Abstract

The search for competitiveness has led organizations to recognize the importance of implementing collaborative methods. In this context, Collaborative Planning, Forecasting, and Replenishment (CPFR) seek to relate customer demands to replenishment needs throughout the supply chain. The literature points to implementation difficulties, such as trust between partners and commitment, and to overcome these difficulties, the digital technologies of Industry 4.0 are emerging as an essential support. This paper aims to research the applicability and contribution of Industry 4.0 digital technologies to the CPFR, considering each stage of the CPFR. A systematic literature review identified an unexplored gap: the use and contribution of Industry 4.0 digital technologies to the functioning of the CPFR. Considering the sequence of the CPFR stages and their dependence on each other, a roadmap can be developed for using Industry 4.0 digital technologies in each stage of the CPFR. It was, therefore, possible to create a roadmap indicating, based on current literature, which Industry 4.0 digital technologies can enhance SCM at each stage of the CPFR. This roadmap has two significant contributions: (i) to guide companies in prioritizing the implementation of these technologies in support of supply chain objectives and (ii) to serve as a basis for further empirical studies, highlighting the development of this roadmap through its application in real situations.

1. Introduction

In recent years, the pursuit of competitiveness has led organizations to recognize the importance of developing efficient collaborative methods in their supply chains (Gomes et al. 2022). Collaboration initiatives generate joint actions among partners with common objectives, which include sharing information among suppliers, manufacturers, distributors, retailers, and other supply chain partners in a Supply Chain Management (SCM) environment (Gomes and Neto 2015; Liao et al. 2023). This management results in cost reductions due to inventory reductions, improved efficiency, enhanced service levels, reduced personnel needs, improved deliveries through cycle time reduction, innovation and adaptation, and risk reduction (Lenart-Gansiniec 2019). Companies are aware that collaboration enables the improvement of the supply chain with quicker responses, leading to increased efficiency (Hill et al. 2018). The most comprehensive and significant collaborative method is Collaborative Planning, Forecasting, and Replenishment (Gomes and Neto 2015).

Collaborative Planning, Forecasting and Replenishment (CPFR) originated in 1995 through a partnership between Walmart, Warner-Lambert, Surgency, and the software companies SAP and Manugistics to connect customer demand to replenishment needs throughout the supply chain. This partnership resulted in a set of processes helping organizations eliminate demand and supply uncertainties by improving communication among supply chain partners. Shortly after, in 1998, the Voluntary Interindustry Commerce Standards Association (VICS) established a committee to identify the best practices and guidelines for CPFR. According to (Attaran and Attaran 2007), major retailers, consumer goods manufacturers, and consulting and software suppliers participated in this project. VICS’s involvement and many companies’ participation in CPFR validation and testing were crucial for the tool’s consolidation. The authors (Hemant et al. 2022) explain that in CPFR, collaboration is the “foundation” of the tool, defining objectives, metrics, performance indicators, information sharing, resources, and a governance policy. The critical and decisive characteristic of CPFR for successful supply chain results is communication among chain agents in increasingly shorter times. The present research cites digital technologies stemming from the Industry 4.0 concept as facilitators. To this end, communication systems that interconnect companies to promote information sharing and the automation of subroutines are increasingly necessary (Gomes 2022). In the current wave of so-called Industry 4.0, interconnectivity and automation tools meet the objectives of the CPFR.

The Industry 4.0 concept was introduced around 2011, bringing forth various tools to support organizations, including big data, artificial intelligence, the Internet of Things, and cloud computing, among others (Lenart-Gansiniec 2019). The introduction of Industry 4.0 impacted supply chain management, potentially transitioning from isolated manufacturing activities to optimized and fully integrated product and data flows within the value chain (Strange and Zucchella 2017). According to (Majeed and Rupasinghe 2017), companies need to integrate these technologies into their processes to achieve greater competitiveness and sustainability throughout the supply chain, although there are still barriers and challenges to overcome (Silva et al. 2023; Peres et al. 2020). For (Nozari et al. 2022), the evolution of the supply chain results from the adoption of new technologies in warehouses, responding to the demand for flexible and integrated logistics. This allows the chain to adapt to seasonal product variations and customer needs.

Ten years after the emergence of I4.0, other challenges, and approaches have emerged (Kagermann and Wahlster 2022). According to the Federal Ministry for Economic Affairs and Climate Actions (Plattform Industrie 4.0—2030 Vision n.d.) of Germany, Industry 4.0 is currently driven by new forms of economic activity and work in global and digital ecosystems: today’s rigid and narrowly defined value chains are being replaced by flexible, highly dynamic and globally connected value networks, with new forms of cooperation. Today’s strategic fields of action are characterized by autonomy, interoperability, and sustainability. The implementation of Industry 4.0 must address these fields of action together, and they are guiding principles for the next decade of Industry 4.0 expansion worldwide. There are many paths and directions to follow in the next decade of Industry 4.0 (Winter et al. 2022), seeking a balance between autonomy, interoperability, and sustainability. Industry 4.0 technologies are creating digital ecosystems and will be able to analyze various data types, both process and environmental. (Chalmeta and Santos-deLeón 2020; Sautter 2021). Authors (Kunrath et al. 2023) state that technologies promoting integration between the factory and external suppliers and optimizing the delivery of raw materials and final products in the supply chain are characteristic of a smart supply chain.

From this perspective, the authors identified the possibility of researching the use and contribution of Industry 4.0 digital technologies to the operation of the CPFR. Therefore, this article aims to study the applicability and contribution of Industry 4.0 digital technologies to the CPFR, considering each stage of the CPFR. Considering the sequence of the stages of the CPFR and the dependence between them, a roadmap can be created for the use of Industry 4.0 digital technologies in each stage of the CPFR. This roadmap can guide companies in prioritizing the implementation of these technologies in support of supply chain objectives.

2. Theoretical Background

This section details the main concepts used in this work. These are supply chain management, Industry 4.0, and CPFR.

2.1. Supply Chain Management

According to (Gomes et al. 2022), supply chain management is a set of operations that facilitates and improves processes intended to strengthen ties with suppliers so that everyone benefits from consumers. This management also optimizes collaboration and trust among different partners by developing a process integrating planning, implementation, coordination, and control of all business processes and activities (Cahyono et al. 2023). Therefore, the starting point for supply chain management is inventory, which efficiently measures the system’s performance from various stakeholders’ perspectives. In summary, Supply Chain Management (SCM) seeks to manage this network of relationships, involving all stakeholders from suppliers to consumers, aiming to provide high value to customers and reduce supply chain costs. Accordingly, (Tan et al. 1998) observed six characteristics of SCM practices: SC integration, information sharing, SC characteristics, customer service management, geographical proximity, and Just-in-Time capabilities. Through these practices and a well-defined information flow, it is possible to ensure that services are provided efficiently, from raw materials to distribution.

2.2. Industry 4.0

According to (Dalenogare et al. 2018), Industry 4.0 was coined in 2011 through a German government initiative in partnership with universities and private companies. Significant transformations began with integrating information and communication technologies (ICT) with manufacturing systems. According to Sony and Naik (2019), Industry 4.0 drives a cyber–physical production system based on integrating knowledge to achieve greater agility in production systems. (Frank et al. 2019) assert that integrating Industry 4.0 technologies with the supply chain gives rise to a smart supply chain, demonstrating that these technologies facilitate horizontal integration with stakeholders, making planning, demand forecasting, and replenishment easier. The authors (Chien and Kuo 2013) report the importance of this integration as a means for companies to combine resources in collaborative manufacturing, driving innovation capacity improvements and increasing the added value of their products. There are also technologies incorporated into final products (Smart products) that can provide feedback useful for developing new products (Tao et al. 2018). This facilitates new product developers, enabling them to make necessary corrections and improvements, thereby increasing service levels and product quality.

Industry 4.0 Technologies

Several technologies are employed in Industry 4.0, and according to (Dalenogare et al. 2018), these technologies can be organized into two layers: cutting-edge technologies and base technologies. The authors (Nara et al. 2021) identify 16 essential technologies to drive the development of Industry 4.0. A brief explanation of each of the 16 technologies is presented below:

- Internet of Things (IoT): IoT establishes a global infrastructure connecting physical and virtual objects, allowing continuous communication and data exchange (Miranda et al. 2021).

- Cloud Computing: Cloud computing is a data storage technology that facilitates remote information retrieval, enabling information sharing and coordinating various activities (Jensen et al. 2015).

- Big Data Analytics: Big data can generate information, create digital twins of the factory, and facilitate advanced predictive analysis to avoid events that may affect production (Dalenogare et al. 2018).

- Cyber–Physical Systems: This technology creates Integrated Cyber–Physical Systems (IMSs) with virtual reality interfaces, connecting humans and machines (Chen et al. 2015).

- Artificial Intelligence: Artificial intelligence reproduces human intelligence, enabling machines to learn and solve complex problems, facilitating decision-making (Lee et al. 2015).

- Autonomous and Collaborative Robots: Robots, through automation, act as collaborative work partners, efficiently performing work activities (Chen et al. 2015).

- Intelligent Sensors: These sensors increase process safety, efficiency, and flexibility by generating and receiving information and data where they are deployed (Oztemel and Gursev 2020).

- System Integration: This technology aims to integrate systems and subsystems, hardware, and software through the IoT (Auger et al. 2017).

- Mobile Systems and Devices: Mobile systems and devices, such as smartphones, tablets, wearables, and custom mobile apps, facilitate monitoring, equipment control, and efficient communication with employees (Almada-Lobo 2015).

- Digitalization and Virtualization: Digitalization involves the interaction between virtualized structural elements managed by service-oriented architectures, integrating the physical and informational worlds to align technical and business areas within an organization (Borangiu et al. 2019).

- Machine-to-Machine Communication: Machine-to-Machine (M2M) communication is used in various industrial areas, facilitating the efficient and flexible tracking of materials, pallets, and trucks (Weyrich et al. 2014).

- Simulation: Simulation is widely used in the industry, particularly in SCM, as a decision-making support tool, allowing for the early analysis of situations before they occur (Kunrath et al. 2023).

- Industrial Internet: Industrial internet technology provides connectivity within the industrial environment, using tools like Wi-Fi, WiMAX, and Bluetooth to enhance connectivity between systems, devices, and people, increasing productivity (Malik et al. 2021).

- Additive Manufacturing: Additive manufacturing is a technique where material layers are deposited only where needed, allowing for more sustainable production (Baierle et al. 2020).

- Cybersecurity: Companies can suffer significant losses from cyberattacks, making it essential to develop strategies for secure machine connectivity, aiming to enhance the performance of the entire value chain (Lezzi et al. 2018).

- Augmented and Virtual Reality: Augmented reality pairs computer images with users’ vision, relating the real world to the virtual world (Akbari et al. 2022). The industry has various applications related to SCM, such as inventory levels and order picking (Kunrath et al. 2023).

2.3. Collaborative Planning, Forecasting, and Replenishment (CPFR)

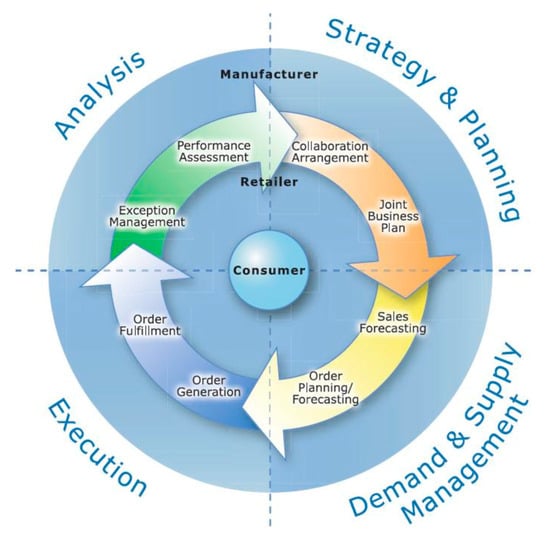

Around 1995, in a partnership between Walmart, Warner-Lambert, Surgency, and the software companies SAP and Manugistics, an initiative emerged that sought to collaboratively coordinate purchasing planning, forecasting, and asset replenishment activities between supply chain stakeholders: Collaborative Planning, Forecasting, and Replenishment (CPFR). In 2004, the Voluntary Interindustry Commerce Stand (VICS) realized that it was necessary to correct problems related to the initial project and integrate new technologies to make it easier to use (Gomes 2022). Figure 1 shows how the CPFR works and its elements:

Figure 1.

Manufacturer and retailer tasks in CPFR phases.

The authors (Singhry and Abd Rahman 2019) explain that CPFR is a facilitator for companies, with its main function being sales forecasting, encompassing functions such as interventions when changes occur in demand patterns, adjustments in inventory to ensure products on the shelf, influencing the coordination of supply chain companies, coordinating the synchronization of manufacturing processes, and ensuring demand forecasting processes. According to (Gomes et al. 2022), CPFR is a set of procedures that facilitate relationships between buyers and retailers, encouraging them to contribute to demand forecasting and order placement in order to reduce the “bullwhip effect”. Additionally, it facilitates obtaining more accurate replenishment and forecast plans, significantly reduces inventory for manufacturers, suppliers, and wholesalers, generates increased sales, and enhances service levels (Peterson 2013; Gomes et al. 2022).

CPFR is divided into three basic stages: Planning, Forecasting, and Replenishment. Each stage is explained below.

- Planning: Authors (Panaihfar et al. 2015) emphasize the importance of collaborative SCM planning, which can be divided into two stages: Initial agreement and joint business planning. According to (Cassivi 2006), planning is a critical stage where stakeholders express interest in developing collaboration initiatives and necessary documentation. (Ramanathan and Gunasekaran 2014) explain the connection between collaborative planning, execution planning, and decision-making, emphasizing that effective supply chain collaboration requires key elements of planning, execution, and decision-making.

- Forecasting: According to (Panahifar et al. 2015a), collaborative forecasting has a significant goal, which is to reduce the bullwhip effect and improve the supply chain. However, (Panahifar et al. 2015b) state that the primary objective of collaborative forecasting is to increase forecast accuracy. Additionally, it facilitates supply chain visibility and predicts demand and cycle time (Yu et al. 2010). Furthermore, this stage identifies and resolves exceptions. In the six collaborative forecasting sub-stages, sales and order forecasting exceptions are identified and resolved.

- Replenishment: This stage involves order creation, where orders are generated based on sales forecasts (Liu and Sun 2012), correlating forecasting activity with collaborative replenishment. According to (Panaihfar et al. 2015), collaborative replenishment distributes replenishment activities throughout the supply chain and facilitates collaborative inventory management in operations. However, both suppliers and retailers need to review the collaborative replenishment plan (Lyu et al. 2010).

3. Materials and Methods

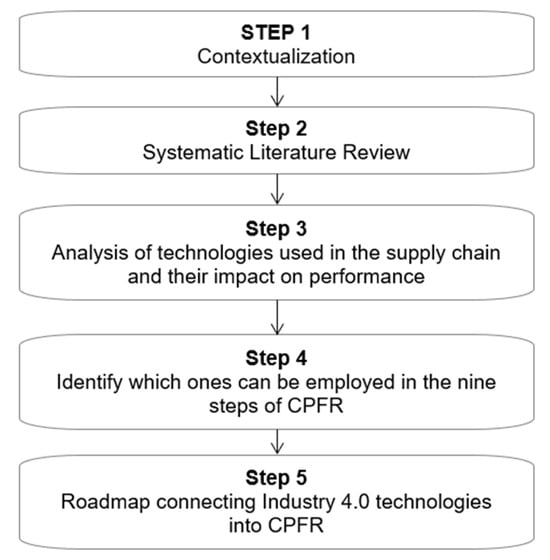

Five steps were followed to meet the research objective, presented in Figure 2 and explained in detail. The research method presented below is well-established in the literature and has been used in a number of studies (Silva et al. 2023).

Figure 2.

Methodology steps.

Step 1—Contextualization: This is where the research guidelines are put together based on the central objective of the research. All the research was related to implementing Industry 4.0 technologies in the CPFR method to improve SCM and, consequently, collaboration between business partners.

Step 2—Systematic Literature Review: This step identifies the Industry 4.0 technologies being studied concerning the supply chain. During the contextualization stage, some research showed that the use of Industry 4.0 technologies in the supply chain can be called a smart supply chain, so the term was included in the searches. The Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) method was used for the systematic literature review. This methodology aims to establish stages for the selection and analysis of articles. Keywords were chosen to delimit the topic based on the following questions: (i) What are the main technologies of Industry 4.0 related to the supply chain? (ii) Which of these technologies can be used in each of the stages of the CPFR? The keywords were Supply Chain Management, Collaborative Planning, Forecasting, and Replenishment; CPFR; Industry 4.0; Technology 4.0; Smart Supply Chain. Table 1 shows the search process for the articles.

Table 1.

Search terms.

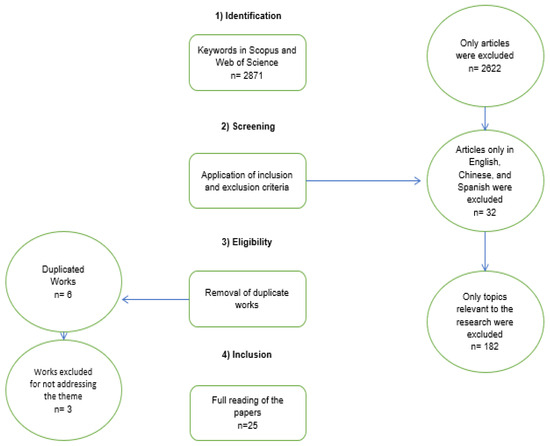

The four phases of the prism method were used as inclusion and exclusion criteria: identification, screening, eligibility, and inclusion. Figure 3 shows the flowchart for selecting the articles.

Figure 3.

Flowchart for selecting the articles according to the PRISMA method (Mühl and de Oliveira 2022).

In the first stage (identification stage), 2871 articles were identified using the Boolean keywords. In the second stage, the inclusion and exclusion criteria were applied. For the first exclusion criterion, only articles, a total of 2622 articles were excluded. For the second criterion, only articles in English, Chinese, and Spanish, 32 articles were excluded. The third criterion, topics relevant to the research, excluded 182 articles that did not fit the theme. In the third stage (eligibility), two situations were important for conducting the work. The first situation was that there were duplicate articles, so six duplicate articles were identified. In the second situation, we excluded papers that did not address the proposed topic from the eligibility stage. To help filter the articles, the qualitative analysis software Nvivo was used to ensure all the articles were analyzed following the same reading and analysis system. Finally, in the inclusion stage, 25 articles that were relevant to the research were selected and then analyzed in full.

Step 3—Analysis of technologies used in the supply chain and their impact on performance: In Step 3, the final sample of articles was read in full to identify within the sample which positive and negative impacts on companies were mentioned in each manuscript.

Step 4—Identify which ones can be employed in the nine steps of CPFR: After reading and analyzing qualitative data in Steps 2 and 3, in Step 4, we identified which technologies were related to each of the nine sub-steps of CPFR.

Step 5—Roadmap connecting Industry 4.0 technologies into CPFR: With the complete analysis of Steps 2–4, it was possible to build the proposed roadmap, which integrates Industry 4.0 technologies into CPFR. The roadmap was developed to facilitate and enhance the implementation of the CPFR.

4. Results and Discussions

This section presents the research results, highlighting the technologies related to the supply chain and then giving rise to the proposed roadmap.

4.1. Industry 4.0 Technologies Related to the Supply Chain

After analyzing the 25 articles selected in Stage 2 of the methodology, eleven technologies were identified as most adherent to the supply chain. These eleven technologies are shown in Table 2.

Table 2.

Industry 4.0 technologies used in the smart supply chain.

According to Table 2, the technologies mentioned in the articles were the Internet of Things and big data analysis. As (Szozda 2017) explains, the Internet of Things provides various benefits for supply chain management, allowing machines, people, and products to connect in real time, generating data that can be used throughout the supply chain. Additionally, IoT can be considered an enabling technology for other technologies (Kunrath et al. 2023), ensuring item location, shipping quality, fleet tracking, and fleet control across the supply chain links (Aksentijević et al. 2015). Big data analysis was often mentioned in the articles as a tool that can contribute to raw material purchasing and the formulation of pricing strategies (Liu 2013). However, (Kunrath et al. 2023) assert that its use in the smart supply chain requires a strong technical team to collect and process information intelligently. According to (Tseng et al. 2019), big data analysis can improve smart supply chain performance in terms of operational risks, chain impacts, increasing economic benefits, and social development, allowing companies to maintain their competitive advantages.

As the third most mentioned technology, cloud computing can be a differentiator because it has unlimited storage capacity, facilitating decision-making, training, and collaboration among all supply chain stakeholders (Wang et al. 2015). Its use in the supply chain creates competitive advantages for companies, allowing real-time visualization of all produced data, improving operations management, and ultimately, SCM (Schaefer et al. 2023; Frank et al. 2019). However, the most significant benefit is that it enhances collaboration and communication among SC stakeholders, facilitated through the use of applications that share information in real-time and improve decision-making, reducing costs and enhancing customer service (Wang et al. 2015).

Autonomous and collaborative robots and artificial intelligence were mentioned less frequently. The authors (Shao et al. 2021) report on a Pakistani packaging industry facing issues with dents in its final products. In this case, a meeting was held with suppliers and customers, taking the initiative to implement smart sensors to identify packaging dimension errors. However, they faced issues due to the excessive time required by the operator to confirm errors via images. Consequently, a meeting with the company’s technical team resulted in the decision to use artificial intelligence, big data analysis, and cloud computing. Artificial intelligence was employed to learn, through images, the different types of dents the packages had. At the same time, cloud and big data analysis were used to store and process AI data.

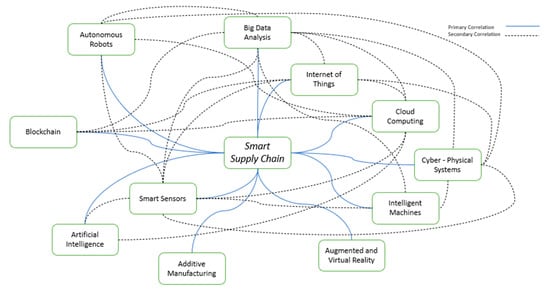

The other technologies are not yet fully consolidated; however, as (Szozda 2017) highlights, technologies can work separately but become more efficient when integrated. Therefore, this article is important in promoting the potential integration of these technologies. In this regard, (Kunrath et al. 2023) sought to study these correlations with the principle of a future trend of intelligent distribution networks within the supply chain, describing the frequency with which sets of technologies appeared together. Figure 4 presents the correlation between Industry 4.0 technologies and the supply chain.

Figure 4.

Correlations between technologies and the smart supply chain.

Figure 4 shows two types of correlation: the primary correlation, which represents the direct link between the technology and a process in the supply chain, and the secondary correlation, which represents the link between two or more technologies improving a process in the supply chain. Although most related articles do not present case studies with direct applications of these technologies in the supply chain, they highlight the possible improvements that can be achieved with their application. In addition, the articles also address the possible benefits of their use and their difficulties, such as the cost of implementation, the qualification of technical staff, and the time needed to implement them.

According to (Dalenogare et al. 2018), significant transformations began with integrating information and communication technologies (ICT) with manufacturing systems and Artificial intelligence (AI). AI plays a fundamental role in several critical areas of modern technology. In the Internet of Things (IoT), AI can optimize the collection and analysis of data generated by connected devices, enabling intelligent process automation and real-time decision-making. In cloud computing, AI can improve operational efficiency by optimizing resource allocation and improving data security. In extensive data analysis, AI can identify complex patterns and valuable insights in large data sets, driving informed decision-making. In the context of Blockchain, AI can improve the security and integrity of the technology, detecting suspicious activity and identifying fraud. Robots benefit from AI by learning and adapting to new tasks and environments, extending their capabilities to perform and interact with humans. In additive manufacturing, AI can optimize the design of parts and production processes, reducing costs and manufacturing time. Smart sensors driven by AI can collect and interpret data more efficiently, enabling greater measurement accuracy and reliability. AI can improve immersion and interactivity in virtual reality, creating more personalized and immersive experiences. Finally, AI allows closer integration between the physical and digital worlds in cyber–physical systems, enabling more autonomous and adaptable systems in a wide range of industrial and consumer applications.

4.2. Roadmap for Connecting Industry 4.0 Technologies to the Basic Model of Collaborative Planning, Forecasting, and Replenishment (CPFR)

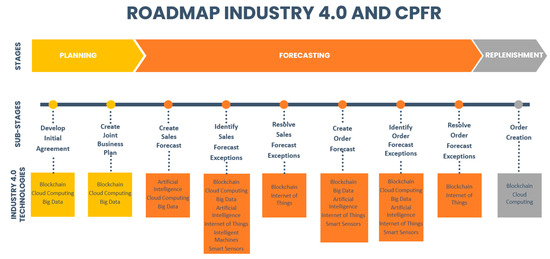

Based on the content analysis of the articles selected in the systematic literature review, seven technologies were identified that can facilitate the implementation of CPFR. These are Blockchain, cloud computing, big data analysis, Internet of Things, artificial intelligence, smart machines, and smart sensors. As a result, a roadmap was developed that was responsible for connecting the stages of the CPFR with the digital technologies best suited to each stage, as shown in Figure 5.

Figure 5.

Roadmap for connecting Industry 4.0 technologies to the basic model of CPFR.

The following sections explain how each Industry 4.0 technology can contribute to each stage and sub-stage of CPFR.

4.2.1. Planning

In the planning stage, there are two sub-stages: developing the initial agreement and creating a joint business plan.

Develop Initial Agreement

In this sub-stage, negotiations begin among the involved parties. Rules and goals for cooperation are established, resulting in a formal agreement. Important steps for the initial agreement include

- Definition of goals and objectives among participating companies;

- Evaluation of resources and systems;

- Definition of shared data;

- Definition of resolution criteria;

- Definition of the review cycle based on process evaluation;

- Publication of the initial agreement.

Three technologies can be utilized: Blockchain, cloud computing, and big data analysis. Blockchain can streamline contracts by creating digital twins that interact and can be automatically modified, facilitating the definition of rules and goals without direct interaction (Zhang et al. 2023; Radmanesh et al. 2023). Big data analysis can be used with the other two technologies for resolution criteria and a definition of the review cycle based on process evaluation. It provides the necessary analysis for resolution criteria definition through its processing capacity based on supplier data stored in the cloud, facilitating exception triggers and their rules (Chiappetta Jabbour et al. 2020; Kunrath et al. 2023; Zhang et al. 2023).

Create a Joint Business Plan

In this sub-stage, partners work together to develop activities that define corporate and business strategies, including setting joint goals related to sales, replenishment rates, pricing decisions, inventory management, promotional plans, the number of involved stores, technical requirements, service levels, product design initiatives, and policies for safety stocks. Relevant factors like target products, brand quantity, item quantity, best and worst-performing products, product target locations, replenishment times, and minimum and maximum order rates are delineated. Technologies that can be used are Blockchain, cloud computing, and big data analysis. Blockchain and cloud promote real-time interaction with stakeholders (Treiblmaier 2018; Radmanesh et al. 2023), storing data, while big data analysis can identify market trends and patterns (Shukla and Tiwari 2017; Chiappetta Jabbour et al. 2020; Kunrath et al. 2023).

4.2.2. Forecasting

The forecasting stage can be divided into six sub-stages: create a sales forecast, identify exceptions in sales forecasting, resolve exceptions in sales forecasting, create an order forecast, identify exceptions in the order forecast, and resolve exceptions in the order forecast.

Create Sales Forecast

The main objective in this sub-stage is to feed the database with information for creating forecasts. Considerations include sales points and promotion planning. Cloud computing, big data analysis, and artificial intelligence can be employed for sales forecasting. Cloud computing is used to store found data, while artificial intelligence, in conjunction with big data analysis, can capture and identify patterns to predict future market demands through collected data, facilitating partners to develop production and inventory strategies (Büyüközkan and Göçer 2018; Frank et al. 2019).

Identify Exceptions in Sales Forecast

The main goal is to observe exception triggers defined in the initial stage. Identifying stock percentage, forecast accuracy, and safety stock with replenishment times are crucial for buyer-related triggers. For sellers, forecast accuracy and order fulfillment are important. When an exception is identified, a review of the initial agreement may be necessary to adapt to the new scenario. Considerations for this stage include data related to transportation limitations, production capacity, and suppliers (Gomes 2022). Technologies that could facilitate this stage are the Internet of Things, intelligent sensors, big data analysis, cloud computing, artificial intelligence, intelligent machines, and Blockchain. Intelligent machines, through the Internet of Things, can provide real-time production information for production capacity (Büyüközkan and Göçer 2018; Biswas et al. 2023). Intelligent sensors can provide information on stock levels and order fulfillment for the stock percentage (Ding et al. 2018). Artificial intelligence, big data analysis, and cloud computing can collect historical data to adjust and scale a new safety stock with replenishment times (Kunrath et al. 2023; Shao et al. 2021). Blockchain would facilitate the readjustment of the initial agreement through smart contracts (Radmanesh et al. 2023).

Resolve Exceptions in Sales Forecast

This activity is based on resolving and clarifying exceptions, generating a new forecast when issues are resolved, and accelerating the process. Blockchain, along with the Internet of Things, can be extremely efficient in collecting the information described in the previous sub-stage and making necessary adjustments in this new forecast (Treiblmaier 2018; Radmanesh et al. 2023).

Create Order Forecast

In this sub-stage, data collected from sales points are interconnected with the individual strategies of each partner. Data such as stock and replenishment time, specific to each situation, are considered to generate an order forecast. Detailed information about transportation times is necessary (Gomes 2022). Technologies that can be used include the Internet of Things, along with intelligent sensors, to provide relevant data from each sales point (Ding et al. 2018; Chiappetta Jabbour et al. 2020; Kunrath et al. 2023). Big data analysis would facilitate the processing of this sales and stock data, allowing companies to find trends and patterns that can be used for improvement and to make the entire supply chain more efficient (Chiappetta Jabbour et al. 2020). Blockchain and intelligent sensors can be used to track products throughout the supply chain, while artificial intelligence can create demand and stock models (Radmanesh et al. 2023; Kunrath et al. 2023).

Identify Exceptions in Order Forecast

In this stage, all products representing exceptions are identified collaboratively and corrected, and a new order forecast is created and approved. The result is a list of all the items that meet the exception criteria defined in the initial agreement. Intelligent sensors and the Internet of Things can be used to identify products that represent exceptions (Wu et al. 2016; Ding et al. 2018).

Artificial intelligence, cloud, and big data analysis could be used to store, scale, and predict possible exceptions, generating this new order forecast (Shao et al. 2021). Finally, Blockchain could capture and update adjustments in the initial agreement in real-time (Radmanesh et al. 2023; Venkatesh et al. 2020).

Resolve Exceptions in Sales Forecast

The actions developed in this sub-stage aim to solve the exceptions identified in the previous stage. The final product is a corrected sales forecast that will be used for order generation (Kilger and Reuter 2005). Technologies like the Internet of Things and Blockchain can capture these data and transmit them in real time to the involved parties, enabling real-time monitoring, predictive analyses, and supply chain optimization (Treiblmaier 2018; Radmanesh et al. 2023).

4.2.3. Replenishment

Finally, after all previously executed stages and the strategic information of CPFR partners are shared, replenishment orders are generated, which will be considered for production and availability by CPFR partners. Technologies like cloud computing and Blockchain can facilitate all stakeholders, as information can be provided in real-time, allowing more efficient decision-making (Büyüközkan and Göçer 2018; Kunrath et al. 2023; Radmanesh et al. 2023).

5. Conclusions

Through the systematic literature review, an unexplored gap was identified: the use and contribution of Industry 4.0 digital technologies to the functioning of the CPFR. The current literature provides essential research, but all in isolation, considering single technologies or technologies applied to only one specific area of SCM. Therefore, this article aimed to research the applicability and contribution of Industry 4.0 digital technologies to the CPFR, considering all the stages of the CPFR. The CPFR is basically characterized by a sequence of stages dependent on each other, i.e., it is impossible to skip stages. It was, therefore, possible to develop a roadmap indicating, based on current literature, which Industry 4.0 digital technologies can enhance SCM at each stage of the CPFR. This roadmap has two significant contributions: (i) to guide companies in prioritizing the implementation of these technologies in support of supply chain objectives and (ii) to serve as a basis for further empirical studies, highlighting the development of this roadmap through its application in real situations.

The roadmap could clarify definitions for each CPFR sub-stage as it connects its stages with technologies. Stakeholders can identify which technologies can be used to develop this collaborative proposal. Blockchain stood out the most among the seven technologies, although it was not the most mentioned technology in the articles. Its applicability has great potential and can benefit implementing Collaborative Planning, Forecasting, and Replenishment (CPFR). However, for the maximum use of this technology, it must be used in conjunction with other technologies. The main benefits of this technology are smart contracts and distributed decision-making processes, making the process more transparent for the involved parties, as both the joint business plan and the definitions of goals and strategies can be decided together. This technology, along with cloud computing and big data analysis, will allow the involved parties to know about negotiations and historical data from suppliers. These data will enable transparent and accessible decisions, rules, and goals.

In the analysis of the forecast stage, the roadmap highlighted the technologies of the Internet of Things, intelligent sensors, Blockchain, big data analysis, and artificial intelligence. The integration of these technologies will facilitate interaction between the demands of the involved parties, identification of stock percentage and forecast accuracy, providing information, and defining safety stock with replenishment times. IoT and intelligent sensors will provide real-time data on sales points, which will be processed by big data analysis, seeking to identify patterns and generate an efficient forecast. Finally, artificial intelligence can contribute to demand and stock models based on the collected data, providing a clearer and more accurate view for companies. Blockchain and the Internet of Things can facilitate product traceability along the supply chain, ensuring transparency and reliability. For the treatment of exceptions, Blockchain and IoT stood out for making adjustments in real time to initial agreements. In this case, the framework becomes efficient, as it allows, through the proposed technologies, the clarity that agreements, exceptions, and exception handling are transparent for all interested parties in the SCM.

The roadmap proposes using Blockchain and cloud computing technologies in the collaborative replenishment stage. These tools can provide, through appropriate synchronization between production and availability of CPFR partners, support for decision-making in a faster and more efficient way.

Finally, to make the implementation process clearer and more transparent for stakeholders, the roadmap’s objectives have been achieved, as activities related to CPFR sub-stages will be available to everyone in real time. This reduces the lack of trust in collaborative partners. Furthermore, the roadmap showed that the main obstacles to CPFR implementation can be mitigated through a more transparent process.

6. Limitations, Challenges, and Future Directions

This research had its limitations. One limitation was that it did not address the issue of sustainability in the supply chain. This topic was not discussed because the focus was on understanding the digital technologies involved in the different stages of the CPFR. However, we believe this limitation could indicate the way forward for future research, with this article serving as a basis.

In the introduction, we mentioned that three fields would have to be studied together over the next decade: autonomy, interoperability, and sustainability. In this research, we highlight the fields of autonomy and interoperability through the roadmap, using the digital technologies arising from the I4.0 concept as an aid. As an opportunity and direction for future research, we highlight the further development of this roadmap through its application in an actual situation. Through this application, the field of sustainability can also be assessed, verifying the post-application impacts. In addition to the post-application effects, there are also pre-application impacts to be analyzed, such as the increasing need to use electricity, which highlights the importance that renewable energy generation can have, as some studies have already shown. (Bildirici and Ersin 2023; Bildirici et al. 2023).

Finally, future directions lead to the use of this roadmap as a guide for companies in prioritizing the implementation of these technologies in support of supply chain objectives and ii) to serve as a basis for further empirical studies, highlighting the development of this roadmap through its application in real situations.

Author Contributions

Conceptualization, G.A.F.R.D.S., I.C.B. and L.d.C.G.; methodology, G.A.F.R.D.S., I.C.B. and L.d.C.G.; software, G.A.F.R.D.S., I.C.B. and L.d.C.G.; validation, G.A.F.R.D.S., I.C.B., R.G.d.F.C., F.A.P.P. and L.d.C.G.; formal analysis, G.A.F.R.D.S., I.C.B., R.G.d.F.C., F.A.P.P. and L.d.C.G.; investigation, G.A.F.R.D.S., I.C.B. and L.d.C.G.; resources, G.A.F.R.D.S., I.C.B. and L.d.C.G.; data curation, G.A.F.R.D.S., I.C.B., R.G.d.F.C., F.A.P.P. and L.d.C.G.; writing—original draft preparation, G.A.F.R.D.S., I.C.B. and L.d.C.G.; writing—review and editing, I.C.B. and L.d.C.G.; visualization, I.C.B. and L.d.C.G.; supervision, I.C.B. and L.d.C.G.; project administration, I.C.B. and L.d.C.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ada, Erhan, Muruvvet Deniz M. D. Sezer, Yigit Kazancoglu, and Raneen Khaleel. 2023. Towards the Smart Sustainable and Circular Food Supply Chains through Digital Technologies. International Journal of Mathematical, Engineering and Management Sciences 8: 374–402. [Google Scholar] [CrossRef]

- Akbari, Mohammadreza, Nghiep Ha, and Seng Kok. 2022. A Systematic Review of AR/VR in Operations and Supply Chain Management: Maturity, Current Trends and Future Directions. Journal of Global Operations and Strategic Sourcing 15: 534–65. [Google Scholar] [CrossRef]

- Aksentijević, Saša, David Krnjak, and Edvard Tijan. 2015. Logistics Environment Awareness System Prototype Based on Modular Internet of Things Platform. Pomorstvo 29: 170–79. [Google Scholar]

- Almada-Lobo, Francisco. 2015. The Industry 4.0 Revolution and the Future of Manufacturing Execution Systems (MES). Journal of Innovation Management 3: 16–21. [Google Scholar] [CrossRef]

- Attaran, Mohsen, and Sharmin Attaran. 2007. Collaborative Supply Chain Management: The Most Promising Practice for Building Efficient and Sustainable Supply Chains. Business Process Management Journal 13: 390–404. [Google Scholar] [CrossRef]

- Auger, Antoine, Ernesto Exposito, and Emmanuel Lochin. 2017. Survey on Quality of Observation within Sensor Web Systems. IET Wireless Sensor Systems 7: 163–77. [Google Scholar] [CrossRef]

- Baierle, Ismael Cristofer, Guilherme Brittes Benitez, Elpidio Oscar Benitez Nara, Jones Luis Schaefer, and Miguel Afonso Sellitto. 2020. Influence of Open Innovation Variables on the Competitive Edge of Small and Medium Enterprises. Journal of Open Innovation: Technology, Market, and Complexity 6: 179. [Google Scholar] [CrossRef]

- Bildirici, Melike, and Özgür Ömer Ersin. 2023. Nexus between Industry 4.0 and Environmental Sustainability: A Fourier Panel Bootstrap Cointegration and Causality Analysis. Journal of Cleaner Production 386: 135786. [Google Scholar] [CrossRef]

- Bildirici, Melike, Fazıl Kayıkçı, and Özgür Ömer Ersin. 2023. Industry 4.0 and Renewable Energy Production Nexus: An Empirical Investigation of G20 Countries with Panel Quantile Method. Sustainability 15: 14020. [Google Scholar] [CrossRef]

- Biswas, Sanjib, Aparajita Sanyal, Darko Božanić, Adis Puška, and Dragan Marinković. 2023. Critical Success Factors for 5G Technology Adaptation in Supply Chains. Sustainability 15: 5539. [Google Scholar] [CrossRef]

- Borangiu, Theodor, Damien Trentesaux, André Thomas, Paulo Leitão, and Jose Barata. 2019. Digital Transformation of Manufacturing through Cloud Services and Resource Virtualization. Computers in Industry 108: 150–62. [Google Scholar] [CrossRef]

- Büyüközkan, Gülçin, and Fethullah Göçer. 2018. Digital Supply Chain: Literature Review and a Proposed Framework for Future Research. Computers in Industry 97: 157–77. [Google Scholar] [CrossRef]

- Cahyono, Yoyok, Dwi Purwoko, Intan Rachmina Koho, Asri Setiani, Supendi, Paulus Israwan Setyoko, Mulia Sosiady, and Hadion Wijoyo. 2023. The Role of Supply Chain Management Practices on Competitive Advantage and Performance of Halal Agroindustry SMEs. Uncertain Supply Chain Management 11: 153–60. [Google Scholar] [CrossRef]

- Cassivi, Luc. 2006. Collaboration Planning in a Supply Chain. Supply Chain Management 11: 249–58. [Google Scholar] [CrossRef]

- Chalmeta, Ricardo, and Nestor J. Santos-deLeón. 2020. Sustainable Supply Chain in the Era of Industry 4.0 and Big Data: A Systematic Analysis of Literature and Research. Sustainability 12: 4108. [Google Scholar] [CrossRef]

- Chen, Danfang, Steffen Heyer, Suphunnika Ibbotson, Konstantinos Salonitis, Jón Garar Steingrímsson, and Sebastian Thiede. 2015. Direct Digital Manufacturing: Definition, Evolution, and Sustainability Implications. Journal of Cleaner Production 107: 615–25. [Google Scholar] [CrossRef]

- Chiappetta Jabbour, Charbel Jose, Paula De Camargo Fiorini, Nelson Oly Ndubisi, Maciel M. Queiroz, and Éderson Luiz Piato. 2020. Digitally-Enabled Sustainable Supply Chains in the 21st Century: A Review and a Research Agenda. The Science of The Total Environment 725: 138177. [Google Scholar] [CrossRef] [PubMed]

- Chien, Chen Fu, and Ren Tsun Kuo. 2013. Beyond Make-or-Buy: Cross-Company Short-Term Capacity Backup in Semiconductor Industry Ecosystem. Flexible Services and Manufacturing Journal 25: 310–42. [Google Scholar] [CrossRef] [PubMed]

- Dalenogare, Lucas Santos, Guilherme Brittes Benitez, Néstor Fabián Ayala, and Alejandro Germán Frank. 2018. The Expected Contribution of Industry 4.0 Technologies for Industrial Performance. International Journal of Production Economics 204: 383–94. [Google Scholar] [CrossRef]

- Dalenogare, Lucas Santos, Matheus Malta Baseggio, Néstor Fabián Ayala, Marie Anne Le Dain, and Alejandro Germán Frank. 2019. The Contribution of Smart Glasses for PSS. Procedia CIRP 83: 318–23. [Google Scholar] [CrossRef]

- Ding, Kai, Pingyu Jiang, and Shilong Su. 2018. RFID-Enabled Social Manufacturing System for Inter-Enterprise Monitoring and Dispatching of Integrated Production and Transportation Tasks. Robotics and Computer-Integrated Manufacturing 49: 120–33. [Google Scholar] [CrossRef]

- Enrique, Daisy Valle, Laura Visintainer Lerman, Paulo Renato de Sousa, Guilherme Brittes Benitez, Fernando M. Bigares Charrua Santos, and Alejandro G. Frank. 2022. Being Digital and Flexible to Navigate the Storm: How Digital Transformation Enhances Supply Chain Flexibility in Turbulent Environments. International Journal of Production Economics 250: 108668. [Google Scholar] [CrossRef]

- Frank, Alejandro Germán, Lucas Santos Dalenogare, and Néstor Fabián Ayala. 2019. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. International Journal of Production Economics 210: 15–26. [Google Scholar] [CrossRef]

- Furstenau, Leonardo Bertolin, Carolina Zani, Stela Xavier Terra, Michele Kremer Sott, Kim Kwang Raymond Choo, and Tarcisio Abreu Saurin. 2022. Resilience Capabilities of Healthcare Supply Chain and Supportive Digital Technologies. Technology in Society 71: 102095. [Google Scholar] [CrossRef]

- Gomes, Leonardo de Carvalho. 2022. Mitigation of Supply Chain Vulnerability Through Collaborative Planning, Forecasting, and Replenishment (CPFR). International Series in Operations Research and Management Science 332: 95–119. [Google Scholar] [CrossRef]

- Gomes, Leonardo de Carvalho, and Francisco José Kliemann Neto. 2015. Collaborative Methods in Supply Chain Management: Implementation Challenges. RAE Revista de Administracao de Empresas 55: 563–77. [Google Scholar] [CrossRef]

- Gomes, Leonardo de Carvalho, Gustavo Adoolffo Francisco Ramos da Silva, and Rafaella Martins Aliatti. 2022. Métodos Colaborativos Em Cadeias de Suprimentos: Uma Revisão Teórica. Conjecturas 22: 971–99. [Google Scholar] [CrossRef]

- Hackius, Niels, and Moritz Petersen. 2017. Blockchain in Logistics and Supply Chain: Trick or Treat? Reinforced Plastics 9783745043: 3–18. [Google Scholar] [CrossRef]

- Hemant, Joshi, Rajagopal Rajesh, and Yash Daultani. 2022. Causal Modelling of the Enablers of CPFR for Building Resilience in Manufacturing Supply Chains. RAIRO—Operations Research 56: 2139–58. [Google Scholar] [CrossRef]

- Hill, Craig A., G. Peter Zhang, and Keith E. Miller. 2018. Collaborative Planning, Forecasting, and Replenishment & Firm Performance: An Empirical Evaluation. International Journal of Production Economics 196: 12–23. [Google Scholar] [CrossRef]

- Jensen, Paul D., S. D. Yap, A. Boyle-Gotla, J. Janoschka, C. Carney, M. Pidou, and D. J. Batstone. 2015. Anaerobic Membrane Bioreactors Enable High Rate Treatment of Slaughterhouse Wastewater. Biochemical Engineering Journal 97: 132–41. [Google Scholar] [CrossRef]

- Kagermann, Henning, and Wolfgang Wahlster. 2022. Ten Years of Industrie 4.0. Science 4: 26. [Google Scholar] [CrossRef]

- Kilger, Christoph, and Boris Reuter. 2005. Collaborative Planning. In Supply Chain Management and Advanced Planning. Berlin and Heidelberg: Springer, pp. 259–78. [Google Scholar] [CrossRef]

- Kunrath, Tobias Leonardo, Aline Dresch, and Douglas Rafael Veit. 2023. Supply Chain Management and Industry 4.0: A Theoretical Approach. Brazilian Journal of Operations and Production Management 20: 1263. [Google Scholar] [CrossRef]

- Lee, Jay, Behrad Bagheri, and Hung An Kao. 2015. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manufacturing Letters 3: 18–23. [Google Scholar] [CrossRef]

- Lenart-Gansiniec, Regina. 2019. Organizational Learning in Industry 4.0. European Management Studies 17: 96–108. [Google Scholar] [CrossRef]

- Lezzi, Marianna, Mariangela Lazoi, and Angelo Corallo. 2018. Cybersecurity for Industry 4.0 in the Current Literature: A Reference Framework. Computers in Industry 103: 97–110. [Google Scholar] [CrossRef]

- Liao, Longhui, Chuan Yang, and Lirong Quan. 2023. Construction Supply Chain Management: A Systematic Literature Review and Future Development. Journal of Cleaner Production 382: 135230. [Google Scholar] [CrossRef]

- Liu, Huan. 2013. Big Data Drives Cloud Adoption in Enterprise. IEEE Internet Computing 17: 68–71. [Google Scholar] [CrossRef]

- Liu, Xiaohui, and Youwang Sun. 2012. Information Integration of CPFR in Inbound Logistics of Automotive Manufacturers Based on Internet of Things. Journal of Computers 7: 349–55. [Google Scholar] [CrossRef]

- Lyu, Jung, Jr., Jyh Hong Ding, and Ping Shun Chen. 2010. Coordinating Replenishment Mechanisms in Supply Chain: From the Collaborative Supplier and Store-Level Retailer Perspective. International Journal of Production Economics 123: 221–34. [Google Scholar] [CrossRef]

- Majeed, Aabid Abdul, and Thashika D. Rupasinghe. 2017. Internet of Things (IoT) Embedded Future Supply Chains for Industry 4.0: An Assessment from an ERP-Based Fashion Apparel and Footwear Industry. International Journal of Supply Chain Management 6: 25–40. [Google Scholar]

- Malik, Praveen Kumar, Rohit Sharma, Rajesh Singh, Anita Gehlot, Suresh Chandra Satapathy, Waleed S. Alnumay, Danilo Pelusi, Uttam Ghosh, and Janmenjoy Nayak. 2021. Industrial Internet of Things and Its Applications in Industry 4.0: State of The Art. Computer Communications 166: 125–39. [Google Scholar] [CrossRef]

- Miranda, Bruno Varella, Guilherme Fowler A. Monteiro, and Vinicius Picanço Rodrigues. 2021. Circular Agri-Food Systems: A Governance Perspective for the Analysis of Sustainable Agri-Food Value Chains. Technological Forecasting and Social Change 170: 120878. [Google Scholar] [CrossRef]

- Mühl, Diego Durante, and Letícia de Oliveira. 2022. A Bibliometric and Thematic Approach to Agriculture 4.0. Heliyon 8: E09369. [Google Scholar] [CrossRef] [PubMed]

- Nara, Elpidio Oscar Benitez, Matheus Becker da Costa, Ismael Cristofer Baierle, Jones Luis Schaefer, Guilherme Brittes Benitez, Leonardo Moraes Aguiar Lima do Santos, and Lisianne Brittes Benitez. 2021. Expected Impact of Industry 4.0 Technologies on Sustainable Development: A Study in the Context of Brazil’s Plastic Industry. Sustainable Production and Consumption 25: 102–22. [Google Scholar] [CrossRef]

- Nozari, Hamed, Agnieszka Szmelter-Jarosz, and Javid Ghahremani-Nahr. 2022. Analysis of the Challenges of Artificial Intelligence of Things (AIoT) for the Smart Supply Chain (Case Study: FMCG Industries). Sensors 22: 2931. [Google Scholar] [CrossRef] [PubMed]

- Oztemel, Ercan, and Samet Gursev. 2020. Literature Review of Industry 4.0 and Related Technologies. Journal of Intelligent Manufacturing 31: 127–82. [Google Scholar] [CrossRef]

- Panahifar, Farhad, Cathal Heavey, P. J. Byrne, and Hamed Fazlollahtabar. 2015a. A Framework for Collaborative Planning, Forecasting and Replenishment (CPFR): State of the Art. Journal of Enterprise Information Management 28: 838–71. [Google Scholar] [CrossRef]

- Panahifar, Farhad, P. J. Byrne, and Cathal Heavey. 2015b. A Hybrid Approach to the Study of CPFR Implementation Enablers. Production Planning & Control 26: 1090–109. [Google Scholar] [CrossRef]

- Panaihfar, Farhad, Cathal Heavey, and P. J. Byrne. 2015. Developing Retailer Selection Factors for Collaborative Planning, Forecasting and Replenishment. Industrial Management and Data Systems 115: 1292–324. [Google Scholar] [CrossRef]

- Peres, Fernanda Araujo Pimentel, Thiago Neves Peres, Flávio Sanson Fogliatto, and Michel Jose Anzanello. 2020. Strategies for Synchronizing Chocolate Conching Batch Process Data Using Dynamic Time Warping. Journal of Food Science and Technology 57: 122–33. [Google Scholar] [CrossRef] [PubMed]

- Peterson, H. Christopher. 2013. Fundamental Principles of Managing Multi-Stakeholder Engagement. International Food and Agribusiness Management Review 16: 11–22. [Google Scholar]

- Plattform Industrie 4.0—2030 Vision. n.d. Available online: https://www.plattform-i40.de/IP/Navigation/EN/Industrie40/Vision/vision.html (accessed on 23 April 2024).

- Radmanesh, Seyyed Alireza, Alireza Haji, and Omid Fatahi Valilai. 2023. Blockchain-Based Architecture for a Sustainable Supply Chain in Cloud Architecture. Sustainability 15: 9072. [Google Scholar] [CrossRef]

- Ramanathan, Usha, and Angappa Gunasekaran. 2014. Supply Chain Collaboration: Impact of Success in Long-Term Partnerships. International Journal of Production Economics 147, Pt B: 252–59. [Google Scholar] [CrossRef]

- Samir, Tetouani, Chouar Abdelsamad, Soulhi Aziz, and Elalami Jamila. 2019. Big Data Research on the Green Internet of Things in New Smart-Logistics. International Journal of Innovative Technology and Exploring Engineering 8: 534–37. [Google Scholar] [CrossRef]

- Sautter, Björn. 2021. Shaping Digital Ecosystems for Sustainable Production: Assessing the Policy Impact of the 2030 Vision for Industrie 4.0. Sustainability 13: 12596. [Google Scholar] [CrossRef]

- Schaefer, Jones Luís, Paulo Roberto Tardio, Ismael Cristofer Baierle, and Elpidio Oscar Benitez Nara. 2023. GIANN—A Methodology for Optimizing Competitiveness Performance Assessment Models for Small and Medium-Sized Enterprises. Administrative Sciences 3: 56. [Google Scholar] [CrossRef]

- Shao, Xue Feng, Wei Liu, Yi Li, Hassan Rauf Chaudhry, and Xiao Guang Yue. 2021. Multistage Implementation Framework for Smart Supply Chain Management under Industry 4.0. Technological Forecasting and Social Change 162: 120354. [Google Scholar] [CrossRef]

- Shukla, Manish, and Manoj Kumar Tiwari. 2017. Big-Data Analytics Framework for Incorporating Smallholders in Sustainable Palm Oil Production. Production Planning and Control 28: 1365–77. [Google Scholar] [CrossRef]

- Silva, Francisco Tardelli da, Ismael Cristofer Baierle, Ricardo Gonçalves de Faria Correa, Miguel Afonso Sellitto, Fernanda Araujo Pimentel Peres, and Liane Mahlmann Kipper. 2023. Open Innovation in Agribusiness: Barriers and Challenges in the Transition to Agriculture 4.0. Sustainability 15: 8562. [Google Scholar] [CrossRef]

- Singhry, Hassan Barau, and Azmawani Abd Rahman. 2019. Enhancing Supply Chain Performance through Collaborative Planning, Forecasting, and Replenishment. Business Process Management Journal 25: 625–46. [Google Scholar] [CrossRef]

- Sony, Michael, and Subhash Naik. 2019. Key ingredients for evaluating Industry 4.0 readiness for organizations: A literature review. Benchmarking: An International Journal 27: 2213–32. [Google Scholar] [CrossRef]

- Strange, R., and A. Zucchella. 2017. Industry 4.0, Global Value Chains and International Business. Multinational Business Review 25: 174–84. [Google Scholar] [CrossRef]

- Szozda, Natalia. 2017. Industry 4.0 and Its Impact on the Functioning of Supply Chains. LogForum 13: 401–14. [Google Scholar] [CrossRef]

- Tachizawa, Elcio M., María J. Alvarez-Gil, and María J. Montes-Sancho. 2015. How ‘Smart Cities’ Will Change Supply Chain Management. Supply Chain Management 20: 237–48. [Google Scholar] [CrossRef]

- Tan, Keah Choon, Robert B. Handfield, and D. R. Krause. 1998. Enhancing the Firm’s Performance through Quality and Supply Base Management: An Empirical Study. International Journal of Production Research 36: 2813–37. [Google Scholar] [CrossRef]

- Tao, Fei, Jiangfeng Cheng, Qinglin Qi, Meng Zhang, He Zhang, and Fangyuan Sui. 2018. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. International Journal of Advanced Manufacturing Technology 94: 3563–76. [Google Scholar] [CrossRef]

- Tjahjono, Benny, C. Esplugues, Enrique Ares, and G. Pelaez. 2017. What Does Industry 4.0 Mean to Supply Chain? Procedia Manufacturing 13: 1175–82. [Google Scholar] [CrossRef]

- Treiblmaier, Horst. 2018. The Impact of the Blockchain on the Supply Chain: A Theory-Based Research Framework and a Call for Action. Supply Chain Management 23: 545–59. [Google Scholar] [CrossRef]

- Tseng, Ming Lang, Kuo Jui Wu, Ming K. Lim, and Wai Peng Wong. 2019. Data-Driven Sustainable Supply Chain Management Performance: A Hierarchical Structure Assessment under Uncertainties. Journal of Cleaner Production 227: 760–71. [Google Scholar] [CrossRef]

- van Lopik, Katherine, Murray Sinclair, Richard Sharpe, Paul Conway, and Andrew West. 2020. Developing Augmented Reality Capabilities for Industry 4.0 Small Enterprises: Lessons Learnt from a Content Authoring Case Study. Computers in Industry 117: 103208. [Google Scholar] [CrossRef]

- Venkatesh, V. G., Kai Kang, Bill Wang, Ray Y. Zhong, and Abraham Zhang. 2020. System Architecture for Blockchain Based Transparency of Supply Chain Social Sustainability. Robotics and Computer-Integrated Manufacturing 63: 101896. [Google Scholar] [CrossRef]

- Wang, Lihui, Martin Törngren, and Mauro Onori. 2015. Current Status and Advancement of Cyber-Physical Systems in Manufacturing. Journal of Manufacturing Systems 37: 517–27. [Google Scholar] [CrossRef]

- Weyrich, Michael, Jan Philipp Schmidt, and Christof Ebert. 2014. Machine-to-Machine Communication. IEEE Software 31: 19–23. [Google Scholar] [CrossRef]

- Winter, Johannes, Anna Frey, and Jan Biehler. 2022. Towards the Next Decade of Industrie 4.0—Current State in Research and Adoption and Promising Development Paths from a German Perspective. Science 4: 31. [Google Scholar] [CrossRef]

- Wu, Lifang, Xiaohang Yue, Alan Jin, and David C. Yen. 2016. Smart Supply Chain Management: A Review and Implications for Future Research. International Journal of Logistics Management 27: 395–417. [Google Scholar] [CrossRef]

- Yu, Ming Min, Shih Chan Ting, and Mu Chen Chen. 2010. Evaluating the Cross-Efficiency of Information Sharing in Supply Chains. Expert Systems with Applications 37: 2891–97. [Google Scholar] [CrossRef]

- Zhang, Abraham, Jason X. Wang, Muhammad Farooque, Yulan Wang, and Tsan Ming Choi. 2021. Multi-Dimensional Circular Supply Chain Management: A Comparative Review of the State-of-the-Art Practices and Research. Transportation Research Part E: Logistics and Transportation Review 155: 102509. [Google Scholar] [CrossRef]

- Zhang, Guoqing, Yiqin Yang, and Guoqing Yang. 2023. Smart Supply Chain Management in Industry 4.0: The Review, Research Agenda and Strategies in North America. Annals of Operations Research 322: 1075–17. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).