Analysis of the Possibility of Environmental Pollution by Composted Biodegradable and Oxo-Biodegradable Plastics

Abstract

1. Introduction

2. Materials and Methods

- 12 non-irradiated samples,

- 12 samples irradiated for 20 h,

- 12 samples irradiated for 50 h.

3. Results

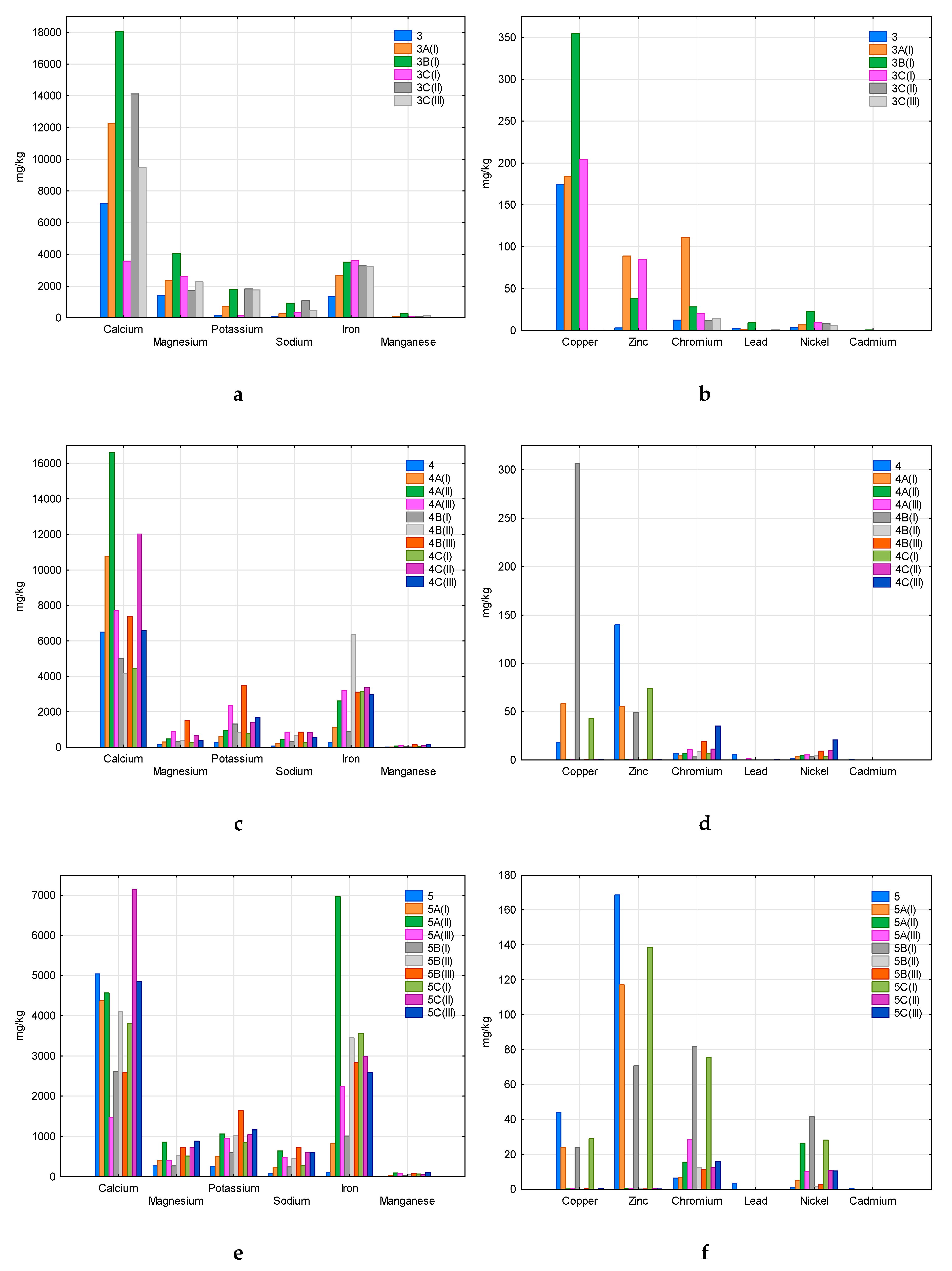

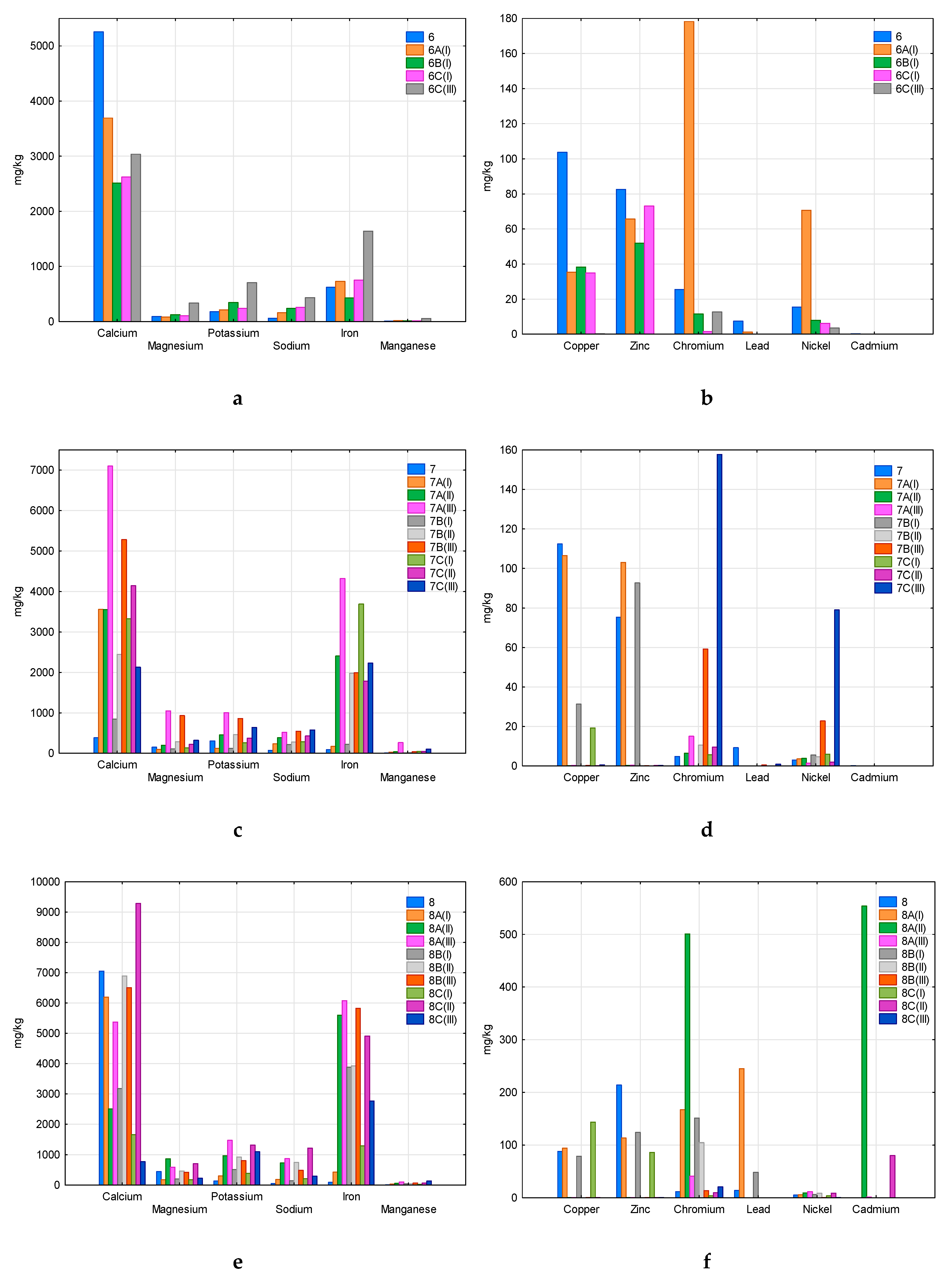

3.1. Chemical Composition of Composted Bioplastics

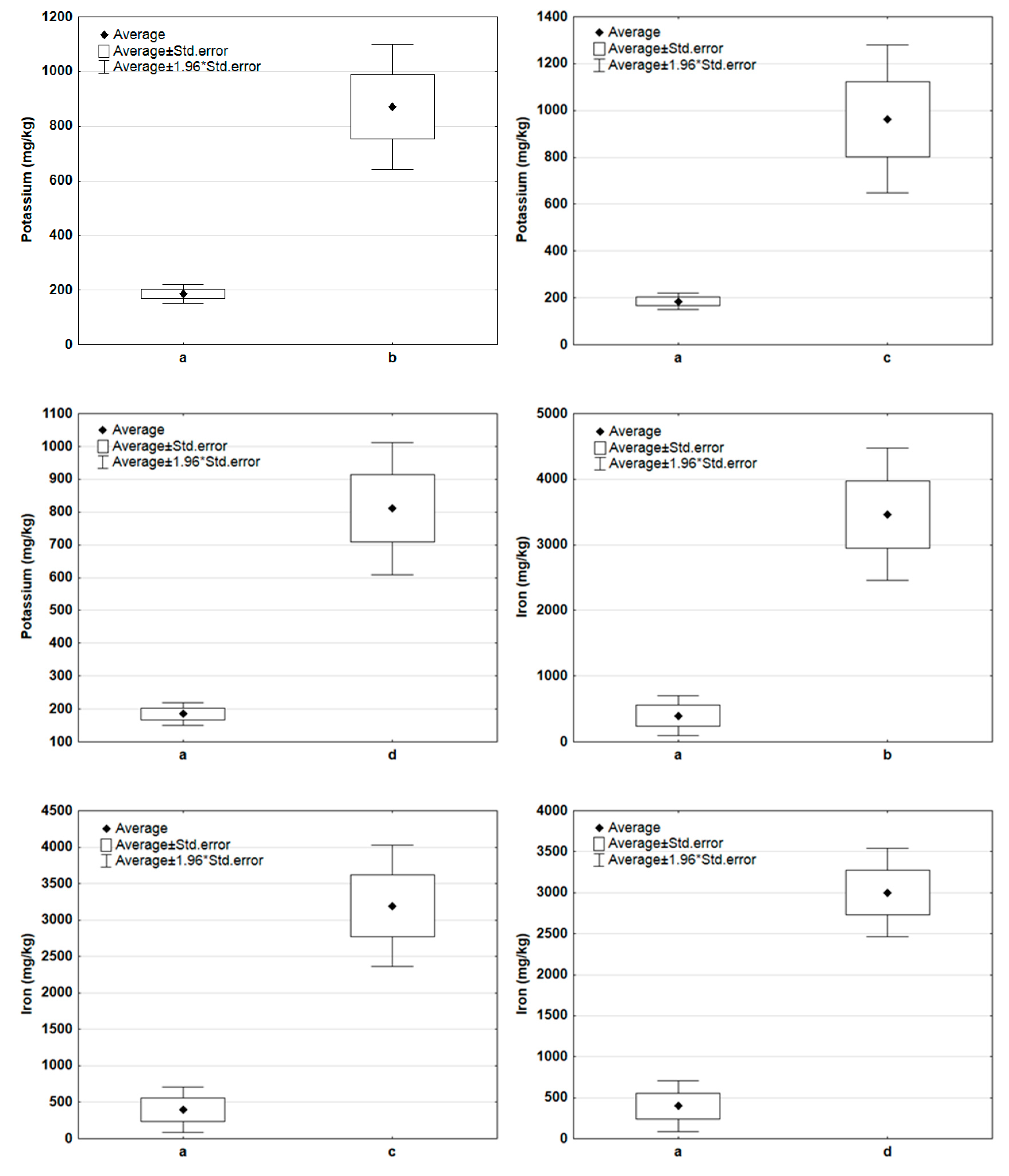

3.2. Influence of Irradiation on the Plastic Degradation Processes and Changes in their Composition

- a–b: K, Na, Fe, Mn, Cu, Zn,

- a–c: K, Na, Fe, Mn, Zn, Pb, Cd,

- a–d: K, Na, Fe, Mn, Cu, Zn, Pb.

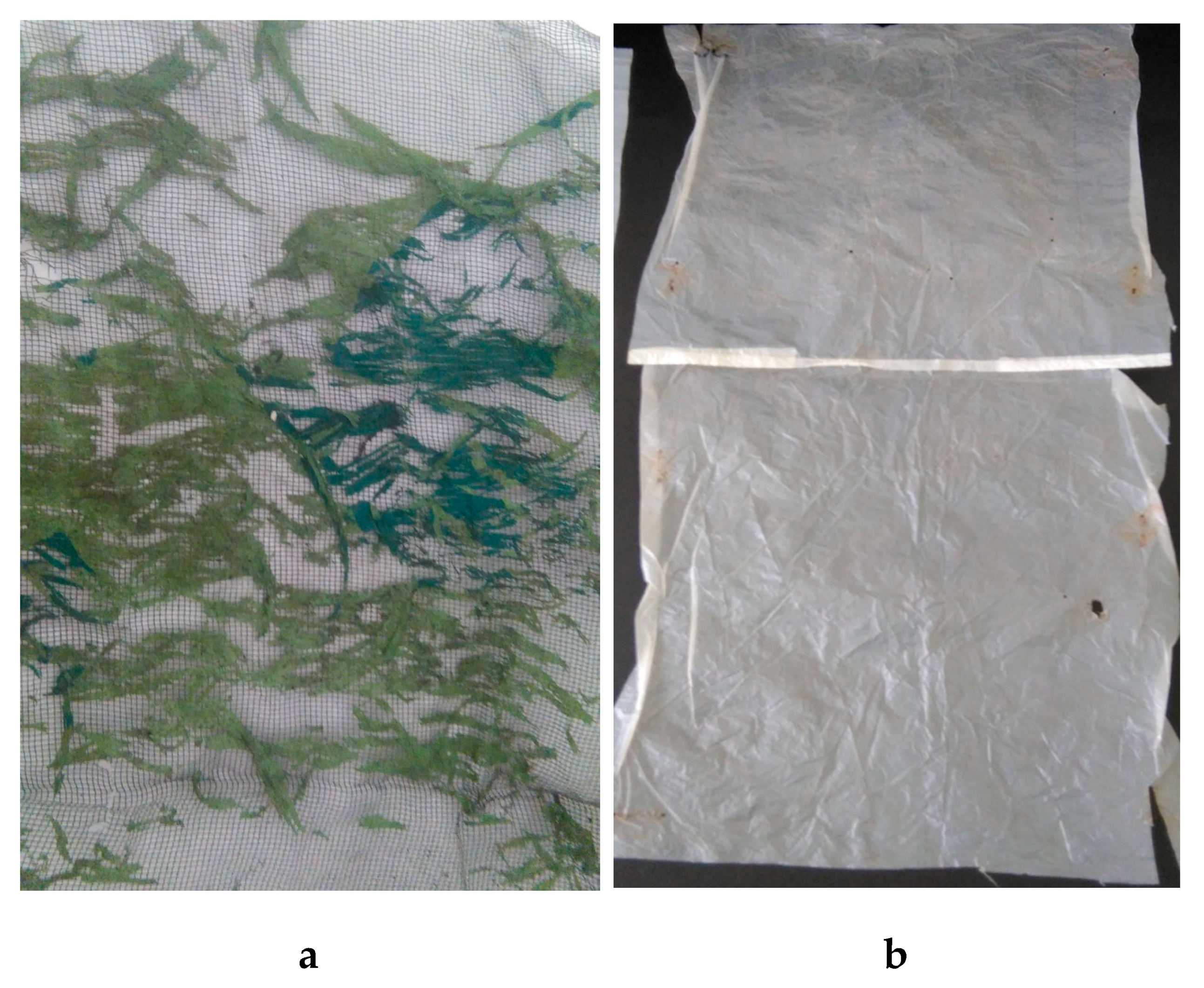

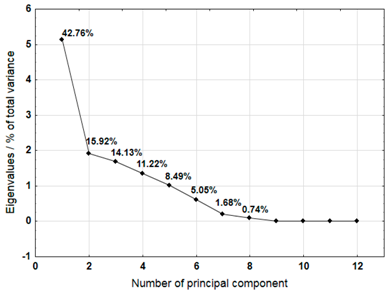

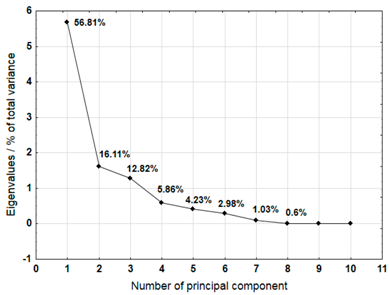

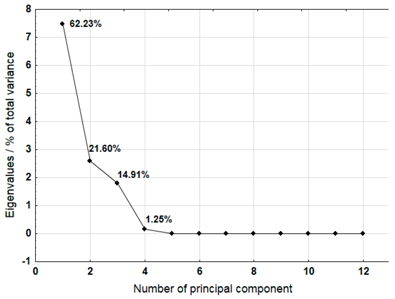

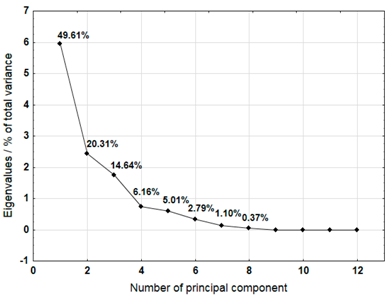

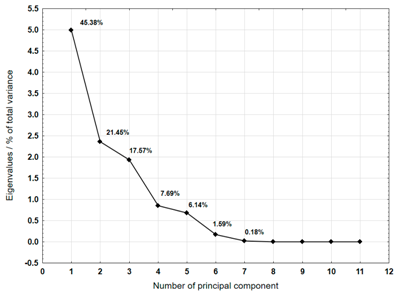

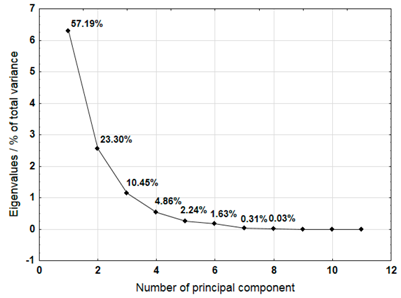

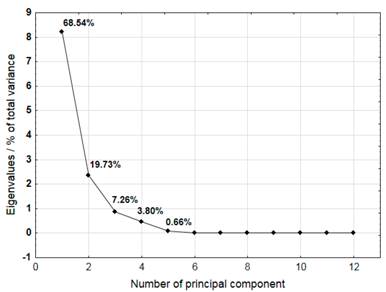

3.3. Selection of Ingredients that Best Characterise the Biodegradable and Oxo-biodegradable Plastics Analysed

3.4. Biodegradable and Oxo-biodegradable Plastics As a Source of Microplastics

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thakur, S.; Chaudhary, J.; Sharma, B.; Verma, A.; Tamulevicius, S.; Thakur, V.K. Sustainability of bioplastics: Opportunities and challenges. Curr. Opin. Green Sustain. Chem. 2018, 13, 68–75. [Google Scholar] [CrossRef]

- Christopher, B. Biopolymers: Biodegradable Alternatives to Traditional Plastics. In Green Chemistry: An Inclusive Approach; Béla, T., Timothy, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 753–770. [Google Scholar]

- Da Luz, J.M.R.; Paes, S.A.; Nunes, M.D.; Silva, M.D.C.S.D.; Kasuya, M.C.M. Degradation of Oxo-Biodegradable Plastic by Pleurotus ostreatus. PLOS ONE 2013, 8, 69386. [Google Scholar] [CrossRef] [PubMed]

- Bismarck, A.; Aranberri-Askargorta, I.; Lampke, T.; Wielage, B.; Stamboulis, A.; Shenderovich, I.; Limbach, H.-H. Surface characterization of flax, hemp and cellulose fibers; Surface properties and the water uptake behavior. Polym. Compos. 2002, 23, 872–894. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kerdchoechuen, O.; Laohakunjit, N. Biodegradable foam tray from cassava starch blended with natural fiber and chitosan. Ind. Crop. Prod. 2012, 37, 542–545. [Google Scholar] [CrossRef]

- What Makes Green Plastics Green? Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=11&ved=2ahUKEwijy43spLflAhVUMd4KHU1gDQcQFjAKegQIBBAC&url=https%3A%2F%2Fpdfs.semanticscholar.org%2F00f0%2Fd5de50ede924c1f1973a73eab40af466e0f7.pdf&usg=AOvVaw3Pye84bHWTIOkwFc3xHj7z (accessed on 25 October 2019).

- Ojeda, T.F.; Dalmolin, E.; Forte, M.M.; Jacques, R.J.; Bento, F.M.; Camargo, F.A. Abiotic and biotic degradation of oxo-biodegradable polyethylenes. Polym. Degrad. Stab. 2009, 94, 965–970. [Google Scholar] [CrossRef]

- Yashchuk, O.; Portillo, F.; Hermida, É.B. Degradation of Polyethylene Film Samples Containing Oxo-Degradable Additives. Procedia Mater. Sci. 2012, 1, 439–445. [Google Scholar] [CrossRef]

- Contat-Rodrigo, L. Thermal characterization of the oxo-degradation of polypropylene containing a pro-oxidant/pro-degradant additive. Polym. Degrad. Stab. 2013, 98, 2117–2124. [Google Scholar] [CrossRef]

- Jolanta, W.-K.; Tomasz, R.; Gabriel, B.; Mieczysław, S.; Tomasz, K.; Vijay, K.T. Recent progress in biodegradable polymers and nanocomposite-based packaging materials for sustainable environment. Int. J. Polym. Anal. Ch. 2018, 23, 383–395. [Google Scholar]

- Bradney, L.; Wijesekara, H.; Palansooriya, K.N.; Obadamudalige, N.; Bolan, N.S.; Ok, Y.S.; Rinklebe, J.; Kim, K.-H.; Kirkham, M. Particulate plastics as a vector for toxic trace-element uptake by aquatic and terrestrial organisms and human health risk. Environ. Int. 2019, 131, 104937. [Google Scholar] [CrossRef]

- Alam, O.; Billah, M.; Yajie, D. Characteristics of plastic bags and their potential environmental hazards. Resour. Conserv. Recycl. 2018, 132, 121–129. [Google Scholar] [CrossRef]

- Alam, O.; Wang, S.; Lu, W. Heavy metals dispersion during thermal treatment of plastic bags and its recovery. J. Environ. Manag. 2018, 212, 367–374. [Google Scholar] [CrossRef] [PubMed]

- Pivnenko, K.; Eriksen, M.; Martín-Fernández, J.; Eriksson, E.; Astrup, T.F. Recycling of plastic waste: Presence of phthalates in plastics from households and industry. Waste Manag. 2016, 54, 44–52. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Zhang, L.; Huang, Q.; Yang, Y.; Nie, Z.; Cheng, J.; Yang, J.; Wang, Y.; Chai, M. Contamination and risk of heavy metals in soils and sediments from a typical plastic waste recycling area in North China. Ecotoxicol. Environ. Saf. 2015, 122, 343–351. [Google Scholar] [CrossRef] [PubMed]

- Rochman, C.M.; Browne, M.A.; Halpern, B.S.; Hentschel, B.T.; Hoh, E.; Karapanagioti, H.K.; Rios-Mendoza, L.M.; Takada, H.; Teh, S.; Thompson, R.C. Classify plastic waste as hazardous. Nature 2013, 494, 169–171. [Google Scholar] [CrossRef]

- Munier, B.; Bendell, L.I. Macro and micro plastics sorb and desorb metals and act as a point source of trace metals to coastal ecosystems. PLOS ONE 2018, 13, e0191759. [Google Scholar] [CrossRef]

- Jundong, W.; Jinping, P.; Zhi, T.; Yifan, G.; Zhiwei, Z.; Qiuqiang, C.; Liqi, C. Microplastics in the surface sediments from the Beijiang River litteroal zone: Composition, abundance, surface textures and interaction with heavy metals. Chemosphere 2017, 171, 248–258. [Google Scholar]

- Rochman, C.M.; Hentschel, B.T.; Teh, S.J. Long-Term Sorption of Metals Is Similar among Plastic Types: Implications for Plastic Debris in Aquatic Environments. PLOS ONE 2014, 9, e85433. [Google Scholar] [CrossRef]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: A review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef]

- Harrison, J.P.; Boardman, C.; O’Callaghan, K.; Delort, A.-M.; Song, J. Biodegradability standards for carrier bags and plastic films in aquatic environments: A critical review. R. Soc. Open Sci. 2018, 5, 171792. [Google Scholar] [CrossRef]

- Poonam, K. Diversity of plastic degrading microorganisms and their appraisal on biodegradable plastic. Appl. Ecol. Environ. Res. 2013, 11, 441–449. [Google Scholar] [CrossRef]

- Giacomucci, L.; Raddadi, N.; Soccio, M.; Lotti, N.; Fava, F. Polyvinyl chloride biodegradation by Pseudomonas citronellolis and Bacillus flexus. New Biotechnol. 2019, 52, 35–41. [Google Scholar] [CrossRef] [PubMed]

- Tobias, P.H.; Carolin, V.; Johanna, K.; Katharina, L.; Frederik, R.W. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Edit. 2019, 58, 50–62. [Google Scholar]

- Oluranti, A.; Rotimi, S.; Touhami, M.; Ismael, A.; Odunayo, I. Polyolefins and the environment. In Polyolefin Fibres: Structure, Properties and Industrial Applications, 2nd ed.; Samuel, C.O.U., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 89–133. [Google Scholar]

- Ann, -C.A.; Minna, H. Designed to degrade. Science 2017, 358, 872–873. [Google Scholar]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Du, Y.-L.; Cao, Y.; Lu, F.; Li, F.; Cao, Y.; Wang, X.-L.; Wang, Y.-Z. Biodegradation behaviors of thermoplastic starch (TPS) and thermoplastic dialdehyde starch (TPDAS) under controlled composting conditions. Polym. Test. 2008, 27, 924–930. [Google Scholar] [CrossRef]

- Kalita, N.K.; Nagar, M.K.; Mudenur, C.; Kalamdhad, A.; Katiyar, V. Biodegradation of modified Poly (lactic acid) based biocomposite films under thermophilic composting conditions. Polym. Test. 2019, 76, 522–536. [Google Scholar] [CrossRef]

- Eubeler, J.P.; Bernhard, M.; Knepper, T.P. Environmental biodegradation of synthetic polymers II. Biodegradation of different polymer groups. TrAC Trends Anal. Chem. 2010, 29, 84–100. [Google Scholar] [CrossRef]

- Selke, S.; Auras, R.; Nguyen, T.A.; Aguirre, E.C.; Cheruvathur, R.; Liu, Y. Evaluation of Biodegradation-Promoting Additives for Plastics. Environ. Sci. Technol. 2015, 49, 3769–3777. [Google Scholar] [CrossRef]

- Shruti, V.C.; Gurusamy, K.-M. Bioplastics: Missing link in the era of Microplastics. Sci. Total Environ. 2019, 697, 134139. [Google Scholar] [CrossRef]

- Weithmann, N.; Möller, J.N.; Löder, M.G.J.; Piehl, S.; Laforsch, C.; Freitag, R. Organic fertilizer as a vehicle for the entry of microplastic into the environment. Sci. Adv. 2018, 4, eaap8060. [Google Scholar] [CrossRef]

- Markowicz, F.; Król, G.; Szymańska-Pulikowska, A. Biodegradable Package – Innovative Purpose or Source of the Problem. J. Ecol. Eng. 2019, 20, 228–237. [Google Scholar] [CrossRef]

- Dana, A.; Magdalena, D.V. Biodegradation of Degradable/Biodegradable Plastic Material in Controlled Composting Environment. Pol. J. Environ. Stud. 2014, 23, 1465–1474. [Google Scholar]

- Baranowska, I. (Ed.) Handbook of Trace analysis. Fundamentals and Applications; Springer International Publishing: Cham, Switzerland, 2016; p. 453. [Google Scholar]

- Jaishankar, M.; Tseten, T.; Anbalagan, N.; Mathew, B.B.; Beeregowda, K.N. Toxicity, mechanism and health effects of some heavy metals. Interdiscip. Toxicol. 2014, 7, 60–72. [Google Scholar] [CrossRef] [PubMed]

- Warne, R.W. The Micro and Macro of Nutrients across Biological Scales. Integr. Comp. Boil. 2014, 54, 864–872. [Google Scholar] [CrossRef]

- Treister, R.; Nielsen, C.S.; Stubhaug, A.; Farrar, J.T.; Pud, D.; Sawilowsky, S.; Oaklander, A.L. Experimental comparison of parametric versus nonparametric analyses of data from the cold pressor test. J. Pain 2015, 16, 537–548. [Google Scholar] [CrossRef]

- Zhu, S.; Chen, H.; Wang, M.; Guo, X.; Lei, Y.; Jin, G.; Zhu, A.S.; Chen, B.H.; Wang, C.M.; Guo, D.X.; et al. Plastic solid waste identification system based on near infrared spectroscopy in combination with support vector machine. Adv. Ind. Eng. Polym. Res. 2019, 2, 77–81. [Google Scholar] [CrossRef]

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation Coefficients: Appropriate Use and Interpretation. Anesth. Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

- Frias, J.; Nash, R. Microplastics: Finding a consensus on the definition. Mar. Pollut. Bull. 2019, 138, 145–147. [Google Scholar] [CrossRef]

- Act of 10 July 2007 on fertilizers and fertilization. Journal of Laws of the Republic of Poland 2018, item 1259 (with changes) [in Polish]. Available online: http://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20180001259/O/D20181259.pdf (accessed on 26 October 2019).

- Regulation of the Minister of Agriculture and Rural Development of 18 June 2008 regarding the implementation of certain provisions of the Act on fertilizers and fertilization. Journal of Laws of the Republic of Poland 119/2008, item 765 [in Polish]. Available online: http://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20081190765/O/D20080765.pdf (accessed on 26 October 2019).

- Zhao, J.-H.; Wang, X.-Q.; Zeng, J.; Yang, G.; Shi, F.-H.; Yan, Q. Biodegradation of poly(butylene succinate) in compost. J. Appl. Polym. Sci. 2005, 97, 2273–2278. [Google Scholar] [CrossRef]

- Magdalena, V.; Dana, A.; Jana, K.; František, T. Evaluation of biodegradability of plastics bags in composting conditions. Ecol. Chem. Eng. S 2014, 21, 45–57. [Google Scholar]

- Dana, A.; Maja, R.; Jan, Z.; Helena, D.; Jakub, E.; Jindrich, K.; Martin, B.; Magdalena, D.V. SEM Analysis and Degradation Behavior of Conventional and Bio-Based Plastics During Composting. Acta Univ. Agric. Silvic. Mendelianae Brun. 2018, 66, 349–356. [Google Scholar]

- Zafar, U.; Nzeram, P.; Langarica-Fuentes, A.; Houlden, A.; Heyworth, A.; Saiani, A.; Robson, G.D. Biodegradation of polyester polyurethane during commercial composting and analysis of associated fungal communities. Bioresour. Technol. 2014, 158, 374–377. [Google Scholar] [CrossRef] [PubMed]

- Acosta-Coley, I.; Mendez-Cuadro, D.; Rodriguez-Cavallo, E.; De La Rosa, J.; Olivero-Verbel, J. Trace elements in microplastics in Cartagena: A hotspot for plastic pollution at the Caribbean. Mar. Pollut. Bull. 2019, 139, 402–411. [Google Scholar] [CrossRef] [PubMed]

- Carlos, J.; Judith, S.; Isabel, C.; Angel, F. Study of the Biodisintegration on a Painted Bioplastic Material Waste. Mater. Plast. 2015, 52, 116–121. [Google Scholar]

- Unmar, G.; Mohee, R. Assessing the effect of biodegradable and degradable plastics on the composting of green wastes and compost quality. Bioresour. Technol. 2008, 99, 6738–6744. [Google Scholar] [CrossRef]

- Dilkes-Hoffman, L.; Pratt, S.; Lant, P.; Laycock, B. The Role of Biodegradable Plastic in Solving Plastic Solid Waste Accumulation. In Plastics to Energy; Al-Salem, S.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 469–505. [Google Scholar]

- Brennecke, D.; Duarte, B.; Paiva, F.; Caçador, I.; Clode, J.C. Microplastics as vector for heavy metal contamination from the marine environment. Estuarine, Coast. Shelf Sci. 2016, 178, 189–195. [Google Scholar] [CrossRef]

- Laskar, N.; Kumar, U. Plastics and microplastics: A threat to environment. Environ. Technol. Innov. 2019, 14, 100352. [Google Scholar] [CrossRef]

- Gallo, F.; Fossi, C.; Weber, R.; Santillo, D.; Sousa, J.; Ingram, I.; Nadal, A.; Romano, D. Marine litter plastics and microplastics and their toxic chemicals components: The need for urgent preventive measures. Environ. Sci. Eur. 2018, 30, 13. [Google Scholar] [CrossRef]

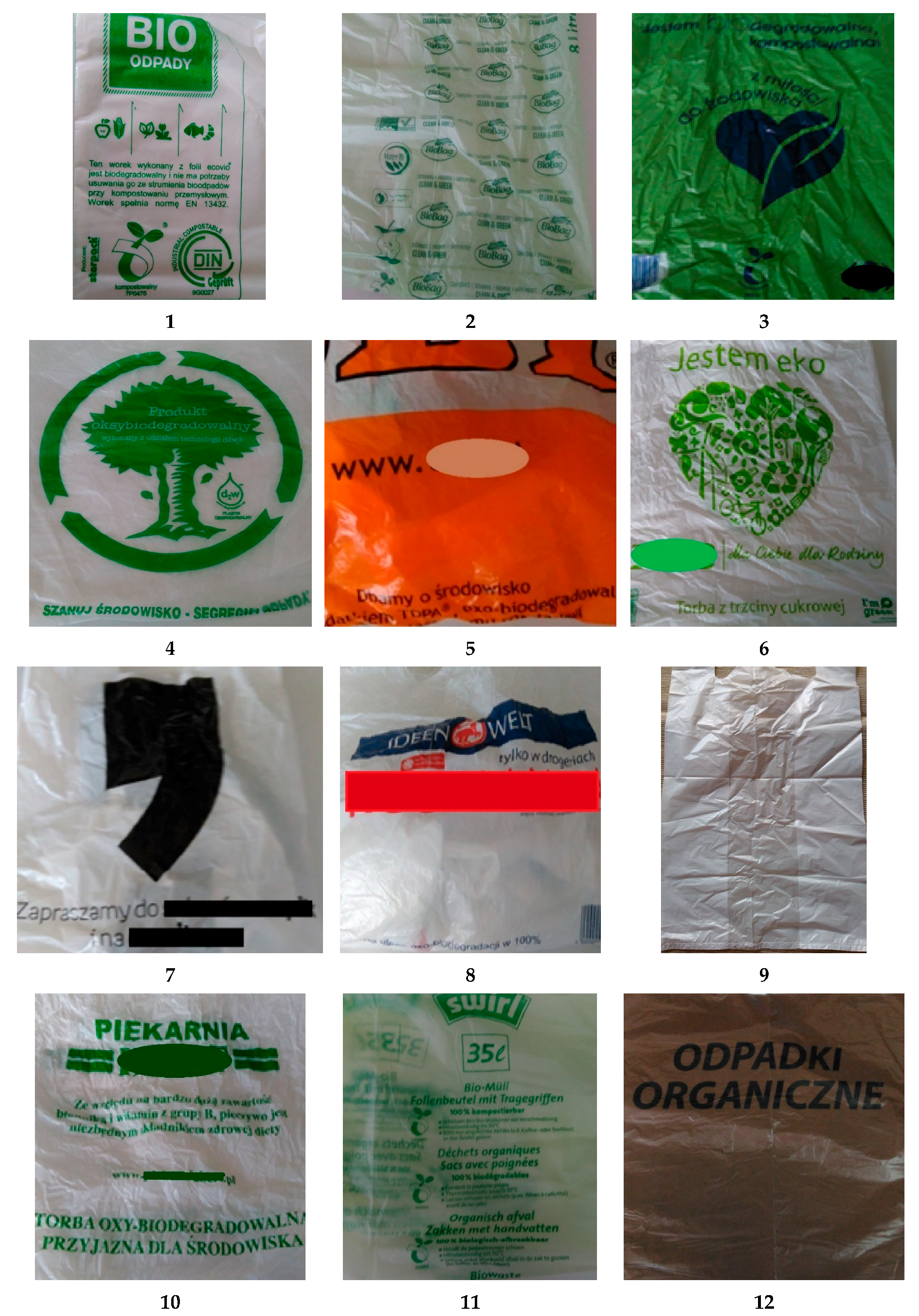

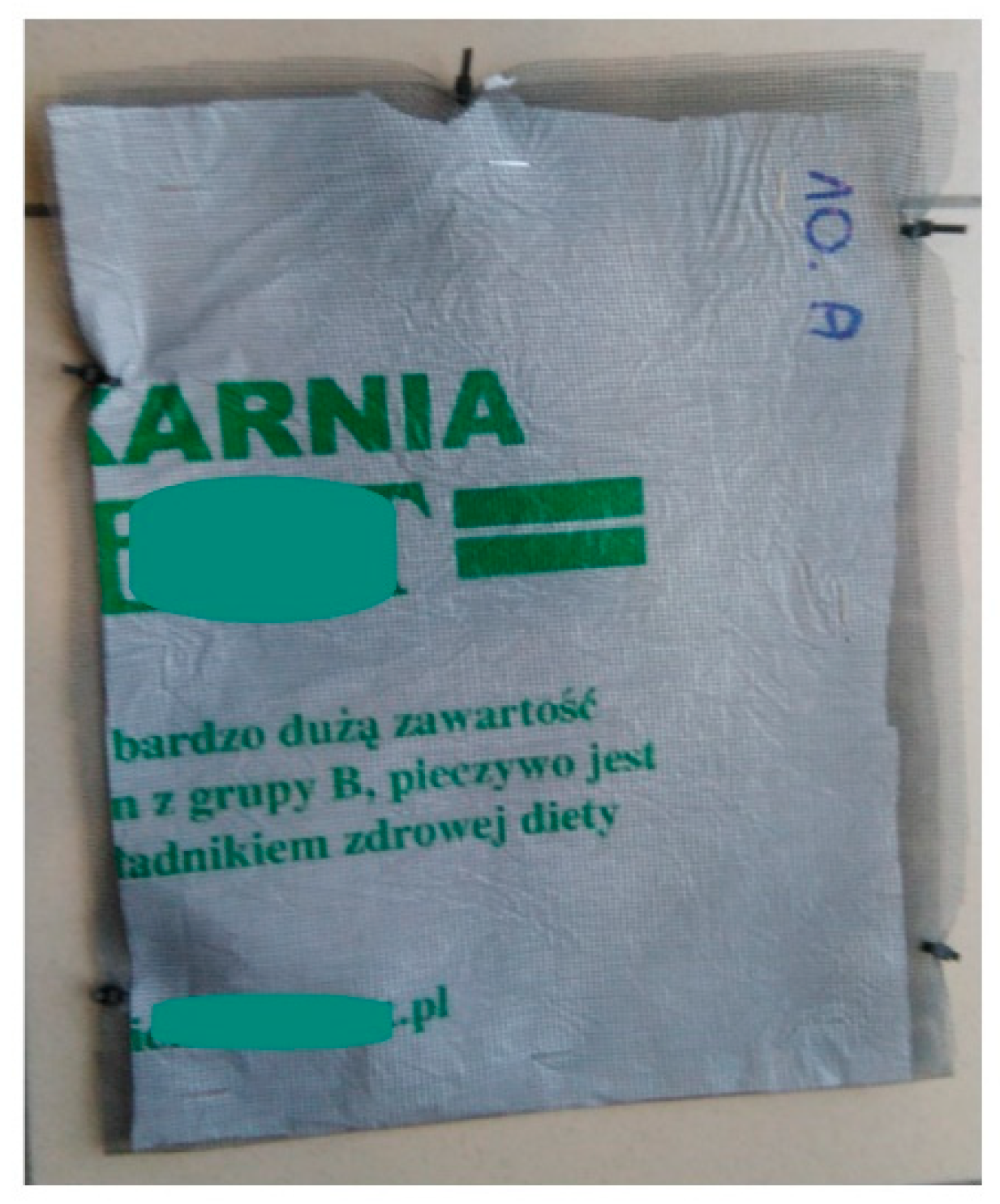

| Sample Number | Type of Raw Material/Polymer | Manufacturer’s Information | Characteristics of the Polymer | |||

|---|---|---|---|---|---|---|

| Form | Colour | Use | Type | |||

| 1. | Compostable in industrial conditions, two certificates in accordance with norm EN 13432 | There is no need to remove from the stream of bio-waste at the composting industry | foil, elastic, soft | milky, translucent, imprinted | bags for biodegradable waste | biodegradable, compostable |

| 2. | Compostable at home conditions, two certificates in accordance with norm EN 13432 | It is degraded in composting conditions in a period of approximately 45 days | foil, elastic, soft, thin, rubber | milky, green, translucent | bags for biodegradable waste | biodegradable, compostable |

| 3. | Compostable, a certificate in accordance with norm EN 13432 | Made on the basis of corn and potato starch, decomposed by bacteria from 6 weeks to one year | foil, elastic, soft, starch coating | green, opaque, matt, imprinted | packaging of products, including foodstuffs | biodegradable, compostable |

| 4. | Oxo-biodegradable, HDPE and d2w additive | It is decomposed under the influence of oxygen, UV and heat, use within 18 months | foil, elastic, soft, matt | milky, white, translucent, imprinted | packaging of products, including foodstuffs | oxo-biodegradable |

| 5. | Oxo-biodegradable, PE and TDPA additive | It is subject to accelerated decomposition | foil, elastic, slippery to the touch | orange, imprinted, opaque, glossy | packaging of products | oxo-biodegradable |

| 6. | Biodegradable, LDPE and sugar cane | Sugar cane content above 85%, renewable raw material, 100% recyclable | foil, elastic, slippery to the touch | white, opaque, glossy, imprinted | packaging of products, including foodstuffs | biodegradable |

| 7. | Oxo-biodegradable, PE and d2w additive | Thanks to the addition of d2w, the bag is 100% biodegradable | foil, elastic, slippery to the touch | white, opaque, glossy | packaging of products, including foodstuffs | oxo-biodegradable |

| 8. | Oxo-biodegradable, HDPE | The bag is oxo-biodegradable 100% | foil, elastic, soft, slippery to the touch | milky, white, imprinted, opaque | packaging of products, including foodstuffs | oxo-biodegradable |

| 9. | Oxo-biodegradable, HDPE and d2w additive | It has the Oxo-biodegradable Plastics Association mark | foil, rigid, slippery to the touch | milky, white, translucent, matt | packaging of products, including foodstuffs | oxo-biodegradable |

| 10. | Oxo-biodegradable, HDPE | The bag is oxo-biodegradable 100% | foil, rigid, slippery to the touch | white, opaque, glossy, imprinted | packaging of products, including foodstuffs | oxo-biodegradable |

| 11. | HDPE | Bags for organic waste | foil, elastic | brown | bags for organic waste | probably oxo-biodegradable |

| 12. | Compostable, a certificate in accordance with norm EN 13432 | Bags for biodegradable waste | foil, elastic, soft | milky, green, translucent | bags for biodegradable waste | biodegradable, compostable |

| Sample Number | Content (mg/kg) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ca | Mg | K | Na | Fe | Mn | Cu | Zn | Cr | Pb | Ni | Cd | |

| 1 | 6835.1 | 1939.2 | 134.4 | 72.5 | 110.8 | 3.0 | 22.245 | 7.845 | 5.385 | 1.874 | 1.55 | 0.2 |

| 2 | 85.3 | 31.8 | 172.4 | 89.2 | 72.5 | 1.8 | 15.72 | 7.955 | 3.405 | 7.05 | 2.685 | 0.255 |

| 3 | 7194 | 1421.7 | 163.6 | 98.2 | 1329.9 | 22.5 | 174.38 | 3.033 | 12.345 | 2.155 | 3.81 | 0.16 |

| 4 | 6505.8 | 140.2 | 274.7 | 79.1 | 287.1 | 14.6 | 18.075 | 139.95 | 6.85 | 5.965 | 1.2 | 0.31 |

| 5 | 5041.4 | 269.3 | 255.6 | 83.4 | 106.1 | 3.1 | 43.83 | 168.65 | 6.42 | 3.53 | 1.045 | 0.325 |

| 6 | 5255.9 | 89.7 | 179.2 | 59.4 | 622.4 | 6.6 | 103.67 | 82.54 | 25.435 | 7.45 | 15.47 | 0.25 |

| 7 | 384.9 | 150.9 | 305.6 | 71.8 | 86.8 | 7.1 | 112.37 | 75.415 | 4.785 | 9.265 | 2.98 | 0.165 |

| 8 | 7052.8 | 442.4 | 136.9 | 48.3 | 90.2 | 11.8 | 87.88 | 213.72 | 11.78 | 14.0 | 5.27 | 0.2 |

| 9 | 1458.8 | 282.5 | 190.7 | 10.9 | 88.7 | 5.3 | 91.525 | 133.42 | 13.07 | 37.325 | 1.63 | 0.225 |

| 10 | 635.1 | 128.1 | 148.8 | 16.3 | 241.8 | 3.3 | 54.09 | 141.12 | 10.085 | 30.57 | 4.28 | 0.295 |

| 11 | 67.6 | 27.4 | 137.8 | 125.4 | 68.5 | 1.2 | 120.86 | 9.7 | 8.865 | 47.095 | 1.385 | 0.195 |

| 12 | 245.2 | 174.8 | 124 | 89.3 | 1678.3 | 9.4 | 95.035 | 194.09 | 10.6 | 12.845 | 2.395 | 0.28 |

| Variable | Student’s t-Test | Mann–Whitney U Test | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Average a | Average b | t | p | Sum of Ranks a | Sum of Ranks b | U | Corrected Z | p | |

| Ca | 3396.825 | 5597.682 | −1.381 | 0.176885 | 174 | 421 | 96 | −1.279 | 0.200781 |

| Mg | 424.833 | 515.5 | −0.469 | 0.641979 | 162 | 433 | 84 | −1.712 | 0.086938 |

| K | 185.308 | 871.182 | −4.295 | 0.000152 | 102 | 493 | 24 | −3.874 | 0.000107 |

| Na | 70.317 | 478.5 | −5.436 | 0.000006 | 78 | 517 | 0 | −4.739 | 0.000002 |

| Fe | 398.592 | 3465.605 | −4.323 | 0.00014 | 97 | 498 | 19 | −4.054 | 0.00005 |

| Mn | 7.475 | 69.532 | −4.016 | 0.000335 | 86 | 509 | 8 | −4.451 | 0.000009 |

| Cu | 78.306 | 31.313 | 2.536 | 0.016296 | 289 | 306 | 53 | 2.829 | 0.00467 |

| Zn | 98.119 | 36.784 | 2.757 | 0.009561 | 297 | 298 | 45 | 3.117 | 0.001826 |

| Cr | 9.919 | 52.24 | −1.291 | 0.205895 | 195 | 400 | 117 | −0.523 | 0.601264 |

| Pb | 14.927 | 11.326 | 0.232 | 0.817785 | 330 | 265 | 12 | 4.666 | 0.000003 |

| Ni | 3.642 | 9.739 | −1.361 | 0.182934 | 152.5 | 442.5 | 74.5 | −2.054 | 0.039948 |

| Cd | 0.238 | 25.261 | −0.729 | 0.471341 | 318 | 277 | 24 | 4.198 | 0.000027 |

| Variable | Student’s t-Test | Mann–Whitney U Test | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Average a | Average c | t | p | Sum of Ranks a | Sum of Ranks c | U | Corrected Z | p | |

| Ca | 3396.825 | 4934.571 | −1.012 | 0.319298 | 180 | 381 | 102 | −0.879 | 0.37915 |

| Mg | 424.833 | 592.381 | −0.593 | 0.557685 | 159 | 402 | 81 | −1.665 | 0.09584 |

| K | 185.308 | 963.857 | −3.636 | 0.000994 | 95 | 466 | 17 | −4.061 | 0.000049 |

| Na | 70.317 | 521.905 | −5.277 | 0.00001 | 79 | 482 | 1 | −4.659 | 0.000003 |

| Fe | 398.592 | 3192.605 | −4.835 | 0.000034 | 92 | 469 | 14 | −4.173 | 0.00003 |

| Mn | 7.475 | 53.548 | −2.877 | 0.007202 | 87 | 474 | 9 | −4.361 | 0.000013 |

| Cu | 78.306 | 42.189 | 1.185 | 0.244974 | 288 | 273 | 42 | 3.125 | 0.001779 |

| Zn | 98.119 | 27.779 | 3.466 | 0.001572 | 293 | 268 | 37 | 3.312 | 0.000926 |

| Cr | 9.919 | 25.866 | −1.361 | 0.183174 | 192 | 369 | 114 | −0.431 | 0.666817 |

| Pb | 14.927 | 3.137 | 2.629 | 0.013191 | 306 | 255 | 24 | 4.087 | 0.000044 |

| Ni | 3.642 | 8.332 | −1.597 | 0.120425 | 141.5 | 419.5 | 63.5 | −2.320 | 0.020315 |

| Cd | 0.238 | 0.039 | 5.827 | 0.000002 | 318 | 243 | 12 | 4.640 | 0.000003 |

| Variable | Student’s t-Test | Mann–Whitney U Test | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Average a | Average d | t | p | Sum of Ranks a | Sum of Ranks d | U | Corrected Z | p | |

| Ca | 3396.825 | 5271.917 | −1.091 | 0.282788 | 191 | 475 | 113 | −1.024 | 0.306066 |

| Mg | 424.833 | 588.333 | −0.707 | 0.484454 | 170 | 496 | 92 | −1.728 | 0.083929 |

| K | 185.308 | 810.917 | −4.260 | 0.000153 | 93 | 573 | 15 | −4.312 | 0.000016 |

| Na | 70.317 | 495.125 | −5.226 | 0.000009 | 78 | 588 | 0 | −4.816 | 0.000001 |

| Fe | 398.592 | 3002.338 | −6.394 | 0.0000003 | 86 | 580 | 8 | −4.547 | 0.000005 |

| Mn | 7.475 | 70.117 | −4.921 | 0.000022 | 84 | 582 | 6 | −4.614 | 0.000004 |

| Cu | 78.306 | 26.08 | 2.913 | 0.006282 | 321 | 345 | 45 | 3.305 | 0.000948 |

| Zn | 98.119 | 27.404 | 3.483 | 0.001384 | 327 | 339 | 39 | 3.507 | 0.000454 |

| Cr | 9.919 | 20.566 | −1.105 | 0.276784 | 187 | 479 | 109 | −1.158 | 0.246969 |

| Pb | 14.927 | 0.154 | 4.890 | 0.000024 | 366 | 300 | 0 | 5.289 | 0.0000001 |

| Ni | 3.642 | 10.997 | −1.577 | 0.124103 | 140 | 526 | 62 | −2.735 | 0.006239 |

| Cd | 0.238 | 3.358 | −0.655 | 0.516915 | 354 | 312 | 12 | 5.023 | 0.000001 |

| Group | a | b | c | d |

|---|---|---|---|---|

| a | Mann–Whitney U test: K, Na, Fe, Mn, Cu, Zn, Pb, Ni, Cd | Mann–Whitney U test: K, Na, Fe, Mn, Cu, Zn, Pb, Ni, Cd | Mann–Whitney U test: K, Na, Fe, Mn, Cu, Zn, Pb, Ni, Cd | |

| b | Student’s t-test: K, Na, Fe, Mn, Cu, Zn | no statistically significant differences were found | no statistically significant differences were found | |

| c | Student’s t-test: K, Na, Fe, Mn, Zn, Pb, Cd | no statistically significant differences were found | no statistically significant differences were found | |

| d | Student’s t-test: K, Na, Fe, Mn, Cu, Zn, Pb | no statistically significant differences were found | no statistically significant differences were found |

| Sample 3 | |||||||

| Variable | Component 1 | Component 2 | Component 3 |  | |||

| Ca | −0.752 | 0.318 | −0.056 | ||||

| Mg | −0.925 | −0.279 | −0.137 | ||||

| K | −0.588 | 0.745 | −0.190 | ||||

| Na | −0.650 | 0.638 | −0.179 | ||||

| Fe | −0.552 | 0.213 | −0.654 | ||||

| Mn | −0.949 | 0.004 | −0.146 | ||||

| Cu | −0.611 | −0.735 | 0.258 | ||||

| Zn | −0.086 | −0.808 | −0.562 | ||||

| Cr | 0.004 | −0.554 | −0.545 | ||||

| Pb | −0.883 | −0.156 | 0.398 | ||||

| Ni | −0.983 | −0.077 | 0.043 | ||||

| Cd | −0.835 | −0.268 | 0.470 | ||||

| Sample 4 | |||||||

| Variable | Component 1 | Component 2 | Component 3 | Component 4 |  | ||

| Ca | 0.034 | 0.109 | 0.222 | 0.896 | |||

| Mg | 0.716 | 0.573 | 0.346 | −0.115 | |||

| K | 0.773 | 0.533 | 0.070 | −0.288 | |||

| Na | 0.843 | −0.041 | 0.429 | −0.165 | |||

| Fe | 0.409 | −0.621 | 0.450 | −0.174 | |||

| Mn | 0.910 | 0.063 | −0.384 | 0.099 | |||

| Cu | −0.615 | 0.288 | −0.306 | −0.403 | |||

| Zn | −0.824 | 0.207 | −0.256 | −0.214 | |||

| Cr | 0.780 | −0.115 | −0.591 | 0.038 | |||

| Pb | 0.432 | −0.150 | 0.054 | −0.357 | |||

| Ni | 0.678 | −0.159 | −0.689 | 0.136 | |||

| Cd | 0.018 | 0.842 | 0.039 | 0.158 | |||

| Sample 5 | |||||||

| Variable | Component 1 | Component 2 | Component 3 |  | |||

| Ca | 0.280 | −0.082 | 0.922 | ||||

| Mg | 0.867 | 0.261 | 0.340 | ||||

| K | 0.839 | 0.088 | −0.299 | ||||

| Na | 0.965 | 0.098 | −0.091 | ||||

| Fe | 0.574 | 0.604 | 0.244 | ||||

| Mn | 0.719 | 0.448 | −0.191 | ||||

| Cu | −0.921 | 0.146 | 0.156 | ||||

| Zn | −0.845 | 0.095 | 0.236 | ||||

| Cr | −0.726 | 0.575 | −0.202 | ||||

| Ni | −0.530 | 0.770 | 0.041 | ||||

| Sample 6 | ||||

| Variable | Component 1 | Component 2 | Component 3 |  |

| Ca | 0.668 | −0.549 | −0.503 | |

| Mg | −0.903 | −0.396 | −0.164 | |

| K | −0.935 | −0.296 | −0.125 | |

| Na | −0.993 | 0.011 | 0.096 | |

| Fe | −0.804 | −0.346 | −0.403 | |

| Mn | −0.886 | −0.274 | −0.374 | |

| Cu | 0.909 | −0.410 | 0.045 | |

| Zn | 0.940 | 0.180 | 0.202 | |

| Cr | 0.274 | 0.598 | −0.752 | |

| Pb | 0.734 | −0.636 | −0.239 | |

| Ni | 0.362 | 0.605 | −0.709 | |

| Cd | 0.679 | −0.723 | −0.122 | |

| Sample 7 | ||||

| Variable | Component 1 | Component 2 | Component 3 |  |

| Ca | −0.622 | 0.645 | −0.326 | |

| Mg | −0.800 | 0.342 | −0.341 | |

| K | −0.946 | 0.173 | −0.144 | |

| Na | −0.936 | −0.197 | −0.104 | |

| Fe | −0.727 | 0.425 | 0.299 | |

| Mn | −0.715 | 0.366 | −0.337 | |

| Cu | 0.690 | −0.029 | −0.642 | |

| Zn | 0.767 | −0.108 | −0.591 | |

| Cr | −0.592 | −0.795 | −0.088 | |

| Pb | −0.559 | −0.808 | −0.139 | |

| Ni | −0.467 | −0.866 | −0.073 | |

| Sample 8 | ||||

| Variable | Component 1 | Component 2 | Component 3 |  |

| Ca | −0.350 | 0.021 | 0.883 | |

| Mg | −0.898 | −0.409 | 0.038 | |

| K | −0.915 | 0.294 | 0.011 | |

| Na | −0.887 | −0.052 | 0.392 | |

| Fe | −0.864 | −0.005 | −0.045 | |

| Mn | −0.496 | 0.595 | −0.415 | |

| Cu | 0.885 | −0.185 | 0.078 | |

| Zn | 0.886 | −0.262 | 0.150 | |

| Cr | −0.165 | −0.888 | −0.355 | |

| Pb | 0.619 | −0.294 | 0.353 | |

| Ni | −0.486 | −0.519 | 0.431 | |

| Cd | −0.438 | −0.761 | −0.428 | |

| Sample 9 | ||||

| Variable | Component 1 | Component 2 | Component 3 |  |

| Ca | 0.539 | −0.707 | −0.418 | |

| Mg | −0.899 | −0.396 | −0.057 | |

| K | −0.871 | −0.379 | 0.046 | |

| Na | −0.677 | −0.683 | 0.173 | |

| Fe | −0.500 | 0.174 | 0.800 | |

| Mn | −0.633 | 0.356 | −0.212 | |

| Cu | 0.923 | −0.010 | 0.286 | |

| Zn | 0.818 | 0.182 | 0.424 | |

| Cr | −0.180 | 0.627 | −0.590 | |

| Pb | 0.617 | −0.582 | −0.433 | |

| Ni | 0.299 | −0.413 | 0.490 | |

| Sample 10 | ||||

| Variable | Component 1 | Component 2 | Component 3 |  |

| Ca | 0.810 | 0.406 | 0.342 | |

| Mg | 0.945 | 0.178 | 0.095 | |

| K | 0.953 | −0.101 | 0.083 | |

| Na | 0.889 | 0.377 | −0.086 | |

| Fe | 0.874 | 0.176 | −0.285 | |

| Mn | 0.650 | −0.675 | −0.321 | |

| Cu | −0.805 | 0.209 | −0.199 | |

| Zn | −0.916 | 0.261 | −0.122 | |

| Cr | 0.362 | −0.754 | 0.387 | |

| Pb | 0.076 | −0.826 | −0.528 | |

| Ni | 0.484 | 0.604 | −0.585 | |

| Sample 11 | ||||

| Variable | Component 1 | Component 2 | Component 3 |  |

| Ca | −0.556 | −0.712 | −0.350 | |

| Mg | −0.989 | 0.018 | 0.061 | |

| K | −0.814 | 0.077 | 0.380 | |

| Na | −0.701 | −0.427 | 0.535 | |

| Fe | −0.964 | 0.042 | −0.129 | |

| Mn | −0.652 | 0.577 | −0.484 | |

| Cu | 0.994 | −0.087 | −0.005 | |

| Zn | 0.994 | −0.089 | −0.005 | |

| Cr | 0.281 | −0.933 | −0.079 | |

| Pb | 0.994 | −0.088 | −0.004 | |

| Ni | −0.630 | −0.660 | −0.241 | |

| Cd | 0.994 | −0.088 | −0.004 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markowicz, F.; Szymańska-Pulikowska, A. Analysis of the Possibility of Environmental Pollution by Composted Biodegradable and Oxo-Biodegradable Plastics. Geosciences 2019, 9, 460. https://doi.org/10.3390/geosciences9110460

Markowicz F, Szymańska-Pulikowska A. Analysis of the Possibility of Environmental Pollution by Composted Biodegradable and Oxo-Biodegradable Plastics. Geosciences. 2019; 9(11):460. https://doi.org/10.3390/geosciences9110460

Chicago/Turabian StyleMarkowicz, Florentyna, and Agata Szymańska-Pulikowska. 2019. "Analysis of the Possibility of Environmental Pollution by Composted Biodegradable and Oxo-Biodegradable Plastics" Geosciences 9, no. 11: 460. https://doi.org/10.3390/geosciences9110460

APA StyleMarkowicz, F., & Szymańska-Pulikowska, A. (2019). Analysis of the Possibility of Environmental Pollution by Composted Biodegradable and Oxo-Biodegradable Plastics. Geosciences, 9(11), 460. https://doi.org/10.3390/geosciences9110460