1. Introduction

In 1955, the American Standards Association [

1] suggested the following indices for giving numerical values to certain components of surface roughness:

where,

CLA and

Z1 stands for center line average and root mean square respectively,

L is the distance over which the average is taken, is the amplitude of the roughness about the center line and

dx is the small constant distance between two adjacent amplitude readings.

A few years later, Myers [

2] reported that although many different surfaces have the same

RMS (or

CLA) value, their geometrical properties differ greatly, suggesting the following three new characteristics:

and

where,

L = Σ(Δ

xi)

p + Σ(Δ

xi)

n is the total profile distance,

xi is segment of

L and the subscripts

p and

n mean positive and negative slope respectively. In this respect, the experimental work carried out by Myers [

2] showed that the most useful characteristic in predicting friction was the

Z2 one.

In 1979, Tse and Cruden [

3] put again the above

Z-characteristics into question. The objective was a convincing correlation with the joint roughness coefficient (JRC). In this respect, the ten standards profiles of Barton and Choubey [

4] were used (these profiles are shown in the

Appendix A). The JRC coefficient is of particular importance for calculating the peak shear strength of rock surfaces through Barton and Choubey’s empirical equation:

where,

τpeak is the maximum shear strength, σ

n is normal stress,

φr is the residual friction angle of discontinuity and JCS is the joint compressive strength. JCS can be estimated using the Schmidt hammer [

5]. In addition to the

Z-characteristics, in their comparison, Tse and Cruden [

3] used the following statistical indices:

and

where,

y(

x) is the amplitude of asperity height at the distance,

x, along the length,

L, and Δ

x is a constant distance lag.

MSV, ACF and

SF stand for mean square values, autocorrelation function and structure function respectively, the latter has been proposed by Sayles and Thomas [

6]. Tse and Cruden [

3] confirmed that, among all

Z-characteristics, the

Z2 one performed better, whilst for the

SF index they found that it was as good as

Z2. Indeed, they gave JRC-log

Z2 and JRC-log

SF relationships having R-squared values as high as 0.972 and 0.968 respectively. Yu and Vayssade [

7] reported an infinitesimal improvement based on the JRC-

and JRC-

relationships. It is mentioned that, Tse and Cruden [

3] used a laborious procedure to eliminate possible errors, something that apparently increased the R-squared value of their correlations. The authors attempted to reproduce the JRC-log

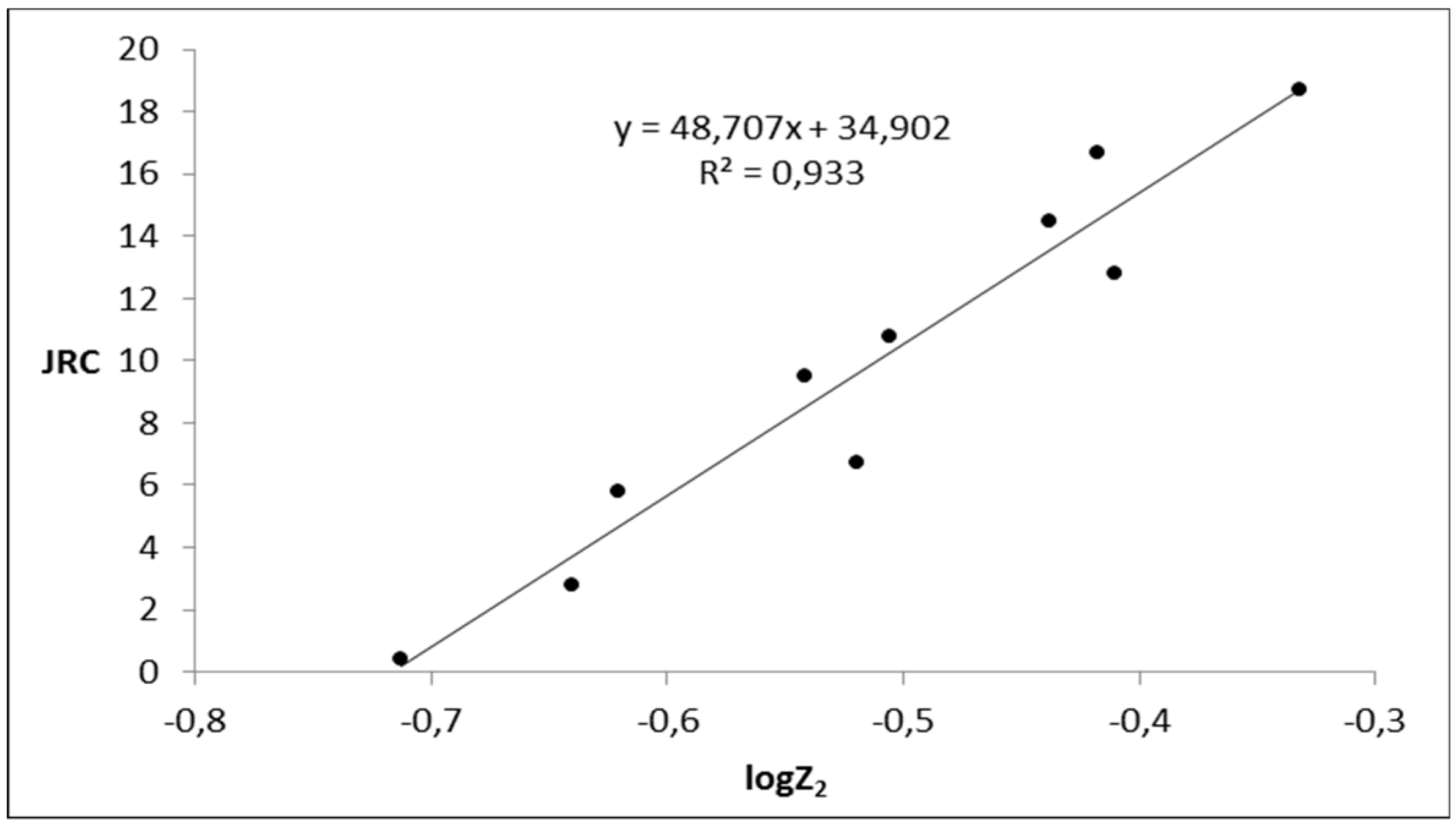

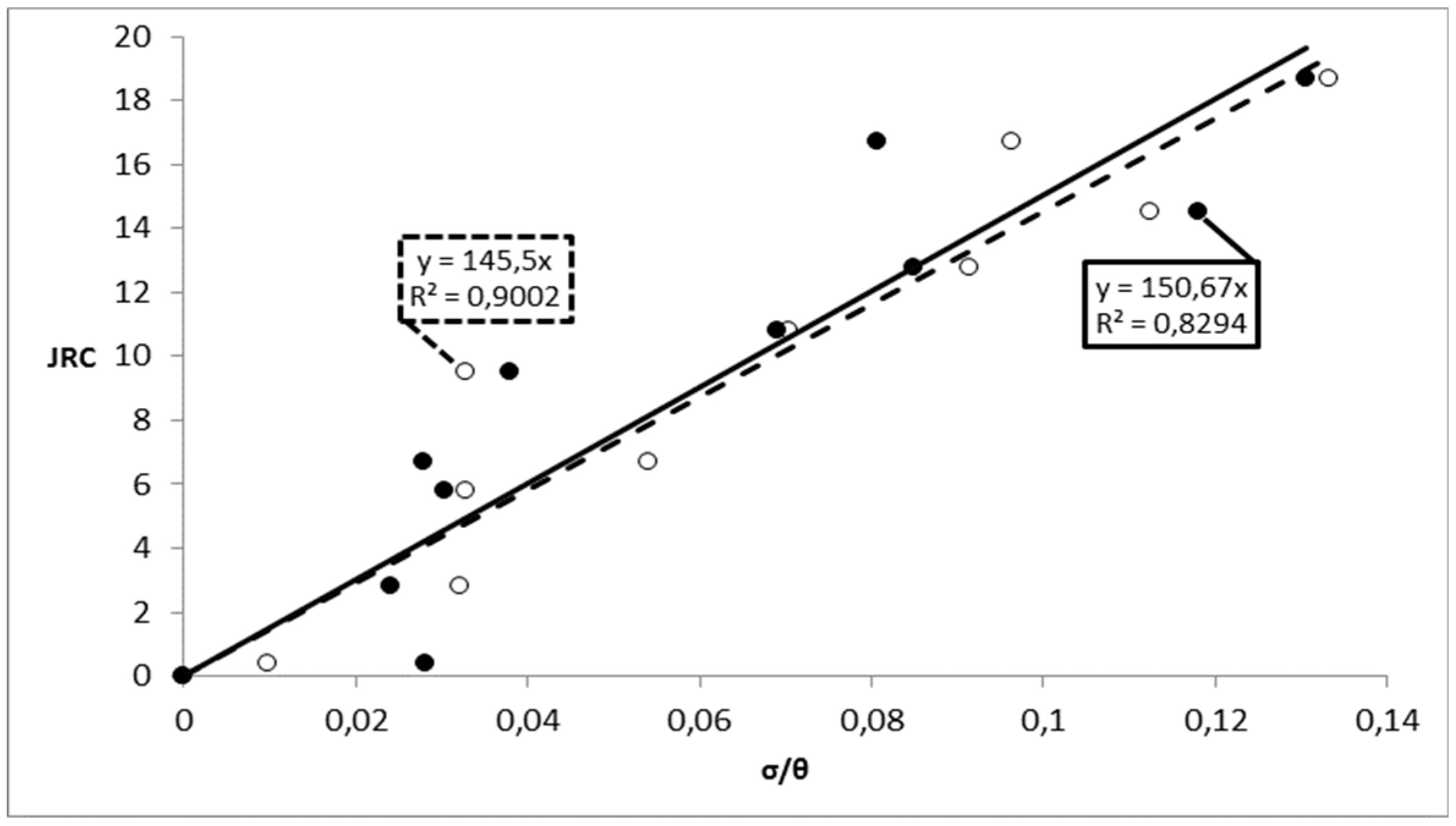

Z2 relationship and they found that:

with R

2 = 0.933. The original Barton and Choubey’s [

4] image depicting the ten standard JRC profiles was used. The graph of

Figure 1 was drawn based on 1024 sampling points for each of these profiles after subtracting the linear trend. The digitalization was done with Wolfram Mathematica. It was only verified that the digitized images coincide visually with Barton and Choubey’s profiles having involved no further fine tuning of the digitization. Apparently, the result depends on both sampling and the quality of image. This is in keeping with the very notion of the standard profiles. Besides, the goal of this paper is not a refined JRC-log

Z2 (or similar) relationship which will just increase R

2 by a few second decimal units. It is noted that, the various sources of error are discussed in Gao and Wong [

8].

Since Tse and Cruden [

3], numerous other researchers have either evaluated the existing methods for estimating the JRC coefficient or proposed new ones [

7,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22], e.g., Yang et al. [

12] and Yu and Vayssade [

7] found R

2 = 0.986 and 0.910 for the JRC-log

Z2 relationship respectively. However, the

Z2 characteristic remains the most popular one, apparently due to its simplicity and efficiency. A review of these methods is out of scope of the present paper. In this respect, the authors suggest the works done by Li and Zhang [

13] and Li and Huang [

14]. Instead, the present work intends to embed the estimation of the joint roughness coefficient (JRC) in the framework of the random fields. The random field method is a probabilistic approach to geotechnical problems which involves modeling the spatial variability of the pertinent physical quantities as a fundamental part of the (assumed) underlying probabilistic structure.

2. Methods

The geometric description uses the information contained in the details of the shape of the curve to provide a measure of roughness in a deterministic way. There are many levels of complexity in the geometric description of the profile going all the way to fractal geometry. A recent literature review of empirical equations for estimating JRC by using the fractal dimension

D has been offered by Li and Huang [

14]. As mentioned above, an elementary and attractive choice is to use the quantity

Z2 defined by Equation (3).

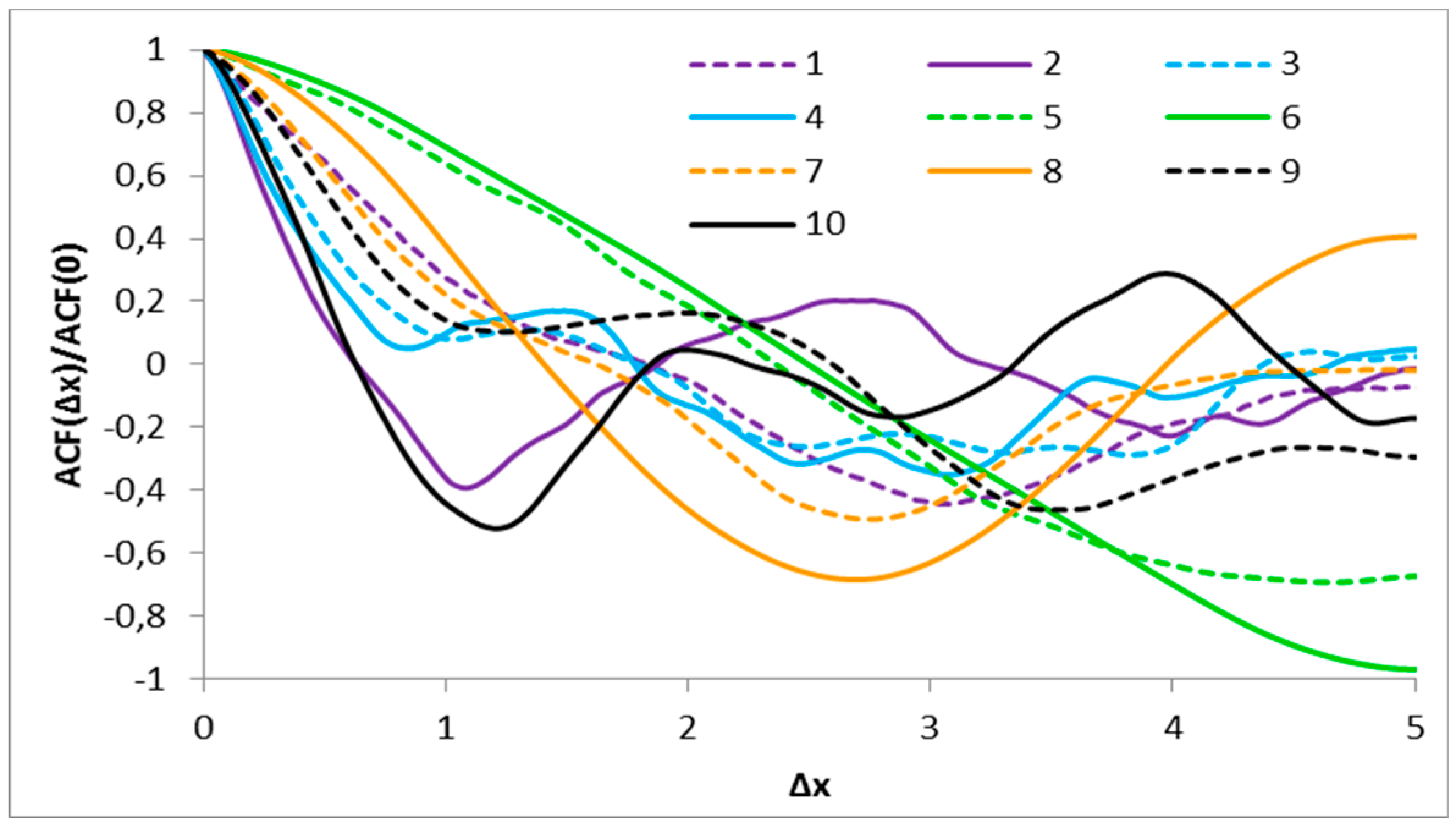

On the other hand, in statistical description, roughness is understood as the estimated value of a certain statistic, treating the profile as a collection of events that obey an underlying probabilistic structure. The autocorrelation function (ACF; Equation (8)) is an example of such a statistic. For example, for zero correlation distance (Δx = 0), the correlation function computes an estimate of the variance σ2 of the profile regarding the height y at each point x as a random variable with a fixed variance.

In Tse and Cruden [

3], the structure function (

SF) defined by Equation (9) has been correlated with the JRC value of the ten standard profiles, which treated Δ

x as fixed and equal to the length of the interval between two successive sampling points. This showed that it is as good an index as

Z2. This is not surprising because if Δ

x is the sampling interval, the discrete version of Equations (8) and (9) essentially coincide. Still, the statistical information contained in the

ACF as a function over its entire natural range (−

L/2,

L/2) has neither been exploited nor been put in a statistical framework. This is done herein with the statistical description of roughness based on random fields. In this respect, a profile as a whole is regarded as a single realization of an underlying probabilistic structure where the function

ACF(Δ

x) over the whole of its natural range (−

L/2,

L/2) is assumed to have a fixed and pre-defined form. This form is denoted by C(Δx) and called the variance function of the random field [

23]. The exact definitions are given below.

A function y over −∞ ≤

x ≤ ∞ is a (stationary Gaussian) random field if every number y

(x) is a Gaussian random variable with (constant) mean value

μ and point-variance

σ2, i.e.,

where, E[…] denotes the expectation value of the quantity inside the brackets over a large number of realizations of the random field, and every two random variables y(x), y(x + Δx) (associated with two different positions x, x + Δx along the interval) are correlated in a given manner, i.e.,

These define completely the Gaussian random field. The variance function C(Δx) can be chosen in a variety of ways depending on the nature of the quantity being attempted to model. Clearly, C(0) = σ

2 by Equations (11) and (12). Therefore, defining the normalized variance function:

which satisfies

ρ(0) = 1. The coordinates in the description of the profiles are chosen so that the mean value μ is zero, so there is no difference between the autocorrelation and variance function of the profile.

A very convenient choice is the Gaussian variance function:

The spatial correlation length

θ is defined by

(e.g., see [

23,

24]) noting that the variance function is even.

It is also noted, that the correlation length is related to the value of the derivatives of the variance function at zero. In particular the value of the second derivative reads:

The integral definition above defines, for any variance function, a macro-scale, while the derivative definition defines a micro-scale. These definitions are usual in other areas where correlation functions are used, e.g., in the theory of turbulence [

25]. In general, if the micro-scale can be defined at all, they could be entirely different. The fact that they are both related to the single length

θ is of course due to the fact that the model variance function used here involves by definition the single length

θ. This feature is realized, in some sense, by the roughness profiles. The argument is as follows.

Consider the Z

2 characteristic defined in Equation (3). If y(x) is a random field, then the index (Z

2)

2 is a random variable. It can be easily shown that its expectation value is:

The index (Z

2)

2 can be regarded as a statistic that estimates the value of the (a priori fixed) quantity 2πσ

2/

θ2. In all, in regard of estimates:

It is also reminded that Z

2 correlates very well with the roughness coefficient JRC, which must be related to both the macro- and micro-scale of the profile. This recalls the almost perfect correlations found by Tse and Cruden [

3], Yang et al. [

12] and Yu and Vayssade [

7]. However, Z

2 is rather related more to the micro-scales of the profile than to the macro-scales, due to the derivative involved in its definition. Therefore, it is concluded that, first, a single length may be adequate when modelling a roughness profile with a random field and second, that the quantity σ/

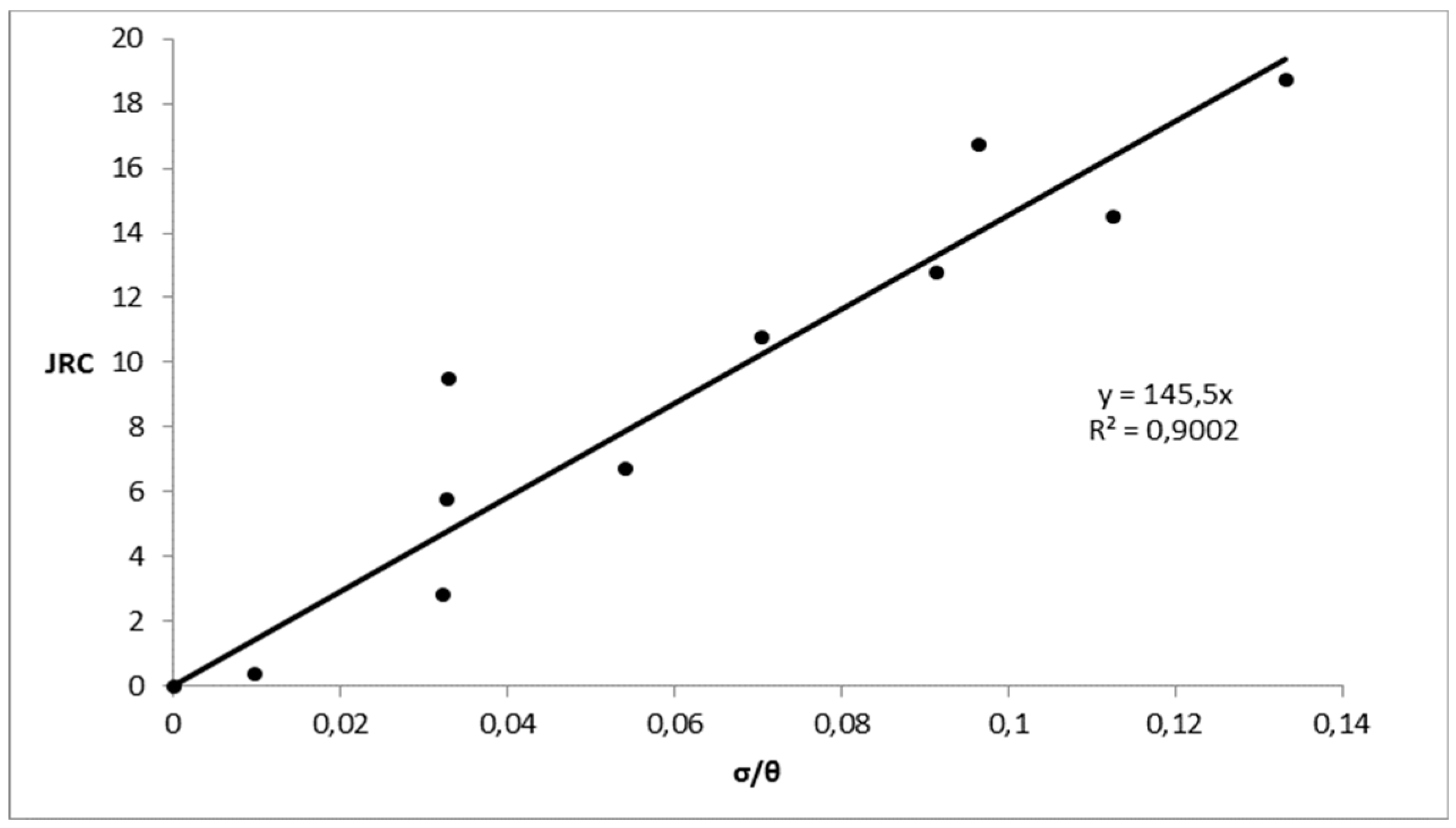

θ is a good candidate for quantifying the roughness coefficient JRC in the framework of the random fields.

4. Discussion

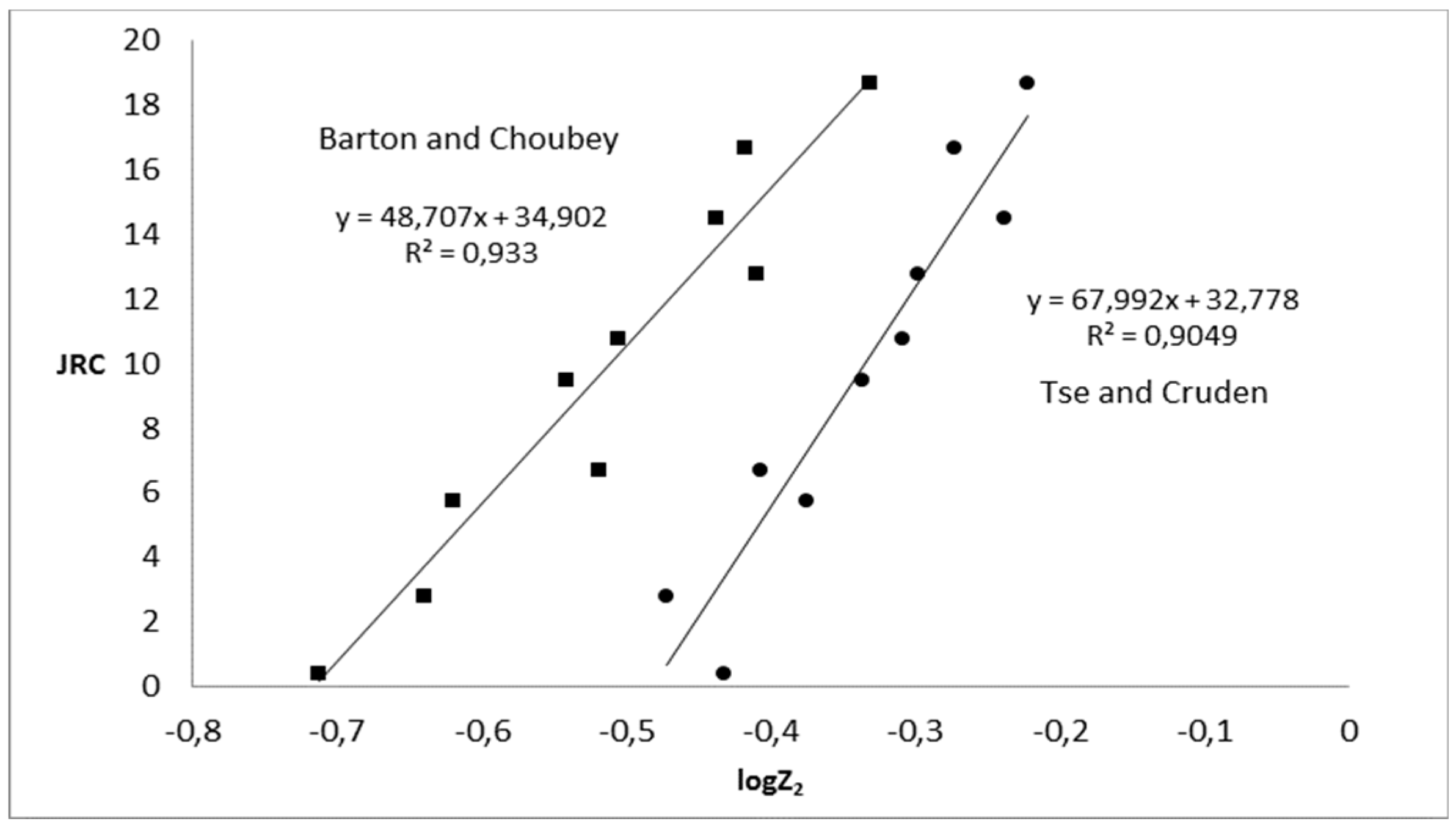

The authors revisited the problem of determining the joint roughness coefficient (JRC) included in the Barton-Bandis failure criterion from the point of view of digitalized profiles of discontinuities. However, numerous indices have been correlated with JRC, with the geometric characteristic Z2 being, probably, the most popular one. Based on the international literature, the statistical measure SF (Structure Function), has been a good alternative giving also very strong correlations with JRC.

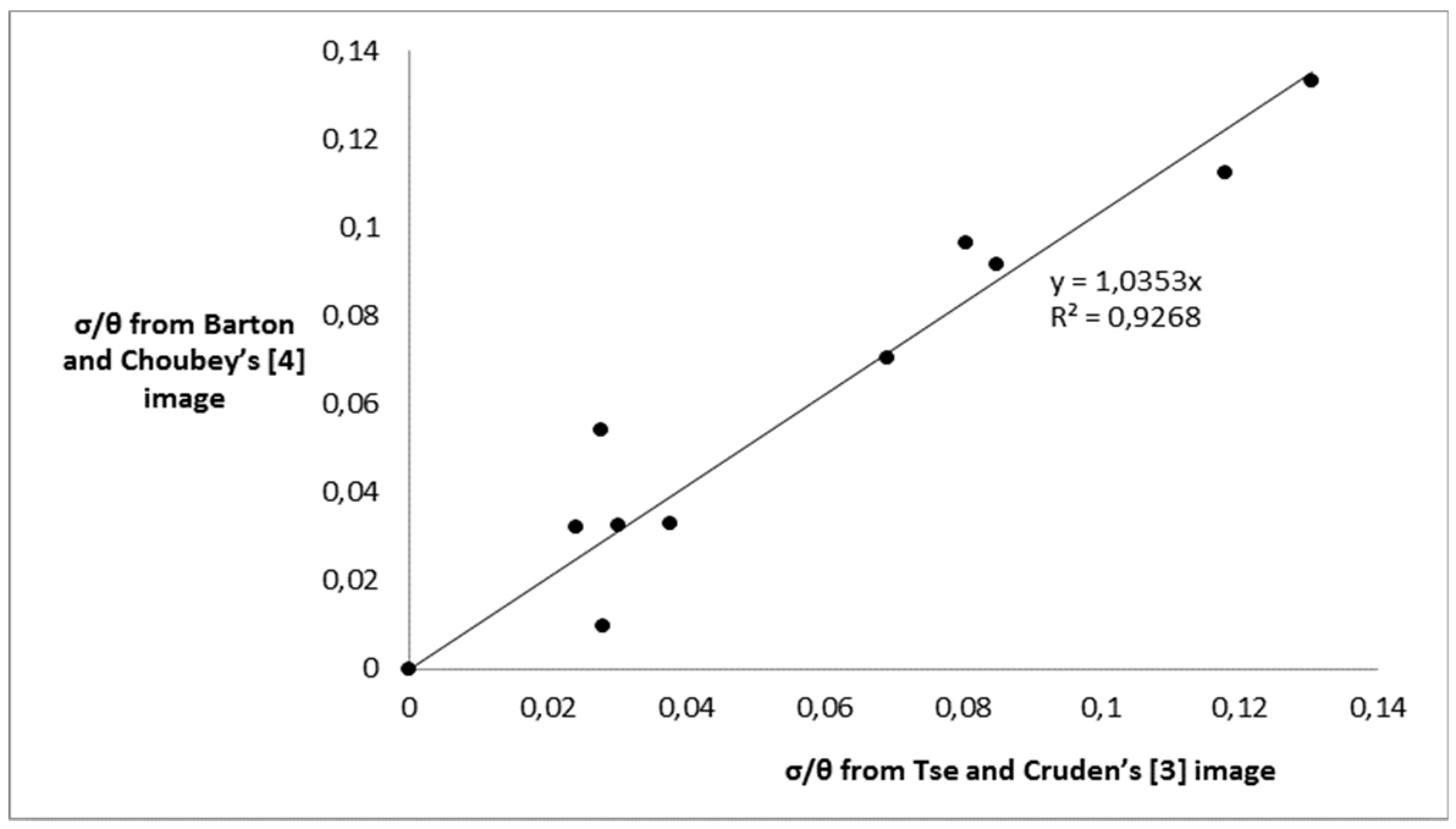

As the random fluctuation of discontinuities can be considered as being random fields, the present paper targeted on embedding the estimation of the joint roughness coefficient (JRC) in the framework of the theory of random fields. The analysis showed that the fluctuation of discontinuities in both micro- and macro scale was related to a single length and more specifically to the spatial correlation length,

θ (essential parameter in the theory of random fields). Indeed, it was found that the quantity σ/

θ was a good candidate for quantifying the roughness coefficient JRC. Usually, the determination of

θ relies on the best fit of a suitably chosen model variance function to the normalized autocorrelation function. The stability of the proposed σ/

θ index as a roughness measure was compared against the characteristic

Z2. In this respect, the two indices were applied to images of the same discontinuity profiles and more specifically, the ten standard JRC profiles given by Barton and Choubey [

4], but of different quality. From the results, it is clear that the estimates for JRC by the proposed method appear to be much more stable, in contrast to

Z2 or, as explained earlier,

SF (structure function).

The fact that the R-squared value for the JRC-σ/

θ relationship of

Figure 3 (R

2 = 0.9002), although very strong, was not perfectly strong can be attributed to three main reasons. First, no fine tuning of the digitization of Barton and Choubey’s [

4] figure was involved. Second, the ten JRC profiles were representative of the two-dimensional cross-sections, whilst their JRC values were average values referring to the respective three-dimensional fluctuating surface of the rock blocks. Third, despite the versatility of the random field method, the derived

θ values depended on the extend of the sampling domain [

28,

29]. An extensive parallel research conducted by the authors (paper under preparation) indicated that, for eliminating this kind of error in the proposed JRC-σ/

θ relationship, a domain at least 35

θ in length was required to be considered. Indeed, as the domain length increases (in this respect, the length of discontinuity) the

θ value reaches asymptotically its maximum value for the specific random field. This is in agreement with the empirical scale correction relationship suggested by Barton and Bandis [

30]:

where, JRC

n and JRC

o are the joint roughness coefficients corresponding to samples of length L

n and L

o = 10 cm respectively. More specifically, Equation (22) shows that, the JRC

n value decreases as the L

n/L

o ratio increases towards a minimum asymptotic value. On the other hand, as L

n/L

o increases, the σ/

θ ratio and thus, the JRC value decreases (recall the JRC-σ/θ relationship in

Figure 3) towards a minimum asymptotic value. Based on the

θ values given in

Table 2, the rock joint profiles should be at least 2 to 9 times longer than the 10 cm of the original Barton and Choubey’s [

4] profiles (value depending on the fluctuation pattern of each profile) for effectively determining the JRC.

The above has been supported by the experimental findings of Barton and Choubey [

4]. In this respect, Barton and Choubey performed three tilt tests on a 40 × 45 cm joint area (sliding along the long dimension) and they found an (average) joint roughness coefficient value equal to 5.5. The same sample was sawn by Barton and Choubey into 18 samples 4.9 × 9.8 cm in size (samples by 45/9.8 = 4.6 times shorter in the shear direction than the original joint area). The shear direction was marked so that each of the small specimens could be tilt-tested, push-tested and shear box tested in the same direction as the original tilt test of the 45 cm long joint. The results of this investigation are summarized in

Table 3. From the table in question it is inferred that: (i) The (mean) JRC value depends greatly on the type of test; (ii) the standard deviation alone is not a good index for indicating the proper type of test; and (iii) the best estimate was obtained from the tilt test (please compare the JRC

n = 5.12 value with the JRC

n = 5.5 for the 40 × 45 cm joint area). The latter could be attributed to test compatibility, as the 40 × 45 cm joint area was also tested on a tilt test configuration.

For considering the extent of the pattern of fluctuations on the JRC value, the authors suggest that the JRC be determined based on joint profiles of adequate length. This suggestion is independent of the method adopted (i.e., determination of JRC in the field, in the laboratory or based on correlations e.g., with Z2 or SF). For discontinuities with large scale waviness, apparently, this length should be even greater. A test joint surface length is adequate when considering greater length, as the JRC value remains practically the same.

It is noted that, if the present method is adopted, no correction for the influence of scale on JRC (such as the one proposed by Barton and Bandis [

30]; see Equation (22)), is required. However, because of the greater possibility of weaknesses in a large surface, it is likely that the average joint wall compressive strength (JCS) decreases with increasing scale. In this respect, Barton and Bandis’ [

30] scale correction for JCS (recall Equation (6)) is suggested. It is additionally mentioned that, Barton and Bandis’s [

30] scale correction was derived from shear tests over a ten-fold range of block sizes, involving linear extrapolation outside the block size range 0.1 m to 1 m. On the contrary, the proposed method is straightforward, not involving such procedures.

Finally, as the problem is clearly one dimensional, and since sliding will take place along a specific direction, the final JRC value should be an average value derived from a number of profiles parallel to the direction of sliding. In this respect, the JRC = 145.5 σ/θ relationship is a convenient and reliable tool for such an analysis. Refinement of this relationship based on longer sampling domain lengths is subject matter of future research by the authors, although it is believed that this best fit equation will not dramatically change.