Comparative Analysis of Fracturing Definitions in Boreholes and Underground Workings

Abstract

:1. Introduction

2. Materials and Methods

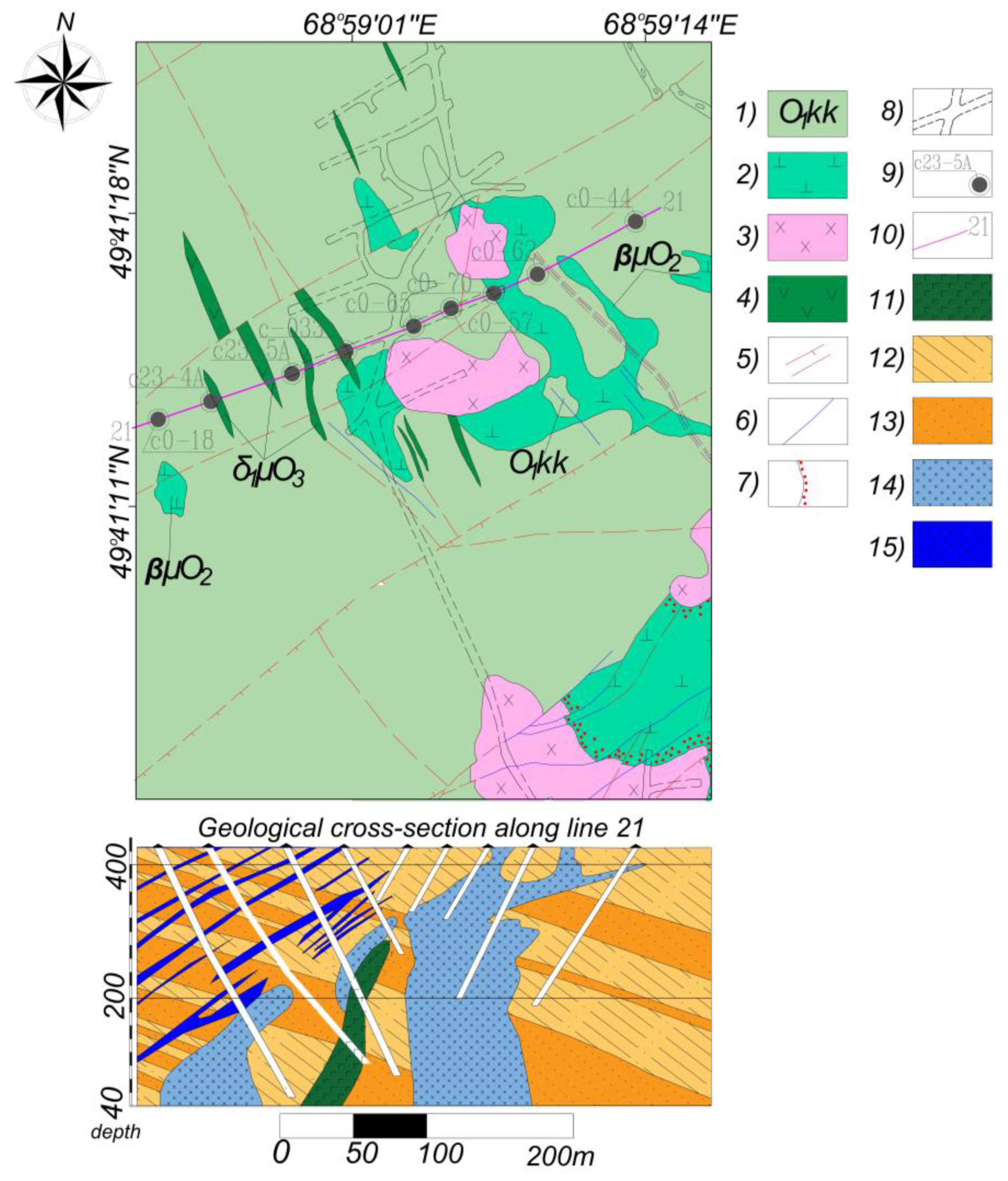

2.1. Geological Characteristics of the Deposit

2.2. Tectonic Features and Ore Mineralization

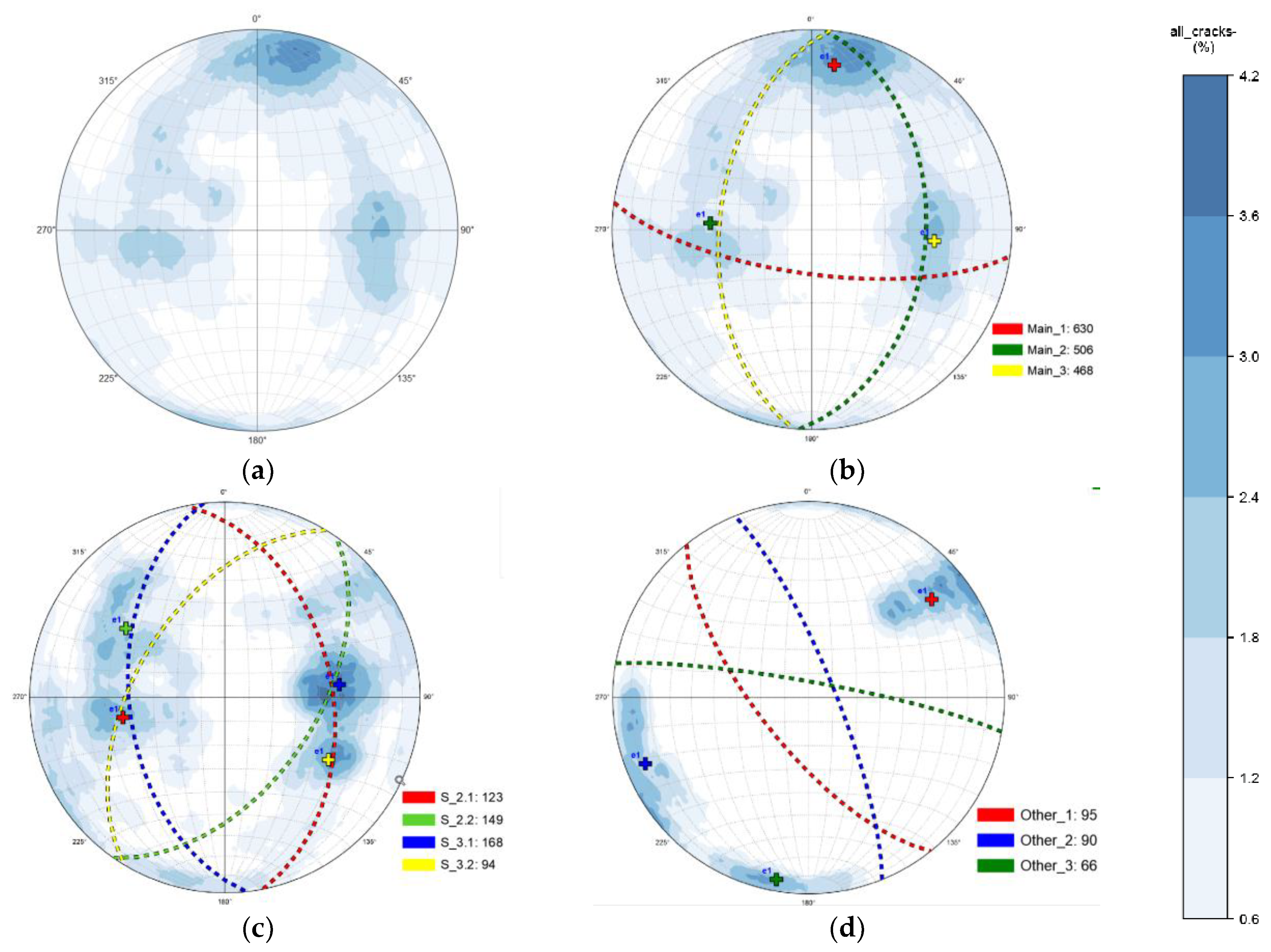

2.3. Identification of Fracture Systems Based on the General Measurement Database

2.3.1. Methodology for Identifying Main Fracture Systems

2.3.2. Analysis of Possible Errors in Fracture Measurements

2.4. Methodology for Determining the Physical and Mechanical Properties of Rocks

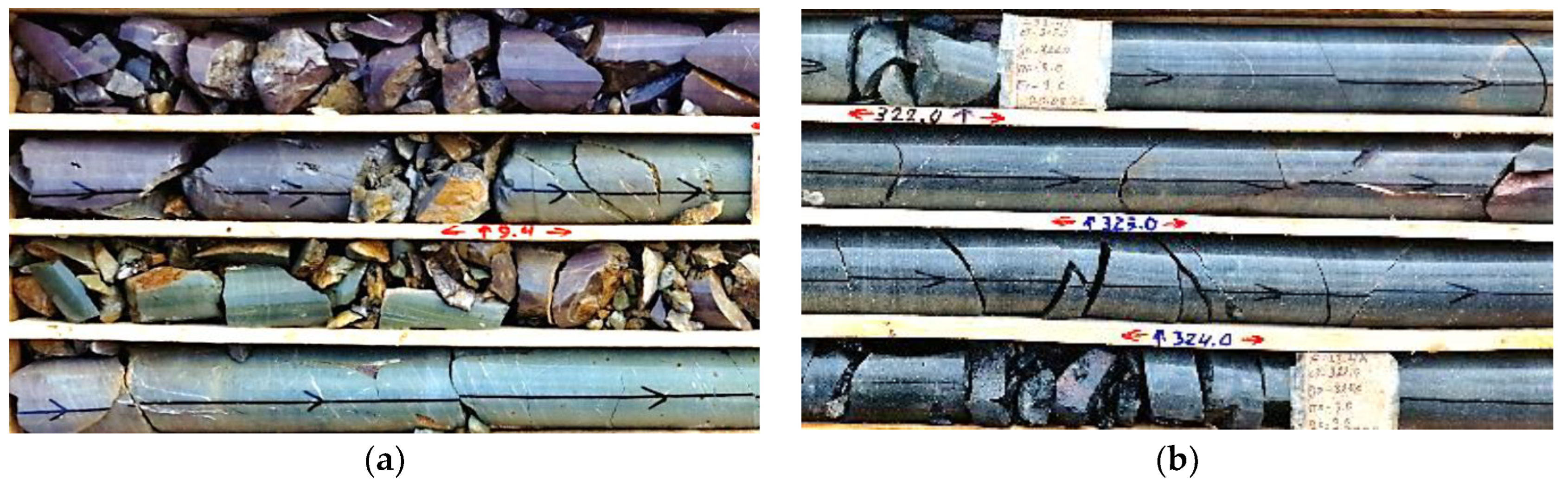

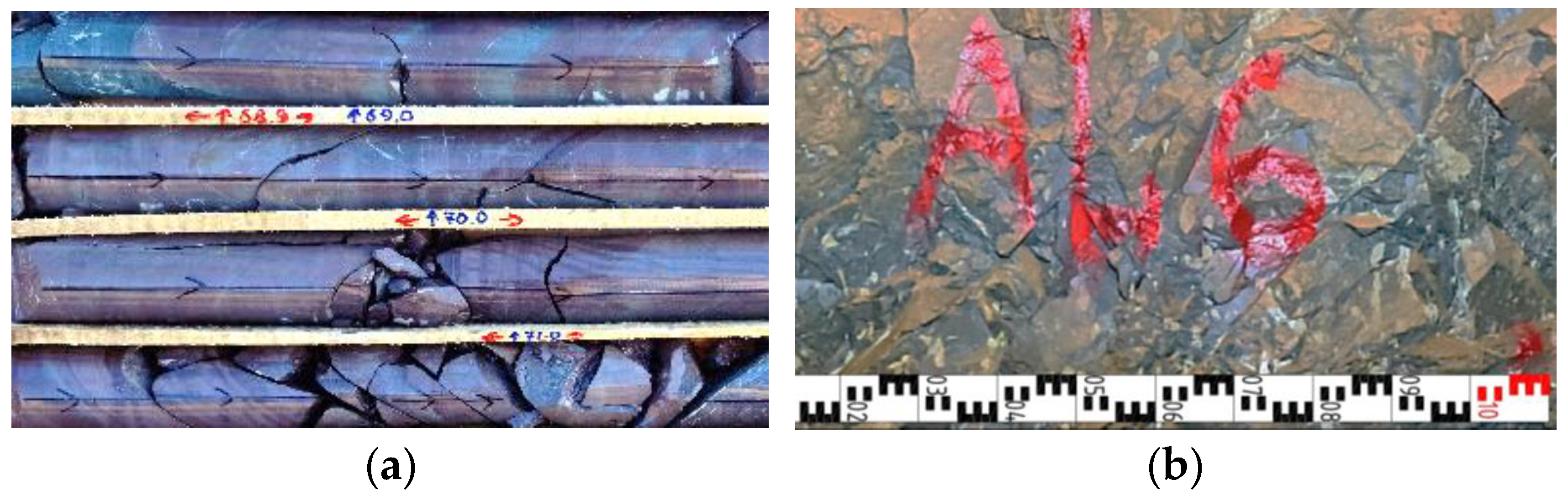

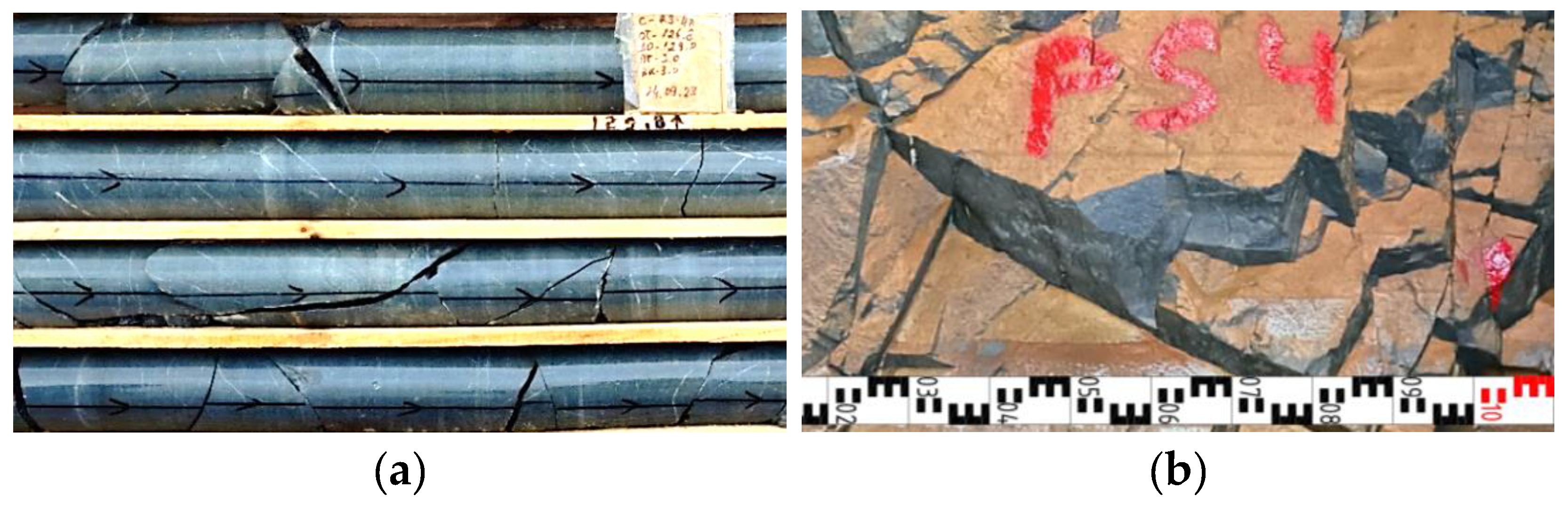

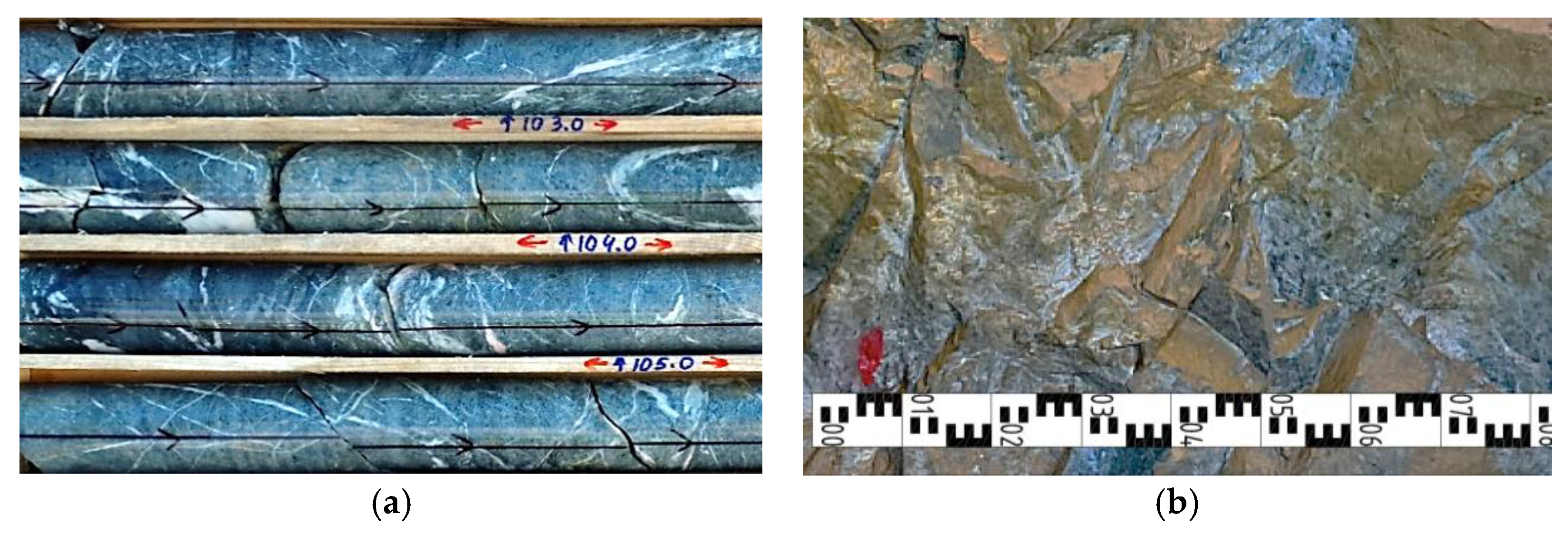

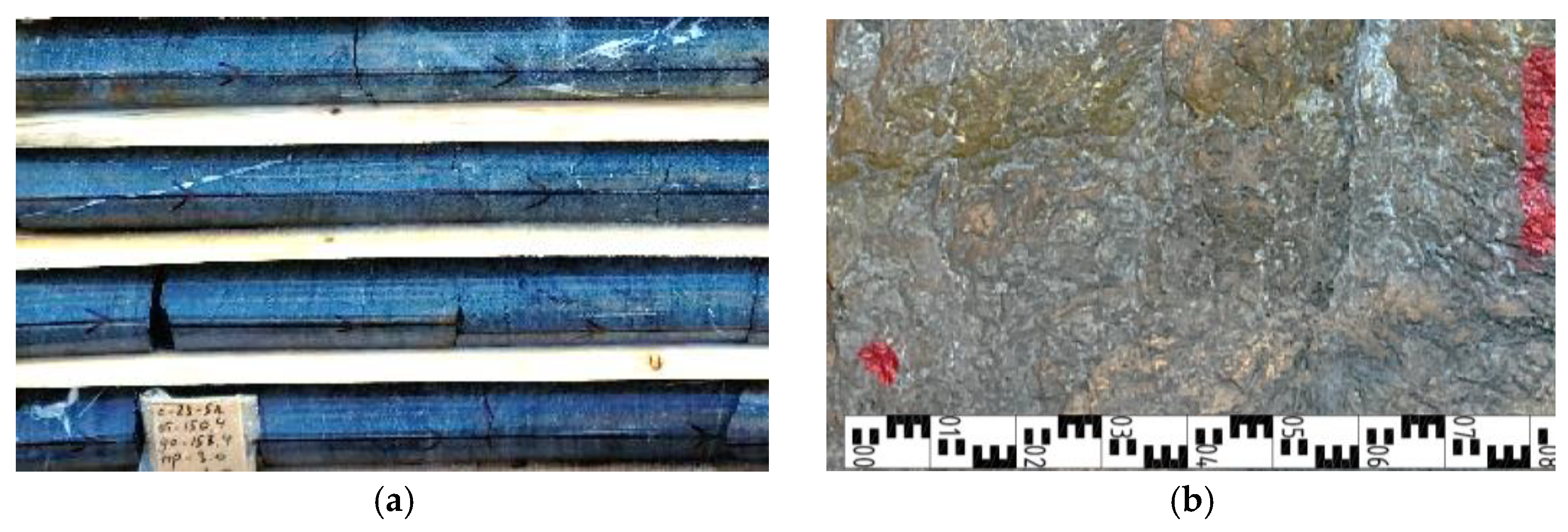

2.4.1. Drilling and Core Sampling Methods

2.4.2. Identification of Engineering–Geological Elements

2.4.3. Determination of the Physical and Mechanical Properties of Rocks

3. Results

3.1. Establishing the Relationship Between Fracture Systems Identified for All EGEs and the Main Fracture Systems

3.2. Results of Determining the Physical and Mechanical Properties of Rocks for Assessing the Stability Parameters of Open-Pit Slopes and Underground Excavations

- -

- The highest compressive strength is observed in sandstones (96.60 MPa), indicating a high mechanical reliability and low fracturing.

- -

- Siltstones and diorites show similar strength values (approximately 95–96 MPa), suggesting relatively stable conditions within these rock masses.

- -

- Quartz diorites (81.72 MPa) exhibit a comparatively lower strength, which may indicate greater fracturing and a reduced slope stability in this rock type.

- -

- Porosity is higher in siltstones and sandstones (0.97%), indicating greater permeability and the need to consider hydrogeological conditions during design.

- -

- Poisson’s ratio is approximately the same across all rock types (0.21–0.23), suggesting similar deformation behavior of the rock mass.

3.3. Evaluation of the Geological Index of Rock Strength Certificates Based on Borehole Core from Geological Profile 21

3.4. Evaluation of the Blockiness of the Rock Mass

Analysis of Errors in RQD Value Calculation

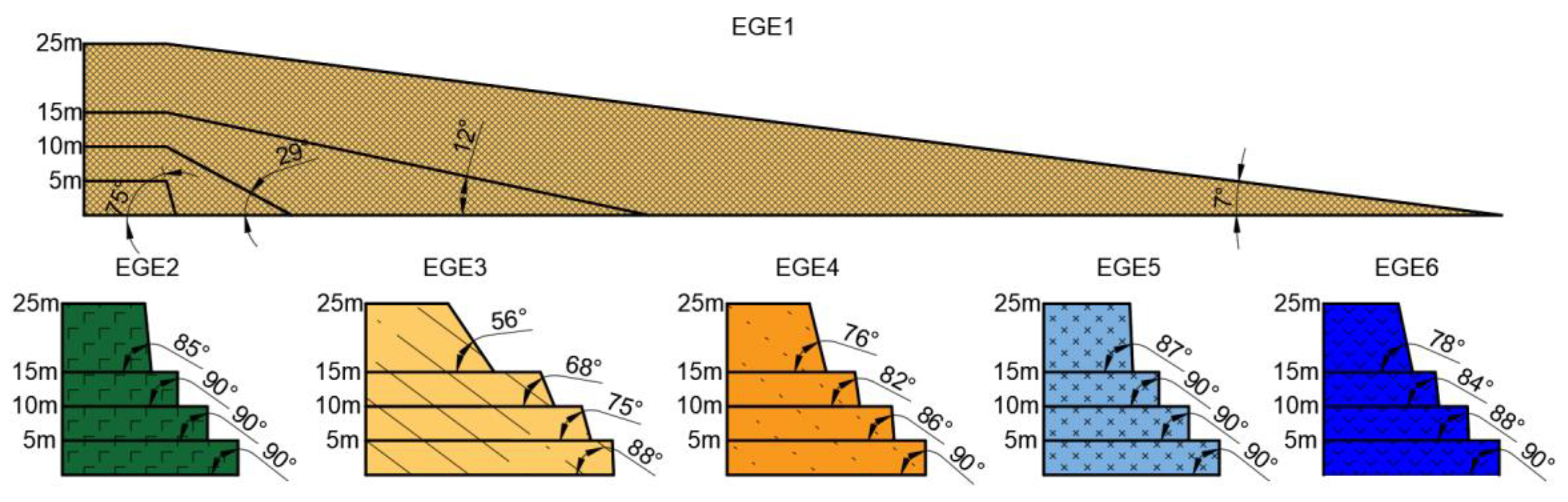

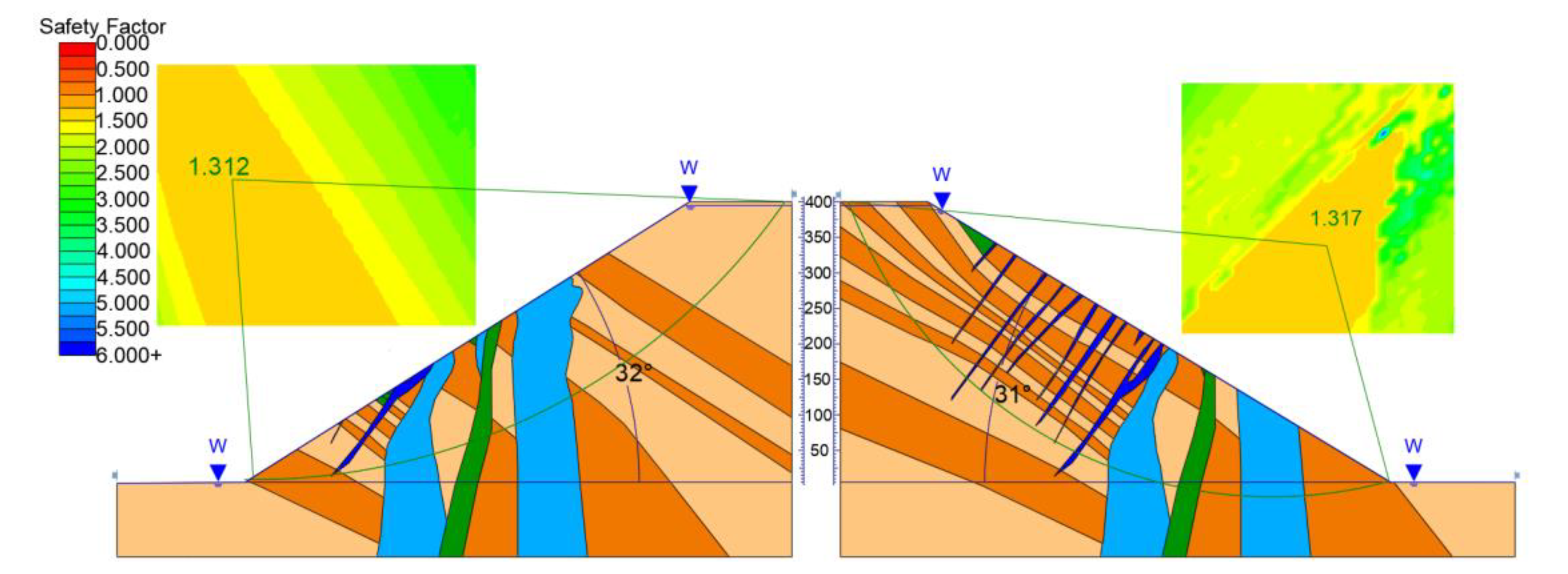

3.5. Determination of Parameters for Stable Quarry Slope

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burzunova, Y.P. Rock fractures near faults: Specific features of structural-paragenetic analysis. Geodyn. Tectonophys. 2017, 8, 673–693. [Google Scholar] [CrossRef]

- Seminsky, K.Z.; Cheremnykh, A.V. Jointing patterns and stress tensors in Cenozoic sediments of the Baikal rift: Development of the structural-genetic approach. Russ. Geol. Geophys. 2011, 52, 353–367. [Google Scholar] [CrossRef]

- Ramsey, J.M.; Chester, F.M. Hybrid fracture and the transition from extension fracture to shear fracture. Nature 2004, 428, 63–66. [Google Scholar] [CrossRef]

- Roman, A.T.; Portnov, V.S.; Askarova, N.S. Tectonic peculiarities of the Zhailma structure formation. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2022, 3, 11–16. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Engineering Rock Mass Classification; Wiley: New York, NY, USA, 1989; 251p. [Google Scholar]

- Laubscher, D.H. A geomechanics classification system for the rating of rock mass in mine design. J. Sth. Afr. Inst. Min. Met. 1990, 90, 257–273. [Google Scholar]

- Kuzmin, E.V.; Uzbekova, A.P. Rating classifications of rock masses: Application, creation, development. GIA 2004, 4, 201–202. [Google Scholar]

- Rahnama, M.; Gloaguen, R. TecLines: A MATLAB-Based toolbox for tectonic lineament analysis from satellite images and DEMs. Remote Sens. 2014, 6, 5938–5958. [Google Scholar] [CrossRef]

- Naved, M.; Devi, V.A.; Gaur, L.; Elngar, A.A. IoT-Enabled Convolutional Neural Networks Techniques and Applications; River Publishers: New York, NY, USA, 2023; 409p. [Google Scholar] [CrossRef]

- Gorbunova, N.; Mirkushov, O. Determination of the State of Rock Mass by the Mathematical Modeling Method. IOP Conf. Ser. Earth Environ. Sci. 2021, 720, 012088. [Google Scholar]

- International science and technology conference “Earth science”. IOP Conf. Ser. Earth Environ. Sci. 2021, 720, 012088. [CrossRef]

- Horibe, T.; Kobayashi, R. Physical properties of coal-measures rocks under triaxial pressure. J. Min. Soc. Jpn. 1958, 74, 142–146. [Google Scholar]

- Paterson, M.S. A high-pressure, high-temperature apparatus for rock deformation. Intern. J. Rock Mech. Min. Sci. 1970, 7, 517–526. [Google Scholar]

- Zhang, H.; Li, C.C. Effects of confining stress on the post-peak behavior and fracture angle of Fauske Marble and Iddefjord Granite. Rock Mech. Rock Eng. 2019, 52, 1377–1385. [Google Scholar]

- Zong, Y.; Han, L.; Jin, Y.; Zhao, W.; Meng, L. Experimental Investigation on the Post-Peak Short-Term and Creep Behavior of Fractured Sandstone. Energies 2020, 13, 598. [Google Scholar] [CrossRef]

- Nguyen, T.S.; Li, Z.; Su, G.; Nasseri, M.H.B.; Young, R.P. Hydro-mechanical behavior of an argillaceous limestone considered as a potential host formation for radioactive waste disposal. J. Rock Mech. Geotech. Eng. 2018, 10, 1063–1081. [Google Scholar] [CrossRef]

- Rostekhnadzor Order No. 439 of 13.11.2020; “On the Approval of Federal Regulations and Rules in the Field of Industrial Safety”, “Rules for Ensuring the Stability of Quarry Slopes and Benches, Open Pit Cuts, and Embankment Slopes”.

- Gushchin, V.V.; Epimakhov, Y.A. Recommendations for Studying Rock Fracturing During Engineering-Geological Surveys for Construction; Stroyizdat: Moscow, Russia, 1974; 36p. [Google Scholar]

- Pan, M.V.; Cheremnykh, S.N. Fracturing and Properties of Fractured Rocks; Nedra: Kopingsvik, Sweden, 1970; 150p. [Google Scholar]

- Wyllie, D.C.; Mah, C.W. Rock Slope Engineering: Civil and Mining, 4th ed.; Spon Press: London, UK, 2004; 425p. [Google Scholar]

- Read, J.R.L.; Stacey, P.F. Guidelines for Open Pit Slope Design, 1st ed.; CRC Press/Balkema: Leiden, The Netherlands, 2009; 494p. [Google Scholar]

- Malchenko, E.G.; Roman, A.T.; Portnoy, V.S.; Askarova, N.S. Peculiarities of the formation of the Zhailma volcano-tectonic deep. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2023, 1, 26–31. [Google Scholar] [CrossRef]

- Sherman, S.I.; Seminsky, K.Z.; Bornyakov, S.A.; Adamovich, A.N.; Lobatskaya, R.M.; Lysak, S.V.; Levi, K.G. Faulting in the Lithosphere. In Extension Zones; Nauka: Novosibirsk, Russia, 1992; 228p. [Google Scholar]

- Popov, I.I.; Nizammetdinov, F.K.; Okatov, R.P.; Dolgonosov, V.N. Natural and Technogenic Foundations of Slope and Bench Stability Management at Quarries; Gylim: Almaty, Kazakhstan, 1997. [Google Scholar]

- Patterns of changes in the strength characteristics of rocks of the Shuak massif. In Proceedings of the 6th IEEE International Symposium on Logistics and Industrial Informatics, Karaganda, Kazakhstan, 23–25 October 2024. [CrossRef]

- Identification of fracture systems based on drilling data and existing underground mining work during engineering-geological surveys. In Proceedings of the 6th IEEE International Symposium on Logistics and Industrial Informatics, Karaganda, Kazakhstan, 23–25 October 2024. [CrossRef]

- Epifantsev, O.G.; Pletenchuk, N.S. Rock Fracturing: Fundamentals of Theory and Methods of Study (Methodological Recommendations); SibGIU: Novokuznetsk, Russia, 2008; T66, 41p. [Google Scholar]

- GOST R 51776-2001; Rocks. Methods for Determination of Strength and Deformability Characteristics. Interstate Council for Standardization, Metrology, and Certification (ISC); Standartinform: Moscow, Russia, 2001. (In Russian)

- Shchedrina, N.N. Development of Methods for Evaluating Mechanical Properties of Sedimentary Rock Massifs at Deposits with Unstudied Subsidence Processes. Ph.D. Dissertation, Institute of Comprehensive Exploitation of Mineral Resources, Russian Academy of Sciences, Moscow, Russia, 2014; 131p. (In Russian). [Google Scholar]

- Elmo, D.; Rogers, S.; Stead, D.; Eberhardt, E. Discrete Fracture Network approach to characterise rock mass fragmentation and implications for geomechanical upscaling. Min. Technol. 2014, 123, 149–161. [Google Scholar] [CrossRef]

| Fracture System | Strike | Dip | Dip Azimuth | Measurements |

|---|---|---|---|---|

| Main_1 | 265.1 | 18.5 | 355.1 | 630 |

| Main_2 | 257.3 | 75.7 | 347.3 | 506 |

| Main_3 | 359.0 | 38.6 | 89.0 | 468 |

| Fracture Systems | Subsystem | Strike | Dip | Dip Azimuth | Measurements |

|---|---|---|---|---|---|

| Main_1 | - | 236.5 | 20.2 | 326.5 | 338 |

| Main_2 | - | 257.7 | 77.5 | 347.7 | 200 |

| S_2.1 | 84.1 | 84.9 | 174.1 | 123 | |

| S_2.2 | 137.2 | 74.7 | 227.2 | 149 | |

| Main_3 | - | 6.1 | 40.8 | 96.1 | 274 |

| S_3.1 | 266.4 | 86.9 | 356.4 | 168 | |

| S_3.2 | 97.5 | 62.9 | 187.5 | 94 | |

| Small (residual) fractures obtained after excluding larger ones | Other_1 | 239.5 | 69.8 | 329.5 | 95 |

| Other_2 | 157.0 | 11.0 | 247.0 | 90 | |

| Other_3 | 103.3 | 66.6 | 193.3 | 66 |

| Mean Arithmetic Error, Degree | Root Mean Square Deviation, Degree | Confidence Interval (For 95%), Degree | |

|---|---|---|---|

| Dip angles | 2.73° | 4.50° | ±1.22° |

| Azimuth angles | 2.36° | 1.77° | ±0.48° |

| Fractures | General System for All Rock Types | Characteristics of Fracture Systems of the Rock Mass by EGE, Degrees | Fracture Genesis | ||||

|---|---|---|---|---|---|---|---|

| Name | Parameters 1 | N 1,2 | n | EGE 3 Siltstones Na | EGE 4 Sandstones Np | EGE 5 Quartz Diorites Nqd | |

| Submeridional | 3/60 | 1 (180/77) 18 (335/86) | 75 4 | 3a (191/76) | 1p (180/81) | 1qd (175/66) | Tectonic fractures of the main system |

| Sublatitudinal | 276/70 | 2 (264/51) 5 (256/82) | 36 07 | 1a (268/53) | 2p (221/81) 7p (288/53) 8p (254/47) | 3qd (269/52) | Secondary system of tectonic fractures |

| 3 (120/46) | 99 | 2a (122/21) 4a (120/51) | 5p (113/58) | - | Additional systems of tectonic fractures | ||

| Northeastern | 70/68.2 | 4 (69/45) | 09 | 5a (79/45) | 4p (71/51) | 2qd (64/39) | Tectonic fracture systems |

| 6 (218/84) | 8 | - | 2p (221/81) | - | |||

| 7 (148/65) | 9 | 6a (150/71) | - | - | Fractures of tectonic reactivation | ||

| 8 (79/76) | 5 | - | 6p (73/80) | 4qd (82/89) | |||

| 13 (176/51) | 8 | - | 3p (174/54) | - | |||

| Rock, EGE № | Density, g/cm3 Bulk/Particle | Porosity, % | Compressive Strength, MPa, Dry/Wet | Tensile Strength limitRc dry, MPa | Brittleness Coefficient | Shear Strength Limit: 30°, 35°, 45° (for Dispersed Rocks Under Triaxial Compression) | Poisson’s Ratio, ν | Young’s Modulus (E), GPa | Strength Coefficient | |

|---|---|---|---|---|---|---|---|---|---|---|

| Cohesion Strength C, MPa | Internal Friction Angle, Degrees | |||||||||

| Diorites EGE 2. | 2.82 2.86 | 0.33 | 93.18 68.97 | 9.23 | 10.10 | 14.66 | 40.25 | 0.21 | 86.42 | 11.78 |

| Siltstones EGE 3. | 2.77 2.79 | 0.97 | 95.98 78.70 | 9.53 | 10.10 | 15.12 | 40.35 | 0.22 | 91.01 | 13.98 |

| Sandstones EGE 4. | 2.75 2.78 | 0.97 | 96.60 81.22 | 9.58 | 10.08 | 15.21 | 40.69 | 0.22 | 91.12 | 15.45 |

| Quartz diorite EGE 5 | 2.79 2.82 | 0.14 | 81.72 64.36 | 8.06 | 10.16 | 12.83 | 37.54 | 0.23 | 76.97 | 13.42 |

| Diorite–porphyrites. EGE 6 | 2.79 2.81 | 0.65 | 93.70 71.37 | 9.20 | 10.20 | 14.68 | 39.86 | 0.22 | 91.12 | 15.20 |

| Measurement Ranges of RQD/GSI by Borehole Runs Within the EGE Interval, % | Average Value by Boreholes, % | Average Value for Core RQD/GSI, % | Average Value for Underground Working RQD/GSI, % | |||

|---|---|---|---|---|---|---|

| Borehole | ||||||

| C-23-4A | C-23-5A | C-23-4A | C-23-5A | |||

| EGE-2 Diorites | 70–71 55–56 | 54–58 47–49 | 70 55 | 56 48 | 63 51 | - |

| EGE-3 Siltstones | 23–73 21–46 | 33–76 26–48 | 49 34 | 51 47 | 50 35 | 53 34 |

| EGE-4 Sandstones | 19–53 29–46 | 43–68 41–54 | 39 38 | 55 47 | 47 42 | 51 38 |

| EGE-5 Quartz diorites | 66–77 53–58 | - | 72 55 | - | 72 55 | 75 56 |

| EGE-6 Diorite porphyrites | 33–78 36–59 | 27–63 33–51 | 58 47 | 46 42 | 52 44 | 58 48 |

| Rock Characteristics | Uniaxial Compressive Strength Limit, MPa | Structural Index (Intact Rock Parameter) (mb) | Young’s Modulus, MPa | Cohesion Strength, MPa | Internal Friction Angle, Degrees |

|---|---|---|---|---|---|

| EGE—2 Diorites | 1.503 | 0.483 | 2305 | 1.433 | 29.29 |

| EGE—3 Siltstones | 0.359 | 0.067 | 925 | 0.541 | 14.13 |

| EGE—4 Sandstones | 0.699 | 0.270 | 1161 | 1.092 | 25.16 |

| EGE—5 Quartz diorites | 1.864 | 1.005 | 2385 | 1.778 | 34.27 |

| EGE—6 Diorite porphyrites | 0.813 | 0.458 | 1467 | 0.813 | 28.83 |

| Classification of Rocks by Fracturing | Degree of Fracturing (Rock Mass Blockiness) | Number of Fractures Per 1 m of Intersection Lines and Maximum Number (Fracturing Modulus) Mt | Blockiness modulus (Mk), Pieces Per Meter | Rock Quality Designation (RQD), % | Fracture Intensity (Jt) | Average Size of Fragments, m | Content, % (in the Rock Mass of Fragments in mm) | Weak zone Coefficient | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 300 | 700 | 1000 | ||||||||

| I | Practically monolithic (exclusively large block) | <2 | <3 | >95 | 1 | >0.17 | 100 | 100 | 100 | <0.05 |

| II | Slightly fractured (very large block) | 3–2 | 4–3 | 75–95 | 6–2 | 0.15–0.17 | 100 | 80–100 | 40–100 | 0.05–0.15 |

| III | Moderately fractured (large block) | 5–3 | 8–4 | 50–75 | 11–6 | 0.08–015 | 70–100 | 30–80 | 5–40 | 0.05–0.20 |

| IV | Highly fractured (medium block) | >15 | 10–15 | 30–50 | 15–11 | 0.06–0.08 | 10–70 | 30 | 5 | 0.20–0.40 |

| V | Extremely fractured, destroyed (small block) | >15 | >15 | <30 | >15 | <0.06 | 10 | 0 | - | >40 |

| Parameters | Diorites (EGE-2) | Siltstones (EGE-3) | Sandstones (EGE-4) | Quartz Diorites (EGE-5) | Diorite Porphyrites (EGE-6) |

|---|---|---|---|---|---|

| RQD, %, average | 63 | 50 | 47 | 72 | 52 |

| Fracturing modulus (Mt) | 4.8 | 8.0 | 7.2 | 3 | 5 |

| Weak zone coefficient | 0.12 | 0.30 | 0.30 | 0.11 | 0.06 |

| Size of structural block elements (Mk), m | 0.12 | 0.09 | 0.60 | 0.15 | 0.11 |

| Degree of fracturing | Medium | Strong | Strong | Medium | Medium |

| Rock Characteristics Forming the Bench Elements | Slope Angles of the Bench (Degrees) at Different Heights (m) | |||

|---|---|---|---|---|

| 5 | 10 | 15 | 25 | |

| EGE 1 Weathering crust | 75 | 29 | 12 | 7 |

| EGE 2 Diorites | 90 | 90 | 90 | 85 |

| EGE 3 Siltstones | 88 | 75 | 68 | 56 |

| EGE 4 Sandstones | 90 | 86 | 82 | 76 |

| EGE 5 Quartz diorites | 90 | 90 | 90 | 87 |

| EGE 6 Diorite porphyrites | 90 | 88 | 84 | 78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Portnov, V.; Askarova, N.; Medvedev, V.; Vyzhva, S.; Puchkov, V.; Dosetova, G.; Kryazheva, T.; Rakhimova, G. Comparative Analysis of Fracturing Definitions in Boreholes and Underground Workings. Geosciences 2025, 15, 161. https://doi.org/10.3390/geosciences15050161

Portnov V, Askarova N, Medvedev V, Vyzhva S, Puchkov V, Dosetova G, Kryazheva T, Rakhimova G. Comparative Analysis of Fracturing Definitions in Boreholes and Underground Workings. Geosciences. 2025; 15(5):161. https://doi.org/10.3390/geosciences15050161

Chicago/Turabian StylePortnov, Vassilyi, Nazym Askarova, Vladislav Medvedev, Serhii Vyzhva, Vitalii Puchkov, Gulnara Dosetova, Tatyana Kryazheva, and Galiya Rakhimova. 2025. "Comparative Analysis of Fracturing Definitions in Boreholes and Underground Workings" Geosciences 15, no. 5: 161. https://doi.org/10.3390/geosciences15050161

APA StylePortnov, V., Askarova, N., Medvedev, V., Vyzhva, S., Puchkov, V., Dosetova, G., Kryazheva, T., & Rakhimova, G. (2025). Comparative Analysis of Fracturing Definitions in Boreholes and Underground Workings. Geosciences, 15(5), 161. https://doi.org/10.3390/geosciences15050161