Abstract

The study aims to analyse warehouse value-added services (VAS) data for a third-party logistics (3PL) service provider, which leads to identifying service improvements and cost-cutting opportunities in performing VAS for clients using Pareto analysis as a quality tool. Using a case study approach, qualitative and quantitative data were collected from a leading 3PL firm in Belgium. The approach is conducted by applying major steps of Pareto analysis. Two pharmaceutical products were analysed according to medical general classification, namely narcotic analgesics (NA) and ophthalmic antihistamines and decongestants (OAD). The results showed that the Pareto principle is proven in the NA—ticketing case, and five activities consumed 83.3 percent of the total time of VAS operations. Furthermore, in the OAD—display case, the Pareto principle is proven and six activities were validated as they accounted for 81.26 percent of the total time of primary VAS operations. The study recommended a solution to each of the four causes of delay, including lack of training/best practices, inefficient space utilization, lack of automation, and lack of cohesiveness and planning. Despite the recognized importance of avoiding warehouse operation inefficiencies, the literature lacks studies applied to practice, and few contributions exist regarding analysing 3PL service providers’ warehousing VAS operations data. This study identified all VAS activities for temperature-controlled pharmaceutical products. Moreover, the study proposes a warehouse operations improvement framework for non-automated 3PL warehouses and guides managers through Pareto analysis to cut costs and improve service level.

1. Introduction

Design of warehouses and management of their operations systems are aspects that are still debated in the literature (Manzini et al. 2015; Laosirihongthong et al. 2018). Particularly, the extant literature reveals an increasing interest in the field of evaluating warehouse operations performance (Baruffaldi et al. 2020). Identification of key warehousing operations, observing activities under each main operation, and monitoring enable detecting problems that cause inefficiencies and identifying potential opportunities for improvement (Laosirihongthong et al. 2018). However, there is a gap and lack of studies in addressing issues related to investigating the warehousing processes in detail for the purpose of optimizing specific tasks or activities related to warehouse operations (Davarzani and Normann 2015; Baruffaldi et al. 2020).

Third-party logistics (3PL) is a business outsourcing arrangement in which a firm outsources its operations to a specialized service provider that provides customized on-demand transportation, warehousing, distribution, and freight-forwarding services. Furthermore, 3PL providers make it easier for products to move by processing papers, monitoring activity, and funding transactions (Sangka et al. 2019). In high dynamic environments, such as warehouses of third-party logistics (3PL) service providers, a more holistic view of warehouse-specific tasks and operations would facilitate development of improvement decisions, which, consequently, contribute to improvement in overall warehouse performance (Baruffaldi et al. 2019; Tubis et al. 2021).

Further, 3PL service providers manage inventory and shipments according to specific requirements by clients, with objectives of increasing shipment handling processes efficiency, managing storage spaces, and satisfying the needs of the clients (Shi et al. 2016; Baruffaldi et al. 2019). To maintain continuous deals with the clients and build robust relationships with them, 3PL service providers need to be flexible in warehouse operations and provide a satisfactory level of customer service with the pressure of being profitable (Hamdan and Rogers 2008; Baruffaldi et al. 2020). In order to provide flexibility for clients, automation in warehouses is not recommended, which indicates the need for tailored tools and activities for managing and improving warehouse operations (Davarzani and Normann 2015; Fannon et al. 2021).

Therefore, 3PL service providers who offer value-added services (VAS) can gain more business opportunities with the increasing trend of outsourcing. However, in order to provide VAS to clients, 3PL companies are facing many challenges. First, 3PL service providers require incessant review of warehouse processes on a continuous basis in accordance with clients’ business needs and requirements (Sangka et al. 2019). Second, 3PL companies need to enhance efficiency of warehouse operations due to variable costs associated with warehouse activities (Karim et al. 2021; Biadacz 2020). Finally, 3PL companies should be flexible and efficient according to the provided value-added services (Baruffaldi et al. 2019).

Based on these reasons, this paper proposes a warehouse operations improvement framework suitable for 3PL non-automated warehouses that leads managers through analysis of warehouse VAS activities. The framework used in the study is built as a systematic multi-stage procedure that begins with collecting existing historical data from the case company, observing all warehouse VAS activities, creating a map for the identified VAS activities with the expected time needed for implementing each activity, applying Pareto analysis, and developing a solution for the highlighted activities to improve efficiency and level of service. Therefore, the proposed framework builds on the existing 3PL warehouse system in order to monitor and control systems and operations.

The dynamic activities of 3PL have been the subject of earlier studies, but it has proven difficult to come to a consensus on how these activities have changed through time in the context of providing value to customers in the contemporary environment (Herrera and Yang 2017; Darko and Vlachos 2022). Value-added activities have been investigated in literature reviews; however, it is difficult for 3PL to improve and stand out from the competition in their customer services (Juga et al. 2018; Jum’a 2020). To offer value-added services that will make 3PL competitive, 3PL must establish a profitable cooperative relationship with its customers (Darko and Vlachos 2022). Furthermore, 3PLs should analyse their VAS activities in order to satisfy customers and improve the efficiency of their VAS processes (Karim et al. 2021; Biadacz 2020). As a practical study, this paper attempts to assist 3PL decision-makers in improving efficiency and profit. Improvements can be achieved by identifying various VAS activities, helping in assigning appropriate workers to complete VAS activities, developing proper standard operating procedures for conducting VAS activities, and appropriately pricing the 3PL-provided VAS.

Although the importance of topics related to avoiding warehouse operation inefficiencies is recognized, the literature lacks studies applied to practice (Davarzani and Normann 2015; Richards 2017; Karim et al. 2021), and few contributions are made when investigating warehousing operations of 3PL service providers (Baruffaldi et al. 2020).

Thus, the aim of the proposed framework is to develop a method for 3PL service providers to analyse warehouse value-added services data, prioritize each operation activity, and implement an improvement scenario that saves costs and improves service quality for clients. Consequently, the framework helps practitioners to make better decisions regarding pricing of warehouse value-added services for each specific item or group of items through Pareto methodology.

2. Literature Review

Today, the warehouse is more crucial than it has ever been in success (or failure) of enterprises (Faber et al. 2013; Richards 2017). In the highly competitive business environment of today, a warehouse is not just a place to store inventory but also to manage and operate value-added services (Karim et al. 2021). This assertion is supported by Jum’a (2020), who emphasizes that well-managed storage activities may provide greater value to the client. Moussa et al. (2019) corroborates this perspective by emphasizing the relevance of warehouses for supply chain competitiveness.

In a 3PL firm, warehouse operations are typically highly specialized and customer-specific (Frankin and Johannesson 2013). Improving the efficiency of a warehouse process is, therefore, a very important factor in controlling actions (Kolinski and Sliwczynski 2015). Thus, in recent years, the concept of quality tools has begun to acquire wider awareness inside supply chains in this scenario of creating value and reducing waste in warehouse activities (Pereira et al. 2020). Accordingly, warehouses are under continual pressure to boost efficiency and accuracy while lowering costs and increasing customer service (Karim et al. 2021).

2.1. Third-Party Logistics Providers

The extraordinary internationalization of supply chains has coincided with the rise of 3PL in the last three decades (Shi et al. 2016). Recently, many supply chains increasingly rely on 3PL. Many businesses have outsourced their logistical processes to 3PL providers to focus on their core strengths, which saves operating costs and enhances service quality (Langley 2013; Biadacz 2020). The benefits of outsourcing logistics to 3PL providers are mostly ascribed to the cost savings, improved performance, and enhanced capacity of organizations to focus on their core business (Sangka et al. 2019; Ruiz-Pérez et al. 2020).

While 3PL business has grown significantly over the last decade (Baruffaldi et al. 2019), most of that expansion has been concentrated in the traditional 3PL services of warehousing and domestic transportation (Shi et al. 2018; Rivera et al. 2016). Although the two essential logistics operations are transportation and warehousing and they are still significant in 3PL providers’ service offerings, the variety of services provided by 3PL providers has continuing to expand. Leading 3PLs set themselves apart by implementing unique VAS and full supply chain solutions (Shi et al. 2016). 3PLs can access supply chain segments with greater VAS processes by delivering these services as opposed to the typically supplied transport and warehousing-based services.

As a result, in line with the growing movement of outsourcing, the need for value-added services has increased in recent decades (Baruffaldi et al. 2019). Customers of 3PL companies have become more demanding and less loyal toward certain providers as competition in the 3PL industry has intensified (Frankin and Johannesson 2013). Consequently, 3PL providers must be able to offer a diverse range of solutions that are tailored to the customer’s specific needs. Complete distribution, customized packaging, warehousing solutions, inventory management, a customer service centre, and many other VAS activities are examples of value-added services (VAS) (Frankin and Johannesson 2013).

3PL companies must have the necessary resources and knowledge to match the features of a product. Customer requirements that relate to provision of particular services in connection to the product are known as product-related needs. A product, for example, can be repackaged or enhanced at the customer’s request; such services are more commonly employed in the case of complicated, high-value items (Jager et al. 2009; Fannon et al. 2021). 3PL providers began offering customisation services (Darko and Vlachos 2022), since this segment of the supply chain has greater VAS activities.

2.2. Value-Added Services in Warehouses

Transportation and warehousing nowadays constitute a minimum standard of logistics services and form part of the service offerings of most 3PL providers (Barker et al. 2021). As a result, if 3PLs mainly offer non-differentiated basic services, they will have a minimal profit margin (Pereira et al. 2020). These value-added services assist 3PL providers in generating new income streams and achieving much greater financial returns. They also allow major 3PL providers to handle larger sections of their clients’ supply chains, giving them a competitive advantage in a competitive industry (Shi et al. 2016). Moreover, the idea is that, by broadening the breadth of services provided, 3PLs may strengthen their relationships with clients, possibly leading to a position as a value-added solution provider (Abushaikha et al. 2018). Value-added services refer to the services that a company delivers during the servitisation process that add value to the product (Zhang et al. 2015; Alkalha et al. 2022). According to Berglund et al. (1999), VAS is the challenge that providers face to provide their customers with services that add more value to their customers’ business than the customers would be able to achieve themselves.

VAS in logistics is a broad phrase that likely encompasses a wide range of value-added services (Jum’a 2020). Today, a huge number of 3PLs offer value-added services (VAS) (Anderson et al. 2011). Companies’ competitiveness is increasing, and this is represented in supply chains, which must function in a leaner manner without compromising product distribution quality (Pereira et al. 2020). Value-added services are activities that enterprises might develop together to enhance their efficiency and/or effectiveness (Mou and Jiang 2021). Their scope of operations will frequently grow beyond their traditional transportation- and warehousing-based activities to include other value-chain elements by providing unique services (Shi et al. 2018) with additional or exceptional value above and beyond the basic and the standard value (Mou and Jiang 2021). Examples of VAS provided by the vast majority of the larger 3PL providers include bundling and labelling, item customization, postponement, cross-docking and invoicing, and so on. These services and activities frequently empower 3PL differentiation and offer an upper hand when a client chooses the 3PL, just as expanded benefit for the 3PL supplier (Anderson et al. 2011). As a result, according to Bowersox et al. (1996), companies may boost sales by providing distinctive product packaging, creating personalized labels, offering information services, placing price labels on items, and building point-of-sale displays, among other things. 3PL firms that specialize in such activities execute the vast majority of value-added services that the buyer and seller agree on (Jager et al. 2009).

In many situations, VAS are very client-specific, and 3PL provides them in response to customer requests or identified needs, even if the customer does not define them (Jager et al. 2009). As a result, new VAS are frequently linked to increased service customisation and customer-specific functionalities (Darko and Vlachos 2022). According to new research conducted by Statista (2021), the value-added warehousing and distribution market in the United States in 2020 had a revenue of more than USD 46 billion. Value-added services may be split into several categories according to the activities performed by 3PLs, according to Bowersox et al. (1996). Customer-focused VAS enable alternate distribution methods for 3PL experts, such as direct shop delivery or home delivery. Picking, packaging, and repacking services are very widespread, allowing a basic product to be distributed in unique configurations chosen by the client. On the other hand, promotion-focused VAS entail creation of point-of-sale displays and other services aimed at increasing sales. Point-of-sale displays may also mix items from several vendors in a single display for a specific business. Gifts and promotional items are frequently handled and sent by the supplier, while other 3PLs just provide basic VAS, such as outsourcing a company’s basic customer service (order processing, inventory management, reverse logistics, and billing). Many companies also provide comprehensive logistical services. Table 1 provides a detailed classification of non-standard services in several functional domains, including warehousing (Herrera and Yang 2017).

Table 1.

VAS in different areas of logistics, adopted from (Herrera and Yang 2017).

2.3. Total Quality Management Tools Used to Improve Warehouse Operations Efficiency

TQM has received much attention in academia during the last two decades, and it has become a well-known field of research. Year after year, TQM indicators have been used to improve various performance assessment models from concept to actual implementation (Ivančić 2014; Pandey et al. 2021). Warehouse operations are essential for ensuring customer satisfaction continuity and have a significant impact on cost savings. As a result, warehouse management should focus on ways to improve process efficiency through use of a variety of management principles, including quality management (Sugathadasa et al. 2021). TQM has an impact on all parts of logistics that affect its efficiency (Zimon 2017). A standard quality management system also significantly improves correct execution of warehousing activities. In other words, proper management performance is projected to lead to better logistical services and, as a result, increased customer satisfaction (Sugathadasa et al. 2021; Gotzamani et al. 2010). Because of these reasons, TQM principles are increasingly being applied to the logistics area (Kopecki et al. 2016), and companies have invested heavily in TQM programs to improve internal quality and capabilities during the previous decade (Zimon 2017).

As the responsibilities of warehouse operations have increased over time, customer needs, such as order accuracy (correct order at the right time and in the right quantity), have become increasingly important (Accorsi et al. 2014). Along with the requirements, the warehousing process must account for a range of costs, including inventory, administrative, resource operational, and construction costs, among others (Martin 2018), leading us to conclude that implementing the TQM concept is the next step toward a thorough overhaul of a company’s key operational processes (Zimon 2017; Pandey et al. 2021). As a result, in recent years, the concept of quality tools has begun to gain popularity inside supply chains in the context of creating value and decreasing waste in warehouse activities. Because the primary tasks of logistics and quality management are merging, it is worth noting that implementing standardized quality management systems in logistics firms is the most logical practice (Zimon 2017).

2.4. Pareto Analysis in Warehouse Operations

Warehouse operations are crucial structures that permit smooth product flow in supply chains as well as central entities in competitive supply chains for handling and storing goods (Baghizadeh et al. 2022). A representative overview of the entire warehouse VAS can be achieved by using the Pareto rationale. The Pareto principle is employed to mathematically define the most important issues in warehouse activities (De Jesus Pacheco et al. 2023). The 80/20 rule is one of the most effective guidelines in warehousing operations, as well as many other corporate activities. In terms of business, the 80/20 principle has been widely adopted, especially in the field of comprehensive quality management (Ivančić 2014). According to Pareto analysis, the bulk of problems (80%) can be traced back to a few basic causes (20%), or 80% of problems can be solved with 20% of the effort (Brooks 2014).

Although VAS are important in warehouses, many 3PLs do not operate or perform to their full potential since they participate in several non-VAS activities. In this instance, non-value-adding activities produce various forms of operational waste because they neither improve warehouse performance nor customer pleasure (De Jesus Pacheco et al. 2023). As a result, finding and eliminating operational waste in warehouses has emerged as a major obstacle to improving efficiency of warehouse operations and supply chains (Baghizadeh et al. 2022; De Jesus Pacheco et al. 2023).

This method of analysis is frequently used in decision-making situations or in resolving complex problems, such as warehousing operations (Ahmed and Ahmed 2011). The strength of this principle in management science is that it fosters change in order to ensure continuous development while also providing a technique for prioritizing resource allocation in order to optimize returns. It is not sufficient to “work hard” but is also necessary to “work smart” on the correct things (Ivančić 2014). Therefore, significant reasons must be recognized and addressed to attain a higher level of quality, ensuring that the entire process runs smoothly (Ivančić 2014).

Pareto analysis leads you to identify critical success factors that must be addressed to ensure an organization’s success, and thus they reflect those management or organizational areas that require special and ongoing attention from managers (Ruiz-Pérez et al. 2020; Tubis et al. 2021). Since it is used to uncover deficiencies in an organization, such as insufficient planning, monitoring, scheduling, reviewing, and document management, the theory can be applied to nearly any sort of system, process, or activity (Ivančić 2014; Ruiz-Pérez et al. 2020).

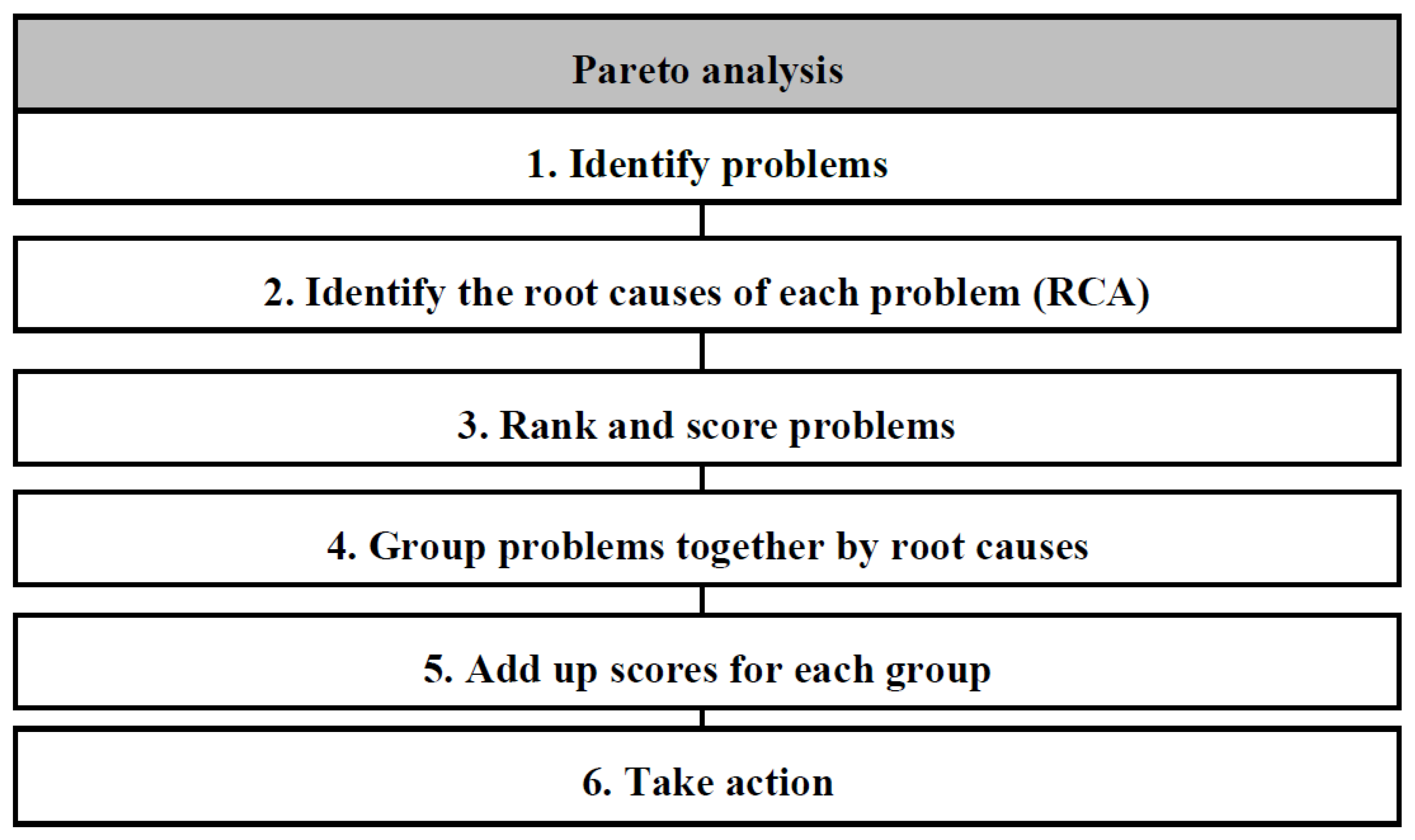

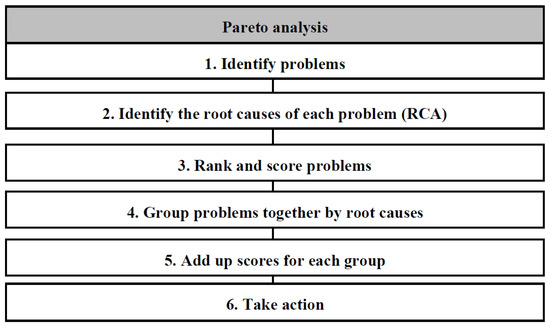

The Pareto graph is a diagram that depicts the few significant contributors to the majority of quality concerns. Identify a list of concerns, then conduct a root-cause analysis (RCA) and map each of the issues before summing the scores of each group. At this point, the attempt to locate the source of the problem should be obvious, and the focus should be on finding a remedy or solution to the fundamental cause of the difficulties for the highest scoring party. In this way, Pareto analysis not only identifies the most important problem to solve but also how to solve it. Figure 1 shows the basic steps of Pareto analysis.

Figure 1.

Basic steps of Pareto analysis, adopted from (Brooks 2014).

2.5. VAS in Warehouse Context

Companies need to have access to a variety of information on customer service, demands, wants, and other factors in order to serve their customers more efficiently and competitively than their rivals (Jum’a et al. 2022). The importance of warehouses in the supply chain can be emphasized because they play a vital role in storage of items from the point of production until they are delivered to customers on demand (Juga et al. 2018). A warehouse today serves as a management and operational hub for value-added services in the fiercely competitive business environment (Jum’a 2020; Darko and Vlachos 2022). The demands on warehouses to boost productivity and accuracy while lowering costs and enhancing customer service are constant (Karim et al. 2021). The Pareto principle argues that only 20% of the work results in 80% of the benefit. Alternatively, 20% of causes are responsible for 80% of problems (Ruiz-Pérez et al. 2020). Pareto analysis pinpoints the issues or tasks with the greatest potential reward. Application can help people prioritize problems and tasks, identify problems, and better organize workloads. It can also increase productivity and profitability (Tubis et al. 2021). In addition to assisting 3PL in competing and surviving in a challenging commercial environment, VAS can influence clients’ behaviour favourably from the standpoint of marketing strategies (Juga et al. 2018; Abideen and Mohamad 2020). More specifically, they can produce several advantages, such as higher sales income, lower financial risk, and better market diversity (Herrera and Yang 2017). Companies that use data and real-time information can achieve a major competitive advantage through the firm’s services (Jum’a et al. 2022). Therefore, many scholars have addressed the importance of VAS in firm warehouses in various ways.

One study demonstrated that customers expect 3PLs to add value beyond logistics and warehousing by taking on more decision-making roles, such as overseeing their interactions with 3PLs, and by providing tailored services that will help them compete (Darko and Vlachos 2022). The study does, however, indicate that, although shippers are very concerned about transportation and warehousing, they are also increasingly expecting a 3PL to handle additional value-added services to their offerings in order to remain competitive (Darko and Vlachos 2022). Similarly, another study aimed at developing a framework for value-added services of cold chain logistics, with examples from four aspects (customized service, integrated service, consultation/solution, and strategic alliance service), as well as its value-added mechanism for improving the core competencies of the entire cold chain. Then, several improvements were suggested by considering the shortcomings of the current cold chain logistics methods between the two countries (Wang 2018). Moreover, a study conducted by Soinio et al. (2012) intended to integrate the viewpoints of small- and medium-sized enterprises (SME) and 3PLs. The goal was to construct a theory-based framework that had already been put to the test and could assist both service providers and SMEs in finding fresh opportunities to advance their logistics (Soinio et al. 2012). In addition to suggesting novel logistics service delivery methods, including value-added activities for SME clients, the study provides a methodology for classifying logistics services for SMEs (Soinio et al. 2012).

A study by Raghuram and Arjunan (2022) developed a framework for designing a lean warehouse that has been incorporated and validated in a heavy machinery manufacturer. This framework will make it easier for future lean-based warehouse designers to apply simple step-by-step processes to achieve the goal with the greatest accuracy. The steps that were followed can be summarized as defining lean processes and eliminating non-value-added activities, such as kitting for unique parts (Abushaikha et al. 2018; Raghuram and Arjunan 2022). Likewise, a study indicated that discrete event simulation was effective in simulating future state lead time significant reduction, which aids in better decision-making. Total lead time, process time, value-added, and non-value-added percentage all improved (Abideen and Mohamad 2020).

Another study showed that perceived service quality and value-added services are crucial in developing a brewery company’s brand equity. Value-added services have a direct effect on level of service quality overall, and they also have an indirect effect on the operational aspect of service quality in logistics (Juga et al. 2018). Further, Olya et al. (2018) conducted a study that mimics the causal processes that result in both favourable and unfavourable rankings for value-added services. Marketers, investors, and policymakers can use configurable conditions showing a high/low degree of value-added services as a guiding approach (Olya et al. 2018). Meanwhile, Karim et al. (2021) developed a model that considered the category of “manpower productivity,” which is defined as value-added services, such as kitting, replenishing, packing, and labelling, that are typically carried out by labour and depend on consumer demand and warehouse availability. In order to increase the effectiveness and efficiency of the current supply chain management, this was completed to ensure that the value-added services offered by the warehouse were taken into consideration (Karim et al. 2021).

Finally, a study by Herrera and Yang (2017) supported knowledge of the relationship between the customer and the VAS offering, as well as the significance of this relationship for 3PL firms. The decision-making process for VAS offerings and the contributing elements are also described in this study (Herrera and Yang 2017). The study provides a framework for understanding the pertinent components of VAS and their relationships as well as further examples of how strategically and operationally crucial it is for both the customer and the supplier to have an acceptable VAS offering. Depending on the customer’s logistics situation, 3PL businesses might utilize these results to carefully select target areas for VAS offerings (Herrera and Yang 2017).

Table 2 summarizes the most relevant studies that investigated the relationship between value-added services and company overall service performance in the context of warehouses from various industries.

Table 2.

Summary of warehouse value-added-services-related studies.

3. Materials and Methods

3.1. Sampling and Data Collection

Between December 2018 and February 2019, data were collected from a leading 3PL firm in Belgium that provides a wide range of temperature-controlled logistics solutions for two industries: life sciences and healthcare, and food and perishables. In Belgium and Europe, its technologically equipped vehicle fleet provides safe transfer of temperature-controlled drugs.

In this study, warehouse VAS activities were extracted by observing fifteen product types, and Pareto analysis was conducted on two main pharmaceutical products. The products were named according to their medical classification according to the American Society of Health-System Pharmacists to protect the confidentiality of product information. First product is narcotic analgesics and second product is ophthalmic antihistamines and decongestants.

The case company was having a serious price problem; they were delivering services based on an estimate of the value-added services they provided to a specific product in the VAS department with an unclear timetable of various activities. VAS department does not have a process map that contains all the processes offered by the department because they do not know the exact time spent on each process and activity for each individual product.

3.2. Method of Data Analysis

The methodology used in this study consisted of six major steps adopted from Brooks (2014), including identifying problems, identify root causes of these problems, rank and score problems, group problems together by root causes, add up scores for each group of problems, and suggest corrective actions.

3.3. Pareto Analysis Methodology

This research adopted the six steps of Pareto analysis suggested by Brooks (2014). As the Pareto analysis shows previously in Figure 1, data from calculations, total participation, observations, interviews, and reports were used to illustrate the major elements of VAS department processes operations according to the first two steps. After that, the cause–effect relationship of these problems can be determined using an RCA, which outlines the nature and essence of the problems. The RCA has a set of fundamental steps that have been established (Brooks 2014): first, data collection that includes collection of information and problem notification should be completed in a systematic manner. Moreover, determine the length of time this problem has occurred and determine the problem’s frequency (quantify) and impact (if the problem is not solved). Second is defining and classifying potential causes, which includes identifying how and under what conditions problems happen, and, if these problems are resolved, what other problems arise. Next step is defining root causes, and here we should identify the factors that contribute to the problems and their relationships. In steps three, four, and five, the significance and importance of each of the identified issues are ranked, rated, and grouped together. Finally, in step six, an action plan including improvement actions can be established to solve the issues.

4. Results and Discussion

4.1. Steps 1 and 2: Identify Problems and Identify the Root Causes of Each Problem

The first step of Pareto analysis is to identify problems associated with the VAS department’s time-consuming approaches to activities. Manual calculations were employed in the initial step. Root cause analysis (RCA), a well-known method employed in the second step of Pareto analysis, was utilized to investigate the problems’ root causes.

The VAS department in the case company provides a variety of customized services to their clients that vary by type of service, type of product, and level of customization required during specific period, such as seasonal periods that require more customization in service, such as during the Christmas season.

After participating in VAS operations and observing 15 different products for 3 months, we were able to develop a process map for all the activities provided by the VAS department, as well as timing each process in a highly precise manner. We timed five different co-workers at various times of the day, on various days of the week, several times for each process, allowing us to have an accurate average time spent on each activity and visualize the exact processes in the VAS department.

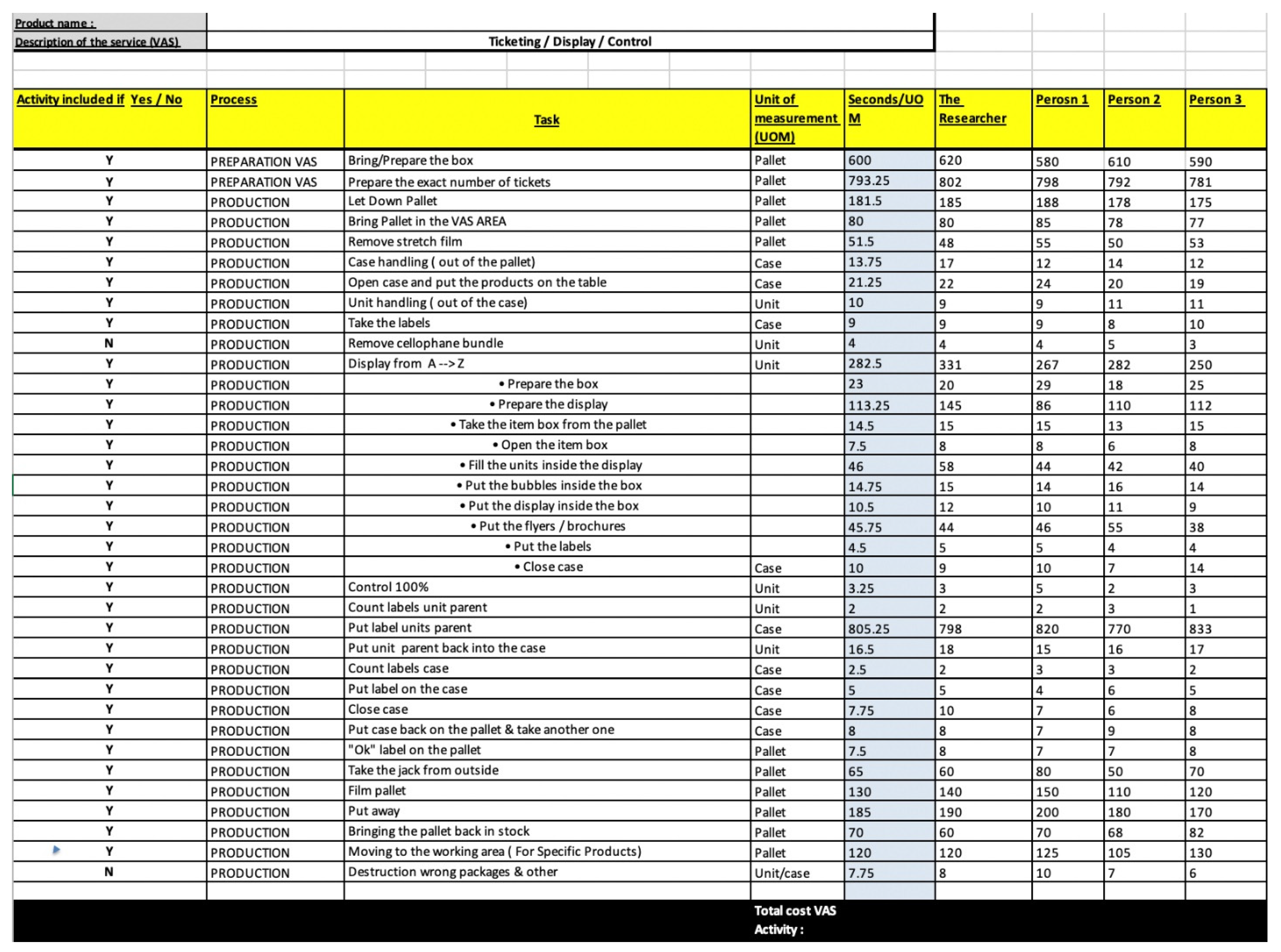

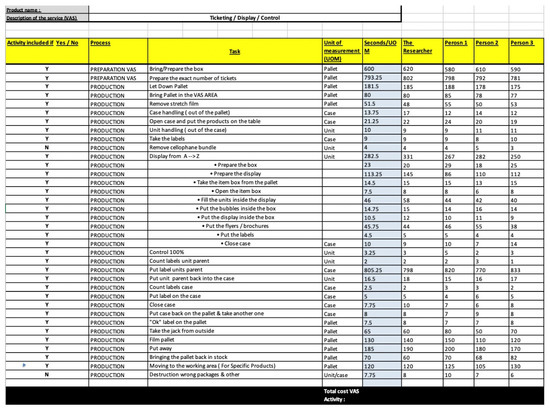

We initially identified process mapping all VAS activities by creating explicit activity names and times. Moreover, a complete template was designed that includes all VAS activities and can be adjusted to include activities related to the nature of the product. As a result, this template can be used with any product in the VAS department.

Figure 2 presents the template that was developed through observation and participation with VAS workers team. This detailed template serves as a reference for future work within the VAS department of the case company and encompasses a comprehensive list of all VAS activities. Column 1 specifies whether a VAS activity is included in the service provided to the client, indicated by “(Yes)” or “(No)” to denote if the time consumed in the activity will be calculated in the total cost. Column 2 denotes the location where the process occurs. Column 3 designates the task name. Column 4 signifies the unit of measurement for the corresponding process. Column 5 represents the duration. The remaining columns showcase the duration for the various employees and the researcher himself as this research was conducted through the full participation of the researcher, who was involved in the process and served as a worker for the duration of one month to create this comprehensive template.

Figure 2.

The general template for timing VAS activities. Note: display from A to Z (contains 10 sub processes, such as take the item box from the pallet, open the item box, fill the units inside the display, put the bubbles inside the box, etc.).

Moreover, this template enables easy utilization by the management of the VAS in the case study company. The process is straightforward, starting with recording the product name, followed by selection of the appropriate value-added services activity, such as ticketing, display, or control. Additionally, each product has its own unique template, reflecting its specific characteristics, as some processes may be involved in a particular VAS activity while others are not. Furthermore, this results in an accurate pricing mechanism for the product and the corresponding service provided by thoroughly analysing and breaking down the activities by comprehensive analysis of the VAS activities involved and precise determination of the duration of each.

To protect the confidentiality of product information, all names of pharmaceutical products, 15 different products that have had their processes measured, will be named under their medical classification according to the American Society of Health-System Pharmacists, Cerner Multum, and IBM Watson Micromedex.

The company case provides three main VAS: ticketing, display, and control based on the activities provided in Figure 2. Ticketing VAS includes printing barcodes, labelling and re-labelling, and adding and removing from bulk packages. Display VAS includes assembly of products, making the display, and arranging the products on the display. Control VAS includes product testing in terms (checking out any discrepancy in the product).

We chose two warehouse VAS, including ticketing and display, because clients request them heavily. Moreover, we applied Pareto analysis on these two VAS (ticketing and display) based on a product that has high turnover, which means that the product is stored and dispatched in large quantities. We excluded control VAS since it is rarely requested by clients.

The comprehensive observation of all procedures in the VAS department, as well as the attempt to comprehend the fundamental cause of the problem in order to categorize it, resulted in four primary causes of delay: inefficient space utilization, lack of training/best practices, lack of automation, and lack of cohesiveness and planning.

4.2. Steps 3, 4, and 5: Rank, Score, Group Problems (Prioritization)

Following the creation of the basic template and the time of all activities, we begin to rank and prioritize the activities using Pareto analysis. The Pareto principle must illustrate the critical few activities in order to be validated, allowing for identification of which processes consumed the most time in the overall VAS activities.

In principle, we conducted a Pareto analysis to score and prioritize the critical few from the trivial many of the 24–26 activities implemented. The data analysis reveals that Pareto analysis led us to these five activities, which appear to be the most critical every time for all products. The results of this analysis were the primary activities and the causes of delay, which represented the focus of the research on corrective actions. Table 3 shows narcotic analgesics—ticketing data gathered.

Table 3.

Analysis of narcotic analgesics—ticketing.

Table 3 displays the findings of the timing observation and analysis performed on narcotic analgesics—ticketing, providing a detailed overview of the time allocated to each activity type specific to this particular product and service type implemented. The causes of delay for each activity have been meticulously determined through a thorough examination of the warehouse and VAS department, presented as a proportion of cost. This information provides a valuable representation of the operational efficacy of the narcotic analgesics—ticketing system and identifies potential areas for enhancement.

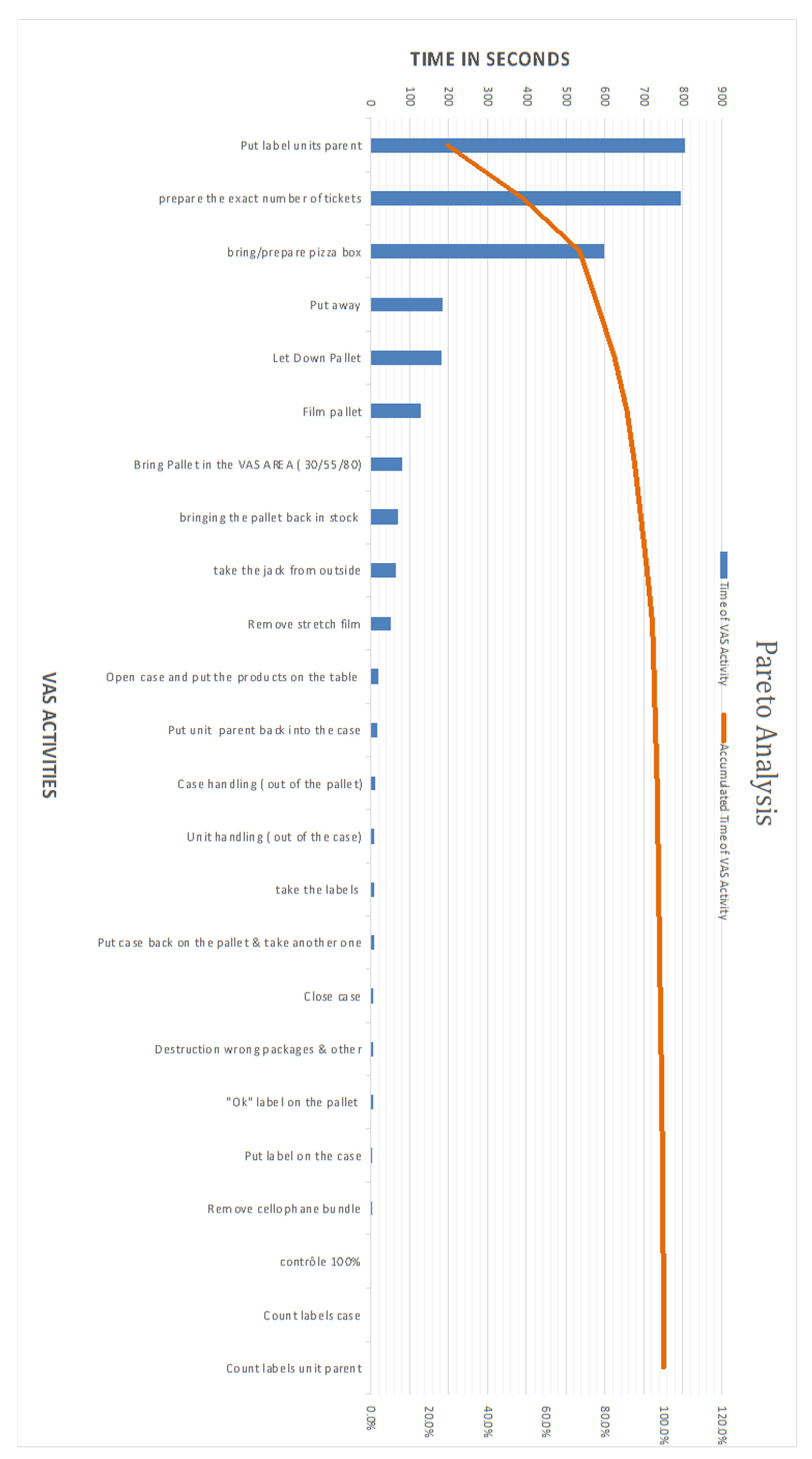

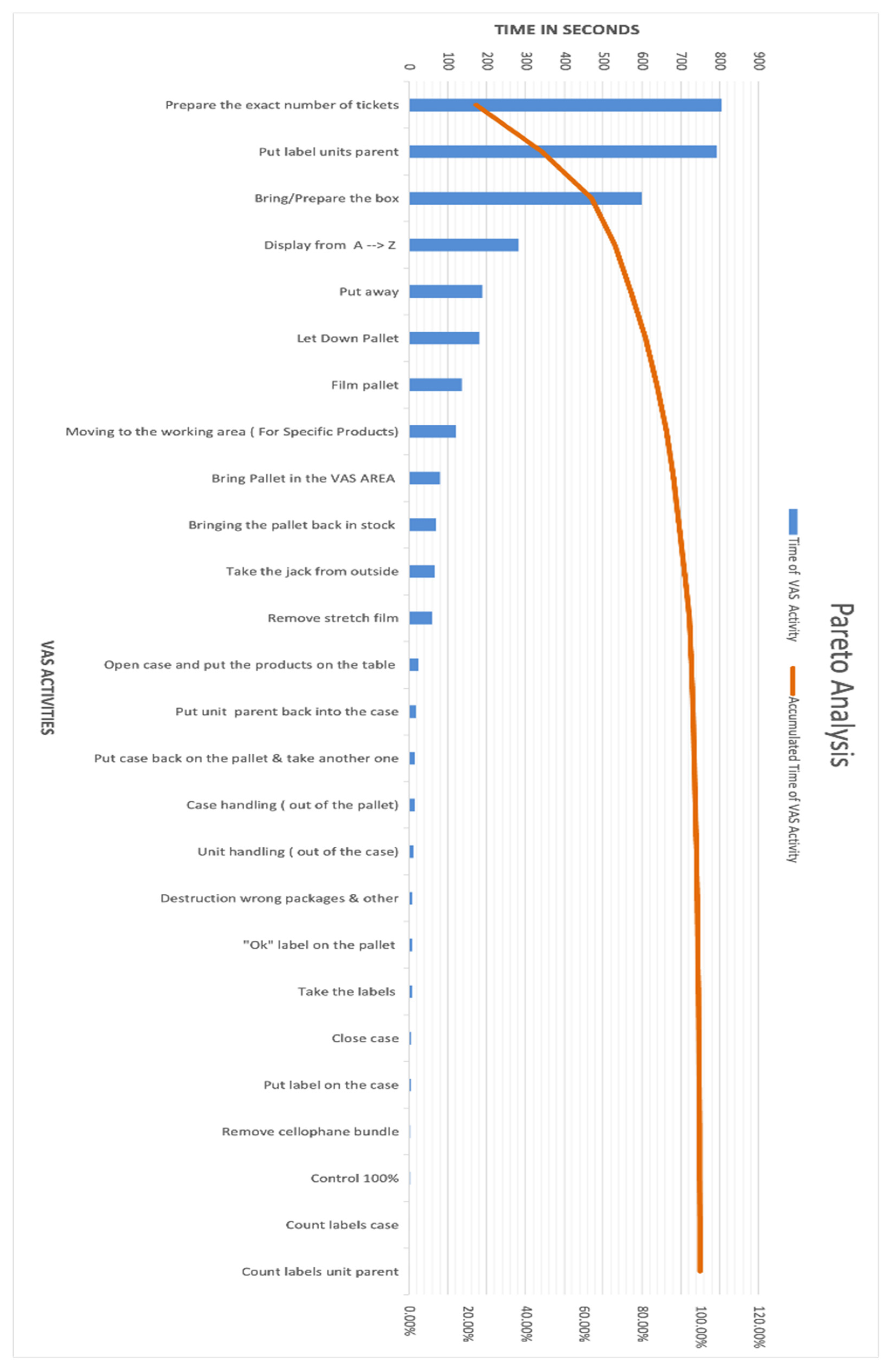

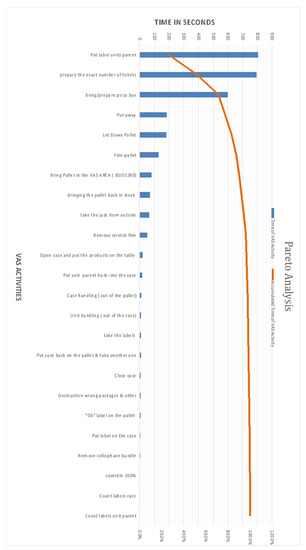

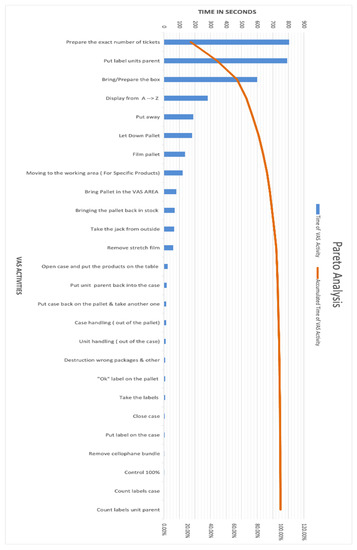

When we analysed VAS processes on narcotic analgesics—ticketing, we found that there are 20% of activities we spend 80% of VAS operation resources and time on, as shown in Figure 3.

Figure 3.

Pareto analysis for narcotic analgesics—ticketing.

As depicted in Figure 3, a Pareto analysis was conducted for product narcotic analgesics with respect to service type “Ticketing”. The figure presents a comprehensive representation of all the activities involved in provision of ticketing services for narcotic analgesics, along with the corresponding time expenditure depicted in seconds. The value-added services (VAS) activities are represented on the X-axis, while the time spent on each activity is indicated on the Y-axis in seconds. The dotted line in the figure symbolizes the 80/20 rule, which postulates that 80% of the time invested in narcotic analgesics—ticketing is attributed to 20% of the essential activities. This analysis provides valuable insight into the primary activities and associated difficulties, facilitating implementation of corrective measures aimed at rectifying identified issues.

The Pareto principle is proven in this scenario; the point where the cumulative curve crosses the last column can be depicted graphically, where the first five activities out of twenty-four consume 83.3 percent of the total time of VAS operations. These 20% activities are as follows:

- Put label units parent (put price label or QR code sticker on each individual item)

- Prepare the exact number of tickets/labels (count exactly the right number of price label or QR code sticker for each employee per case)

- Bring/prepare the box (picking up the specific box from the station and build it as a box from flat cartoon to box)

- Put away (put away the finished pallet in the specific area)

- Let down pallet (bringing the pallet from the warehouse aisles to the added value services station area)

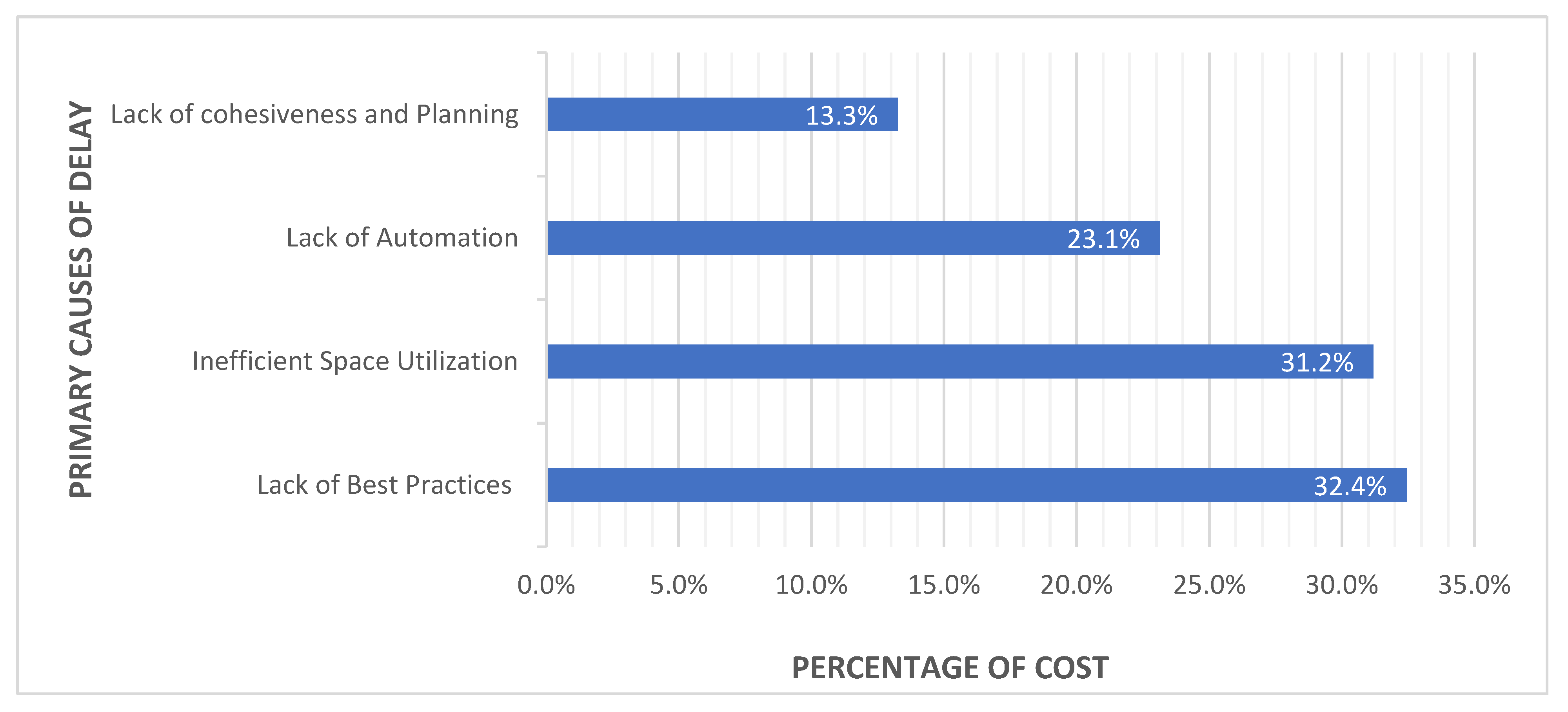

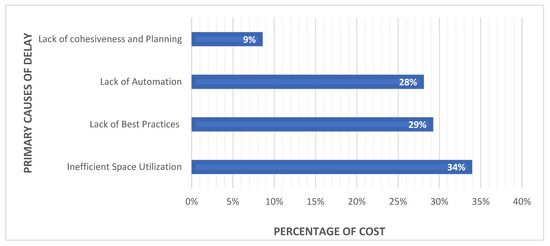

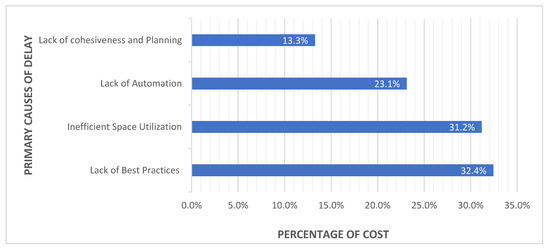

We use this study to combine causes of delay by proportion of cost, then aggregate the scores for each category discovered to order the primary causes influencing the VAS department as follows, as shown in Figure 4, which illustrates the primary causes of delay in relation to percentage of cost.

Figure 4.

The primary causes of delay in relation to the percentage of cost—narcotic analgesics.

- Inefficient space utilization 34%

- Lack of training/best practices 29%

- Lack of automation 28%

- Lack of cohesiveness and planning 9%

As shown in Figure 4, the analysis was used to classify the causes of delay based on the proportion of cost. Figure 4 illustrates the results of our analysis, displaying the primary causes of delay and their respective cost percentages. The scores of each group were calculated and aggregated to arrive at a ranking of the primary factors impacting the value-added services (VAS) department. This methodology facilitated combination of the causes of delay and their respective cost contributions, enabling us to determine the predominant factors influencing the VAS department.

Another example for Pareto analysis on ophthalmic antihistamines and decongestants—display, Table 4 shows ophthalmic antihistamines and decongestants—display data gathered.

Table 4.

Ophthalmic antihistamines and decongestants—display.

Table 4 presents the results of the timing observation and analysis carried out on ophthalmic antihistamines and decongestants—display. The table provides a comprehensive overview of the time expenditure associated with each activity type specific to this particular product and service. The causes of delay for each activity have been meticulously determined through an extensive examination of the warehouse and the value-added services (VAS) department, presented as a proportion of cost. This information constitutes a valuable evaluation of the operational efficiency of the ophthalmic antihistamines and decongestants—display system and serves to identify potential areas for improvement.

When we analysed VAS processes on ophthalmic antihistamines and decongestants—display, we found that there are 20% of activities we spend 80% of VAS operation resources and time on, as shown in Figure 5.

Figure 5.

Pareto analysis for ophthalmic antihistamines and decongestants—display.

Figure 5 shows a Pareto diagram applied to the VAS activities, which is the subject of this study.

As shown in Figure 5, we conducted a Pareto analysis for the product ophthalmic antihistamines and decongestants in relation to the service type “Display.” Figure 5 presents a breakdown of all the activities involved in provision of display services for ophthalmic antihistamines and decongestants, along with the corresponding time expenditure in seconds. The X-axis represents the value-added services (VAS) activities, while the Y-axis displays the duration in seconds. The dotted line in the figure symbolizes the 80/20 rule, which states that 80% of the time allocated to ophthalmic antihistamines and decongestants—display is attributed to 20% of the critical activities. Identification of the key activities and corresponding challenges through this analysis enables implementation of corrective actions aimed at rectifying the issues.

The Pareto principle is proven in this scenario, where the first six activities out of twenty-six consume 81.26 percent of the total time of VAS operations. These 20% activities are as follows:

- Prepare the exact number of tickets/labels

- Put label units parent

- Bring/prepare the box

- Display from A to Z

- Put away

- Let down pallet

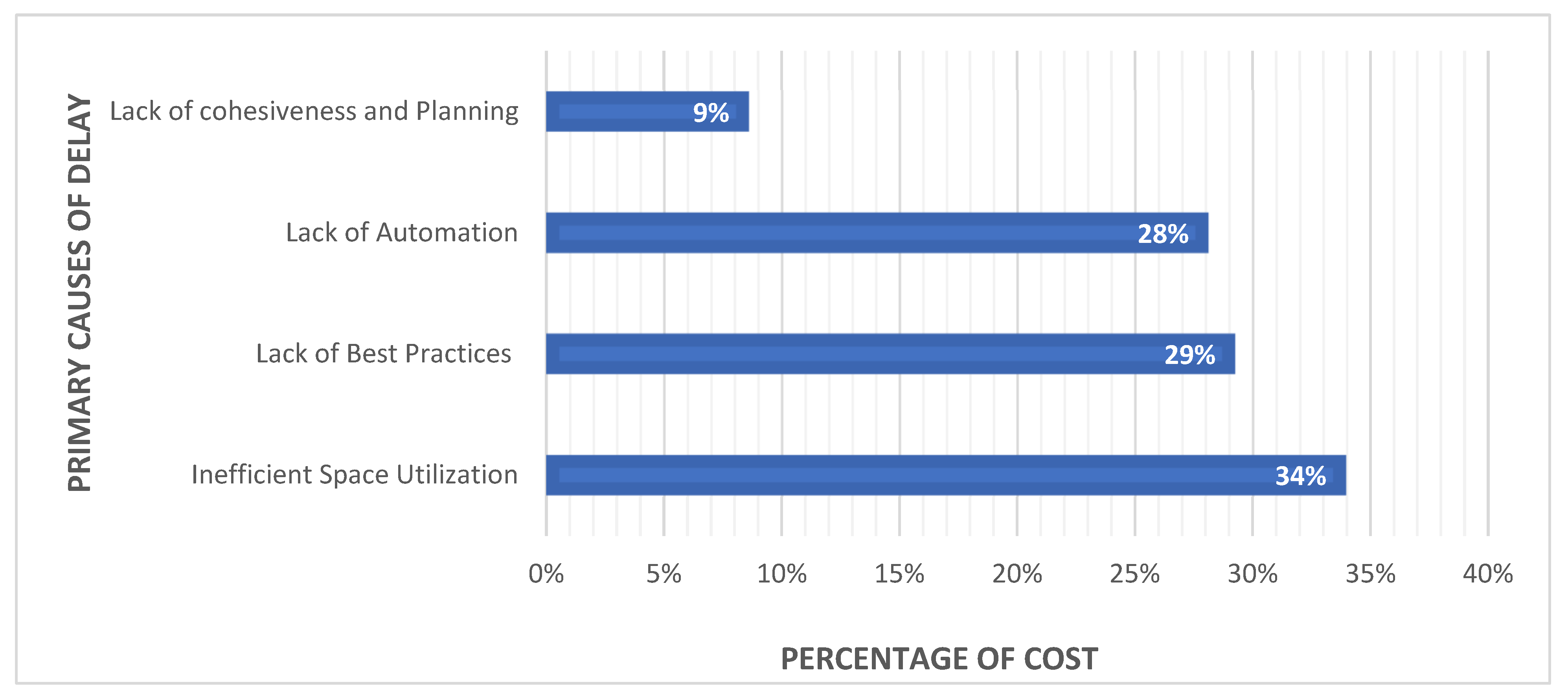

Again, we utilize this analysis to classify causes of delay by the percentage of the cost, then add up the scores for each group to be able to arrange the primary causes impacting the VAS department, as shown in Figure 6, which illustrates the primary causes of delay in relation to percentage of cost:

Figure 6.

The primary causes of delay in relation to the percentage of cost—ophthalmic antihistamines and decongestants.

- Lack of training/best practices 32.4%

- Inefficient space utilization 31.2%

- Lack of automation 23.1%

- Lack of cohesiveness and planning 13.3%

In Figure 6, we utilize this analysis to classify the causes of delay based on the proportion of cost. Figure 6 illustrates the results of our analysis, displaying the primary causes of delay and their respective cost percentages for the analysis performed on ophthalmic antihistamines and decongestants—display. The scores of each group were determined and aggregated to yield a ranking of the primary factors affecting the value-added services (VAS) department. This approach enabled combination of the causes of delay and their cost impact, allowing us to identify the major factors influencing the VAS department.

4.3. Step 6: Corrective Actions

Corrective actions represent Pareto analysis’ final step. The following are recommendations for the VAS department regarding key VAS activities based on Figure 4 and Figure 6. First, to deal with the “Lack of automation” problem, we need to automate the exact number of tickets preparation process. The process of preparing the exact number of tickets/labels is time-consuming for co-workers and adds little value to the product, but it is critical for quality control because it is an indicator in the process that you have the right number of items in your case and the same number of labels, so, if you find one more label, it means there is a product that has not been labelled. This process is critical to all the products and services used throughout VAS activities. We can save a significant amount of money by automating it with a standard machine that makes small holes every 50 labels, for example, so that the employees do not waste time and we save a significant amount of money. Second, regarding the problem of “Lack of Training/Best Practices”, we recommend teaching best practices to all co-workers. We noticed that there is large variation between the staff members in the put label units parent activity. A few of the staff members finish this process early and the rest finish it later after almost 100 s on average, so the variation here is more than one minute and this is per case. If we compare it on a larger scale, say per pallet, the variation will have a huge impact on the efficiency of the activity, as well as the price offered. The solution is to develop a standard operating procedure for all activities that employees must follow in order to avoid bottlenecks in operations. Third, for the problem of “Inefficient Space Utilization”, we recommend utilizing the warehouse spaces and optimizing the routes that serve the VAS department. The main reason behind this problem is inefficient space utilization in the following activities: bring/prepare the box, put away, and let down pallet. The location where they bring/prepare the boxes is too far away from the VAS operational area, nearly 10 min via forklift, and the employees need to drastically reduce wasted time in a procedure that adds little value. As a result, the employees can move the boxes area closer to them in order to save time, especially with better route planning. This problem arose as a result of our observations as well as a lack of warehouse space utilization and planning. Another observed example is that the forklift driver wasted 22–24 min carrying the boxes from one of the warehouse locations, which led to the co-workers waiting 22–24 min because the box area is too far away from the pallets area. Fourth is the problem of “Lack of cohesiveness and planning”. This problem is because, in the case company, the VAS department has four permanent employees and the rest are temporary for three to four months. Every three to four months, the VAS department has new faces, new people, and they do not know each other; this was plainly visible as a problem. The permeant employees should conduct sufficient training for all incoming temporary employees to deal with the problem.

5. Conclusions

This study particularly focuses on a warehouse VAS operations improvement framework suitable for 3PL non-automated warehouses that leads managers through analysis of warehouse VAS activities benefiting from the Pareto principle. This framework will provide a method for prioritizing resource allocation in order to maximize returns and to achieve a higher degree of warehouse operations quality. Moreover, the VAS activities pricing system will improve by identifying and optimizing activities for the most critical VAS processes involved. The case study was conducted on a leading 3PL firm that provides a wide range of temperature-controlled logistics solutions. The methodology used in Pareto analysis consisted of six major steps, including identifying problems, identifying root causes of these problems, ranking and scoring problems, grouping problems together by root causes, adding up scores for each group of problems, and suggesting corrective actions. The data collected were qualitative by gathering the data via total participation and observation and quantitative by developing a timed list of VAS activities.

The analysis aimed to identify the problems in the value-added services (VAS) department of the case company and investigate the root causes of these problems. The first step of the Pareto analysis involved manual calculations to identify the problems and the second step utilized the root cause analysis (RCA) method to investigate the root causes. After observing and participating in VAS operations for three months, the researchers were able to develop a detailed process map and timing of all activities provided by the VAS department. The resulting template can be used as a reference for future work in the VAS department and enables easy utilization by management to accurately price products and services. This comprehensive analysis of VAS activities provides valuable insights and information for improving the efficiency and effectiveness of the VAS department in the case company.

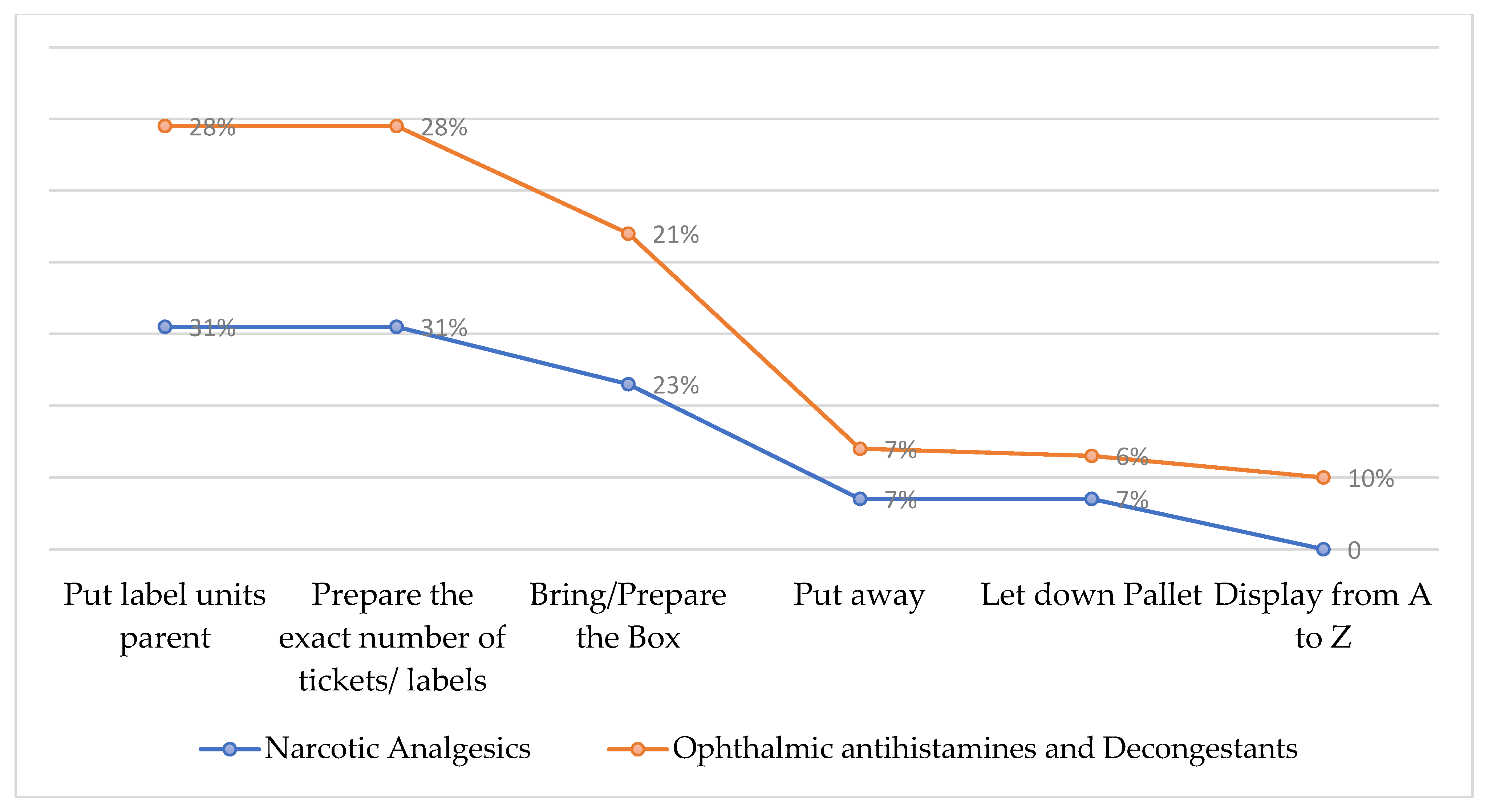

Two operational cases were discussed through the steps of Pareto analysis. The results showed that the Pareto principle is validated in the narcotic analgesics—ticketing case when five of twenty-four total activities are considered: put label units parent, prepare the exact number of tickets/labels, bring/prepare the box, put away, and let down pallet as they consume 83.3 percent of the total time of VAS operations. Moreover, the ophthalmic antihistamines and decongestants—display case has been confirmed based on six of the twenty-six total activities: prepare the exact number of tickets/labels, put label units parent bring/prepare the box, display from A to Z, put away, and let pallet down as they consume 81.26 percent of the total time of VAS operations. The study recommended solutions for each of the four causes of delay in VAS operations, including lack of training/best practices, inefficient space utilization, lack of automation, and lack of cohesiveness and planning.

The intersection of the cumulative curve and the last column is readily discernible from the graphical representation. To be deemed valid, the Pareto principle must demonstrate the dichotomy between the “vital few” and the “trivial many,” thereby illuminating the processes that have consumed most of the time within the overall value-added services (VAS) activities. In the case of narcotic analgesics—ticketing, the Pareto principle is validated as the first five of twenty-four activities account for 83.3% of the total time spent in VAS operations. These activities are put label units parent, prepare the exact number of tickets/labels, bring/prepare the box, put away, and let down pallet. In the case of ophthalmic antihistamines and decongestants—display, the first six of twenty-six activities account for 81.26% of the total time spent in VAS operations, and these activities are prepare the exact number of tickets/labels, put label units parent, bring/prepare the box, display from A to Z, let pallet down, and put away.

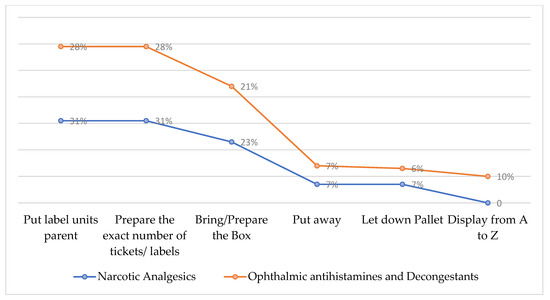

Figure 7 presents a comparison of the vital activity findings from Pareto analysis of both ophthalmic antihistamines/decongestants and narcotic analgesics. It is evident that the vital VAS activities are nearly identical for both products despite the differing types of services provided. One product, ophthalmic antihistamines, requires one additional activity, display, which is deemed a vital activity upon analysis.

Figure 7.

A comparison between vital VAS (20% of Pareto analysis) of ophthalmic antihistamines and decongestants and narcotic analgesics.

Ticketing and displaying services provided by the VAS department are the most prevalent services offered by the department. The findings from this analysis reflect the main processes that consume the majority of time and resources in the department, providing valuable insight into the key activities that could be improved for maximum impact. This conclusion was reached through implementation of this analysis on over 15 different products in the department.

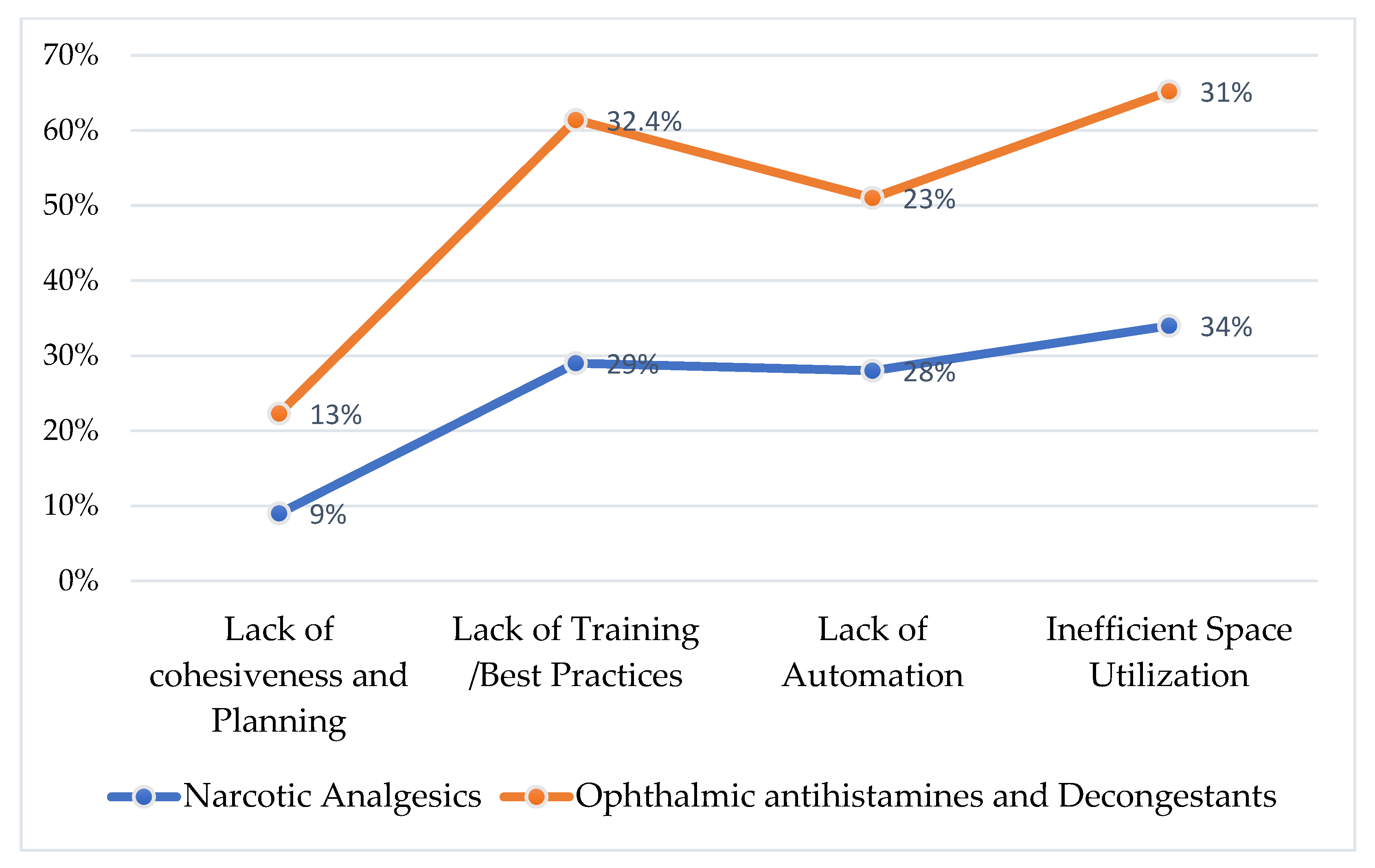

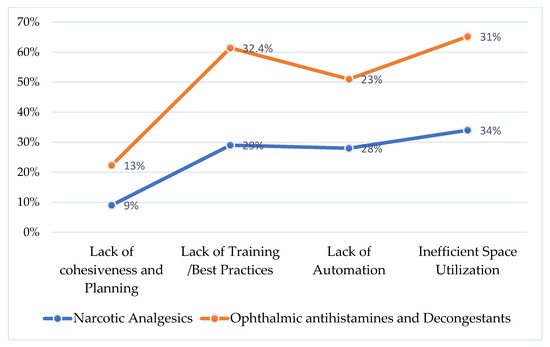

Comparison of classification of delay causes by cost percentage for ophthalmic antihistamines/decongestants and narcotic analgesics is depicted in Figure 8. The results revealed that inefficient space utilization and lack of training/best practices were the main sources of delay in the VAS operations, with the order of significance varying between the two products. To address these inefficiencies, the study proposed solutions with the objective of improving the overall performance of the VAS operations, thereby elevating the standard of service provided to clients.

Figure 8.

A comparison of the causes of delay in terms of the percentage of cost for ophthalmic antihistamines and decongestants and narcotic analgesics.

The observed disparity in performance and variation in task order can be attributed to the inherent demands of display training in our given example regarding OAD. The case company, with a significant proportion of temporary workers and limited presence of permanent staff, lacks comprehensive training and best practice protocol for each task. This resulted in a longer learning curve for new workers, leading to reduced overall productivity given the dominance of temporary labour in the workforce.

The results showed that the vital activities regarding the 20/80 rule for both products were nearly identical. The study also identified the main sources of delay in VAS operations, including inefficient space utilization and lack of training/best practices. To improve the overall performance of VAS operations, the study proposed solutions, such as automating the preparation process of the exact number of tickets, teaching best practices to all employees, and optimizing warehouse space utilization and routes. Implementation of these recommendations aims to address these inefficiencies and improve overall VAS operations performance, thus increasing the level of service provided to clients.

Moreover, the study identified all VAS activities for temperature-controlled pharmaceutical products and proposed a warehouse operations improvement framework for non-automated 3PL warehouses. The framework provides guidance to managers in conducting Pareto analysis to cut costs and improve service levels. This study contributes to the literature by filling the gap in addressing the lack of studies applied to practice and analysing 3PL service providers’ warehousing VAS operations data. The comprehensive template developed in the study can be used as a reference for future work within the VAS department of the case company and can be adjusted to accommodate different products and services.

Accordingly, the study provided 3PL companies with the following solutions for overcoming the identified problems based on Pareto analysis, including automating the exact number of tickets preparation process, teaching best practices to all co-workers, utilizing warehouse spaces and optimizing the routes that serve the VAS department, and dealing with a lack of cohesiveness and planning.

The study provides decision-makers with practical implications. Similar 3PL companies can adopt an appropriate approach to pricing operations in VAS departments. The Pareto methodology can be applied to improve organizational efficiency and enhance operational aspects within VAS departments in order to help them identify the most significant causes of a problem. The study provided practical solutions to the identified problems, which can help to improve decision-making inside 3PL companies, resulting in lower costs, higher profits, and meeting the needs of the targeted clients. Finally, the study identified all warehousing activities related to a 3PL service provider that deals with temperature-controlled pharmaceuticals products.

There are several limitations to the study. First, the study only focused on VAS activities related to temperature-controlled pharmaceutical products and did not cover all product types and their associated VAS operations. This limits the generalizability of the findings to other products and services. Second, the study did not include the effects of seasonal changes on VAS operations, which could result in different findings if considered. In the future, further studies could focus on investigating the impact of different product types on VAS operations and exploring the effect of seasonal changes on VAS activities. Another area of future work could be to validate application of Pareto analysis for VAS operations in different 3PL companies and industries. Additionally, studies could be conducted to explore the potential of integrating emerging technologies, such as artificial intelligence and machine learning, regarding improvements in VAS operations of 3PL companies. These future studies would provide valuable insights and information to support continued improvement in VAS operations of 3PL companies.

Author Contributions

Conceptualization, L.J. and M.E.B.; methodology, M.E.B.; software, M.E.B.; validation, L.J. and M.E.B.; formal analysis, M.E.B.; investigation, M.E.B.; resources, L.J. and M.E.B.; data curation, L.J. and M.E.B.; writing—original draft preparation, L.J. and M.E.B.; writing—review and editing, L.J.; visualization, M.E.B.; supervision, L.J.; project administration, L.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abideen, Ahmed, and Fazeeda Binti Mohamad. 2020. Improving the performance of a Malaysian pharmaceutical warehouse supply chain by integrating value stream mapping and discrete event simulation. Journal of Modelling in Management 16: 70–102. [Google Scholar] [CrossRef]

- Abushaikha, Ismail, Loay Salhieh, and Neil Towers. 2018. Improving distribution and business performance through lean warehousing. International Journal of Retail & Distribution Management 46: 780–800. [Google Scholar]

- Accorsi, Riccardo, Riccardo Manzini, and Fausto Maranesi. 2014. A decision-support system for the design and management of warehousing systems. Computers in Industry 65: 175–86. [Google Scholar] [CrossRef]

- Ahmed, Mohiuddin, and Nafis Ahmed. 2011. An application of Pareto analysis and cause-and-effect diagram (CED) for minimizing rejection of raw materials in lamp production process. Management Science and Engineering 5: 87–95. [Google Scholar]

- Alkalha, Ziad, Zu’bi B. M. Al-Zu’bi, and Luay Jum’a. 2022. Investigating the impact of servitization architecture and development on supply Chain design. Supply Chain Forum: An International Journal 23: 68–80. [Google Scholar] [CrossRef]

- Anderson, Edward J., Tim Coltman, Timothy M. Devinney, and Byron Keating. 2011. What drives the choice of a third-party logistics provider? Journal of Supply Chain Management 47: 97–115. [Google Scholar] [CrossRef]

- Baghizadeh, Komeyl, Nafiseh Ebadi, Dominik Zimon, and Luay Jum’a. 2022. Using Four Metaheuristic Algorithms to Reduce Supplier Disruption Risk in a Mathematical Inventory Model for Supplying Spare Parts. Mathematics 11: 42. [Google Scholar] [CrossRef]

- Barker, Jordan M., Andrew R. Gibson, Adriana R. Hofer, Christian Hofer, Issam Moussaoui, and Marc A. Scott. 2021. A competitive dynamics perspective on the diversification of third-party logistics providers’ service portfolios. Transportation Research Part E: Logistics and Transportation Review 146: 102219. [Google Scholar] [CrossRef]

- Baruffaldi, Gulia, Riccardo Accorsi, and Riccardo Manzini. 2019. Warehouse management system customization and information availability in 3pl companies: A decision-support tool. Industrial Management & Data Systems 119: 251–73. [Google Scholar]

- Baruffaldi, Gulia, Riccardo Accorsi, Riccardo Manzini, and E. Ferrari. 2020. Warehousing process performance improvement: A tailored framework for 3PL. Business Process Management Journal 26: 1619–41. [Google Scholar] [CrossRef]

- Berglund, Magnus, P. V. Laarhoven, G. Sharman, and S. Wandel. 1999. Third-party logistics: Is there a future? The International Journal of Logistics Management 10: 59–70. [Google Scholar] [CrossRef]

- Biadacz, Renata. 2020. Quality cost management in the SMEs of Poland. The TQM Journal 33: 1–38. [Google Scholar] [CrossRef]

- Bowersox, Donald J., David J. Closs, and O. K. Helferich. 1996. Logistical Management. New York: McGraw-Hill, vol. 6. [Google Scholar]

- Brooks, Chad. 2014. What is a pareto analysis? Business News Daily Senior 29: 1–5. [Google Scholar]

- Darko, Eric Owusu, and Ilias Vlachos. 2022. Creating Valuable Relationships with Third-Party Logistics (3PL) Providers: A Multiple-Case Study. Logistics 6: 38. [Google Scholar] [CrossRef]

- Davarzani, Hoda, and Andreas Normann. 2015. Toward a relevant agenda for warehousing research: Literature review and practitioners’ input. Logistics Research 8: 1–18. [Google Scholar] [CrossRef]

- De Jesus Pacheco, Diego Augusto, Daniel M. Clausen, and Jendrik Bumann. 2023. A multi-method approach for reducing operational wastes in distribution warehouses. International Journal of Production Economics 256: 108705. [Google Scholar] [CrossRef]

- Faber, Nynke, Rene B. M. De Koster, and Ale Smidts. 2013. Organizing warehouse management. International Journal of Operations & Production Management 33: 1230–56. [Google Scholar]

- Fannon, S. R., J. Eduardo Munive-Hernandez, and Felican Campean. 2021. Mastering continuous improvement (CI): The roles and competences of mid-level management and their impact on the organisation’s CI capability. The TQM Journal 34: 102–24. [Google Scholar] [CrossRef]

- Frankin, Sanne, and Karolina Johannesson. 2013. Analyzing Warehouse Operations in a 3PL Company. Master of Science thesis, Chalmers University of Technology, Gothenburg, Sweden. [Google Scholar]

- Gotzamani, Katerina, Pantelis Longinidis, and Fotis Vouzas. 2010. The logistics services outsourcing dilemma: Quality management and financial performance perspectives. Supply Chain Management: An International Journal 15: 438–53. [Google Scholar] [CrossRef]

- Hamdan, Amer, and K. Jamie Rogers. 2008. Evaluating the efficiency of 3PL logistics operations. International Journal of Production Economics 113: 235–44. [Google Scholar] [CrossRef]

- Herrera, Quintana Arcelly Ingrid, and Lisui Yang. 2017. Understanding Value-Added Service Offering by 3PL Providers: VAS as a Source of Competitive Advantage for the Provider and the Customer. Master thesis, Jönköping University, Småland, Sweden. [Google Scholar]

- Ivančić, Valentina. 2014. Improving the decision making process trought the Pareto principle application. Ekonomska misao i praksa 2: 633–56. [Google Scholar]

- Jager, Kerstin, Per Hilletofth, and Sandor Ujvari. 2009. From standard 3PL provider to service developer: A case study from the Swedish furniture industry. World Review of Intermodal Transportation Research 2: 376–90. [Google Scholar] [CrossRef]

- Juga, Jari, Jouni Juntunen, and Mikko Paananen. 2018. Impact of value-adding services on quality, loyalty and brand equity in the brewing industry. International Journal of Quality and Service Sciences 10: 61–71. [Google Scholar] [CrossRef]

- Jum’a, Luay, Muhammad Ikram, Ziad Alkalha, and Maher Alaraj. 2022. Do companies adopt big data as determinants of sustainability: Evidence from manufacturing companies in Jordan. Global Journal of Flexible Systems Management 23: 479–94. [Google Scholar] [CrossRef]

- Jum’a, Luay. 2020. The effect of value-added activities of key suppliers on the performance of manufacturing firms. Polish Journal of Management Studies 22: 231–46. [Google Scholar] [CrossRef]

- Karim, Nur Hazwani, Noorul Shaiful Fitri Abdul Rahman, Rudiah Md Hanafiah, Saharuddin Abdul Hamid, Alisa Ismail, A. S. Abd Kader, and Mohd Shaladdin Muda. 2021. Revising the warehouse productivity measurement indicators: Ratio-based benchmark. Maritime Business Review 6: 49–71. [Google Scholar] [CrossRef]

- Kolinski, Adam, and Boguslaw Sliwczynski. 2015. IT support of production efficiency analysis in ecological aspect. In Technology Management for Sustainable Production and Logistic. Berlin/Heidelberg: Springer, pp. 205–19. [Google Scholar]

- Kopecki, Tomasz, Jerzy Bakunowicz, and Tomasz Lis. 2016. Post-critical deformation states of composite thin-walled aircraft load-bearing structures. Journal of Theoretical and Applied Mechanics 54: 195–204. [Google Scholar] [CrossRef]

- Langley, C. J. 2013. Third-Party Logistics Study: The State of Logistics Outsourcing. Atlanta: Capgemini Consulting. [Google Scholar]

- Laosirihongthong, Tritos, Dotun Adebanjo, Premarante Samaranayake, Nachiappan Subramanian, and S. Boon-itt. 2018. Prioritizing warehouse performance measures in contemporary supply chains. International Journal of Productivity and Performance Management 67: 1703–26. [Google Scholar] [CrossRef]

- Manzini, Riccardo, Yavuz Bozer, and Sunderesh Heragu. 2015. Decision models for the design, optimization and management of warehousing and material handling systems. International Journal of Production Economics 170: 711–16. [Google Scholar] [CrossRef]

- Martin, Heinrich. 2018. Warehousing and Transportation Logistics: Systems, Planning, Application and Cost Effectiveness. London: Kogan Page Publishers. [Google Scholar]

- Mou, Jin-Jin, and Ying-Mei Jiang. 2021. Value-added Service of Distribution Center on Integrated Cold Chain Performance. In E3S Web of Conferences. Les Ulis: EDP Sciences, vol. 261, p. 03042. [Google Scholar]

- Moussa, Fatima Zahra Ben, Ronald De Guio, Sebastien Dubois, Ivana Rasovska, and Rachid Benmoussa. 2019. Study of an innovative method based on complementarity between ARIZ, lean management and discrete event simulation for solving warehousing problems. Computers & Industrial Engineering 132: 124–40. [Google Scholar]

- Olya, Hossein, Levent Altinay, and Glauco De Vita. 2018. An exploratory study of value added services. Journal of Services Marketing 32: 334–45. [Google Scholar] [CrossRef]

- Pandey, Priyanka, Nishant Agrawal, Teena Saharan, and R. D. Raut. 2021. Impact of human resource management practices on TQM: An ISM-DEMATEL approach. The TQM Journal 34: 199–228. [Google Scholar] [CrossRef]

- Pereira, Caroline Morito, Rosley Anholon, Izabela Simon Rampasso, Osvaldo L.G. Quelhas, Walter Leal Filho, and Luis Antonio Santa-Eulalia. 2020. Evaluation of lean practices in warehouses: An analysis of Brazilian reality. International Journal of Productivity and Performance Management 70: 1–20. [Google Scholar] [CrossRef]

- Raghuram, P., and Mahesh Kuman Arjunan. 2022. Design framework for a lean warehouse–a case study-based approach. International Journal of Productivity and Performance Management 71: 2410–31. [Google Scholar] [CrossRef]

- Richards, Gwynne. 2017. Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse. London: Kogan Page Publishers. [Google Scholar]

- Rivera, Liliana, Yossi Sheffi, and Desiree Knoppen. 2016. Logistics clusters: The impact of further agglomeration, training and firm size on collaboration and value added services. International Journal of Production Economics 179: 285–94. [Google Scholar] [CrossRef]

- Ruiz-Pérez, Fernando, Álvaro Lleó, Elisabeth Viles, and Daniel Jurburg. 2020. Enhancing participation through organizational drivers. The TQM Journal 33: 823–40. [Google Scholar] [CrossRef]

- Sangka, Bayu Khresana, Shams Rahman, Aswini Yadlapalli, and Ferry Jie. 2019. Managerial competencies of 3PL providers. The International Journal of Logistics Management 30: 1054–77. [Google Scholar] [CrossRef]

- Shi, Yangyan, Abraham Zhang, Tiru Arthanari, Yanping Liu, and T. C. E. Cheng. 2016. Third-party purchase: An empirical study of third-party logistics providers in China. International Journal of Production Economics 171: 189–200. [Google Scholar] [CrossRef]

- Shi, Ye, Xiaolong Guo, and Yugang Yu. 2018. Dynamic warehouse size planning with demand forecast and contract flexibility. International Journal of Production Research 56: 1313–25. [Google Scholar] [CrossRef]

- Soinio, Juho, Kari Tanskanen, and Max Finne. 2012. How logistics-service providers can develop value-added services for SMEs: A dyadic perspective. The International Journal of Logistics Management 23: 31–49. [Google Scholar] [CrossRef]

- Statista. 2021. Size of the Value-Added Warehousing and Distribution (VAWD) Market in the United States from 2010 to 2020. Available online: https://www.statista.com/statistics/957494/value-added-warehousing-distribution-market-size-united-states/ (accessed on 1 December 2021).

- Sugathadasa, R., Deshan Wakkumbura, H. Niles Perera, and Amila Thibbotuwawa. 2021. Analysis of risk factors for temperature-controlled warehouses. Operations and Supply Chain Management: An International Journal 14: 320–37. [Google Scholar] [CrossRef]

- Tubis, Agnieszka A., Jacek Ryczyński, and Arkadiusz Żurek. 2021. Risk assessment for the use of drones in warehouse operations in the first phase of introducing the service to the market. Sensors 21: 6713. [Google Scholar] [CrossRef] [PubMed]

- Wang, Shuyn. 2018. Developing value added service of cold chain logistics between China and Korea. Journal of Korea Trade 22: 247–64. [Google Scholar] [CrossRef]

- Zhang, Xumei, Xiaopeng Han, Xiangyu Liu, Ru Liu, and Jinzhong Leng. 2015. The pricing of product and value-added service under information asymmetry: A product life cycle perspective. International Journal of Production Research 53: 25–40. [Google Scholar] [CrossRef]

- Zimon, Dominik. 2017. The impact of TQM philosophy for the improvement of logistics processes in the supply chain. International Journal for Quality Research 11: 3–16. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).