Abstract

In this mini-review, we compiled various types of Polyvinyl-alcohol-based hydrogel construction recipes and methodologies, categorizing them based on their added materials or production methods for wastewater applications. This classification is vital for identifying recipes that require improvement in future research and for analyzing their practical parameters, such as durability, surface area, and cleaning efficiency. To evaluate their potential for long-term use, we examined the durability of these groups. D- and E-type media demonstrated notable durability, exhibiting lower degradation rates compared to A- and B-types. Additionally, we gathered information on the measuring technologies available for assessing the specific surface area of these media, a crucial parameter for both biological and adsorbent applications. Based on the available data, we recommend enhancing the quality and quantity of measurements by integrating and improving microscopic analysis and adsorption techniques. Furthermore, these hydrogels showed superior cleaning capacities compared to traditional carriers, with D- and E-types excelling in adsorption capabilities, while the C-type exhibited exceptional potential for biological treatment.

1. Introduction

Since the onset of the Industrial Revolution, the increasing aggregation of populations within urban areas, propelled by enhanced employment opportunities, has rendered the development of sophisticated sewage systems and urban wastewater treatment technologies essential. Initially, wastewater treatment predominantly utilized physical processes, which proved inadequate for removing significant organic pollutants. In response to these shortcomings, biological treatment methods emerged in the early 20th century [1]. The foundational technologies, such as the Emscher settler and activated sludge tanks, have since laid the groundwork for contemporary biological treatment systems.

Over time, evolving urbanization trends have emphasized the need for wastewater treatment technologies that combine high efficiency with minimal spatial requirements. These trends led to the development of innovative solutions, such as the Kaldnes Moving Bed™ technology in the 1980s in Norway [2]. This system uses moving biofilm carriers designed to host microorganisms in a structured biofilm, significantly enhancing the removal of organic pollutants compared to traditional activated sludge systems [3]. Moving Bed Biofilm Reactor (MBBR) technologies have since gained widespread adoption globally, with various manufacturers producing carriers featuring diverse materials, sizes, and properties [3]. With the rapid advancements in material sciences, various innovative media have been developed, including materials such as polyvinyl alcohol (PVA), polyurethane, polypropylene, and other plastics. A review by [4] on polymeric biofilm carriers identified PVA as the most promising material among these due to its superior biofilm attaching capacity. Over time, PVA-based materials have been developed in numerous shapes and forms owing to their exceptional reactivity; various additives can be incorporated into their structure to enhance their properties. However, there are aspects that need to be pointed out, making room for future improvements, like their minor degradability over time and reusing cycles, sometimes their special need for unique technological elements, and also their industrial applications and experiments beyond laboratory scale, which are not as broad as other MBBR technologies. In this context, we collected and categorized the available PVA-based media based on their production methods and the additives used.

Both production recipients and added materials play a critical role in determining the durability of the media. For each type, we have compiled the available information on their long-term durability and degradation rates, particularly regarding pollutant removal efficiency. The degradation rate provides insights into the usability of the media and also informs the frequency of media refills required for industrial applications.

The material composition of carriers plays a critical role in microbial adherence, directly influencing pollutant removal capabilities. Additionally, the material composition and production methods determine various properties, including the composition, size—typically defined by the longest cross-sectional dimension—and specific surface area (SSA). SSA, which refers to the surface area per unit mass or volume of the media, dictates the available space for microbial growth. We analyzed these parameters across the categorized media types, as they significantly affect biofilm formation and pollutant removal efficiency [5]. Through this critical review, we identified the strengths and weaknesses of each PVA media type, providing valuable insights for future advancements and further studies.

2. Bridging the Gap: Revisiting PVA Hydrogel Research

Between April and August 2024, with supplementary updates in June and July 2025, we conducted a comprehensive literature search to identify experimental studies on polyvinyl alcohol (PVA)–based hydrogels and aerogels. Our strategy combined focused queries on the websites of major publishers—Elsevier, MDPI, Springer, and IWA Publishing—with broader topic searches via Google Scholar, ResearchGate, and select university repositories. To capture practical and industrial developments, we also incorporated data gathered at IFAT [6] drawing on presentations and unpublished materials from industry participants. All records were screened against predefined inclusion criteria, with priority given to peer-reviewed experimental research and detailed material characterization methods. We framed our search around terms such as PVA, hydrogels, PVA-based hydrogels and aerogels, microcarriers and biocarriers, and, in the context of moving-bed biofilm reactor (MBBR) wastewater treatment, cleaning efficiency, specific surface area, media size, carrier size, size measurement, and size distribution—along with various combinations of these keywords.

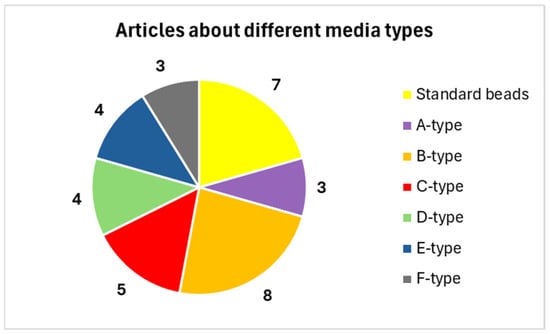

Our selection yielded a total of 34 articles (Figure 1) that specifically describe the fabrication and characterization of these materials. To organize the diverse approaches and modifications reported in these studies, we categorized the articles into seven distinct sections based on the production methods employed and the types of additives introduced into the PVA matrices. These types are named from A to F with the following categories in line: PVA-based foams (A), PVA beads with sodium alginate (B), PVA spheres via emulsification (C), PVA cubes with inorganic particles (D), PVA with other polymers (E), and PVA beads with graphene oxide (F). We made this categorization for all types of PVA-based carriers that are applicable in wastewater treatment that we found in various articles. This structured framework allows us to clearly compare and contrast the various strategies and to understand how different processing conditions and incorporated materials influence the properties of the resulting systems.

Figure 1.

Distribution of articles between media types.

It is also worth noting that while numerous articles emphasize the outstanding cleaning performance and diverse modification strategies for PVA beads, only 10 studies have reported on the long-term durability and degradation of these materials. This discrepancy highlights the need for further experiments under real-life conditions and demonstrates that this area of research remains both emerging and highly relevant.

The need for this review is underscored by the evolving interest in PVA-based systems. Notably, while only 4 of the collected articles were published between 1997 and 2010, a significant 9 articles have appeared in the past five years (after 2020). This marked increase in publication frequency highlights the contemporary relevance and rapid development of research in this field. It also reflects a growing recognition of the potential applications and advantages offered by these materials in areas such as environmental remediation, biomedical engineering, and beyond.

Furthermore, although there exist several reviews on PVA-based media, none have specifically consolidated and analyzed the experimental findings related to these types of carriers. By gathering and systematically distributing the available data on PVA-based systems, our review fills a critical gap in the literature. It not only synthesizes recent advances but also provides insights into emerging trends and challenges, thereby serving as a valuable resource for researchers aiming to develop next-generation hydrogel and aerogel carriers.

3. Previous Reviews on This Topic

Several review articles have summarized the various types of microorganism carriers used in wastewater treatment, particularly in the context of moving bed biofilm reactors (MBBRs). For instance, Barwal and Chaudhary [3] provided a detailed overview of available MBBR media by compiling data on size, specific surface area, cleaning capacity, and kinetics. They concluded that the success of MBBR processes fundamentally depends on the media’s capacity to support a robust microbial community.

Similarly, Kawan et al. [7] emphasized the advantages of MBBR technology over traditional activated sludge systems. Their review focused primarily on design parameters such as the size and shape of the media, which are critical for efficient mass transfer and biofilm development. However, they did not address the influence of the carrier’s material composition on overall process efficiency.

Madan et al. [8] further highlighted the superior cleaning performance of MBBR systems compared with conventional activated sludge operations. Despite their comprehensive evaluation of process efficiency and operational stability, their review did not explore the potential of polyvinyl alcohol (PVA)-based carriers—a material that may offer unique benefits due to its hydrophilicity and biofilm compatibility.

In contrast, Al-Amshawee et al. [4] offered a more material-centric review by examining five biocarrier materials (PVA, polyurethane, polyvinyl chloride, polyethylene, and polypropylene) as well as waste tire derivatives. Their analysis revealed that among the materials studied, PVA stands out due to its exceptional performance in chemical oxygen demand (COD) removal. Yet, they highlighted concerns regarding the long-term durability and biodegradability of PVA-based biocarriers. Despite presenting significant insights into PVA performance, the review did not focus exclusively on PVA media.

Mok et al. [9] took a further step in assessing PVA-based systems by gathering literature on the adsorption properties of these materials. Their review underscored the potential of modifying PVA media to enhance dye adsorption. However, this work was limited to dye removal processes and did not address other critical wastewater components, such as organic matter and nutrient removal.

The closest to our topic is the review written by Hasan et al. [10], which comprehensively gathered information on the potential of PVA-based biocarriers in wastewater applications. Their work summarized factors that affect the usability and efficiency of PVA-based biocarriers, such as hydraulic retention times, organic load rates, and biological affinity to colonize the surface of PVA media. Their works structure is quite similar to those who compiled the traditional MBBR carriers, just in case for PVA-based media. Yet their article lacks and highlights the need for comparison of PVA beads with different additives and with various structures.

Collectively, while these studies underscore the operational advantages of MBBR systems, they do not fully account for the impact of the structural and chemical properties of the carrier materials on treatment efficacy. The material composition—an aspect crucial to determining media performance—remains underexplored. In this context, further research is needed to specifically address how PVA-based carriers can be optimized for long-term stability and enhanced pollutant removal beyond dye adsorption.

4. Types of PVA-Based Media in Wastewater Treatment

Early wastewater treatment technologies experimented with materials such as grit, rock filters, wood, and cork as carrier media. However, it was soon discovered that free-floating media provided optimal conditions for biological activity [11]. With the rapid growth of the plastics industry in the 1970s, synthetic materials like polyethene (PE), polypropylene (PP), and high-density polyethene (HDPE) became widely used in Moving Bed Biofilm Reactor (MBBR) systems [3].

Polyvinyl alcohol (PVA), a water-soluble synthetic polymer, has become an essential material in light industries (e.g., packaging, textiles, and papermaking), food production, and wastewater treatment. PVA is particularly suitable for constructing carrier media due to its high reactivity, ease of polymerization, and excellent biocompatibility, making it highly effective for applications involving biological activity.

While synthetic polymers are generally effective for wastewater treatment, achieving durable media for long-term industrial use is challenging. Okazaki et al. [12] tested three types of hydrogel-based carriers: PEG (polyethylene glycol), polyacrylamide, and PVA media. From all three Based on tensile strength and fold tests, PVA-based carriers produced via a freeze-thaw process were the most durable.

The freeze-thaw method has established PVA as a robust and efficient material for carrier production in wastewater treatment applications. Since then, numerous methods for producing stable PVA-based beads have been developed. We have collected and classified these methods based on the production process and the materials added to the gel structure. Table 1 summarizes various PVA-based media’s key characteristics, advantages, and drawbacks.

Table 1.

Classified PVA media based on their production method and added materials.

In addition to these types, other PVA applications merit attention despite lacking outstanding properties. For instance, Chen et al. [13] developed PVA carriers by mixing wastewater sludge with a 20% (w/v) PVA solution, forming spheres through boric acid saturation and subsequent gel hardening in sodium phosphate solution. Similarly, El-Naas et al. [14] employed a freeze-thaw method to produce PVA beads to immobilize Pseudomonas putida.

Prefabricated PVA beads, such as those from Kuraray Inc., also demonstrate microorganism immobilization capabilities. These, called “standard PVA beads,” which are unmodified chemically or physically prior to application, have been successfully used in various studies (e.g., [15,16,17,18]; cited in [19]).

Hereby we collected and categorized the most promising and available PVA-based media based on their fabrication method and construction materials.

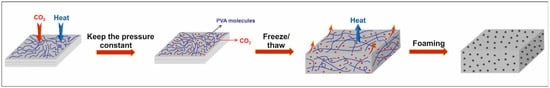

4.1. A-Type Media

PVA-based foams have been widely explored due to their high porosity and ease of production, yet their application is not common in wastewater treatment. To produce this type of media, constant pressure conditions often followed by freezing/thawing methods to release the added carbonate are required (Figure 2). X. Bai et al. [20] created PVA foams by mixing calcium carbonate powder with PVA in boiling water, followed by adding hydrochloric acid to produce CO2 bubbles. The resulting foam was frozen overnight, cut into small cubes, and treated with NaOH. Similarly, X. Li et al. [21] employed a calcium carbonate–hydrochloric acid method but incorporated a freeze-thaw process for enhanced properties. Abdeen and Mustafa [22] improved foam structure and durability by adding epichlorohydrin for chemical crosslinking.

Figure 2.

Production method of A-type media.

While Li and Abdeen’s studies primarily investigate the adsorption of metals and oils using PVA-based materials, Bai’s research focuses on the immobilization of microorganisms. Among the tested carriers, crosslinked PVA foams demonstrated superior performance in supporting nitrifying bacteria, making them the most effective medium in Bai’s study.

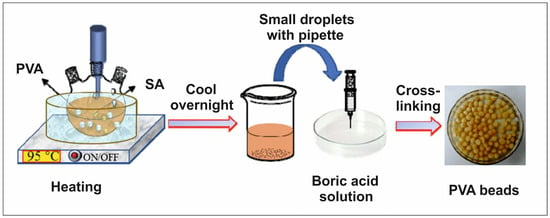

4.2. B-Type Media

Hydrogels made from PVA and sodium alginate (SA) are quick and efficient to produce (Figure 3). The method utilizes sodium alginate blended with poly (vinyl alcohol), which undergoes thermal treatment to promote hydrogen bonding between the polymer chains. The addition of a chemical crosslinking agent further enhances the mechanical strength and stability of the resulting composite. Often boric acid is used for initiating crosslinking, as Toh et al. [23] used immobilized PVA-Sodium Alginate beads crosslinked with boric acid to degrade o-cresol. Other researchers, such as Zain et al. [24], Lee and Cho [25], and Chou et al. [26], adapted similar methods with varying crosslinking agents to optimize structure and efficiency. Specific applications included immobilizing microorganisms like Pseudomonas putida [27], Nitrosomonas, Nitrobacter [28], and Acinetobacter sp. [29] for wastewater treatment, with each study focusing on improving biodegradation capacities through tailored crosslinking methods.

Figure 3.

Production of PVA-based media with SA.

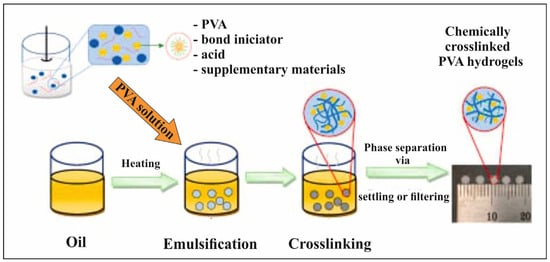

4.3. C-Type Media

PVA capsules and spheres made via emulsification have shown promise for enhancing activated sludge (AS) systems. They show exceptional small size and pumping capabilities, yet their production method and measurement remain challenging. Their production starter solution, composed of poly (vinyl alcohol) (PVA), water, and various acids to maintain a low pH, is prepared, along with a chemical initiator for crosslinking. This hydrophilic mixture is then poured into an oil phase, where emulsification occurs, forming microcapsules. Within these emulsion droplets, the crosslinking reaction takes place, resulting in the formation of stable PVA beads. Their production (Figure 4) often requires heating, like Guerrero et al. [30], who developed PVA capsules to improve nitrogen removal efficiency, using a high-temperature emulsion process with benzaldehyde and oil. Microcarriers in the micrometre range, such as those developed by Cvetkovic et al. [31], were produced by mixing PVA with AS and dispersing it into a chilled soybean oil phase containing lecithin, resulting in smaller particles with high surface area.

Figure 4.

Phases of PVA-based media production.

4.4. D-Type Media

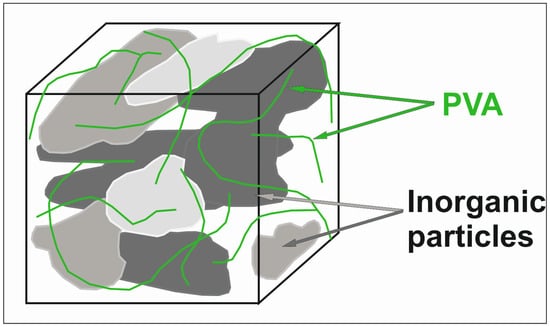

Many scientists in the previous types discovered that adding various materials to the PVA matrix helps its physical strength and makes it more durable against biological degradation. The following types are created not based on their producing method but on the added materials, such as different inorganic parts. There are several approaches to incorporating inorganic particles into PVA matrices. One method involves using oxide precursors, which generate inorganic nanoparticles within the polymer matrix through thermal treatment or chemical crosslinking. Alternatively, pre-synthesized inorganic particles can be directly dispersed into the PVA solution, followed by crosslinking induced by mechanical stress such as stirring or ultrasonication.

PVA cubes modified with inorganic nanoparticles (Figure 5) have been used to enhance both stability and pollutant removal. Jiang et al. [32] combined PVA cubes with ZnO nanoparticles to immobilize Ochrobactrum sp. for quinoline removal. Su et al. [33] incorporated Fe3O4 nanoparticles for nitrate and metal removal. The inclusion of nanomaterials such as TiO2 and Fe3O4 in PVA-based media [34] has further strengthened the mechanical and adsorption properties of these media, with tailored crosslinking methods enhancing their long-term performance.

Figure 5.

The schematic of D-type media.

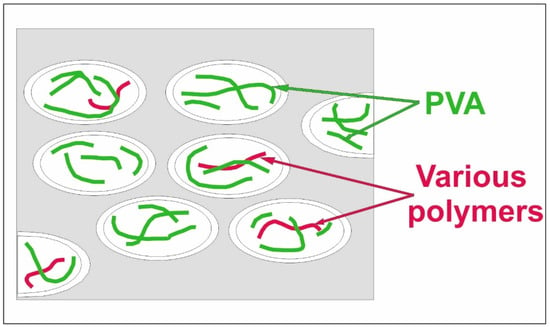

4.5. E-Type Media

Inorganic particles added the right way, as described in the previous chapter, improve the strength of PVA, yet various polymers like β-cyclodextrin or other additives have been developed to increase adsorption capacities (Figure 6). Sharma et al. [35] created a β-cyclodextrin-PVA composite for dye removal using a multi-step process involving ultrasonication and crosslinking with citric acid. Shin et al. [36] improved mechanical strength by incorporating PEG and phosphate buffers into PVA-based media. Other researchers, such as Hou et al. [37], used cyclodextrin-modified polyacrylic acid for host-guest interactions, achieving high crosslinking densities.

Figure 6.

PVA polymer media with additives.

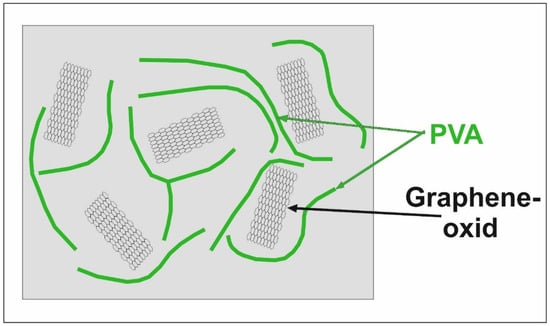

4.6. F-Type Media

The lesser-known group of PVA-based media is F-type, yet they show some potential, and also for a comprehensive review, we felt the urge to add this type as well. Incorporating graphene oxide (GO) into the structure of PVA beads (Figure 7) results in high mechanical strength and increased specific surface area, making it a good overall choice for upgrading PVA-based carriers. Yu et al. [38] produced PVA-GO spheres by blending GO with PVA-sodium alginate and crosslinking the mixture with boric acid and calcium chloride. Dai et al. [39] and Joshi et al. [40] improved adsorption capacities by combining GO with materials like kaolinite clay, creating porous structures through freeze-drying processes. These advanced composites demonstrate excellent potential for applications in MBBR technologies.

Figure 7.

The unique structure of PVA beads with added graphene oxide.

5. Durability of PVA Beads

PVA beads can be produced using various methods, allowing for the incorporation of different materials into their structure to suit diverse wastewater treatment applications. However, to be practical and effective, PVA-based media must withstand the physical, mechanical, and biological stresses inherent in wastewater treatment systems. Below, we summarize the durability of PVA-based media based on existing studies.

PVA-based media are highly effective for intensifying activated sludge (AS) cleaning systems and immobilizing various bacteria. Despite their potential, durability challenges persist. For example, Guerrero et al. [30] reported a 30% release of added PVA in chemical oxygen demand (COD) in effluent during the first 5 weeks of an 8-week experiment where the temperature was between 16.6 and 19.2, the dissolved oxygen concentration was held between 0.3 and 3.4 mg/L, the pH varied between 6.5 and 8.1 (after an initial drop to around 3), and the loading rate of the reactors was between 1.2 and 2.2 kg/m3 during the experimental period. Similarly, Jiang et al. [29] observed an 8.8% reduction in cleaning efficiency after 10 reuses. Their experiment varied, however, as they did not hold consecutive experiments, but they removed phenol (up to 600 mg/L) from wastewater and then stored it for up to 35 days at 4 °C. When stored for a few days and then reused 10 times, the removal efficiency dropped by 8.8%: however, after storing for 35 days, the rate dropped by 50%. Toh et al. [23] noted that o-cresol biodegradation capacity decreased by over 15% after three reuses at low influent concentrations (100 mg/L). This reduction was even more pronounced at higher concentrations (400–800 mg/L); after 3 cycles some of the beads disassembled. Between the cycles the beads were rinsed with distilled water 2–3 times, so no major physical or chemical impact occurred. Zain et al. [24] addressed dissolution issues by using higher amounts of sodium alginate and sodium sulfate to improve structural stability.

The long-term performance of polymerized PVA beads remains uncertain. Chemically crosslinked media often exhibit greater durability than their physically crosslinked counterparts. However, even chemically crosslinked PVA beads may degrade over time.

5.1. Enhancements to Improve Durability

Incorporating materials into the structure of PVA-based carriers can enhance their strength and durability. At D, E, and F, different types of materials were added to the PVA media structure for improving durability: for instance, Zhang et al. [34] reported only a 1.8% mass loss over a 15-day continuous reuse of Fe3O4-enhanced PVA–SA–diatomite beads. Each cycle involved a fresh batch of synthetic wastewater with a hydraulic retention time (HRT) of 24 h. The experiments were conducted in vitro using 100–300 mL reactors, with influent containing 500 mg/L COD and 50–300 mg/L ammonium nitrogen. Jiang et al. [31] demonstrated that ZnO nanoparticle-functionalized PVA cubes exhibited only minimal degradation after five consecutive reuse cycles for quinoline removal (initial concentration: 300 mg/L). Between each cycle, the carriers were autoclaved at 121 °C for 25 min and reinoculated with fresh organisms. Su et al. [33] used similar regeneration methods but with Fe3O4 particles added to the PVA matrices. They used their media 10 times, between each a rinsing and heat sterilizing. Their media did not decrease in terms of TN removal, yet their Mn(II) and Cd(II) decreased from 94.16 to 98.30 percent to 74.60 and 89.53 percent, respectively. They also reported that added materials detached from PVA cubes after ten reuses, although the PVA cube structure itself remained intact.

Zhu et al. [29] investigated the adsorption capacity of PVA/CH (chitosan) media for dyes and set adsorption kinetics for their media. They removed the adsorbed dyes with 0.1 M HNO3 solution between each use up to four cycles, and their adsorption ability reduced from 91.1 to 86.2 percent. Surkatti et al. [41] reported a 12% reduction in bead mass after three weeks of continuous use for p-cresol degradation up to 200 mg/L, while adding TiO2 to the carriers, the mass reduction is only 5% for the same period of time and experimental setup.

These findings indicate that advanced PVA media are more suitable for real-world applications than unmodified beads. While they show greater durability and adaptability for immobilizing various organisms, further improvements are needed to match the longevity of traditional carriers, which can last for decades.

5.2. Discussion and Challenges of PVA Beads Durability

Table 2 summarizes the durability issues associated with various types of PVA-based media. The data highlight significant reductions in mass and performance for media without added materials such as inorganic particles or polymer enhancements. Despite the substantial body of research on PVA media applications, fewer studies focus specifically on their durability, mass loss, or cleaning capacity over time.

Table 2.

Durability of Different Types of PVA-Based Media.

It remains unclear whether observed mass loss and cleaning efficiency reductions are due to residual production materials or an inherent trend toward complete media degradation. Further research is needed to explore the role of production methods in influencing media stability and its effect on the durability of PVA-based media. Also, maintaining their adsorption and cleaning efficiency is important. Understanding and addressing these challenges is crucial to advancing the practical application of PVA-based media in wastewater treatment systems.

6. Methods for Measuring and Calculating Size and Specific Surface Area

After discussing the durability of PVA-based media, it is critical to examine methods for measuring their key parameters—size and specific surface area (SSA). These parameters significantly influence the cleaning capacity of the media, as they determine the available surface for colonization by microorganisms and the adsorption of pollutants. Increased SSA directly correlates with the media’s capacity to bind and remove pollutants effectively for adsorptive applications. For biological applications, protected SSA is also a form factor in biofilm development, as shear stress is a significant factor in the biofilm structure and growth rate [42].

Traditional carriers, such as AnoxKaldnes, have well-documented data regarding their size, shape, surface area, and specific surface area. In contrast, PVA-based carriers, hydrogels, and aerogels lack such comprehensive information. Standard techniques for measuring size and SSA in these media include variable pressure scanning electron microscopy (VPSEM), porosimetric analysis, and adsorption-desorption methods. These techniques are tailored to the unique structural characteristics of PVA-based carriers, particularly their high porosity and diverse material composition. Hereby we collected the strengths and weaknesses of methods that are used for determining size, biofilm thickness, and SSA for PVA-based carriers.

6.1. Microscopic Analysis

Microscopy is commonly used to analyze both the size and porosity of PVA-based media. Variable Pressure Scanning Electron Microscopy (VPSEM) is frequently combined with image processing software for biofilm and carrier dimension analysis [43,44,45,46]. Scanning Electron Microscopy (SEM) is also used for porosity analysis, often paired with sample preparation techniques such as cryogenic fracturing in liquid nitrogen and gold sputtering [37,38]. Light microscopy is applied by Kloknicer et al. [47] combined with 0.5% triphenyl tetrazolium chloride to stain living microorganisms for size and surface area analysis.

Using these methods allows for detailed visualization, size measurement, and the separation of living parts from non-living organisms and the media itself. However, it is worth noting that such techniques require deep knowledge and a software background for image analysis, as well as a significant amount of time to statistically analyze the media’s surface. Additionally, these methods are limited to the outer surface area, while microorganisms can penetrate porous surfaces inside the media.

6.2. Adsorption Methods

Adsorption techniques are effective for calculating specific surface area (SSA) and internal porosity. Nitrogen adsorption-desorption is a widely used method for SSA determination, employing apparatus such as the Micromeritics Tri-Star II [48] and TriStar 3000 [40]. Methylene blue adsorption with the Langmuir equation is also used by Bai et al. [20] for SSA determination. Physisorption analysis, evaluated by Zhang et al. [34], was used to determine porosity and SSA in PVA-based carriers. These methodologies show accurate detection of the media’s internal and outer surface. Carefully chosen adsorbents may be suitable for determining the actual size of the available surface for microorganisms. However, these methods cannot analyse the shape and size of the media and are also limited for biofilm thickness measurement. Media often have internal and external surface areas that offer different environments for microorganisms to attach to, which is worth separating in calculations. Yet, when measuring SSA with adsorption, the ratio of these areas remains unknown.

6.3. Porosimetry

Porosimeters are instruments for measuring pore size and distribution, providing an easy and automated way to determine parameters for PVA-based media. Shin et al. [36] used porosimetry to calculate pore sizes in PVA-based carriers. Additionally, photometric analysis using fluorescein reagents is also possible [36]. This method is time-efficient and accurate yet often limited due to the unique structural properties of different types of PVA-based media.

6.4. Challenges and Future Directions

While various techniques exist for measuring the size and SSA of PVA-based media (Table 3), no single method is universally applicable. Microscopic techniques provide detailed structural insights but are time-intensive, whereas adsorption and porosimetry offer efficient SSA calculations but cannot measure size or shape directly. The increasing miniaturization of PVA-based carriers presents additional challenges, as smaller media make porosity and SSA detection increasingly difficult.

Table 3.

Summarized Comparison of Methods for Measuring Size and Specific Surface Area.

The development of smaller and more durable media is essential to advancing biological wastewater treatment. This creates an urgent need for new standards and methodologies tailored to the unique properties of PVA-based carriers. These methods should enable accurate, reliable measurements of size, porosity, and surface area while accommodating the diverse structural characteristics of modern carrier media.

Combining adsorption techniques with microscopic analysis provides a comprehensive analytical method for determining the main characteristics of biofilms. This approach allows for calculating and measuring the overall inner and outer surface area, which is useful for determining the actual biofilm and its growth potential on a media. By choosing absorbents such as BSA (bovine serum albumin), it is possible to accurately determine the surface area available for microorganisms, as demonstrated by Mahdavinia et al. [49] and Xue et al. [50], who utilized protein-based adsorptions similar to the initial stage of biofilm formation. For microscopic analysis, using SEM or light microscopy may be suitable; however, improving image processing techniques is necessary for these methods to be effective.

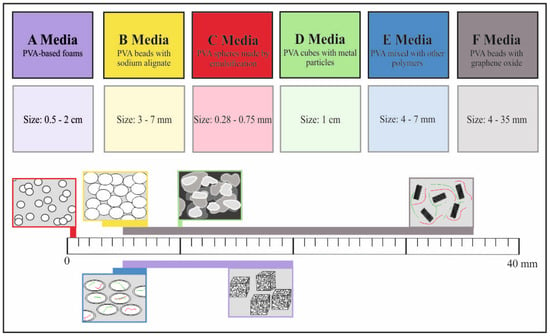

7. Size Range and Specific Surface Area of PVA Carriers

Moving Bed Biofilm Reactor (MBBR) technology is an advanced method in biological wastewater treatment [51]. It leverages microorganisms attached to surfaces rather than living in flocs. Biofilm-based systems are more stable and can better withstand fluctuations in organic load and exposure to toxic pollutants. Microorganisms in biofilms are denser and more efficient, enabling higher wastewater cleaning capacities within smaller reactor footprints. To maximize the cleaning efficiency of MBBR systems, the size of the media must be minimized while maximizing their specific surface area (SSA).

Traditional media carriers typically range in size from 2.2 to 50 mm in length or 9 to 64 mm in width [3,52,53,54,55]. Their SSA values vary between 78 and 5500 m2/m3, with protected surface areas between 66 and 900 m2/m3 [56,57,58,59,60,61]. For PVA-based carriers, while various production methods exist, detailed data on their size and SSA are more limited. These types of media have a wide range of sizes, which we summarized in Figure 8. to demonstrate the difference between the types.

Figure 8.

Size comparison of different types of PVA media.

7.1. Standard PVA Beads

Standard PVA beads, often referred to as “eggs,” are porous with diameters ranging from 3 to 4 mm. Studies by Hoa et al. [15], Zhang et al. [16], and Gani et al. [18], cited in Wang et al. [19], used pre-made beads from Kuraray Co. Ltd. with estimated SSA values of 2500 to 6000 m2/m3. Custom-produced beads by Chen et al. [13] and Nie & Gu [62], which incorporated sludge during fabrication, demonstrated improved biofilm attachment and were similarly sized.

7.2. A-Type Media

A-Type media are generally larger than standard beads. For instance, Bai et al. [20] produced foam cubes with dimensions of 2 × 2 × 2 cm and an SSA of 177 m2/g, though the material density was not reported, complicating direct comparisons. Abdeen & Moustafa [22] fabricated foam discs (0.5 cm thick, 1.2 cm diameter), while Li et al. [21] produced 0.5 × 0.5 × 0.5 cm cubes. These larger sizes may still achieve high SSA due to their foam-like structures.

7.3. B-Type Media

Hydrogels made with PVA, sodium alginate (SA), and calcium chloride typically range from 3 to 7 mm in diameter. Toh et al. [23] and Zain et al. [24] produced hydrogels in the 3–6 mm range, while Lee & Cho [25] achieved 3–7 mm with a phosphorylated hydrogel variant. As reported by Mideksa et al. [48], SSA values for these hydrogels fall between 16 and 23 m2/g.

7.4. C-Type Media

C-Type media represents the most minor PVA-based carriers, produced via oil-in-water emulsion methods. Cvetkovic et al. [30] achieved sizes ranging from 280 to 480 µm by optimizing oil-to-PVA ratios and stirring speeds. Other studies, such as Fleit et al. [63] and Sandor et al. [64,65], reported sizes from 50 to 750 µm for PVA-PAA microcarriers. However, due to their small size and high porosity, measuring SSA for C-Type media remains challenging.

7.5. D-Type Media

D-Type media, such as PVA-based carriers with added inorganic nanoparticles, are generally larger. Jiang et al. [32] used ZnO nanoparticle-enhanced PVA cubes (1 × 1 × 1 cm) with a pore size of 20–100 µm. Su et al. [33] produced similarly sized cubes infused with Fe3O4. SSA values for these media range between 27.77 and 29.96 m2/g [37].

7.6. E-Type Media

PVA-based media combined with polymers, such as PEG or β-cyclodextrin, exhibit SSA values from 17.34 to 64.7 m2/g. Shin et al. [36] reported media sizes between 4 and 7 mm, while Sharma et al. [35] noted pore diameters of 4.12 nm. These media are smaller than PVA cubes but have lower porosity and SSA.

7.7. F-Type Media

F-Type media include PVA-GO composites, which can be both large and highly porous. Joshi et al. [40] produced media with dimensions of 35 mm (height) × 23 mm (diameter) but did not report SSA. Dai et al. [39] fabricated PVA/GO aerogels with 20 × 20 × 8 mm dimensions and 95% porosity. Yu et al. [38] developed modified PVA-GO-GLU gels with SSA values of 194.4 to 229.2 m2/mL, the highest among known PVA-based media.

7.8. Summary of Size and SSA Data

Hereby in Table 4. we summarized the available data. The size range of standard PVA beads, A-Type, B-Type, and E-Type media falls within the lower spectrum of conventional carriers, with A-Type media achieving higher SSA than others with similar sizes. D-Type and F-Type media align more closely with traditional carrier dimensions, but F-Type media exhibits the highest SSA of all PVA-based media studied. C-Type media represent the smallest carriers, but their SSA is difficult to measure due to their intricate structures.

Table 4.

Summary of Size and Specific Surface Area of PVA-Based Media.

The data highlight the potential for PVA-based media to optimize MBBR performance. However, further research is needed to standardize SSA measurement techniques. Future research must also determine the specific surface area (SSA) of media based on volume rather than mass, as the surface area per reactor volume is a critical factor in wastewater treatment.

8. Cleaning Efficiency of MBBR Systems

The primary goal of developing novel microorganism-carrying materials for wastewater treatment is to enhance cleaning efficiency and remove pollutants that neither traditional activated sludge (AS) nor conventional moving bed biofilm (MBBR) systems can effectively process. MBBR systems demonstrate superior pollutant removal rates compared to conventional AS systems [7,66,67], primarily due to their higher biomass concentration and biofilm stability.

For example, Zhu et al. [29] utilized polycaprolactone (PCL) and polyurethane foam (PUF) carriers for ammonium and total organic carbon (TOC) removal, achieving 90% and 65% removal rates with PUF and 72% and 56% with PCL at 14-h hydraulic retention time (HRT). Similarly, Ashkanani et al. [68] evaluated AnoxKaldnes media (K3, K5, and M3) for ammonium removal, with rates of 87.3%, 71.8%, and 47.2% at 20 °C. Shitu et al. [69] reported removal rates of 86.67% and 91.65% for K5 and sponge media, respectively, at 6 HRT. Delnavaz et al. [70] achieved 75–90% cleaning efficiency using clay aggregate carriers at 8HRT with influent COD concentrations of 750–1000 mg/L.

These results are summarized in Table 5. highlight the potential of MBBR systems for high-efficiency pollutant removal within smaller reactor footprints. The hereby mentioned media are conventional carriers, which means that by further increasing specific surface area (SSA) through advanced carriers, even greater cleaning efficiencies are achievable. Al Amshawee et al. [4] reviewed the performance of PVA-based carriers, identifying them as highly effective for COD removal due to their ability to biodegrade and adsorb compounds beyond the capacity of conventional systems.

Table 5.

Cleaning efficiency of conventional MBBR media with retention times.

8.1. Performance of PVA-Based Media

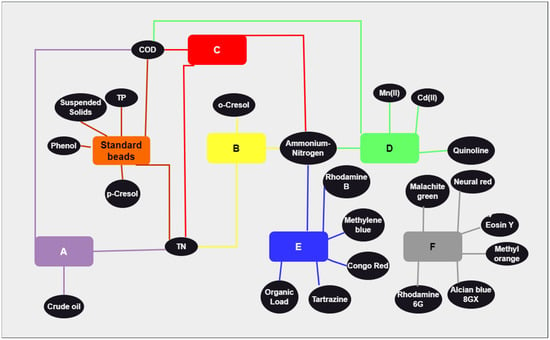

With different added materials, there are a broad range of pollutants that can be removed from wastewater both via adsorption and biological removal, degradation. We summarized in Figure 9. the removable materials based on the media type.

Figure 9.

Removable pollutants via the types of PVA-based media.

It is worth noting that while this list is not fully complete, not all types of media have been tested with each of the pollutants, which leads towards matrix-like experiment setups to analyze the full potential of each group of media. Below we analyze the characteristics and number of pollutants with the reactor setups where the experiments were carried out.

8.2. Standard PVA Beads

Standard PVA beads, such as those produced by Kuraray, exhibit excellent cleaning performance. Wang et al. [19] achieved organic compound removal rates of up to 1.5 kg/m3·day. Hoa et al. [15] used PVA beads with anammox bacteria, achieving 83% total nitrogen (TN) removal at 4 HRT with an influent concentration of 605 mg/L. Zhang et al. [16] attained a 96% COD removal efficiency at an organic loading rate (OLR) of 25 g/L*day and 10 HRT. Gani et al. [18] reported removal rates of 84–98% for total phosphorus (TP) and 85–94% for suspended solids. Jiang et al. [29] immobilized Acinetobacter sp. on PVA beads, achieving 96% phenol degradation (800 mg/L initial concentration) within 30 h. Surkatti et al. [27] immobilized Pseudomonas putida on PVA beads, removing 85% of p-cresol with an initial concentration of 200 mg/L.

8.3. A-Type Media

PVA-based foams are not widely available, yet a few experiments can be used to determine their efficiency. Abdeen & Moustafa [22] used this type to adsorb crude oil with a 5 g/L initial concentration. Their results show it is highly pH dependent, with the peak capacity at a pH of 9. The lowest measured capacity was at pH 7 with 67.6%. Lee & Cho [25] used PVA foams for COD and TN removal; as they set the proper COD/N ratio, the efficiency went up to 92% of COD and 61% of TN. They fixed the HRT at 12 h with an initial concentration of 0.5–2.4 gCOD/L.

8.4. B-Type Media

B-Type media, primarily PVA-alginate carriers, demonstrate high efficiency for ammonium and COD removal; Chou et al. [26] achieved near 100% ammonium-nitrogen removal at 40 HRT with an initial concentration of 0.6 g/L. Lee & Cho [25]: Reported 70% TN and 90% COD removal at 12 HRT with an influent COD of 2.4 g/L and nitrogen of 0.43 g/L. It is also possible to remove complex pollutants, as Toh et al. [23] biodegraded o-cresol at 6.00–9.66 mg/L*h rates.

8.5. C-Type Media

Micro-sized PVA carriers, such as PVA-PAA microcarriers, have demonstrated promising cleaning capacities with traditional wastewater pollutants. Fleit et al. [63]: Achieved near 100% nitrification and denitrification efficiency at 9.5–10.5 HRT with 60 g/m3 influent. Kloknicer et al. [47]: Reported 99.4% ammonium, 94.3% COD, and 75.0% TN removal with a daily inflow of 27 m3 and COD influent concentrations of 729–1308 mg/L. Cvetkovic et al. [31]: Achieved 95.6% reducible COD removal with an initial concentration of 100 kg/m3·day. These show incredible pollutant removal rates, yet their ability to remove more complex molecules or other hazardous materials, such as heavy metals, remains unknown.

8.6. D-Type Media

D-Type media, such as PVA-based media modified with nanoparticles, exhibit high pollutant removal efficiency for ammonium removal. Zhang et al. [34] achieved 95% ammonium-nitrogen removal with Fe3O4 PVA beads at 12 HRT. Su et al. [33] reported near 100% ammonium removal and 74.3% denitrification efficiency. These media also show potential in COD removal, as Surkatti et al. [41] achieved 89% COD removal with TiO2-modified PVA beads. Additionally, Su et al. [33] removed heavy metals such as Mn(II) and Cd(II) with removal rates of 91.16% and 96.19%, respectively, at a remarkable 10 HRT.

8.7. E-Type Media

E-Type media, composed of PVA with PEG or β-cyclodextrin, have shown remarkable adsorption capacities compared with PVA beads without modifications. Sharma et al. [35] Reported adsorption capacities are 366 mg/g for Congo red and 1436 mg/g for tartrazine dyes (TD). Hou et al. [36] Recorded 6.12–25.86 mg/g adsorption capacities for methylene blue (MB) and rhodamine B dyes (RD). Joshi et al. [40] achieved 535 mg/g adsorption capacity for MB with kaolinite clay-PVA-GO carriers. Mok et al. [9] summarized in a systematic review the dye adsorption capacity of PVA-based gels both with and without modifications. They found that for MB 13.80–23.30 mg/g and 276.20 mg/g for bromothymol blue is the maximum adsorption capacity of unmodified PVA beads. Their paper dealt with added materials to PVA matrices such as PAA (poly-acrylic acid), PVA-CH (chitosan), and β-cyclodexrin, amongst other PVA-based carriers. Their studies show remarkably high adsorption capacities up to ~1200 mg/g. This review clearly shows that these modifications significantly increase the adsorption capacity of PVA-based media. It is also possible to remove ammonium and COD from wastewater with these media; however, it is a slightly less researched topic. Shin et al. [36] achieved 99% ammonium and 85% organic load removal.

8.8. F-Type Media

Adding graphene oxide to the PVA matrix significantly increases the dye adsorption capacity, as stated in the Dai et al. [39] article. They experimented with aerogels and various dyes, like methylene blue, malachite green, and Congo red. Their experiments lasted a relatively high HRT of 48 h. The removal efficiency varied between 10% and above 90% based on the dye type. Joshi et al. [40] also examined the dye adsorption capacity of F-type aerogels. However, they determined the adsorption capacity of media in mg/g, which is more useful in technological applications. Their capacity ranged from 80 mg/g up to 380 mg/g based on the dye they used.

8.9. Summarized Cleaning Capacities

As we discussed the cleaning capacity, the available data shows excellent potential in any PVA-based media. The results indicate that technologies applied with these carriers tend to remove a significant number of pollutants from water in a short time. With the addition of other polymeric materials, not only can the adsorption capacity be increased, but also the number of pollutants that can be adsorbed is also widened. We have summarized the available data about the media in Table 6.

Table 6.

Cleaning capacity of each media type.

Both standard PVA beads and other types of media can remove pollutants via material degradation (e.g., ammonium to nitrate). However, D and E media can also adsorb various types of pollutants like metals and complex molecules such as dyes. Among all types of media for ammonium and organic compound degradation via microorganisms, B media can remove the highest concentration but with a very high retention time (up to 40 h). In contrast, C media is also capable of significant pollutant removal, yet with much shorter retention times (9.5–12 h). Standard PVA beads, B, and D can also decompose complex compounds like cresols or quinoline. All mentioned media types have great capacity in adsorption or biological cleaning, although most experiments were conducted on a laboratory scale. It is also evident that not all media types have been tested with every compound, indicating that their full potential is not yet thoroughly researched. Further research should focus on the scalability of these media, as well as their removal potential for a range of pollutants. This includes simple biological treatments like nitrification, as well as more complex molecules such as dyes, cresols, and various types of metals.

9. Conclusions

PVA-based carriers offer small size, high specific surface area (SSA), and the ability to immobilize various microorganisms, making them an innovative solution for advanced wastewater treatment. To analyze cleaning efficiency, we summarized the PVA-based media into 6 types (A to F) based on constructing recipes. Added materials directly affect the media durability; adding inorganic particles (D type) improves durability from up to a 30% degradation rate (A Media) to minor structural degradation. Mixing with polymers also added to the strength of the media structure (maximum 4.9% adsorption capacity decrease), yet both improved media types show degradation, like added parts detaching and adsorption capacity losses, which should be minimized during future developments.

Analyzing media surface area and size requires effective analytical methods. Due to the unique structure of PVA-based media, none of these techniques provide comprehensive results on their own. Adsorption methods are effective for determining porosity and surface area, while microscopic measurements are more suited for assessing biofilm thickness and outer surface area. A combination of these techniques is recommended to obtain comprehensive insights, though both require improvements from a biological perspective. Adsorption methods often utilize dyes, which may attach differently than proteins and microorganisms. To address this, using protein adsorption, such as with BSA, can be a viable solution. For enhancing microscopic analyses, techniques like live biomass staining and color-based separations should be applied. However, to reduce the time-intensive nature of such analyses, investment in automated software is crucial.

Types A and D fall within the centimeter range, which is slightly larger, while types B, E, and F are in the millimeter range, aligning with the size range of traditional media. However, type C is notably smaller (lower millimeter, micrometer range) than all other types. Beyond size variations, all PVA-based media demonstrate significantly higher (m2/m3 range versus m2/mL range) specific surface areas compared to conventional carriers. The available data on specific surface area (SSA) is often incomplete, with results frequently reported per mass or per volume. To standardize measurements, the density of the media should be determined, or standardized methods for SSA measurement should be adopted. Furthermore, some media, such as type C, lack SSA data, possibly due to their extremely small size, which poses measurement challenges and necessitates further research.

Type E demonstrates exceptional capabilities in removing dyes and complex molecules, which makes it promising for testing pharmaceutical residue removal rates. Conversely, type C exhibits low retention times (9.5 to 12 h) for extremely high COD and nitrogen (60 g/m3 nitrogen, 1.308 g/L COD) concentrations. However, there remains significant scope for further investigation, as the adsorption capacities of types A, B, and C are still unknown. Additionally, type C’s ability to degrade complex molecules such as o-cresol or quinoline requires further research. Overall, literature suggests that type D can remove the broadest range of pollutants. Combined with its overall durability, this makes it an excellent candidate for further research and industrial applications.

Funding

This research was funded by The MICROBI—Use of intelligent microreactors in biological wastewater treatment Project no. 2019-1.1.1-PIACI-KFI-2019-00118 has been implemented with support from the National Research, Development and Innovation Fund of Hungary, financed under the 2019-1.1.1-PIACI KFI funding scheme. This article has been implemented with support from the Cultural and Innovational Ministry of Hungary, the National Research, Development and Innovation Fund of Hungary (KDP-2023), and the KDP scholarship (via C2254300 ref. number). The APC was funded by Óbuda University.

Data Availability Statement

Data is available upon request from the authors.

Acknowledgments

During the preparation of this manuscript/study, the authors used ChatGPT-4 and MS Copilot (which is based on ChatGPT-4) for the purposes of improving the better understanding of the article. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

Tamás Kloknicer, Anita Szabó and Sándor Dániel Benjámin Sándor are employees, Genoveva Filipcsei is an Extrernal consultant, Anita Szabó is an owner and CEO of Inno-Water Inc., which may be considered a potential conflicts of interest. This affiliation did not influence the design, execution, analysis, or interpretation of the research presented in this manuscript. Other than the aformentioned, the authors have no other financial or non-financial interests to declare.

References

- Förstner, U. (Ed.) Környezetvédelmi Technika. Moly. 1993. Available online: https://moly.hu/konyvek/ulrich-forstner-kornyezetvedelmi-technika (accessed on 18 September 1993).

- Ødegaard, H.; Rusten, B.; Siljudalen, J. The development of the Moving Bed Biofilm Process—From Idea to Commercial Product. In Proceedings of the WEC/EWPCA/IWEM Speciality Conference, Innovations 2000, Cambridge, UK, 7–10 July 1998. [Google Scholar]

- Barwal, A.; Chaudhary, R. To study the performance of biocarriers in moving bed biofilm reactor (MBBR) technology and kinetics of biofilm for retrofitting the existing aerobic treatment systems: A review. Rev. Environ. Sci. Bio/Technol. 2014, 13, 285–299. [Google Scholar] [CrossRef]

- Al-Amshawee, S.; Yunus, M.Y.B.M.; Vo, D.-V.N.; Tran, N.H. Biocarriers for biofilm immobilization in wastewater treatments: A review. Environ. Chem. Lett. 2020, 18, 1925–1945. [Google Scholar] [CrossRef]

- Hlady, V.; Buijs, J. Protein adsorption on solid surfaces. Curr. Opin. Biotechnol. 1996, 7, 72–77. [Google Scholar] [CrossRef]

- IFAT Munich. (13–17 May 2024). *IFAT Munich 2024: World’s leading trade fair for environmental technologies*. Messe München. Available online: https://ifat.de/en/ (accessed on 23 August 2025).

- Kawan, J.A.; HA, H.; Suja, F.; Jaafar, O.; Abd-Rahman, R. A review on sewage treatment and polishing using moving bed bioreactor (Mbbr). J. Eng. Sci. Technol. 2016, 11, 1098–1120. Available online: https://www.researchgate.net/publication/308138755 (accessed on 15 June 2024).

- Madan, S.; Madan, R.; Hussain, A. Advancement in biological wastewater treatment using hybrid moving bed biofilm reactor (MBBR): A review. Appl. Water Sci. 2022, 12, 141. [Google Scholar] [CrossRef]

- Mok, C.F.; Ching, Y.C.; Muhamad, F.; Abu Osman, N.A.; Hai, N.D.; Che Hassan, C.R. Adsorption of Dyes Using Poly(vinyl alcohol) (PVA) and PVA-Based Polymer Composite Adsorbents: A Review. J. Polym. Environ. 2020, 28, 775–793. [Google Scholar] [CrossRef]

- Hasan, H.A.; Mohd Saharuddin, S.N.D.; Muhamad, M.H. Unlocking the potential of polyvinyl alcohol (PVA) as a biocarrier for enhanced wastewater treatment: A comprehensive review. J. Water Process Eng. 2025, 74, 107780. [Google Scholar] [CrossRef]

- Water Environment Federation; Rhodes, R.; Copithorn, D.S. Biofilm Reactors WEF MOP 35; McGraw Hill Professional: Columbus, OH, USA, 2010. [Google Scholar]

- Okazaki, M.; Hamada, T.; Fuji, H.; Mizobe, A.; Matsuzawa, S. Development of Poly(vinyl alcohol) Hydrogel for Waste Water Cleaning. I. Study of Poly(vinyl alcohol) Gel as a Carrier for Immobilizing Microorganisms. J. Appl. Polym. Sci. 1995, 58, 2235–2241. [Google Scholar] [CrossRef]

- Chen, K.-C.; Lee, S.-C.; Chin, S.-C.; Houng, J.-Y. Simultaneous carbon-nitrogen removal in wastewater using phosphorylated PVA-immobilized microorganisms. Enzym. Microb. Technol. 1998, 23, 311–320. [Google Scholar] [CrossRef]

- El-Naas, M.H.; Mourad, A.-H.I.; Surkatti, R. Evaluation of the characteristics of polyvinyl alcohol (PVA) as matrices for the immobilization of Pseudomonas putida. Int. Biodeterior. Biodegrad. 2013, 85, 413–420. [Google Scholar] [CrossRef]

- Hoa, T.T.H.; Khanh, L.N.; Zhijun, L.; Fujii, T.; Rouse, J.D.; Furukawa, K. Nitrogen Removal by Immobilized Anammox Sludge using PVA Gel as Biocarrier. Jpn. J. Water Treat. Biol. 2006, 42, 139–149. [Google Scholar] [CrossRef]

- Zhang, W.; Xie, Q.; Rouse, J.D.; Qiao, S.; Furukawa, K. Treatment of high-strength corn steep liquor using cultivated Polyvinyl alcohol gel beads in an anaerobic fluidized-bed reactor. J. Biosci. Bioeng. 2009, 107, 49–53. [Google Scholar] [CrossRef] [PubMed]

- Levstek, M.; Plazl, I.; Rouse, J. Estimation of the Specific Surface Area for a Porous Carrier. Acta Chim. Slov. 2010, 57, 45–51. [Google Scholar]

- Gani, K.M.; Singh, J.; Singh, N.K.; Ali, M.; Rose, V.; Kazmi, A.A. Nitrogen and carbon removal efficiency of a polyvinyl alcohol gel based moving bed biofilm reactor system. Water Sci. Technol. 2015, 73, 1511–1519. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, Y.; Feng, M.; Wang, L. Study of the treatment of domestic sewage using PVA gel beads as a biomass carrier. J. Water Reuse Desalination 2017, 8, 340–349. [Google Scholar] [CrossRef]

- Bai, X.; Ye, Z.; Li, Y.; Zhou, L.; Yang, L. Preparation of crosslinked macroporous PVA foam carrier for immobilization of microorganisms. Process Biochem. 2010, 45, 60–66. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Zhang, S.; Ye, Z. Preparation and characterization of new foam adsorbents of poly(vinyl alcohol)/chitosan composites and their removal for dye and heavy metal from aqueous solution. Chem. Eng. J. 2012, 183, 88–97. [Google Scholar] [CrossRef]

- Abdeen, Z.; Moustafa, Y.M. Treatment of Oily Wastewater by Using Porous PVA Hydrogels as Oil Adsorbent. J. Dispers. Sci. Technol. 2015, 37, 799–805. [Google Scholar] [CrossRef]

- Toh, R.-H.; Seng, C.-E.; Lim, P.-E.; Adnan, R.; Sujari, A. Biodegradation ofo-cresol by polyvinyl alcohol–alginate immobilized mixed culture. Desalination Water Treat. 2013, 51, 7216–7222. [Google Scholar] [CrossRef]

- Zain, N.A.M.; Suhaimi, M.S.; Idris, A. Development and modification of PVA–alginate as a suitable immobilization matrix. Process Biochem. 2011, 46, 2122–2129. [Google Scholar] [CrossRef]

- Lee, J.; Cho, M.H. Removal of nitrogen in wastewater by polyvinyl alcohol (PVA)-immobilization of effective microorganisms. Korean J. Chem. Eng. 2010, 27, 193–197. [Google Scholar] [CrossRef]

- Chou, W.-P.; Tseng, S.-K.; Ho, C.-M.; Wu, Z.-Z.; Feng, Y.-J.; Hsia, T.-H. Highly efficient partial nitrification by polyvinyl alcohol–alginate immobilized cells. J. Chin. Inst. Eng. 2012, 35, 793–801. [Google Scholar] [CrossRef]

- Surkatti, R.; El-Naas, M.H. Biological treatment of wastewater contaminated with p-cresol using Pseudomonas putida immobilized in polyvinyl alcohol (PVA) gel. J. Water Process Eng. 2014, 1, 84–90. [Google Scholar] [CrossRef]

- Cao, G.; Zhao, Q.; Sun, X.; Zhang, T. Characterization of nitrifying and denitrifying bacteria coimmobilized in PVA and kinetics model of biological nitrogen removal by coimmobilized cells. Enzym. Microb. Technol. 2002, 30, 49–55. [Google Scholar] [CrossRef]

- Zhu, H.-Y.; Fu, Y.-Q.; Jiang, R.; Yao, J.; Xiao, L.; Zeng, G.-M. Novel magnetic chitosan/poly(vinyl alcohol) hydrogel beads: Preparation, characterization and application for adsorption of dye from aqueous solution. Bioresour. Technol. 2012, 105, 24–30. [Google Scholar] [CrossRef]

- Guerrero, J.A.; Almeida-Naranjo, C.E.; Alejandra, C. Improvement of nutrients removal from domestic wastewater by activated-sludge encapsulation with polyvinyl alcohol (PVA). J. Environ. Sci. Health Part A 2019, 54, 721–727. [Google Scholar] [CrossRef] [PubMed]

- Cvetkovic, S.; Bugarski, B.; Obradovic, B. Activated sludge-loaded polyvinyl alcohol microparticles for starch wastewater treatment in an airlift bioreactor. Korean J. Chem. Eng. 2017, 35, 324–327. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, Y.; Liu, Y.; Hou, S. A Novel ZnONPs/PVA-Functionalized Biomaterials for Bacterial Cells Immobilization and its Strengthening Effects on Quinoline Biodegradation. Curr. Microbiol. 2017, 75, 316–322. [Google Scholar] [CrossRef]

- Su, J.F.; Bai, Y.H.; Huang, T.L.; Wei, L.; Gao, C.Y.; Wen, Q. Multifunctional modified polyvinyl alcohol: A powerful biomaterial for enhancing bioreactor performance in nitrate, Mn(II) and Cd(II) removal. Water Res. 2020, 168, 115152. Available online: https://www.sciencedirect.com/science/article/pii/S0043135419309261 (accessed on 22 April 2020). [CrossRef]

- Zhang, Y.; Yu, Z.; Hu, Y.; Song, C.; Li, F.; He, W.; Wang, X.; Li, Z.; Lin, H. Immobilization of nitrifying bacteria in magnetic PVA–SA-diatomite carrier for efficient removal of NH4+-N from effluents. Environ. Technol. Innov. 2021, 22, 101407. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, M.; Yadav, L.; Agarwal, M.; Gupta, R. Sustainable solution for wastewater management: Fabrication of cost-effective β-cyclodextrin incorporated chitosan polyvinyl alcohol composite hydrogel film for the efficient adsorption of anionic congo red and tartrazine dyes. Sep. Purif. Technol. 2025, 355, 12. Available online: https://www.sciencedirect.com/science/article/pii/S1383586624034890?via%3Dihub (accessed on 27 October 2024). [CrossRef]

- Shin, D.; Kim, J.; Park, C. Study on physical and chemical characteristics of microorganism immobilized media for advanced wastewater treatment. J. Water Process Eng. 2019, 29, 100784. [Google Scholar] [CrossRef]

- Hou, N.; Wang, R.; Wang, F.; Bai, J.; Zhou, J.; Zhang, L.; Hu, J.; Liu, S.; Jiao, T. Fabrication of Hydrogels via Host–Guest Polymers as Highly Efficient Organic Dye Adsorbents for Wastewater Treatment. ACS Omega 2020, 5, 5470–5479. [Google Scholar] [CrossRef]

- Yu, Y.; Shu, Y.; Ye, L. In situ crosslinking of poly (vinyl alcohol)/graphene oxide-glutamic acid nano-composite hydrogel as microbial carrier: Intercalation structure and its wastewater treatment performance. Chem. Eng. J. 2018, 336, 306–314. [Google Scholar] [CrossRef]

- Dai, J.; Huang, T.; Tian, S.; Xiao, Y.; Yang, J.; Zhang, N.; Wang, Y.; Zhou, Z. High structure stability and outstanding adsorption performance of graphene oxide aerogel supported by polyvinyl alcohol for waste water treatment. Mater. Des. 2016, 107, 187–197. [Google Scholar] [CrossRef]

- Joshi, P.; Raturi, A.; Srivastava, M.; Khatri, O.P. Graphene oxide, kaolinite clay and PVA-derived nanocomposite aerogel as a regenerative adsorbent for wastewater treatment applications. J. Environ. Chem. Eng. 2022, 10, 108597. [Google Scholar] [CrossRef]

- Surkatti, R.; van Loosdrecht, M.C.M.; Hussein, I.A.; El-Naas, M.H. PVA-TiO2 Nanocomposite Hydrogel as Immobilization Carrier for Gas-to-Liquid Wastewater Treatment. Nanomaterials 2024, 14, 249. [Google Scholar] [CrossRef]

- Liu, Y.; Tay, J.-H. The essential role of hydrodynamic shear force in the formation of biofilm and granular sludge. Water Res. 2002, 36, 1653–1665. [Google Scholar] [CrossRef]

- Bjornberg, C.; Lin, W.; Zimmerman, R. Effect of Temperature on Biofilm Growth Dynamics and Nitrification Kinetics in a Full-Scale MBBR System. Proc. Water Environ. Fed. 2009, 2009, 4407–4426. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source Platform for biological-image Analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Hoang, V.; Delatolla, R.; Abujamel, T.; Mottawea, W.; Gadbois, A.; Laflamme, E.; Stintzi, A. Nitrifying moving bed biofilm reactor (MBBR) biofilm and biomass response to long term exposure to 1 °C. Water Res. 2014, 49, 215–224. [Google Scholar] [CrossRef]

- Arabgol, R.; Vanrolleghem, P.A.; Delatolla, R. Influence of MBBR carrier geometrical properties and biofilm thickness restraint on biofilm properties, effluent particle size distribution, settling velocity distribution, and settling behaviour. J. Environ. Sci. 2022, 122, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Kloknicer, T.; Sándor, D.B.; Szabó, A. New containerized wastewater treatment technology: System description and evaluation of treatment capacity of a highly efficient MBBR system. Hidrol. Közlöny 2024, 104, 35–44. [Google Scholar] [CrossRef]

- Mideksa, E.; Teychene, J.; Sartor, V.; Claparols, C.; Guigui, C.; Tourrette, A. Preparation and Characterization of Novel Polyvinyl Alcohol-Alginate Beads for Quorum Quenching Application in Membrane Bioreactors. J. Polym. Environ. 2024, 32, 5837–5856. [Google Scholar] [CrossRef]

- Mahdavinia, G.R.; Soleymani, M.; Etemadi, H.; Sabzi, M.; Atlasi, Z. Model protein BSA adsorption onto novel magnetic chitosan/PVA/laponite RD hydrogel nanocomposite beads. Int. J. Biol. Macromol. 2018, 107, 719–729. [Google Scholar] [CrossRef]

- Xue, B.; Tong, X.D.; Sun, Y. Characterization of PVA-Based Magnetic Affinity Support for Protein Adsorption. Sep. Sci. Technol. 2001, 36, 2449–2461. [Google Scholar] [CrossRef]

- Water Technologies, Seimens. BioSphereTM Moving Bed Biological Systems. Proven Fixedfilm Technology Ideal for BNR Upgrades and Capacity Expansions. 2013. Available online: https://tratamentodeagua.com.br/wp-content/uploads/2016/05/BIOSPHERE%C2%AE-MOVING-BED-BIOLOGICAL-SYSTEMS-PROVEN-FIXED-FILM-TECHNOLOGY-IDEAL-FOR-BNR-UPGRADES-AND-CAPACITY-EXPANSIONS.pdf (accessed on 18 September 2024).

- Aygun, A.; Nas, B.; Berktay, A. Influence of High Organic Loading Rates on COD Removal and Sludge Production in Moving Bed Biofilm Reactor. Environ. Eng. Sci. 2008, 25, 1311–1316. [Google Scholar] [CrossRef]

- Das, A.; Naga, R.N. Activated Sludge Process with MBBR Technology at ETP. IPPTA J. 2011, 23, 135–137. [Google Scholar]

- Kermani, M.; Bina, B.; Movahedian, H.; Amin, M.M.; Nikaein, M. Application of Moving Bed Biofilm Process for Biological Organics and Nutrients from Municipal Wastewater. Am. J. Environ. Sci. 2008, 4, 675–682. [Google Scholar] [CrossRef]

- China Plastic MBBR for Water Treatment Manufacturer—EPC Service. 2024. Fxsinocom. Available online: https://www.fxsino.com/plastic-mbbr-for-water-treatment (accessed on 18 September 2024).

- Available online: https://www.ztsmallboss.com/ (accessed on 15 May 2024).

- Available online: https://www.ssiaeration.com/ (accessed on 15 May 2024).

- Available online: https://www.hel-x.eu/ (accessed on 23 June 2024).

- Available online: https://www.bio-fil.es/ (accessed on 17 May 2024).

- Available online: https://www.mutag.com/ (accessed on 20 May 2024).

- Available online: https://nexom.com/ (accessed on 15 May 2024).

- Nie, Q.; Gu, F. Preparation of Composite Carrier Material Immobilized Activated Sludge and Application in Treating Wastewater. Adv. Mater. Res. 2010, 113–116, 301–304. [Google Scholar] [CrossRef]

- Fleit, E.; Melicz, Z.; Sándor, D.; Zrínyi, M.; Filipcsei, G.; László, K.; Dékány, I.; Király, Z. IASON—Intelligent Activated Sludge Operated by Nanotechnology—Hydrogel Microcarriers in Wastewater Treatment. In Colloids for Nano-and Biotechnology; Springer: Berlin/Heidelberg, Germany, 2007; pp. 209–217. [Google Scholar] [CrossRef]

- Sándor, D.; Zajzon, G.; Fleit, E.; Szabó, A. Comparison of nitrification process using biofilm formed on intelligent hydrogel microcarriers and the conventional activated sludge technology. In Proceedings of the 6th IWA International Young Water Professionals Conference, Budapest, Hungary, 10–13 July 2012. [Google Scholar]

- Sándor, D.B.; Szabó, A.; Fleit, E.; Bakacsi, Z.; Zajzon, G. PVA-PAA hydrogel micro-carrier for the improvement of phase separation efficiency of biomass in wastewater treatment. Pollack Period. 2017, 12, 91–102. [Google Scholar] [CrossRef]

- Horan, N.J.; Gohar, H.; Hill, B. Application of a granular activated carbon-biological fluidised bed for the treatment of landfill leachates containing high concentrations of ammonia. Water Sci. Technol. 1997, 36, 369–375. [Google Scholar] [CrossRef]

- Lee, W.-N.; Kang, I.-J.; Lee, C.-H. Factors affecting filtration characteristics in membrane-coupled moving bed biofilm reactor. Water Res. 2006, 40, 1827–1835. [Google Scholar] [CrossRef] [PubMed]

- Ashkanani, A.; Almomani, F.; Khraisheh, M.; Bhosale, R.; Tawalbeh, M.; AlJaml, K. Bio-carrier and operating temperature effect on ammonia removal from secondary wastewater effluents using moving bed biofilm reactor (MBBR). Sci. Total Environ. 2019, 693, 133425. [Google Scholar] [CrossRef]

- Shitu, A.; Zhu, S.; Qi, W.; Tadda, M.A.; Liu, D.; Ye, Z. Performance of novel sponge biocarrier in MBBR treating recirculating aquaculture systems wastewater: Microbial community and kinetic study. J. Environ. Manag. 2020, 275, 111264. [Google Scholar] [CrossRef]

- Delnavaz, M.; Ayati, B.; Ganjidoust, H. Biodegradation of Aromatic Compounds Using Moving Bed Biofilm Reactors. Iran. J. Environ. Health Sci. Eng. 2008, 5, 243–250. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).