to meet environmental compliance, which results in higher costs “downstream” of the process. To reduce these costs, required by institutions and social bodies, companies tend to focus their attention “upstream” of the process due to the respect of environmental standards imposed by law. In order to reduce these costs, under the social and institutional pressure, the companies tend to move the focus “upstream” of the processes. An in-depth analysis of product Life Cycle, from cradle to grave, becomes, thus, crucial. In this way, it is possible to identify, at each stage, the most appropriate solutions, in terms of the change in the mix of raw materials, modification of the process, to reduce at source the quantity and harmfulness of the solid, liquid, and gaseous emissions. These interventions to protect the environment upstream of the production processes involve significant advantages for companies, related to public inspection bodies, and to reduce long-term business management costs.

The evolution of the “clean” approaches to the manufacturing issues can be referred to the conceptualization of the Industrial Ecology (IE). As previously mentioned, IE aims at reducing waste and pollution by using by-products or waste deriving from certain production processes, such as raw materials for others. Applying IE in production systems implies adopting a manufacturing approach in which the environment provides a positive contribution to the system’s competitiveness by maximizing efficiency in the use of raw materials and natural resources. In the field of IE, tools for the design, assessment and management of production systems from the perspective of eco-compatibility have gradually found a place (e.g., Design for X [

35] and Life Cycle Assessment [

36]). If, from a theoretical point of view, principles and tools of IE provide solutions that enlarge the perspective of environmental management in manufacturing [

37], from the operational point of view is still missing, by companies a strategic vision of this variable, which has not yet been fully internalized while representing the next pillar of competitiveness.

5. From Efficiency to Eco-Efficiency: The Relationship Value/Waste in Manufacturing

When, in 1999, the World Business Council for Sustainable Development (WBCSD) developed the concept of eco-efficiency, its intention was help measure performances in terms of economic and environmental sustainability in business. The WBCSD affirmed that “

the eco-efficiency is achieved by providing competitive products and services that satisfy human needs and lead to higher quality of life, progressively reducing the ecological impact and use of natural resources throughout the life cycle of a product, in line with the carrying capacity of the Earth” [

2]. Eco-efficiency indicators primarily serves as a decision-making tools for internal management to evaluate performance, set targets, and initiate improvement measures; they also represents important tools for communicating to internal and external stakeholders. In order to calculate eco-efficiency, the WBCSD has developed the following equation, which merges value and ecological aspects into an efficiency ratio:

This relation summarizes the above-mentioned goal of “create more value with less impact”. Eco-efficiency progressively leads the assessment of the environmental impact of processes and products to be one of the main strategic and operational criteria of choice in business. Issues relating to the reduction of resource use, as well as the decrease of airborne, waterborne, and soil emissions and waste released should be dealt with a preventive approach integrated into the production process. Such an approach includes the redesign of products, the introduction of cleaner technologies, the reduction of harmful substances, a change in patterns of consumption, the minimization of waste. The environmental impact in the life cycle of a processes, products or economic activities is minimized when it is possible to reduce the amount of materials and energy flowing through them; if the reduction is achieved without reducing the level of service, and, thus, the final value, an improvement in the overall process efficiency can be obtained by eliminating waste and unnecessary costs. Eco-efficiency makes a direct connection between environmental goals and firm profitability by incorporating the efficient use of the environment into the firm’s strategic planning.

In the light of the notions/concepts of efficiency and eco-efficiency, over the past two decades numerous studies have been developed. Starting from the “clean” (including the IE approaches) or the “lean” manufacturing standpoint they have investigated the links between the concepts of value, waste, productivity, strategies, competitive advantage, and their application to manufacturing contexts, even in the broad sense of the supply chain/life cycle perspective.

5.1. “Clean” Manufacturing and Competitiveness

Already, in 1995, Porter and Van der Linde [

38] stated that pollution is often a form of economic waste, considering scraps, harmful substances, energy discharged into the environment has forms of resources that have been used incompletely, inefficiently, or ineffectively. In this article, focusing on the concept of resource productivity, they explore hidden costs along the life cycle of a product that are also sources of pollution, and that reveals flaws in the product design or process development. Later, Handfield

et al. [

39] published in the Journal of Operations Management a taxonomy of environmentally friendly (“green”) operation management best practices within the VC (1996), integrating interviews with managers of five major companies operating in the furniture industry. The results of this work have shown that to be successful, strategies for environmental management should be integrated into every stage of the VC, and how, their implementation may lead to benefits in terms of competitive advantage. In 1998, Easty and Porter [

40] analyzed the potentials of IE as a tool for shaping firm strategy and competitiveness. They observed that IE, moving from the goal of

resource productivity, may lead to innovations that improve efficiency, lower costs, and raise the value created by a production process. In particular, thy stated that the systems perspective of IE can help companies find ways to add value or reduce costs both within their own production processes and up and down the supply chain. However, they also point out that, despite having a high value as a tool for the discovery of new sources of competitive advantage cannot be a fundamental element of the entire production strategies, because there are other sources of cost reductions or increase in value and why, in the short period, the increase in costs due to investments “green”, would grant a temporary competitive advantage to competitors. From a more practical point of view, Tsoulfas and Pappis [

41] addressed the problem of identifying environmental principles for the design and operation of supply chains, moving from a background of environmental principles for achieving eco-efficiency and building of environmentally friendly organizational systems. Using a “cradle to grave” approach they provide some remarks regarding the benefit for companies: first, a sustainable approach can lead to internal cost savings from a more efficient use of resources; second, sustainability can open new markets; third, opportunities abound to assist other companies and communities in emerging markets. The external validity of the assumptions that the implementation of eco-efficient business strategies is associated with higher firm value has been verified by Sinkin

et al. [

42], who, in 2008, published a study of 90 eco-efficient company, compared with 341 companies not eco-efficient. They posit that, firms, which adopt eco-efficient business strategies, are highly valued by the market than similar firms that do not adopt eco-efficient business strategies. This suggests that the adoption of eco-efficient business practices can be associated with increased firm value. More recently, within an editorial article opening a special issue of the Journal of Industrial Ecology related to the Third International Conference on Eco-efficiency, Lifset [

43] confirms that eco-efficiency has always been a part of Industrial Ecology, sometimes implicitly (with some sub-fields of research), and at other times explicitly, through conferences and research articles. He recognizes that recent contributions generally focus on a more macro-level set of issues rather than the early work in eco-efficiency, which tended to assess individual products and processes and highlight some limitations in the development of the field: the need for systems-level thinking and the need of methodological development in the field.

5.2. “Lean” Manufacturing and Environmental Issue

However, in 1996, Florida [

44] emphasized the links between the concepts of lean and clean manufacturing, exploring the relationship between advanced production practices and innovative approaches to environmentally conscious manufacturing. Through a survey and a field research, he brings to light two sets of results that support the existence of this positive connection. First, that LM approaches create opportunity for the development of green strategies moving from the same principles: continuous and productivity improvement, quality, cost reduction, and technological innovation; second, that close relations among the actors of the supply chain (from suppliers to end users) can enable the simultaneous adoption of the lean and green strategies. Some authors reached the same findings, analyzing the relations between the quality and the environmental management standards. Subsequently, King and Lenox [

45], conducting an empirical analysis of the environmental performance of more than 17,000 manufacturing companies during the period 1991–1996, found that those companies that adopt the ISO 9000 standards was more likely to adopt the ISO 14000 standards. In addition they show that LM can positively contribute to the adoption of green strategies, acting on the marginal costs of pollution prevention and on the managerial capabilities. During the same period, other researchers obtained conflicting results, such as Rothenberg

et al. [

46], analyzing the relationship between LM and environmental performance in 31 automobile companies between North America and Japan. The statistical part of their study showed no significant links between emissions reductions and JIT procedures, especially in respect of the investments in technology. The qualitative analysis instead revealed direct positive relationships between some aspects of the LM (buffer minimization, work systems, and human resource practices) and the propensity of managers to improve the efficiency in the use of resources, as the LM focuses on general waste reduction, provides managers with the basic skills and an attitude focused on continuous improvement. A clear representation of the indirect effects on the environment of the LM has been provided by Moreira

et al. [

47]. One of the most significant contributions to the ongoing debate on lean and clean manufacturing comes from the U.S. Environmental Protection Agency (EPA). Since the early 2000s, the EPA has initiated a series of surveys among the largest U.S. firms to investigate the links between the use of Lean approaches and environmental performance. Those studies have shown that the adoption of Lean approaches in many cases had enabled the company to achieve significant improvements on resource productivity with important implications on the environment. Moreover, the continuous improvement and the elimination of wastes were very similar and close to the organizational culture encouraged by the EPA, to promote, through the development and promotion of environmental management systems, pollution prevention and waste minimization. On the basis of these findings, the EPA has launched initiatives systematic research on this issue that led to the publication of numerous scientific papers and applications, such as a report in 2003 [

48] and a toolkit in 2006 [

49], development of case studies, and specific documentation for some productive sectors to integrate environmental considerations into initiatives and Lean methods (

Table 1). In particular, the report of 2003 states that

“Lean manufacturing is a leading manufacturing paradigm being applied in many sectors of the U.S. economy, where improving product quality, reducing production costs, and being “first to market” and quick to respond to customer needs are critical to competitiveness and success. Lean principles and methods focus on creating a continual improvement culture that engages employees in reducing the intensity of time, materials, and capital necessary for meeting a customer’s needs. While lean production’s fundamental focus is on the systematic elimination of non-value added activity and waste from the production process, the implementation of lean principles and methods also results in improved environmental performance”.

Table 1.

Environmental impacts linked with manufacturing wastes (Adapted from [

48,

49]).

Table 1.

Environmental impacts linked with manufacturing wastes (Adapted from [48,49]).

| Waste Type | Environmental Impacts |

|---|

| Transports | |

| Waiting | Potential material spoilage or component damage causing waste Wasted energy from heating, cooling, and lighting during production downtime

|

| Motions | More packaging required to protect components during movement Damage and spills during transport Transportation of hazardous materials requires special shipping and packaging to prevent risk during accidents

|

| Inventory | More packaging to store WIP

Waste from deterioration or damage to stored WIP More materials needed to replace damaged WIP More energy used to heat, cool, and light inventory space

|

| Overprocessing | More parts and raw materials consumed per unit of production Unnecessary processing increases wastes, energy use, and emissions

|

| Overproduction | More raw materials and energy consumed in making the unnecessary products Extra products may spoil or become obsolete requiring disposal Extra hazardous materials used result in extra emissions, waste disposal, worker exposure, etc.

|

| Defects | Raw materials and energy consumed in making defective products Defective components require recycling or disposal More space required for rework and repair, increasing energy use for heating, cooling, and lighting

|

More recently, some studies, in a broad perspective of investigation, have considered the relationship between Lean and Green approaches in global supply chains, highlighting possible synergies, trade-offs and conflicts between the two. In 2010, Mollenkopf

et al. [

50] have shown that although some aspects of the LM approaches, such as the reduction of the flow of materials through the supply chain, has undeniable positive effects on the environment (reduction of materials extracted, produced, packaged, handled and transported), on the other hand, JIT delivery methods, based on the reduction of lot-sizing, being more numerous may affect negatively. The authors highlight the need to develop tools to solve such conflicts and help the managerial decision making to find solutions that take into account Lean, Green an Supply Chain Management goals. In respect of this, studies have been published trying to reproduce, in a comprehensive model, these different perspectives. Newly, Hajmohammad

et al. [

51] hypothesized a model that suggests that supply management as well as LM activities provides means by which environmental actions can be encouraged. Although the study sample was limited to a sample of Canadian manufacturing plants, the empirical evidence provides the interesting findings that a suitable route to facilitate the implementation and adoption of environmental practices is by setting an adequate operating context based on lean and supply management principles.

6. Discussion: The Environmental Load as the 9th Muda

The real gap that still exists in integrating lean and clean manufacturing lies in the ability of businesses to integrate the two perspectives at the operational level, as Kidwell [

52] said:

“Lean usually helps the environment without really intending to many companies were saving money by taking steps that also benefited the environment, even when they were not consciously trying to do so”. The large part of the environmental loads (related to the choice of resources and energy used and the management of solid, liquid, and gaseous emissions released into the environment) represents, for manufacturing companies, wastes that do not produce value for the customer, while generating costs. Equally important, for a real lean and clean manufacturing, is the development and the integration, at the operational level, of the tools capable of detecting such inefficiencies and improving the production system.

LM already incorporates the most important management variables (C, T, Q, V) and is able to detect problems and propose solutions to manage them efficiently; on the other hand, IE offers approaches and tools to manage the environment variable in an eco-efficient manner. Both LM and IE have a system-oriented perspective of analysis and focus on the reduction of wastes. The starting point for the development of production lean and clean can be sought in the synergistic relationships between the concepts of Value and Wastes (in terms of Muda and scraps). The environmental variable will be accepted by manufacturers as part of the strategic and operational choices only when they will be convinced that is capable of producing beneficial effects in terms of competitiveness. It could become possible if companies learn to consider the “environmental load” as an additional Muda; this would allow detecting hidden sources of waste and pursuing higher levels of eco-efficiency. At the time when the 8th Muda was introduced, the expansion of the boundaries of the manufacturing system allowed companies to further improve the internal efficiency and, therefore, the competitive advantage: a product is not in line with customers needs means that internal resources (T and C) have been used in a wrong direction. Similarly, a further extension of the boundaries of the production system, adopting an approach based on the life cycle would allow to detect new sources of internal efficiency, a reduction in the intensity of matter or energy in a process or a product, with the same performance, allowing to save costs of materials, energy, handling, transport; a proper management of hazardous or toxic substances, can reduce the costs of any penalties or compensation for damages related to products; investing in recovery and recycling of waste materials would allow to diversify the business, and get at significantly lower cost of quality secondary raw materials. As well as for the first eight, the 9th Muda implies the implementation of identification and intervention tools that can be usefully provided by the IE:

Identification tools—The sources of the 9

th Muda could be detected using Life Cycle Oriented tools (Life-Cycle Assessment (LCA) [

36] and Life-Cycle Costing (LCC)) [

53], capable in identifying those solutions that would feature the lowest overall environmental impact, and, consistently with that, an improved operational and economic performance of the industrial system. LCA is a methodological framework, defined in international standards (ISO 14040 series), for identifying and assessing the environmental impacts generated by a product, process or activity throughout its life cycle. All activities or processes in a product’s life, indeed, result into environmental impacts due to consumption of resources, releases of substances into the natural environment, and other environmental exchanges (e.g., radiation). LCC is a method to forecast, analyze and design costs and profitability, which considers the whole life extension of a product, service, process, or project. Given that, optimizing decisions and choices requires a joint evaluation of environmental impacts and economic costs and benefits, there is the need to combine LCC and LCA. The integration of management accounting tools (such as LCC) and environmental management systems and tools, such as LCA, is typical in the logic of Life Cycle Management (LCM). In an LCM context, LCC—which might be defined as “parallel to LCA” or “LCA-type LCC”—is designed to analyze all the internal and external costs (incurred or estimated) associated with a system, product, process, or activity, and met throughout their life cycle referred to a specific functional unit. The simultaneous use of LCA and LCC allows to achieve the minimization of environmental impact and the improvement of eco-efficiency at a system level. Despite considered as complex and expensive procedures, both in terms of time and costs, LCA and related tools are recently undergoing a wide spread, which is having a positive impact on their applicability, also in the context of manufacturing. There are numerous examples of free and reliable on-line software and many efforts are being made to simplify procedures and develop increasingly targeted sectoral guidelines; the same can be said for the collection of data through the integration of LCA and Enterprise Resources Planning software and tools. The purpose is to increase as much as possible the timeliness and the flexibility of such tools in order to provide a reliable and timely database for the production decisions-making.

Intervention tools—Recently, new design approaches have introduced into the design process issues related to environmental aspects of a process or a product, both in terms of resources, energy, and waste; those approaches were classified under the generic concept of DfE (Design for Environment), also known as Eco-design, Environmental Design or Sustainable Design. Principles of DfE include: dematerialization, product-life extension, closing the product life cycle, enhancement in energy efficiency, improvements in product distribution, and reduction of environmental impacts [

54]. The adoption of DfE can affect products, production processes, or both. Analyses and interventions should focus on those rules and organizational routines allowing companies to get their typical output. DfE implementation will require a deep knowledge of the state of the art of manufacturing processes; the breakdown of processes into elementary units; the identification of those elements, which may contribute to improving the environmental performances; the identification of possible alternatives and the choice of the most efficient ones; and the subsequent verification of the validity of the choice(s) made. Re-design is a crucial step in an eco-efficient manufacturing context to enhance/improve the environmental standards and performance of existing processes and products.

This new perspective will provide significant insights about the possibility of reducing the overall environmental impact of products, due to the efficient use of resources and energy needed to activate the production processes; this means an increase in competitiveness of the whole manufacturing system by reducing wastes.

Figure 3 illustrates how, by internalizing the environmental variable (E) in the strategic and operational business decision-making, and adopting a life cycle-based perspective, it is possible to go beyond the objectives of internal efficiency and market efficacy, towards those more ambitious of eco-efficiency.

Figure 3.

Manufacturing variables in the perspective of eco-efficiency.

Figure 3.

Manufacturing variables in the perspective of eco-efficiency.

With the adoption of an eco-efficient approach, enterprises will be also demanded to have the ability to steer a process that extends beyond the mere manufacturing and which, starting from design, goes throughout a product’s life cycle, implementing methods and skills capable of integrating suppliers and clients in such renewed perspective. Industrial cooperation and integration must be considered essential, as regards both physical and information flows [

55].

7. Conclusions

Cost, time, and quality have been the pillars on which was focused the competitiveness of manufacturing companies over the last century. More recent trends focusing on a renewed interest in environmental issues and socio-ethical values have gradually imposed the transition towards low impact economies. The full integration of the environmental variable in the production decision-making should lead to a more rational and eco-efficient use of resources and reduction of pollution and wastes. However, a gap still remains to simultaneously achieve the economic and the environmental goals, e.g., due to the companies’ limited economic resources, the lack of knowledge of some tools, the business size and the resistance to change. An interesting and promising perspective for achieving internal efficiency, market effectiveness and environmental eco-efficiency is that of integrating the Lean Manufacturing (LM) and the Industrial Ecology (IE) approaches and tools. LM, perspective yet includes the most important management variables (cost, time, quality, value) and is aimed at implementing solutions to manage them efficiently; approaches and tools developed within IE research field allow to manage the environment aspects of manufacturing in an eco-efficient way. Both LM and IE have a system-oriented perspective of analysis and focus on the reduction of wastes. Starting from the concepts of Value and Wastes, this study presented and overviewed about the evolutionary dynamics of manufacturing and its strategic and operational most relevant variables, and proposed a renewed perspective of integration of Lean and Clean approaches and tools by introducing the environmental load as the 9th type of Muda. The identification and intervention tools can be in that case the Life Cycle Assessment/Life Cycle Costing, and the Eco-Design procedures. The recognized complexity of such tools and the lack of empirical studies are limiting their diffusion as support tools for an eco-efficient manufacturing, especially in the case of small-medium enterprises; this can be considered one of the major potential challenges in integrating the two perspectives of LM and IE and the next steps of the research will be directed in such a direction.