The Effect of Sustainability on New Product Development in Manufacturing—Internal and External Practices

Abstract

:1. Introduction

2. Theoretical Framework

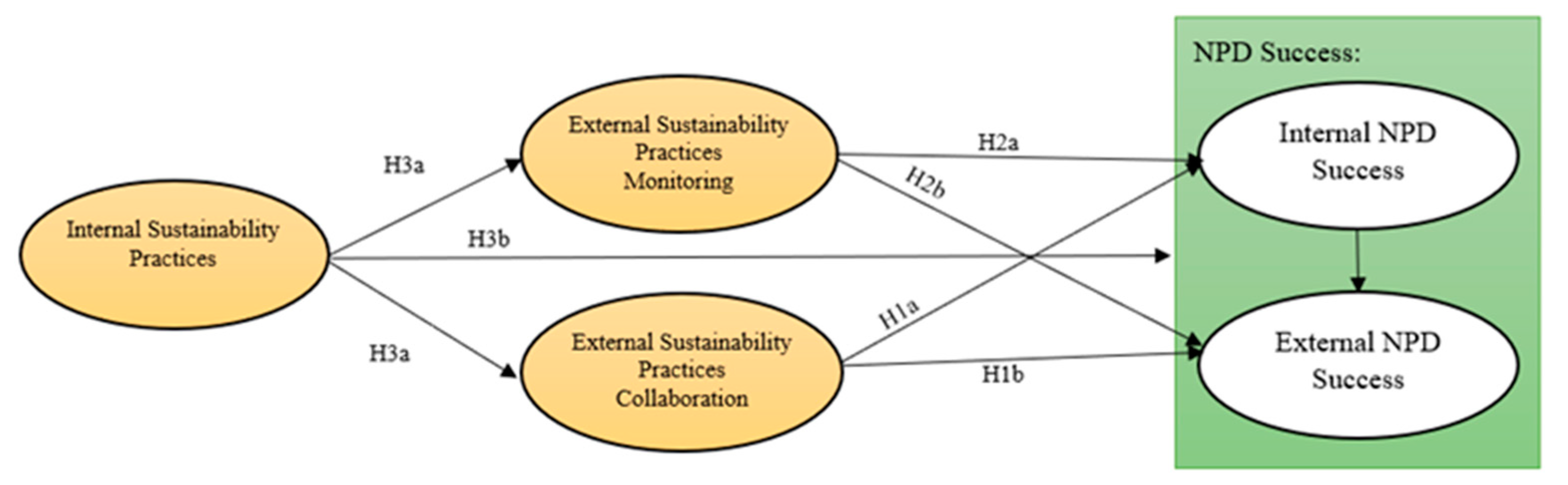

3. Hypothesis Development

3.1. External Sustainability Practices (Collaboration) and NPD Success

3.2. External Sustainability Practices (Monitoring) and NPD Success

3.3. Internal Sustainability Practices and NPD Success

4. Methodology

4.1. Sample and Data Collection

4.2. Measures

- In line with the concept behind NRBV, the Internal Sustainability Practices (ISP) of this study refers to a firm´s evaluation of the efficiency of its own processes, not only through prevention and controlling practices but also environmental improvement through the reduction of environmental accidents and disposal of excess materials or equipment (Montabon et al. 2007).

- External Collaborative Sustainability Practices (ESPc) include interorganisational collaborative practices between focal firms and their suppliers (Danese et al. 2019).

- External Monitoring Sustainability Practices (ESPm) refer to sustainability-related supplier assessment practices imposed by focal firms (Danese et al. 2019).

- The external success of the NPD (ENPD) construct refers to the external (or market) dimension of NPD success (García et al. 2008) that includes customer satisfaction and overall commercial success items.

- The internal success of the NPD (INPD) construct refers to the internal (or operational) dimension of NPD success (García et al. 2008) that includes time to market, ease of manufacturing, and unit manufacturing cost items.

- The industry to which the sample plant belongs labelled as Industry. The industry control variables were created by coding dummy variables for each sector. Due to dispersion of sectors amongst firms, the mechanical sector with the highest homogeneous industry group (110 firms, 40% of the sample) was chosen to use as reference for control of the analysis (Kähkönen et al. 2017).

- The level of development of the country in which the sample manufacturing firm is located is labelled as Developed.

- Due to the distribution of the number of employees as indicator of firm size being right skewed, the logarithm transformation was used to improve the normal distribution of the size.

- The percentage of plant sales from products introduced in the last five years is labelled as R&D_Intensity.

- The number of employees working in R&D for new product design/redesign development practices is labelled as R&D_Size.

4.3. Data Analysis and Results

4.4. Measurement Assessment

4.5. Structural Model Evaluation

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Variables | Items | Description | Mean | Std. Dev. | Mean Ave. |

| ISP | 3.924 | ||||

| S-Int01 | Water efficiency | 3.651 | 0.901 | ||

| S-Int02 | Reducing waste in internal processes (e.g., improving yield or efficiency) | 3.990 | 0.730 | ||

| S-Int03 | Improving the workforce environment (e.g., indoor air quality) | 4.033 | 0.733 | ||

| S-Int04 | Pollution prevention (eliminating emissions or waste) | 4.044 | 0.773 | ||

| S-Int05 | Pollution control (scrubbing, waste treatment) | 4.113 | 0.917 | ||

| S-Int06 | Decreasing the likelihood or impact of an environmental accident | 3.904 | 0.811 | ||

| S-Int07 | Complying with an industry-wide code of conduct | 3.901 | 0.890 | ||

| S-Int08 | Environmental improvements in the disposition of your organization’s scrap or excess material (re-use, recycling, etc.) | 4.025 | 0.757 | ||

| S-Int09 | Environmental improvements in the disposition of your organization’s equipment | 3.657 | 0.863 | ||

| ESPc | 3.102 | ||||

| S-ExtC01 | Encouraging suppliers to improve the environmental performance of their processes | 3.179 | 1.035 | ||

| S-ExtC02 | Providing design specification to suppliers in line with environmental requirements (e.g., green purchasing, blacklist of raw materials) | 3.273 | 1.117 | ||

| S-ExtC03 | Co-development with suppliers to reduce the environmental impact of the product (e.g., eco-design, green packaging, recyclability) | 3.064 | 0.982 | ||

| S-ExtC04 | Involvement of suppliers in the re-design of internal processes (e.g., remanufacturing, reduction of by-products) | 2.893 | 1.000 | ||

| ESPm | 3.144 | ||||

| S-ExtM01 | Requesting that your suppliers sign a code of environmental conduct | 2.984 | 1.258 | ||

| S-ExtM02 | Visiting suppliers’ plants or ensuring that they are not using sweatshop labour | 3.016 | 1.122 | ||

| S-ExtM03 | Ensuring that suppliers comply with child labour laws | 3.256 | 1.352 | ||

| S-ExtM04 | Incorporating environmental considerations in evaluating and selecting suppliers | 3.321 | 0.989 | ||

| ENPD | 3.715 | ||||

| NPDS_Ext01 | Customer satisfaction | 3.780 | 0.699 | ||

| NPDS_Ext02 | Overall commercial success | 3.650 | 0.723 | ||

| INPD | 3.262 | ||||

| NPDS_Int01 | Time to market | 3.224 | 0.850 | ||

| NPDS_Int02 | Ease of manufacturing | 3.388 | 0.755 | ||

| NPDS_Int03 | Unit manufacturing cost | 3.175 | 0.803 |

| 1 | The association only considers the individual effect of sustainability practices on NPD success. There are many other factors affecting NPD success, the effects of which have not been included in the model. These include lean practices (e.g., Oliveira et al. 2018); employee involvement (e.g., Rangus and Slavec 2017); employees´ collective motivation (e.g., Zhao and Chadwick 2014), and early supplier integration (e.g., Goldberg and Schiele 2018). |

References

- Adams, Richard, Sally Jeanrenaud, John Bessant, David Denyer, and Patrick Overy. 2016. Sustainability-oriented Innovation: A Systematic Review. International Journal of Management Reviews 18: 180–205. [Google Scholar] [CrossRef]

- Ageron, Blandine, Angappa Gunasekaran, and Alain Spalanzani. 2012. Sustainable supply management: An empirical study. International Journal of Production Economics 140: 168–82. [Google Scholar] [CrossRef]

- Ahmad, Shamraiz, Kuan Yew Wong, Ming Lang Tseng, and Wai Peng Wong. 2018. Sustainable product design and development: A review of tools, applications and research prospects. Resources, Conservation and Recycling 132: 49–61. [Google Scholar] [CrossRef]

- Andreev, Pavel, Hanan Maoz, Tsipi Heart, and Nava Pliskin. 2009. Validating formative partial least squares (PLS) models: Methodological review and empirical illustration. Paper presented at the ICIS 2009 Proceedings—Thirtieth International Conference on Information Systems, Phoenix, AZ, USA, December 15–18. [Google Scholar]

- Brulhart, Franck, Sandrine Gherra, and Magalie Marais. 2017. Are environmental strategies profitable for companies? The key role of natural competences from a resource-based view. Management Decision 55: 2126–48. [Google Scholar] [CrossRef]

- Busse, Christian, Martin C. Schleper, Menglei Niu, and Stephan M. Wagner. 2016. Supplier development for sustainability: Contextual barriers in global supply chains. International Journal of Physical Distribution and Logistics Management 46: 442–68. [Google Scholar] [CrossRef]

- Buysse, Kristel, and Alain Verbeke. 2003. Proactive environmental strategies: A stakeholder management perspective. Strategic Management Journal 24: 453–70. [Google Scholar] [CrossRef]

- Carey, Sinéad, Benn Lawson, and Daniel R. Krause. 2011. Social capital configuration, legal bonds and performance in buyer-supplier relationships. Journal of Operations Management 29: 277–88. [Google Scholar] [CrossRef] [Green Version]

- Chen, Yinfei, and Injazz J. Chen. 2019. Mixed sustainability motives, mixed results: The role of compliance and commitment in sustainable supply chain practices. Supply Chain Management 24: 622–36. [Google Scholar] [CrossRef]

- Cheng, Colin C. J. 2020. Sustainability Orientation, Green Supplier Involvement, and Green Innovation Performance: Evidence from Diversifying Green Entrants. Journal of Business Ethics 161: 393–414. [Google Scholar] [CrossRef]

- Chiarini, Andrea. 2012. Lean Organization: From the Tools of the Toyota Production System to Lean Office. Berlin and Heidelberg: Springer Science & Business Media, vol. 3. [Google Scholar]

- Claudy, Marius C., Mark Peterson, and Mark Pagell. 2016. The Roles of Sustainability Orientation and Market Knowledge Competence in New Product Development Success. Journal of Product Innovation Management 33: 72–85. [Google Scholar] [CrossRef]

- Cohen, Jacob. 1988. Statistical Power Analysis for the Behavioral Sciences. Abingdon, UK: Routledge. [Google Scholar]

- Cousins, Paul D., and Benn Lawson. 2007. The effect of socialization mechanisms and performance measurement on supplier integration in new product development. British Journal of Management 18: 311–26. [Google Scholar] [CrossRef]

- Croom, Simon, Vidal Natalia, Spetic Wellington, Marshall Donna, and McCarthy Lucy. 2018. Impact of social sustainability orientation and supply chain practices on operational performance. International Journal of Operations and Production Management 38: 2344–66. [Google Scholar] [CrossRef] [Green Version]

- Danese, Pamela, Andrea Lion, and Andrea Vinelli. 2019. Drivers and enablers of supplier sustainability practices: A survey-based analysis. International Journal of Production Research 57: 2034–56. [Google Scholar] [CrossRef]

- De Stefano, M. Cristina, and María J. Montes-Sancho. 2018. Supply chain environmental R&D cooperation and product performance: Exploring the network dynamics of positional embeddedness. Journal of Purchasing and Supply Management 24: 288–303. [Google Scholar] [CrossRef]

- Du, Shuili, Goksel Yalcinkaya, and Ludwig Bstieler. 2016. Sustainability, Social Media Driven Open Innovation, and New Product Development Performance*. Journal of Product Innovation Management 33: 55–71. [Google Scholar] [CrossRef]

- Elkington, John. 1998. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environmental Quality Management 8: 37–51. [Google Scholar] [CrossRef]

- Fish, Lynn A. 2015. Managerial Best Practices to Promote Sustainable Supply Chain Management & New Product Development. Vienna: InTech. [Google Scholar]

- García, Nuria, M. José Sanzo, and Juan A. Trespalacios. 2008. New product internal performance and market performance: Evidence from Spanish firms regarding the role of trust, interfunctional integration, and innovation type. Technovation 28: 713–25. [Google Scholar] [CrossRef]

- Geng, Ruoqi, S. Afshin Mansouri, and Emel Aktas. 2017. The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies. International Journal of Production Economics 183: 245–58. [Google Scholar] [CrossRef] [Green Version]

- Gerstlberger, Wolfgang, Mette Præst Knudsen, and Ian Stampe. 2014. Sustainable development strategies for product innovation and energy efficiency. Business Strategy and the Environment 23: 131–44. [Google Scholar] [CrossRef]

- Gimenez, Cristina, and Elcio M. Tachizawa. 2012. Extending sustainability to suppliers: A systematic literature review. Supply Chain Management 17: 531–43. [Google Scholar] [CrossRef]

- Gimenez, Cristina, and Vicenta Sierra. 2013. Sustainable Supply Chains: Governance Mechanisms to Greening Suppliers. Journal of Business Ethics 116: 189–203. [Google Scholar] [CrossRef]

- Gmelin, Harald, and Stefan Seuring. 2014. Determinants of a sustainable new product development. Journal of Cleaner Production 69: 1–9. [Google Scholar] [CrossRef]

- Gmelin, Harald, and Stefan Seuring. 2018a. Social and Environmental Dimensions of Organizations and Supply Chains. Cham: Springer International Publishing. [Google Scholar] [CrossRef]

- Gmelin, Harald, and Stefan Seuring. 2018b. Sustainability and New Product Development: Five Exploratory Case Studies in the Automotive Industry. In Social and Environmental Dimensions of Organizations and Supply Chains. Cham: Springer, pp. 211–32. [Google Scholar]

- Goldberg, Janina, and Holger Schiele. 2018. Early Supplier Integration: Assessing Supplier Innovation Ideas. IEEE Engineering Management Review 46: 94–102. [Google Scholar] [CrossRef]

- González-Benito, Javier, and Óscar González-Benito. 2006. A review of determinant factors of environmental proactivity. Business Strategy and the Environment 15: 87–102. [Google Scholar] [CrossRef]

- Gualandris, Jury, Robert D. Klassen, Stephan Vachon, and Matteo Kalchschmidt. 2015. Sustainable evaluation and verification in supply chains: Aligning and leveraging accountability to stakeholders. Journal of Operations Management 38: 1–13. [Google Scholar] [CrossRef] [Green Version]

- Hair, Joseph F., Jr., G. Tomas M. Hult, Christian Ringle, and Marko Sarstedt. 2016. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM). Thousand Oaks: Sage publications. [Google Scholar]

- Hallstedt, Sophie I., Anthony W. Thompson, and Pia Lindahl. 2013. Key elements for implementing a strategic sustainability perspective in the product innovation process. Journal of Cleaner Production 51: 277–88. [Google Scholar] [CrossRef]

- Hart, Stuart L. 1995. A natural-resource-based view of the firm. Academy of Management Review 20: 986–1014. [Google Scholar] [CrossRef] [Green Version]

- Hemonnet-Goujot, Aurélie, Delphine Manceau, and Céline Abecassis-Moedas. 2019. Drivers and Pathways of NPD Success in the Marketing–External Design Relationship. Journal of Product Innovation Management 36: 196–223. [Google Scholar] [CrossRef]

- Henseler, Jörg, Christian M. Ringle, and Marko Sarstedt. 2014. A new criterion for assessing discriminant validity in variance-based structural equation modeling. Journal of the Academy of Marketing Science 43: 115–35. [Google Scholar] [CrossRef] [Green Version]

- Jabbour, Charbel Jose Chiappetta, Daniel Jugend, Ana Beatriz Lopes De Sousa Jabbour, Angappa Gunasekaran, and Hengky Latan. 2015. Green product development and performance of Brazilian firms: Measuring the role of human and technical aspects. Journal of Cleaner Production 87: 442–51. [Google Scholar] [CrossRef]

- Jansson, Johan, Jonas Nilsson, Frida Modig, and Gabriella Hed Vall. 2017. Commitment to Sustainability in Small and Medium-Sized Enterprises: The Influence of Strategic Orientations and Management Values. Business Strategy and the Environment 26: 69–83. [Google Scholar] [CrossRef]

- Jin, Zhongqi, Jyoti Navare, and Richard Lynch. 2019. The relationship between innovation culture and innovation outcomes: Exploring the effects of sustainability orientation and firm size. R and D Management 49: 607–23. [Google Scholar] [CrossRef]

- Kähkönen, Anni Kaisa, Katrina Lintukangas, Paavo Ritala, and Jukka Hallikas. 2017. Supplier collaboration practices: Implications for focal firm innovation performance. European Business Review 29: 402–18. [Google Scholar] [CrossRef]

- Karaman Kabadurmus, Fatma Nur. 2020. Antecedents to supply chain innovation. International Journal of Logistics Management 31: 145–71. [Google Scholar] [CrossRef]

- Laari, Sini, Juuso Töyli, Tomi Solakivi, and Lauri Ojala. 2016. Firm performance and customer-driven green supply chain management. Journal of Cleaner Production 112: 1960–70. [Google Scholar] [CrossRef]

- Lawson, Benn, Daniel Krause, and Antony Potter. 2015. Improving Supplier New Product Development Performance: The Role of Supplier Development. Journal of Product Innovation Management 32: 777–92. [Google Scholar] [CrossRef]

- Lee, Ki Hoon, and Ji Whan Kim. 2011. Integrating suppliers into green product innovation development: An empirical case study in the semiconductor industry. Business Strategy and the Environment 20: 527–38. [Google Scholar] [CrossRef]

- Lee, Su-Yol. 2015. The effects of green supply chain management on the supplier’s performance through social capital accumulation. Supply Chain Management 20: 42–55. [Google Scholar] [CrossRef]

- Lintukangas, Katrina, Anni Kaisa Kähkönen, and Jukka Hallikas. 2019. The role of supply management innovativeness and supplier orientation in firms’ sustainability performance. Journal of Purchasing and Supply Management 25: 100558. [Google Scholar] [CrossRef]

- Marshall, Donna, Lucy McCarthy, Ciarán Heavey, and Paul McGrath. 2015. Environmental and social supply chain management sustainability practices: Construct development and measurement. Production Planning and Control 26: 673–90. [Google Scholar] [CrossRef]

- Mazzola, Erica, Manfredi Bruccoleri, and Giovanni Perrone. 2015. Supply chain of innovation and new product development. Journal of Purchasing and Supply Management 21: 273–84. [Google Scholar] [CrossRef] [Green Version]

- Moldavska, Anastasiia, and Torgeir Welo. 2017. The concept of sustainable manufacturing and its definitions: A content-analysis based literature review. Journal of Cleaner Production 166: 744–55. [Google Scholar] [CrossRef]

- Montabon, Frank, Robert Sroufe, and Ram Narasimhan. 2007. An examination of corporate reporting, environmental management practices and firm performance. Journal of Operations Management 25: 998–1014. [Google Scholar] [CrossRef]

- Nepal, Bimal P., Om Prakash Yadav, and Rajesh Solanki. 2011. Improving the npd process by applying lean principles: A case study. EMJ-Engineering Management Journal 23: 65–81. [Google Scholar] [CrossRef]

- Neutzling, Daiane Mülling, Anna Land, Stefan Seuring, and Luis Felipe Machado do Nascimento. 2018. Linking sustainability-oriented innovation to supply chain relationship integration. Journal of Cleaner Production 172: 3448–58. [Google Scholar] [CrossRef]

- Nidumolu, Ram, Coimbatore K. Prahalad, and Madhavan R. Rangaswami. 2009. Why sustainability is now the key driver of innovation. Harvard Business Review 87: 56–64. [Google Scholar]

- Obal, Michael, Todd Morgan, and George Joseph. 2020. Integrating sustainability into new product development: The role of organizational leadership and culture. Journal of Small Business Strategy 30: 43–57. [Google Scholar]

- Oliveira, Gilson Adamczuk, Kim Hua Tan, and Bruno Turmina Guedes. 2018. Lean and green approach: An evaluation tool for new product development focused on small and medium enterprises. International Journal of Production Economics 205: 62–73. [Google Scholar] [CrossRef]

- Pagell, Mark, and Zhaohui Wu. 2009. Building a more complete theory of sustainable supply chain management using case studies of 10 exemplars. Journal of Supply Chain Management 45: 37–56. [Google Scholar] [CrossRef]

- Paulraj, Antony, Injazz J. Chen, and Constantin Blome. 2017. Motives and Performance Outcomes of Sustainable Supply Chain Management Practices: A Multi-theoretical Perspective. Journal of Business Ethics 145: 239–58. [Google Scholar] [CrossRef]

- Peng, David Xiaosong, and Fujun Lai. 2012. Using partial least squares in operations management research: A practical guideline and summary of past research. Journal of Operations Management 30: 467–80. [Google Scholar] [CrossRef]

- Petersen, Kenneth J., Robert B. Handfield, and Gary L. Ragatz. 2003. A model of supplier integration into new product development. Journal of Product Innovation Management 20: 284–99. [Google Scholar] [CrossRef]

- Podsakoff, Philip M., Scott B. MacKenzie, Jeong-Yeon Lee, and Nathan P. Podsakoff. 2003. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. Journal of Applied Psychology 88: 879–903. [Google Scholar] [CrossRef] [PubMed]

- Pujari, Devashish. 2006. Eco-innovation and new product development: Understanding the influences on market performance. Technovation 26: 76–85. [Google Scholar] [CrossRef]

- Putnam, Robert D. 1995. Tuning in, tuning out: The strange disappearance of social capital in America. PS: Political Science & Politics 28: 664–83. [Google Scholar]

- Rangus, Kaja, and Alenka Slavec. 2017. The interplay of decentralization, employee involvement and absorptive capacity on firms’ innovation and business performance. Technological Forecasting and Social Change 120: 195–203. [Google Scholar] [CrossRef]

- Rossi, Marta, Michele Germani, and Alessandra Zamagni. 2016. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. Journal of Cleaner Production 129: 361–73. [Google Scholar] [CrossRef]

- Sancha, Cristina, Christina W. Y. Wong, and Cristina Gimenez. 2019. Do dependent suppliers benefit from buying firms’ sustainability practices? Journal of Purchasing and Supply Management 25: 100542. [Google Scholar] [CrossRef]

- Shi, Victor Guang, S. C. Lenny Koh, James Baldwin, and Federica Cucchiella. 2012. Natural resource based green supply chain management. Supply Chain Management 17: 54–67. [Google Scholar] [CrossRef]

- Shmueli, Galit, Marko Sarstedt, Joseph F. Hair, Jun-Hwa Cheah, Hiram Ting, Santha Vaithilingam, and Christian M. Ringle. 2019. Predictive model assessment in PLS-SEM: Guidelines for using PLSpredict. European Journal of Marketing 53: 2322–47. [Google Scholar] [CrossRef]

- Tuli, Prashant, and Ravi Shankar. 2015. Collaborative and lean new product development approach: A case study in the automotive product design. International Journal of Production Research 53: 2457–71. [Google Scholar] [CrossRef]

- Wang, Jing, and Jun Dai. 2018. Sustainable supply chain management practices and performance. Industrial Management and Data Systems 118: 2–21. [Google Scholar] [CrossRef]

- Wang, Yuan, Sachin B. Modi, and Tobias Schoenherr. 2021. Leveraging sustainable design practices through supplier involvement in new product development: The role of the suppliers’ environmental management capability. International Journal of Production Economics 232: 107919. [Google Scholar] [CrossRef]

- Wlazlak, Paraskeva, Kristina Säfsten, Per Hilletofth, and Glenn Johansson. 2018. Integration of Suppliers’ Workflows in the OEMs’ New Product Development Process. Procedia Manufacturing 25: 479–86. [Google Scholar] [CrossRef]

- Wong, Chee Yew, Christina W. Y. Wong, and Sakun Boon-itt. 2020. Effects of green supply chain integration and green innovation on environmental and cost performance. International Journal of Production Research 58: 4589–609. [Google Scholar] [CrossRef]

- Woo, Chungwon, Moon Gyu Kim, Yanghon Chung, and Jae Jeung Rho. 2016. Suppliers’ communication capability and external green integration for green and financial performance in Korean construction industry. Journal of Cleaner Production 112: 483–93. [Google Scholar] [CrossRef]

- Wu, Guo-Ciang, Jyh-Hong Ding, and Ping-Shun Chen. 2012. The effects of GSCM drivers and institutional pressures on GSCM practices in Taiwan’s textile and apparel industry. International Journal of Production Economics 135: 618–36. [Google Scholar] [CrossRef]

- Zhang, Junfeng, and Wei-ping Wu. 2013. Social capital and new product development outcomes: The mediating role of sensing capability in Chinese high-tech firms. Journal of World Business 48: 539–48. [Google Scholar] [CrossRef]

- Zhao, Zheng Jane, and Clint Chadwick. 2014. What we will do versus what we can do: The relative effects of unit-level NPD motivation and capability. Strategic Management Journal 35: 1867–80. [Google Scholar] [CrossRef]

| Country | Industry | Total | ||

|---|---|---|---|---|

| Electronics | Mechanical | Transportation Equipment | ||

| China | 8 | 15 | 3 | 26 |

| Germany | 5 | 11 | 8 | 24 |

| Sweden | 1 | 4 | 0 | 5 |

| Switzerland | 2 | 0 | 1 | 3 |

| Japan | 6 | 6 | 9 | 21 |

| Korea | 8 | 5 | 12 | 25 |

| Spain | 7 | 6 | 8 | 21 |

| Italy | 7 | 17 | 5 | 29 |

| Israel | 13 | 2 | 0 | 15 |

| Brazil | 2 | 7 | 6 | 15 |

| Finland | 6 | 6 | 5 | 17 |

| Taiwan | 19 | 10 | 1 | 30 |

| UK | 4 | 5 | 4 | 13 |

| Vietnam | 8 | 7 | 6 | 21 |

| USA | 3 | 3 | 2 | 8 |

| Austria | 1 | 6 | 1 | 8 |

| Constructs | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. ISP | 0.730 | |||||||||

| 2. ESPc | 0.645 | 0.843 | ||||||||

| 3. ESPm | 0.626 | 0.753 | 0.784 | |||||||

| 4. ENPD | 0.149 | 0.236 | 0.220 | − | ||||||

| 5. INPD | 0.193 | 0.296 | 0.287 | 0.643 | − | |||||

| 6. R&D_Size | 0.164 | 0.171 | 0.074 | 0.027 | −0.061 | − | ||||

| 7. R&D_Intensity | 0.048 | 0.064 | 0.054 | 0.093 | 0.156 | −0.028 | − | |||

| 8. Firm_Size | 0.325 | 0.237 | 0.209 | 0.000 | −0.029 | 0.506 | 0.059 | – | ||

| 9. Industry | −0.001 | −0.057 | −0.054 | 0.069 | −0.022 | −0.096 | −0.083 | −0.059 | – | |

| 10. Development | −0.128 | −0.245 | −0.238 | −0.133 | −0.197 | 0.032 | −0.180 | −0.160 | −0.046 | – |

| Mean | 3.924 | 3.102 | 3.144 | 3.715 | 3.262 | 80.620 | 52.384 | 6.033 | 0.391 | 0.673 |

| Std. Dev. | 0.597 | 0.874 | 0.957 | 0.624 | 0.636 | 195.534 | 27.685 | 1.056 | 0.488 | 0.469 |

| Constructs | Indicators | Mean | Std. Dev. | Item Loading | Item Weight | T-Stat. | p-Value | Alpha Cronbach | Composite Reliability | Communality (AVE) | VIF |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ISP | 0.890 | 0.911 | 0.533 | ||||||||

| S-Int01 | 3.651 | 0.901 | 0.683 | 18.523 | |||||||

| S-Int02 | 3.990 | 0.730 | 0.739 | 24.046 | |||||||

| S-Int03 | 4.033 | 0.733 | 0.718 | 22.066 | |||||||

| S-Int04 | 4.044 | 0.773 | 0.785 | 28.219 | |||||||

| S-Int05 | 4.113 | 0.917 | 0.663 | 16.181 | |||||||

| S-Int06 | 3.904 | 0.811 | 0.781 | 29.596 | |||||||

| S-Int07 | 3.901 | 0.890 | 0.739 | 22.369 | |||||||

| S-Int08 | 4.025 | 0.757 | 0.712 | 18.238 | |||||||

| S-Int09 | 3.657 | 0.863 | 0.740 | 23.945 | |||||||

| ESPc | 0.864 | 0.907 | 0.710 | ||||||||

| S-ExtC01 | 3.179 | 1.035 | 0.869 | 55.139 | |||||||

| S-ExtC02 | 3.273 | 1.117 | 0.784 | 28.214 | |||||||

| S-ExtC03 | 3.064 | 0.982 | 0.851 | 32.735 | |||||||

| S-ExtC04 | 2.893 | 1.000 | 0.864 | 45.701 | |||||||

| ESPm | 0.792 | 0.864 | 0.614 | ||||||||

| S-ExtM01 | 2.984 | 1.258 | 0.771 | 25.821 | |||||||

| S-ExtM02 | 3.016 | 1.122 | 0.800 | 28.562 | |||||||

| S-ExtM03 | 3.256 | 1.352 | 0.774 | 24.442 | |||||||

| S-ExtM04 | 3.321 | 0.989 | 0.790 | 29.114 | |||||||

| ENPD | |||||||||||

| NPDS_Ext01 | 3.780 | 0.699 | 0.289 | 10.259 | 0.000 | 1.398 | |||||

| NPDS_Ext02 | 3.650 | 0.723 | 0.816 | 42.561 | 0.000 | 1.398 | |||||

| INPD | |||||||||||

| NPDS_Int01 | 3.224 | 0.850 | 0.516 | 14.302 | 0.000 | 1.257 | |||||

| NPDS_Int02 | 3.388 | 0.755 | 0.412 | 17.289 | 0.000 | 1.548 | |||||

| NPDS_Int03 | 3.175 | 0.803 | 0.345 | 9.717 | 0.000 | 1.381 |

| Path | Hypotheses | Path Coefficients (Direct Effect) | F2 | p-Values | Confidence Interval (2.5%, 95.5%) | Path Coefficients (Indirect Effect) | Total Effect |

|---|---|---|---|---|---|---|---|

| 1.ESPc -> INPD | H1 | 0.198 ** | 0.017 | 0.034 | (0.011, 0.377) | 0.198 ** (p = 0.034) | |

| 2.ESPc -> ENPD | H1 | 0.041 | 0.001 | 0.637 | (−0.128, 0.210) | 0.125 ** (p = 0.041) | 0.167 * (p = 0.088) |

| 3.ESPm-> INPD | H2a | 0.160 * | 0.011 | 0.065 | (−0.015, 0.332) | 0.160 * (p = 0.065) | |

| 4.ESPm -> ENPD | H2b | 0.024 | 0.000 | 0.748 | (−0.127, 0.171) | 0.102 * (p = 0.071) | 0.126 (p = 0.223) |

| 5.INPD-> ENPD | 0.634 *** | 0.603 | 0.000 | (0.553, 0.723) | 0.634 *** (p = 0.000) | ||

| 6.ISP -> ESPc | H3a | 0.645 *** | 0.711 | 0.000 | (0.581, 0.709) | 0.645 *** (p = 0.000) | |

| 7.ISP -> ESPm | H3a | 0.626 *** | 0.645 | 0.000 | (0.559, 0.695) | 0.626 *** (p = 0.000) | |

| 8.ISP -> INPD | H3b | −0.035 | 0.001 | 0.690 | (−0.205, 0.140) | 0.228 *** (p = 0.000) | 0.193 *** (p = 0.001) |

| 9.ISP -> ENPD | H3b | −0.019 | 0.000 | 0.812 | (−0.181, 0.140) | 0.164 ** (p = 0.011) | 0.145 ** (p = 0.035) |

| Control Variables: | |||||||

| 10.R&D_Size -> ENPD | 0.082 ** | 0.008 | 0.046 | (−0.003, 0.161) | 0.082 ** (p = 0.046) | ||

| 11.R&D_Intensity -> ENPD | 0.004 | 0.000 | 0.935 | (−0.085, 0.087) | 0.004 (p = 0.935) | ||

| 12.Firm_Size (Log) -> ENPD | −0.026 | 0.001 | 0.645 | (−0.141, 0.081) | −0.026 (p = 0.645) | ||

| 13.Industry (Mechanical) -> ENPD | 0.094 ** | 0.015 | 0.039 | (0.005, 0.183) | 0.094 ** (p = 0.039) | ||

| 14.Developed -> ENPD | 0.004 | 0.000 | 0.927 | (−0.086, 0.101) | 0.004 (p = 0.927) | ||

| Hypothesis | Result (Direct Effect) | Result (Indirect Effect) |

|---|---|---|

| H1 | Partially Supported | Supported |

| H2a | Supported | |

| H2b | Not Supported | Supported |

| H3a | Supported | |

| H3b | NotSupported | Supported |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmadi-Gh, Z.; Bello-Pintado, A. The Effect of Sustainability on New Product Development in Manufacturing—Internal and External Practices. Adm. Sci. 2021, 11, 115. https://doi.org/10.3390/admsci11040115

Ahmadi-Gh Z, Bello-Pintado A. The Effect of Sustainability on New Product Development in Manufacturing—Internal and External Practices. Administrative Sciences. 2021; 11(4):115. https://doi.org/10.3390/admsci11040115

Chicago/Turabian StyleAhmadi-Gh, Zahra, and Alejandro Bello-Pintado. 2021. "The Effect of Sustainability on New Product Development in Manufacturing—Internal and External Practices" Administrative Sciences 11, no. 4: 115. https://doi.org/10.3390/admsci11040115

APA StyleAhmadi-Gh, Z., & Bello-Pintado, A. (2021). The Effect of Sustainability on New Product Development in Manufacturing—Internal and External Practices. Administrative Sciences, 11(4), 115. https://doi.org/10.3390/admsci11040115