Coupled Effect of Wet-Dry Cycles and Rainfall on Highway Slope Made of Yazoo Clay

Abstract

:1. Introduction

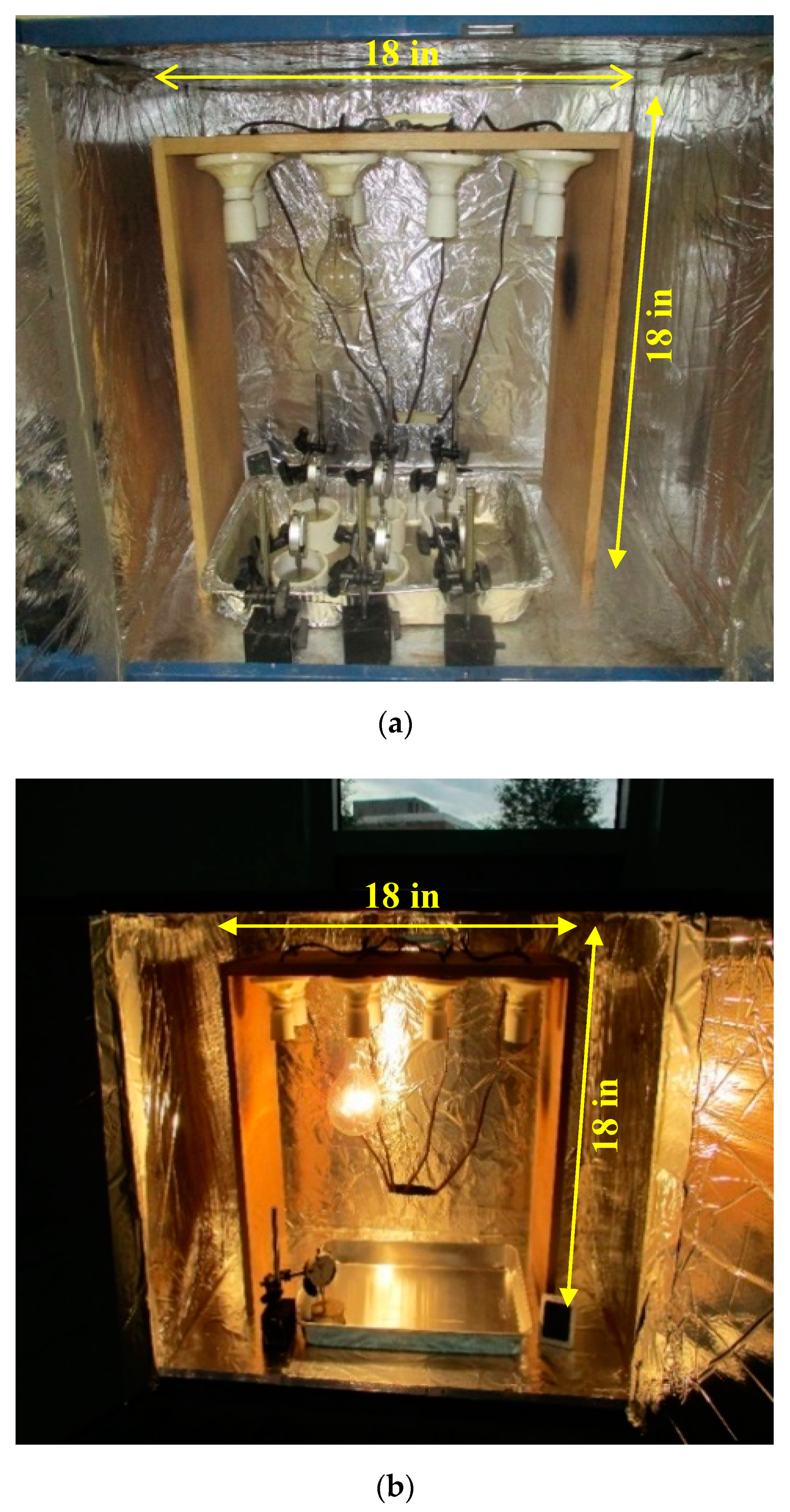

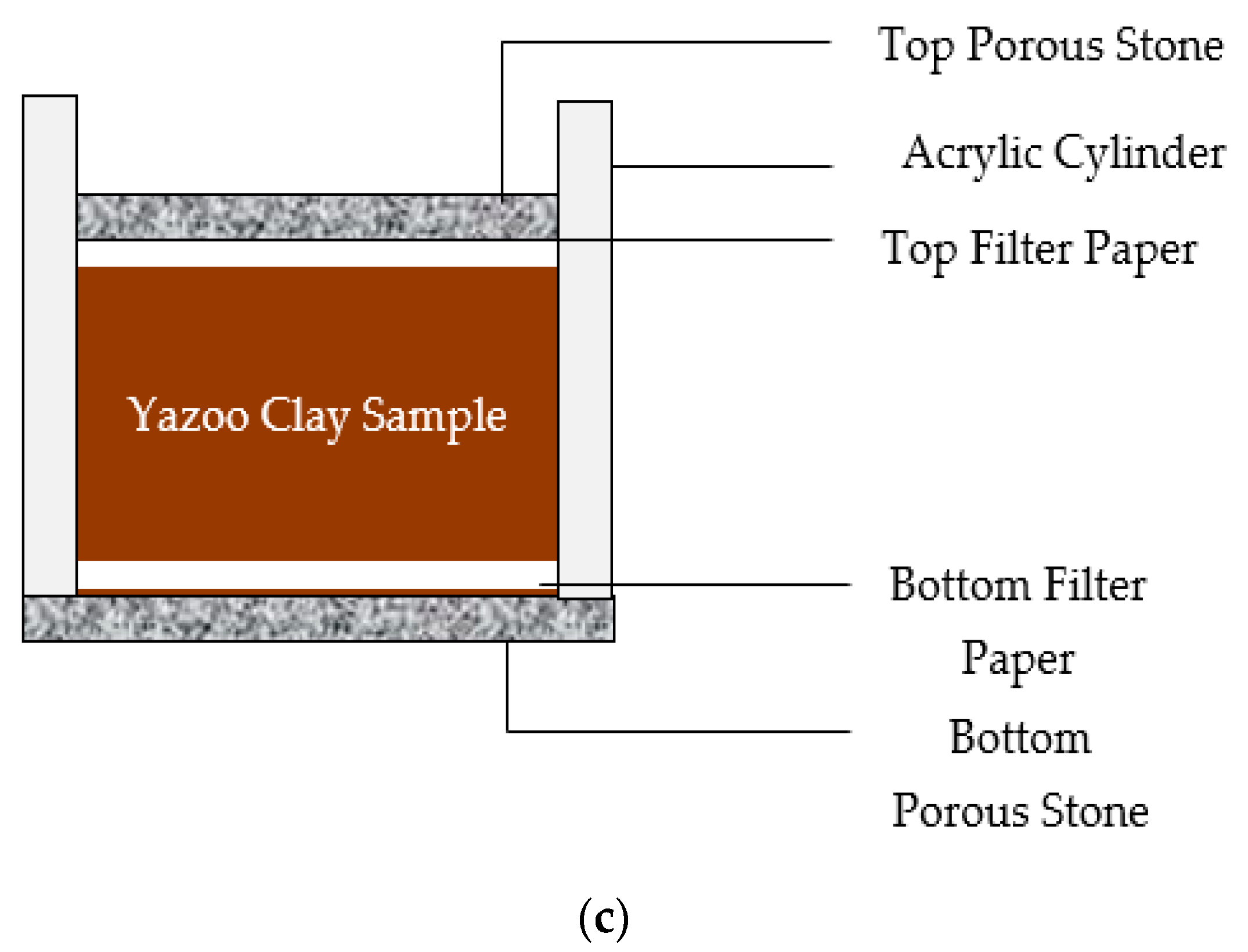

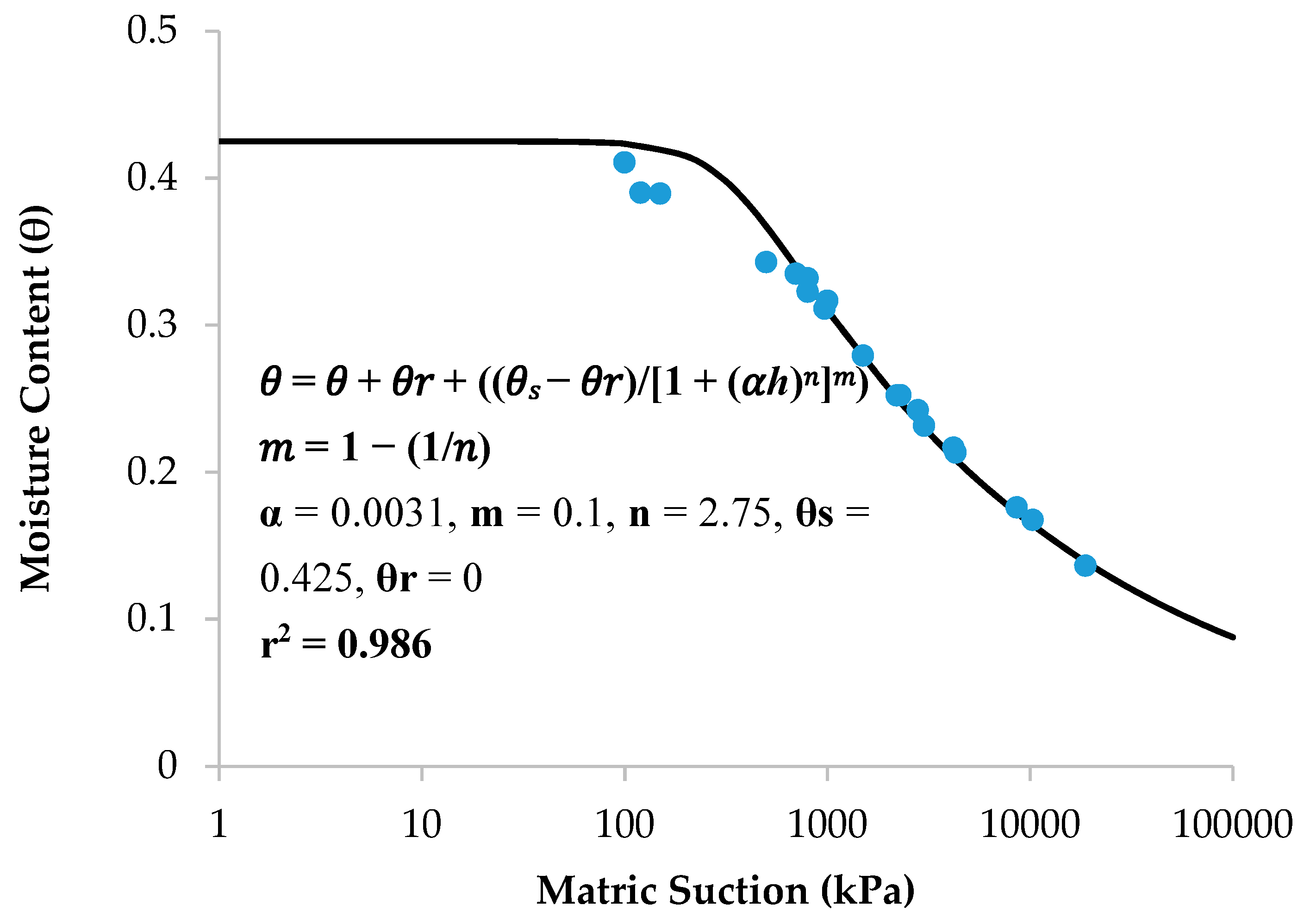

2. Methodology

3. Results and Discussions

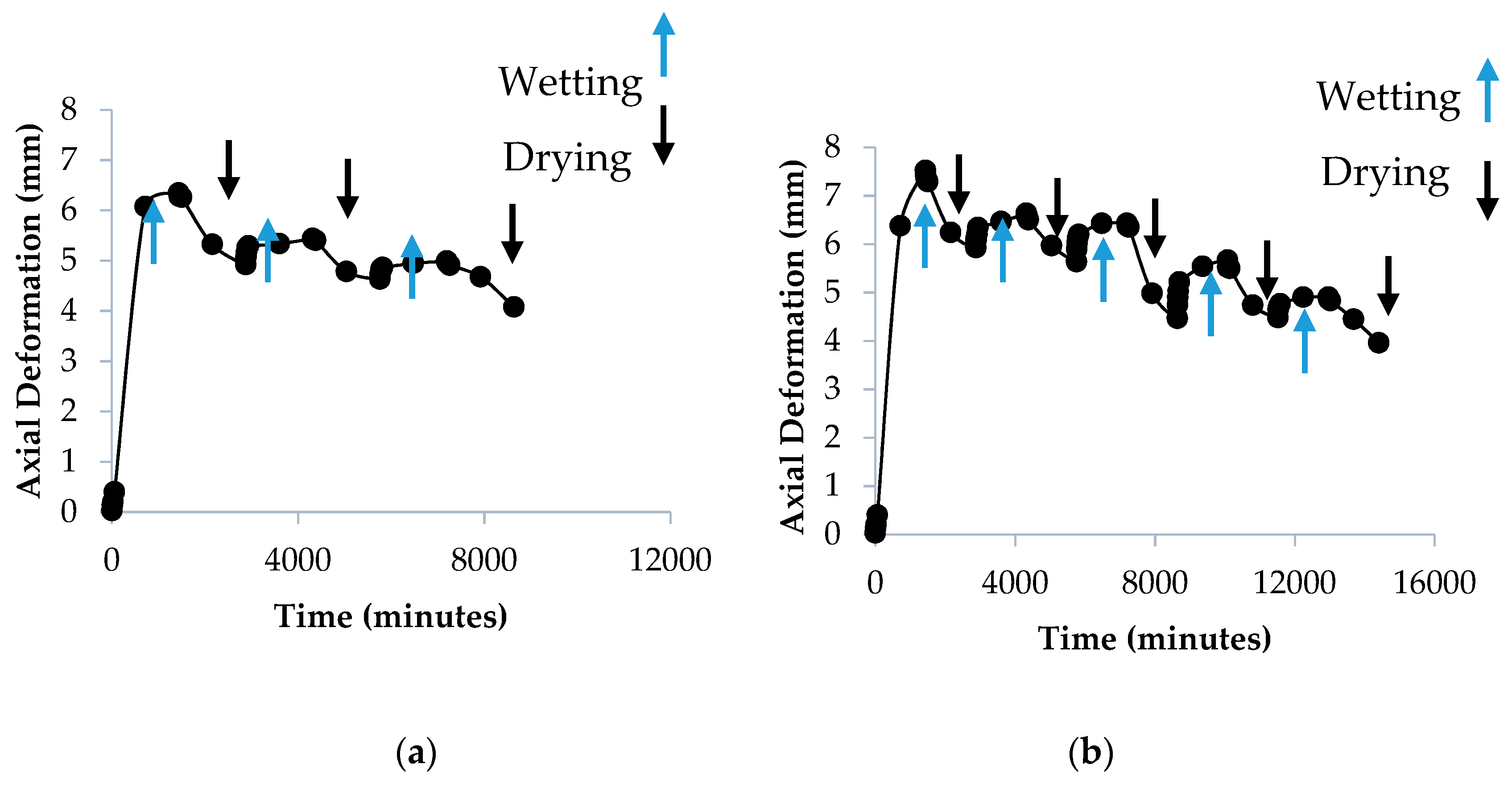

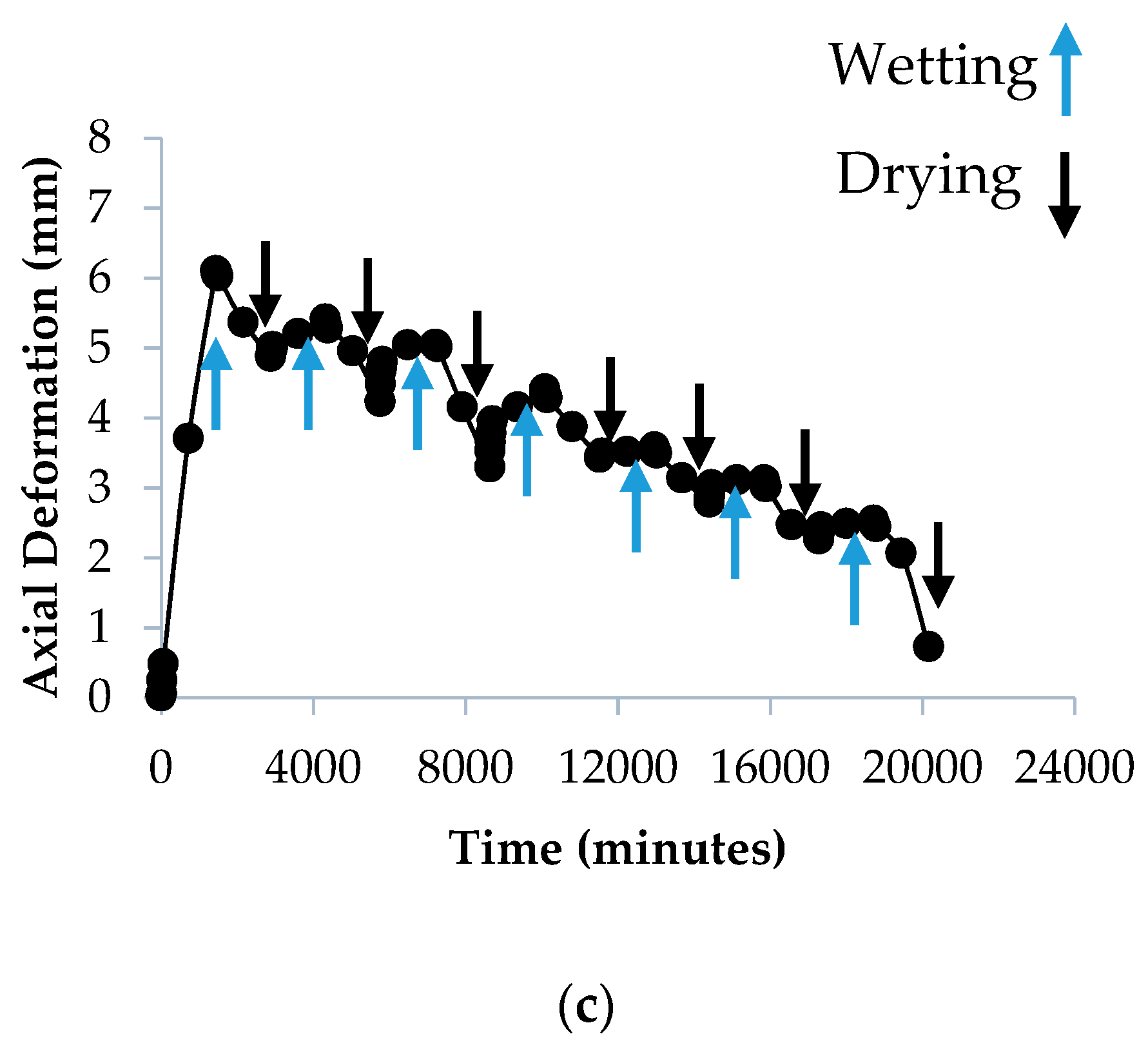

3.1. Effect of the Wet-Dry Cycle on Vertical Deformation

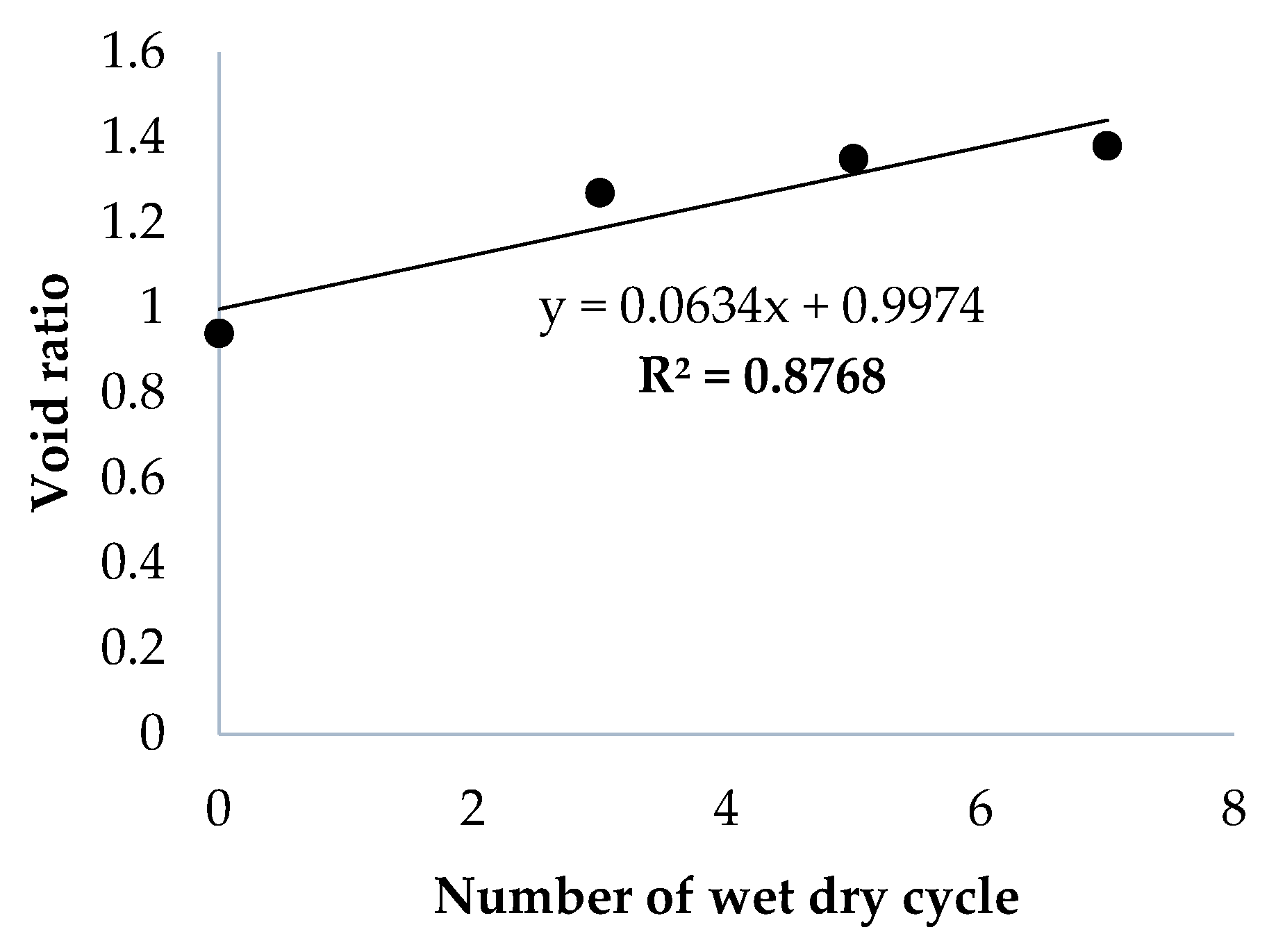

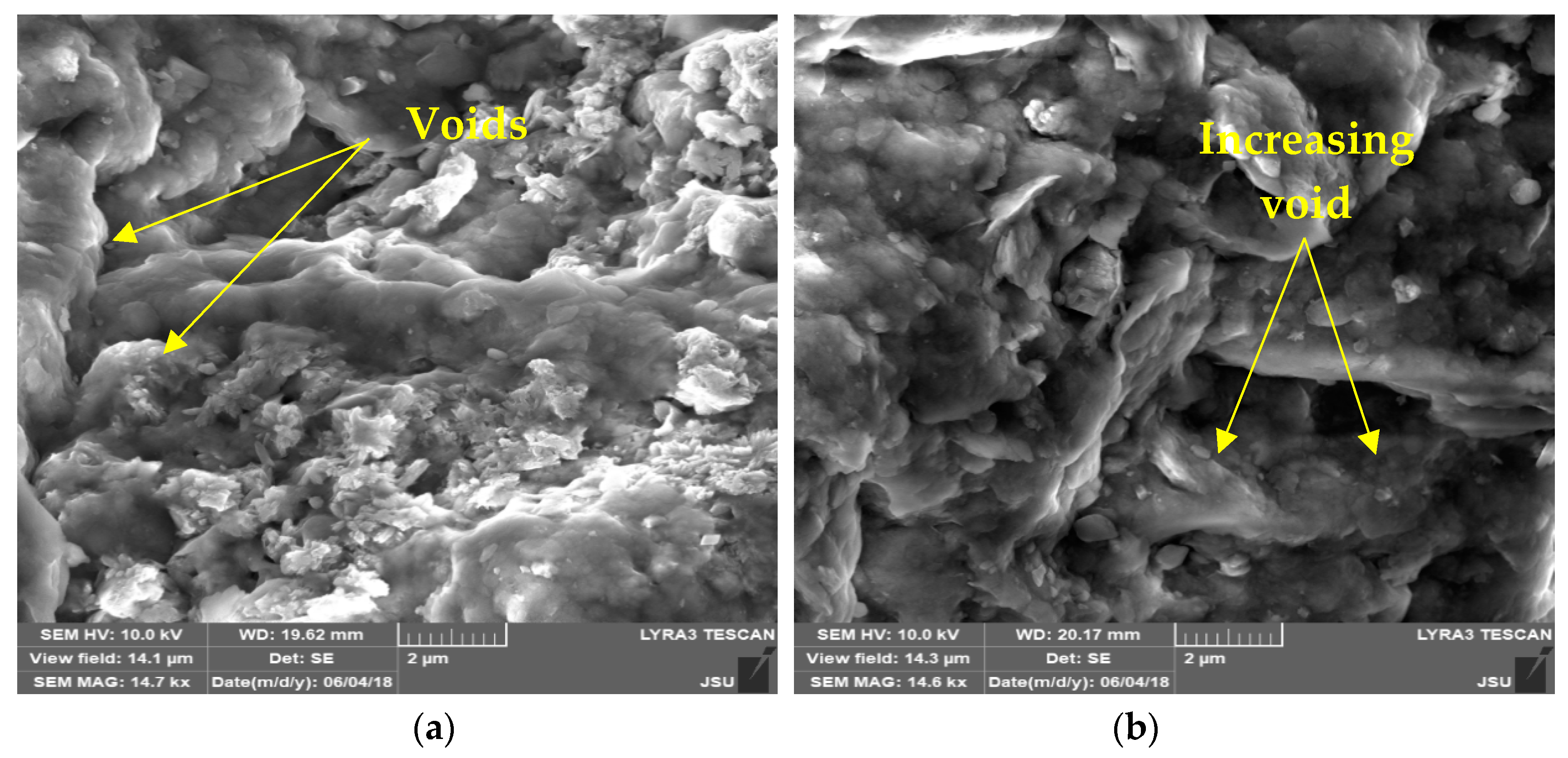

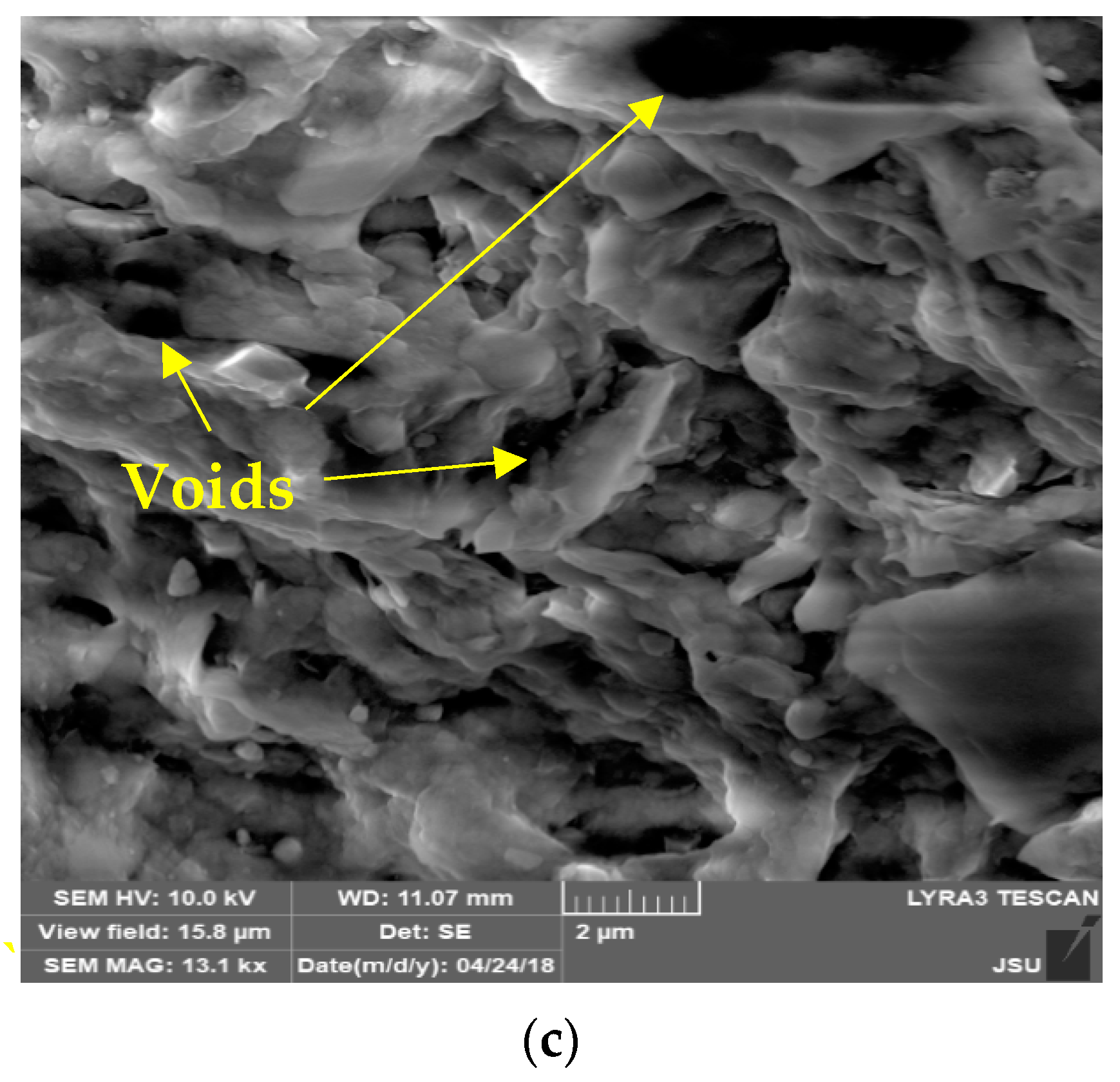

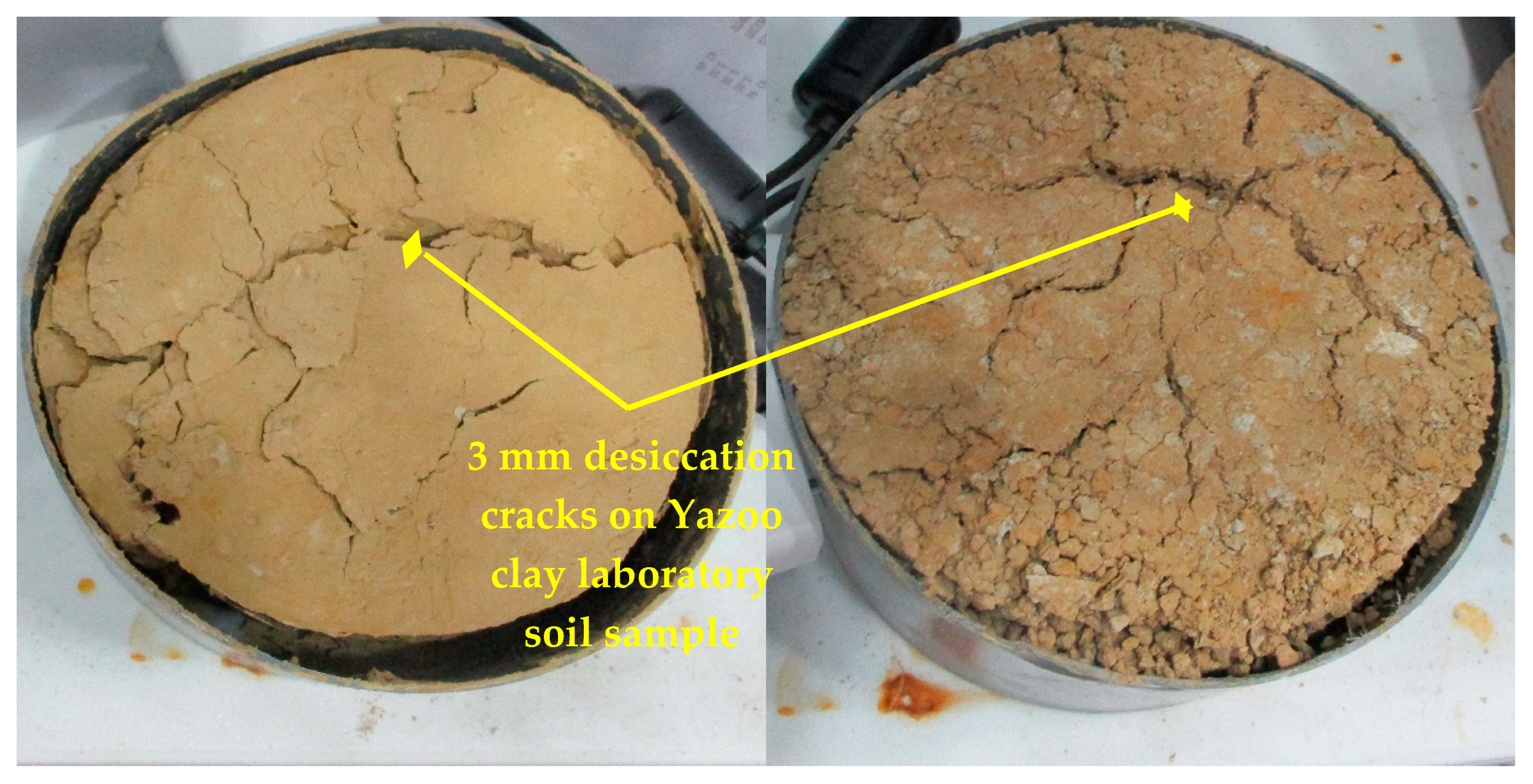

3.2. Effect of the Wet-Dry Cycle on Void Ratio

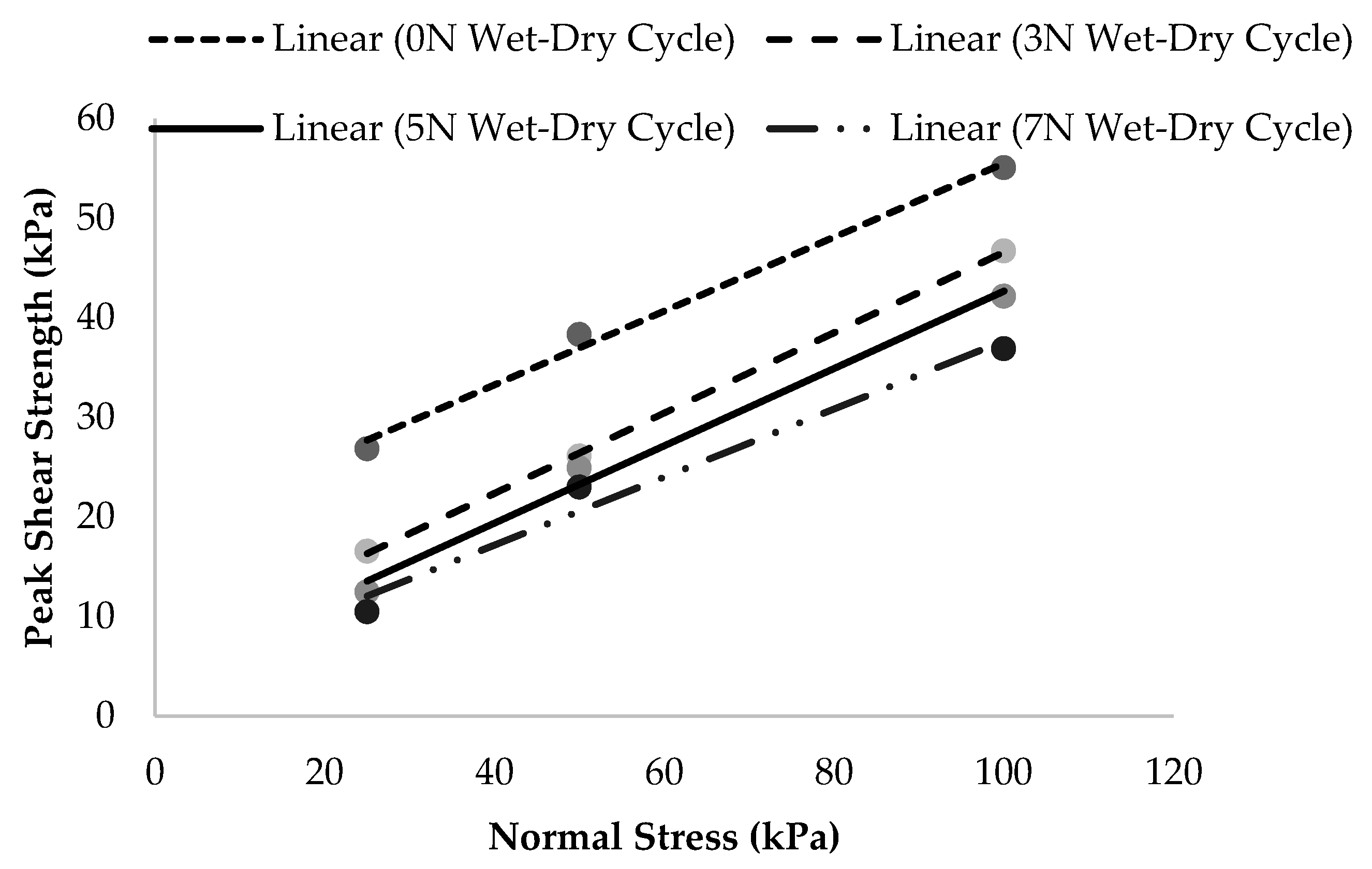

3.3. Effect of the Wet-Dry Cycle on Shear Strength

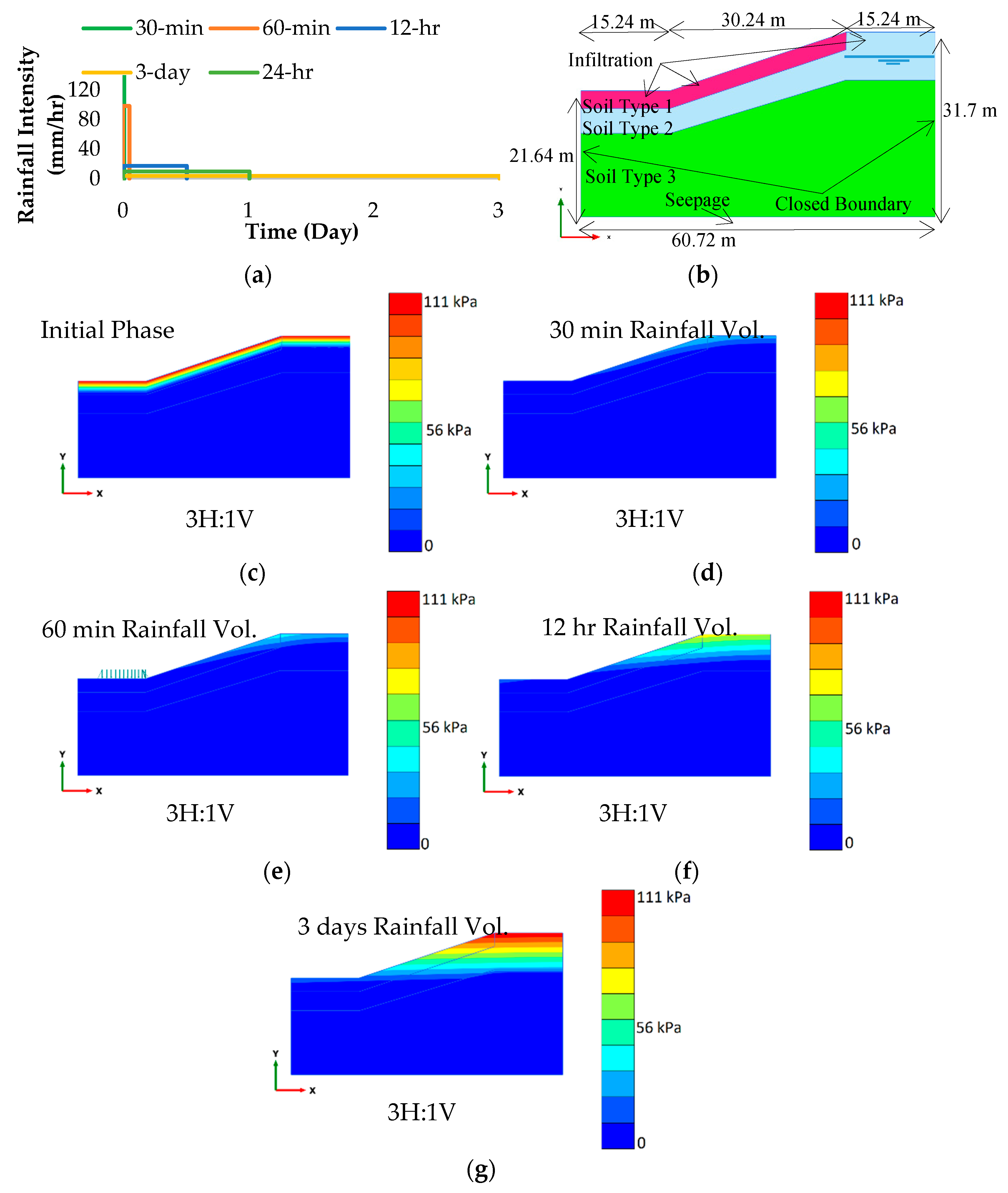

3.4. Effect of Rainfall on Slope Failure

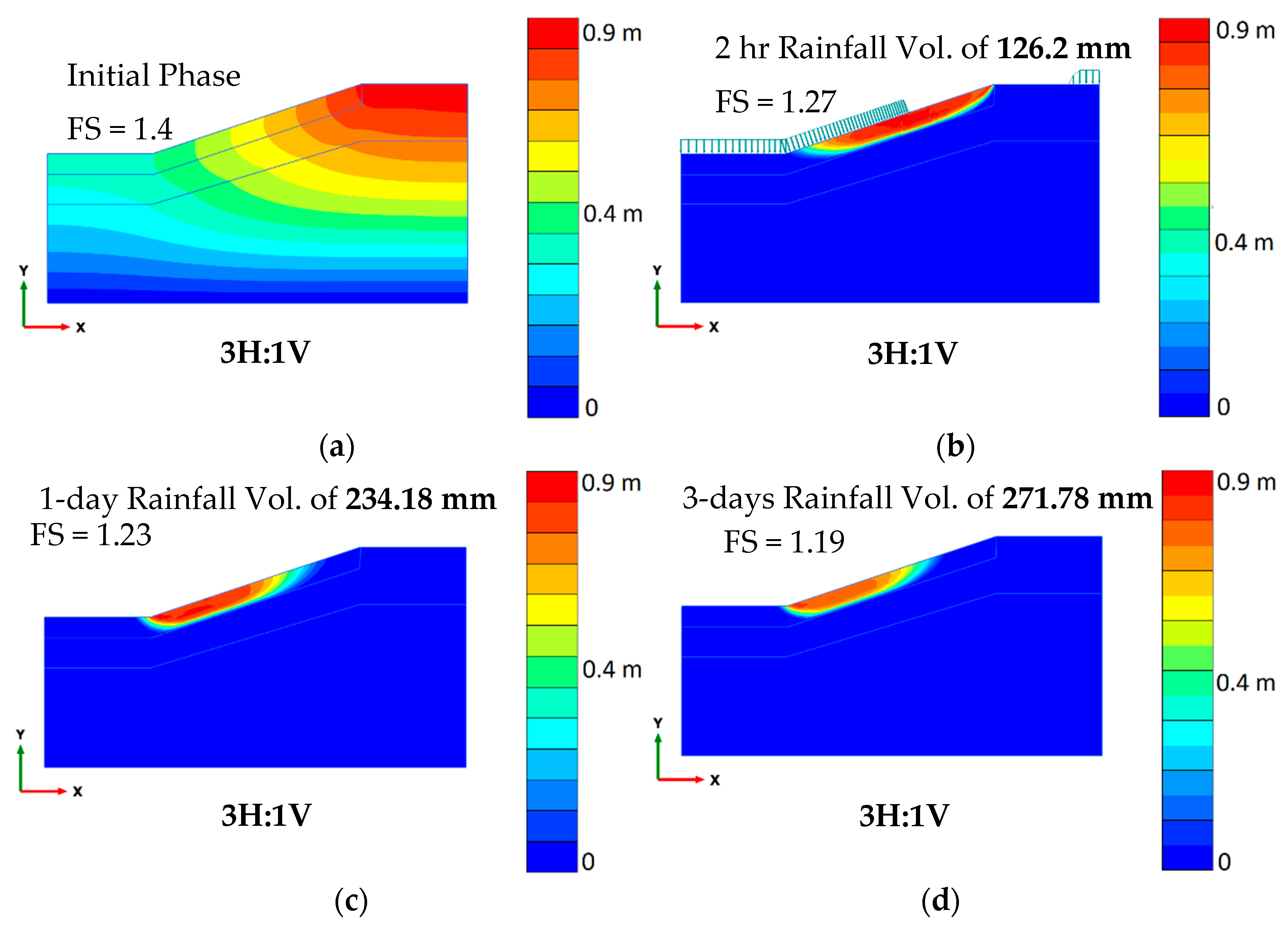

Flow Analyses Results

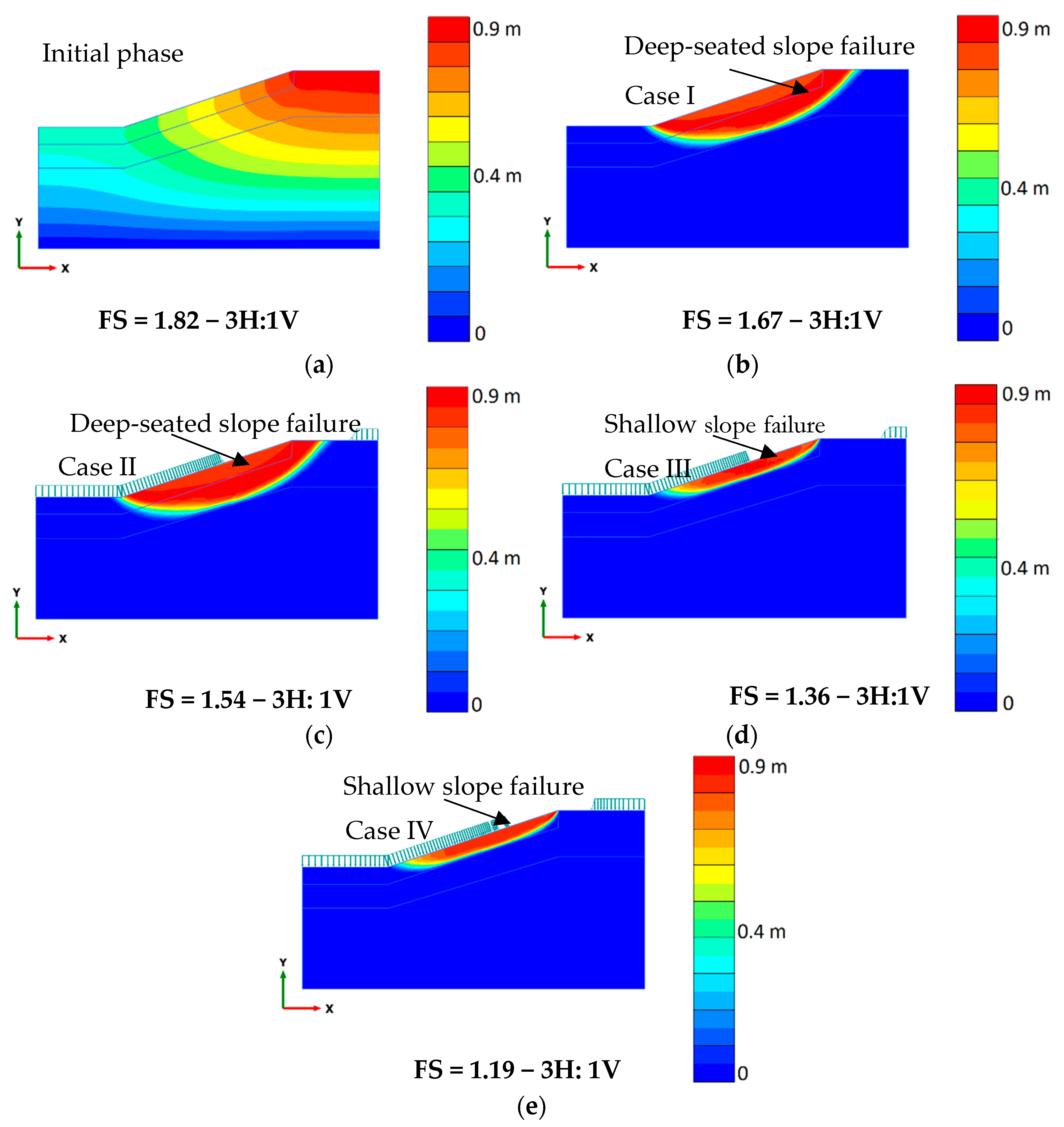

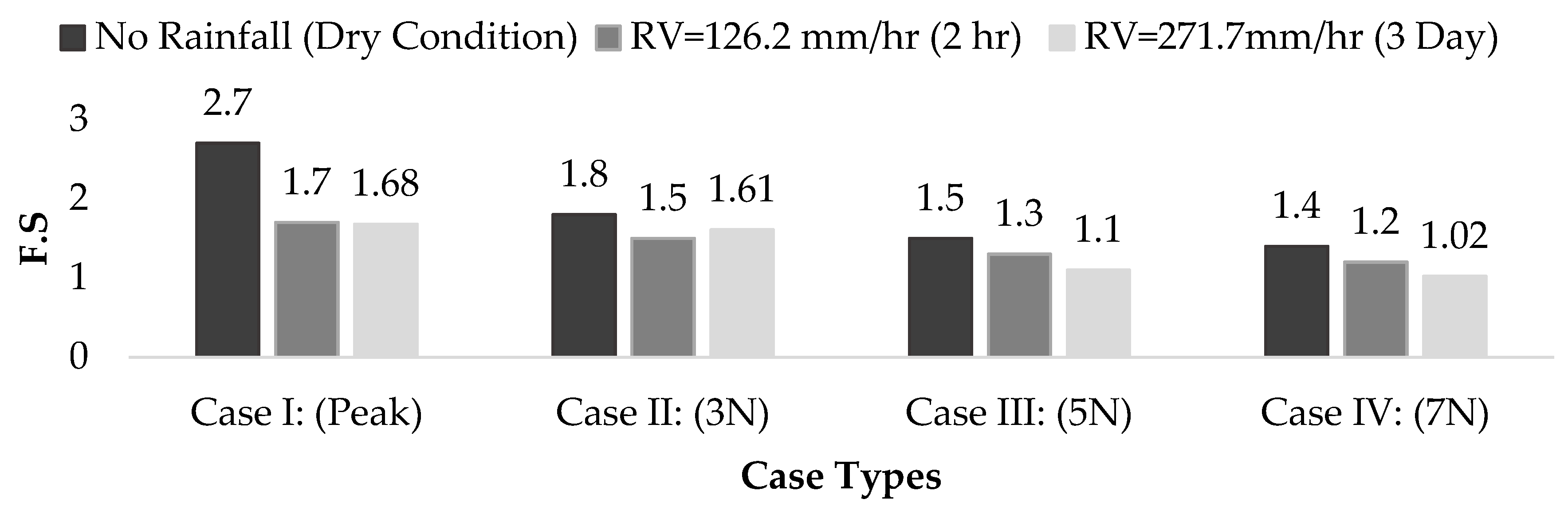

3.5. Stability Analysis Results

4. Conclusions

- ▪

- It is evident that the variation in numbers of wet-dry cycles increases the void ratio of Yazoo clay. With changes in the void ratio of Yazoo clay, the shear strength of the soil, especially cohesion, dropped significantly. With seven wet-dry cycles, a 77% drop in cohesion was observed.

- ▪

- The stability analysis of slopes made of Yazoo clay with a different number of wet-dry cycle shear strengths on the topsoil decreased from 2.7 to 1.4 as the number of wet-dry cycle increased.

- ▪

- Considering the effect of two rainfall periods of Rv = 126.2 mm (2 h) and Rv = 271.7 mm at three days, the factor of safety reduced from 1.7 to 1.2 and 1.68 to 1.02, respectively, considering the effect of 3, 5 and 7 wet-dry cycles in the topsoil. It is clearly observed that the factor of safety reached a critical value, which is a coupled effect of the changes in shear strength due to 7 wet-dry cycles and saturation due to sustained rainfall for three days.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Nelson, J.; Miller, J.D. Expansive Soils: Problems and Practice in Foundation and Pavement Engineering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1992. [Google Scholar]

- Buhler, R.L.; Cerato, A.B. Stabilization of Oklahoma Expansive Soils using Lime and Class C Fly Ash. In Proceedings of the Geo-Denver 2007, Denver, CO, USA, 18–21 February 2007; pp. 1–10. [Google Scholar]

- El-Sohby, M.A.; El-Sayed, A.R. Some factors are affecting swelling of clayey soils. J. Geotech. Eng. 1981, 12, 19–39. [Google Scholar]

- Fredlund, D.G.; Rahardjo, H. Soil Mechanics for Unsaturated Soils; John and Wiley and Sons, Inc.: Hoboken, NJ, USA, 1993. [Google Scholar]

- Hanafy, E.; Knodel, P. Swelling/Shrinkage Characteristic Curve of Desiccated Expansive Clays. Geotech. Test. J. 1991, 14, 206. [Google Scholar]

- Puppala, A.J.; Manosuthkij, T.; Nazarian, S.; Hoyos, L.R. Threshold moisture content and matric suction potentials in expansive clays prior to initiation of cracking in pavements. Can. Geotech. J. 2011, 48, 519–531. [Google Scholar] [CrossRef]

- Ahmed, A.; Hossain, S.; Khan, M.S.; Shishani, A. Data-Based Real-Time Moisture Modeling in Unsaturated Expansive Subgrade in Texas. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 86–95. [Google Scholar] [CrossRef]

- Landris, T.; Lee, P.E., Jr. State Study 151 and 236: Yazoo Clay Investigation; MDOT State Study 236; US Army Corps of Engineers: Washington, DC, USA, 2012.

- Douglas, S.C.; Dunlap, G.T. Light commercial construction on Yazoo clay. In Proceedings of the Second Forensic Engineering Congress, San Juan, Puerto Rico, USA, 21–23 May 2000; pp. 607–616. [Google Scholar]

- Taylor, A.C. Mineralogy and engineering properties of the Yazoo clay formation. Jackson Group. Master’s Thesis, Mississippi State University, Mississippi State, MS, USA, 2005. [Google Scholar]

- Das, B.M.; Sobhan, K. Principles of Geotechnical Engineering, 8th ed.; Cengage Learning: Boston, MA, USA, 2013; ISBN-13 978-1133108665. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D.; Sheahan, T.C. An Introduction to Geotechnical Engineering; Pearson: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

- Johnson, L.D. Properties of expansive clay soils, Jackson field test section study; U.S. Army Engineer Waterways Experiment Station: Vicksburg, MI, USA, Report 1, Misc. Paper S73-28; 1973. [Google Scholar]

- Rogers, L.E.; Wright, S.G. The Effects of Wetting and Drying on the Long-Term Shear Strength Parameters for Compacted Beaumont Clay; FHWA/TX-87/40+436-2F; Center for Transportation Research, University of Texas at Austin: Austin, TX, USA, 1986. [Google Scholar]

- Day, R.W.; Axten, G.W. Surficial Stability of Compacted Clay Slopes. J. Geotech. Eng. 1989, 115, 577–580. [Google Scholar] [CrossRef]

- Baum, R.L.; Chleborad, A.F. Landslides Triggered by Pacific Northwest Storms in the Puget Lowland, Washington; Information Reports; Washington State Department of Natural Resources: Washington, DC, USA, 1998.

- Cai, F.; Ugai, K. Numerical Analysis of Rainfall Effects on Slope Stability. Int. J. Géoméch. 2004, 4, 69–78. [Google Scholar] [CrossRef]

- Collins, B.D.; Znidarcic, D. Stability Analyses of Rainfall Induced Landslides. J. Geotech. Geoenviron. Eng. 2004, 130, 362–372. [Google Scholar] [CrossRef]

- Pando, M.A.; Ruiz, M.E.; Larsen, M.C. Rainfall-Induced Landslides in Puerto Rico: An Overview. In Proceedings of the Geo-Frontiers 2005, Austin, TX, USA, 24–26 January 2005. [Google Scholar]

- Tohari, A.; Nishigaki, M.; Komatsu, M. Laboratory Rainfall-Induced Slope Failure with Moisture Content Measurement. J. Geotech. Geoenviron. Eng. 2007, 133, 575–587. [Google Scholar] [CrossRef]

- Cascini, L.; Cuomo, S.; Pastor, M.; Sorbino, G. Modeling of rainfall-induced shallow landslides of the flow-type. J. Geotech. Geoenviron. Eng. 2009, 136, 85–98. [Google Scholar] [CrossRef]

- Rahimi, A.; Rahardjo, H.; Leong, E.-C. Effect of hydraulic properties of soil on rainfall-induced slope failure. Eng. Geol. 2010, 114, 135–143. [Google Scholar] [CrossRef]

- Conte, E.; Troncone, A. Simplified approach for the analysis of rainfall-induced shallow landslides. J. Geotech. Geoenviron. Eng. 2011, 138, 398–406. [Google Scholar] [CrossRef]

- Tiwari, B.; Upadhyaya, S. Influence of Antecedent Rainfall on Stability of Slopes. In Proceedings of the Geo-Congress 2014, Atlanta, GA, USA, 23–26 February 2014; pp. 3243–3251. [Google Scholar]

- Damiano, E.; Mercogliano, P. Potential Effects of Climate Change on Slope Stability in Unsaturated Pyroclastic Soils. Landslide Sci. Pract. 2013, 15–25. [Google Scholar] [CrossRef]

- Hossain, J. Geohazard Potential of Rainfall Induced Slope Failure on Expansive Clay. Ph.D. Thesis, University of Texas at Arlington, Arlington, TX, USA, 2013. [Google Scholar]

- Lu, Y.; Zapata, C.E. Temperature effects on the unsaturated hydraulic properties of two fine grained soils and their influence on moisture movement under an airfield test facility. In Proceedings of the Geotechnical and Structural Engineering Congress 2016, Phoenix, AZ, USA, 14–17 February 2016. [Google Scholar]

- Pino, A.; Pedaria, A.; Puppala, A.; Hoyos, L.R. Evaluation of swell behavior of expansive clays from specific moisture capacity. In Proceedings of the E3S Web of Conferences, Paris, France, 12–14 September 2016; p. 14011. [Google Scholar]

- Lawrence, M.; Jiang, Y. Porosity, Pore Size Distribution, Micro-structure. In Bio-Aggregates Based Building Materials; RILEM State-of-the-Art Reports; Amziane, S., Collet, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- ASTM D3080/D3080M-11, Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions; ASTM International: West Conshohocken, PA, USA, 2011.

- Khan, M.S.; Ivoke, J.; Nobahar, M.; Kibria, G. Effect of Wet-Dry Cycles on the Void Ratio of Expansive Yazoo Clay Soil. In Proceedings of the Eighth International Conference on Case Histories in Geotechnical Engineering, Philadelphia, PA, USA, 24–27 March 2019. [Google Scholar]

- Nobahar, M.; Khan, M.; Ivoke, J.; Amini, F. Impact of Rainfall Variation on Slope Made of Expansive Yazoo Clay Soil in Mississippi. Transp. Infrastruct. Geotechnol. 2019. [Google Scholar] [CrossRef]

- Bulut, R.; Wray, W.K. Free energy of water suction in filter papers. Geotechnical Testing J. 2005, 28, 355–364. [Google Scholar]

- Houston, S.L.; Houston, W.N.; Zapata, C.E.; Lawrence, C. Geotechnical engineering practice for collapsible soils. Geotech. Geol. Eng. 2001, 19, 333–355. [Google Scholar] [CrossRef]

- Alonso, E.; Romero, E.; Hoffmann, C.; Garcia-Escudero, E. Expansive bentonite-sand mixtures in cyclic controlled-suction drying and wetting. Eng. Geol. 2005, 81, 213–226. [Google Scholar] [CrossRef]

- Rosenbalm, D.; Zapata, C.E. Effect of Wetting and Drying Cycles on the Behavior of Compacted Expansive Soils. J. Mater. Civ. Eng. 2017, 29, 4016191. [Google Scholar] [CrossRef]

- Tripathy, S.; Rao, K.S.; Fredlund, D.G. Water content—Void ratio swell-shrink paths of compacted expansive soils. Can. Geotech. J. 2002, 39, 938–959. [Google Scholar] [CrossRef]

- Basma, A.A.; Al-Homoud, A.S.; Malkawi, A.I.H.; AlBashabsheh, M.A. Swelling shrinkage behavior of expansive natural clays. Appl. Clay Sci. 1996, 11, 211–227. [Google Scholar] [CrossRef]

- Barton, C.D. Clay minerals. In Encyclopedia of Soil Science; Marcel Dekker: New York, NY, USA, 2002; pp. 187–192. [Google Scholar]

- Zornberg, J.G.; Kuhn, J.; Wright, S. Determination of Field Suction Values, Hydraulic Properties and Shear Strength in High PI Clays; Research Report 0-5202-1; Center for Transportation Research, University of Texas at Austin: Austin, TX, USA, 2007. [Google Scholar]

- Skempton, A.W. First-Time Slides in Over-Consolidated Clays. Géotechnique 1970, 20, 320–324. [Google Scholar] [CrossRef]

- Skempton, A.W. Residual strength of clays in landslides, folded strata and 2493 the laboratory. Géotechnique 1985, 35, 3–18. [Google Scholar] [CrossRef]

- Khan, M.S.; Nobahar, M.; Ivoke, J. Development of Design Protocol: Sustainable Stabilization of Slope Using Recycled Plastic Pin in Mississippi; Maritime Transportation Research and Education Center: Fayetteville, NC, USA, 2017. [Google Scholar]

- Khan, M.S.; Hossain, S.; Ahmed, A.; Faysal, M. Investigation of a shallow slope failure on expansive clay in Texas. Eng. Geol. 2017, 219, 118–129. [Google Scholar] [CrossRef]

- Khan, M.S.; Nobahar, M.; Ivoke, J.; Amini, F. Effect of Rainfall on Slope made of Yazoo Clay Soil in Mississippi. In Proceedings of the Transportation Research Board (TRB) 97th Annual Meeting, Washington, DC, USA, 7–11 January 2018. [Google Scholar]

- Khan, M.S.; Ivoke, J.; Nobahar, M. Effect of Swell-Shrink Characteristics on Landslides in Yazoo Clay; Maritime Transportation Research and Education Center: Fayetteville, NC, USA, 2018. [Google Scholar]

- Griffiths, D.V.; Lane, P.A. Slope stability analysis by finite elements. Géotechnique 1999, 49, 387–403. [Google Scholar] [CrossRef]

- Zapata, C.E.; Andrei, D.; Witczak, M.W.; Houston, W.N. Incorporation of Environmental Effects in Pavement Design. Road Mater. Pavement Des. 2007, 8, 667–693. [Google Scholar] [CrossRef]

| Physical Properties | Values |

|---|---|

| Unified Classification | CH |

| Liquid Limit | 108% |

| Plasticity Index | 84% |

| Dry unit weight | 12.88 kN/m3 |

| Specific Gravity | 2.68 |

| Natural Moisture Content | 35% |

| Number of Samples | No of Wet-Dry Cycles | Investigative Parameters |

|---|---|---|

| 3 | 1 | Void Ratio, Drained Shear Strength |

| 3 | 3 | |

| 3 | 5 | |

| 3 | 7 |

| Mineral Composition of Yazoo Clay Sample | Weight (%) | Weight % Error (+/−1 Sigma) | Normalized Weight (%) | Normalized Weight % Error (+/− Sigma) | Atom % |

|---|---|---|---|---|---|

| Carbon | 1.36 | ±0.11 | 1.36 | ±0.11 | 2.26 |

| Oxygen | 54.14 | ±0.40 | 54.14 | ±0.40 | 67.67 |

| Flourine | 0.00 | --- | 0.00 | --- | 0.00 |

| Magnesium | 1.22 | ±0.08 | 1.22 | ±0.08 | 1.00 |

| Alluminum | 10.90 | ±0.13 | 10.90 | ±0.13 | 8.08 |

| Silicon | 25.21 | ±0.18 | 25.21 | ±0.18 | 17.95 |

| Potassium | 1.44 | ±0.08 | 1.44 | ±0.08 | 0.74 |

| Calcium | 1.53 | ±0.09 | 1.53 | ±0.09 | 0.77 |

| Titanum | 0.46 | ±0.05 | 0.46 | ±0.05 | 0.19 |

| Iron | 3.74 | ±0.21 | 3.74 | ±0.21 | 1.34 |

| Rainfall Duration (h) | Rainfall Intensity (mm/h) | Total Rainfall Volume (RV, mm) |

|---|---|---|

| 0.5 | 141.73 | 70.86 |

| 1 | 98.55 | 98.55 |

| 2 | 63.12 | 126.2 |

| 6 | 29.80 | 178.81 |

| 12 | 17.29 | 207.51 |

| 24 | 9.76 | 234.18 |

| 72 | 3.77 | 271.78 |

| Parameter | Name | Unit | Soil 1 | Soil 2 | Soil 3 |

|---|---|---|---|---|---|

| Bulk unit weight | ϒunsat | kN/m3 | 20 | 20 | 22 |

| Saturated unit | ϒsat | kN/m3 | 21 | 21 | 22 |

| weight | |||||

| Vertical | kv | cm/s | 0.034 | - | - |

| Permeability | |||||

| Horizontal | kh | cm/s | 3.06 × 10−6 | - | - |

| Permeability | |||||

| Poison’s Ratio | v | - | 0.3 | 0.3 | 0.3 |

| Young’s Modulus | E | kN/m2 | 4.788 | 4.788 | 4.788 |

| Cohesion | C | kPa | Presented in Table 6 | 18.4 | 3000 |

| Friction angle | Ф | degree | 20.2 | 35 |

| Case | Wet-Dry Cycles | Cohesion (kPa) | Friction Angle (deg.) |

|---|---|---|---|

| I | 0N | 18.44 | 20.34 |

| II | 3N | 5.98 | 21.99 |

| III | 5N | 4.79 | 20.87 |

| IV | 7N | 4.31 | 18.42 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, S.; Ivoke, J.; Nobahar, M. Coupled Effect of Wet-Dry Cycles and Rainfall on Highway Slope Made of Yazoo Clay. Geosciences 2019, 9, 341. https://doi.org/10.3390/geosciences9080341

Khan S, Ivoke J, Nobahar M. Coupled Effect of Wet-Dry Cycles and Rainfall on Highway Slope Made of Yazoo Clay. Geosciences. 2019; 9(8):341. https://doi.org/10.3390/geosciences9080341

Chicago/Turabian StyleKhan, Sadik, John Ivoke, and Masoud Nobahar. 2019. "Coupled Effect of Wet-Dry Cycles and Rainfall on Highway Slope Made of Yazoo Clay" Geosciences 9, no. 8: 341. https://doi.org/10.3390/geosciences9080341

APA StyleKhan, S., Ivoke, J., & Nobahar, M. (2019). Coupled Effect of Wet-Dry Cycles and Rainfall on Highway Slope Made of Yazoo Clay. Geosciences, 9(8), 341. https://doi.org/10.3390/geosciences9080341