Sustainable Talcum Powder: A Developing Solution for Reduction the Swelling Potential of Expansive Soil

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

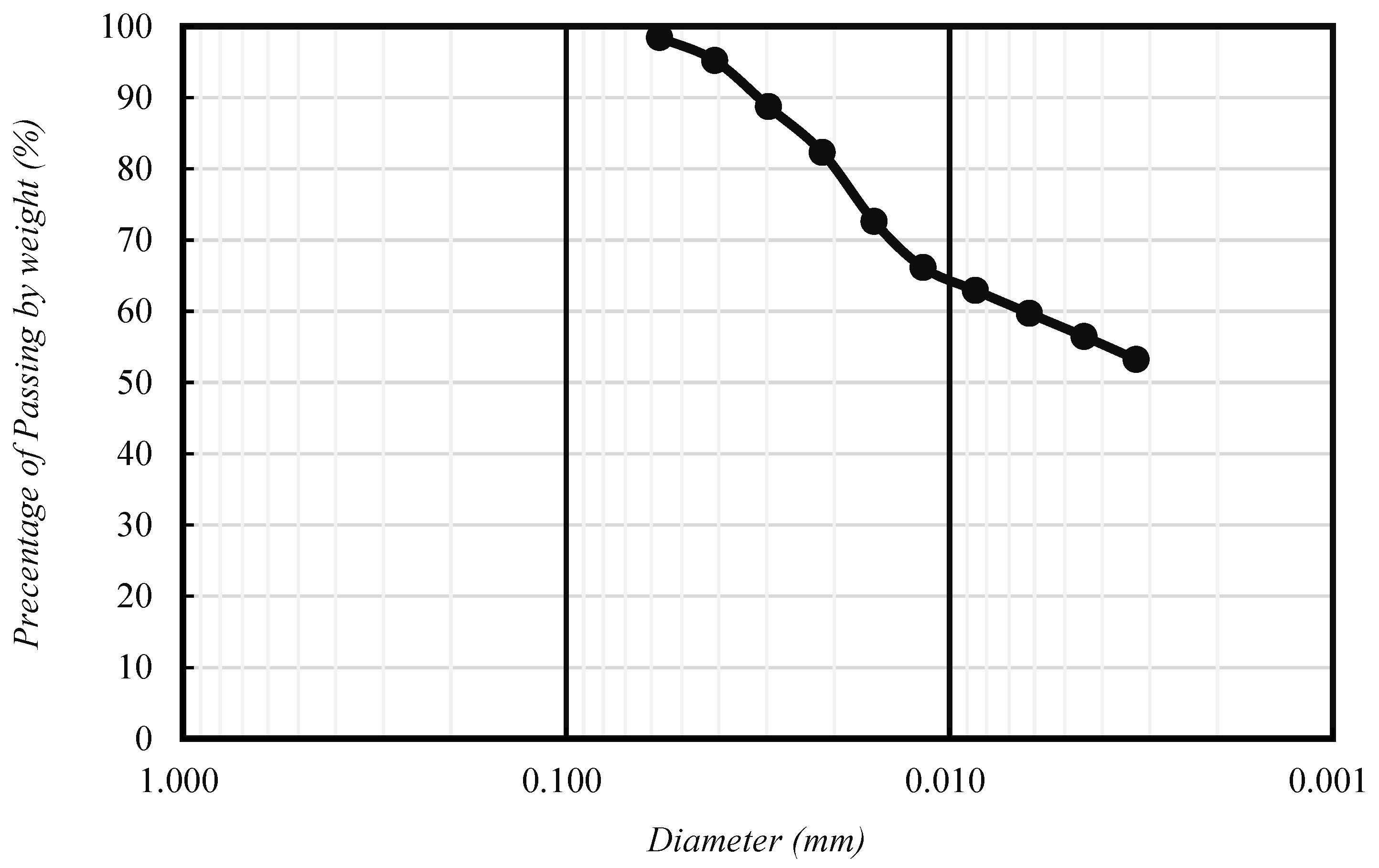

2.1.1. Bentonite

2.1.2. Talcum Powder

2.2. Sample Preparation

3. Experimental Program

3.1. X-Ray Diffraction (XRD)

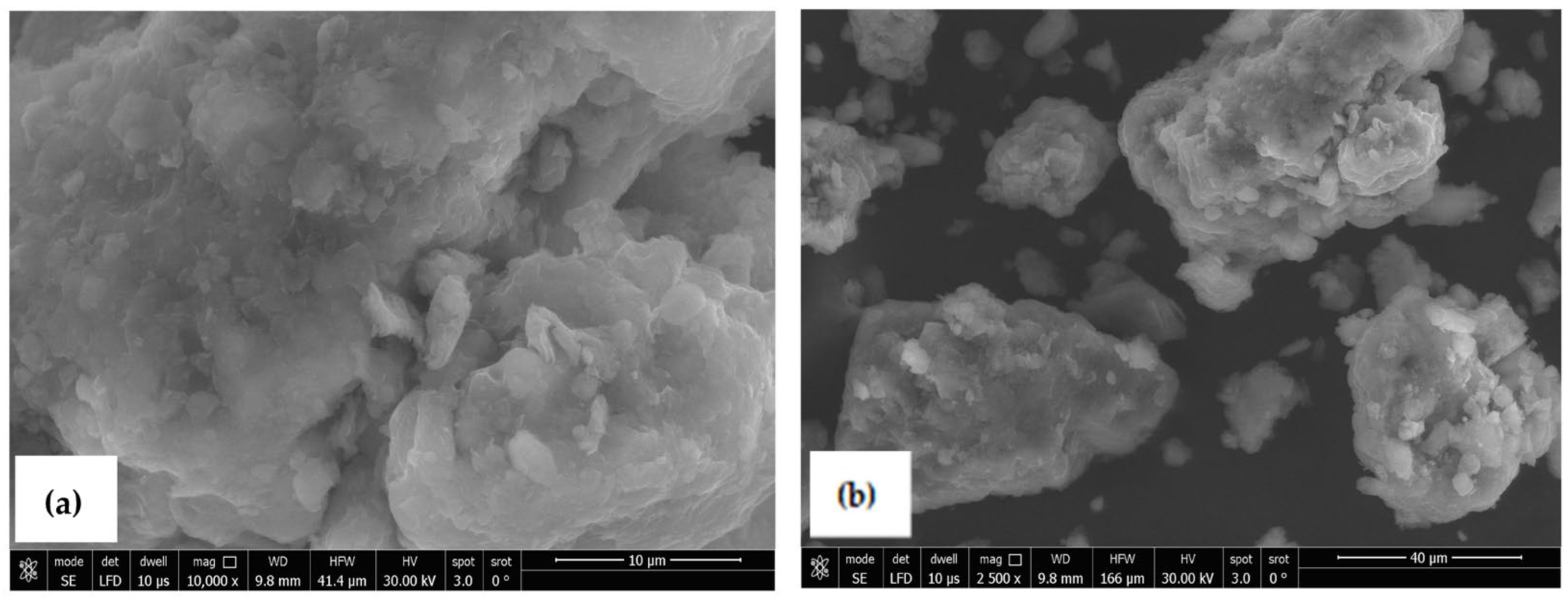

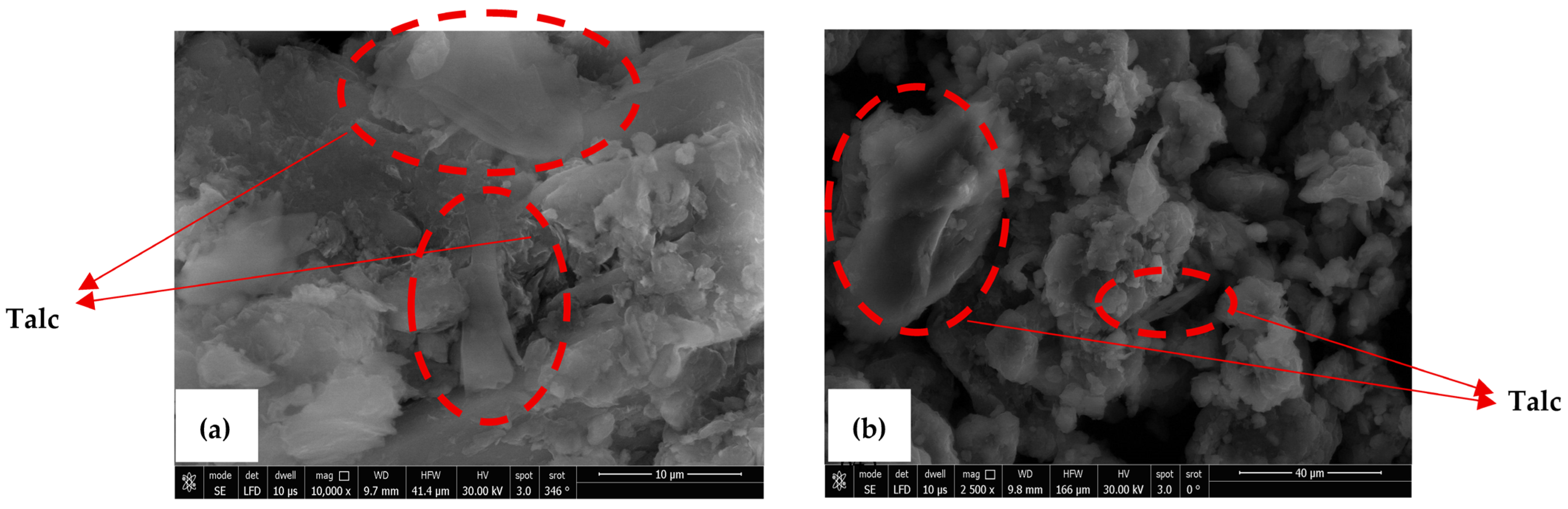

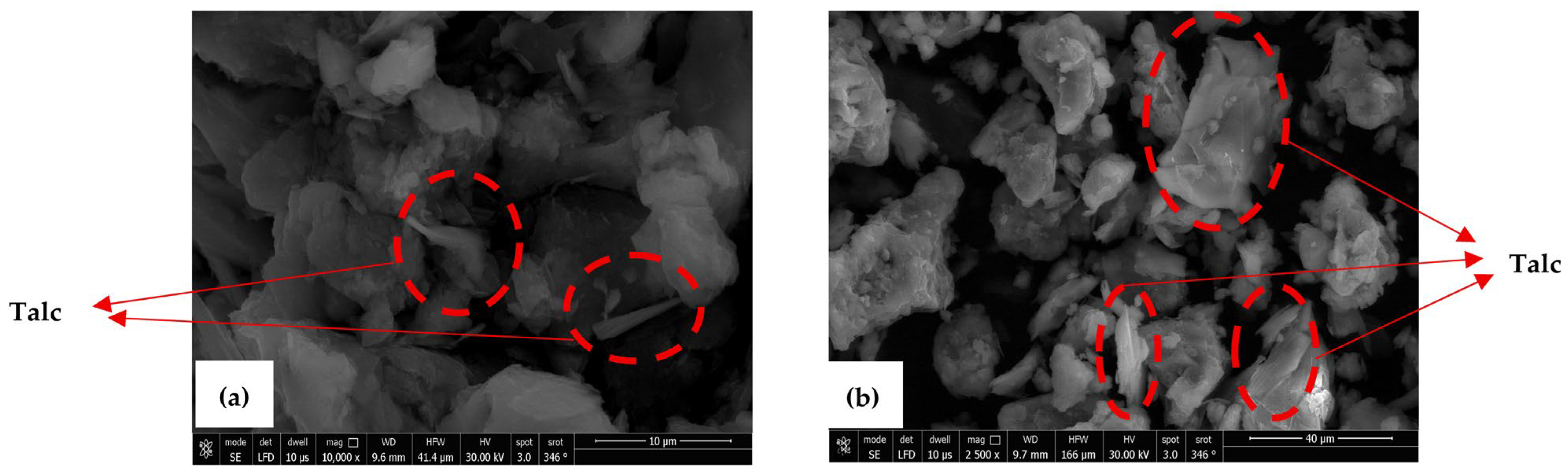

3.2. Scanning Electron Microscope (SEM)

3.3. Free Swell Index

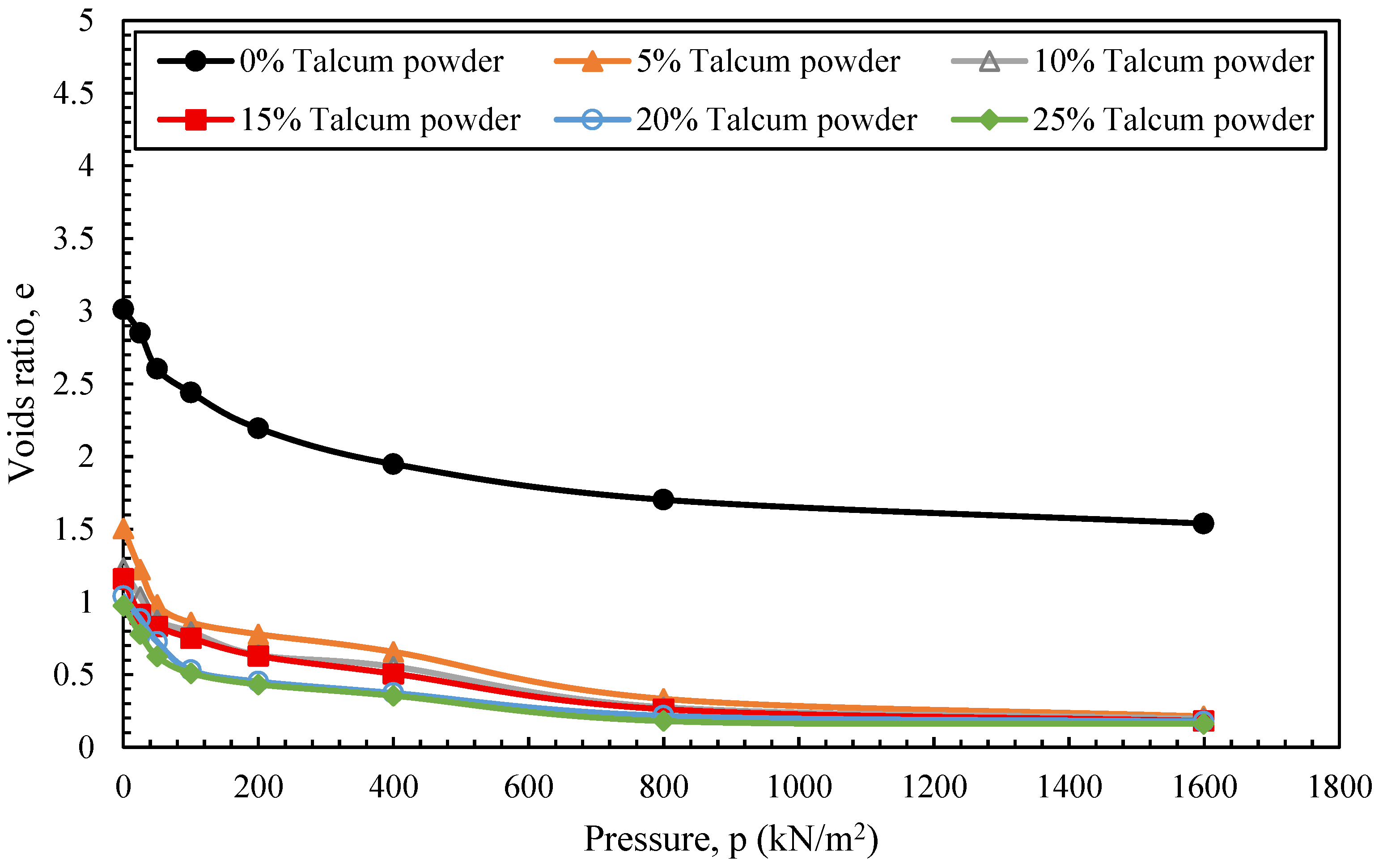

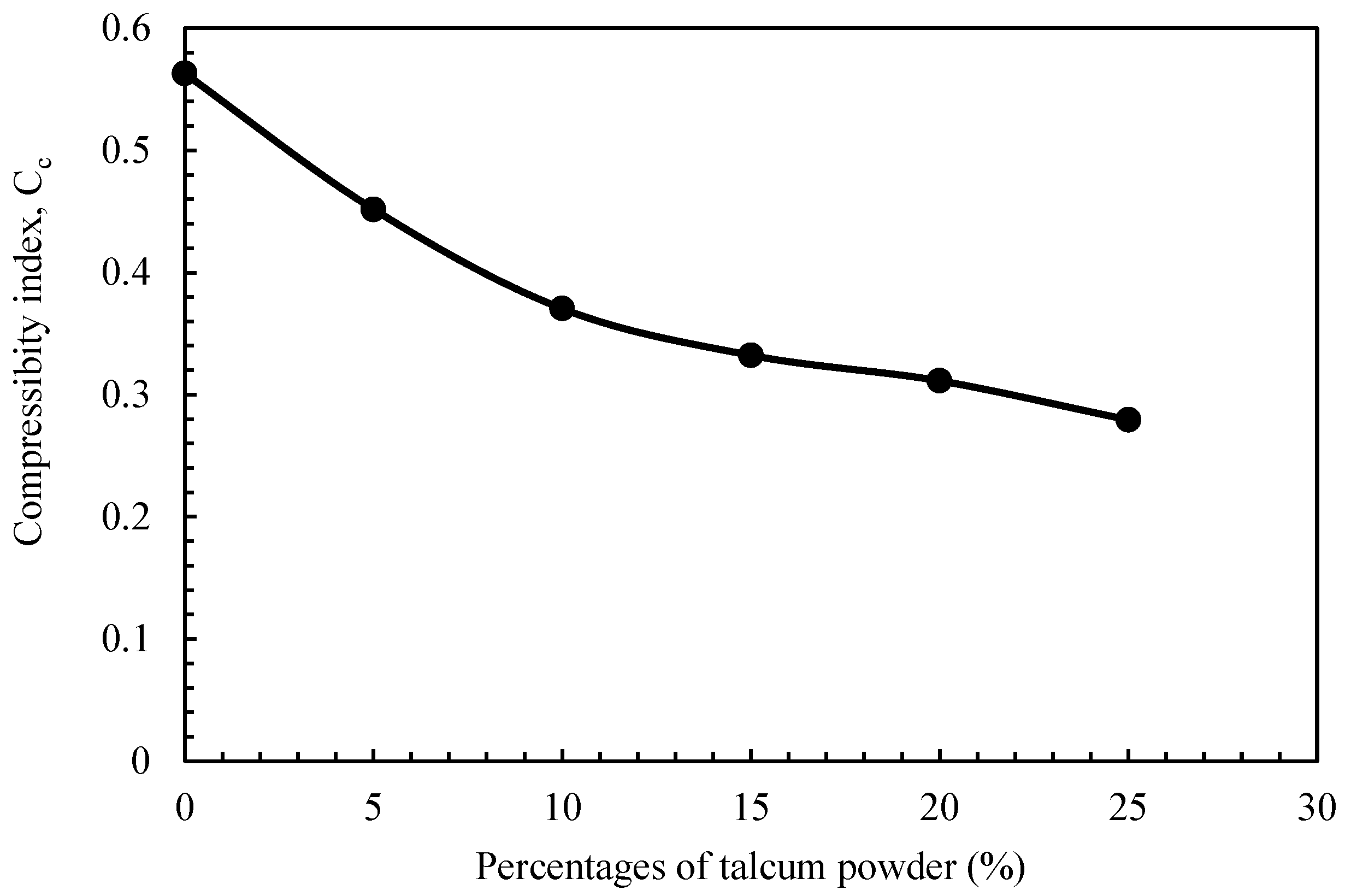

3.4. Oedometer Tests

3.5. Atterberg Limits

3.6. Modified Proctor Test

3.7. Unconfined Compressive Strength

4. Results and Discussion

4.1. Swelling Behavior and Geotechnical Properties of Expansive Soil Before and After Talcum Powder Treatment

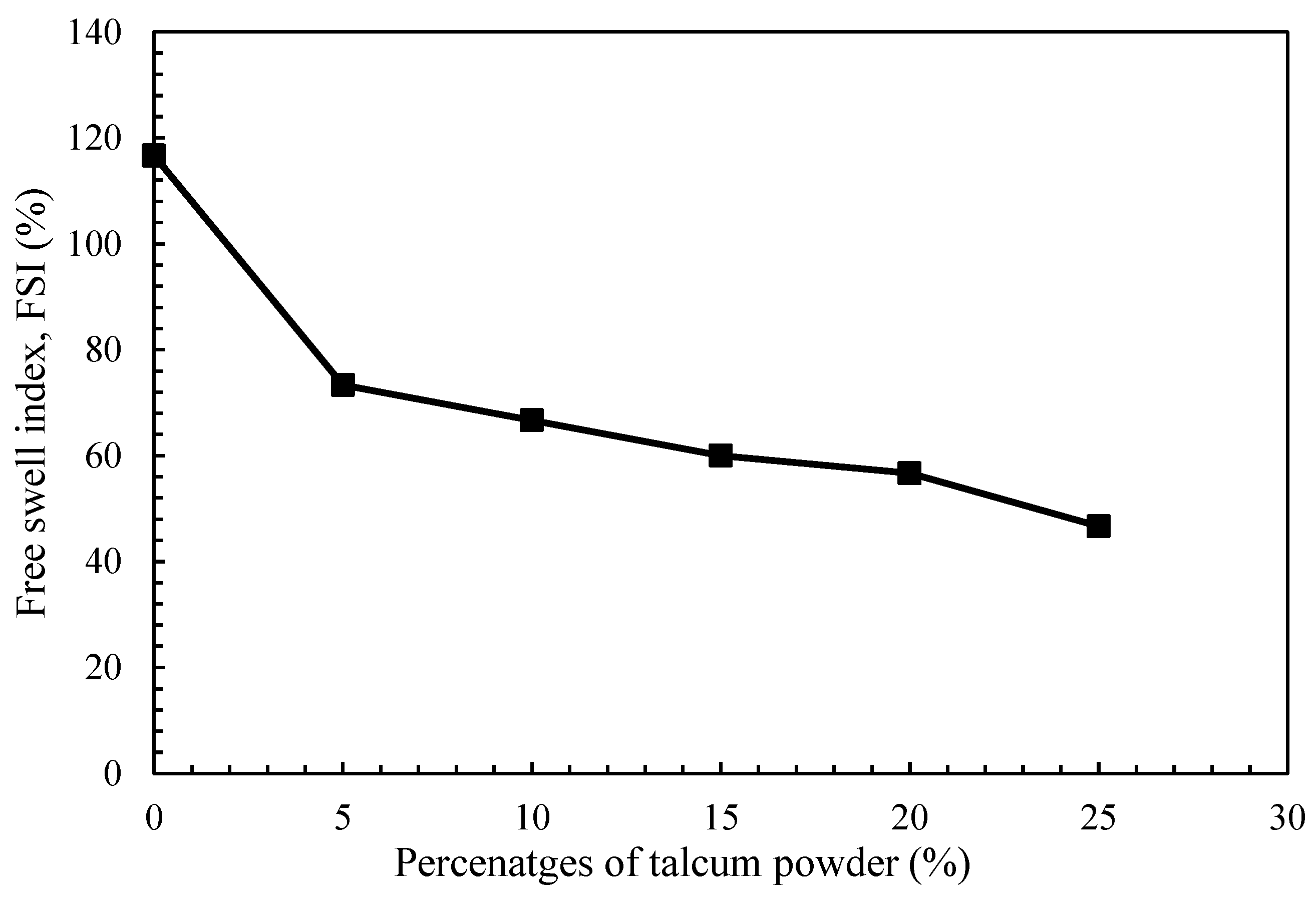

4.1.1. Free Swell Index

4.1.2. Swelling Pressure

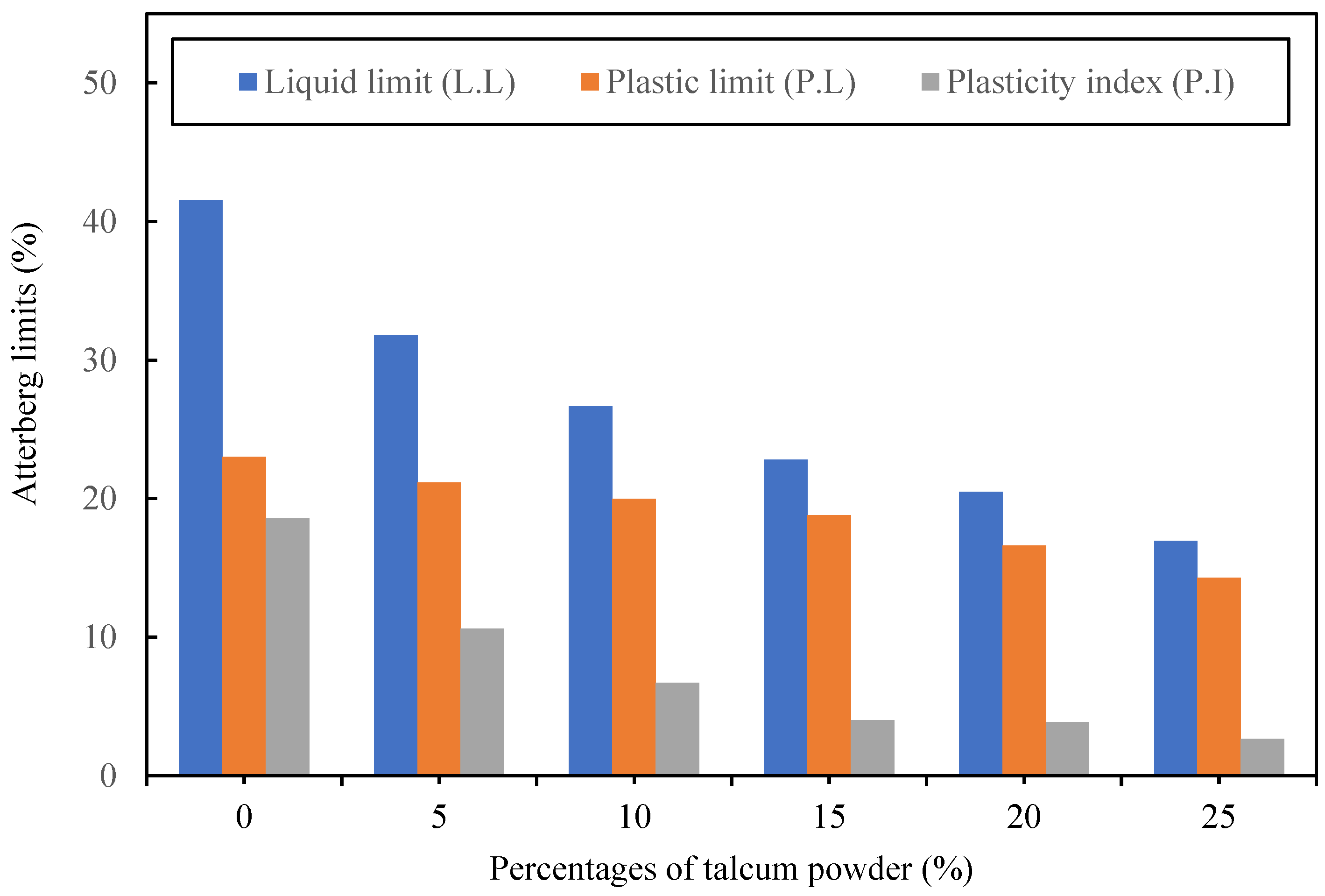

4.1.3. Atterberg Limits

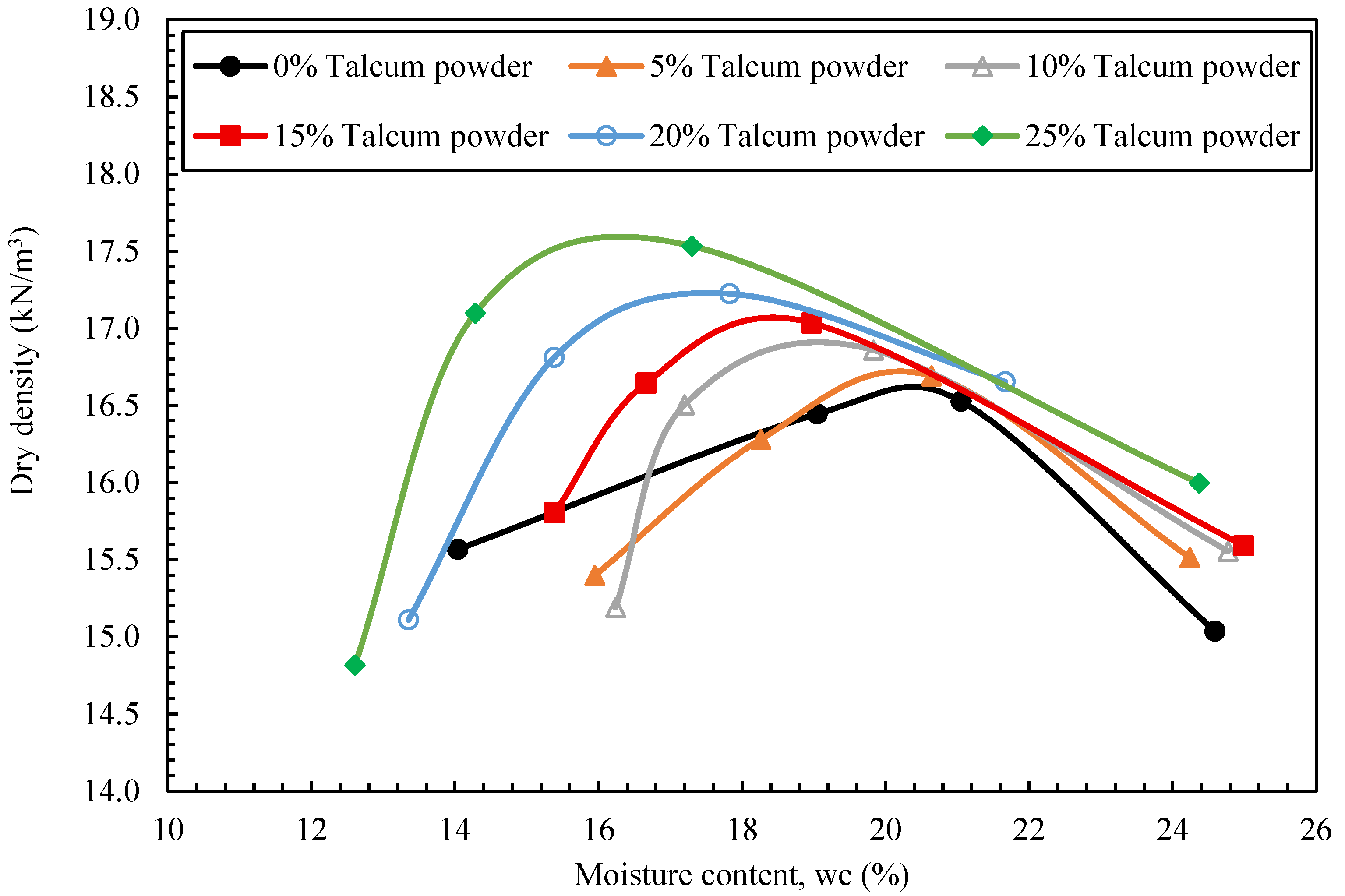

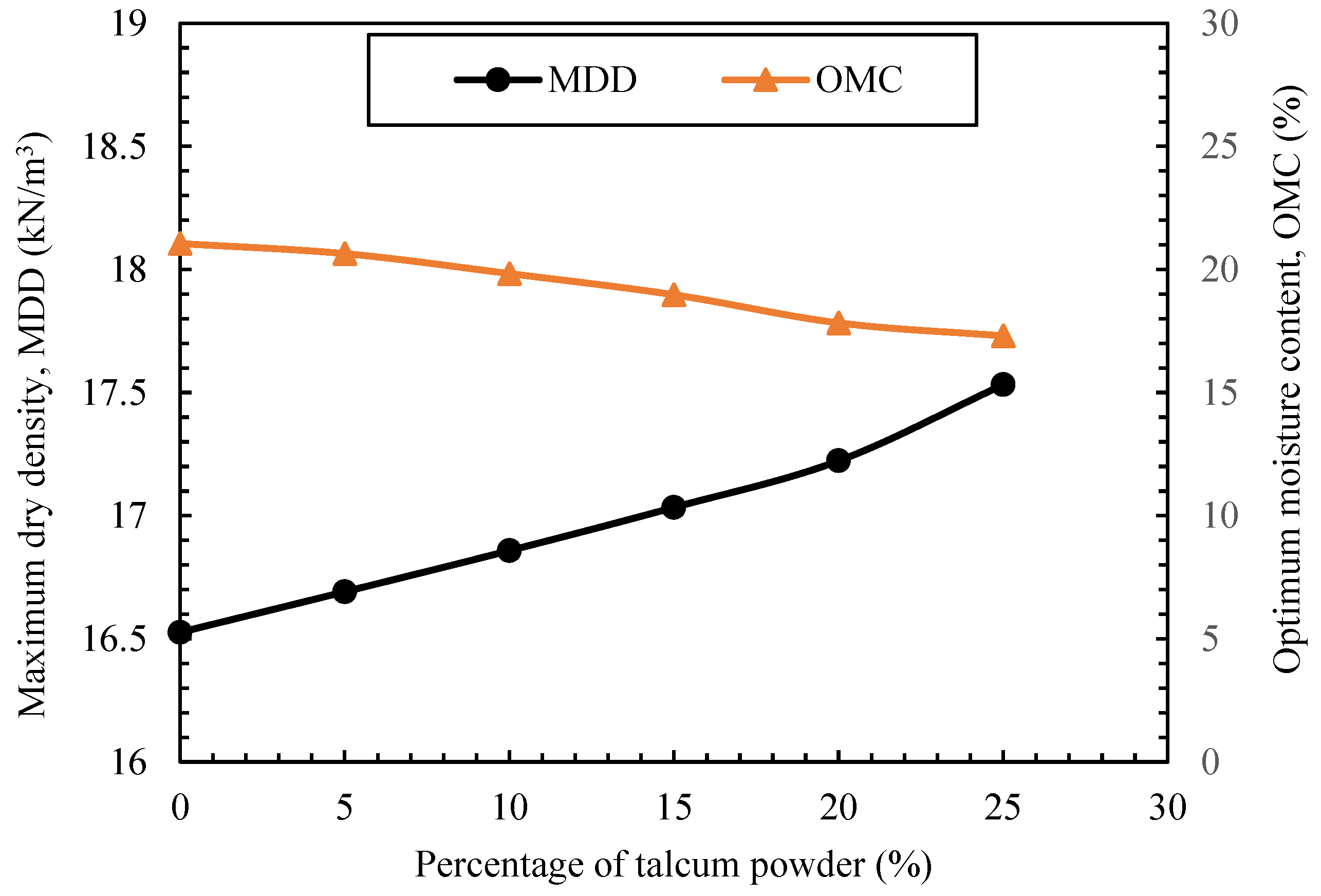

4.1.4. Modified Proctor Test

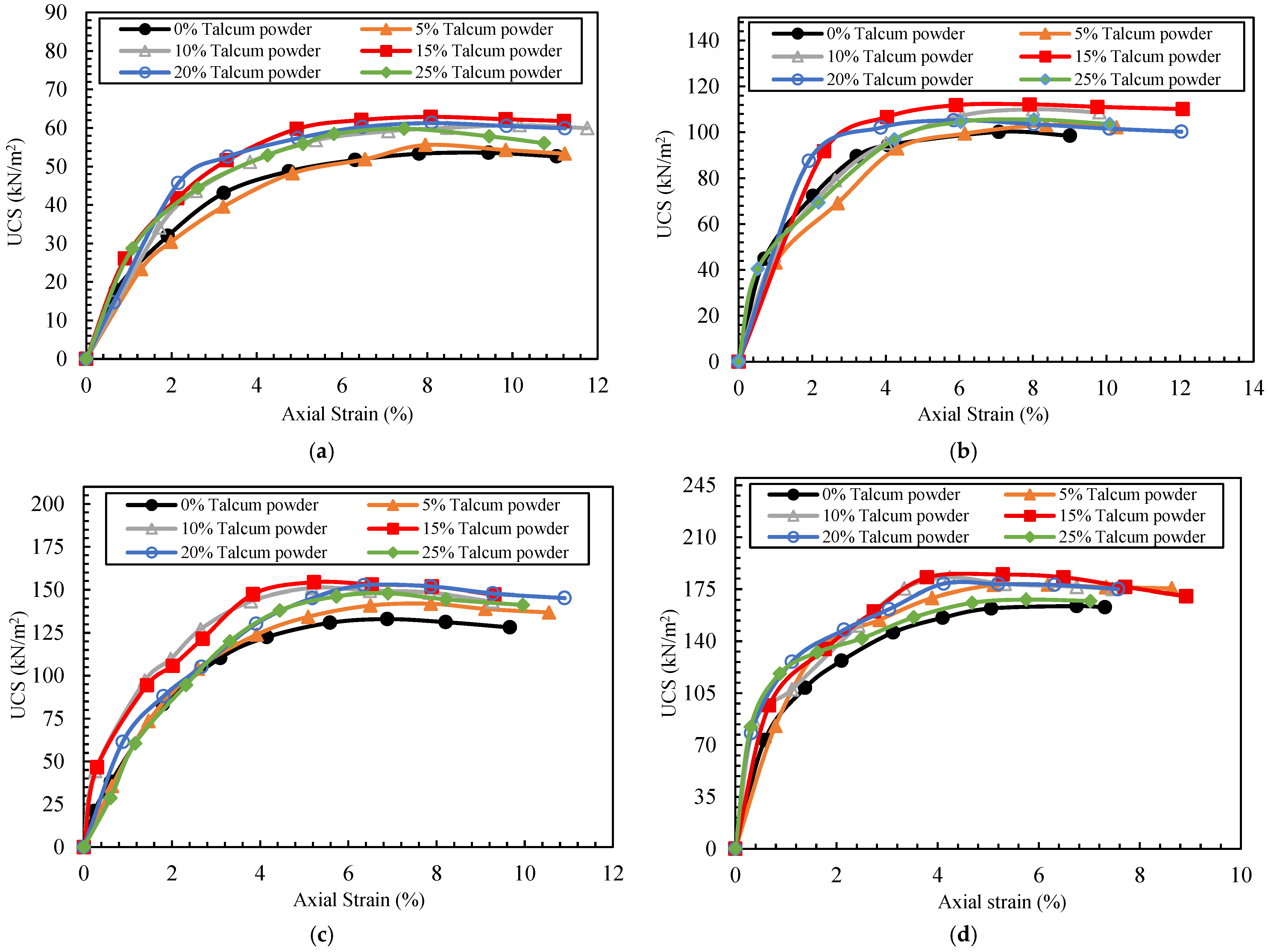

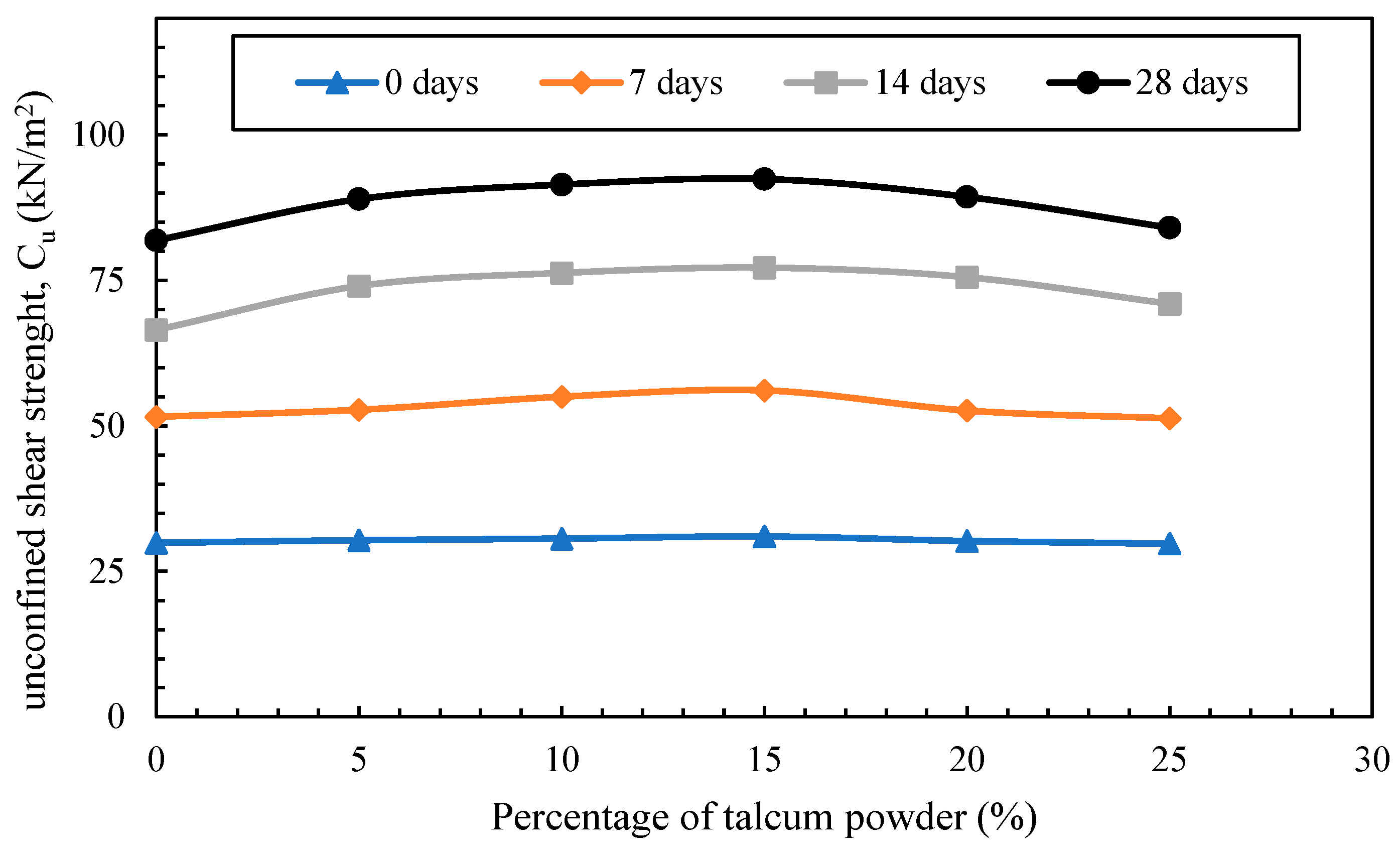

4.1.5. Unconfined Compressive Strength (UCS)

4.2. Morphology Analysis

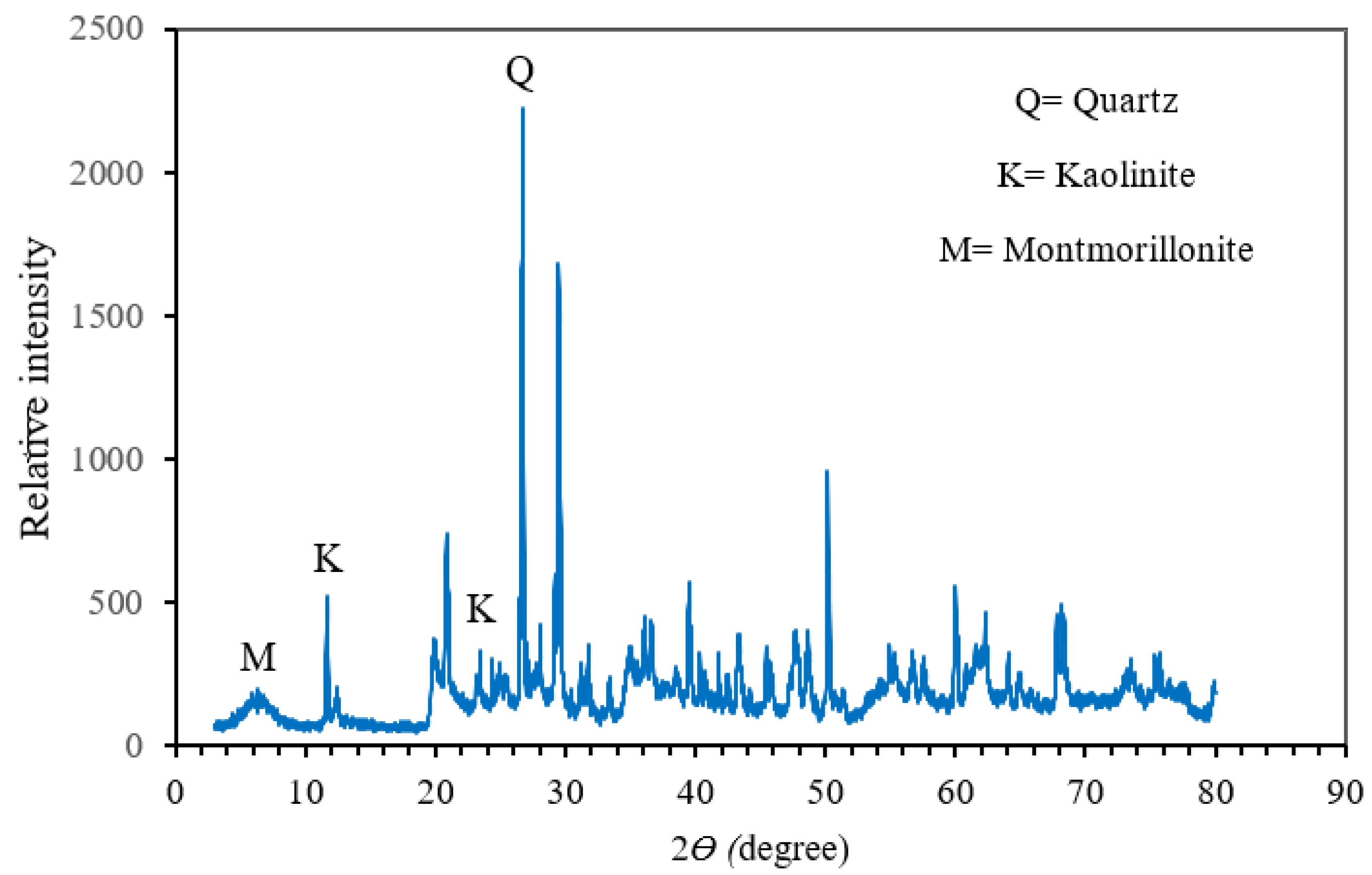

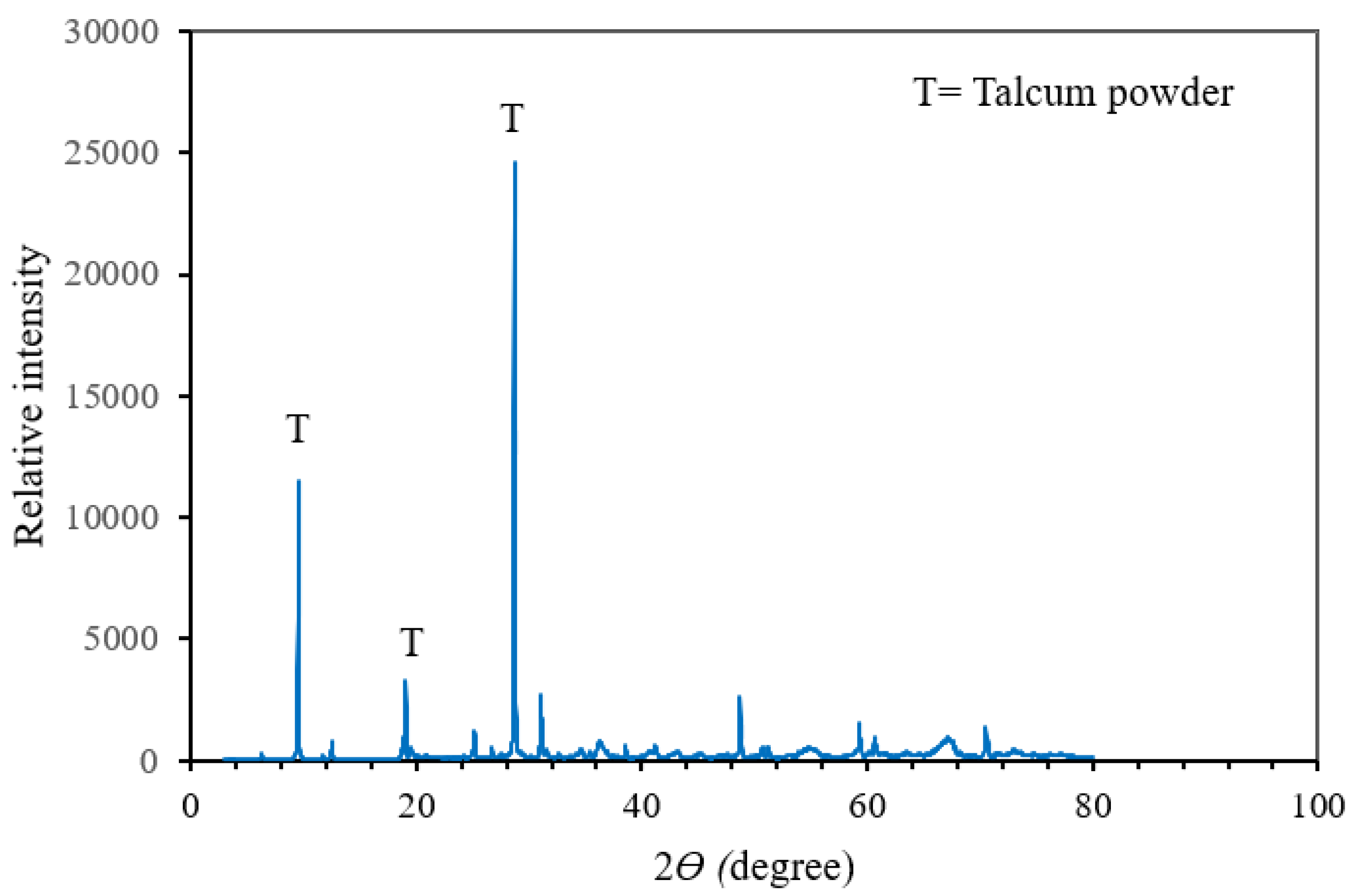

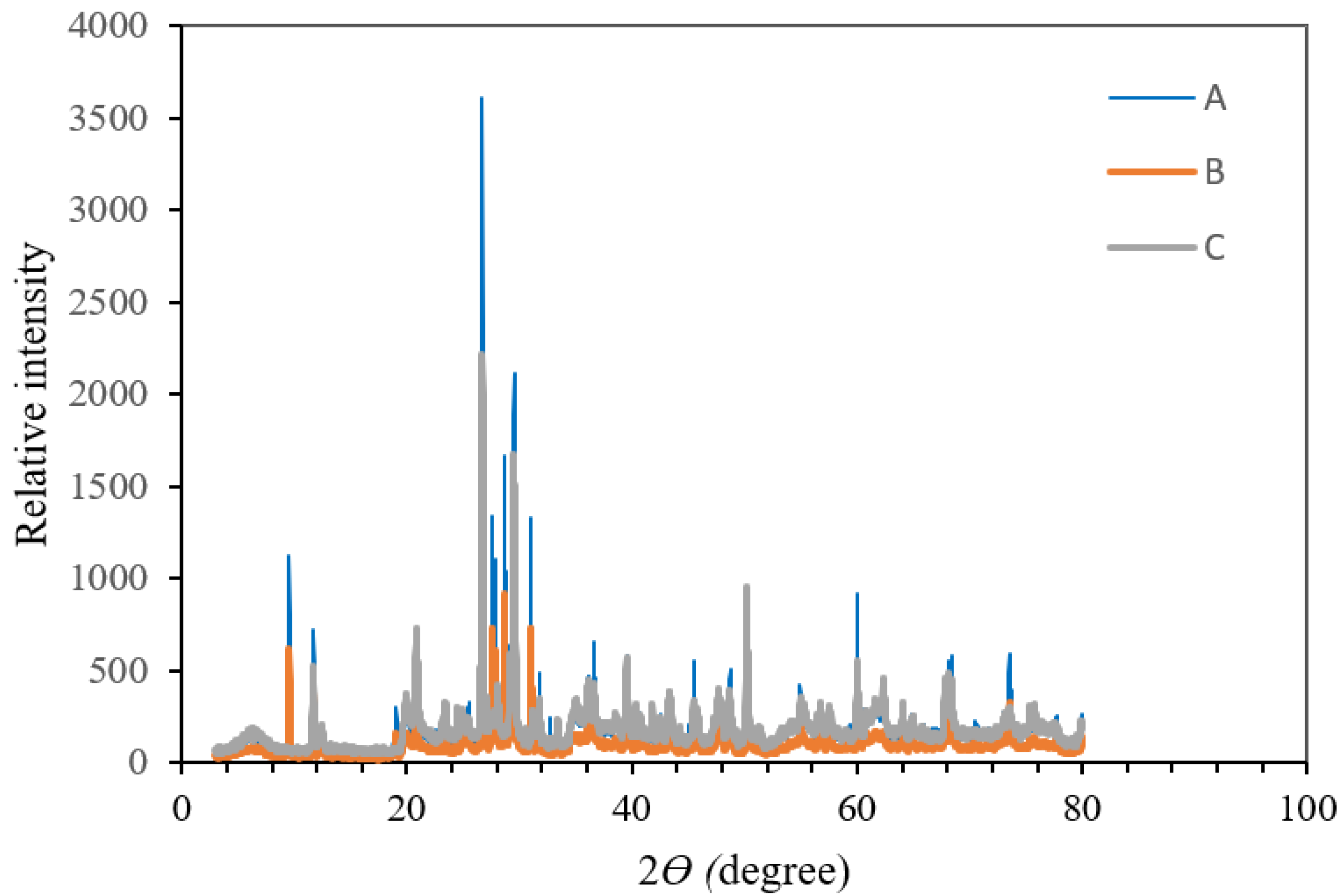

4.2.1. XRD Analysis

4.2.2. SEM Analysis

5. Conclusions

- Talcum powder improves expansive soil properties by reducing the free swell index and swelling pressure. At 25% content, it lowers FSI from 116% to 47% due to its filler effect and structural modification. The oedometer tests confirm enhanced compressibility and strength, validating talcum powder as an effective soil stabilizer.

- The Atterberg limits of the expansive soil decreased with increasing talcum powder content with the plasticity index dropping from 16.93% to 2.64% with 25% talcum powder addition. These reductions show that talcum powder does not react with the soil and reduces the effects of active clay minerals. As a result, the soil exhibits lower plasticity and improved workability, confirming the suitability of talcum powder for stabilizing expansive soils with high plastic behavior.

- The addition of talcum powder was also found to affect the compaction characteristics of the expansive soil. The optimum moisture content decreased from 21.05% to 17.3% while the maximum dry density increased from 16.52 kN/m3 to 17.53 kN/m3 as the talcum powder content increased to 25%. This is due to the fine, inert nature of talcum particles which enhances particle packing and reduces voids. The resulting denser and more stable soil structure improves mechanical performance and reduces moisture sensitivity.

- Talcum powder significantly enhances the strength properties of expansive soil with unconfined compressive strength (UCS) reaching 184.75 kN/m2 at 15% content after 28 days of curing higher than the untreated value of 163.5 kN/m2. Undrained shear strength (Cu) also increases, peaking at 92.5 kN/m2 with 15% talcum content. Strength gains decline slightly beyond 15%, indicating an optimal range of 10–15% for effective stabilization.

- XRD analysis shows a reduction in montmorillonite, which is the key swelling mineral, and the formation of stable talcum powder phases. SEM images reveal that talcum powder, especially at 5% and 10%, reduces porosity, fills interparticle voids and creates a denser, more cohesive soil structure. These changes diminish the flaky bentonite texture enhance particle bonding and improve overall dimensional stability. Thus, talcum powder functions as both a filler and stabilizer, making it a promising additive for reducing swelling and enhancing the engineering properties of expansive soils.

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seco, A.; Ramírez, F.; Miqueleiz, L.; García, B. Stabilization of expansive soils for use in construction. Appl. Clay Sci. 2011, 51, 348–352. [Google Scholar] [CrossRef]

- Avsar, E.; Ulusay, R.; Sonmez, H. Assessments of swelling anisotropy of Ankara clay. Eng. Geol. 2009, 105, 24–31. [Google Scholar] [CrossRef]

- Neslon, J.D.; Miller, D.J. Expansive Soils: Problems and Practice in Foundation and Pavement Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1992. [Google Scholar]

- Croney, D.; Coleman, J.D. Soil moisture suction properties and their effect on the moisture distribution in soils. In Proceedings of the 3rd International Conference on Soil Mechanics and Foundation Engineering (Switzerland), Zürich, Switzerland, 16–27 August 1953; Volume 1, pp. 13–18. [Google Scholar]

- Bishop, A.W.; Blight, G.E. Some aspects of effective stress in saturated and partly saturated soils. Geotechnique 1963, 13, 177–197. [Google Scholar] [CrossRef]

- Jamsawang, P.; Voottipruex, P.; Jongpradist, P. Cement and fly ash for expansive soil stabilization: A comparative study. J. Rock. mech. Geotech. Eng. 2022, 14, 825–835. [Google Scholar] [CrossRef]

- Malkawi, A.I.H.; Nusairat, J.; Al-Sharif, M. Effectiveness of limestone powder in expansive clay stabilization. Case Stud. Constr. Mater. 2024, 20, e01677. [Google Scholar]

- Thirumalai, R.; Kameshwar, R. Fly ash treated expansive soils: Swelling, strength and microstructure. Sustain. Mater. Technol. 2021, 27, e00250. [Google Scholar] [CrossRef]

- Pandey, S.; Sharma, P. Some physical properties treatment of expansive soil using Marble waste powder. Int. J. Eng. Res. Technol. 2014, 3, 1112–1116. [Google Scholar]

- Khamees, H.F. Effect of Quarry dust on engineering properties of expansive soil. J. Eng. 2019, 25, 78–90. [Google Scholar]

- Sakr, M.; Azzam, W.R.; Meguid, M.A.; Ghoneim, H.A. Evolution of Micro-metakaolin and Ferric chloride solution in stabilizing expansive soils. Proc. Inst. Civ. Eng. Ground Improv. 2022, 177, 103–115. [Google Scholar]

- Sabouang, C.N.; Mbey, J.A.; Thomas, F.; Njopwouo, D. Talc as raw material for cementitious products formulation. J. Asian Ceram. Soc. 2014, 2, 263–267. [Google Scholar] [CrossRef]

- Bruno, M.; Prencipe, M.; Valdré, G. Ab initio quantum-mechanical modeling of pyrophyllite (Al2Si4O10(OH)2) and talc (Mg3Si4O10(OH)2) surfaces. Phys. Chem. Miner. 2006, 33, 63–71. [Google Scholar] [CrossRef]

- Golubeva, O.Y.; Korytkova, E.N.; Gusarov, V.V. Hydrothermal synthesis of magnesium silicate montmorillonite for polymer-clay nanocomposites. Russ. J. Appl. Chem. 2005, 78, 26–32, Translated from Zhurnal prikladnoi khimii 78, 28–35. [Google Scholar] [CrossRef]

- Jadhav, N.R.; Paradkar, A.R.; Salunkhe, N.H.; Karade, R.S.; Mane, G.G. TALC: A versatile pharmaceutical excipient. World J. Pharm. Pharm. Sci. 2013, 2, 4639–4660. [Google Scholar]

- Benkadja, R.; Belouahri, B. Influence of oil on the magnitude and rate of collapse of soils. J. Civ. Eng. Res. Pract. 2010, 7, 1–12. [Google Scholar] [CrossRef]

- Sakr, M.A.; Sawaf, M.A.; Nazir, A.K.; Rabah, A.K. Behavior of collapsible soils stabilized with fibers. Alex. Int. Conf. Struct. Geotech. Eng. 2014, 8, 119–129. [Google Scholar]

- Elmashad, M.E. Effect of chemical additives on consistency, infiltration rate and swelling characteristics of bentonite. Water Sci. 2017, 31, 177–188. [Google Scholar] [CrossRef]

- Zheng, C.; Yuan, Y. Study on the effect of water content on physical properties of bentonite. PLoS ONE 2025, 20, e0303522. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Li, H.; Chen, Z. Relationship between expansion rate and initial moisture content of medium expansive soil. Geomech. Eng. 2021, 25, 205–214. [Google Scholar]

- Holtz, W.G.; Gibbs, H.J. Engineering properties of expansive clays. Trans. ASCE 1956, 121, 641–663. [Google Scholar] [CrossRef]

- ASTM D5890-08; Standard Test Methods for Free Swell of Soils. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

- ASTM D1557-08; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

- ASTM D4546-08; Standard Test Methods for One-Dimensional Swell or Collapse of Cohesive Soils. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

- ASTM 2166-08; Standard Test Methods for Unconfined Compressive Strength of Cohesive Soil. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

| Property | Value |

|---|---|

| SiO2 (%) | 55.0 |

| Al2O3 (%) | 22.4 |

| Fe2O3 (%) | 4.2 |

| MgO (%) | 2.2 |

| CaO (%) | 0.8 |

| Na2O (%) | 2.0 |

| K2O (%) | 1.3 |

| Loss on ignition measured at 850 °C for 2 h (%) | 10.0 |

| Property | Value |

|---|---|

| Specific gravity, Gs | 2.63 |

| Unit weight, (kN/m3) | 10.7 |

| Water content (%) | 8.69 |

| Void ratio, e | 3.01 |

| Free swell index, FSI (%) | 116.67 |

| Liquid limit, L.L. (%) | 41.57 |

| Plastic limit, P.L. (%) | 23.01 |

| Plasticity index, P.I. (%) | 18.55 |

| Maximum dry density, dry max. (kN/m3) | 16.52 |

| Optimum moisture content, O.M.C. (%) | 21.05 |

| Property | Value |

|---|---|

| Color | White |

| Specific gravity, Gs | 2.78 |

| Unit weight, (kN/m3) | 7.8 |

| pH (10% solids) | 7.0 |

| SiO2 (%) | 65.0 |

| MgO (%) | 32.0 |

| Al2O3 (%) | >1.0 |

| Fe2O3 (%) | >1.0 |

| CaO (%) | >1.0 |

| Experimental Series | Type of Test | Number of Tests | Test Details |

|---|---|---|---|

| S1 | XRD test | 4 | Untreated soil, talcum powder, and soil treated with 5% and 10% talc. |

| S2 | SEM test | 3 | Natural soil samples treated with 5% and 10% talc at 10 µm and 40 µm particle sizes |

| S3 | Free swell index | 7 | 1 with kerosene, 1 with natural soil, and with different talcum powder contents (5–25%). |

| S4 | Oedometer test | 6 | Natural soil and treated sample at 5 different talc percentages |

| S5 | Atterberg limits | 12 | Liquid limit and plastic limit for untreated and 5 treated soil samples with talc. |

| S6 | Modified Proctor test | 6 | Natural soil and soil with 5 incremental talc percentages (5% to 25%). |

| S7 | Unconfined compressive strength | 24 | Talc contents * 4 curing periods (0, 7, 14, and 28 days) |

| Total | 61 |

| (%) of Talcum Powder | Maximum Dry Density (kN/m3) | Optimum Moisture Content (%) |

|---|---|---|

| 0.0 | 16.52 | 21.05 |

| 5 | 16.69 | 20.64 |

| 10 | 16.85 | 19.83 |

| 15 | 17.03 | 18.97 |

| 20 | 17.22 | 17.83 |

| 25 | 17.53 | 17.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakr, M.; Nazir, A.; Azzam, W.; Eleraky, H. Sustainable Talcum Powder: A Developing Solution for Reduction the Swelling Potential of Expansive Soil. Geosciences 2025, 15, 352. https://doi.org/10.3390/geosciences15090352

Sakr M, Nazir A, Azzam W, Eleraky H. Sustainable Talcum Powder: A Developing Solution for Reduction the Swelling Potential of Expansive Soil. Geosciences. 2025; 15(9):352. https://doi.org/10.3390/geosciences15090352

Chicago/Turabian StyleSakr, Mohamed, Ashraf Nazir, Waseim Azzam, and Hesham Eleraky. 2025. "Sustainable Talcum Powder: A Developing Solution for Reduction the Swelling Potential of Expansive Soil" Geosciences 15, no. 9: 352. https://doi.org/10.3390/geosciences15090352

APA StyleSakr, M., Nazir, A., Azzam, W., & Eleraky, H. (2025). Sustainable Talcum Powder: A Developing Solution for Reduction the Swelling Potential of Expansive Soil. Geosciences, 15(9), 352. https://doi.org/10.3390/geosciences15090352