Conceptualisation of an Ecodesign Framework for Sustainable Food Product Development across the Supply Chain

Abstract

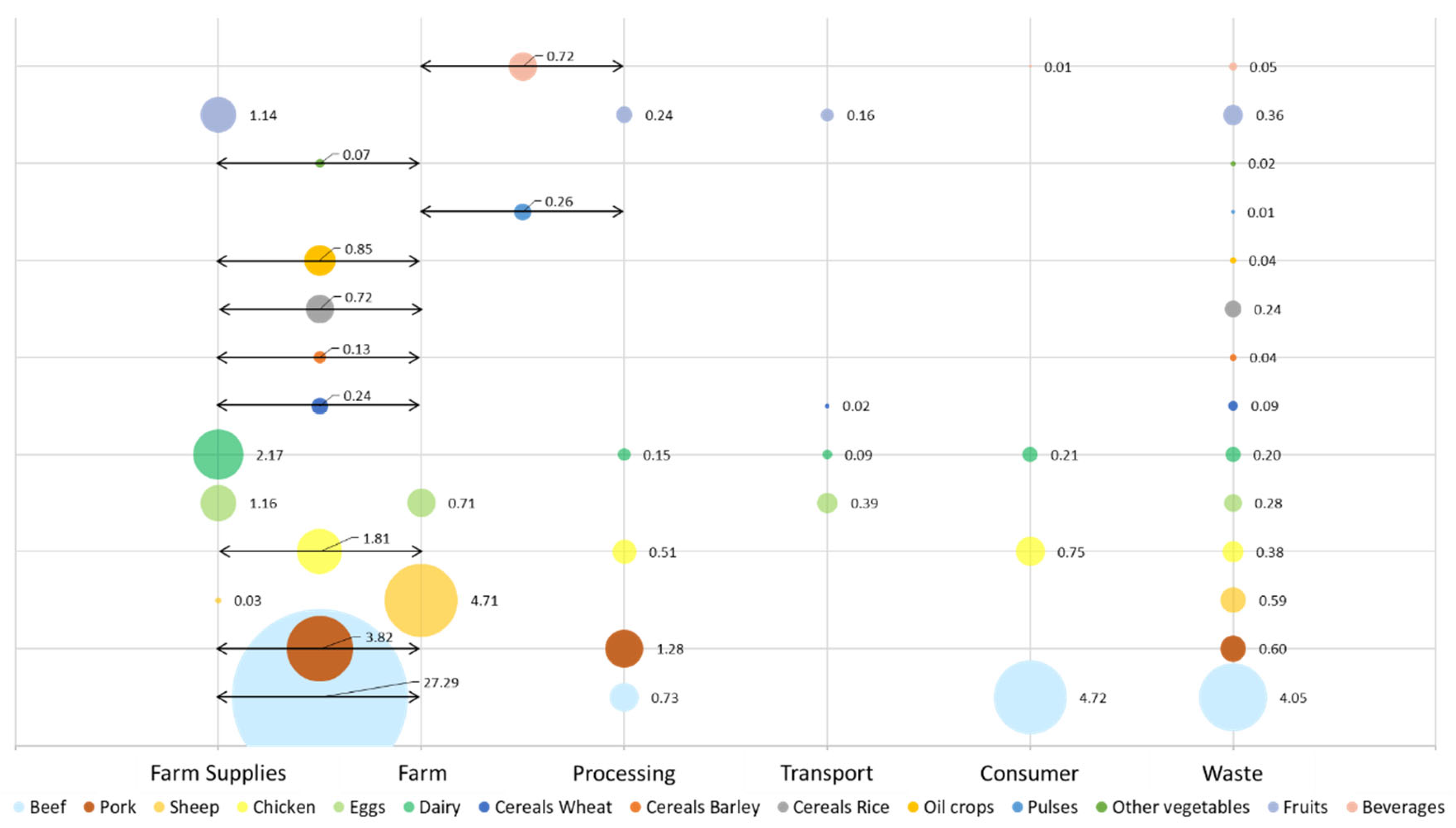

1. Introduction

2. Ecodesign Principles

2.1. Ecodesign Tools Applicable to Food Products

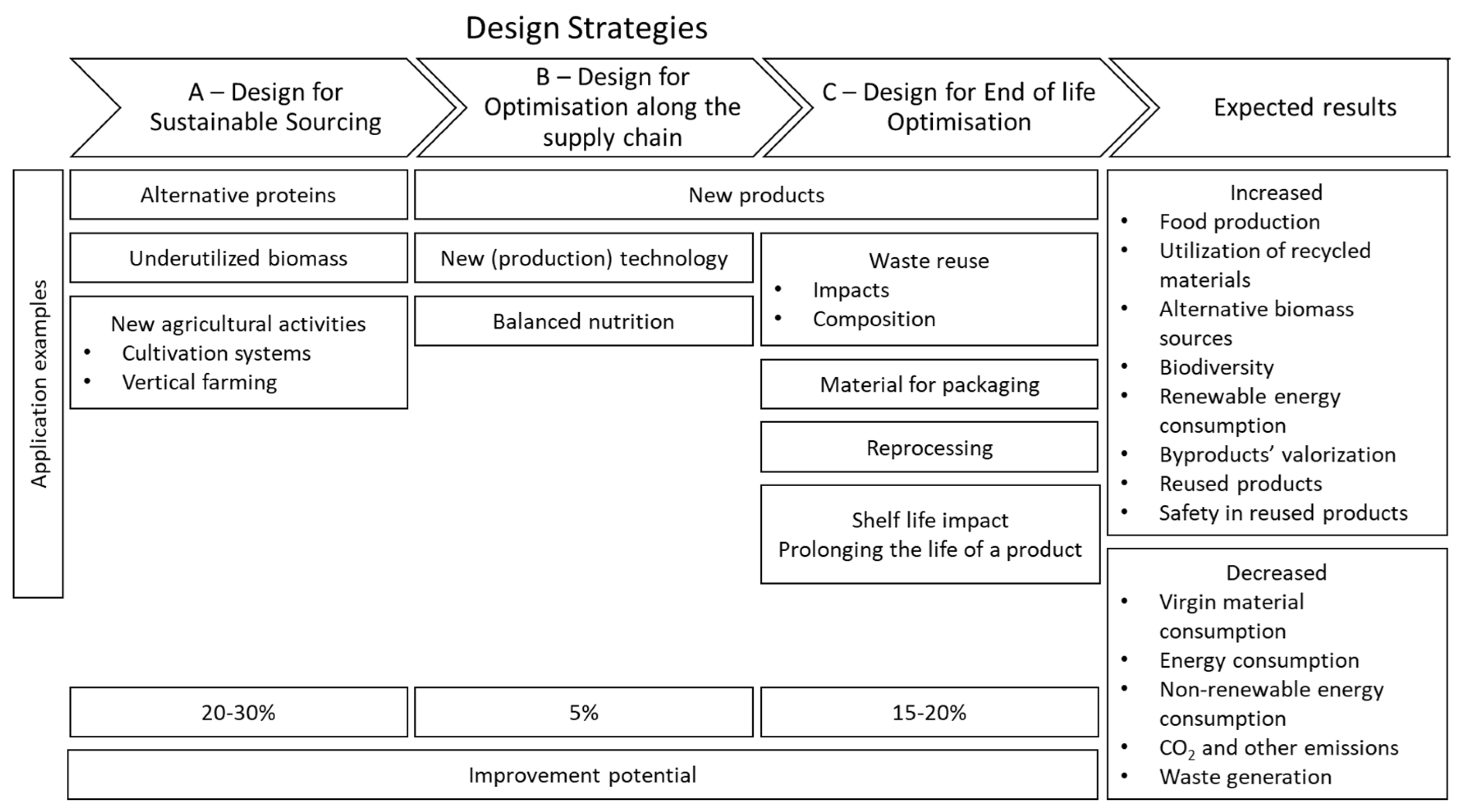

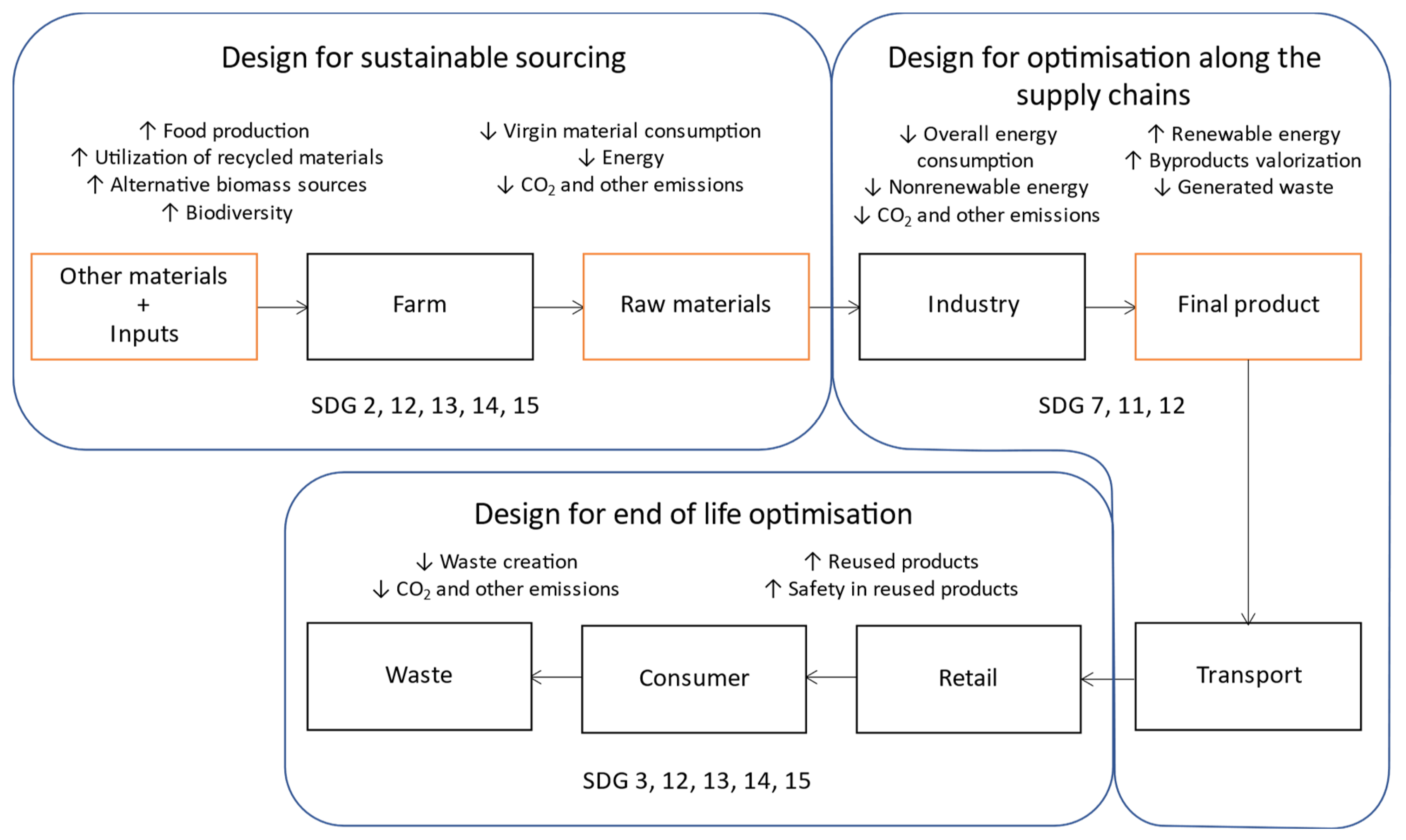

2.2. Framework for Ecodesign of Food Products

2.2.1. Design for Sustainable Sourcing (DfSS)

2.2.2. Design for Optimised Resource Use (DfORU)

2.2.3. Design for End-of-Life Optimisation (DfEO)

3. Ecodesign Principles to Support the Sustainable Development Goals (SDGs)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rabès, A.; Seconda, L.; Langevin, B.; Allès, B.; Touvier, M.; Hercberg, S.; Lairon, D.; Baudry, J.; Pointereau, P.; Kesse-Guyot, E. Greenhouse gas emissions, energy demand and land use associated with omnivorous, pesco-vegetarian, vegetarian, and vegan diets accounting for farming practices. Sustain. Prod. Consum. 2020, 22, 138–146. [Google Scholar] [CrossRef]

- Tilman, D.; Clark, M. Global diets link environmental sustainability and human health. Nature 2014, 515, 518–522. [Google Scholar] [CrossRef]

- Whitmee, S.; Haines, A.; Beyrer, C.; Boltz, F.; Capon, A.G.; de Souza Dias, B.F.; Ezeh, A.; Frumkin, H.; Gong, P.; Head, P.; et al. Safeguarding human health in the Anthropocene epoch: Report of The Rockefeller Foundation–Lancet Commission on planetary health. Lancet 2015, 386, 1973–2028. [Google Scholar] [CrossRef]

- Xu, X.; Sharma, P.; Shu, S.; Lin, T.S.; Ciais, P.; Tubiello, F.N.; Smith, P.; Campbell, N.; Jain, A.K. Global greenhouse gas emissions from animal-based foods are twice those of plant-based foods. Nat. Food 2021, 2, 724–732. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef]

- Willett, W.; Rockström, J.; Loken, B.; Springmann, M.; Lang, T.; Vermeulen, S.; Garnett, T.; Tilman, D.; DeClerck, F.; Wood, A.; et al. Food in the Anthropocene: The EAT–Lancet Commission on healthy diets from sustainable food systems. Lancet 2019, 393, 447–492. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Aveyard, P.; Garnett, T.; Hall, J.W.; Key, T.J.; Lorimer, J.; Pierrehumbert, R.T.; Scarborough, P.; Springmann, M.; Jebb, S.A. Meat consumption, health, and the environment. Science 2018, 361, eaam5324. [Google Scholar] [CrossRef]

- Fyles, H.; Madramootoo, C. Key Drivers of Food Insecurity. In Emerging Technologies for Promoting Food Security; Madramooto, C., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–19. [Google Scholar]

- UNEP. Our Global Food System Is the Primary Driver of Biodiversity Loss. Available online: https://www.unep.org/news-and-stories/press-release/our-global-food-system-primary-driver-biodiversity-loss (accessed on 15 November 2021).

- Bonvoisin, J.; Stark, R.; Seliger, G. Field of Research in Sustainable Manufacturing. In Sustainable Manufacturing: Challenges, Solutions and Implementation Perspectives; Stark, R., Seliger, G., Bonvoisin, J., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 3–20. ISBN 978-3-319-48514-0. [Google Scholar]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food Security: The Challenge of Feeding 9 Billion People. Science 2010, 327, 812–818. [Google Scholar] [CrossRef]

- FAO. Global Food Loss and Food Waste—Extent, Causes and Prevention; FAO: Rome, Italy, 2011. [Google Scholar]

- Ojha, S.; Bußler, S.; Schlüter, O.K. Food waste valorisation and circular economy concepts in insect production and processing. Waste Manag. 2020, 118, 600–609. [Google Scholar] [CrossRef]

- FAO. Food Wastage Footprint & Climate Change; FAO: Rome, Italy, 2015. [Google Scholar]

- FAO. Do Good: Save Food! Available online: http://www.fao.org/3/c0084e/c0084e.pdf (accessed on 8 November 2021).

- Moult, J.A.; Allan, S.R.; Hewitt, C.N.; Berners-Lee, M. Greenhouse gas emissions of food waste disposal options for UK retailers. Food Policy 2018, 77, 50–58. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Environmental Impacts of Food Production—Our World in Data. Available online: https://ourworldindata.org/environmental-impacts-of-food#water-use (accessed on 18 May 2021).

- World Commission on Environment and Development. Brundtland Report—Our Common Future towards Sustainable Development 2; Part II: Common Challenges Population and Human Resources; World Commission on Environment and Development: New York, NY, USA, 1987. [Google Scholar]

- Fullerton, D.; Wu, W. Policies for green design. J. Environ. Econ. Manag. 1998, 36, 131–148. [Google Scholar] [CrossRef]

- European Parliament. Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02009L0125-20121204 (accessed on 23 May 2022).

- Talens Peiró, L.; Polverini, D.; Ardente, F.; Mathieux, F. Advances towards circular economy policies in the EU: The new Ecodesign regulation of enterprise servers. Resour. Conserv. Recycl. 2020, 154, 104426. [Google Scholar] [CrossRef]

- Li, J.; Zeng, X.; Stevels, A. Ecodesign in Consumer Electronics: Past, Present, and Future. Crit. Rev. Environ. Sci. Technol. 2015, 45, 840–860. [Google Scholar] [CrossRef]

- Biron, M. Chapter 5—Thermoplastic Processing. In Thermoplastics and Thermoplastic Composites; Biron, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 767–820. ISBN 9780081025017. [Google Scholar]

- Biron, M. 15—EcoDesign. In Material Selection for Thermoplastic Parts—Practical and Advanced Information for Plastics Engineers; Elsevier: Amsterdam, The Netherlands, 2016; pp. 603–659. ISBN 9780323266987. [Google Scholar]

- Bassani, F.; Rodrigues, C.; Marques, P.; Freire, F. Ecodesign approach for pharmaceutical packaging based on Life Cycle Assessment. Sci. Total Environ. 2021, 816, 151565. [Google Scholar] [CrossRef]

- Chauhan, C.; Dhir, A.; Akram, M.U.; Salo, J. Food loss and waste in food supply chains. A systematic literature review and framework development approach. J. Clean. Prod. 2021, 295, 126438. [Google Scholar] [CrossRef]

- De Grave, A.; Olsen, S.I.; Hansen, H.N.; Arentoft, M. Chapter 25—Sustainability of Micro-Manufacturing Technologies. In Micro-Manufacturing Engineering and Technology; Qin, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2010; pp. 394–404. ISBN 978-0-8155-1545-6. [Google Scholar]

- Jeswiet, J.; Hauschild, M. EcoDesign and future environmental impacts. Mater. Des. 2005, 26, 629–634. [Google Scholar] [CrossRef]

- Navajas, A.; Uriarte, L.; Gandía, L.M. Application of Eco-Design and Life Cycle Assessment Standards for Environmental Impact Reduction of an Industrial Product. Sustainability 2017, 9, 1724. [Google Scholar] [CrossRef]

- Topleva, S.A.; Prokopov, T.V. Integrated business model for sustainability of small and medium-sized enterprises in the food industry. Br. Food J. 2020, 122, 1463–1483. [Google Scholar] [CrossRef]

- Fayole, C.; Fedrigo, D.; Koniecka, K.; Popescu, I. For Better Not Worse: Applying Ecodesign Principles to Plastics in Circular Economy; ECOS: Brussels, Belgium, 2019. [Google Scholar]

- Stevels, A. Application of EcoDesign: Ten years of dynamic development. In Proceedings of the Second International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 11–15 December 2001; pp. 905–915. [Google Scholar] [CrossRef]

- Baptista, A.J.; Peixoto, D.; Ferreira, A.D.; Pereira, J.P. Lean Design-for-X Methodology: Integrating Modular Design, Structural Optimization and Ecodesign in a Machine Tool Case Study. Procedia CIRP 2018, 69, 722–727. [Google Scholar] [CrossRef]

- Rossi, M.; Germani, M.; Zamagni, A. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. J. Clean. Prod. 2016, 129, 361–373. [Google Scholar] [CrossRef]

- Thrane, M.; Flysjö, A. Ecodesign of food products. In Environmental Assessment and Management in the Food Industry; Sonesson, U., Berlin, J., Ziegler, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2010; pp. 234–254. [Google Scholar]

- European Parliament Directive. 2008/98/EC of the European Parliament and the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/eli/dir/2008/98 (accessed on 8 June 2021).

- Khan, F.R.; Katsara, K.; Kenanakis, G.; Alissandrakis, E.; Papadakis, V.M. Honey Quality and Microplastic Migration from Food Packaging: A Potential Threat for Consumer Health? Microplastics 2022, 1, 406–427. [Google Scholar] [CrossRef]

- Etxabide, A.; Young, B.; Bremer, P.J.; Kilmartin, P.A. Non-permanent primary food packaging materials assessment: Identification, migration, toxicity, and consumption of substances. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4130–4145. [Google Scholar] [CrossRef]

- Hübner, R. The Use-Time and Obsolescence of Durable Goods: Evidence from Austria View Project Is Sustainability Already Normal? View Project Ecodesign: Reach, Limits and Challenges 20 Years of Ecodesign-Time for a Critical Reflection; Forum Ware International: Vienna, Austria, 2012; Volume 1. [Google Scholar]

- Saget, S.; Costa, M.; Barilli, E.; Wilton de Vasconcelos, M.; Santos, C.S.; Styles, D.; Williams, M. Substituting wheat with chickpea flour in pasta production delivers more nutrition at a lower environmental cost. Sustain. Prod. Consum. 2020, 24, 26–38. [Google Scholar] [CrossRef]

- Zufia, J.; Arana, L. Life cycle assessment to eco-design food products: Industrial cooked dish case study. J. Clean. Prod. 2008, 16, 1915–1921. [Google Scholar] [CrossRef]

- Polizzi di Sorrentino, E.; Woelbert, E.; Sala, S. Consumers and their behavior: State of the art in behavioral science supporting use phase modeling in LCA and ecodesign. Int. J. Life Cycle Assess. 2016, 21, 237–251. [Google Scholar] [CrossRef]

- Zeng, T.; Durif, F. The Impact of Eco-Design Packaging on Food Waste Avoidance: A Conceptual Framework. J. Promot. Manag. 2020, 26, 768–790. [Google Scholar] [CrossRef]

- Varžinskas, V.; Kazulytė, I.; Grigolaitė, V.; Daugėlaitė, V.; Markevičiūtė, Z. Eco-design Methods and Tools: An Overview and Applicability to Packaging. Environ. Res. Eng. Manag. 2020, 76, 32–45. [Google Scholar] [CrossRef]

- Smetana, S. Life cycle assessment of specific organic waste–based bioeconomy approaches. Curr. Opin. Green Sustain. Chem. 2020, 23, 50–54. [Google Scholar] [CrossRef]

- Guermazi, Z.; Gharsallaoui, M.; Perri, E.; Gabsi, S.; Benincasa, C. Integrated approach for the eco design of a new process through the life cycle analysis of olive oil: Total use of olive by-products. Eur. J. Lipid Sci. Technol. 2017, 119, 1700009. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramírez-Guzman, N.; Londoño-Hernandez, L.; Martinez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macias, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal-Vázquez, M.; Ascacio-Valdes, J.; et al. Food Waste and Byproducts: An Opportunity to Minimize Malnutrition and Hunger in Developing Countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- Asem-Hiablie, S.; Battagliese, T.; Stackhouse-Lawson, K.R.; Alan Rotz, C. A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Assess. 2019, 24, 441–455. [Google Scholar] [CrossRef]

- Rotz, C.A.; Asem-Hiablie, S.; Dillon, J.; Bonifacio, H. Cradle-to-farm gate environmental footprints of beef cattle production in Kansas, Oklahoma, and Texas. J. Anim. Sci. 2015, 93, 2509–2519. [Google Scholar] [CrossRef] [PubMed]

- Lukić, M.; Lilić, S.; Djekic, I.; Radović, Č. Environmental life-cycle assessment in production of pork products. MESO First Croat. Meat J. 2015, 17, 469–476. [Google Scholar]

- Biswas, W.K.; Graham, J.; Kelly, K.; John, M.B. Global warming contributions from wheat, sheep meat and wool production in Victoria, Australia-a life cycle assessment. J. Clean. Prod. 2010, 18, 1386–1392. [Google Scholar] [CrossRef]

- Skunca, D.; Tomasevic, I.; Nastasijevic, I.; Tomovic, V.; Djekic, I. Life cycle assessment of the chicken meat chain. J. Clean. Prod. 2018, 184, 440–450. [Google Scholar] [CrossRef]

- González-García, S.; Gomez-Fernández, Z.; Dias, A.C.; Feijoo, G.; Moreira, M.T.; Arroja, L. Life Cycle Assessment of broiler chicken production: A Portuguese case study. J. Clean. Prod. 2014, 74, 125–134. [Google Scholar] [CrossRef]

- Dekker, S.E.M.; de Boer, I.J.M.; Vermeij, I.; Aarnink, A.J.A.; Koerkamp, P.W.G.G. Ecological and economic evaluation of Dutch egg production systems. Livest. Sci. 2011, 139, 109–121. [Google Scholar] [CrossRef]

- Ulrich, R.; Thoma, G.; Nutter, D.; Wilson, J. Tailpipe greenhouse gas emissions from tank trucks transporting raw milk from farms to processing plants. Int. Dairy J. 2013, 31, S50–S56. [Google Scholar] [CrossRef]

- Nutter, D.W.; Kim, D.S.; Ulrich, R.; Thoma, G. Greenhouse gas emission analysis for USA fluid milk processing plants: Processing, packaging, and distribution. Int. Dairy J. 2013, 31, 57–64. [Google Scholar] [CrossRef]

- Thoma, G.; Popp, J.; Nutter, D.; Shonnard, D.; Ulrich, R.; Matlock, M.; Kim, D.S.; Neiderman, Z.; Kemper, N.; East, C.; et al. Greenhouse gas emissions from milk production and consumption in the United States: A cradle-to-grave life cycle assessment circa 2008. Int. Dairy J. 2013, 31, S3–S14. [Google Scholar] [CrossRef]

- Batalla, I.; Knudsen, M.T.; Mogensen, L.; Del Hierro, Ó.; Pinto, M.; Hermansen, J.E. Carbon footprint of milk from sheep farming systems in Northern Spain including soil carbon sequestration in grasslands. J. Clean. Prod. 2015, 104, 121–129. [Google Scholar] [CrossRef]

- Masuda, K. Measuring eco-efficiency of wheat production in Japan: A combined application of life cycle assessment and data envelopment analysis. J. Clean. Prod. 2016, 126, 373–381. [Google Scholar] [CrossRef]

- Charles, R.; Jolliet, O.; Gaillard, G.; Pellet, D. Environmental analysis of intensity level in wheat crop production using life cycle assessment. Agric. Ecosyst. Environ. 2006, 113, 216–225. [Google Scholar] [CrossRef]

- Soltani, A.; Rajabi, M.H.; Zeinali, E.; Soltani, E. Energy inputs and greenhouse gases emissions in wheat production in Gorgan, Iran. Energy 2013, 50, 54–61. [Google Scholar] [CrossRef]

- Bartzas, G.; Zaharaki, D.; Komnitsas, K. Life cycle assessment of open field and greenhouse cultivation of lettuce and barley. Inf. Process. Agric. 2015, 2, 191–207. [Google Scholar] [CrossRef]

- Xue, J.F.; Pu, C.; Liu, S.L.; Zhao, X.; Zhang, R.; Chen, F.; Xiao, X.P.; Zhang, H.L. Carbon and nitrogen footprint of double rice production in Southern China. Ecol. Indic. 2016, 64, 249–257. [Google Scholar] [CrossRef]

- Mohammadi, A.; Rafiee, S.; Jafari, A.; Keyhani, A.; Dalgaard, T.; Knudsen, M.T.; Nguyen, T.L.T.; Borek, R.; Hermansen, J.E. Joint Life Cycle Assessment and Data Envelopment Analysis for the benchmarking of environmental impacts in rice paddy production. J. Clean. Prod. 2015, 106, 521–532. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Rafiee, S.; Sharifi, M.; Hosseinpour, S.; Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Khanali, M. Use of LCA indicators to assess Iranian rapeseed production systems with different residue management practices. Ecol. Indic. 2017, 80, 31–39. [Google Scholar] [CrossRef]

- Kazemi, H.; Bourkheili, S.H.; Kamkar, B.; Soltani, A.; Gharanjic, K.; Nazari, N.M. Estimation of greenhouse gas (GHG) emission and energy use efficiency (EUE) analysis in rainfed canola production (case study: Golestan province, Iran). Energy 2016, 116, 694–700. [Google Scholar] [CrossRef]

- Abeliotis, K.; Detsis, V.; Pappia, C. Life cycle assessment of bean production in the Prespa National Park, Greece. J. Clean. Prod. 2013, 41, 89–96. [Google Scholar] [CrossRef]

- Tidåker, P.; Karlsson Potter, H.; Carlsson, G.; Röös, E. Towards sustainable consumption of legumes: How origin, processing and transport affect the environmental impact of pulses. Sustain. Prod. Consum. 2021, 27, 496–508. [Google Scholar] [CrossRef]

- Elhami, B.; Khanali, M.; Akram, A. Combined application of Artificial Neural Networks and life cycle assessment in lentil farming in Iran. Inf. Process. Agric. 2017, 4, 18–32. [Google Scholar] [CrossRef]

- Zarei, M.J.; Kazemi, N.; Marzban, A. Life cycle environmental impacts of cucumber and tomato production in open-field and greenhouse. J. Saudi Soc. Agric. Sci. 2019, 18, 249–255. [Google Scholar] [CrossRef]

- Romero-Gámez, M.; Audsley, E.; Suárez-Rey, E.M. Life cycle assessment of cultivating lettuce and escarole in Spain. J. Clean. Prod. 2014, 73, 193–203. [Google Scholar] [CrossRef]

- Alaphilippe, A.; Simon, S.; Brun, L.; Hayer, F.; Gaillard, G. Life cycle analysis reveals higher agroecological benefits of organic and low-input apple production. Agron. Sustain. Dev. 2013, 33, 581–592. [Google Scholar] [CrossRef]

- McLaren, S.J.; Hume, A. Nalanie Mitraratne Carbon management for the primary agricultural sector in new Zealand: Case studies for the pipfruit and kiwifruit industries. In Proceedings of the VII International Conference on Food LCA, Bary, Italy, 22–24 September 2010; Volume 1, pp. 293–298. [Google Scholar]

- Longo, S.; Mistretta, M.; Guarino, F.; Cellura, M. Life Cycle Assessment of organic and conventional apple supply chains in the North of Italy. J. Clean. Prod. 2017, 140, 654–663. [Google Scholar] [CrossRef]

- Manfredi, M.; Vignali, G. Life cycle assessment of a packaged tomato puree: A comparison of environmental impacts produced by different life cycle phases. J. Clean. Prod. 2014, 73, 275–284. [Google Scholar] [CrossRef]

- Tabatabaie, S.M.H.; Murthy, G.S. Cradle to farm gate life cycle assessment of strawberry production in the United States. J. Clean. Prod. 2016, 127, 548–554. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Mousazadeh, H. Environmental impact assessment of open field and greenhouse strawberry production. Eur. J. Agron. 2013, 50, 29–37. [Google Scholar] [CrossRef]

- Mohammadi-Barsari, A.; Firouzi, S.; Aminpanah, H. Energy-use pattern and carbon footprint of rain-fed watermelon production in Iran. Inf. Process. Agric. 2016, 3, 69–75. [Google Scholar] [CrossRef]

- Tsangas, M.; Gavriel, I.; Doula, M.; Xeni, F.; Zorpas, A.A. Life cycle analysis in the framework of agricultural strategic development planning in the Balkan region. Sustainability 2020, 12, 1813. [Google Scholar] [CrossRef]

- Dwivedi, P.; Spreen, T.; Goodrich-Schneider, R. Global warming impact of Florida’s Not-From-Concentrate (NFC) orange juice. Agric. Syst. 2012, 108, 104–111. [Google Scholar] [CrossRef]

- FAO; WHO. Sustainable Healthy Diets—Guiding Principles; FAO: Rome, Italy, 2019. [Google Scholar]

- Pairotti, M.B.; Cerutti, A.K.; Martini, F.; Vesce, E.; Padovan, D.; Beltramo, R. Energy consumption and GHG emission of the Mediterranean diet: A systemic assessment using a hybrid LCA-IO method. J. Clean. Prod. 2015, 103, 507–516. [Google Scholar] [CrossRef]

- Springmann, M.; Clark, M.; Mason-D’Croz, D.; Wiebe, K.; Bodirsky, B.L.; Lassaletta, L.; de Vries, W.; Vermeulen, S.J.; Herrero, M.; Carlson, K.M.; et al. Options for keeping the food system within environmental limits. Nature 2018, 562, 519–525. [Google Scholar] [CrossRef]

- Smetana, S.; Mathys, A.; Knoch, A.; Heinz, V. Meat alternatives: Life cycle assessment of most known meat substitutes. Int. J. Life Cycle Assess. 2015, 20, 1254–1267. [Google Scholar] [CrossRef]

- Haas, R.; Schnepps, A.; Pichler, A.; Meixner, O. Cow Milk versus Plant-Based Milk Substitutes: A Comparison of Product Image and Motivational Structure of Consumption. Sustainability 2019, 11, 5046. [Google Scholar] [CrossRef]

- Khandpur, N.; Martinez-Steele, E.; Sun, Q. Plant-Based Meat and Dairy Substitutes as Appropriate Alternatives to Animal-Based Products? J. Nutr. 2021, 151, 3–4. [Google Scholar] [CrossRef]

- Vanstone, M.; Giacomini, M.; Smith, A.; Brundisini, F.; DeJean, D.; Winsor, S. How Diet Modification Challenges Are Magnified in Vulnerable or Marginalised People with Diabetes and Heart Disease: A Systematic Review and Qualitative Meta-Synthesis; Ontario Health Technology Assessment Series; Health Quality Ontario: Toronto, ON, Canada, 2013; Volume 13. [Google Scholar]

- Commission on Sustainable Agriculture and Climate Change. Achieving Food Security in the Face of Climate Change Final Report from the Commission on Sustainable Agriculture and Climate Change Commission Secretariat; CGIAR Research Program on Climate Change, Agriculture and Food Security, Denmark; CGIAR Secretariat: Washington, DC, USA, 2012. [Google Scholar]

- FAO. Sustainable Agriculture for Biodiversity—Biodiversity for Sustainable Agriculture; FAO: Rome, Italy, 2018. [Google Scholar]

- Zhao, J.; Zeng, Z.; He, X.; Chen, H.; Wang, K. Effects of monoculture and mixed culture of grass and legume forage species on soil microbial community structure under different levels of nitrogen fertilisation. Eur. J. Soil Biol. 2015, 68, 61–68. [Google Scholar] [CrossRef]

- Mentis, M. Environmental rehabilitation of damaged land. For. Ecosyst. 2020, 7, 19. [Google Scholar] [CrossRef]

- FAO. Soil Is a Non-Renewable Resource; FAO: Rome, Italy, 2015. [Google Scholar]

- Mayes, S.; Massawe, F.J.; Alderson, P.G.; Roberts, J.A.; Azam-Ali, S.N.; Hermann, M. The potential for underutilised crops to improve security of food production. Bot. Food Secur. J. Exp. Bot. 2012, 63, 1075–1079. [Google Scholar] [CrossRef]

- Stamp, P.; Messmer, R.; Walter, A. Competitive underutilised crops will depend on the state funding of breeding programmes: An opinion on the example of Europe. Plant Breed. 2012, 131, 461–464. [Google Scholar] [CrossRef]

- Magrini, M.-B.; Anton, M.; Chardigny, J.-M.; Duc, G.; Duru, M.; Jeuffroy, M.-H.; Meynard, J.-M.; Micard, V.; Walrand, S. Pulses for Sustainability: Breaking Agriculture and Food Sectors Out of Lock-In. Front. Sustain. Food Syst. 2018, 2, 64. [Google Scholar] [CrossRef]

- Cassman, K.G.; Wood, S.; Choo, P.S.; Cooper, D.H.; Devendra, C.; Dixn, J.; Gaskell, J.; Khan, S.; Lal, R.; Lipper, L.; et al. Cultivated systems. In Ecosystems and Human Well-Being: Current State and Trends; Hassan, R., Scholes, R., Ash, N., Eds.; Island Press: Washington, DC, USA, 2005; pp. 745–794. [Google Scholar]

- Tomasi, N.; Pinton, R.; Dalla Costa, L.; Cortella, G.; Terzano, R.; Mimmo, T.; Scampicchio, M.; Cesco, S. New ‘solutions’ for floating cultivation system of ready-to-eat salad: A review. Trends Food Sci. Technol. 2015, 46, 267–276. [Google Scholar] [CrossRef]

- The Eat-Lancet Commission. Healthy Diets From Planet; Food Planet Health; The Eat-Lancet Commission: London, UK, 2019. [Google Scholar]

- Tziva, M.; Negro, S.O.; Kalfagianni, A.; Hekkert, M.P. Understanding the protein transition: The rise of plant-based meat substitutes. Environ. Innov. Soc. Transit. 2020, 35, 217–231. [Google Scholar] [CrossRef]

- Tello, A.; Aganovic, K.; Parniakov, O.; Carter, A.; Heinz, V.; Smetana, S. Product development and environmental impact of an insect-based milk alternative. Futur. Foods 2021, 4, 100080. [Google Scholar] [CrossRef]

- Grasso, A.C.; Hung, Y.; Olthof, M.R.; Verbeke, W.; Brouwer, I.A. Older consumers’ readiness to accept alternative, more sustainable protein sources in the European Union. Nutrients 2019, 11, 1904. [Google Scholar] [CrossRef]

- Iannuzzi, E.; Sisto, R.; Nigro, C. The willingness to consume insect-based food: An empirical research on italian consumers. Agric. Econ. 2019, 65, 454–462. [Google Scholar] [CrossRef]

- Smetana, S.; Profeta, A.; Voigt, R.; Kircher, C.; Heinz, V. Meat substitution in burgers: Nutritional scoring, sensorial testing, and Life Cycle Assessment. Futur. Foods 2021, 4, 100042. [Google Scholar] [CrossRef]

- Jairath, G.; Mal, G.; Gopinath, D.; Singh, B. A holistic approach to access the viability of cultured meat: A review. Trends Food Sci. Technol. 2021, 110, 700–710. [Google Scholar] [CrossRef]

- Gerber, P.J.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C.; Dijkman, J.; Falcucci, A.; Tempio, G. Tackling Climate Change through Livestock—A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013. [Google Scholar]

- Mogensen, L.; Heusale, H.; Sinkko, T.; Poutanen, K.; Sözer, N.; Hermansen, J.E.; Knudsen, M.T. Potential to reduce GHG emissions and land use by substituting animal-based proteins by foods containing oat protein concentrate. J. Clean. Prod. 2020, 274, 122914. [Google Scholar] [CrossRef]

- Lardy, G.; Anderson, V.; Dahlen, C. Alternative Feeds for Ruminants; North Dakota State University: Fargo, ND, USA, 2018. [Google Scholar]

- Beck, V.; Ladwig, B. Ethical consumerism: Veganism. Wiley Interdiscip. Rev. Clim. Chang. 2021, 12, e689. [Google Scholar] [CrossRef]

- Leitzmann, C. Vegetarian nutrition: Past, present, future. Am. J. Clin. Nutr. 2014, 100, 496S–502S. [Google Scholar] [CrossRef] [PubMed]

- Sijtsema, S.J.; Onwezen, M.C.; Reinders, M.J.; Dagevos, H.; Partanen, A.; Meeusen, M. Consumer perception of bio-based products—An exploratory study in 5 European countries. NJAS Wageningen J. Life Sci. 2016, 77, 61–69. [Google Scholar] [CrossRef]

- De Bauw, M.; Matthys, C.; Poppe, V.; Franssens, S.; Vranken, L. A combined Nutri-Score and ‘Eco-Score’ approach for more nutritious and more environmentally friendly food choices? Evidence from a consumer experiment in Belgium. Food Qual. Prefer. 2021, 93, 104276. [Google Scholar] [CrossRef]

- Weber, A. Mobile apps as a sustainable shopping guide: The effect of eco-score rankings on sustainable food choice. Appetite 2021, 167, 105616. [Google Scholar] [CrossRef] [PubMed]

- Barthel, M.; Fava, J.A.; Harnanan, C.A.; Strothmann, P.; Khan, S.; Miller, S. Hotspots Analysis: Providing the Focus for Action. In Life Cycle Management, LCA Compendium—The Complete World of Life Cycle Assessment; Sonnemann, G., Margni, M., Eds.; Springer Open: Berlin/Heidelberg, Germany, 2015; pp. 149–167. [Google Scholar]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Philibert, C. Renewable Energy for Industry—From Green Energy to Green Materials and Fuels; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Silva, V.L.; Sanjuán, N. Opening up the black box: A systematic literature review of life cycle assessment in alternative food processing technologies. J. Food Eng. 2019, 250, 33–45. [Google Scholar] [CrossRef]

- European Commission. Delivering the European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en (accessed on 11 August 2021).

- Wicki, S.; Hansen, E.G. Green technology innovation: Anatomy of exploration processes from a learning perspective. Bus. Strateg. Environ. 2019, 28, 970–988. [Google Scholar] [CrossRef]

- Ekins, P.; Zenghelis, D. The costs and benefits of environmental sustainability. Sustain. Sci. 2021, 16, 949–965. [Google Scholar] [CrossRef]

- Cecere, G.; Corrocher, N.; Gossart, C.; Ozman, M. Lock-in and path dependence: An evolutionary approach to eco-innovations. J. Evol. Econ. 2014, 24, 1037–1065. [Google Scholar] [CrossRef]

- Gesellschaft, F. Energy Efficiency in Production: Future Action Fields; Franhaufer: Munich, Germany, 2008. [Google Scholar]

- Mardiana-Idayu, A.; Riffat, S.B. Review on heat recovery technologies for building applications. Renew. Sustain. Energy Rev. 2012, 16, 1241–1255. [Google Scholar] [CrossRef]

- Eurostat. SHARES (Renewables)—Energy. Available online: https://ec.europa.eu/eurostat/web/energy/data/shares (accessed on 11 August 2021).

- Tlais, A.Z.A.; Fiorino, G.M.; Polo, A.; Filannino, P.; Di Cagno, R. High-Value Compounds in Fruit, Vegetable and Cereal Byproducts: An Overview of Potential Sustainable Reuse and Exploitation. Molecules 2020, 25, 2987. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Guillemat, B.; Vitrac, O. Rational Design of Packaging: Toward Safer and Ecodesigned Food Packaging Systems. Front. Chem. 2019, 7, 349. [Google Scholar] [CrossRef] [PubMed]

- Djuric Ilic, D.; Eriksson, O.; Ödlund (former Trygg), L.; Åberg, M. No zero burden assumption in a circular economy. J. Clean. Prod. 2018, 182, 352–362. [Google Scholar] [CrossRef]

- Ekvall, T.; Assefa, G.; Björklund, A.; Eriksson, O.; Finnveden, G. What life-cycle assessment does and does not do in assessments of waste management. Waste Manag. 2007, 27, 989–996. [Google Scholar] [CrossRef]

- Vågsholm, I.; Arzoomand, N.S.; Boqvist, S. Food Security, Safety, and Sustainability—Getting the Trade-Offs Right. Front. Sustain. Food Syst. 2020, 4, 16. [Google Scholar] [CrossRef]

- Sales, F.C.V.; De Souza, M.; Trento, L.R.; Pereira, G.M.; Borchardt, M.; Milan, G.S. Food Waste in Distribution: Causes and Gaps to Be Filled. Sustainability 2023, 15, 3598. [Google Scholar] [CrossRef]

- Norton, A.; Fearne, A. Sustainable value stream mapping in the food industry. In Handbook of Waste Management and Co-Product Recovery in Food Processing; Elsevier Inc.: Amsterdam, The Netherlands, 2009; Volume 2, pp. 3–22. ISBN 9781845697051. [Google Scholar]

- Elsayed, M.; Ran, Y.; Ai, P.; Azab, M.; Mansour, A.; Jin, K.; Zhang, Y.; Abomohra, A.E.F. Innovative integrated approach of biofuel production from agricultural wastes by anaerobic digestion and black soldier fly larvae. J. Clean. Prod. 2020, 263, 121495. [Google Scholar] [CrossRef]

- Kumar, R.; Ghosh, A.K.; Pal, P. Synergy of biofuel production with waste remediation along with value-added co-products recovery through microalgae cultivation: A review of membrane-integrated green approach. Sci. Total Environ. 2020, 698, 134169. [Google Scholar] [CrossRef]

- Salomone, R.; Saija, G.; Mondello, G.; Giannetto, A.; Fasulo, S.; Savastano, D. Environmental impact of food waste bioconversion by insects: Application of Life Cycle Assessment to process using Hermetia illucens. J. Clean. Prod. 2017, 140, 890–905. [Google Scholar] [CrossRef]

- Pleissner, D.; Rumpold, B.A. Utilisation of organic residues using heterotrophic microalgae and insects. Waste Manag. 2018, 72, 227–239. [Google Scholar] [CrossRef] [PubMed]

- Soro, A.B.; Noore, S.; Hannon, S.; Whyte, P.; Bolton, D.J.; O’Donnell, C.; Tiwari, B.K. Current sustainable solutions for extending the shelf life of meat and marine products in the packaging process. Food Packag. Shelf Life 2021, 29, 100722. [Google Scholar] [CrossRef]

- Vaclavik, V.A.; Christian, E.W. Essentials of Food Science, 3rd ed.; Vaclavik, V.A., Christian, E.W., Eds.; Food Science Texts Series; Springer: New York, NY, USA, 2008; ISBN 978-0-387-69939-4. [Google Scholar]

- Augusto, P.E.D.; Soares, B.M.C.; Castanha, N. Conventional Technologies of Food Preservation. In Innovative Technologies for Food Preservation; Barba, F.J., Sant’Ana, A.S., Orlien, V., Koubaa, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–23. [Google Scholar]

- Júnior, L.M.; Cristianini, M.; Padula, M.; Anjos, C.A.R. Effect of high-pressure processing on characteristics of flexible packaging for foods and beverages. Food Res. Int. 2019, 119, 920–930. [Google Scholar] [CrossRef]

- Muntean, M.-V.; Marian, O.; Barbieru, V.; Cătunescu, G.M.; Ranta, O.; Drocas, I.; Terhes, S. High Pressure Processing in Food Industry—Characteristics and Applications. Agric. Agric. Sci. Procedia 2016, 10, 377–383. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Rather, I.A.; Koh, W.Y.; Paek, W.K.; Lim, J. The Sources of Chemical Contaminants in Food and Their Health Implications. Front. Pharmacol. 2017, 8, 830. [Google Scholar] [CrossRef]

- European Parliament. Regulation (EU) No 1169/2011 of the European Parliament and of the Council on the Provision of Food Information to Consumers. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02011R1169-20180101 (accessed on 9 June 2021).

- European Parliament. Commission Implementing Regulation (EU) 2017/2470. Available online: https://eur-lex.europa.eu/eli/reg_impl/2017/2470/2020-02-03 (accessed on 12 July 2021).

- Sabaté, J.; Soret, S. Sustainability of plant-based diets: Back to the future. Am. J. Clin. Nutr. 2014, 100, 476S–482S. [Google Scholar] [CrossRef]

- Soret, S.; Mejia, A.; Batech, M.; Jaceldo-Siegl, K.; Harwatt, H.; Sabaté, J. Climate change mitigation and health effects of varied dietary patterns in real-life settings throughout North America. Am. J. Clin. Nutr. 2014, 100, 490S–495S. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Castellani, V.; Sala, S. Environmental impacts of food consumption in Europe. J. Clean. Prod. 2017, 140, 753–765. [Google Scholar] [CrossRef]

- Bučko, S.; Katona, J.; Popović, L.; Vaštag, Ž.; Petrović, L.; Vučiniće-Vasić, M. Investigation on solubility, interfacial and emulsifying properties of pumpkin (Cucurbita pepo) seed protein isolate. LWT Food Sci. Technol. 2015, 64, 609–615. [Google Scholar] [CrossRef]

- Machovina, B.; Feeley, K.J.; Ripple, W.J. Biodiversity conservation: The key is reducing meat consumption. Sci. Total Environ. 2015, 536, 419–431. [Google Scholar] [CrossRef] [PubMed]

- Schott, A.B.S.; Andersson, T. Food waste minimisation from a life-cycle perspective. J. Environ. Manag. 2015, 147, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Rohn, H.; Pastewski, N.; Lettenmeier, M.; Wiesen, K.; Bienge, K. Resource efficiency potential of selected technologies, products and strategies. Sci. Total Environ. 2014, 473–474, 32–35. [Google Scholar] [CrossRef]

- Liu, R.; Gailhofer, P.; Gensch, C.-O.; Köhler, A.; Wolff, F.; Monteforte, M.; Urrutia, C.; Cihlarova, P.; Williams, R. Impacts of the Digital Transformation on Innovation across Sectors; OECD: Berlin, Germany, 2019. [Google Scholar]

- Smetana, S. The concepts of food eco-design for efficient biomass recovery, components up-cycling and food waste reduction. In Proceedings of the LCM2019 The 9th International Conference on Life Cycle Management, Poznan, Poland, 1–4 September 2019. [Google Scholar]

- Lara, A.; Arturo, C.; Athès, V.; Buche, P.; Della Valle, G.; Farines, V.; Fonseca, F.; Guillard, V.; Kansou, K.; Kristiawan, M.; et al. The virtual food system: Innovative models and experiential feedback in technologies for winemaking, the cereals chain, food packaging and eco-designed starter production. Innov. Food Sci. Emerg. Technol. 2018, 46, 54–64. [Google Scholar] [CrossRef]

- United Nations. THE 17 GOALS Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 27 April 2021).

- United Nations. Special Edition: Progress towards the Sustainable Development Goals. In A Concise Encyclopedia of the United Nations; Brill Nijhoff: Leiden, The Netherlands, 2019; Volume 7404, pp. 147–152. [Google Scholar]

- UN. Concept note on Circular Economy for the SDGs: From Concept to Practice—General Assembly and ECOSOC Joint Meeting; United Nations: New York, NY, USA, 2018. [Google Scholar]

| Ecodesign Strategy | General Principles | Reference |

|---|---|---|

| Design for sustainable sourcing |

| [31,39] |

| Design for optimised resource/optimisation/LCA |

| [27,31,33,39] |

| Design for environmentally sound and safe use phase/for energy efficiency |

| [27,31,34] |

| Design for prolonged product use/disassembly/maintenance |

| [27,31,34,39] |

| Design for reuse/recycling/recovery & material recycling |

| [27,31,34,39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, B.Q.; Vasconcelos, M.W.; Smetana, S. Conceptualisation of an Ecodesign Framework for Sustainable Food Product Development across the Supply Chain. Environments 2023, 10, 59. https://doi.org/10.3390/environments10040059

Silva BQ, Vasconcelos MW, Smetana S. Conceptualisation of an Ecodesign Framework for Sustainable Food Product Development across the Supply Chain. Environments. 2023; 10(4):59. https://doi.org/10.3390/environments10040059

Chicago/Turabian StyleSilva, Beatriz Q., Marta W. Vasconcelos, and Sergiy Smetana. 2023. "Conceptualisation of an Ecodesign Framework for Sustainable Food Product Development across the Supply Chain" Environments 10, no. 4: 59. https://doi.org/10.3390/environments10040059

APA StyleSilva, B. Q., Vasconcelos, M. W., & Smetana, S. (2023). Conceptualisation of an Ecodesign Framework for Sustainable Food Product Development across the Supply Chain. Environments, 10(4), 59. https://doi.org/10.3390/environments10040059