Research on the Distribution and Escape Characteristics of Dust at the Blasting Pile in an Open-Pit Mining Area

Abstract

1. Introduction

2. Materials and Methods

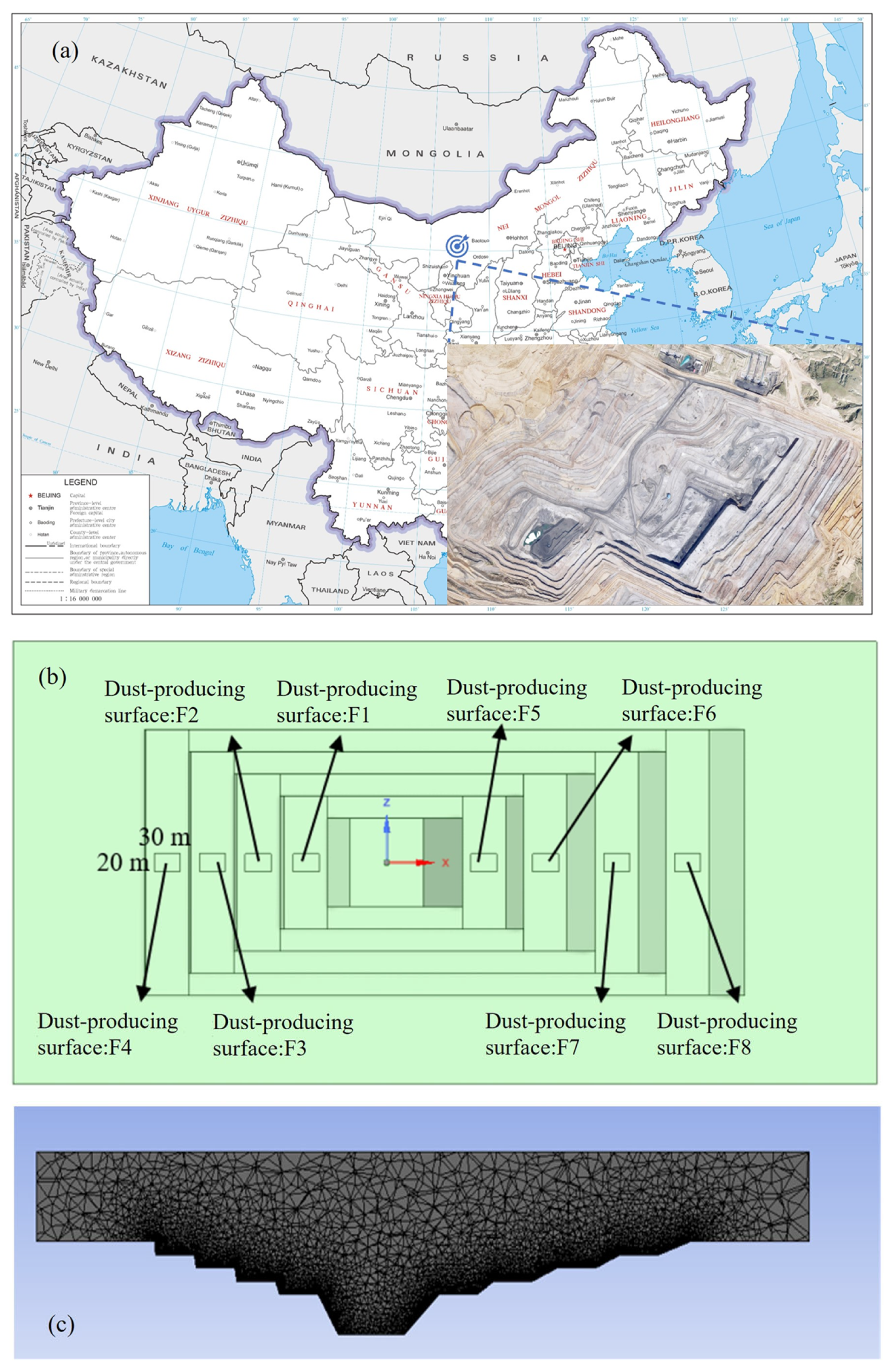

2.1. Numerical Calculation Model

2.2. Model Reliability

2.3. Numerical Simulation Parameter Setting

3. Results and Discussion

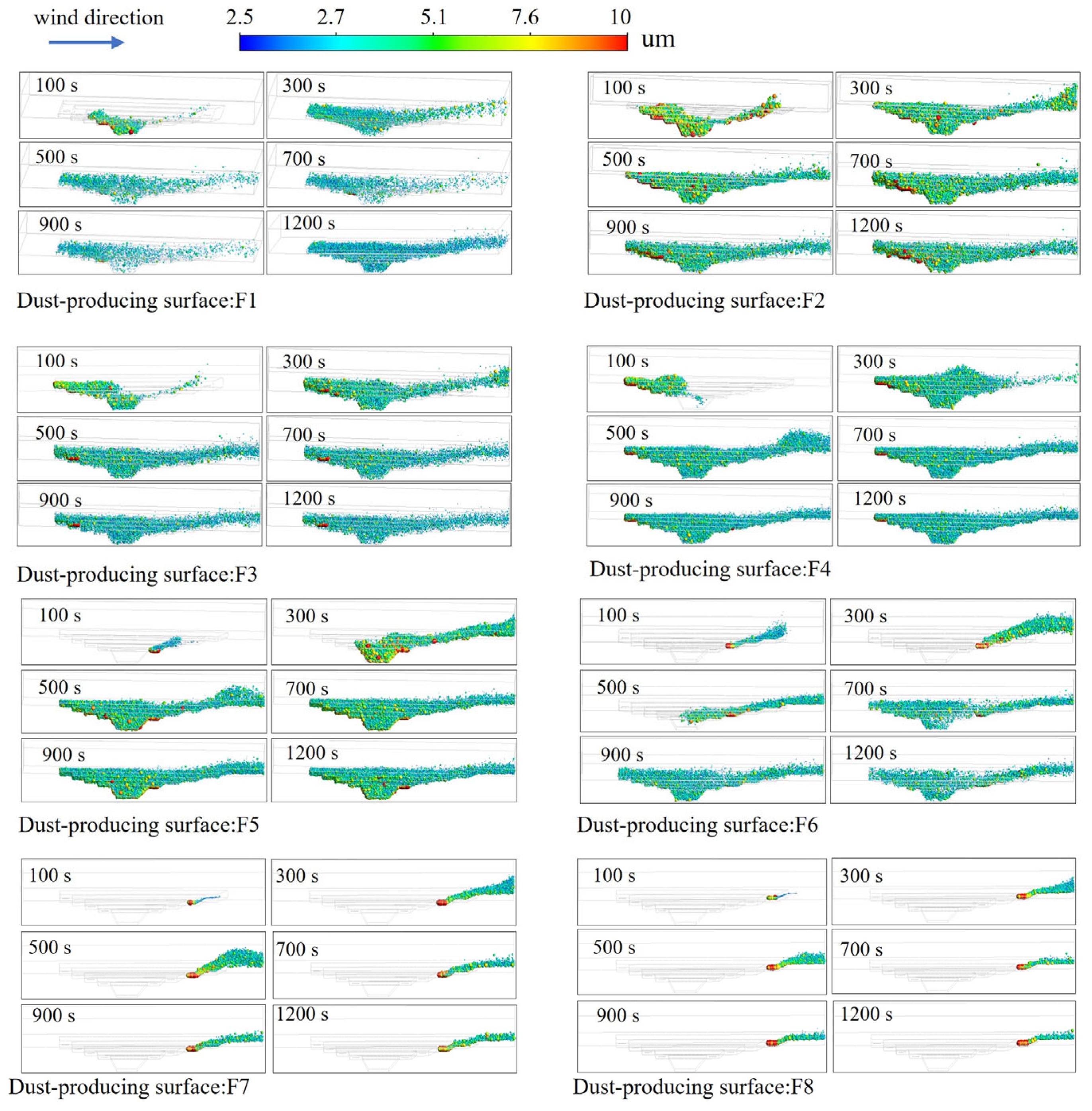

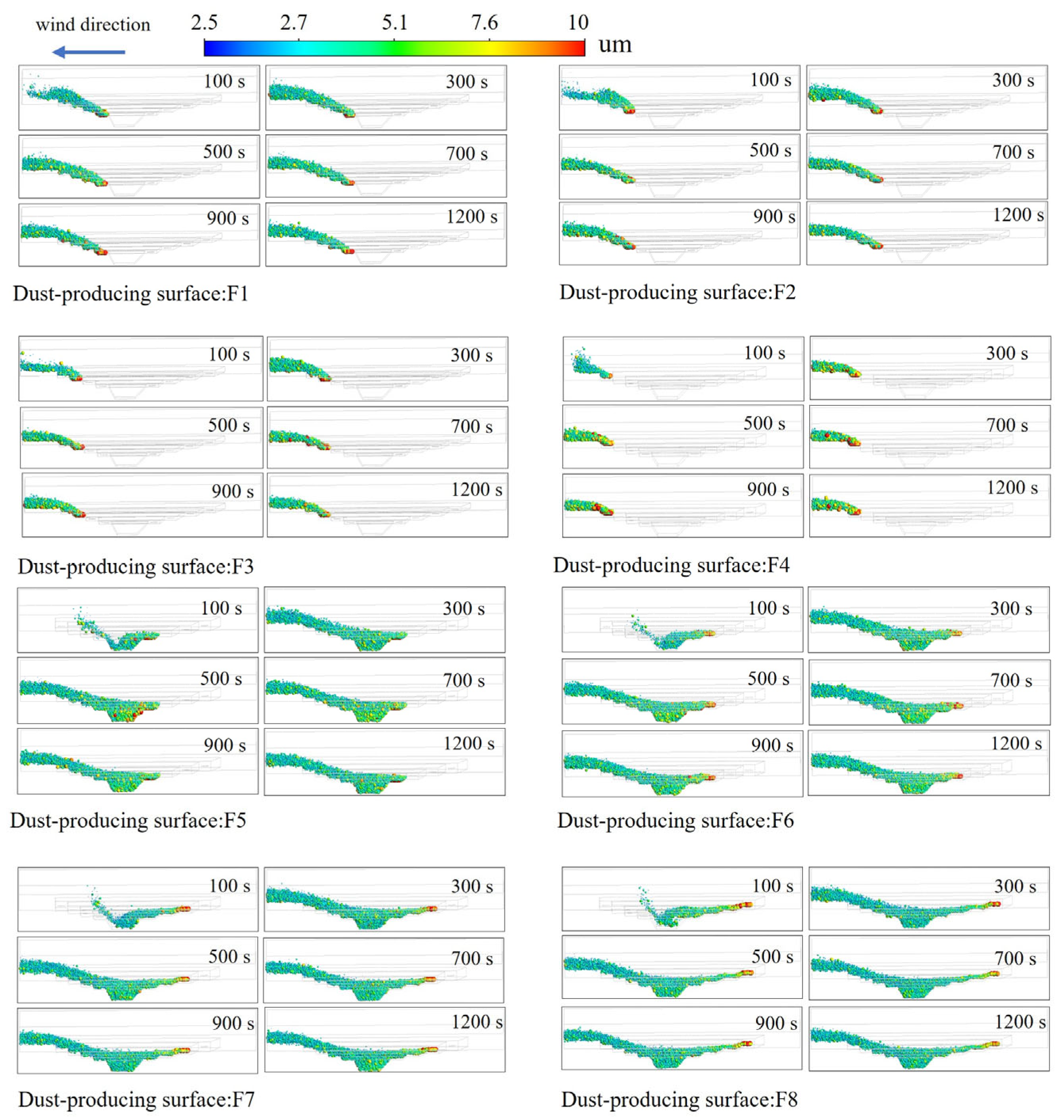

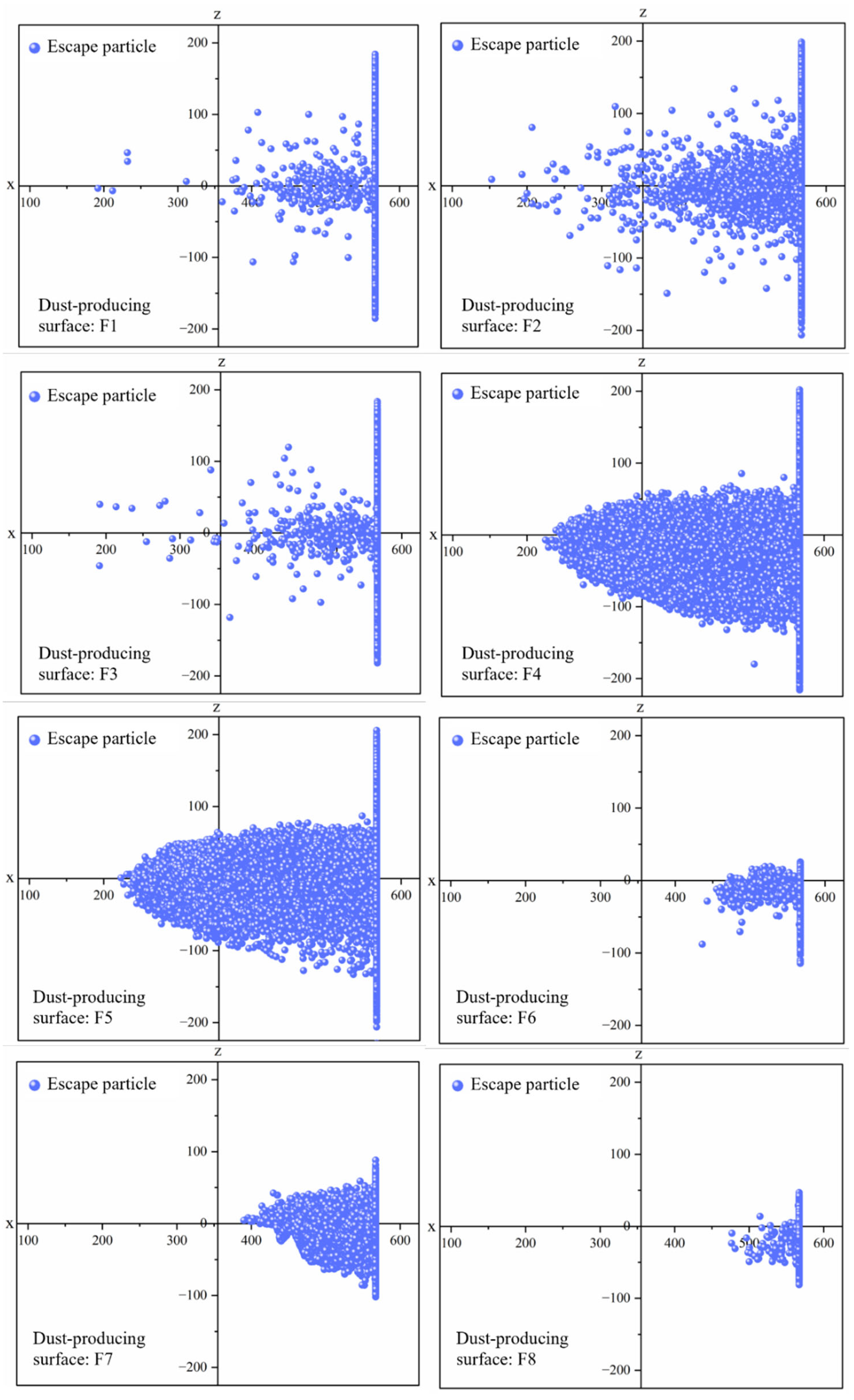

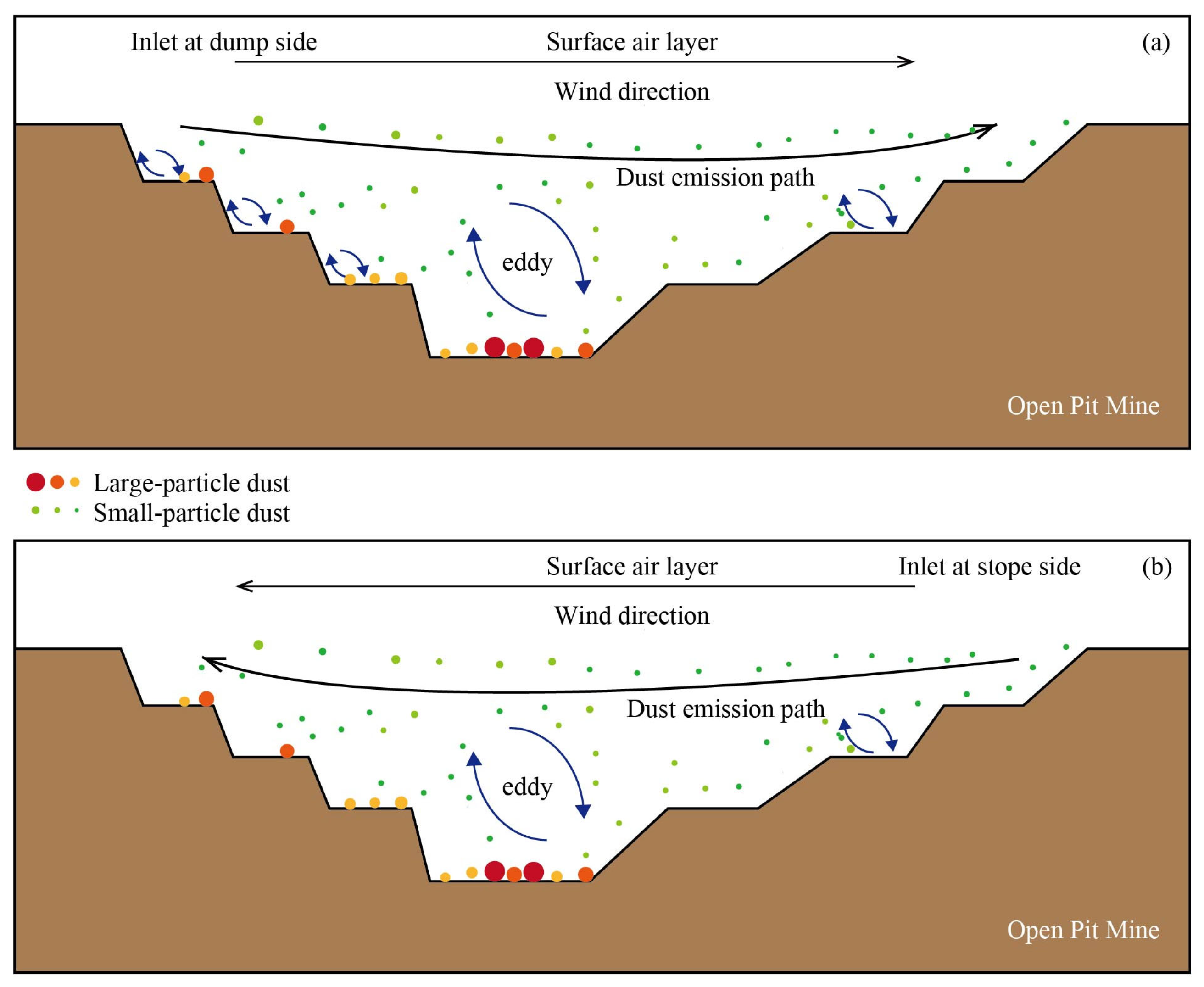

3.1. Spatial Distribution of Dust Diffusion at Blast Sites Under Different Wind Directions

3.1.1. Airflow from the Dump Side

3.1.2. Airflow from the Stope Side

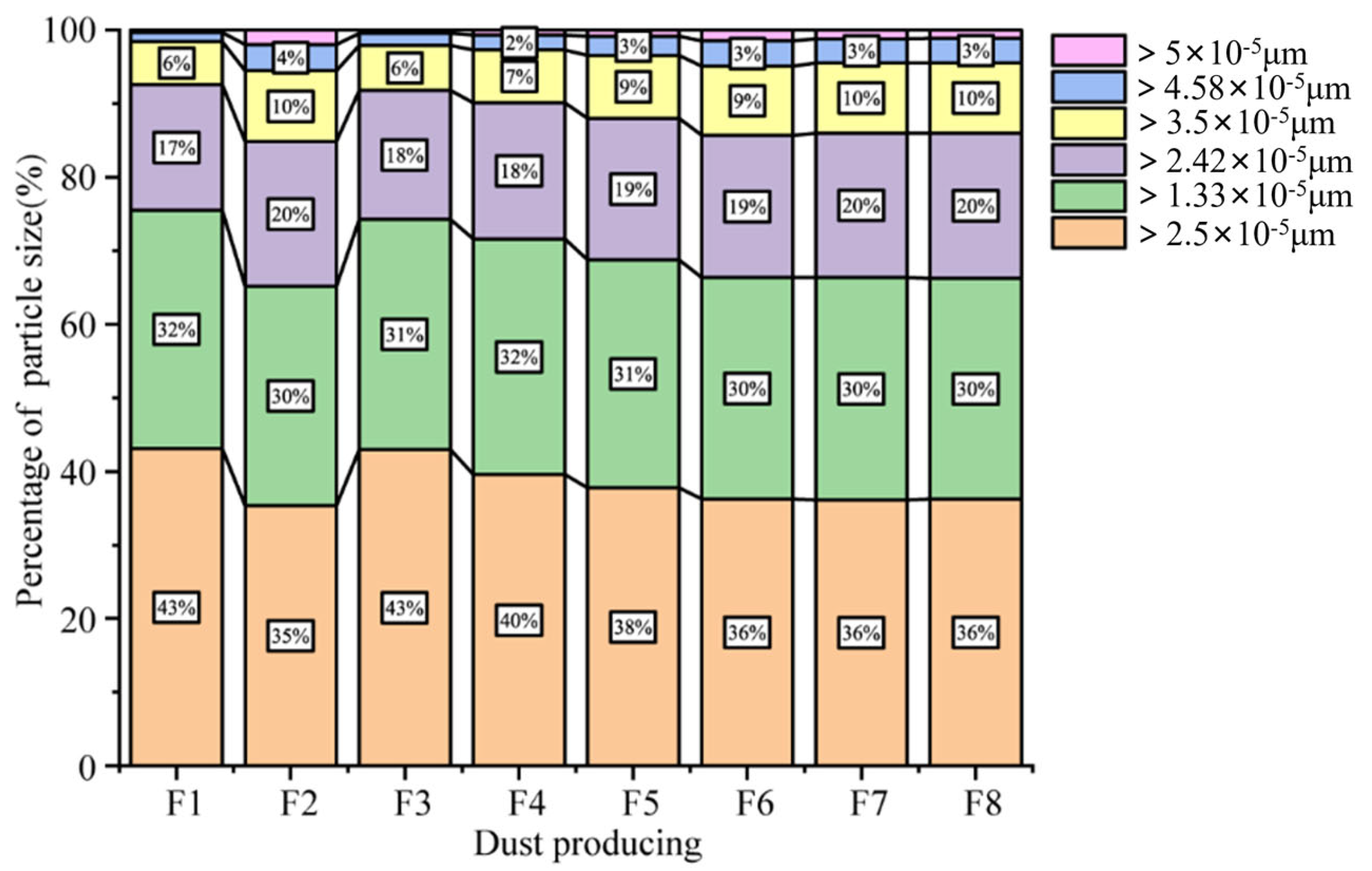

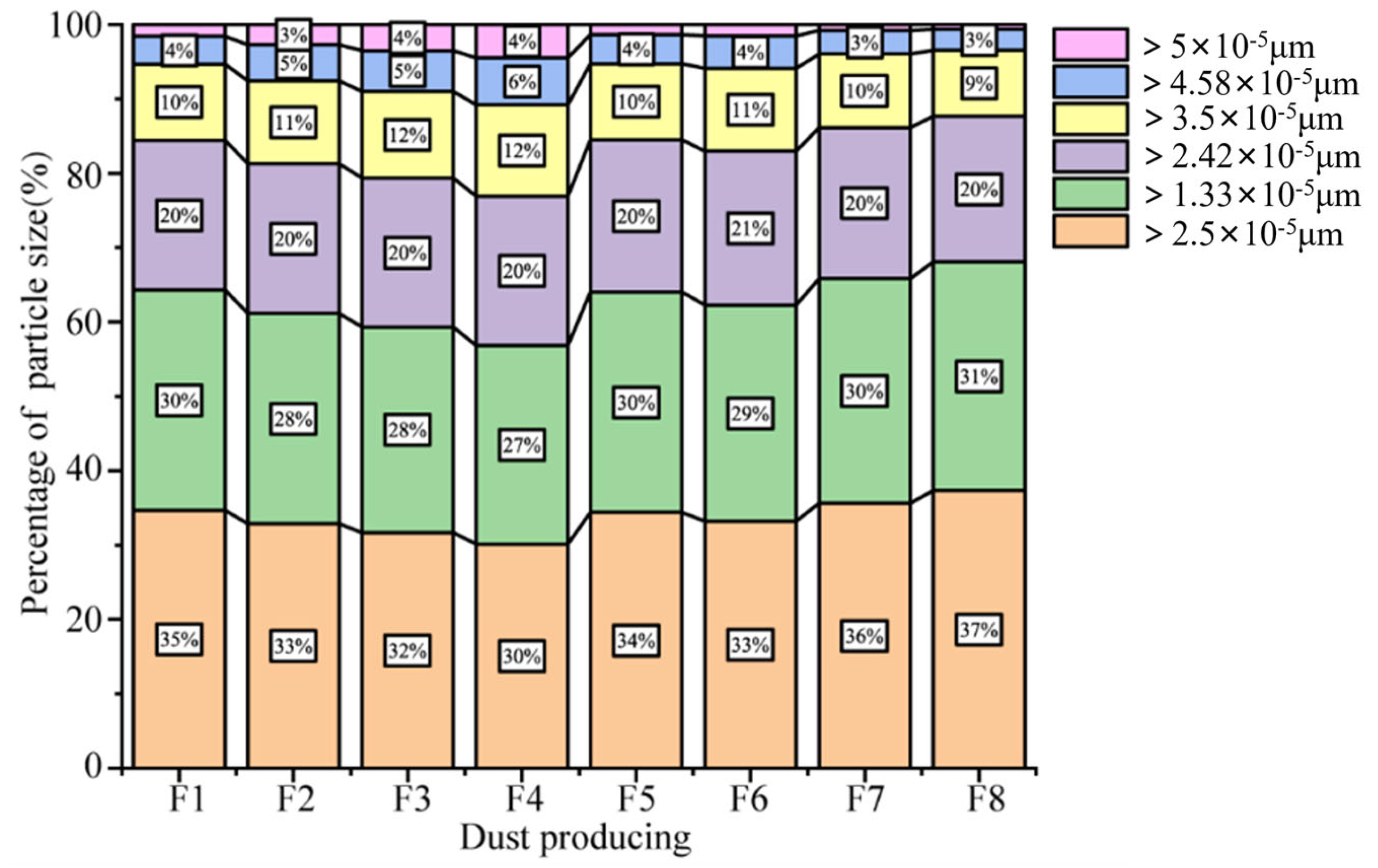

3.2. Statistical Rule of Escaping Dust at Explosion Site Under Different Wind Direction

3.2.1. Statistical Law of Dust Escape by Air Inlet on Dumping Side

3.2.2. Statistical Rule of Dust Escaping from Side Inlet Wind of Stope

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Babii, K.; Chetveryk, M.; Perehudov, V.; Kovalov, K.; Kiriia, R.; Pshenychnyi, V. Features of using equipment for in-pit crushing and conveying technology on the open pit walls with complex structure. Min. Miner. Depos. 2022, 16, 96–102. [Google Scholar] [CrossRef]

- Cheskidov, V.; Gavrilov, V.; Khoyutanov, E.; Reznik, A.; Nemova, N. Specifics of open pit mining in brachysyncline-type coalfields. J. Min. Sci. 2022, 58, 561–570. [Google Scholar] [CrossRef]

- Khussan, B.; Abdiev, A.; Bitimbayev, M.; Kuzmin, S.; Issagulov, S.; Matayev, A. Substantiation and development of innovative container technology for rock mass lifting from deep open pits. Min. Miner. Depos. 2022, 16, 87–95. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, W.; Jiskani, I.M.; Yan, J.; Luo, H. Optimizing open-pit coal mining operations: Leveraging meteorological conditions for dust removal and diffusion. Int. J. Coal Sci. Technol. 2024, 11, 54. [Google Scholar] [CrossRef]

- Zhou, G.; Xu, Y.; Wang, Y.; Zheng, L.; Zhang, Y.; Li, L.; Sun, B.; Li, S.; Zhu, Y. Study on MICP dust suppression technology in open pit coal mine: Preparation and mechanism of microbial dust suppression material. J. Environ. Manag. 2023, 343, 118181. [Google Scholar] [CrossRef]

- Ashfaq, M.; Moghal, A.A.B.; Basha, B.M. The sustainable utilization of coal gangue in geotechnical and geoenvironmental applications. J. Hazard. Toxic Radioact. Waste 2022, 26, 03122003. [Google Scholar] [CrossRef]

- Chebotarev, A.; Sokur, O.; Duryagin, I. Working conditions and occupational health risks of open-pit mining machinery operators. Metallurgist 2024, 67, 1765–1768. [Google Scholar] [CrossRef]

- Fan, L.; Liu, S. Respirable nano-particulate generations and their pathogenesis in mining workplaces: A review. Int. J. Coal Sci. Technol. 2021, 8, 179–198. [Google Scholar] [CrossRef]

- Li, L.; Zhang, R.; Li, Q.; Zhang, K.; Liu, Z.; Ren, Z. Multidimensional spatial monitoring of open pit mine dust dispersion by unmanned aerial vehicle. Sci. Rep. 2023, 13, 6815. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, W.; Jiskani, I.M.; Yang, Y.; Yan, J.; Luo, H.; Han, J. A novel approach to forecast dust concentration in open pit mines by integrating meteorological parameters and production intensity. Environ. Sci. Pollut. Res. 2023, 30, 114591–114609. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, D.; Chen, J.; Ren, S.; Fan, J.; He, Y. Blasting dust diffuse characteristics of spiral tunnel and dust distribution model: Similar experiment and numerical modeling. Environ. Sci. Pollut. Res. 2023, 30, 52340–52357. [Google Scholar] [CrossRef] [PubMed]

- Lutynski, A. Dust Hazards and their Control in Mechanical Processing Plants of Hard Coal Mines. J. Pol. Miner. Eng. Soc. 2021, 2021, 13–18. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, R.; Chun, J.; Xue, Q.; Fan, J. Study on optimization of the dedusting air duct layout in coal mine roadway. Front. Earth Sci. 2022, 10, 855438. [Google Scholar] [CrossRef]

- Amulya, G.; Moghal, A.A.B.; Almajed, A. A state-of-the-art review on suitability of granite dust as a sustainable additive for geotechnical applications. Crystals 2021, 11, 1526. [Google Scholar] [CrossRef]

- Liu, R.; He, Y.; Zhao, Y.; Jiang, X.; Ren, S. Tunnel construction ventilation frequency-control based on radial basis function neural network. Autom. Constr. 2020, 118, 103293. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, D.; He, Y.; Zhang, H.; Chen, J.; Ren, S.; Zhou, Z. Study on cooling measures and ventilation cooling device of high ground temperature tunnel. J. Therm. Anal. Calorim. 2024, 149, 3347–3365. [Google Scholar] [CrossRef]

- Cheng, J. Research on emission factors of suspended particulate matter in bulk material handling workplaces abroad. Environ. Prot. Transp. 1989, 5, 32–37. [Google Scholar]

- Liu, Q.; Guo, R.; Wu, X.; Zhou, C.; Gong, Q.; Wang, J.; Han, J.; Tang, Z.; Lou, Y.; Yang, H.; et al. Study on the dust emission law of coal and gangue piles in open-pit coal mine. Environ. Prot. Transp. 1986, 1, 88–96. [Google Scholar]

- Organiscak, J.A.; Page, S.J. Airborne dust liberation during coal crushing. Coal Perparation 2000, 21, 423–453. [Google Scholar] [CrossRef]

- Sairanen, M.; Rinne, M.; Selonen, O. A review of dust emission dispersions in rock aggregate and natural stone quarries. Int. J. Min. Reclam. Environ. 2018, 32, 196–220. [Google Scholar] [CrossRef]

- Xuan, J.; Robins, A. The effects of turbulence and complex terrain on dust emissions and depositions from coal stockpiles. Atmos. Environ. 1994, 28, 1951–1960. [Google Scholar] [CrossRef]

- Romualdo, L.L.; Santosa, R.S.; Limaa, F.C.; Andradea, L.S.; Ferreirab, I.M.; Pozzac, S.A. Environmental impact monitoring of a minero-chemical complex in catalao urban Area of PTS, PM10 and PM2, 5 by EDX characterization. Chem. Eng. 2015, 43, 1909–1914. [Google Scholar] [CrossRef]

- Krasheninnikov, A.V.; Loktev, D.N.; Soloviev, S.P.; Khazins, V.M. Transport of microparticles as stated by observation data in the open mining pit, 27th International Symposium on Atmospheric and Ocean Optics. Atmos. Phys. 2021, 11916, 1257–1264. [Google Scholar] [CrossRef]

- Sa, Z.; Li, F.; Qin, B.; Pan, X. Numerical simulation study of dust concentration distribution regularity in cavern stope. Saf. Sci. 2012, 50, 857–860. [Google Scholar] [CrossRef]

- Huang, Z.; Ge, S.; Jing, D.; Yang, L. Numerical simulation of blasting dust pollution in open-pit mines. Appl. Ecol. Environ. Res. 2019, 17, 10313–10333. [Google Scholar] [CrossRef]

- Ge, S.; Huang, Z.; Jing, D.; Chen, X.; Han, F. The law of blasting dust in open-pit mines and the optimization of water-blasting mud ratio. J. Liaoning Tech. Univ. (Nat. Sci. Ed.) 2017, 36, 225–231. [Google Scholar]

| Injection | Units | Define |

|---|---|---|

| Injection | Surface | |

| Diameter distribution | Rosin–Rammler | |

| Start time | s | 0 |

| Stop time | s | 600 |

| Material | Coal-hv | |

| Total flow rate | kg/s | 0.2 |

| Min. diameter | m | PM2.5 2.5 × 10−6 |

| Max. diameter | m | PM100 1 × 10−4 |

| Mean diameter | m | PM10 × 10−5 |

| Spread parameter | 1.12 | |

| Time scale constant | 0.15 |

| Boundary Conditions | Units | Define |

|---|---|---|

| Inlet Boundary Type | Velocity Inlet | |

| Inlet Velocity Magnitude | m/s | 0, 1, 3 |

| Turbulent Intensity | % | 5 |

| Hydraulic Diameter | m | 17 |

| Outlet Boundary Type | Outflow | |

| Wall Shear Condition | No Slip | |

| Wall Roughness | Standard | |

| DPM Boundary Type | Trap | |

| DPM Boundary Type | Escape |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Jiao, X.; Liu, R.; Wang, H.; He, Y.; Chen, J.; Lu, X.; Zhang, H. Research on the Distribution and Escape Characteristics of Dust at the Blasting Pile in an Open-Pit Mining Area. Geosciences 2025, 15, 238. https://doi.org/10.3390/geosciences15070238

Cao Y, Jiao X, Liu R, Wang H, He Y, Chen J, Lu X, Zhang H. Research on the Distribution and Escape Characteristics of Dust at the Blasting Pile in an Open-Pit Mining Area. Geosciences. 2025; 15(7):238. https://doi.org/10.3390/geosciences15070238

Chicago/Turabian StyleCao, Yong, Xiaoliang Jiao, Rong Liu, Haoran Wang, Yi He, Jie Chen, Xiang Lu, and Huangqing Zhang. 2025. "Research on the Distribution and Escape Characteristics of Dust at the Blasting Pile in an Open-Pit Mining Area" Geosciences 15, no. 7: 238. https://doi.org/10.3390/geosciences15070238

APA StyleCao, Y., Jiao, X., Liu, R., Wang, H., He, Y., Chen, J., Lu, X., & Zhang, H. (2025). Research on the Distribution and Escape Characteristics of Dust at the Blasting Pile in an Open-Pit Mining Area. Geosciences, 15(7), 238. https://doi.org/10.3390/geosciences15070238