Design of a Technical Decision-Making Strategy to Collect Biomass Waste from the Palm Oil Industry as a Renewable Energy Source: Case Study in Colombia

Abstract

1. Introduction

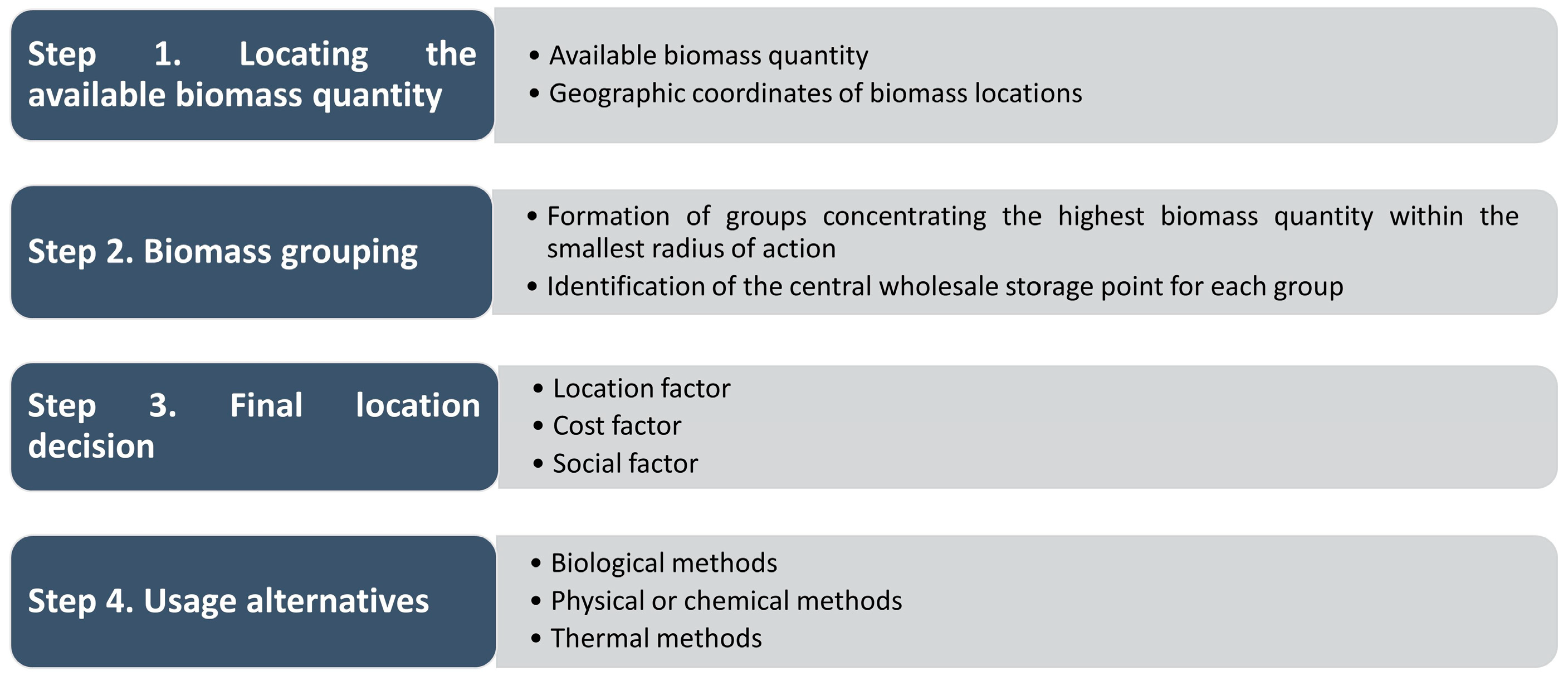

2. Materials and Methods

3. Results and Discussion

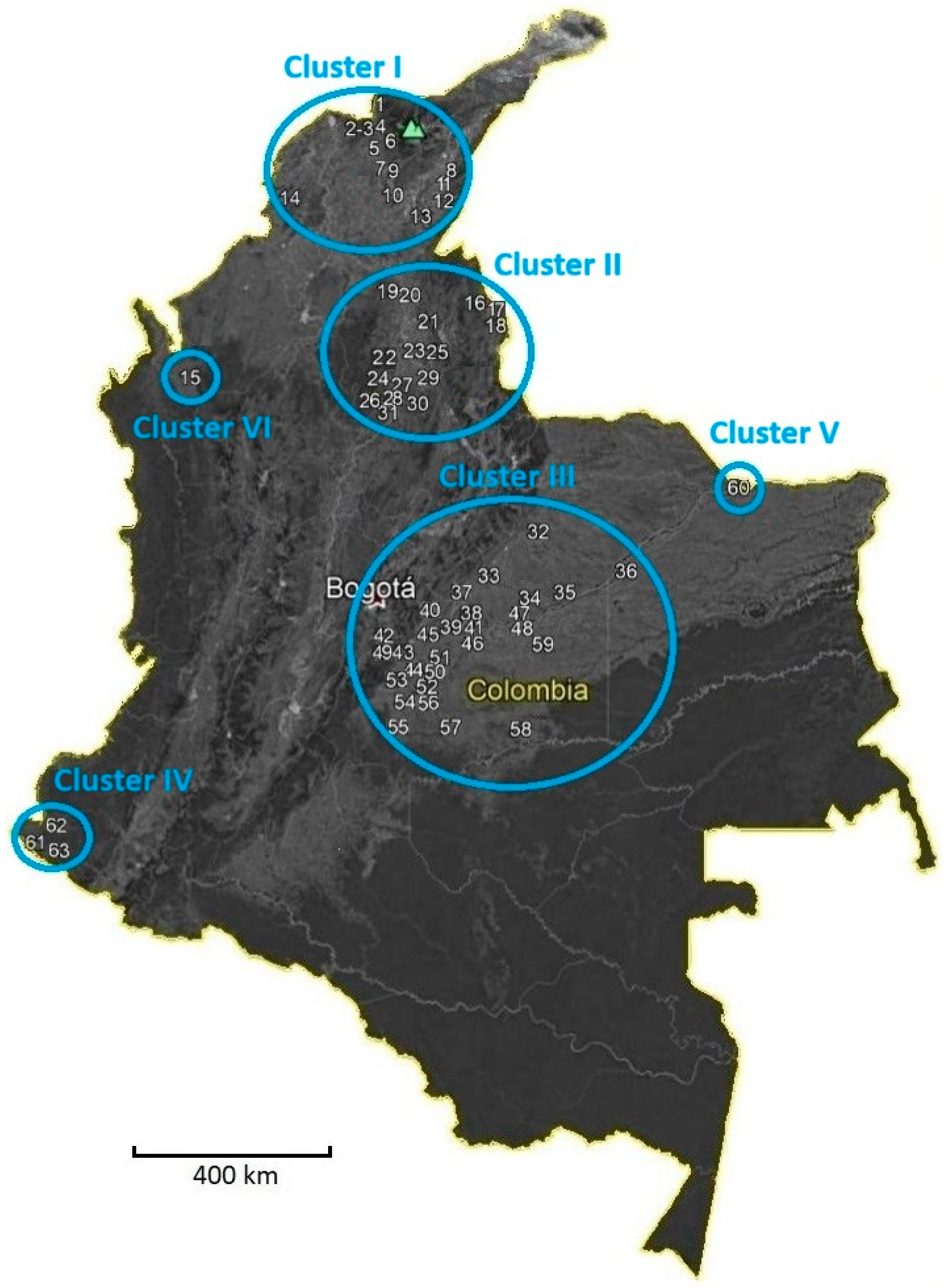

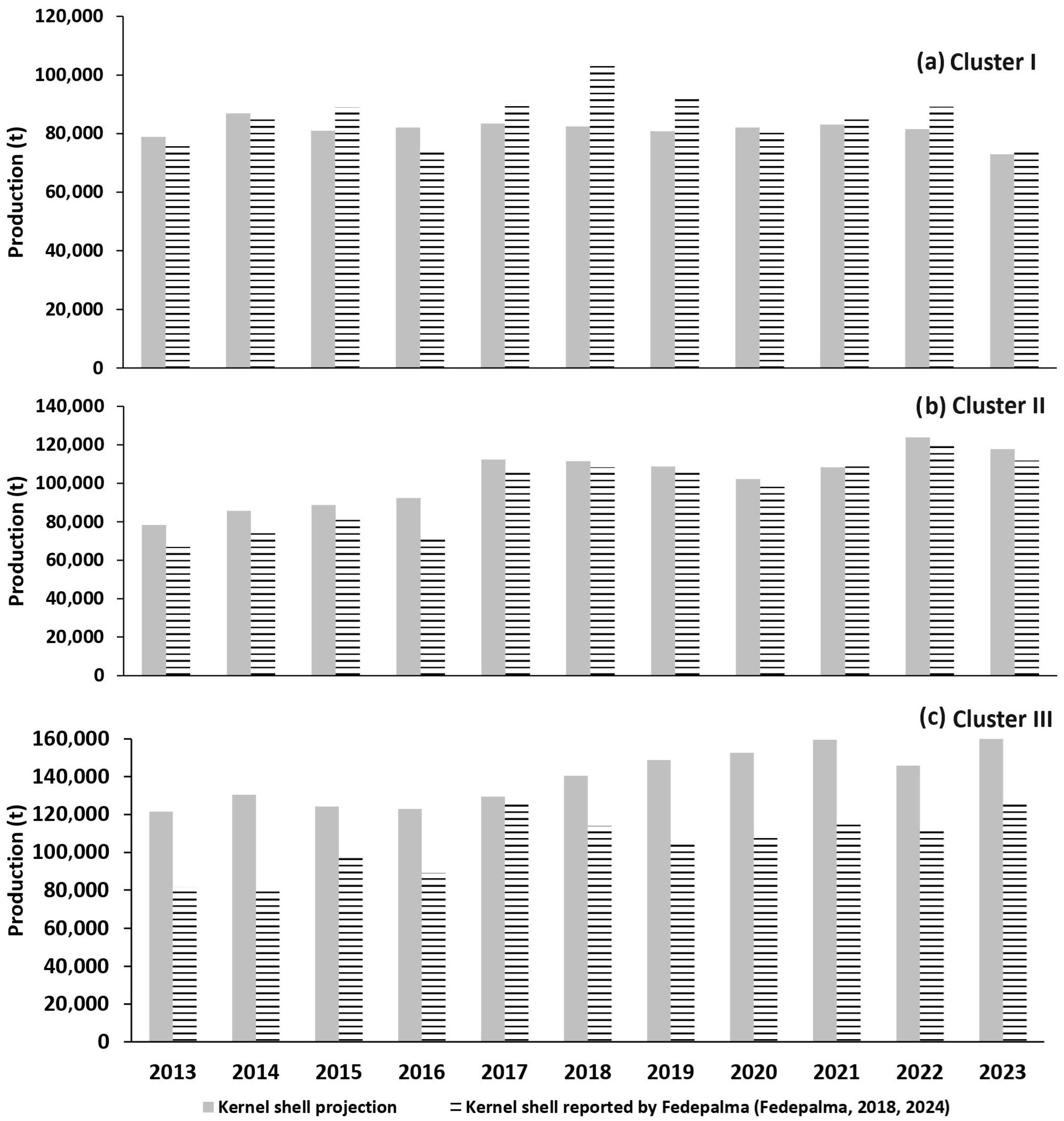

3.1. Location of Available Biomass Waste from the Oil Palm Industry

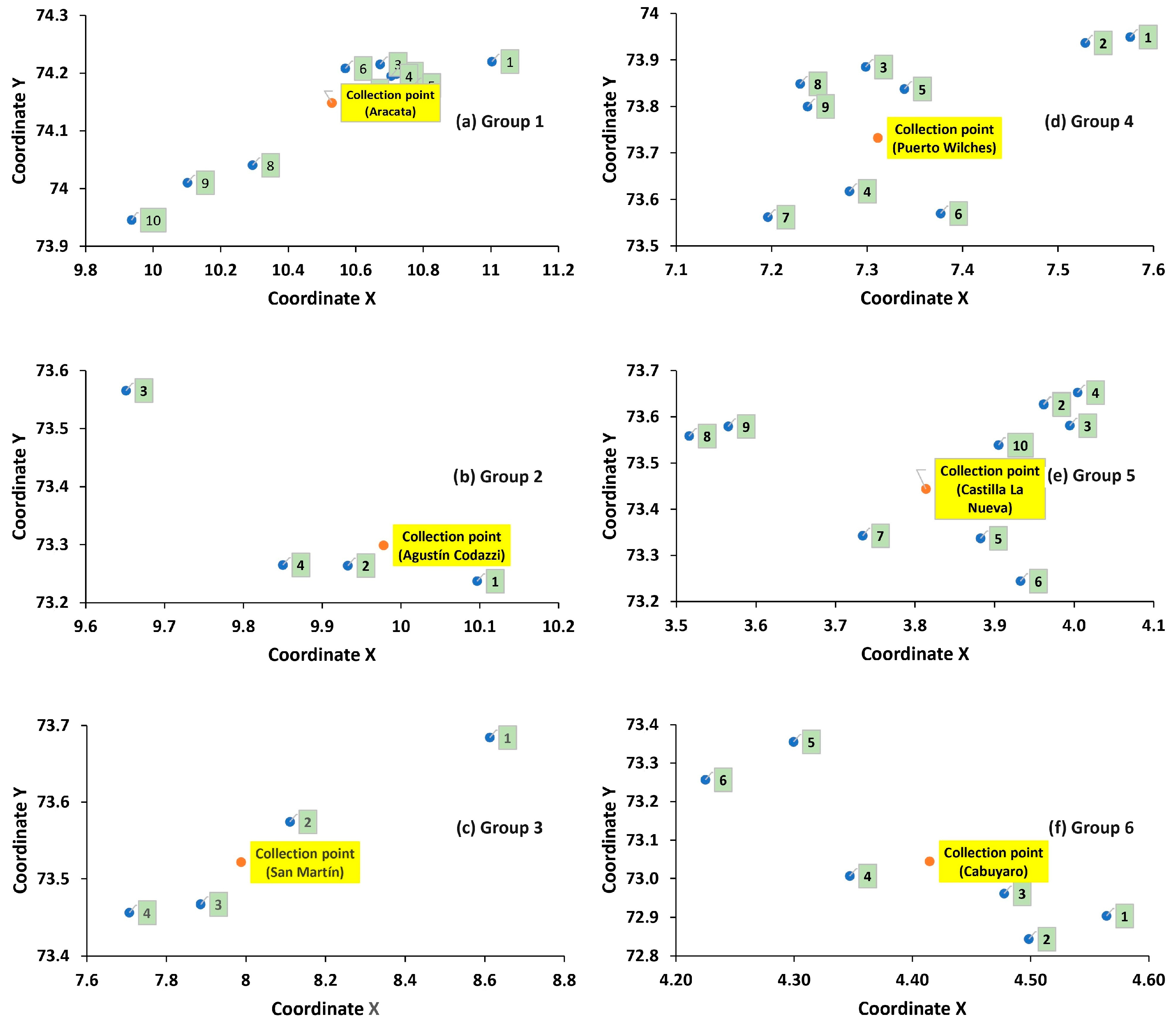

3.2. Biomass Waste Collection

3.3. Final Decision

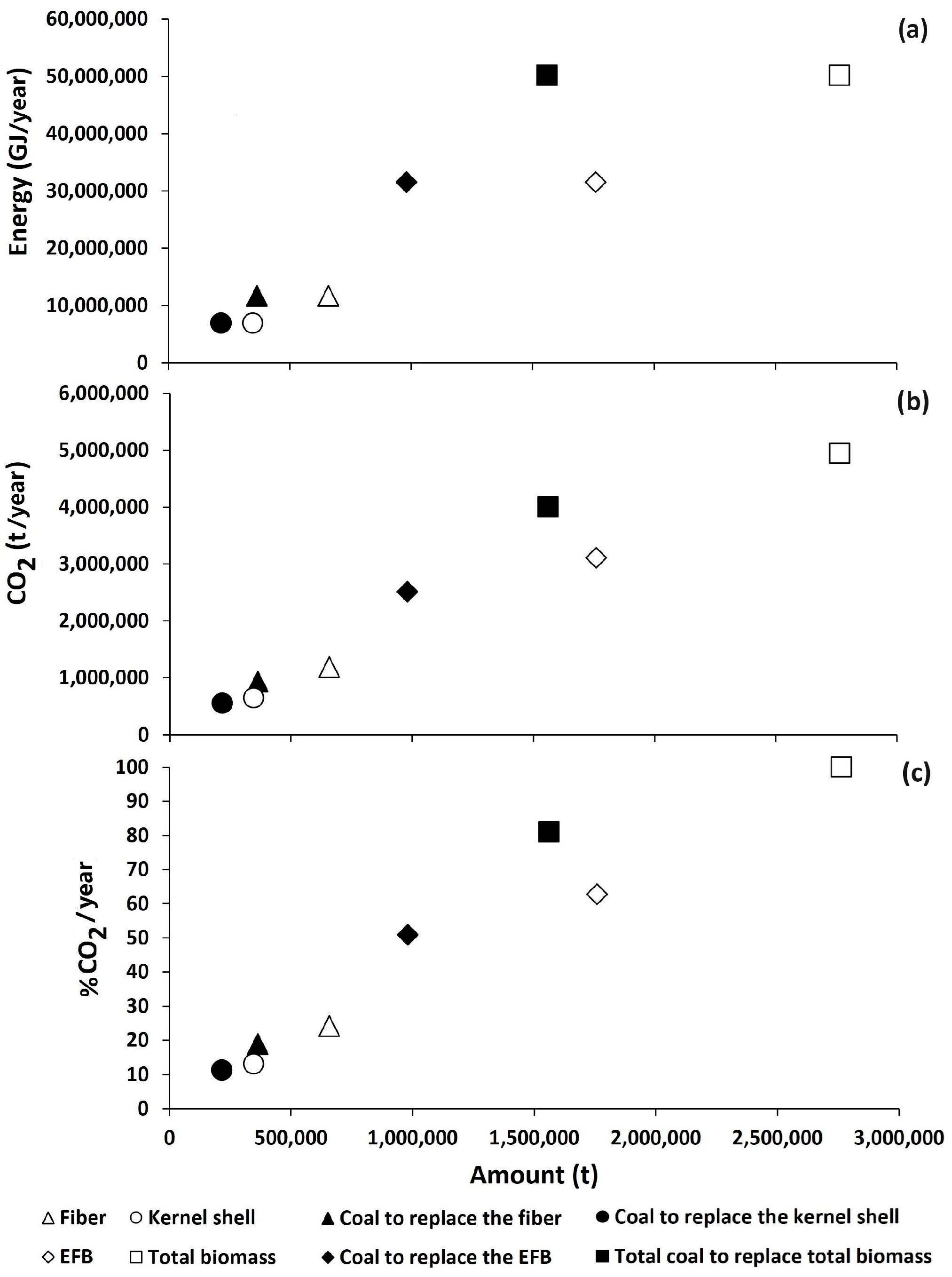

3.4. Alternative Use

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- UPME. Atlas del Potencial Energético de la Biomasa Residual en Colombia; 2010; pp. 1–180. Available online: https://www1.upme.gov.co/siame/Paginas/atlas-del-potencial-energetico-de-la-biomasa.aspx (accessed on 22 September 2024).

- Hosen, M.E.; Siddik, M.N.A.; Miah, M.F.; Kabiraj, S. Biomass energy for sustainable development: Evidence from Asian countries. Environ. Dev. Sustain. 2024, 26, 3617–3637. [Google Scholar] [CrossRef]

- Gutiérrez, A.S.; Eras, J.J.C.; Hens, L.; Vandecasteele, C. The energy potential of agriculture, agroindustrial, livestock, and slaughterhouse biomass wastes through direct combustion and anaerobic digestion. The case of Colombia. J. Clean. Prod. 2020, 269, 122317. [Google Scholar] [CrossRef]

- Montes, C.F.; Felipe, A.; González, R. Potential Use of Waste from Caldense Agroindustry According to Its Structural Composition. Fac. Cienc. Básicas 2018, 14, 143–151. [Google Scholar]

- Ramírez, N.; Arévale, A.; García-Nuñez, J. Inventario de la biomasa disponible en plantas de beneficio para su aprovechamiento y caracterización fisicoquímica de la tusa en Colombia. Rev. Palmas 2015, 36, 41–54. [Google Scholar]

- UNIDO. Informe Final: Observatorio de Energia Renovable Para America Latina y el Caribe. 2013. Available online: https://www.unido.org/sites/default/files/2014-01/Management.Statement.Evaluation.Observatory.ES_0.pdf (accessed on 10 August 2024).

- Macías, R.J.; Ceballos, C.; Ordonez-Loza, J.; Ortiz, M.; Gómez, C.A.; Chejne, F.; Vélez, F. Evaluation of the performance of a solar photovoltaic—Biomass gasifier system as electricity supplier. Energy 2022, 260, 125046. [Google Scholar] [CrossRef]

- Gómez-Navarro, T.; Ribó-Pérez, D. Assessing the obstacles to the participation of renewable energy sources in the electricity market of Colombia. Renew. Sustain. Energy Rev. 2018, 90, 131–141. [Google Scholar] [CrossRef]

- DANE. Boletín Técnico Encuesta Nacional Agropecuaria (ENA). 2019. Available online: https://www.dane.gov.co/index.php/estadisticas-por-tema/agropecuario/encuesta-nacional-agropecuaria-ena (accessed on 26 November 2020).

- Hiloidhari, M.; Sharno, M.A.; Baruah, D.C.; Bezbaruah, A.N. Green and sustainable biomass supply chain for environmental, social and economic benefits. Biomass Bioenergy 2023, 175, 106893. [Google Scholar] [CrossRef]

- Ghimire, M.; Pandey, S.; Woo, J.R. Assessing stakeholders’ risk perception in public-private partnerships for waste-to-energy projects: A case study of Nepal. Energy Sustain. Dev. 2024, 79, 101414. [Google Scholar] [CrossRef]

- Auer, V.; Rauch, P. Wood supply chain risks and risk mitigation strategies: A systematic review focusing on the Northern hemisphere. Biomass Bioenergy 2021, 148, 106001. [Google Scholar] [CrossRef]

- Galik, C.S.; Benedum, M.E.; Kauffman, M.; Becker, D.R. Opportunities and barriers to forest biomass energy: A case study of four U.S. states. Biomass Bioenergy 2021, 148, 106035. [Google Scholar] [CrossRef]

- McCormick, K.; Kåberger, T. Key barriers for bioenergy in Europe: Economic conditions, know-how and institutional capacity, and supply chain co-ordination. Biomass Bioenergy 2007, 31, 443–452. [Google Scholar] [CrossRef]

- Martinez-Valencia, L.; Garcia-Perez, M.; Wolcott, M.P. Supply chain configuration of sustainable aviation fuel: Review, challenges, and pathways for including environmental and social benefits. Renew. Sustain. Energy Rev. 2021, 152, 111680. [Google Scholar] [CrossRef]

- Jazinaninejad, M.; Nematollahi, M.; Zamenjani, A.S.; Tajbakhsh, A. Sustainable operations, managerial decisions, and quantitative analytics of biomass supply chains: A systematic literature review. J. Clean. Prod. 2022, 374, 133889. [Google Scholar] [CrossRef]

- Marques, A.; Rasinmäki, J.; Soares, R.; Amorim, P. Planning woody biomass supply in hot systems under variable chips energy content. Biomass Bioenergy 2018, 108, 265–277. [Google Scholar] [CrossRef]

- James, N.; Ramli, W.; Daud, W.; Kartom, S.; Shahbudin, M.; Irwan, M.; Samsatli, S.; Frederick, J.; Tapia, D.; Azlina, W.; et al. Modelling and optimisation of oil palm biomass value chains and the environment–food–energy–water nexus in peninsular Malaysia. Biomass Bioenergy 2021, 144, 105912. [Google Scholar] [CrossRef]

- Bambara, L.D.F.; Sawadogo, M.; Roy, D.; Blin, J.; Anciaux, D.; Ouiminga, S.K. Wild and cultivated biomass supply chain for biofuel production. A comparative study in West Africa. Energy Sustain. Dev. 2019, 53, 1–14. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Shiwakoti, N.; Stasinopoulos, P. Biomass supply chain environmental and socio-economic analysis: 40-Years comprehensive review of methods, decision issues, sustainability challenges, and the way forward. Biomass Bioenergy 2020, 142, 105777. [Google Scholar] [CrossRef]

- França, L.C.d.J.; e Silva, C.S.J.; Mucida, D.P.; da Costa, J.S.; Gomide, L.R. Towards renewable energy projects under sustainable watersheds principles for forest biomass supply. Biomass Bioenergy 2023, 176, 106916. [Google Scholar] [CrossRef]

- Yildiz, H.; Ayvaz, B.; Kuşakcı, A.; Deveci, M.; Garg, H. Sustainability assessment of biomass-based energy supply chain using multi-objective optimization model. Environ. Dev. Sustain. 2023, 26, 15451–15493. [Google Scholar] [CrossRef]

- Mohtashami, Z.; Bozorgi-Amiri, A.; Tavakkoli-Moghaddam, R. A two-stage multi-objective second generation biodiesel supply chain design considering social sustainability: A case study. Energy 2021, 233, 121020. [Google Scholar] [CrossRef]

- Chen, A.; Liu, Y. Designing globalized robust supply chain network for sustainable biomass-based power generation problem. J. Clean. Prod. 2023, 413, 137403. [Google Scholar] [CrossRef]

- Rentizelas, A.A.; Tatsiopoulos, I.P.; Tolis, A. An optimization model for multi-biomass tri-generation energy supply. Biomass Bioenergy 2009, 33, 223–233. [Google Scholar] [CrossRef]

- Nandi, S.; Gonela, V.; Awudu, I. A resource-based and institutional theory-driven model of large-scale biomass-based bioethanol supply chains: An emerging economy policy perspective. Biomass Bioenergy 2023, 174, 106813. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Shiwakoti, N.; Stasinopoulos, P. Environmental emissions and cost vs. intermodal transportation technological development trade-off for the design of woody biomass supply chain. Procedia CIRP 2022, 109, 134–139. [Google Scholar] [CrossRef]

- Costa, M.; Piazzullo, D.; Di Battista, D.; De Vita, A. Sustainability assessment of the whole biomass-to-energy chain of a combined heat and power plant based on biomass gasification: Biomass supply chain management and life cycle assessment. J. Environ. Manag. 2022, 317, 115434. [Google Scholar] [CrossRef] [PubMed]

- Durmaz, Y.G.; Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 2020, 272, 115259. [Google Scholar] [CrossRef]

- Mirkouei, A.; Haapala, K.R.; Sessions, J.; Murthy, G.S. A mixed biomass-based energy supply chain for enhancing economic and environmental sustainability benefits: A multi-criteria decision making framework. Appl. Energy 2017, 206, 1088–1101. [Google Scholar] [CrossRef]

- Martínez-Valencia, L.; Valle, J.A.; Jessup, E.; Galarza, M.P.; Chejne-Janna, F.; Garcia-Perez, M. Chapter 2—Biomass resources and supply chains. In Thermochemical Conversion of Lignocellulosic Materials; Garcia-Perez, M., Chejne-Janna, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2025; pp. 33–72. [Google Scholar] [CrossRef]

- Ionescu, G.; Bulmǎu, C. Biomass conversion into valuable products within the integrated management of bio-resources. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019. [Google Scholar] [CrossRef]

- Talero, G.; Rincón, S.; Gómez, A. Biomass torrefaction in a standard retort: A study on oil palm solid residues. Fuel 2019, 244, 366–378. [Google Scholar] [CrossRef]

- Marrugo, G.; Valde, C.F.; Chejne, F. Characterization of Colombian Agroindustrial Biomass Residues as Energy Resources. Energy Fuels 2016, 30, 8386–8398. [Google Scholar] [CrossRef]

- Gourich, W.; Song, C.P.; Qua, K.S.; Chan, E.S. The potential of palm bioenergy in achieving Malaysia’s renewable energy target and climate ambition in line with the Paris Agreement. Energy Sustain. Dev. 2023, 76, 101296. [Google Scholar] [CrossRef]

- Montoya, J.; Valdés, C.; Chaquea, H.; Pecha, M.B.; Chejne, F. Surplus electricity production and LCOE estimation in Colombian palm oil mills using empty fresh bunches (EFB) as fuel. Energy 2020, 202, 101296. [Google Scholar] [CrossRef]

- Dalimin, M. Renewable energy update: Malaysia. Renew. Energy 1995, 6, 435–439. [Google Scholar] [CrossRef]

- Nabila, R.; Hidayat, W.; Haryanto, A.; Hasanudin, U.; Iryani, D.A.; Lee, S.; Kim, S.; Kim, S.; Chun, D.; Choi, H.; et al. Oil palm biomass in Indonesia: Thermochemical upgrading and its utilization. Renew. Sustain. Energy Rev. 2023, 176, 113193. [Google Scholar] [CrossRef]

- Abdulrazik, A.; Elsholkami, M.; Elkamel, A.; Simon, L. Multi-products productions from Malaysian oil palm empty fruit bunch (EFB): Analyzing economic potentials from the optimal biomass supply chain. J. Clean. Prod. 2017, 168, 131–148. [Google Scholar] [CrossRef]

- Rhofita, E.I.; Rachmat, R.; Meyer, M.; Montastruc, L. Mapping analysis of biomass residue valorization as the future green energy generation in Indonesia. J. Clean. Prod. 2022, 354, 131667. [Google Scholar] [CrossRef]

- Chang, G.; Shi, P.; Guo, Y.; Wang, L.; Wang, C. Enhanced pyrolysis of palm kernel shell wastes to bio-based chemicals and syngas using red mud as an additive. J. Clean. Prod. 2020, 272, 122847. [Google Scholar] [CrossRef]

- Anvari, S.; Aguado, R.; Jurado, F.; Fendri, M.; Zaier, H.; Larbi, A.; Vera, D. Analysis of agricultural waste/byproduct biomass potential for bioenergy: The case of Tunisia. Energy Sustain. Dev. 2024, 78, 101367. [Google Scholar] [CrossRef]

- Fedepalma. La agroindustria de la palma de aceite en Colombia y en el mundo 2013–2017. In Anuario Estadístico—Statistical Yearbook; Fedepalma: Bogotá, Colombia, 2018. [Google Scholar]

- Fedepalma. Minianuario Estadístico 2024—Principales Cifras de la Agroindustria de la Palma de Aceite en Colombia; Fedepalma: Bogotá, Colombia, 2024. [Google Scholar]

- Piedrahita-Rodríguez, S.; Urrea, S.C.; García, D.A.E.; Ortiz-Sánchez, M.; Solarte-Toro, J.C.; Alzate, C.A.C. Life cycle assessment and potential geolocation of a multi-feedstock biorefinery: Integration of the avocado and plantain value chains in rural zones. Bioresour. Technol. Rep. 2023, 21, 101318. [Google Scholar] [CrossRef]

- Mintransporte, Sistema de Información de Costos Eficientes Para el Transporte Automotor de Carga SICE-TAC—Ministerio de Transporte de Colombia. 2023. Available online: https://plc.mintransporte.gov.co/runtime/empresa/ctl/sicetac/mid/417 (accessed on 28 July 2023).

| Companies | FFB in t/h | Generated Biomass in t/h | Required Steam Flow in t/h | Energy Flow Steam in kcal·h−1 | Required Energy Flow in kcal·h−1 | Required Biomass in t/h | Available Biomass in t/h | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EFB | Kernel Shell | Fiber | Subtotal | EFB | Kernel Shell | Fiber | Subtotal | EFB | Kernel Shell | Fiber | Subtotal | |||||

| A | 37.09 | 8.55 | 2.85 | 5.29 | 16.69 | 19 | 11,868,293 | 13,962,697 | - | 1.16 | 2.09 | 3.26 | 8.55 | 1.69 | 3.20 | 13.43 |

| B | 38.20 | 8.81 | 2.94 | 5.45 | 17.19 | 19 | 12,224,975 | 14,382,323 | - | 1.20 | 2.16 | 3.36 | 8.81 | 1.74 | 3.29 | 13.84 |

| C | 35.36 | 8.15 | 2.72 | 5.04 | 15.91 | 18 | 11,314,338 | 13,310,985 | - | 1.11 | 2.00 | 3.11 | 8.15 | 1.61 | 3.05 | 12.80 |

| D | 19.49 | 4.49 | 1.50 | 2.78 | 8.77 | 10 | 6,236,075 | 7,336,559 | - | 0.61 | 1.10 | 1.71 | 4.49 | 0.89 | 1.68 | 7.06 |

| E | 53.42 | 12.31 | 4.10 | 7.62 | 24.04 | 27 | 17,093,335 | 20,109,806 | - | 1.68 | 3.02 | 4.69 | 12.31 | 2.43 | 4.61 | 19.35 |

| F | 33.96 | 7.83 | 2.61 | 4.85 | 15.28 | 17 | 10,867,408 | 12,785,186 | - | 1.07 | 1.92 | 2.98 | 7.83 | 1.54 | 2.93 | 12.30 |

| G | 29.68 | 6.84 | 2.28 | 4.23 | 13.36 | 15 | 9,496,956 | 11,172,890 | - | 0.93 | 1.68 | 2.61 | 6.84 | 1.35 | 2.56 | 10.75 |

| H | 9.67 | 2.23 | 0.74 | 1.38 | 4.35 | 5 | 3,095,574 | 3,641,851 | - | 0.30 | 0.55 | 0.85 | 2.23 | 0.44 | 0.83 | 3.50 |

| I | 5.55 | 1.28 | 0.43 | 0.79 | 2.50 | 3 | 1,774,754 | 2,087,946 | - | 0.17 | 0.31 | 0.49 | 1.28 | 0.25 | 0.48 | 2.01 |

| J | 13.44 | 3.10 | 1.03 | 1.92 | 6.05 | 7 | 4,300,436 | 5,059,337 | - | 0.42 | 0.76 | 1.18 | 3.10 | 0.61 | 1.16 | 4.87 |

| K | 69.87 | 16.11 | 5.37 | 9.97 | 31.44 | 35 | 22,359,905 | 26,305,771 | - | 2.19 | 3.95 | 6.14 | 16.11 | 3.18 | 6.02 | 25.31 |

| L | 4.65 | 1.07 | 0.36 | 0.66 | 2.09 | 2 | 1,487,398 | 1,749,881 | - | 0.15 | 0.26 | 0.41 | 1.07 | 0.21 | 0.40 | 1.68 |

| M | 32.58 | 7.51 | 2.50 | 4.65 | 14.66 | 16 | 10,424,702 | 12,264,356 | - | 1.02 | 1.84 | 2.86 | 7.51 | 1.48 | 2.81 | 11.80 |

| N | 9.72 | 2.24 | 0.75 | 1.39 | 4.38 | 5 | 3,111,267 | 3,660,314 | - | 0.31 | 0.55 | 0.85 | 2.24 | 0.44 | 0.84 | 3.52 |

| O | 15.33 | 3.53 | 1.18 | 2.19 | 6.90 | 8 | 4,904,517 | 5,770,020 | - | 0.48 | 0.87 | 1.35 | 3.53 | 0.70 | 1.32 | 5.55 |

| Total | 408 | 94.04 | 31.35 | 58.21 | 183.60 | 204 | 130,559,935 | 153,599,923 | - | 12.80 | 23.04 | 35.84 | 94.04 | 18.55 | 35.27 | 147.76 |

| Companies | FFB in t/h | Generated Biomass in t/h | Required Steam Flow in t/h | Energy Flow Steam in kcal·h−1 | Required Energy Flow in kcal·h−1 | Required Biomass in t/h | Available Biomass in t/h | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EFB | Kernel Shell | Fiber | Subtotal | EFB | Kernel Shell | Fiber | Subtotal | EFB | Kernel Shell | Fiber | Subtotal | |||||

| A | 43.33 | 9.99 | 3.33 | 6.18 | 19.50 | 22 | 13,866,545 | 16,313,582 | - | 1.36 | 2.45 | 3.81 | 9.99 | 1.97 | 3.74 | 15.69 |

| B | 45.84 | 10.57 | 3.52 | 6.54 | 20.63 | 23 | 14,669,674 | 17,258,440 | - | 1.44 | 2.59 | 4.03 | 10.57 | 2.08 | 3.95 | 16.60 |

| C | 32.63 | 7.52 | 2.51 | 4.66 | 14.68 | 16 | 10,440,561 | 12,283,013 | - | 1.02 | 1.84 | 2.87 | 7.52 | 1.48 | 2.81 | 11.82 |

| D | 28.89 | 6.66 | 2.22 | 4.12 | 13.00 | 14 | 9,245,566 | 10,877,137 | - | 0.91 | 1.63 | 2.54 | 6.66 | 1.31 | 2.49 | 10.46 |

| E | 90.87 | 20.95 | 6.98 | 12.97 | 40.89 | 45 | 29,079,870 | 34,211,612 | - | 2.85 | 5.13 | 7.98 | 20.95 | 4.13 | 7.83 | 32.91 |

| F | 24.85 | 5.73 | 1.91 | 3.55 | 11.18 | 12 | 7,950,885 | 9,353,982 | - | 0.78 | 1.40 | 2.18 | 5.73 | 1.13 | 2.14 | 9.00 |

| G | 56.68 | 13.06 | 4.35 | 8.09 | 25.51 | 28 | 18,138,396 | 21,339,290 | - | 1.78 | 3.20 | 4.98 | 13.06 | 2.58 | 4.89 | 20.53 |

| H | 80.85 | 18.63 | 6.21 | 11.54 | 36.38 | 40 | 25,871,076 | 30,436,560 | - | 2.54 | 4.57 | 7.10 | 18.63 | 3.68 | 6.97 | 29.28 |

| I | 31.88 | 7.35 | 2.45 | 4.55 | 14.34 | 16 | 10,200,705 | 12,000,830 | - | 1.00 | 1.80 | 2.80 | 7.35 | 1.45 | 2.75 | 11.54 |

| J | 4.38 | 1.01 | 0.34 | 0.62 | 1.97 | 2 | 1,400,119 | 1,647,199 | - | 0.14 | 0.25 | 0.38 | 1.01 | 0.20 | 0.38 | 1.58 |

| K | 38.15 | 8.79 | 2.93 | 5.44 | 17.17 | 19 | 12,207,061 | 14,361,249 | - | 1.20 | 2.15 | 3.35 | 8.79 | 1.73 | 3.29 | 13.82 |

| L | 41.55 | 9.58 | 3.19 | 5.93 | 18.70 | 21 | 13,297,183 | 15,643,745 | - | 1.30 | 2.35 | 3.65 | 9.58 | 1.89 | 3.58 | 15.05 |

| M | 22.97 | 5.29 | 1.76 | 3.28 | 10.34 | 11 | 7,349,609 | 8,646,599 | - | 0.72 | 1.30 | 2.02 | 5.29 | 1.04 | 1.98 | 8.32 |

| N | 7.13 | 1.64 | 0.55 | 1.02 | 3.21 | 4 | 2,282,749 | 2,685,587 | - | 0.22 | 0.40 | 0.63 | 1.64 | 0.32 | 0.62 | 2.58 |

| Total | 550.00 | 126.77 | 42.26 | 78.48 | 247.5 | 275 | 176,000,000 | 207,058,824 | - | 17.25 | 31.06 | 48.31 | 126.77 | 25.00 | 47.42 | 199.19 |

| Companies | FFB in t/h | Generated Biomass in t/h | Required Steam Flow in t/h | Energy Flow Steam in kcal·h−1 | Required Energy Flow in kcal·h−1 | Required Biomass in t/h | Available Biomass in t/h | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EFB | Kernel Shell | Fiber | Subtotal | EFB | Kernel Shell | Fiber | Subtotal | EFB | Kernel Shell | Fiber | Subtotal | |||||

| A | 23.13 | 5.33 | 1.78 | 3.30 | 10.41 | 11.56 | 7,400,423 | 8,706,380 | - | 0.73 | 1.31 | 2.03 | 5.33 | 1.05 | 1.99 | 8.38 |

| B | 106.49 | 24.54 | 8.18 | 15.19 | 47.92 | 53.24 | 34,075,689 | 40,089,046 | - | 3.34 | 6.01 | 9.35 | 24.54 | 4.84 | 9.18 | 38.56 |

| C | 47.91 | 11.04 | 3.68 | 6.84 | 21.56 | 23.96 | 15,331,488 | 18,037,045 | - | 1.50 | 2.71 | 4.21 | 11.04 | 2.18 | 4.13 | 17.35 |

| D | 1.25 | 0.29 | 0.10 | 0.18 | 0.56 | 0.62 | 399,088 | 469,515 | - | 0.04 | 0.07 | 0.11 | 0.29 | 0.06 | 0.11 | 0.45 |

| E | 63.70 | 14.68 | 4.89 | 9.09 | 28.67 | 31.85 | 20,384,326 | 23,981,559 | - | 2.00 | 3.60 | 5.60 | 14.68 | 2.90 | 5.49 | 23.07 |

| F | 42.10 | 9.70 | 3.23 | 6.01 | 18.95 | 21.05 | 13,472,560 | 15,850,071 | - | 1.32 | 2.38 | 3.70 | 9.70 | 1.91 | 3.63 | 15.25 |

| G | 38.08 | 8.78 | 2.93 | 5.43 | 17.14 | 19.04 | 12,185,832 | 14,336,273 | - | 1.19 | 2.15 | 3.35 | 8.78 | 1.73 | 3.28 | 13.79 |

| H | 10.52 | 2.43 | 0.81 | 1.50 | 4.74 | 5.26 | 3,367,317 | 3,961,550 | - | 0.33 | 0.59 | 0.92 | 2.43 | 0.48 | 0.91 | 3.81 |

| I | 14.53 | 3.35 | 1.12 | 2.07 | 6.54 | 7.27 | 4,651,093 | 5,471,874 | - | 0.46 | 0.82 | 1.28 | 3.35 | 0.66 | 1.25 | 5.26 |

| J | 5.16 | 1.19 | 0.40 | 0.74 | 2.32 | 2.58 | 1,651,854 | 1,943,358 | - | 0.16 | 0.29 | 0.45 | 1.19 | 0.23 | 0.45 | 1.87 |

| K | 150.80 | 34.76 | 11.59 | 21.52 | 67.86 | 75.40 | 48,256,504 | 56,772,358 | - | 4.73 | 8.52 | 13.25 | 34.76 | 6.85 | 13.00 | 54.61 |

| L | 23.38 | 5.39 | 1.80 | 3.34 | 10.52 | 11.69 | 7,482,968 | 8,803,492 | - | 0.73 | 1.32 | 2.05 | 5.39 | 1.06 | 2.02 | 8.47 |

| M | 20.03 | 4.62 | 1.54 | 2.86 | 9.01 | 10.02 | 6,410,315 | 7,541,547 | - | 0.63 | 1.13 | 1.76 | 4.62 | 0.91 | 1.73 | 7.25 |

| N | 31.22 | 7.20 | 2.40 | 4.45 | 14.05 | 15.61 | 9,989,431 | 11,752,271 | - | 0.98 | 1.76 | 2.74 | 7.20 | 1.42 | 2.69 | 11.31 |

| O | 53.18 | 12.26 | 4.09 | 7.59 | 23.93 | 26.59 | 17,019,134 | 20,022,511 | - | 1.67 | 3.00 | 4.67 | 12.26 | 2.42 | 4.59 | 19.26 |

| P | 1.51 | 0.35 | 0.12 | 0.21 | 0.68 | 0.75 | 481,976 | 567,031 | - | 0.05 | 0.09 | 0.13 | 0.35 | 0.07 | 0.13 | 0.55 |

| Total | 633.00 | 145.90 | 48.63 | 90.32 | 284.85 | 316.50 | 202,560,000 | 238,305,882 | - | 19.86 | 35.75 | 55.60 | 145.90 | 28.77 | 54.57 | 229.25 |

| Groups | Companies | Distance (km) | Available Biomass (kt·year−1) | Available Biomass (kt·year−1·km−1) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| EFB | Kernel Shell | Fiber | Subtotal | EFB | Kernel Shell | Fiber | Subtotal | |||

| 1 | 10 | 120 | 269.44 | 53.14 | 100.78 | 423.37 | 2.25 | 0.44 | 0.84 | 3.53 |

| 2 | 4 | 90 | 134.41 | 26.51 | 50.28 | 211.2 | 1.49 | 0.29 | 0.56 | 2.35 |

| 3 | 4 | 129 | 232.32 | 45.82 | 86.9 | 365.04 | 1.8 | 0.36 | 0.67 | 2.83 |

| 4 | 9 | 108 | 313.02 | 61.73 | 117.08 | 491.83 | 2.9 | 0.57 | 1.08 | 4.55 |

| 5 | 10 | 160 | 445.31 | 87.82 | 166.57 | 699.7 | 2.78 | 0.55 | 1.04 | 4.37 |

| 6 | 6 | 115 | 363.7 | 71.73 | 136.04 | 571.47 | 3.16 | 0.62 | 1.18 | 4.97 |

| Total | 1758.21 | 346.75 | 657.65 | 2762.61 | 14.38 | 2.84 | 5.38 | 22.6 | ||

| Group 1 | Group 2 | Group 3 | Group 4 | Group 5 | Group 6 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Companies | Distance to Aracataca (km) | Companies | Distance to Codazzi (km) | Companies | Distance to San Martín (km) | Companies | Distance to P. Wilches (km) | Companies | Distance to Castilla (km) | Companies | Distance to Cabuyaru (km) |

| 1 | 58.5 | 1 | 9 | 1 | 90 | 1 | 24 | 1 | 23.7 | 1 | 50.8 |

| 2 | 20 | 2 | 13.3 | 2 | 25.7 | 2 | 18.2 | 2 | 23.7 | 2 | 60 |

| 3 | 15 | 3 | 90 | 3 | 51.4 | 3 | 7.3 | 3 | 49 | 3 | 33.4 |

| 4 | 20 | 4 | 21.1 | 4 | 51.4 | 4 | 40.8 | 4 | 45 | 4 | 25.7 |

| 5 | 39 | --- | --- | --- | --- | 5 | 10.5 | 5 | 53.5 | 5 | 121 |

| 6 | 5 | --- | --- | --- | --- | 6 | 63 | 6 | 65.4 | 6 | 103 |

| 7 | 5 | --- | --- | --- | --- | 7 | 49.6 | 7 | 50.5 | --- | --- |

| 8 | 8 | --- | --- | --- | --- | 8 | 17.2 | 8 | 64.1 | --- | --- |

| 9 | 80 | --- | --- | --- | --- | 9 | 20.3 | 9 | 56.4 | --- | --- |

| 10 | 123 | --- | --- | --- | --- | --- | --- | 10 | 25.7 | --- | --- |

| Group | Central Point (Municipality) | Available Biomass (kt·Year−1) | Cost of Available Biomass (USD·Year−1) | Transport Cost | ||

|---|---|---|---|---|---|---|

| USD·km−1 | USD·Year−1 | USD·t−1 | ||||

| 1 | Aracataca | 423.36 | 4,599,730 | 1.25 | 711,429 | 1.68 |

| 2 | Codazzi | 211.20 | 2,294,620 | 1.19 | 212,363 | 1.01 |

| 3 | San Martín | 365.04 | 3,966,042 | 1.67 | 1,145,035 | 3.14 |

| 4 | Puerto Wilches | 491.83 | 5,343,610 | 1.35 | 839,166 | 1.71 |

| 5 | Castilla La Nueva | 699.70 | 7,602,006 | 2.33 | 3,474,633 | 4.97 |

| 6 | Cabuyaro | 571.47 | 6,208,861 | 2.06 | 3,748,222 | 6.56 |

| Total | 2762.6 | 30,014,869 | 9.85 | 10,130,852 | 19.05 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alean, J.; Bastidas, M.; Boom-Cárcamo, E.; Maya, J.C.; Chejne, F.; Ramírez, S.; Nieto, D.; Ceballos, C.; Saurith, A.; Córdoba-Ramirez, M. Design of a Technical Decision-Making Strategy to Collect Biomass Waste from the Palm Oil Industry as a Renewable Energy Source: Case Study in Colombia. Environments 2025, 12, 165. https://doi.org/10.3390/environments12050165

Alean J, Bastidas M, Boom-Cárcamo E, Maya JC, Chejne F, Ramírez S, Nieto D, Ceballos C, Saurith A, Córdoba-Ramirez M. Design of a Technical Decision-Making Strategy to Collect Biomass Waste from the Palm Oil Industry as a Renewable Energy Source: Case Study in Colombia. Environments. 2025; 12(5):165. https://doi.org/10.3390/environments12050165

Chicago/Turabian StyleAlean, Jader, Marlon Bastidas, Efraín Boom-Cárcamo, Juan C. Maya, Farid Chejne, Say Ramírez, Diego Nieto, Carlos Ceballos, Adonis Saurith, and Marlon Córdoba-Ramirez. 2025. "Design of a Technical Decision-Making Strategy to Collect Biomass Waste from the Palm Oil Industry as a Renewable Energy Source: Case Study in Colombia" Environments 12, no. 5: 165. https://doi.org/10.3390/environments12050165

APA StyleAlean, J., Bastidas, M., Boom-Cárcamo, E., Maya, J. C., Chejne, F., Ramírez, S., Nieto, D., Ceballos, C., Saurith, A., & Córdoba-Ramirez, M. (2025). Design of a Technical Decision-Making Strategy to Collect Biomass Waste from the Palm Oil Industry as a Renewable Energy Source: Case Study in Colombia. Environments, 12(5), 165. https://doi.org/10.3390/environments12050165