Circular Supply Chain Management Assessment: A Systematic Literature Review

Abstract

1. Introduction

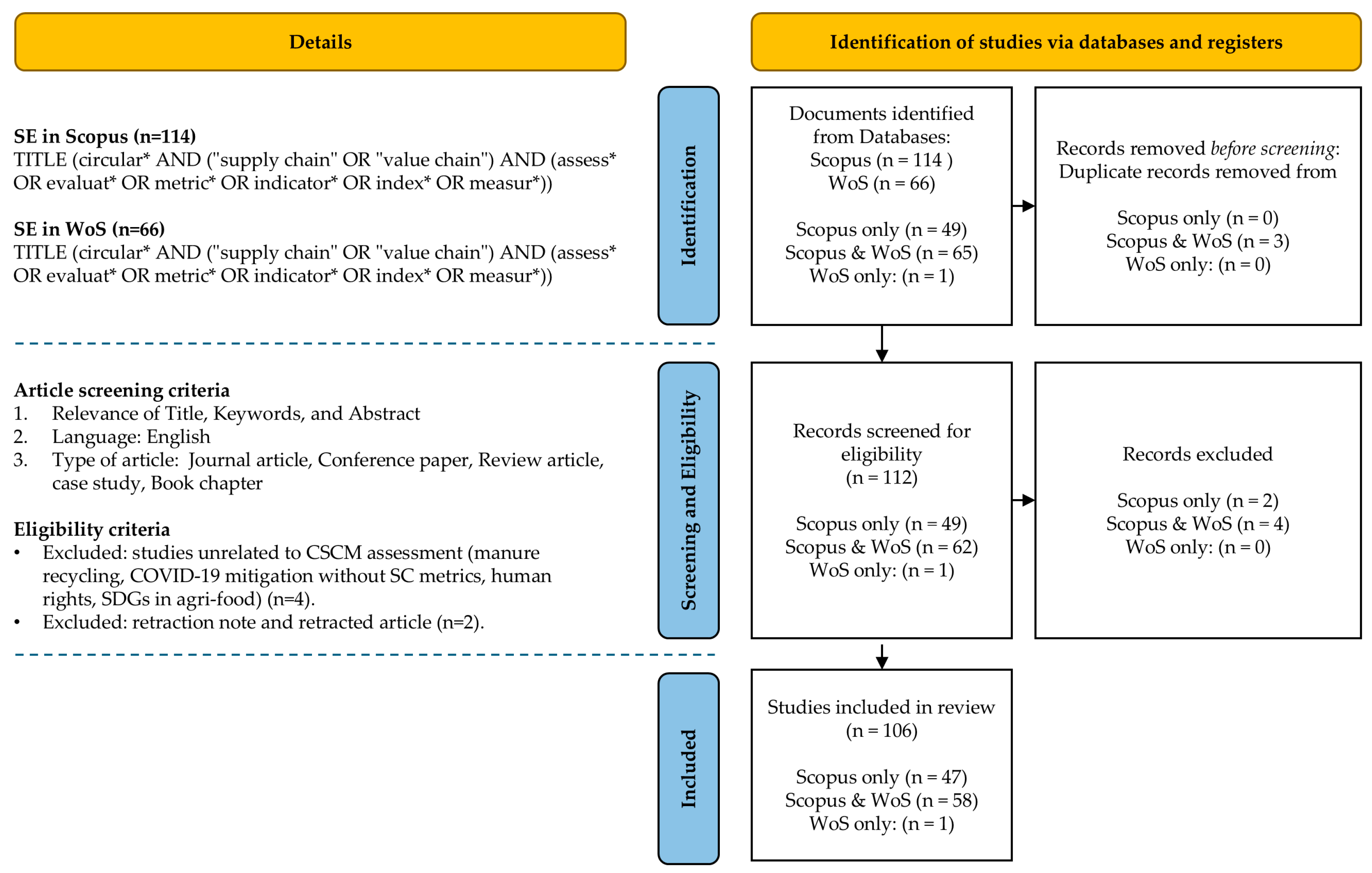

2. Methodology

2.1. Quantitative Analysis

2.2. Qualitative Analysis

3. Results

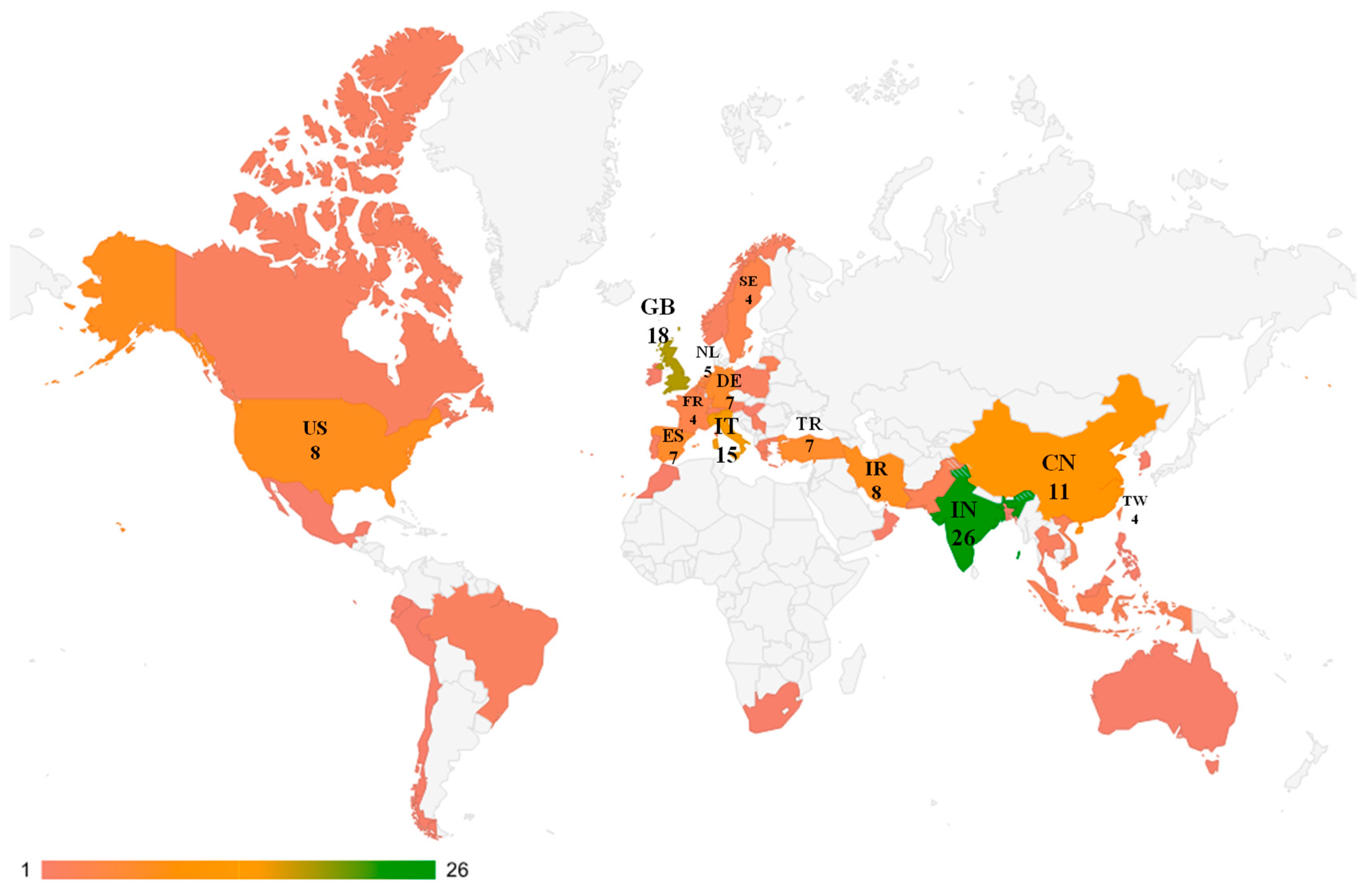

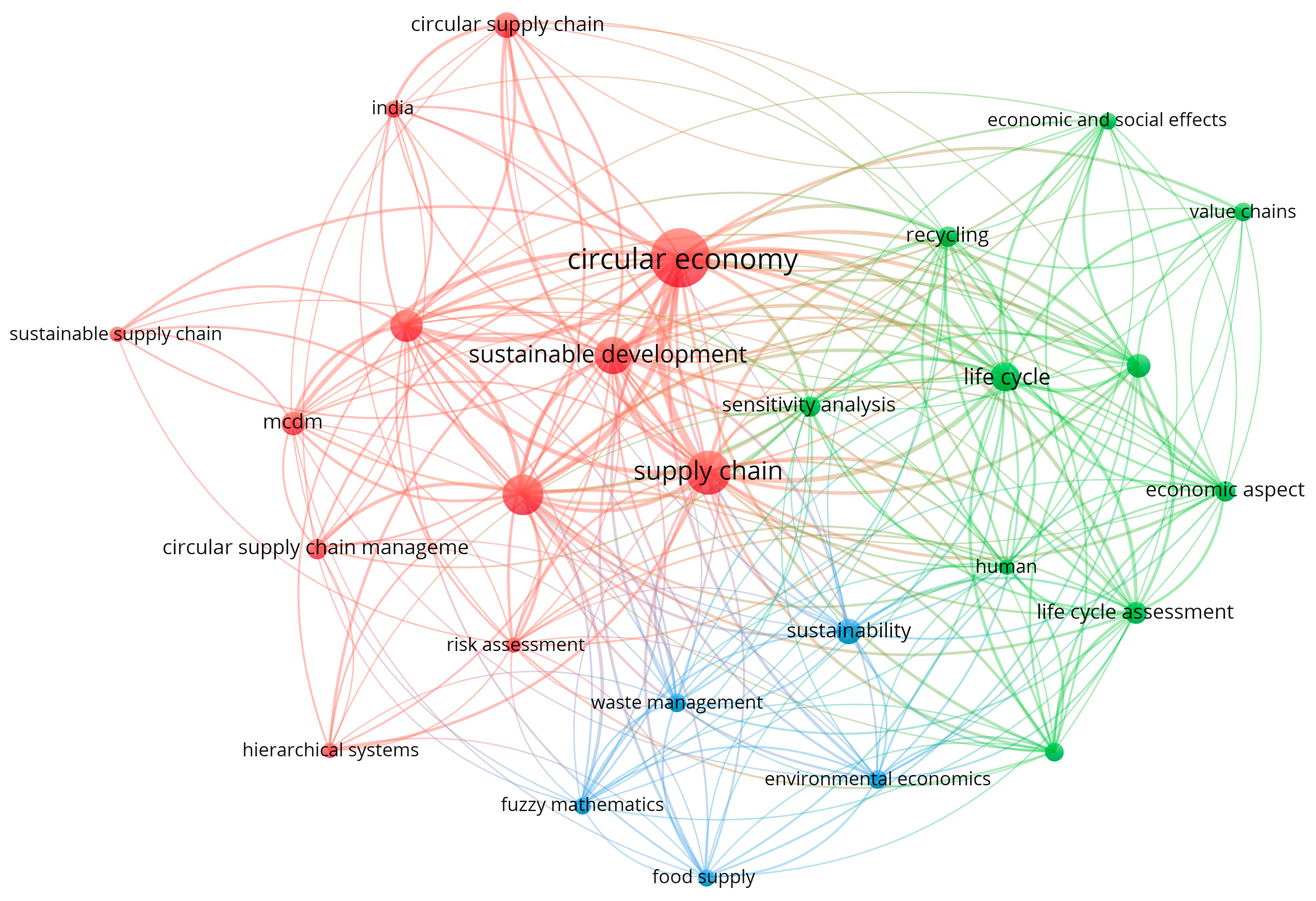

3.1. Bibliometric Analysis

3.2. Components of Assessment Approaches from the Literature Review

3.2.1. Assessment Frameworks

3.2.2. Methodologies for CSCM Assessment

3.2.3. CSCM Barriers and Risks

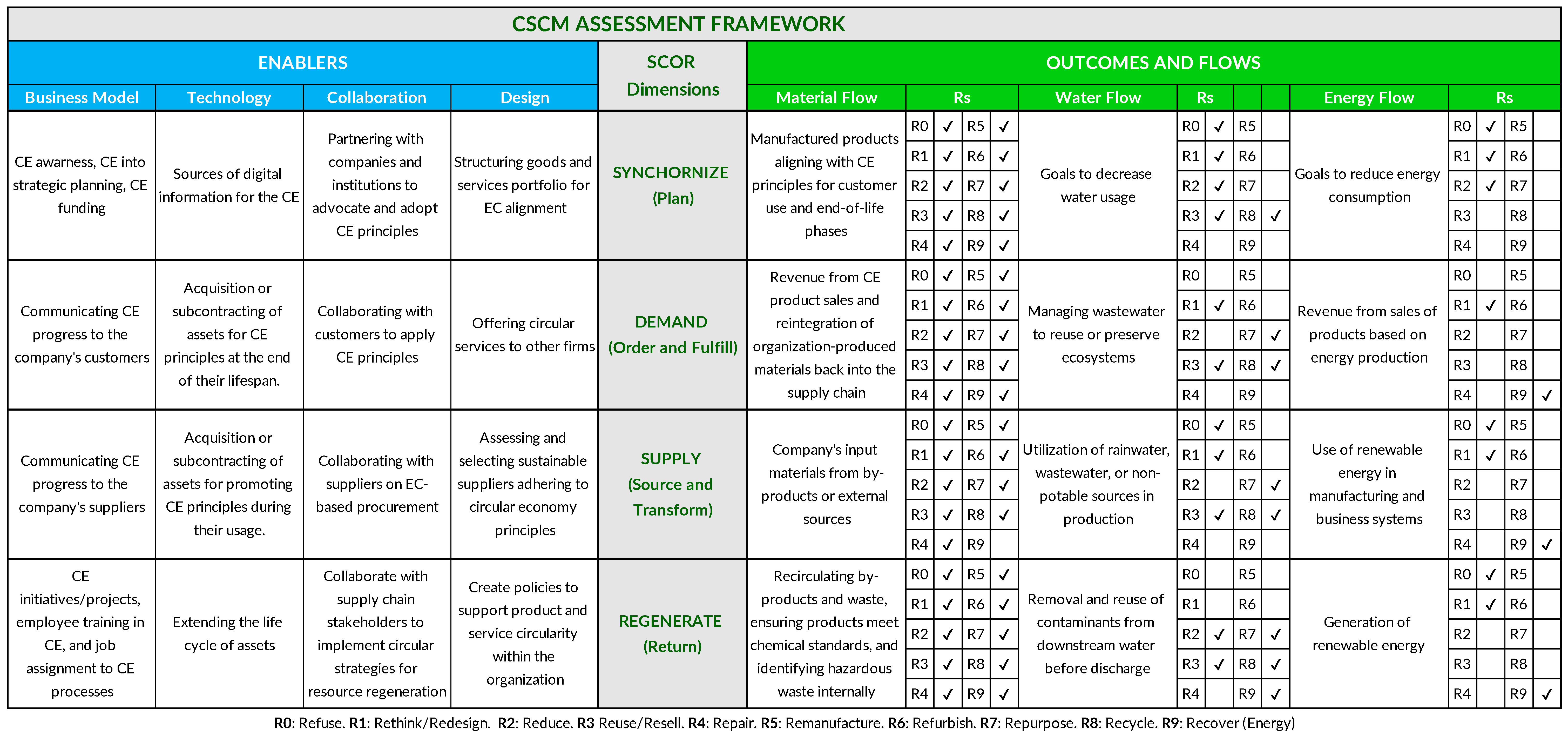

4. Proposed Model for CSCM Assessment

4.1. Enablers

4.1.1. Business Model

4.1.2. Technology

4.1.3. Collaboration

4.1.4. Design

4.2. Resources and Flows

4.3. Circular Economy Strategies

4.4. Proposal for a CSCM Assessment Framework

5. Discussion

Limitations of the Research

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CE | Circular Economy |

| CSCM | Circular Supply Chain Management |

| CSC | Circular Supply Chain |

| GHG | Greenhouse Gas |

| SDGs | Sustainable Development Goals |

| LCA | Life Cycle Assessment |

| SCOR | Supply Chain Operations Reference model |

| BSC | Balanced Scorecard |

| EMF | Ellen MacArthur Foundation |

| MCDM | Multi-Criteria Decision-Making |

| AHP | Analytic Hierarchy Process |

| DEMATEL | Decision-Making Trial and Evaluation Laboratory |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| WoS | Web of Science |

Appendix A

| Title | Document Type | Year | DataBase | Reference |

|---|---|---|---|---|

| A breakthrough in circular economy: Using a closed-loop framework to assess the circularity of supply chains | Article | 2024 | Scopus | [14] |

| A circular economy framework for the assessment of bio-based value chains | Article | 2024 | Scopus | [120] |

| A Classification Tool for Circular Supply Chain Indicators | Conference paper | 2021 | Scopus | [115] |

| A comprehensive framework for assessing circular economy strategies in agri-food supply chains | Article | 2025 | Scopus | [28] |

| A customized multi-cycle model for measuring the sustainability of circular pathways in agri-food supply chains | Article | 2022 | Scopus | [4] |

| A diverse, unbiased group decision-making framework for assessing drivers of the circular economy and resilience in an agri-food supply chain | Article | 2024 | Scopus and WoS | [103] |

| A first assessment of Hong Kong’s circular economy for wastepaper: Material flows, value chains and the role of the semi-formal informal recycling sector | Article | 2024 | Scopus | [31] |

| A framework to model the performance indicators of resilient construction supply chain: An effort toward attaining sustainability and circular practices | Article | 2024 | Scopus and WoS | [102] |

| A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case | Article | 2020 | Scopus and WoS | [22] |

| A multicriteria approach for assessing the maturity of supply chains regarding the implementation of circular economy practices in Brazil | Article | 2024 | Scopus | [100] |

| A multi-criteria assessment of barriers to low-carbon technology adoption for sustainable circular supply chain management: A pathway to sustainability achievement in the carbon trading era | Article | 2025 | Scopus and WoS | [95] |

| A new holistic conceptual framework for green supply chain management performance assessment based on circular economy | Article | 2018 | Scopus and WoS | [62] |

| A proposed circular-SCOR model for supply chain performance measurement in manufacturing industry during COVID-19 | Article | 2023 | Scopus and WoS | [40] |

| A self-assessment tool for evaluating the integration of circular economy and industry 4.0 principles in closed-loop supply chains | Article | 2022 | Scopus | [132] |

| A Systems Perspective on Social Indicators for Circular Supply Chains | Book chapter | 2023 | Scopus | [18] |

| Accounting for circular economy principles in Life Cycle Assessments of extra-virgin olive oil supply chains—Findings from a systematic literature review | Review | 2024 | Scopus | [34] |

| Additives in the food supply chain: Environmental assessment and circular economy implications | Article | 2022 | Scopus and WoS | [72] |

| Advancing the discourse: A next-generation value chain-based taxonomy for circular economy key performance indicators | Article | 2024 | Scopus and WoS | [117] |

| An AI Analysis on the Circular Economy Value Chain: A Portuguese Perspective of Evaluation Business Models | Book chapter | 2024 | Scopus | [107] |

| An integrated decision-making framework for evaluating Industry 5.0 and Circular Economy in supply chain management using Z-numbers | Article | 2025 | Scopus and WoS | [97] |

| An Integrated Fermatean Fuzzy Multi-attribute Evaluation of Digital Technologies for Circular Public Sector Supply Chains | Article | 2023 | Scopus | [82] |

| An investigation of the interrelationship among circular supply chain management indicators in small and medium enterprises | Article | 2024 | Scopus and WoS | [77] |

| Analyzing the circular supply chain management performance measurement framework: the modified balanced scorecard technique | Article | 2022 | Scopus and WoS | [32] |

| Analyzing the key performance indicators of circular supply chains by hybrid fuzzy cognitive mapping and Fuzzy DEMATEL: evidence from healthcare sector | Article | 2022 | Scopus | [83] |

| Assessing a Hierarchical Structure for Circular Supply Chain Management Performance: Improving Firms’ Eco-Innovation and Technological Performance | Article | 2025 | Scopus and WoS | [127] |

| Assessing Circular Economy Opportunities at the Food Supply Chain Level: The Case of Five Piedmont Product Chains | Article | 2022 | Scopus and WoS | [126] |

| Assessing circularity and sustainability of a value chain: A systematic literature review | Article | 2025 | Scopus and WoS | [20] |

| Assessing people-driven factors for circular economy practices in small and medium-sized enterprise supply chains: Business strategies and environmental perspectives | Article | 2021 | Scopus | [16] |

| Assessing smart circular supply chain readiness and maturity level of small and medium-sized enterprises | Article | 2022 | Scopus and WoS | [61] |

| Assessing the impact of digital transformation on green supply chain for achieving carbon neutrality and accelerating circular economy initiatives | Article | 2025 | Scopus and WoS | [122] |

| Assessing the Mitigation Potential of Environmental Impacts From Circular Economy Strategies on an Industrial Sector and Its Value Chain: A Case Study on the Steel Value Chain in Quebec | Article | 2021 | Scopus | [74] |

| Assessing the supply chain management of waste-to-energy on green circular economy in China: an empirical study | Article | 2023 | Scopus | [3] |

| Assessment of constraints in the European Union photovoltaics circular supply chain for enhanced circularity | Article | 2025 | Scopus and WoS | [101] |

| Assessment of green supply chain risk based on circular economy | Conference paper | 2010 | Scopus | [86] |

| Blockchain implementation for circular supply chain management: Evaluating critical success factors | Article | 2022 | Scopus and WoS | [92] |

| Circular Economy indicators for supply chains: A systematic literature review | Article | 2022 | Scopus | [13] |

| Circular economy strategies in supply chain management: an evaluation framework for airport operators | Article | 2025 | Scopus and WoS | [5] |

| Circular supply chain implementation performance measurement framework: a comparative case analysis | Article | 2023 | Scopus and WoS | [45] |

| Comparison of sustainability and circularity indicators: downstream vs. upstream supply chain strategies | Review | 2025 | Scopus and WoS | [130] |

| Constructing evaluation index system of agricultural products supply chain develop circular economic microeconomic organization in process stage | Conference paper | 2013 | Scopus | [21] |

| Data-driven life cycle assessment of the automobile industry in Indonesia: Identifying circular supply chain enablers | Article | 2025 | Scopus and WoS | [84] |

| Driving circular transformation: evaluating and enhancing enablers of circular supply chains | Article | 2025 | Scopus | [94] |

| Environmental and economic assessment of CO2-based value chains for a circular carbon use in consumer products | Article | 2022 | Scopus | [105] |

| Environmental assessment of the entire pork value chain in Catalonia—A strategy to work towards Circular Economy | Article | 2017 | Scopus and WoS | [64] |

| Evaluating and Prioritizing Circular Supply Chain Alternatives in the Energy Context with a Holistic Multi-Indicator Decision Support System | Article | 2024 | Scopus and WoS | [104] |

| Evaluating and ranking the circular supply chain implementation enablers | Article | 2021 | Scopus | [57] |

| Evaluating barriers and challenges of circular supply chains using a decision-making model based on rough sets | Article | 2022 | Scopus | [33] |

| Evaluating challenges of circular economy and Internet of Things in renewable energy supply chain through a hybrid decision-making framework | Article | 2024 | Scopus and WoS | [124] |

| Evaluating Circular Strategies for the Resilience of Agri-Food Business: Evidence From the Olive Oil Supply Chain | Article | 2025 | Scopus and WoS | [66] |

| Evaluating Emergy Analysis at the Nexus of Circular Economy and Sustainable Supply Chain Management | Review | 2021 | Scopus and WoS | [106] |

| Evaluating Nationwide Supply Chain for Circularity of PET and Olefin Plastics | Book chapter | 2024 | Scopus | [112] |

| Evaluating the adoption of circular economy practices in industrial supply chains: An empirical analysis | Article | 2020 | Scopus | [37] |

| Evaluating the Barriers of Circular Supply Chain Implementation Using Pythagorean Fuzzy DEMATEL Method | Conference paper | 2022 | Scopus | [56] |

| Evaluating the circular economy–based big data analytics capabilities of circular agri-food supply chains: the context of Turkey | Article | 2022 | Scopus | [121] |

| Evaluating the circular supply chain adoption in manufacturing sectors: A picture fuzzy approach | Article | 2022 | Scopus and WoS | [1] |

| Evaluating the circular supply chain implementation barriers using Pythagorean fuzzy AHP-DEMATEL approach | Article | 2021 | Scopus and WoS | [24] |

| Evaluation and ranking of solutions to mitigate circular supply chain risks | Article | 2021 | Scopus and WoS | [58] |

| Evaluation of barriers to circular supply chain implementations with the spherical fuzzy AHP method: A case study of battery industry | Article | 2025 | WoS | [87] |

| Evaluation of circular supply chains barriers in the era of Industry 4.0 transition using an extended decision-making approach | Article | 2022 | Scopus | [88] |

| Evaluation of the agri-food supply chain risks: the circular economy context | Article | 2023 | Scopus and WoS | [96] |

| Framework development and evaluation of Industry 4.0 technological aspects towards improving the circular economy-based supply chain | Article | 2022 | Scopus and WoS | [90] |

| Green Supply Chain Circular Economy Evaluation System Based on Industrial Internet of Things and Blockchain Technology under ESG Concept | Article | 2023 | Scopus and WoS | [123] |

| How circular is a value chain? Proposing a Material Efficiency Metric to evaluate business models | Article | 2022 | Scopus and WoS | [19] |

| How could a SME supplier’s value chain be evaluated by circular production principles? | Conference paper | 2022 | Scopus | [80] |

| Identification and evaluation of the contextual relationship among barriers to the circular supply chain in the Pakistani context–an interpretive structural modelling approach | Article | 2022 | Scopus and WoS | [23] |

| Impact of Circular Economy Indicators on the Lithium Supply Chain: A Case Study in Mexico | Article | 2025 | Scopus and WoS | [131] |

| Industry 5.0–Enabled Circular Supply Chain: Evaluating Barriers and Its Solutions | Article | 2025 | Scopus and WoS | [59] |

| Industry readiness measurement for circular supply chain implementation: an Irish dairy industry perspective | Article | 2024 | Scopus and WoS | [98] |

| Integrating BWM, ISM, and MICMAC: Key Performance Indicators for Circular-Ambidexterity Supply Chain Management in Palm Oil Industry | Article | 2025 | Scopus and WoS | [78] |

| Interpretive Structural Modelling Approach to Evaluate Knowledge Sharing Enablers in Circular Supply Chain: A Study of The Indian Manufacturing Sector | Article | 2024 | Scopus and WoS | [118] |

| Investigating the effect of circularity index on a closed loop supply chain with multi-shipment policy | Article | 2024 | Scopus and WoS | [108] |

| Key metrics to measure the performance and impact of reusable packaging in circular supply chains | Article | 2022 | Scopus | [25] |

| Leveraging Enablers and Performance Metrics for Building Industrial Circular Supply Chain: a Hybrid Multi-Criteria Decision-Making Approach | Article | 2025 | Scopus | [26] |

| Life cycle assessment of a circular textile value chain: the case of a garment made from chemically recycled cotton | Article | 2024 | Scopus and WoS | [69] |

| Life Cycle Assessment of Cleaner Concrete Supply Chains Through Decarbonisation and Circularity Scenarios | Conference paper | 2024 | Scopus | [68] |

| Linking methodologies to assess climate impacts and circular economy strategies along supply chains | Article | 2024 | Scopus | [73] |

| Markovian approach to evaluate circularity in supply chain of non ferrous metal industry | Article | 2023 | Scopus and WoS | [8] |

| Measuring circular supply chain risk: A bayesian network methodology | Article | 2021 | Scopus and WoS | [114] |

| Measuring circularity in food supply chain using life cycle assessment; refining oil from Olive Kernel | Article | 2021 | Scopus and WoS | [65] |

| Measuring the Performance of Circular Supply Chain Implementation Using Pythagorean Fuzzy DEMATEL Approach | Conference paper | 2023 | Scopus | [6] |

| Measuring the performance of more circular complex product supply chains | Article | 2020 | Scopus | [15] |

| Model of cluster green supply chain performance evaluation based on circular economy | Conference paper | 2009 | Scopus | [89] |

| Operationalizing sustainability in pharmaceuticals: Green supply chain metrics for circular economy | Article | 2025 | Scopus and WoS | [91] |

| Optimizing and evaluating the performance of integrated supply production centers: A hybrid heuristic-simulation applied to olive oil waste circular supply chains | Article | 2024 | Scopus | [145] |

| Performance assessment of circular driven sustainable agri-food supply chain towards achieving sustainable consumption and production | Article | 2022 | Scopus and WoS | [63] |

| Performance evaluation of reverse logistics in food supply chains in a circular economy using system dynamics | Article | 2021 | Scopus | [60] |

| Performance measurement system for circular supply chain management | Article | 2023 | Scopus and WoS | [7] |

| Performance measurement systems for circular supply chain management: Current state of development | Review | 2021 | Scopus and WoS | [17] |

| Prioritizing Performance Indicators for the Circular Economy Transition in Healthcare Supply Chains | Article | 2025 | Scopus | [93] |

| Prospective evaluation of circular economy practices within plastic packaging value chain through optimization of life cycle impacts and circularity | Article | 2021 | Scopus and WoS | [110] |

| Revisiting circular economy indicators: A circular supply chain perspective | Article | 2024 | Scopus and WoS | [29] |

| Risk assessment in lithium-ion battery circular economy in sustainable supply chain in automotive industry using gray degree of possibility in game theory and MCDM | Article | 2024 | Scopus and WoS | [85] |

| Risk assessment in sustainable supply chain: theoretical and managerial implications for circular economy in emerging economies | Article | 2024 | Scopus and WoS | [113] |

| Social life cycle assessment of product value chains under a circular economy approach: A case study in the plastic packaging sector | Article | 2020 | Scopus | [71] |

| Strategic framework towards measuring a circular supply chain management | Article | 2018 | Scopus and WoS | [27] |

| Sustainability and circularity assessment of biomass-based energy supply chain | Article | 2024 | Scopus | [70] |

| Sustainability assessment in circular inter-firm networks: An integrated framework of industrial ecology and circular supply chain management approaches | Review | 2021 | Scopus and WoS | [36] |

| Sustainability Assessment of Biomass Within Biofuel Supply Chain in Transport Sector Using Circular Economy Framework | Conference paper | 2023 | Scopus | [81] |

| Sustainable circular supplier evaluation in project-driven supply chains with a fuzzy stochastic decision model under uncertainty | Article | 2025 | Scopus | [99] |

| Techno-sustainable analysis of circular economy-indicators for corporate supply chains | Review | 2025 | Scopus | [30] |

| The adoption of circular economy practices in supply chains—An assessment of European Multi-National Enterprises | Article | 2021 | Scopus | [76] |

| The regenerative supply chain: a framework for developing circular economy indicators | Article | 2019 | Scopus and WoS | [9] |

| The role of performance measurement in assessing the contribution of circular economy to the sustainability of a wine value chain | Article | 2022 | Scopus and WoS | [10] |

| To shred or not to shred: A comparative techno-economic assessment of lithium ion battery hydrometallurgical recycling retaining value and improving circularity in LIB supply chains | Article | 2021 | Scopus | [111] |

| Towards circular economy in the agrifood sector: Water footprint assessment of food loss in the Italian fruit and vegetable supply chains | Article | 2022 | Scopus | [75] |

| What Gets Measured Gets Managed-Circular Economy Indicators for the Valorization of By-Products in the Olive Oil Supply Chain: A Systematic Review | Review | 2024 | Scopus and WoS | [75] |

References

- Saraji, M.K.; Streimikiene, D. Evaluating the circular supply chain adoption in manufacturing sectors: A picture fuzzy approach. Technol. Soc. 2022, 70, 102050. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Chen, T.; Arshad, I.; Iqbal, W. Assessing the supply chain management of waste-to-energy on green circular economy in China: An empirical study. Environ. Sci. Pollut. Res. 2023, 30, 100149–100164. [Google Scholar] [CrossRef]

- Stillitano, T.; Falcone, G.; Iofrida, N.; Spada, E.; Gulisano, G.; De Luca, A.I. A customized multi-cycle model for measuring the sustainability of circular pathways in agri-food supply chains. Sci. Total Environ. 2022, 844, 157229. [Google Scholar] [CrossRef]

- Sartzetaki, M.; Karampini, T.; Karagkouni, A.; Drimpetas, E.; Dimitriou, D. Circular economy strategies in supply chain management: An evaluation framework for airport operators. Front. Sustain. 2025, 6, 1558706. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. Measuring the Performance of Circular Supply Chain Implementation Using Pythagorean Fuzzy DEMATEL Approach. In Advanced Engineering Optimization Through Intelligent Techniques; Lecture Notes in Mechanical Engineering; Venkata Rao, R., Taler, J., Eds.; Springer: Singapore, 2023; pp. 287–303. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Performance measurement system for circular supply chain management. Sustain. Prod. Consum. 2023, 36, 171–183. [Google Scholar] [CrossRef]

- Chhimwal, M.; Agrawal, S.; Kumar, G. Markovian approach to evaluate circularity in supply chain of non ferrous metal industry. Resour. Policy 2023, 80, 103260. [Google Scholar] [CrossRef]

- Howard, M.; Hopkinson, P.; Miemczyk, J. The regenerative supply chain: A framework for developing circular economy indicators. Int. J. Prod. Res. 2019, 57, 7300–7318. [Google Scholar] [CrossRef]

- Cavicchi, C.; Vagnoni, E. The role of performance measurement in assessing the contribution of circular economy to the sustainability of a wine value chain. Br. Food J. 2022, 124, 1551–1568. [Google Scholar] [CrossRef]

- Rizos, V.; Tuokko, K.; Behrens, A. The Circular Economy: A Review of Definitions, Processes and Impacts; Centre for European Policy Studies: Brussels, Belgium, 2017. [Google Scholar]

- WBCSD. Vision 2050: Time to Transform; WBCSD: Geneva, Switzerland, 2021. [Google Scholar]

- Calzolari, T.; Genovese, A.; Brint, A. Circular Economy indicators for supply chains: A systematic literature review. Environ. Sustain. Indic. 2022, 13, 100160. [Google Scholar] [CrossRef]

- Shabanpour, H.; Dargusch, P.; Wadley, D.; Farzipoor Saen, R. A breakthrough in circular economy: Using a closed-loop framework to assess the circularity of supply chains. J. Clean. Prod. 2024, 444, 141265. [Google Scholar] [CrossRef]

- Bracquené, E.; Dewulf, W.; Duflou, J.R. Measuring the performance of more circular complex product supply chains. Resour. Conserv. Recycl. 2020, 154, 104608. [Google Scholar] [CrossRef]

- Sawe, F.B.; Kumar, A.; Garza-Reyes, J.A.; Agrawal, R. Assessing people-driven factors for circular economy practices in small and medium-sized enterprise supply chains: Business strategies and environmental perspectives. Bus. Strateg. Environ. 2021, 30, 2951–2965. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Performance measurement systems for circular supply chain management: Current state of development. Sustainability 2021, 13, 12082. [Google Scholar] [CrossRef]

- Hidalgo-Carvajal, D.; Picanço-Rodrigues, V.; Mejía-Argueta, C.; Salinas-Navarro, D.E. A Systems Perspective on Social Indicators for Circular Supply Chains. In The Social Dimensions of the Circular Economy. Greening of Industry Networks Studies; de Souza Campos, L.M., Vázquez-Brust, D.A., Eds.; Springer: Cham, Switzerland, 2023; Volume 10, pp. 27–52. [Google Scholar]

- Brändström, J.; Eriksson, O. How circular is a value chain? Proposing a Material Efficiency Metric to evaluate business models. J. Clean. Prod. 2022, 342, 130973. [Google Scholar] [CrossRef]

- Esteban-Amaro, R.; Estelles-Miguel, S.; Lengua, I.; Yannou, B.; Bouillass, G. Assessing circularity and sustainability of a value chain: A systematic literature review. Bus. Strateg. Environ. 2025, 34, 634–647. [Google Scholar] [CrossRef]

- Gao, Y.; Leng, Z. Constructing evaluation index system of agricultural products supply chain develop circular economic microeconomic organization in process stage. In Proceedings of the 6th International Conference on Information Management, Innovation Management and Industrial Engineering, Xi’an, China, 23–24 November 2013; Volume 2, pp. 196–199. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Shaikh, A.R.; Qazi, A.A.; Appolloni, A. Identification and evaluation of the contextual relationship among barriers to the circular supply chain in the Pakistani context—An interpretive structural modelling approach. Prod. Plan. Control 2022, 35, 1148–1163. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. Evaluating the circular supply chain implementation barriers using Pythagorean fuzzy AHP-DEMATEL approach. Clean. Logist. Supply Chain 2021, 2, 100014. [Google Scholar] [CrossRef]

- Betts, K.; Gutierrez-Franco, E.; Ponce-Cueto, E. Key metrics to measure the performance and impact of reusable packaging in circular supply chains. Front. Sustain. 2022, 3, 910215. [Google Scholar] [CrossRef]

- Vyas, M.; Yadav, G. Leveraging Enablers and Performance Metrics for Building Industrial Circular Supply Chain: A Hybrid Multi-Criteria Decision-Making Approach. Circ. Econ. Sustain. 2025, 5, 209–230. [Google Scholar] [CrossRef]

- Jain, S.; Jain, N.K.; Metri, B. Strategic framework towards measuring a circular supply chain management. Benchmarking Int. J. 2018, 25, 3238–3252. [Google Scholar] [CrossRef]

- Veloso, V.; Santos, A.; Carvalho, A.; Barbosa-Póvoa, A. A comprehensive framework for assessing circular economy strategies in agri-food supply chains. Environ. Dev. Sustain. 2025. [Google Scholar] [CrossRef]

- Lee, S.Y.; Hu, J.; Lim, M.K. Revisiting circular economy indicators: A circular supply chain perspective. J. Purch. Supply Manag. 2024, 30, 100941. [Google Scholar] [CrossRef]

- Halter, F.; Wietschel, L.; Thorenz, A.; Tuma, A. Techno-sustainable analysis of circular economy-indicators for corporate supply chains. J. Clean. Prod. 2025, 503, 145078. [Google Scholar] [CrossRef]

- Chen, P.; Steuer, B. A first assessment of Hong Kong’s circular economy for wastepaper: Material flows, value chains and the role of the semi-formal informal recycling sector. J. Clean. Prod. 2024, 450, 141939. [Google Scholar] [CrossRef]

- Saroha, M.; Garg, D.; Luthra, S. Analyzing the circular supply chain management performance measurement framework: The modified balanced scorecard technique. Int. J. Syst. Assur. Eng. Manag. 2022, 13, 951–960. [Google Scholar] [CrossRef]

- Amiri, M.; Hashemi-Tabatabaei, M.; Ghahremanloo, M.; Keshavarz-Ghorabaee, M.; Zavadskas, E.K.; Salimi-Zavieh, S.G. Evaluating barriers and challenges of circular supply chains using a decision-making model based on rough sets. Int. J. Environ. Sci. Technol. 2022, 19, 7275–7296. [Google Scholar] [CrossRef]

- Cinardi, G.; D’Urso, P.R.; Arcidiacono, C.; Ingrao, C. Accounting for circular economy principles in Life Cycle Assessments of extra-virgin olive oil supply chains—Findings from a systematic literature review. Sci. Total Environ. 2024, 945, 173977. [Google Scholar] [CrossRef]

- Batista, L.; Bourlakis, M.; Smart, P.; Maull, R. In search of a circular supply chain archetype—A content-analysis-based literature review. Prod. Plan. Control 2018, 29, 438–451. [Google Scholar] [CrossRef]

- Walker, A.M.; Vermeulen, W.J.V.; Simboli, A.; Raggi, A. Sustainability assessment in circular inter-firm networks: An integrated framework of industrial ecology and circular supply chain management approaches. J. Clean. Prod. 2021, 286, 125457. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Evaluating the adoption of circular economy practices in industrial supply chains: An empirical analysis. J. Clean. Prod. 2020, 273, 122966. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Publishers: The Hague, The Netherlands, 2017. [Google Scholar]

- Ozbiltekin-Pala, M.; Koçak, A.; Kazancoglu, Y. A proposed circular-SCOR model for supply chain performance measurement in manufacturing industry during COVID-19. Int. J. Qual. Reliab. Manag. 2023, 40, 1203–1232. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Carissimi, M.C.; Creazza, A.; Fontanella Pisa, M.; Urbinati, A. Circular Economy practices enabling Circular Supply Chains: An empirical analysis of 100 SMEs in Italy. Resour. Conserv. Recycl. 2023, 198, 107126. [Google Scholar] [CrossRef]

- Mangla, S.K.; Luthra, S.; Mishra, N.; Singh, A.; Rana, N.P.; Dora, M.; Dwivedi, Y. Barriers to effective circular supply chain management in a developing country context. Prod. Plan. Control 2018, 29, 551–569. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R. Circular supply chain management: A state-of-art review and future opportunities. J. Clean. Prod. 2020, 258, 120859. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R.; Patil, S.K. Circular supply chain implementation performance measurement framework: A comparative case analysis. Prod. Plan. Control 2024, 35, 1332–1351. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, J.X.; Farooque, M.; Wang, Y. Multi-dimensional circular supply chain management: A comparative review of the state-of-the-art practices and research. Transp. Res. Part E 2021, 155, 102509. [Google Scholar] [CrossRef]

- Chrispim, M.C.; Mattsson, M.; Ulvenblad, P. The underrepresented key elements of Circular Economy: A critical review of assessment tools and a guide for action. Sustain. Prod. Consum. 2023, 35, 539–558. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. BMJ 2009, 339, 332–336. [Google Scholar] [CrossRef] [PubMed]

- Sarkis-Onofre, R.; Catalá-López, F.; Aromataris, E.; Lockwood, C. How to properly use the PRISMA Statement. Syst. Rev. 2021, 10, 117. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; Mckenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews Systematic reviews and Meta-Analyses. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: Explanation and elaboration. BMJ 2009, 339, b2700. [Google Scholar] [CrossRef]

- El Mohadab, M.; Bouikhalene, B.; Safi, S. Bibliometric method for mapping the state of the art of scientific production in COVID-19. Chaos Solitons Fractals 2020, 139, 110052. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Marc, W. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Mukherjee, D.; Marc, W.; Kumar, S.; Donthu, N. Guidelines for advancing theory and practice through bibliometric research. J. Bus. Res. 2022, 148, 101–115. [Google Scholar] [CrossRef]

- He, S.; Zhu, D.; Chen, Y.; Liu, X.; Chen, Y.; Wang, X. Application and problems of emergy evaluation: A systemic review based on bibliometric and content analysis methods. Ecol. Indic. 2020, 114, 106304. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. Evaluating the Barriers of Circular Supply Chain Implementation Using Pythagorean Fuzzy DEMATEL Method. In Recent Advances in Manufacturing Modelling and Optimization; Lecture Notes in Mechanical Engineering; Kumar, S., Ramkumar, J., Kyratsis, P., Eds.; Springer: Singapore, 2022. [Google Scholar]

- Lahane, S.; Prajapati, H.; Kant, R. Evaluating and ranking the circular supply chain implementation enablers. J. Eng. Res. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. Evaluation and ranking of solutions to mitigate circular supply chain risks. Sustain. Prod. Consum. 2021, 27, 753–773. [Google Scholar] [CrossRef]

- Majiwala, H.; Kant, R. Industry 5.0–Enabled Circular Supply Chain: Evaluating Barriers and Its Solutions. Bus. Strateg. Dev. 2025, 8, e70151. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ekinci, E.; Mangla, S.K.; Sezer, M.D.; Kayikci, Y. Performance evaluation of reverse logistics in food supply chains in a circular economy using system dynamics. Bus. Strateg. Environ. 2021, 30, 71–91. [Google Scholar] [CrossRef]

- Kayikci, Y.; Kazancoglu, Y.; Gozacan-Chase, N.; Lafci, C.; Batista, L. Assessing smart circular supply chain readiness and maturity level of small and medium-sized enterprises. J. Bus. Res. 2022, 149, 375–392. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, M.; Raut, R.D.; Mangla, S.K.; Choubey, V.K. Performance assessment of circular driven sustainable agri-food supply chain towards achieving sustainable consumption and production. J. Clean. Prod. 2022, 372, 133698. [Google Scholar] [CrossRef]

- Noya, I.; Aldea, X.; González-García, S.; Gasol, C.M.; Moreira, M.T.; Amores, M.J.; Marín, D.; Boschmonart-Rives, J. Environmental assessment of the entire pork value chain in Catalonia—A strategy to work towards Circular Economy. Sci. Total Environ. 2017, 589, 122–129. [Google Scholar] [CrossRef]

- Nikkhah, A.; Firouzi, S.; Dadaei, K.; Van Haute, S. Measuring circularity in food supply chain using life cycle assessment; refining oil from Olive Kernel. Foods 2021, 10, 590. [Google Scholar] [CrossRef]

- Spada, E.; Carlucci, D.; Cembalo, L.; Chinnici, G.; D’Amico, M.; Falcone, G.; Giannoccaro, G.; Gulisano, G.; Iofrida, N.; Stempfle, S.; et al. Evaluating Circular Strategies for the Resilience of Agri-Food Business: Evidence From the Olive Oil Supply Chain. Bus. Strateg. Environ. 2025, 34, 2748–2764. [Google Scholar] [CrossRef]

- Spina, D.; Carbone, R.; Pulvirenti, A.; Rizzo, M.; D’Amico, M.; Di Vita, G. What Gets Measured Gets Managed-Circular Economy Indicators for the Valorization of By-Products in the Olive Oil Supply Chain: A Systematic Review. Agronomy 2024, 14, 2879. [Google Scholar] [CrossRef]

- Josa, I.; Borrion, A. Life Cycle Assessment of Cleaner Concrete Supply Chains Through Decarbonisation and Circularity Scenarios. In Proceedings of the 4th fib International Conference on Concrete Sustainability (ICCS 2024), Guimarães, Portugal, 11–13 September 2024; Springer: Cham, Switzerland, 2024; Volume 574, pp. 209–216. [Google Scholar]

- Hammar, T.; Peñaloza, D.; Hanning, A.-C. Life cycle assessment of a circular textile value chain: The case of a garment made from chemically recycled cotton. Int. J. Life Cycle Assess. 2024, 29, 1880–1898. [Google Scholar] [CrossRef]

- Nguyen, T.Q.; Luu, L.Q.; Martínez-Ramón, N.; Longo, S.; Cellura, M.; Dufour, J. Sustainability and circularity assessment of biomass-based energy supply chain. Heliyon 2024, 10, e38557. [Google Scholar] [CrossRef] [PubMed]

- Reinales, D.; Zambrana-Vasquez, D.; Saez-De-Guinoa, A. Social life cycle assessment of product value chains under a circular economy approach: A case study in the plastic packaging sector. Sustainability 2020, 12, 6671. [Google Scholar] [CrossRef]

- Bimpizas-Pinis, M.; Santagata, R.; Kaiser, S.; Liu, Y.; Lyu, Y. Additives in the food supply chain: Environmental assessment and circular economy implications. Environ. Sustain. Indic. 2022, 14, 100172. [Google Scholar] [CrossRef]

- Lahcen, B.; Eyckmans, J.; Brusselaers, J. Linking methodologies to assess climate impacts and circular economy strategies along supply chains. Sustain. Prod. Consum. 2024, 47, 544–556. [Google Scholar] [CrossRef]

- Binet, F.; Saunier, F.; Margni, M. Assessing the Mitigation Potential of Environmental Impacts From Circular Economy Strategies on an Industrial Sector and Its Value Chain: A Case Study on the Steel Value Chain in Quebec. Front. Sustain. 2021, 2, 738890. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Coluccia, B.; Pacifico, A.M.; Miglietta, P.P. Towards circular economy in the agrifood sector: Water footprint assessment of food loss in the Italian fruit and vegetable supply chains. Ecol. Indic. 2022, 137, 108781. [Google Scholar] [CrossRef]

- Calzolari, T.; Genovese, A.; Brint, A. The adoption of circular economy practices in supply chains—An assessment of European Multi-National Enterprises. J. Clean. Prod. 2021, 312, 127616. [Google Scholar] [CrossRef]

- Primadasa, R.; Tauhida, D.; Christata, B.R.; Rozaq, I.A.; Alfarisi, S.; Masudin, I. An investigation of the interrelationship among circular supply chain management indicators in small and medium enterprises. Supply Chain Anal. 2024, 7, 100068. [Google Scholar] [CrossRef]

- Primadasa, R.; Tauhida, D.; Kusrini, E.; Mansur, A.; Masudin, I. Integrating BWM, ISM, and MICMAC: Key Performance Indicators for Circular-Ambidexterity Supply Chain Management in Palm Oil Industry. Process Integr. Optim. Sustain. 2025, 9, 1253–1275. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Supply chains in circular business models: Processes and performance objectives. Resour. Conserv. Recycl. 2020, 162, 105046. [Google Scholar] [CrossRef]

- Lindahl, E.; Kurdve, M.; Bellgran, M. How could a SME supplier’s value chain be evaluated by circular production principles? Procedia CIRP 2022, 105, 648–653. [Google Scholar] [CrossRef]

- Mohanty, R.; Balachandra, P.; Dasappa, S. Sustainability Assessment of Biomass Within Biofuel Supply Chain in Transport Sector Using Circular Economy Framework. In Proceedings of the 6th Conference of the Transportation Research Group of India (CTRG2021), Tiruchirappalli, India, 14–17 December 2021; Springer: Singapore, 2023; Volume 273, pp. 75–93. [Google Scholar] [CrossRef]

- Evangelista, S.S.; Aro, J.L.; Selerio, E.; Maturan, F.; Atibing, N.M.; Ocampo, L.; Pamucar, D. An Integrated Fermatean Fuzzy Multi-attribute Evaluation of Digital Technologies for Circular Public Sector Supply Chains. Int. J. Comput. Intell. Syst. 2023, 16, 122. [Google Scholar] [CrossRef]

- Dolatabad, A.H.; Mahdiraji, H.A.; Babgohari, A.Z.; Garza-Reyes, J.A.; Ai, A. Analyzing the key performance indicators of circular supply chains by hybrid fuzzy cognitive mapping and Fuzzy DEMATEL: Evidence from healthcare sector. Environ. Dev. Sustain. 2022, 27, 23345–23371. [Google Scholar] [CrossRef] [PubMed]

- Kurrahman, T.; Tsai, F.M.; Sethanan, K.; Lim, M.K.; Tseng, M.-L. Data-driven life cycle assessment of the automobile industry in Indonesia: Identifying circular supply chain enablers. Resour. Conserv. Recycl. 2025, 220, 108338. [Google Scholar] [CrossRef]

- Afroozi, M.A.; Gramifar, M.; Hazratifar, B.; Jowkar, S.; Razavian, S.B.; Keshvari, M.M.; Tabatabaei, S.A.; Sazegar, N.; Bojnourdi, E.Z. Risk assessment in lithium-ion battery circular economy in sustainable supply chain in automotive industry using gray degree of possibility in game theory and MCDM. Front. Appl. Math. Stat. 2024, 10, 1362200. [Google Scholar] [CrossRef]

- Yang, Z.-K.; Li, J. Assessment of green supply chain risk based on circular economy. In Proceedings of the 2010 IEEE 17Th International Conference on Industrial Engineering and Engineering Management, Xiamen, China, 29–31 October 2010; pp. 1276–1280. [Google Scholar]

- Bakkal, S.; Kabadayi, N. Evaluation of barriers to circular supply chain implementations with the spherical fuzzy AHP method: A case study of battery industry. J. Eng. Sci. 2025, 31, 17–36. [Google Scholar] [CrossRef]

- Shang, C.; Saeidi, P.; Goh, C.F. Evaluation of circular supply chains barriers in the era of Industry 4.0 transition using an extended decision-making approach. J. Enterp. Inf. Manag. 2022, 35, 1100–1128. [Google Scholar] [CrossRef]

- Xu, J. Model of cluster green supply chain performance evaluation based on circular economy. In Proceedings of the 2009 Second International Conference on Intelligent Computation Technology and Automation, Changsha, China, 10–11 October 2009; Volume 3, pp. 941–944. [Google Scholar] [CrossRef]

- Agarwal, S.; Tyagi, M.; Garg, R.K. Framework development and evaluation of Industry 4.0 technological aspects towards improving the circular economy-based supply chain. Ind. Rob. 2022, 49, 555–581. [Google Scholar] [CrossRef]

- Kharat, M.G.; Kapoor, S.; Parhi, S.; Kharat, M.G.; Pandey, S. Operationalizing sustainability in pharmaceuticals: Green supply chain metrics for circular economy. Sustain. Futur. 2025, 9, 100413. [Google Scholar] [CrossRef]

- Huang, L.; Zhen, L.; Wang, J.; Zhang, X. Blockchain implementation for circular supply chain management: Evaluating critical success factors. Ind. Mark. Manag. 2022, 102, 451–464. [Google Scholar] [CrossRef]

- Alfina, K.N.; Ratnayake, R.M.C.; Wibisono, D.; Basri, M.H.; Mulyono, N.B. Prioritizing Performance Indicators for the Circular Economy Transition in Healthcare Supply Chains. Circ. Econ. Sustain. 2025, 5, 231–276. [Google Scholar] [CrossRef]

- Yadav, S.; Singh, D. Driving circular transformation: Evaluating and enhancing enablers of circular supply chains. Int. J. Product. Perform. Manag. 2025, 74, 2004–2031. [Google Scholar] [CrossRef]

- Kharayat, T.S.; Gupta, H. A multi-criteria assessment of barriers to low-carbon technology adoption for sustainable circular supply chain management: A pathway to sustainability achievement in the carbon trading era. J. Clean. Prod. 2025, 490, 144722. [Google Scholar] [CrossRef]

- Krstić, M.; Elia, V.; Agnusdei, G.P.; De Leo, F.; Tadić, S.; Miglietta, P.P. Evaluation of the agri-food supply chain risks: The circular economy context. Br. Food J. 2024, 126, 113–133. [Google Scholar] [CrossRef]

- Hosseini Dehshiri, S.J. An integrated decision-making framework for evaluating Industry 5.0 and Circular Economy in supply chain management using Z-numbers. Appl. Soft Comput. 2025, 181, 113504. [Google Scholar] [CrossRef]

- McDaid, C.; Azadnia, A.H.; Onofrei, G.; Tirkolaee, E.B. Industry readiness measurement for circular supply chain implementation: An Irish dairy industry perspective. Ann. Oper. Res. 2024, 342, 477–522. [Google Scholar] [CrossRef]

- Dorfeshan, Y.; Jolai, F.; Mousavi, S.M. Sustainable circular supplier evaluation in project-driven supply chains with a fuzzy stochastic decision model under uncertainty. Appl. Soft Comput. 2025, 179, 113370. [Google Scholar] [CrossRef]

- Tietz Cazeri, G.; Sigahi, T.F.A.C.; Rampasso, I.S.; de Moraes, G.H.S.M.; Zanon, L.G.; de Oliveira Gavira, M.; Paulino Pires Eustachio, J.H.; Leal Filho, W.; Anholon, R. A multicriteria approach for assessing the maturity of supply chains regarding the implementation of circular economy practices in Brazil. Int. J. Sustain. Dev. World Ecol. 2024, 31, 611–625. [Google Scholar] [CrossRef]

- Radavičius, T.; Groesser, S.N.; Tvaronavičienė, M. Assessment of constraints in the European Union photovoltaics circular supply chain for enhanced circularity. J. Clean. Prod. 2025, 489, 144682. [Google Scholar] [CrossRef]

- Singh, A.; Dwivedi, A.; Agrawal, D.; Chauhan, A. A framework to model the performance indicators of resilient construction supply chain: An effort toward attaining sustainability and circular practices. Bus. Strateg. Environ. 2024, 33, 1688–1720. [Google Scholar] [CrossRef]

- Ramos, E.; Rabiee, M.; Tarei, P.K.; Chavez, M.; Coles, P.S. A diverse, unbiased group decision-making framework for assessing drivers of the circular economy and resilience in an agri-food supply chain. Prod. Plan. Control 2024, 36, 1453–1473. [Google Scholar] [CrossRef]

- Nguyen, T.Q.; Longo, S.; Cellura, M.; Luu, L.Q.; Bertoli, A.; Bua, L. Evaluating and Prioritizing Circular Supply Chain Alternatives in the Energy Context with a Holistic Multi-Indicator Decision Support System. Energies 2024, 17, 5179. [Google Scholar] [CrossRef]

- Kaiser, S.; Gold, S.; Bringezu, S. Environmental and economic assessment of CO2-based value chains for a circular carbon use in consumer products. Resour. Conserv. Recycl. 2022, 184, 106422. [Google Scholar] [CrossRef]

- Alkhuzaim, L.; Zhu, Q.; Sarkis, J. Evaluating Emergy Analysis at the Nexus of Circular Economy and Sustainable Supply Chain Management. Sustain. Prod. Consum. 2021, 25, 413–424. [Google Scholar] [CrossRef]

- Pego, A.; Lourenço, J. An AI Analysis on the Circular Economy Value Chain: A Portuguese Perspective of Evaluation Business Models. In Digital Sustainability: Inclusion and Transformation. ISPGAYA 2022, Vila Nova de Gaia, Portugal, 29–30 September 2022; Springer: Cham, Switzerland, 2024; Volume Part F3016, pp. 55–68. ISBN 2524342X. [Google Scholar]

- Hasan, A.; Kausar, A.; Jaggi, C.K. Investigating the effect of circularity index on a closed loop supply chain with multi-shipment policy. J. Clean. Prod. 2024, 470, 143368. [Google Scholar] [CrossRef]

- Rabta, B. An Economic Order Quantity inventory model for a product with a circular economy indicator. Comput. Ind. Eng. 2020, 140, 106215. [Google Scholar] [CrossRef]

- Karayılan, S.; Yılmaz, Ö.; Uysal, Ç.; Naneci, S. Prospective evaluation of circular economy practices within plastic packaging value chain through optimization of life cycle impacts and circularity. Resour. Conserv. Recycl. 2021, 173, 105691. [Google Scholar] [CrossRef]

- Thompson, D.; Hyde, C.; Hartley, J.M.; Abbott, A.P.; Anderson, P.A.; Harper, G.D.J. To shred or not to shred: A comparative techno-economic assessment of lithium ion battery hydrometallurgical recycling retaining value and improving circularity in LIB supply chains. Resour. Conserv. Recycl. 2021, 175, 105741. [Google Scholar] [CrossRef]

- Hossain, T.; Hartley, D.S.; Chaudhari, U.S.; Shonnard, D.R.; Johnson, A.T.; Lin, Y. Evaluating Nationwide Supply Chain for Circularity of PET and Olefin Plastics. In Technology Innovation for the Circular Economy: Recycling, Remanufacturing, Design, System Analysis and Logistics; Wiley: Idaho Falls, ID, USA, 2024; pp. 43–54. ISBN 978-139421429-7. [Google Scholar]

- Bathrinath, R.K.A.B.S.; Mithun, S.; Koppiahraj, A.K. Risk assessment in sustainable supply chain: Theoretical and managerial implications for circular economy in emerging economies. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 4966–4981. [Google Scholar] [CrossRef]

- Chhimwal, M.; Agrawal, S.; Kumar, G. Measuring circular supply chain risk: A bayesian network methodology. Sustainability 2021, 13, 8448. [Google Scholar] [CrossRef]

- Kurt, A.; Cortes-cornax, M.; Cung, V.; Mangione, F. A Classification Tool for Circular Supply Chain Indicators. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems; Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2021; pp. 644–653. ISBN 9783030859145. [Google Scholar]

- EMF. Circulytics: Weighting and Scoring Approach; Ellen MacArthur Foundation, Isle of Wight: Cowes, UK, 2022. [Google Scholar]

- Khedmati-Morasae, E.; Zils, M.; Hopkinson, P.; Nolan, R.; Charnley, F.; Okorie, O.; Abu-Bakar, H. Advancing the discourse: A next-generation value chain-based taxonomy for circular economy key performance indicators. Sustain. Prod. Consum. 2024, 48, 219–234. [Google Scholar] [CrossRef]

- Ganguly, A.; Farr, J. V Interpretive Structural Modelling Approach to Evaluate Knowledge Sharing Enablers in Circular Supply Chain: A Study of The Indian Manufacturing Sector. J. Inf. Knowl. Manag. 2024, 23, 2450076. [Google Scholar] [CrossRef]

- Bressanelli, G.; Pigosso, D.C.A.; Saccani, N.; Perona, M. Enablers, levers and benefits of Circular Economy in the Electrical and Electronic Equipment supply chain: A literature review. J. Clean. Prod. 2021, 298, 126819. [Google Scholar] [CrossRef]

- Tsakalova, M.; Onorato, C.; Karathanasis, A.Z.; Deligkiozi, I. A circular economy framework for the assessment of bio-based value chains. Sustain. Chem. Environ. 2024, 6, 100099. [Google Scholar] [CrossRef]

- Perçin, S. Evaluating the circular economy–based big data analytics capabilities of circular agri-food supply chains: The context of Turkey. Environ. Sci. Pollut. Res. 2022, 29, 83220–83233. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.; Chaudhuri, R.; Chatterjee, S. Assessing the impact of digital transformation on green supply chain for achieving carbon neutrality and accelerating circular economy initiatives. Comput. Ind. Eng. 2025, 201, 110943. [Google Scholar] [CrossRef]

- Qian, C.; Gao, Y.; Chen, L. Green Supply Chain Circular Economy Evaluation System Based on Industrial Internet of Things and Blockchain Technology under ESG Concept. Processes 2023, 11, 1999. [Google Scholar] [CrossRef]

- Hosseini Dehshiri, S.J.; Mostafaeipour, A.; Amiri, M. Evaluating challenges of circular economy and Internet of Things in renewable energy supply chain through a hybrid decision-making framework. J. Environ. Manag. 2024, 370, 122785. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-stenroos, L.; Väisänen, J. Digital technologies catalyzing business model innovation for circular economy—Multiple case study. Resour. Conserv. Recycl. 2021, 164, 105155. [Google Scholar] [CrossRef]

- Fassio, F.; Borda, I.E.P.; Talpo, E.; Savina, A.; Rovera, F.; Pieretto, O.; Zarri, D. Assessing Circular Economy Opportunities at the Food Supply Chain Level: The Case of Five Piedmont Product Chains. Sustainability 2022, 14, 10778. [Google Scholar] [CrossRef]

- Kurrahman, T.; Tsai, F.; Sethanan, K.; Chen, C.-C.; Tseng, M.-L. Assessing a Hierarchical Structure for Circular Supply Chain Management Performance: Improving Firms’ Eco-Innovation and Technological Performance. Bus. Strateg. Environ. 2025, 34, 2035–2064. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Almelhem, M.; Buics, L.; Süle, E. Comparison of sustainability and circularity indicators: Downstream vs. upstream supply chain strategies. Discov. Sustain. 2025, 6, 302. [Google Scholar] [CrossRef]

- Vega-Muratalla, V.O.; Serrano-Arévalo, T.I.; Ramírez-Márquez, C.; Lira-Barragán, L.F.; Ponce-Ortega, J.M. Impact of Circular Economy Indicators on the Lithium Supply Chain: A Case Study in Mexico. Ind. Eng. Chem. Res. 2025, 64, 11406–11427. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.S.; Chiappetta Jabbour, C.J.; Mani, V.; Khan, S.A.R.; Touriki, F.E. A self-assessment tool for evaluating the integration of circular economy and industry 4.0 principles in closed-loop supply chains. Int. J. Prod. Econ. 2022, 245, 108372. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. Int. J. Prod. Econ. 2022, 245, 108402. [Google Scholar] [CrossRef]

- Howard, M.; Yan, X.; Mustafee, N.; Charnley, F.; Böhm, S.; Pascucci, S. Going beyond waste reduction: Exploring tools and methods for circular economy adoption in small-medium enterprises. Resour. Conserv. Recycl. 2022, 182, 106345. [Google Scholar] [CrossRef]

- Torgautov, B.; Zhanabayev, A.; Tleuken, A.; Turkyilmaz, A.; Mustafa, M.; Karaca, F. Circular economy: Challenges and opportunities in the construction sector of Kazakhstan. Buildings 2021, 11, 501. [Google Scholar] [CrossRef]

- Iyer-Raniga, U. Using the ReSOLVE framework for circularity in the building and construction industry in emerging markets. IOP Conf. Ser. Earth Environ. Sci. 2019, 294, 012002. [Google Scholar] [CrossRef]

- MacArthur, D.E.; Zumwinkel, K.; Stuchtey, M.R. Growth Within: A Circular Economy Vision for a Competitive Europe; McKinsey & Company: New York, NY, USA, 2015. [Google Scholar]

- Uvarova, I.; Atstaja, D.; Volkova, T.; Grasis, J.; Ozolina-Ozola, I. The typology of 60R circular economy principles and strategic orientation of their application in business. J. Clean. Prod. 2023, 409, 137189. [Google Scholar] [CrossRef]

- Prochatzki, G.; Mayer, R.; Haenel, J.; Schmidt, A.; Götze, U.; Ulber, M.; Fischer, A.; Arnold, M.G. A critical review of the current state of circular economy in the automotive sector. J. Clean. Prod. 2023, 425, 138787. [Google Scholar] [CrossRef]

- Papamichael, I.; Chatziparaskeva, G.; Pedreño, J.N.; Voukkali, I.; Almendro Candel, M.B.; Zorpas, A.A. Building a new mind set in tomorrow fashion development through circular strategy models in the framework of waste management. Curr. Opin. Green Sustain. Chem. 2022, 36, 100638. [Google Scholar] [CrossRef]

- Papamichael, I.; Pappas, G.; Siegel, J.E.; Inglezakis, V.J.; Demetriou, G.; Zorpas, A.A.; Hadjisavvas, C. Metaverse and circular economy. Waste Manag. Res. 2023, 41, 1393–1398. [Google Scholar] [CrossRef]

- Zorpas, A.A. The hidden concept and the beauty of multiple “R” in the framework of waste strategies development reflecting to circular economy principles. Sci. Total Environ. 2024, 952, 175508. [Google Scholar] [CrossRef]

- Schneider, F.; Hansen, S.; Redeker, J.; Klose, G.I.; Rohwer, V.; Strube, M.; Mennenga, M.; Vietor, T.; Völkerink, O.; Krinke, S.; et al. Novel methodology for the selection and evaluation of R-strategies to support product design for circular economy. In Proceedings of the 6th Product Lifetimes and the Environment Conference (PLATE2025), Aalborg, Denmark, 2–4 July 2025; pp. 2–4. [Google Scholar] [CrossRef]

- Urciuoli, L.; Kougioumtzis, M.A.; Karampinis, E. Optimizing and evaluating the performance of integrated supply production centers: A hybrid heuristic-simulation applied to olive oil waste circular supply chains. J. Clean. Prod. 2024, 480, 144100. [Google Scholar] [CrossRef]

- ASCM. SCOR Digital Standard; ASCM: Chicago, IL, USA, 2022. [Google Scholar]

- ASCM. SCOR Digital Standard: Quick Reference Guide; ASCM: Chicago, IL, USA, 2023. [Google Scholar]

- Mahmoum Gonbadi, A.; Genovese, A.; Sgalambro, A. Closed-loop supply chain design for the transition towards a circular economy: A systematic literature review of methods, applications and current gaps. J. Clean. Prod. 2021, 323, 129101. [Google Scholar] [CrossRef]

| Journal | Publisher | Max Quartil (Scimago) | Docs. |

|---|---|---|---|

| Journal of Cleaner Production | Elsevier | Q1 | 14 |

| Business Strategy and the Environment | Wiley | Q1 | 6 |

| Resources, Conservation and Recycling | Elsevier | Q1 | 5 |

| Sustainable Production and Consumption | Elsevier | Q1 | 5 |

| Sustainability (Switzerland) | MDPI | Q1 | 4 |

| Frontiers in Sustainability | Frontiers Media | Q2 | 3 |

| Science of the Total Environment | Elsevier | Q1 | 3 |

| Production Planning and Control | Taylor and Francis | Q1 | 3 |

| Authors | Affiliation | Country | Documents in Databases | Total Docs. | |

|---|---|---|---|---|---|

| Scopus | Scopus and WoS | ||||

| Kant R. | S. V. National Institute of Technology | India | 3: [6,56,57] | 4: [24,45,58,59] | 7 |

| Lahane S. | S. V. National Institute of Technology | India | 3: [6,56,57] | 3: [24,45,58] | 6 |

| Kazancoglu Y. | Yaşar Universitesi | Turkey | 1: [60] | 3: [40,61,62] | 4 |

| Mangla S.K. | University of Plymouth O P Jindal Global University | United Kingdom India | 1: [60] | 2: [22,63] | 3 |

| Affiliation | Docs | % Docs * |

|---|---|---|

| S.V. National Institute of Technology (India) | 8 | 7.5% |

| University of Tehran (Iran) | 4 | 3.8% |

| Yaşar Üniversitesi (Turkey) | 4 | 3.8% |

| The University of Sheffield (United Kingdom) | 3 | 2.8% |

| Università degli Studi di Catania (Italy) | 3 | 2.8% |

| Università degli Studi di Palermo (Italy) | 3 | 2.8% |

| Università del Salento (Italy) | 3 | 2.8% |

| Allameh Tabataba’i University (Iran) | 3 | 2.8% |

| O.P. Jindal Global University (India) | 3 | 2.8% |

| Sheffield University Management School (United Kingdom) | 3 | 2.8% |

| CE Strategies | 3Rs | 4Rs | 6Rs | 8Rs | 9Rs | 10Rs | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [128] | [38] | [133] | [63] | [135] | [37] | [32] | [8] | [117] | [93] | [114] | [35] | [38] | [120] | [5] | [40] | [39] | [41] | [134] | |

| Refuse | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||||||||||

| Rethink/Redesign | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||||||||||

| Reduce | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Reuse/Resell | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Repair | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Refurbish | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Remanufacture | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Repurpose | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||||||||

| Recycle | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Recover | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||||

| Re-mine | ✔ | ✔ | ✔ | ✔ | |||||||||||||||

| Regenerate | ✔ | ||||||||||||||||||

| Reverse | ✔ | ||||||||||||||||||

| Renewable energy | ✔ | ||||||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano, J.A.; Londoño-Pineda, A.; Campo, E.A.; Gruchmann, T.; Weyers, S. Circular Supply Chain Management Assessment: A Systematic Literature Review. Environments 2025, 12, 374. https://doi.org/10.3390/environments12100374

Cano JA, Londoño-Pineda A, Campo EA, Gruchmann T, Weyers S. Circular Supply Chain Management Assessment: A Systematic Literature Review. Environments. 2025; 12(10):374. https://doi.org/10.3390/environments12100374

Chicago/Turabian StyleCano, Jose Alejandro, Abraham Londoño-Pineda, Emiro Antonio Campo, Tim Gruchmann, and Stephan Weyers. 2025. "Circular Supply Chain Management Assessment: A Systematic Literature Review" Environments 12, no. 10: 374. https://doi.org/10.3390/environments12100374

APA StyleCano, J. A., Londoño-Pineda, A., Campo, E. A., Gruchmann, T., & Weyers, S. (2025). Circular Supply Chain Management Assessment: A Systematic Literature Review. Environments, 12(10), 374. https://doi.org/10.3390/environments12100374