Geomechanical Model Test and Energy Mechanism Analysis of Zonal Disintegration in Deep Surrounding Rock

Abstract

1. Introduction

2. Geomechanical Model Test for Zonal Disintegration in Deep Rock Mass

2.1. Analogical Materials of Model Test

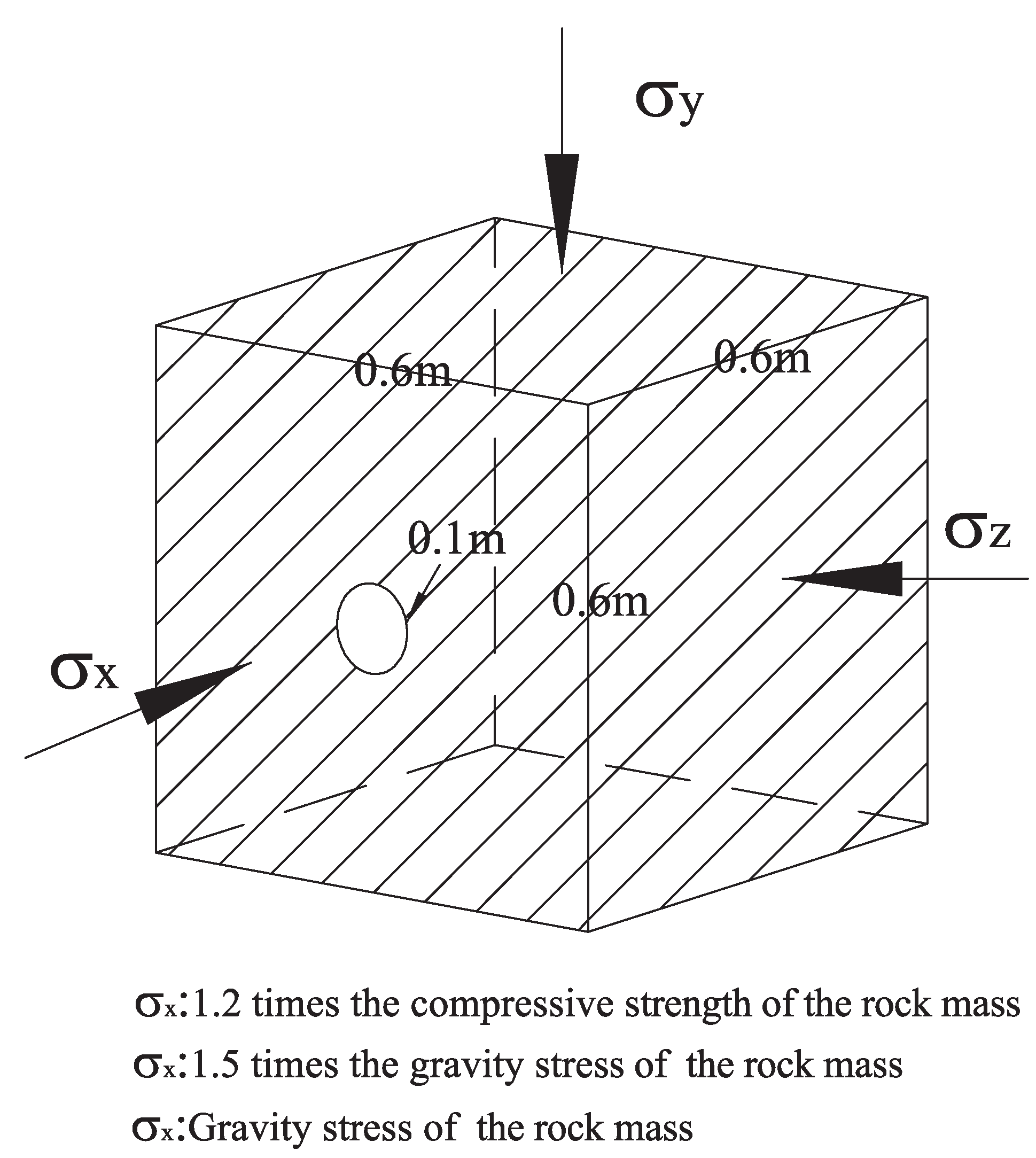

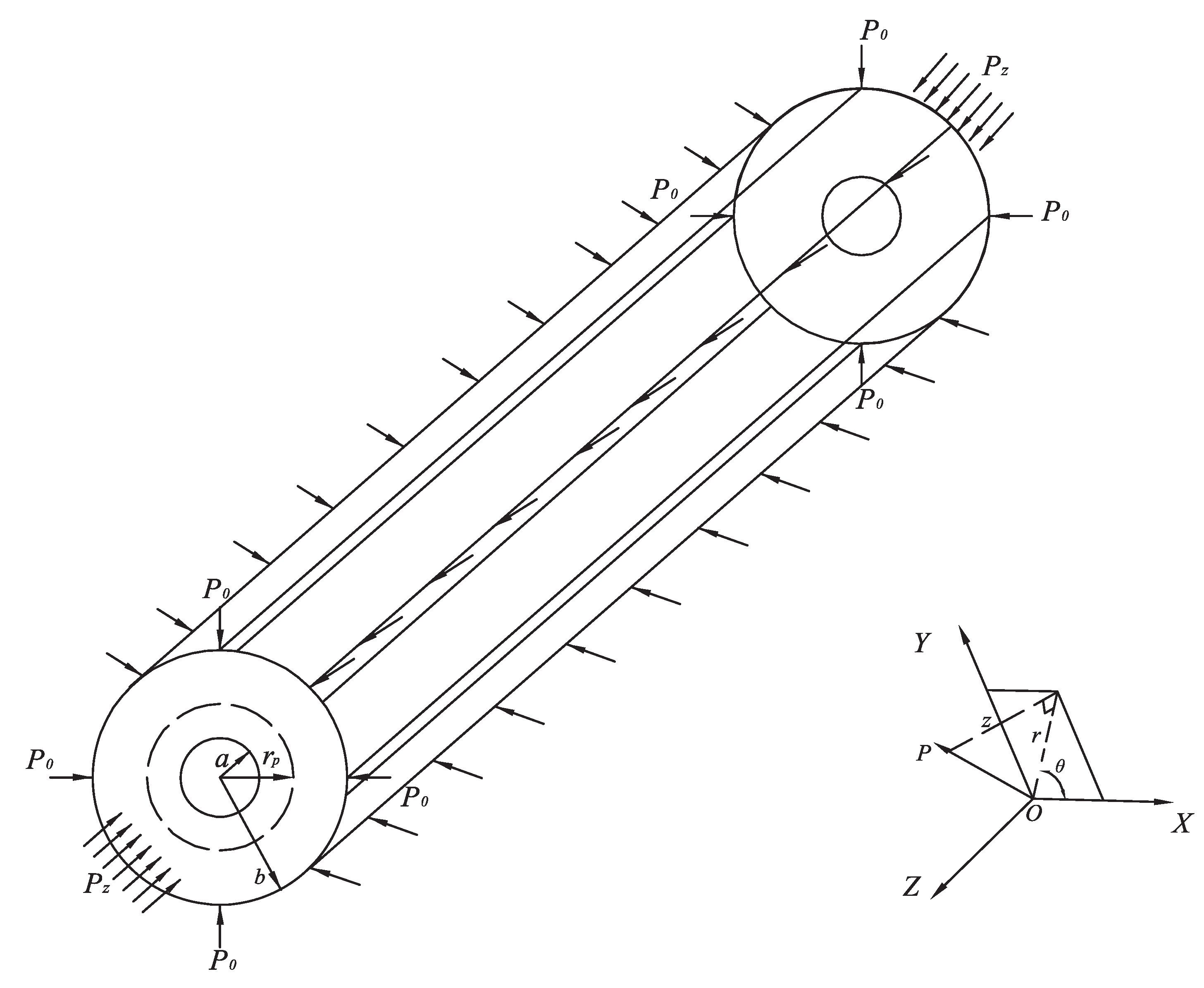

2.2. Model Dimensions and Boundary Conditions

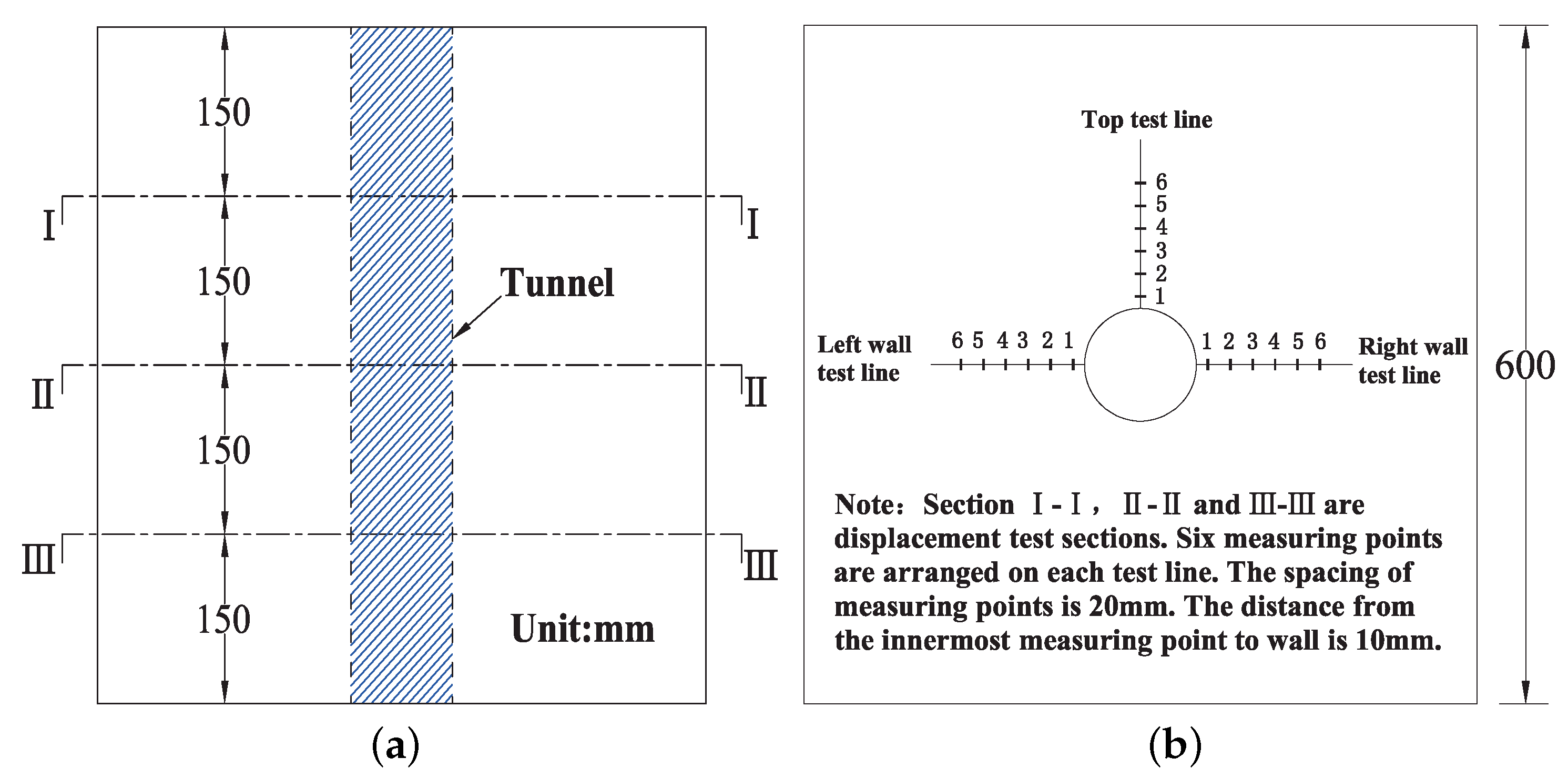

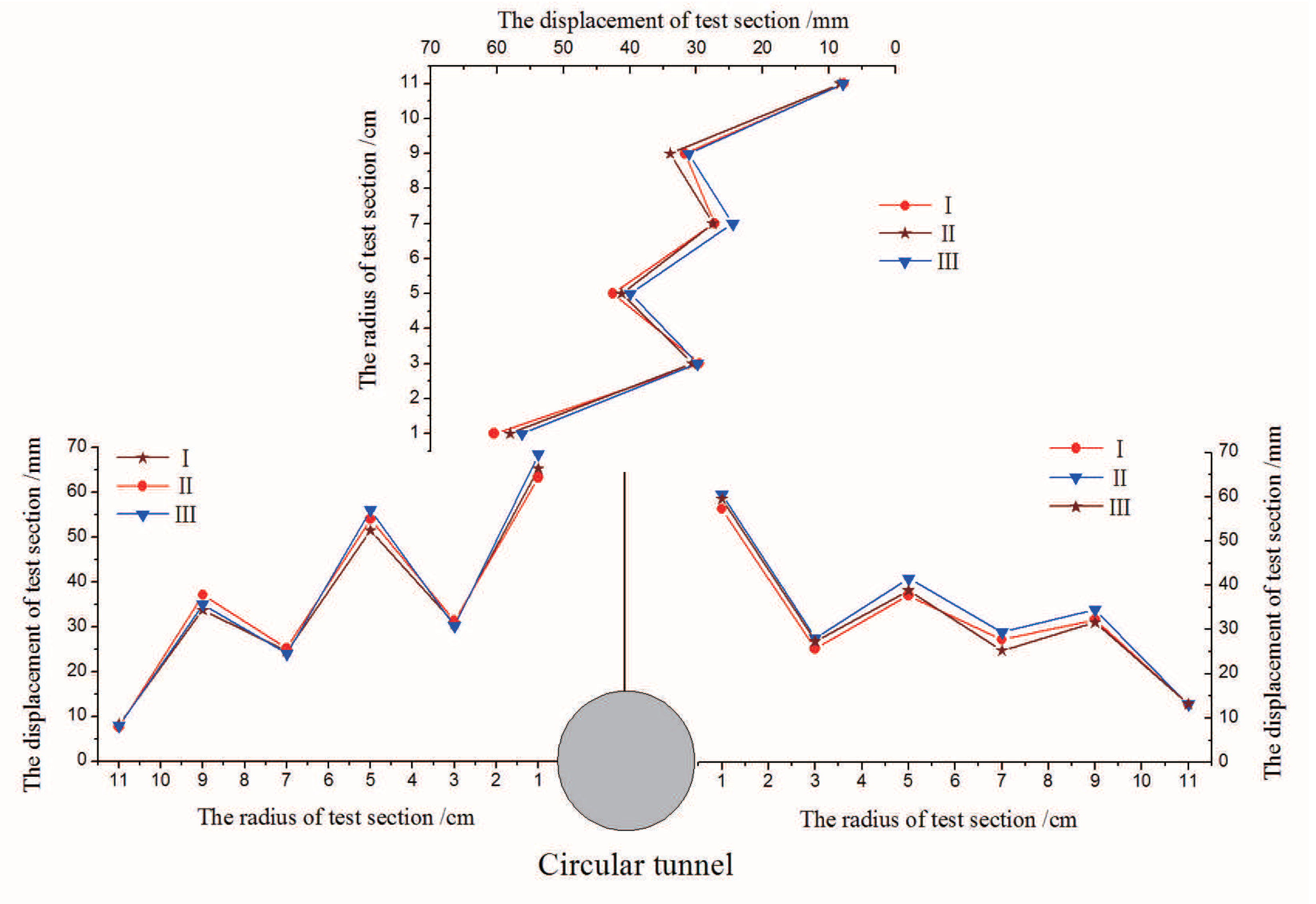

2.3. Layout Scheme of Displacement Measurement

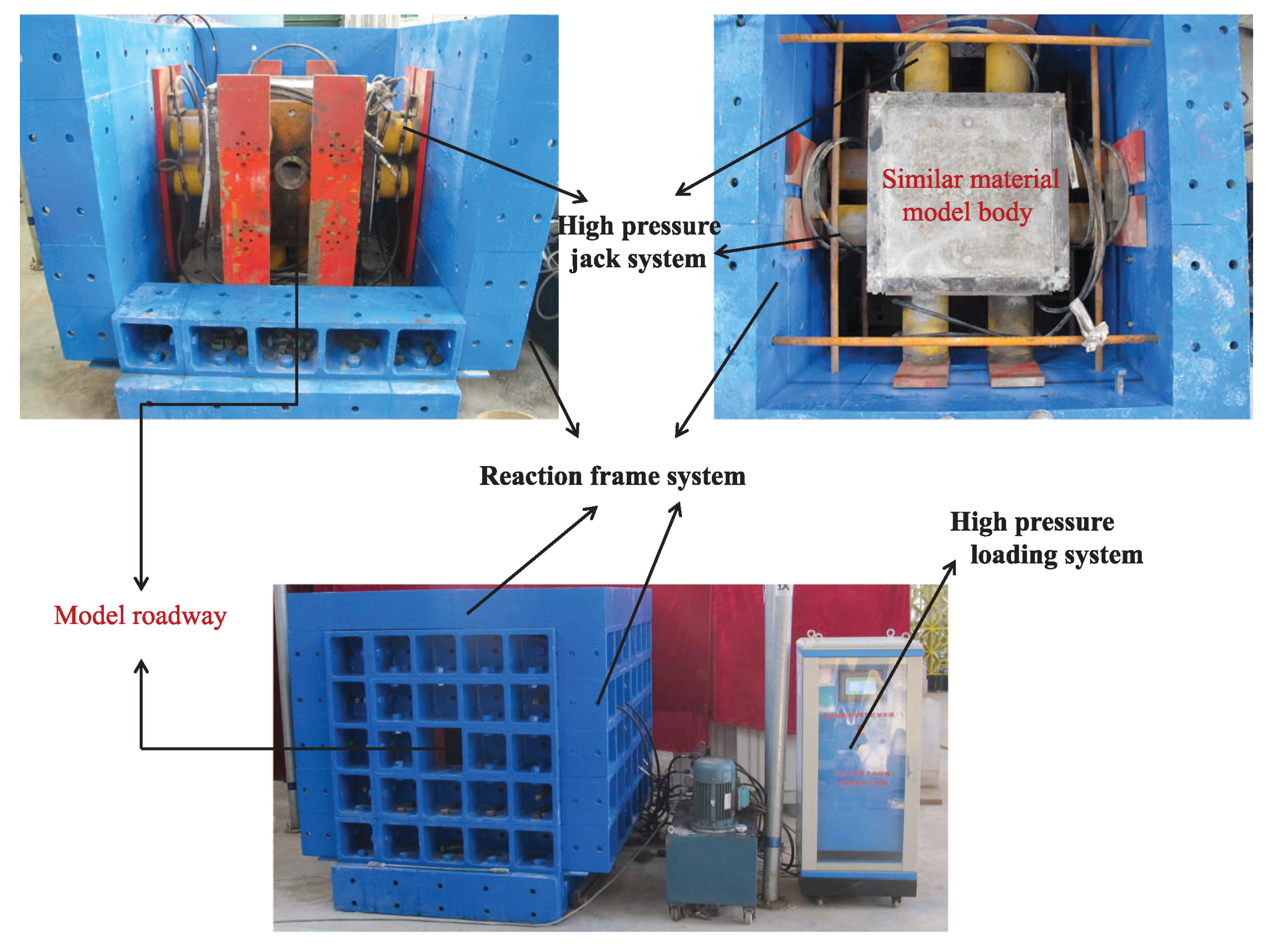

2.4. Model Loading and Excavation

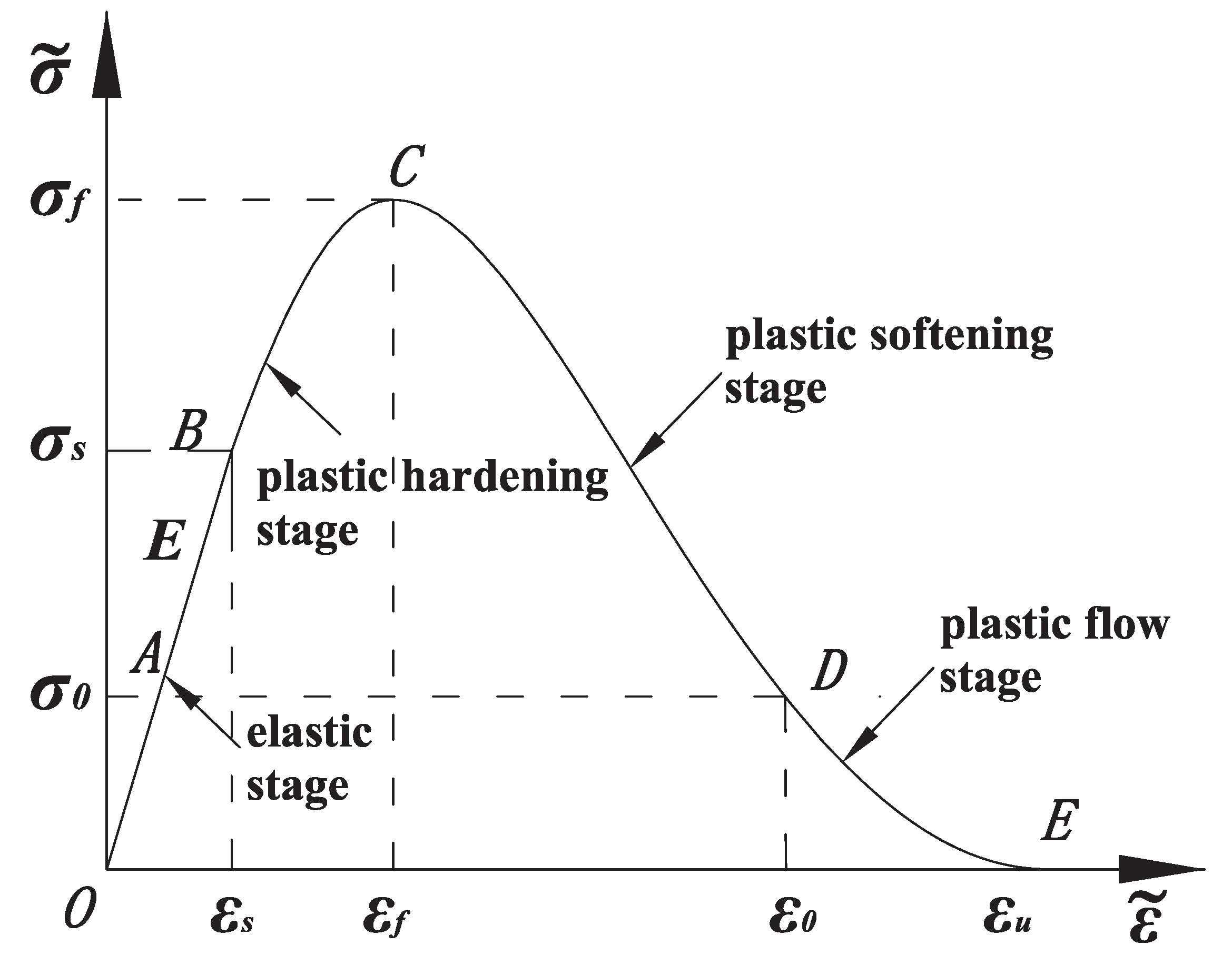

3. Gradient-Dependent Elastoplastic Damage Softening Model of Deep Rock Mass

3.1. The Introduction of Strain Gradient

3.2. The Establishment of Elastoplastic Damage Model

4. Deformation and Stress Analytical Solution in Deep Roadway

4.1. Theoretical Equations Based on Strain Gradient

4.2. The Process of Solving Theoretical Equations

5. Overall Energy Failure Criteria for Rock Unit

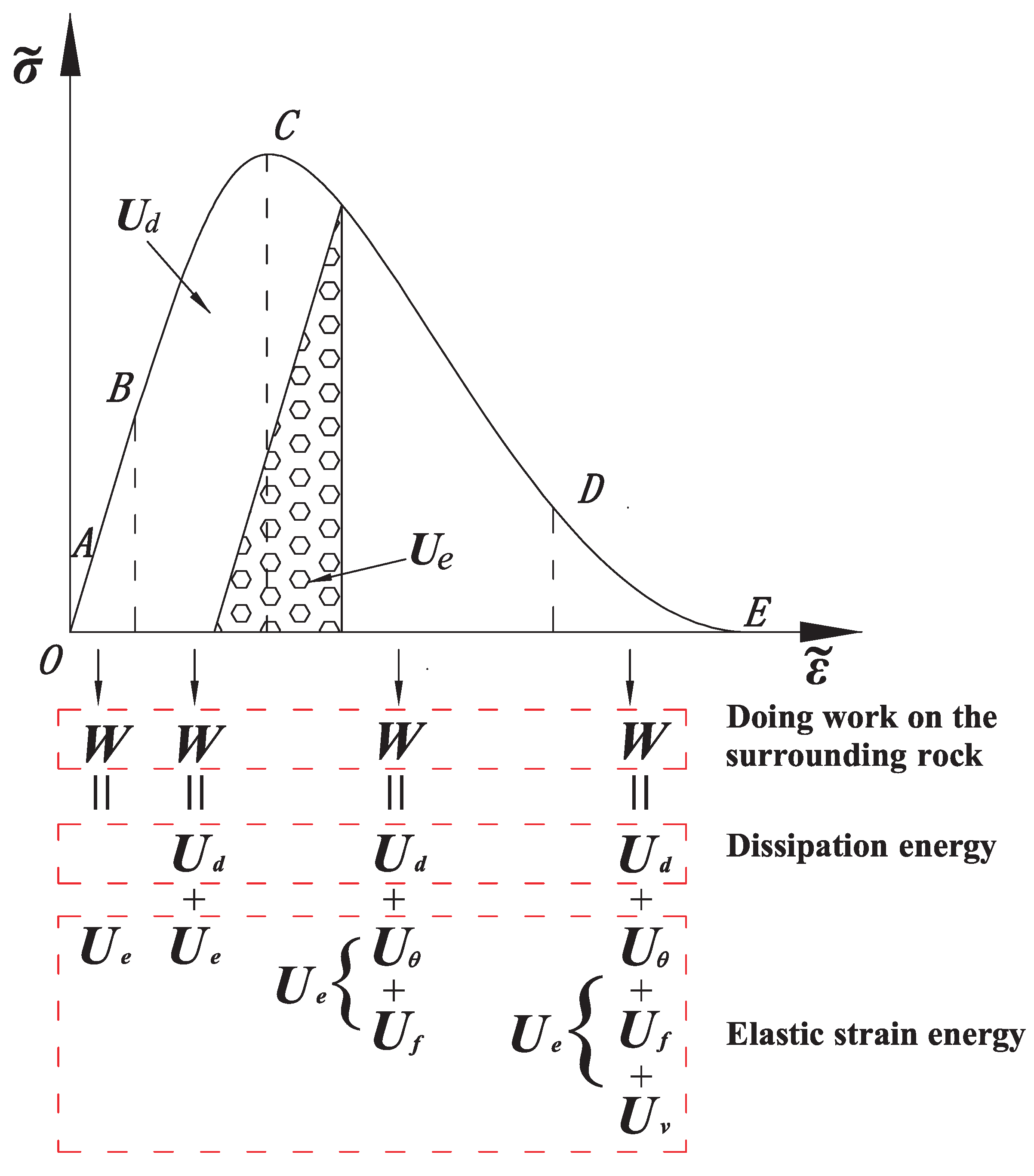

5.1. Energy Conversion Relationship in Deep Rock Mass

5.2. Energy Failure Criterion Analyzed by Principle of Energy Dissipation and Release

5.2.1. Pressure Condition

5.2.2. Tension Condition

6. Analytical Results and Comparative Analysis with Model Test Results

6.1. Selection of Calculation Parameters

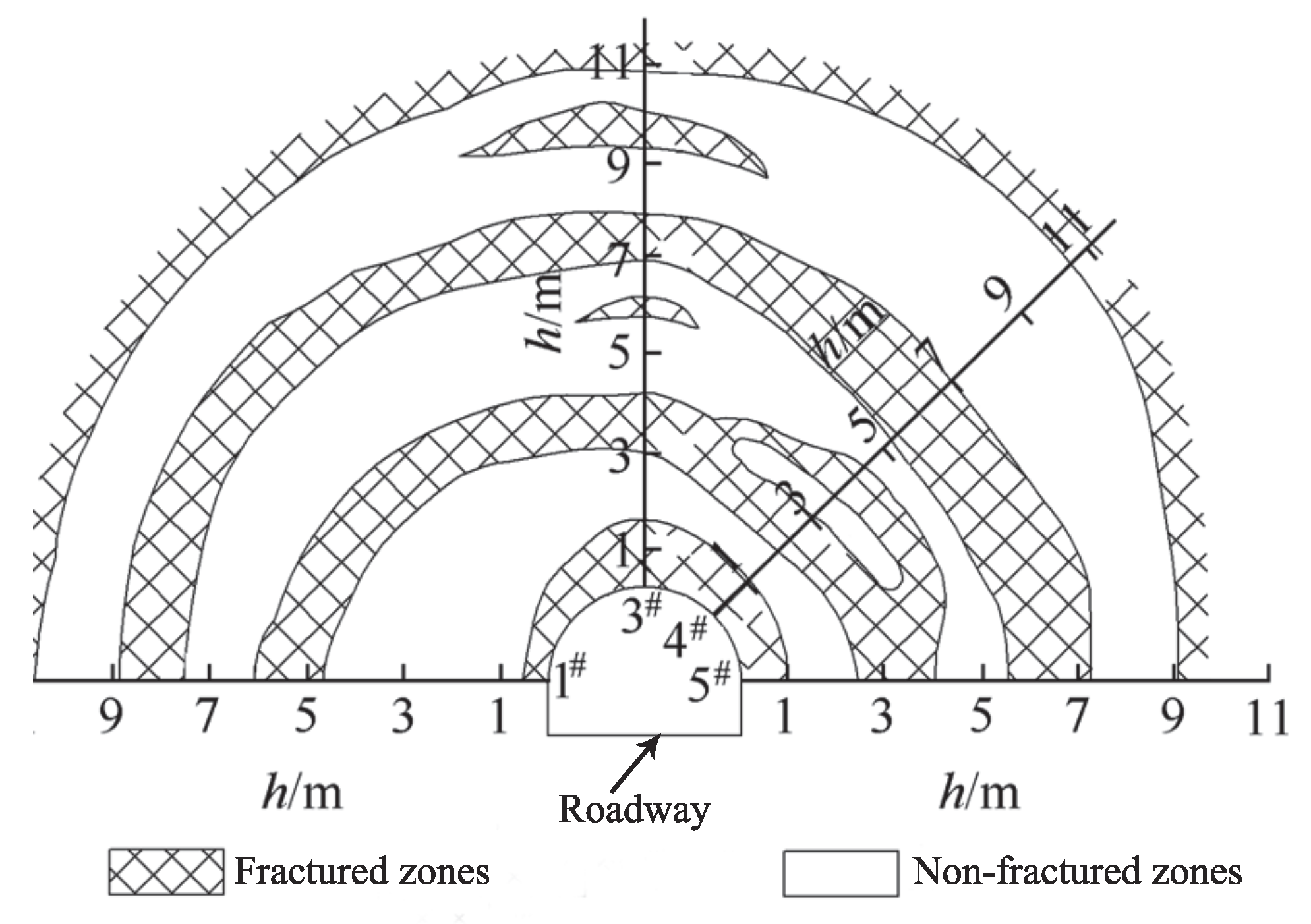

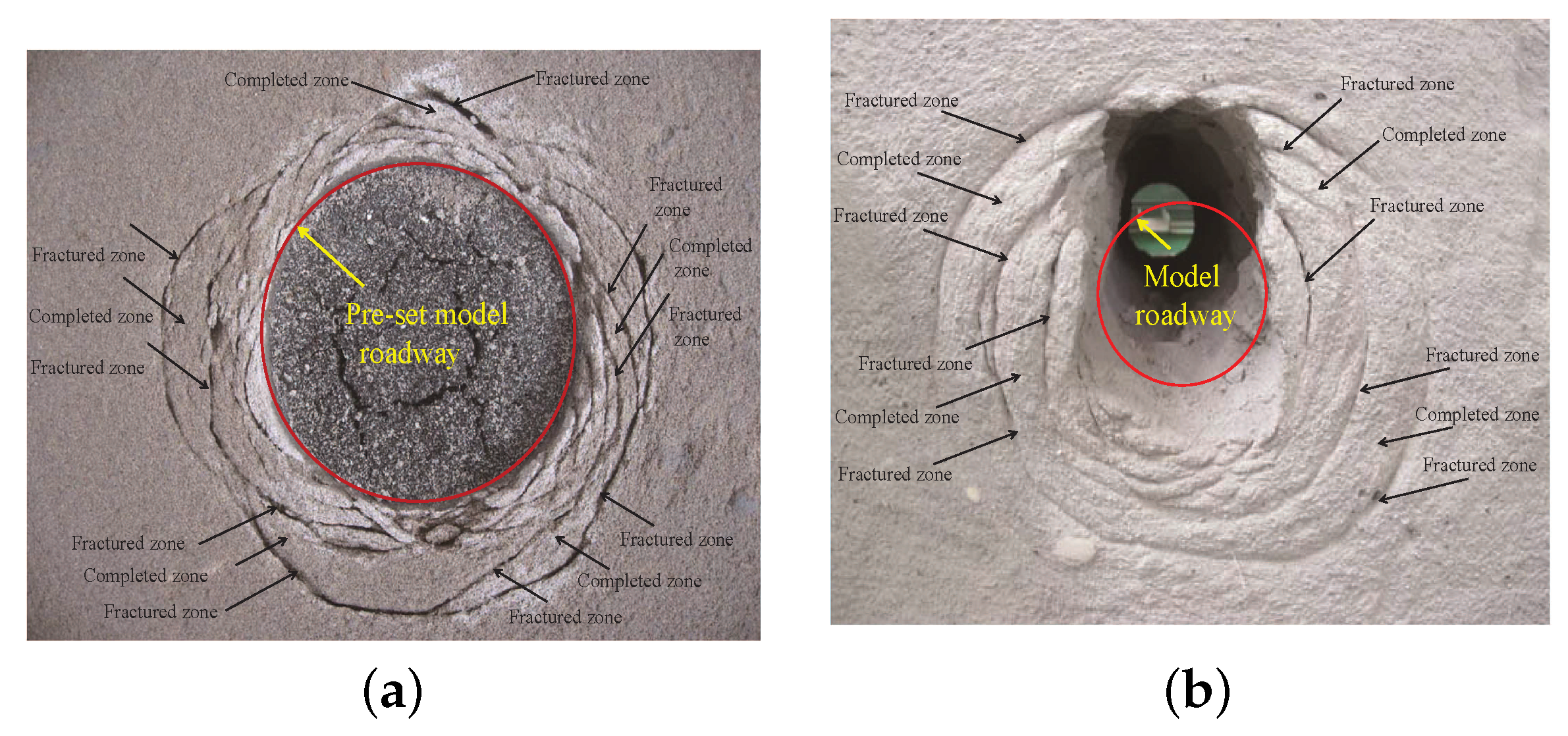

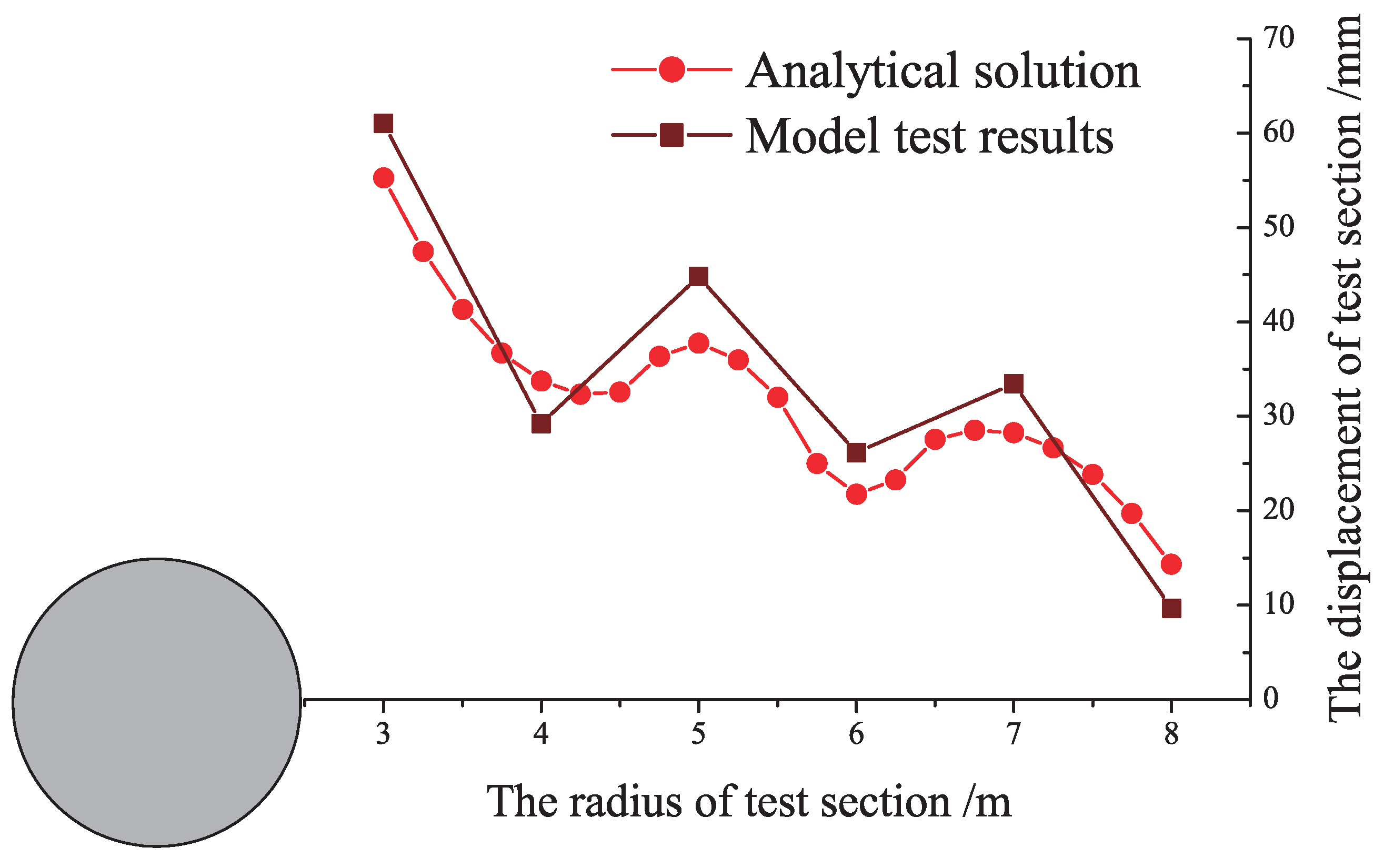

6.2. Comparative Analysis

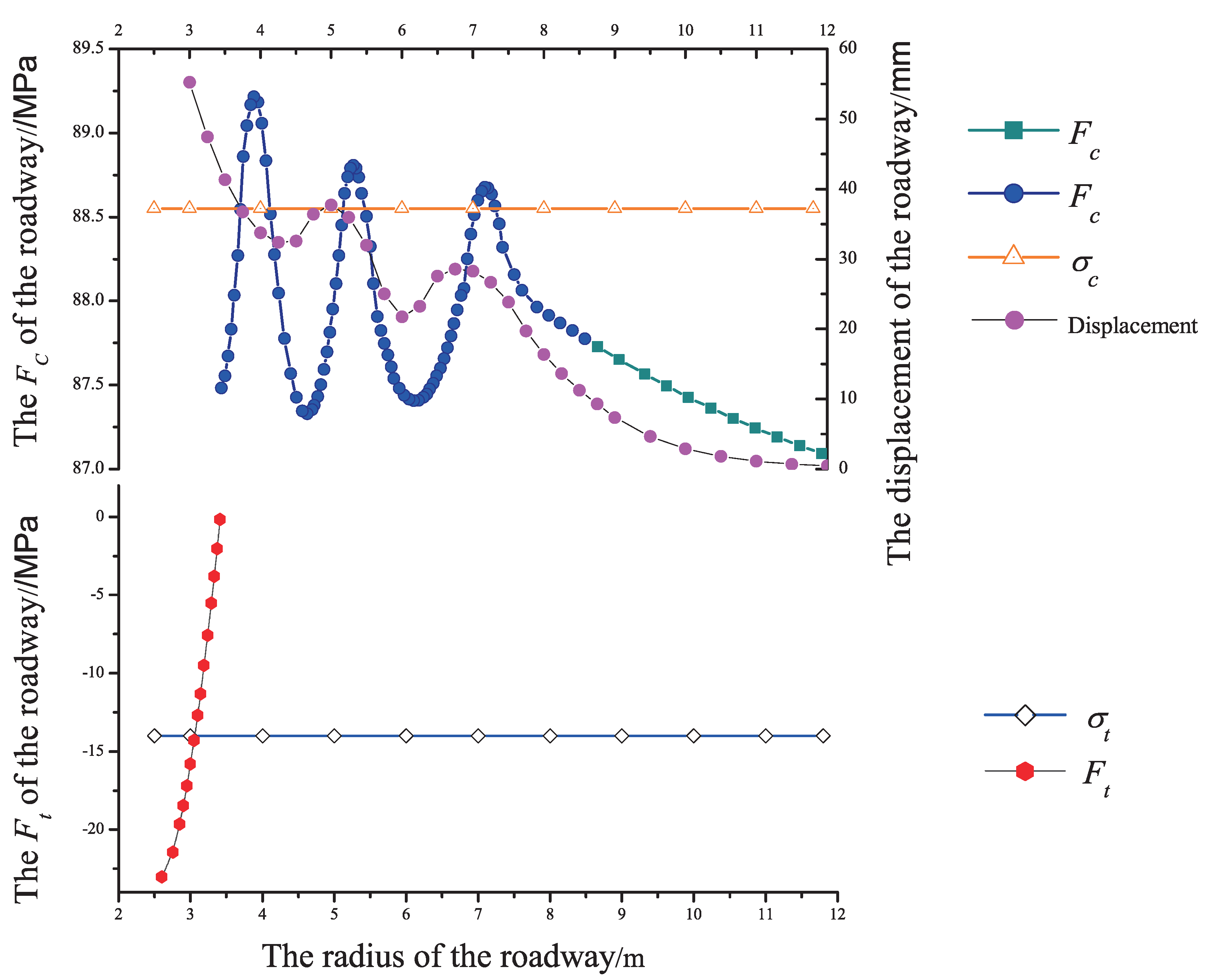

7. Zonal Disintegration Energy Mechanism Analysis

8. Conclusions

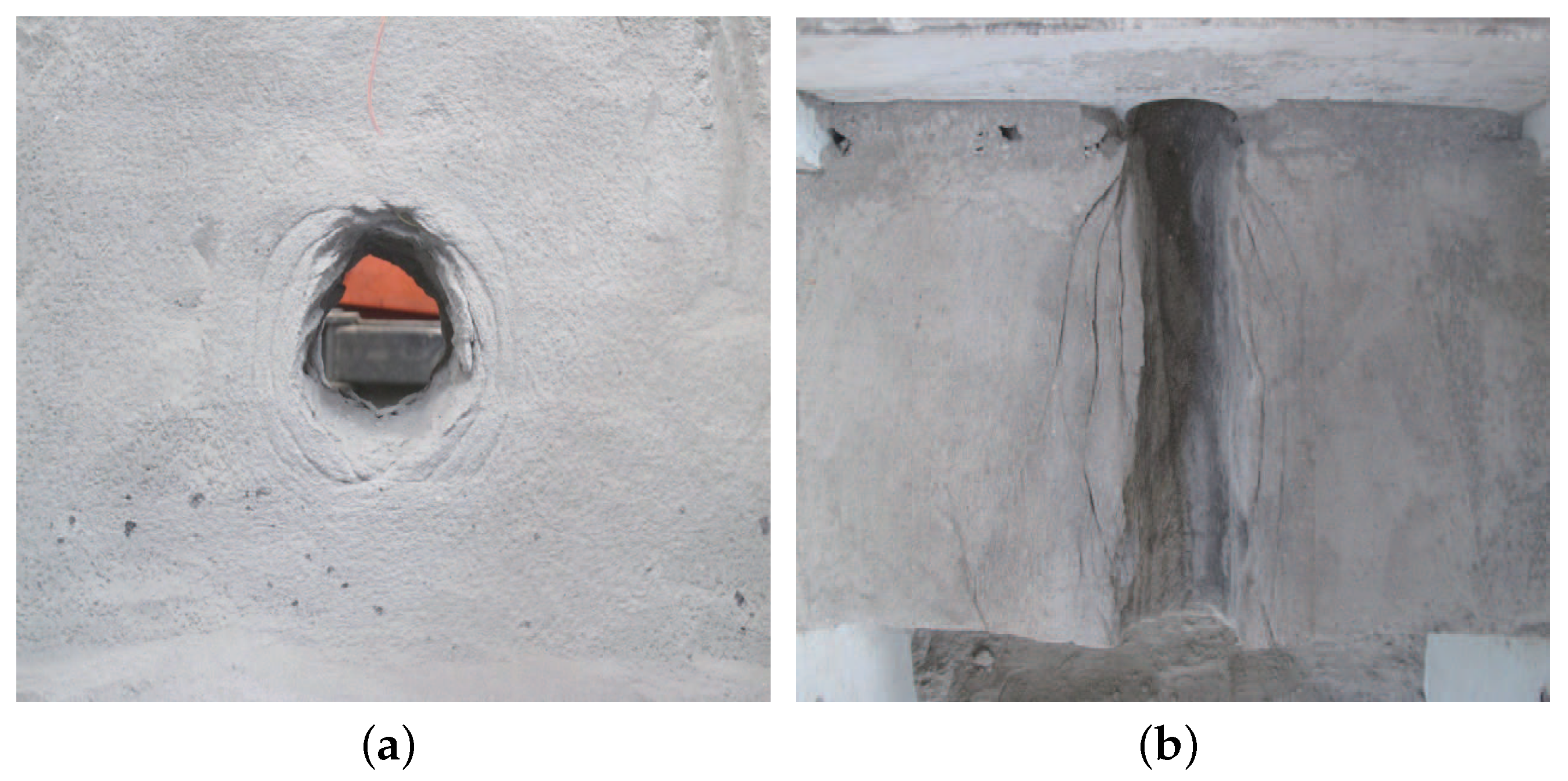

- Taking the deep roadway of Dingji coal mine in China’s Huainan coal mine as engineering background, a 3D geomechanical model test is carried out relying on the analogical materials and high stress loading test system. The zonal disintegration phenomenon is observed, and the oscillation law of displacements are measured.

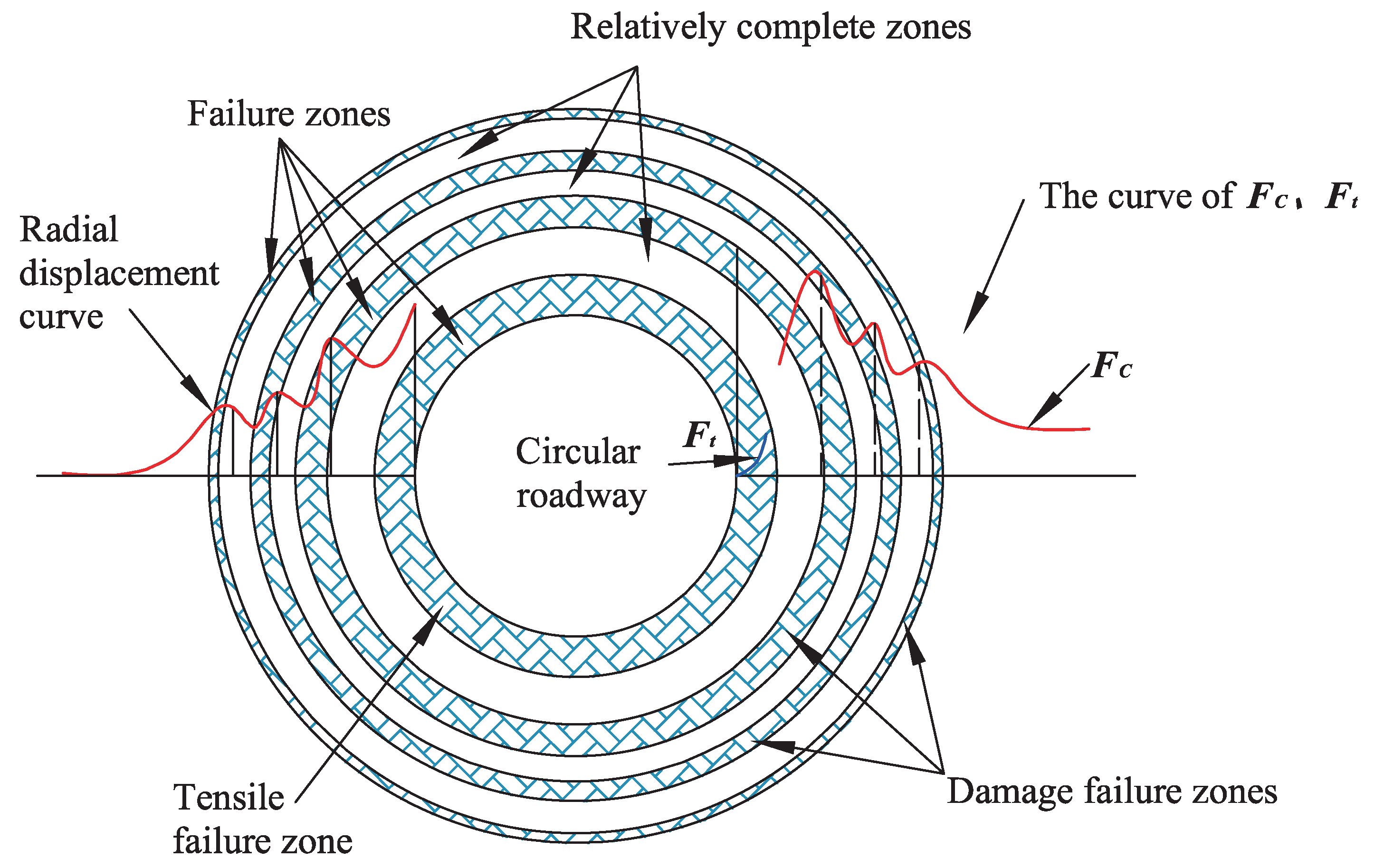

- The zonal disintegration in deep rock mass is a special and regular strain localization phenomenon. The influence of strain gradient should be considered. Based on the strain gradient theory and continuum damage mechanics, the zonal disintegration elastoplastic damage model is established. Based on the principle of energy dissipation and release, the energy failure criteria for zonal disintegration of surrounding rock in deep roadway are established, and the mechanical mechanism and energy evolution law for the occurrence of zonal disintegration are accurately described.

- The analytical solution for zonal disintegration is proposed and consistent with the 3D geomechanical model test. The reliability of zonal disintegration elastoplastic damage moddel and zonal disintegration energy failure criterion are verified effectively.

Author Contributions

Funding

Conflicts of Interest

References

- Shemyakin, E.I.; Fisenko, G.L.; Kurlenya, M.V.; Oparin, V.N.; Reva, V.N.; Glushikhin, F.P.; Rozenbaum, M.A.; Tropp, A.; Kuznetsov, Y.S. Zonal disintegration of rocks around underground workings, part 1: Data of in situ observations. Sov. Min. 1986, 3, 157–168. [Google Scholar] [CrossRef]

- Zhang, T.K.; Pan, Y.S.; Qian, Q.H. Non-Euclidean model for zonal failure of deep roadway under the permeation action. J. China Coal Soc. 2017, 11, 2842–2851. [Google Scholar]

- Qian, Q.; Zhou, X.; Xia, E. Effects of the axial in situ stresses on the zonal disintegration phenomenon in the surrounding rock masses around a deep circular tunnel. J. Min. Sci. 2012, 2, 276–285. [Google Scholar] [CrossRef]

- Qi, C.Z.; Li, K.R.; Bai, J.P.; Chanyshev, A.I.; Liu, P. Strain Gradient Model of Zonal Disintegration of Rock Mass near Deep-Level Tunnels. J. Min. Sci. 2017, 1, 21–33. [Google Scholar] [CrossRef]

- Zhou, X.P.; Bi, J. Zonal disintegration mechanism of cross-anisotropic rock masses around a deep circular tunnel. Theor. Appl. Fract. Mech. 2012, 57, 49–54. [Google Scholar] [CrossRef]

- Zuo, Y.; Xu, T.; Zhang, Y.; Zhang, Y.; Li, S.; Zhao, G.; Chen, C. Numerical study of zonal disintegration within a rock mass around a deep excavated tunnel. Int. J. Geomech. 2011, 4, 471–483. [Google Scholar] [CrossRef]

- Jia, P.; Zhu, W.C. Mechanism of zonal disintegration around deep underground excavations under triaxial stress insight from numerical test. Tunn. Undergr. Space Technol. 2015, 48, 1–10. [Google Scholar] [CrossRef]

- Zhang, Q.Y.; Zhang, X.T.; Wang, Z.C.; Xiang, W.; Xue, J.H. Failure mechanism and numerical simulation of zonal disintegration around a deep tunnel under high stress. Int. J. Rock Mech. Min. Sci. 2017, 2, 344–355. [Google Scholar] [CrossRef]

- Gu, J.; Gu, L.; Chen, A.; Xu, J.; Wei, C. Model test study on mechanism of layered farcture within surrounding rock of tunnels in deep stratum. Chin. J. Rock Mech. Eng. 2008, 27, 433–438. [Google Scholar]

- Zhang, Q.; Zhang, X.; Xiang, W.; Chen, X.; Cao, G.; Xu, X. Model test study of zonal disintegration in deep rock mass under different cavern shapes and loading conditions. Chin. J. Rock Mech. Eng. 2013, 8, 1564–1571. [Google Scholar]

- Polyzos, D.; Fotiadis, D.I. Derivation of mindlin’s first and second strain gradient elastic theory via simple lattice and continuum models. Int. J. Solids Struct. 2012, 3–4, 470–480. [Google Scholar] [CrossRef]

- Wang, X.B.; Pan, Y.S. Instability criterion of shear failure for rock specimen based on gradient-dependent plasticity. Chin. J. Rock Mech. Eng. 2003, 5, 747–750. [Google Scholar]

- Zhou, W.Y.; Yang, Q. Numerical Computational Methods for Rock Mechanics; China Electric Power Press: Beijing, China, 2005. [Google Scholar]

- Peng, R.; Ju, Y.; Wang, J.G.; Xie, H.; Gao, F.; Mao, L. Energy dissipation and release during coal failure under conventional triaxial compression. Rock Mech. Rock Eng. 2015, 2, 509–526. [Google Scholar] [CrossRef]

- Wei, D. Advances in fracture criteria of mixed model fracture in concrete. Mech. Eng. 2006, 6, 9–14. [Google Scholar]

- Nikolic, M.; Ibrahimbegovic, A.; Miscevic, P. Embedded discontinuity approach for representing mode I and mode II failure mechanisms. Int. J. Numer. Methods Eng. 2015, 8, 1507–1526. [Google Scholar] [CrossRef]

- Nikolic, M.; Ibrahimbegovic, A. Rock mechanics model capable of representing initial heterogeneities and full set of 3D failure mechanisms. Comput. Methods Appl. Mech. Eng. 2015, 290, 209–227. [Google Scholar] [CrossRef]

- Xie, H.P.; Peng, R.D.; Ju, Y. Study On energy analysis of rock failure. Chin. J. Rock Mech. Eng. 2005, 24, 2603–2608. [Google Scholar]

- Zhang, Q.Y.; Li, S.C.; Guo, X.H. Research and development of new typed cementatious geotechnical similar material for iron crystal sand and its application. Rock Soil Mech. 2008, 8, 2453–2463. [Google Scholar]

- Wang, C.; Zhang, Q.; Xiang, W. Physical and numerical modeling of the stability of deep caverns in tahe oil field in China. Energies 2008, 10, 769. [Google Scholar] [CrossRef]

- Zhang, Q.; Wen, X.; Yue, Z.; Chao, W.; Liu, C. Development and application of ultra high pressure 3d loading model test system with intelligent numerical control function. Chin. J. Rock Mech. Eng. 2016, 3, 483–493. [Google Scholar]

- Zhang, X.T.; Zhang, Q.Y.; Wen, X.; Qiang, G.; Yuan, S.B.; Chao, W. Model test study of zonal disintegration in deep layered jointed rock mass. Rock Soil Mech. 2014, 8, 2247–2254. [Google Scholar]

- Ostojastarzewski, M. Lattice models in micromechanics. Appl. Mech. Rev. 2002, 55, 35–60. [Google Scholar] [CrossRef]

- Mindlin, R.D. Micro-structure in linear elasticity. Arch. Ration. Mech. Anal. 1964, 1, 51–78. [Google Scholar] [CrossRef]

- Nikolić, M.; Karavelić, E.; Ibrahimbegovic, A.; Miščević, P. Lattice Element Models and Their Peculiarities. Arch. Comput. Methods Eng. 2017, 4, 1–32. [Google Scholar] [CrossRef]

- Mindlin, R.D. Second gradient of strain and surface-tension in linear elasticity. Int. J. Solids Struct. 1965, 4, 417–438. [Google Scholar] [CrossRef]

- Zhao, J.; Pedroso, D. Strain gradient theory in orthogonal curvilinear coordinates. Int. J. Solids Struct. 2008, 11, 3507–3520. [Google Scholar] [CrossRef]

- Fleck, N.; Hutchinson, J. A phenomenological theory for strain gradient effects in plasticity. J. Mech. Phys. Solids 1993, 12, 1825–1857. [Google Scholar] [CrossRef]

- Moës, N.; Belytschko, T. Extended finite element method for cohesive crack growth. Eng. Fract. Mech. 2002, 7, 813–833. [Google Scholar] [CrossRef]

- Simo, J.C.; Oliver, J.; Armero, F. An analysis of strong discontinuities induced by strain-softening in rate-independent inelastic solids. Comput. Mech. 1993, 5, 277–296. [Google Scholar] [CrossRef]

- Zhou, Y.Q.; Sheng, Q.; Leng, X.L.; Xiao, D.F.; Long, F.L. Statistical constitutive model of elastic damage for rock considering residual strength and threshold. J. Yangtze River Sci. Res. Inst. 2016, 1, 125–137. [Google Scholar]

- Geers, M.G.D. Experimental analysis and computational modelling of damage and fracture. Tech. Univ. 2016, 4, 593–617. [Google Scholar]

- Fang, Z.; Harrison, J.P. Application of a local degradation model to the analysis of brittle fracture of laboratory scale rock specimens under triaxial conditions. Int. J. Rock Mech. Min. Sci. 2002, 4, 459–476. [Google Scholar] [CrossRef]

- Yang, G. An Introduction to Elastic-Plastic Mechanics; People’s Education Press: Beijing, China, 2004. [Google Scholar]

- Xie, H.P.; Ju, Y.; Li, L.Y. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin. J. Rock Mech. Eng. 2005, 17, 3003–3010. [Google Scholar]

| Unit Weight | Deformation Modulus | Cohension | Friction Angle | Compression Strength | Poisson Ratio |

|---|---|---|---|---|---|

| (KN·m) | (MPa) | (MPa) | () | (MPa) | |

| 26.2 | 12,970 | 10.00 | 43 | 88.55 | 0.268 |

| Unit Weight | Deformation Modulus | Cohension | Friction Angle | Compression Strength | Poisson Ratio |

|---|---|---|---|---|---|

| (KN·m) | (MPa) | (MPa) | () | (MPa) | |

| 25.9–26.5 | 251–270 | 0.18–0.22 | 40–45 | 1.70–1.90 | 0.24–0.28 |

| Test Sections | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| Top (mm) | I | 60.45 | 29.50 | 42.55 | 27.25 | 31.75 | 7.75 |

| II | 58.05 | 30.65 | 41.25 | 27.50 | 33.95 | 8.35 | |

| III | 56.20 | 29.75 | 39.95 | 24.50 | 31.15 | 7.95 | |

| Left wall (mm) | I | 65.25 | 30.75 | 51.45 | 24.50 | 33.75 | 8.25 |

| II | 63.25 | 31.35 | 54.05 | 25.20 | 37.10 | 7.60 | |

| III | 68.50 | 30.15 | 56.05 | 24.05 | 35.10 | 7.65 | |

| Right wall (mm) | I | 57.25 | 25.75 | 37.75 | 27.75 | 32.25 | 13.05 |

| II | 60.65 | 28.05 | 41.55 | 29.40 | 34.50 | 13.15 | |

| III | 59.55 | 27.30 | 38.85 | 25.25 | 31.60 | 13.20 | |

| Value Type | The Measuring Point | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Model test results | 61.02 | 29.25 | 44.83 | 26.15 | 33.46 | 9.69 |

| Analytical solution | 55.23 | 33.72 | 37.76 | 21.73 | 28.27 | 14.35 |

| Number of Fractured Zone | Model Test Results | Analytical Solution | ||

|---|---|---|---|---|

| Range of Fractured | Average | Range of Fractured | Average | |

| Zone (m) | Radius (m) | Zone (m) | Radius (m) | |

| 1 | 2.50–3.75 | 3.13 | 2.50–3.06 | 2.78 |

| 2 | 4.30–4.75 | 4.52 | 4.72–5.16 | 4.94 |

| 3 | 5.95–6.25 | 6.10 | 6.16–6.44 | 6.30 |

| 4 | 7.90–8.10 | 8.00 | 8.14–8.30 | 8.22 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Q.; Zhang, Q.; Zhang, X.; Zhang, L. Geomechanical Model Test and Energy Mechanism Analysis of Zonal Disintegration in Deep Surrounding Rock. Geosciences 2018, 8, 237. https://doi.org/10.3390/geosciences8070237

Gao Q, Zhang Q, Zhang X, Zhang L. Geomechanical Model Test and Energy Mechanism Analysis of Zonal Disintegration in Deep Surrounding Rock. Geosciences. 2018; 8(7):237. https://doi.org/10.3390/geosciences8070237

Chicago/Turabian StyleGao, Qiang, Qiangyong Zhang, Xutao Zhang, and Longyun Zhang. 2018. "Geomechanical Model Test and Energy Mechanism Analysis of Zonal Disintegration in Deep Surrounding Rock" Geosciences 8, no. 7: 237. https://doi.org/10.3390/geosciences8070237

APA StyleGao, Q., Zhang, Q., Zhang, X., & Zhang, L. (2018). Geomechanical Model Test and Energy Mechanism Analysis of Zonal Disintegration in Deep Surrounding Rock. Geosciences, 8(7), 237. https://doi.org/10.3390/geosciences8070237