One-Part Geopolymer for Stabilising Crushed Rock Road Base Material

Abstract

1. Introduction

2. Materials and Methods

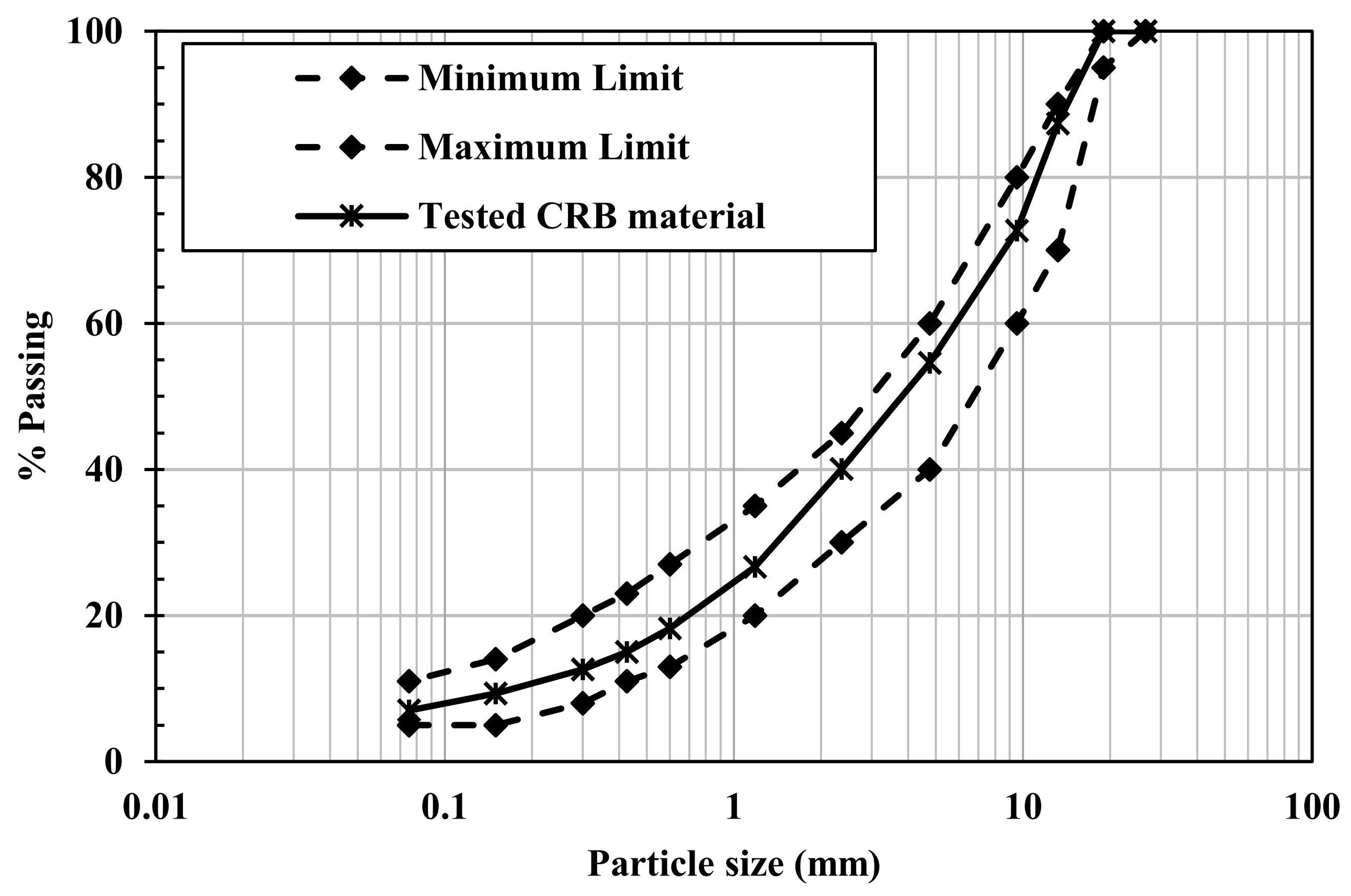

2.1. Crushed Rock Base (CRB)

2.2. One-Part Geopolymer (OPG)

2.3. Specimen Preparation and Testing

3. Results and Discussion

3.1. Unconfined Compressive Strength Tests

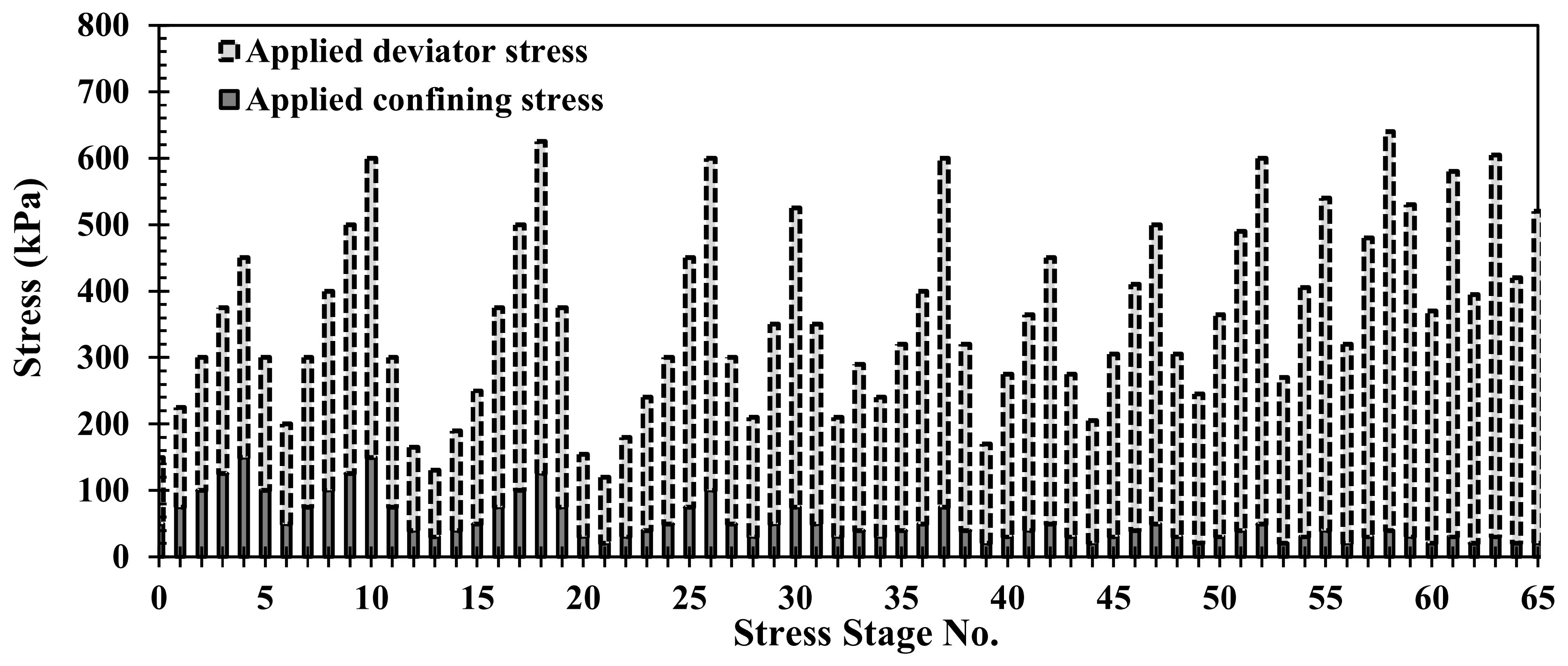

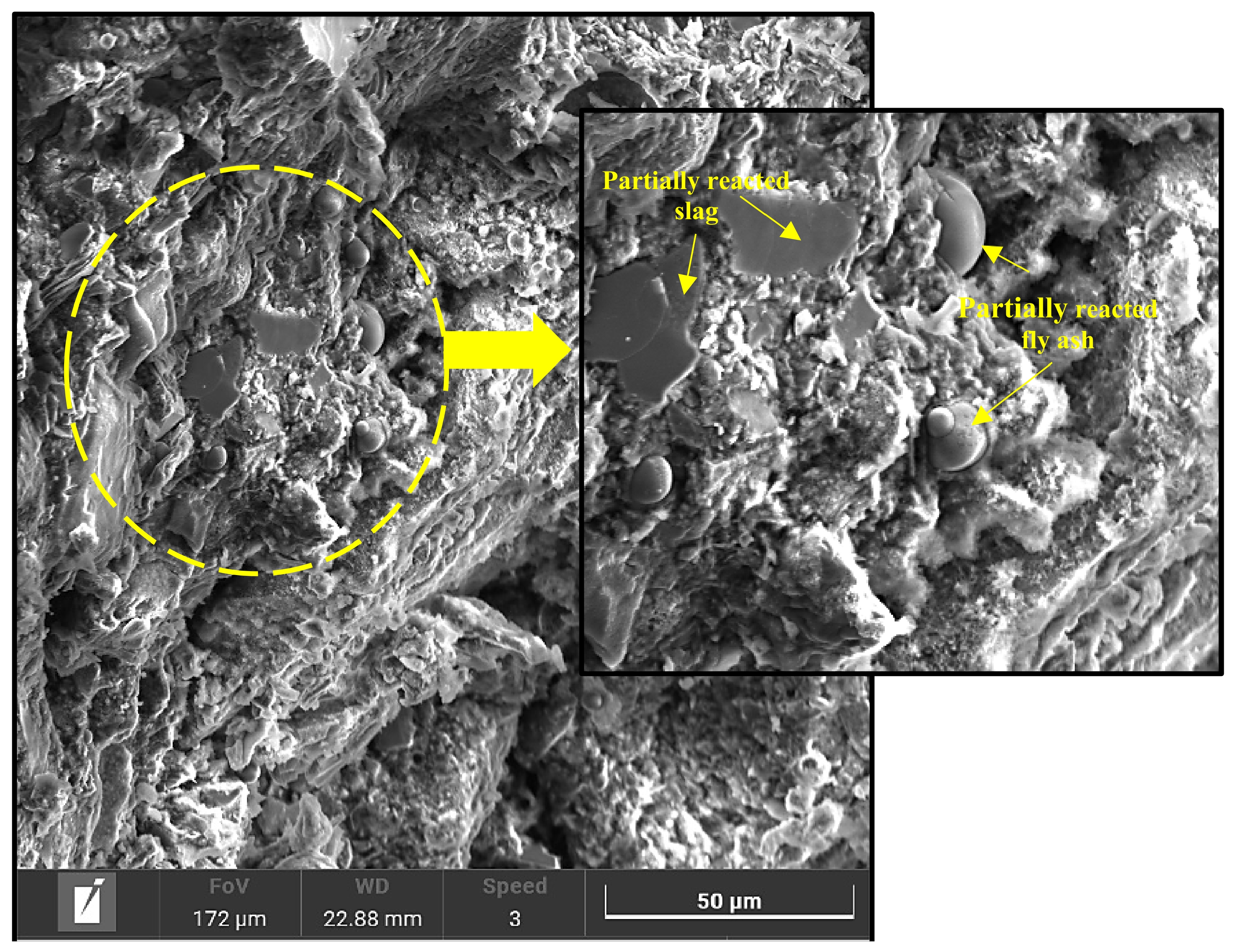

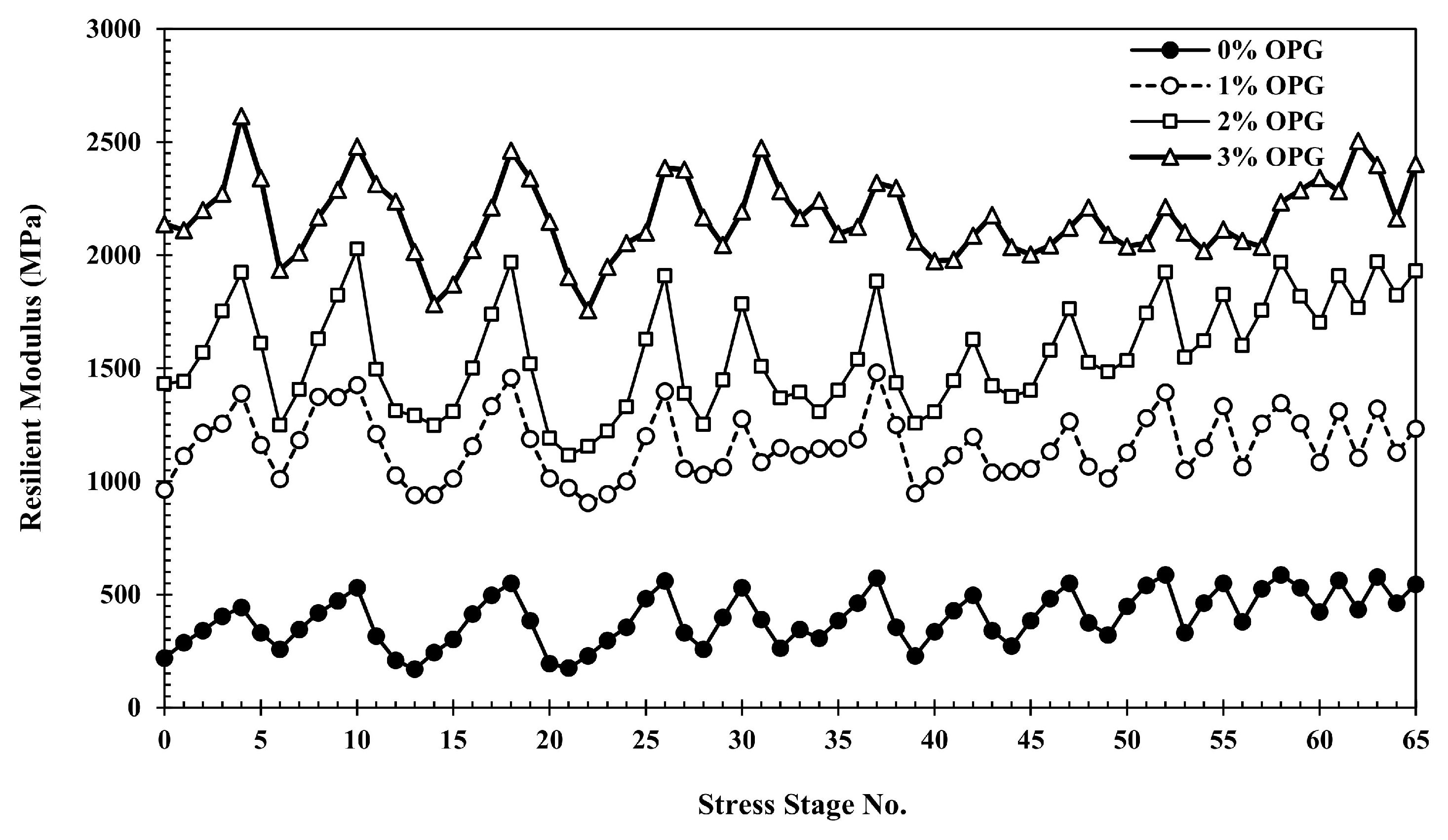

3.2. Repeated Load Triaxial (RLT) Tests

4. Conclusions

- Uniaxial Compressive Strength (UCS) tests revealed that the optimal Na2O content, a component of the solid activator, is 6% by dry weight of the OPG. This concentration resulted in CRB specimens with markedly superior compressive strength compared to those with a 3% Na2O content, while achieving comparable strength to specimens with a 9% Na2O content.

- CRB specimens treated with 1%, 2% and 3% OPG contents displayed compressive strength values exceeding the minimum requirements for use as a bound cemented base material, as stipulated by Austroads. Furthermore, the compressive strength consistently increased with higher OPG contents, from 2 MPa at 1% OPG to approximately 11 MPa at 3% OPG, suggesting that the OPG can effectively enhance the artificial cementation of the CRB particles, resulting in a stiffer material.

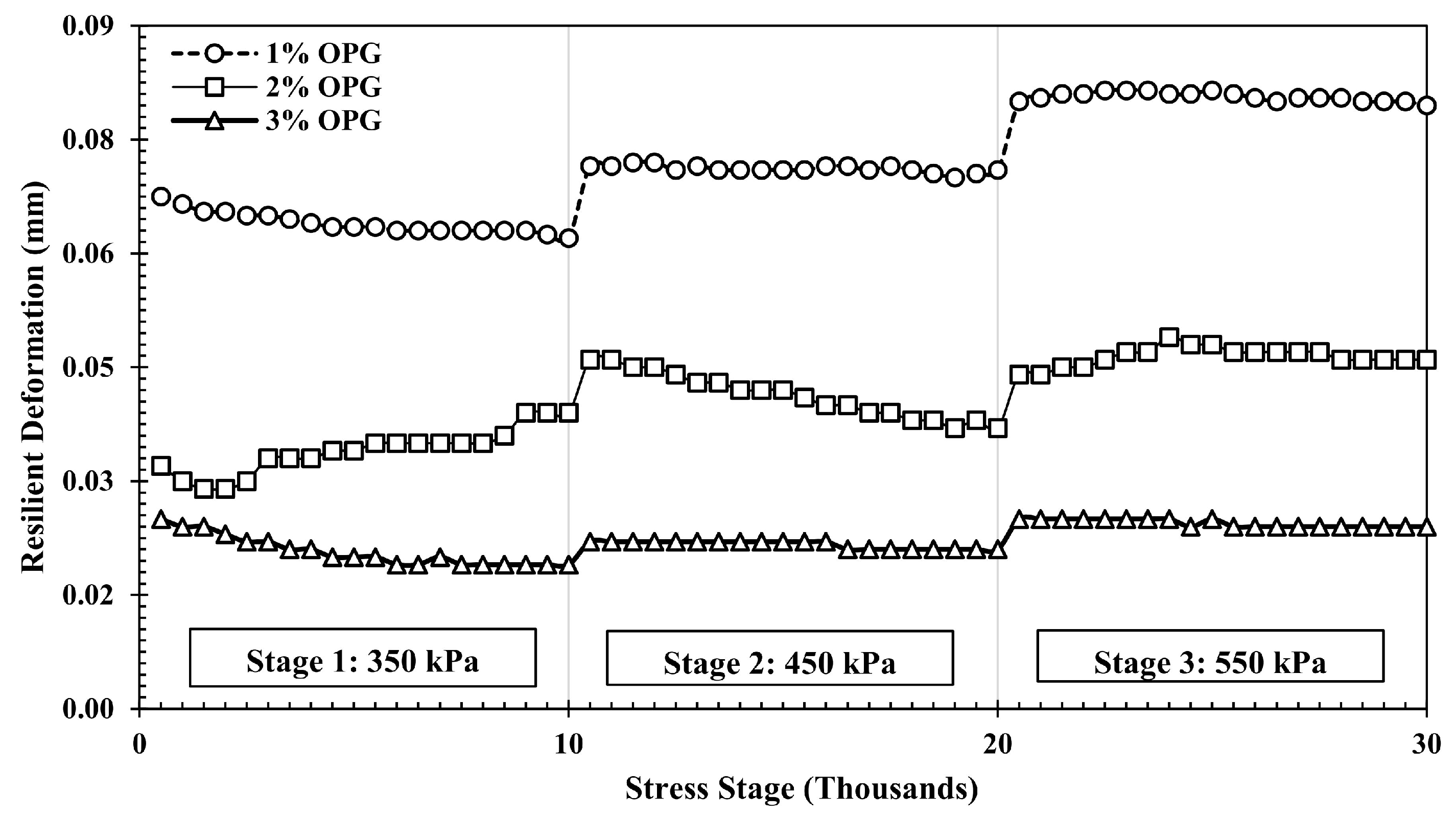

- The results of the resilient modulus demonstrated that the OPG-treated CRB specimens stabilised with 1% OPG achieved values meeting the MRWA requirements for CRB treated with 2% Ordinary Portland Cement (OPC). The specimens with 2% and 3% OPG exhibited superior resilient strength, attaining a maximum average value of 2165 MPa. There is a clear enhancement in the resilient modulus with an increasing OPG content. Moreover, the developed K-θ models indicated a strong correlation between the resilient modulus and bulk stress for the CRB treated with 1% and 2% OPG.

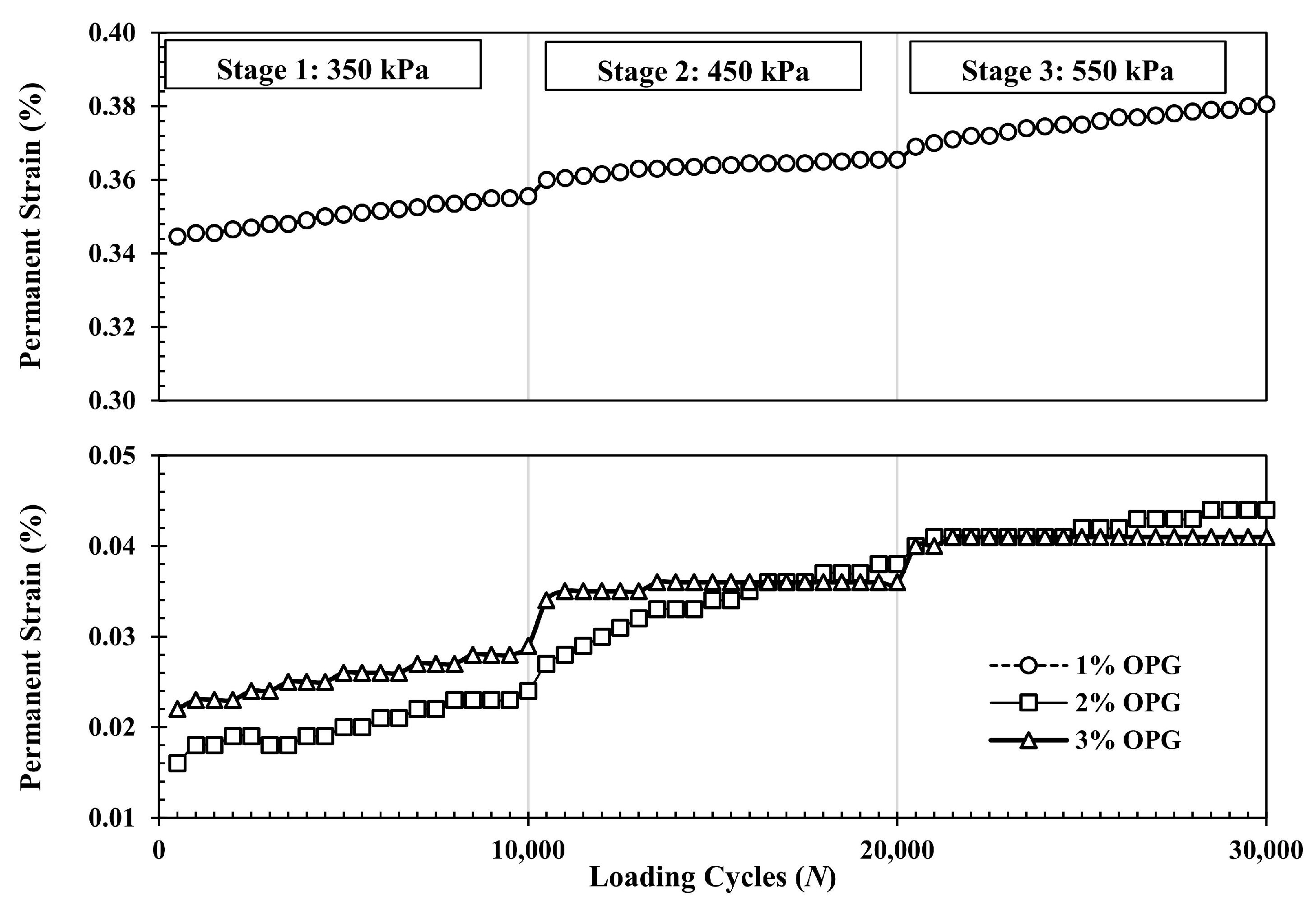

- The CRB specimens treated with 2% and 3% OPG content demonstrated minimal cumulative permanent strain, less than 0.05%, after 30,000 loading cycles. Qualitatively, these specimens are anticipated to remain stable as pavement base materials, whereas those containing 1% OPG are likely to exhibit unstable behaviour.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| OPC | Ordinary Portland Cement |

| OPG | One-Part Geopolymer |

| UCS | Unconfined Compressive Strength |

| RLT | Repeated Load Triaxial |

| Mr | resilient modulus |

References

- Jitsangiam, P.; Nikraz, H. Mechanical behaviours of hydrated cement treated crushed rock base as a road base material in Western Australia. Int. J. Pavement Eng. 2009, 10, 39–47. [Google Scholar] [CrossRef]

- Austroads. Guide to Pavement Technology Part 4D: Stabilised Materials, 2.1st ed.; Austroads Ltd.: Sydney, NSW, Australia, 2019; p. 65. [Google Scholar]

- Determination of Permanent Deformation and Resilient Modulus Characteristics of Unbound Granular Materials Under Drained Conditions (AG:PT/T053); Austroads: Sidney, NSW, Australia, 2007. Available online: https://austroads.com.au/publications/pavement/agpt-t053-07 (accessed on 27 March 2025).

- Austroads; Moffatt, M. (Eds.) Guide to Pavement Technology Part 2: Pavement Structural Design (AGPT02-17), 4th ed.; Austroads Ltd.: Sidney, NSW, Australia, 2017; p. 283. [Google Scholar]

- MAIN ROADS Western Australia. Specification 501 Pavements. 2023. Available online: https://www.mainroads.wa.gov.au/492901/globalassets/technical-commercial/technical-library/specifications/500-series-pavements/specification-501-pavements-pdf.pdf (accessed on 27 March 2025).

- Ettahiri, Y.; Bouargane, B.; Fritah, K.; Akhsassi, B.; Pérez-Villarejo, L.; Aziz, A.; Bouna, L.; Benlhachemi, A.; Novais, R.M. A state-of-the-art review of recent advances in porous geopolymer: Applications in adsorption of inorganic and organic contaminants in water. Constr. Build. Mater. 2023, 395, 132269. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Abdullah, H.H.; Shahin, M.A. Geomechanical Properties of Clay Stabilised with Fly Ash-Based Geopolymer Subjected to Long-Term Sulfate Attack. Int. J. Geosynth. Ground Eng. 2023, 9, 75. [Google Scholar] [CrossRef]

- Sibanda, K.; Shahin, M.A.; Abdullah, H.H. Use of geopolymer for stabilising crushed rock base in road pavement. Aust. Geomech. 2024, 59, 119–129. [Google Scholar] [CrossRef]

- Provis, J.L.; Yong, C.Z.; Duxson, P.; van Deventer, J.S.J. Correlating mechanical and thermal properties of sodium silicate-fly ash geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2009, 336, 57–63. [Google Scholar] [CrossRef]

- Zhang, H.-Y.; Liu, J.-C.; Wu, B. Mechanical properties and reaction mechanism of one-part geopolymer mortars. Constr. Build. Mater. 2021, 273, 121973. [Google Scholar] [CrossRef]

- Provis, J.L.; Rees, C.A. Geopolymer Synthesis Kinetics; Woodhead Publishing: Cambridge, UK, 2009; p. 1. [Google Scholar]

- Tigue, A.A.S.; Dungca, J.R.; Hinode, H.; Kurniawan, W.; Promentilla, M.A.B. Synthesis of a one-part geopolymer system for soil stabilizer using fly ash and volcanic ash. MATEC Web Conf. 2018, 156, 5017. [Google Scholar] [CrossRef]

- Konduru, H.; Karthiyaini, S. Enhancing solidification in one-part geopolymer systems through alkali-thermal activation of bauxite residue and silica fume integration. Case Stud. Constr. Mater. 2024, 21, e03444. [Google Scholar] [CrossRef]

- Min, Y.; Gao, M.; Yao, C.; Wu, J.; Wei, X. On the use of one-part geopolymer activated by solid sodium silicate in soft clay stabilization. Constr. Build. Mater. 2023, 402, 132957. [Google Scholar] [CrossRef]

- Zareechian, M.; Siad, H.; Lachemi, M.; Sahmaran, M. Advancements in cleaner production of one-part geopolymers: A comprehensive review of mechanical properties, durability, and microstructure. Constr. Build. Mater. 2023, 409, 133876. [Google Scholar] [CrossRef]

- Dong, M.; Elchalakani, M.; Karrech, A. Development of high strength one-part geopolymer mortar using sodium metasilicate. Constr. Build. Mater. 2020, 236, 117611. [Google Scholar] [CrossRef]

- MAIN ROADS Western Australia. Particle Size Distribution: Sieving and Decantation Method (WA 115.1:2019). 2019. Available online: https://www.mainroads.wa.gov.au/4aa40b/globalassets/technical-commercial/technical-library/materials-engineering/test-methods/100-series-soil/particle-size-distribution-sieving-and-decantation-method.pdf (accessed on 27 March 2025).

- WA 133.1; Dry Density/Moisture Content Relationship: Modified Compaction Fine and Medium-Grained Soils Test Method. Main Roads Western Australia: Perth, WA, Australia, 2020.

- Standards Australia. Methods of Testing Soils for Engineering Purposes, Method 3.9.1: Soil Classification Tests—Determination of the Cone Liquid Limit of a Soil (AS 1289.3.9.1:2015). 2015. Available online: https://subscriptions-techstreet-com.eu1.proxy.openathens.net/products/830885 (accessed on 27 March 2025).

- Standards Australia. Methods of Testing Soils for Engineering Purposes, Method 3.2.1: Soil Classification Tests—Determination of the Plastic Limit of a Soil (AS 1289.3.2.1:2009). 2009. Available online: https://subscriptions-techstreet-com.eu1.proxy.openathens.net/products/809286 (accessed on 27 March 2025).

- Standards Australia. Supplementary Cementitious Materials, Part 2: Slag—Ground Granulated Blast-Furnace (AS 3582.2). Sydney, NSW, Australia. 2016. Available online: https://subscriptions-techstreet-com.eu1.proxy.openathens.net/products/827429 (accessed on 27 March 2025).

- Australian/New Zealand Standard. Supplementary Cementitious Materials, Part 1: Fly Ash (AS/NZS 3582.1). Sydney, NSW, Australia. 2016. Available online: https://subscriptions-techstreet-com.eu1.proxy.openathens.net/products/827641 (accessed on 27 March 2025).

- Valencia Saavedra, W.G.; Angulo Ramírez, D.E.; Mejía de Gutiérrez, R. Alkali-activated concretes based on fly ash and blast furnace slag: Compressive strength, water absorption and chloride permeability. Ing. Investig. 2020, 40, 72–80. [Google Scholar] [CrossRef]

- Abubakr, A.E.; Soliman, A.M.; Diab, S.H. Effect of activator nature on the impact behaviour of Alkali-Activated slag mortar. Constr. Build. Mater. 2020, 257, 119531. [Google Scholar] [CrossRef]

- WA 143.1; Determination of the Unconfined Compressive Strength of Laboratory Compacted Specimens Test Method. Main Roads Western Australia: Perth, WA, Australia, 2012.

- Abdullah, H.H.; Shahin, M.A.; Walske, M.L. Review of fly-ash-based geopolymers for soil stabilisation with special reference to clay. Geosciences 2020, 10, 249. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Sukmak, P.; Chinkulkijniwat, A.; Arulrajah, A.; Shen, S.-L. Stabilisation of marginal lateritic soil using high calcium fly ash-based geopolymer. Road Mater. Pavement Des. 2016, 17, 877–891. [Google Scholar] [CrossRef]

- Chummuneerat, S. Performance, Evaluation, and Enhancement of Hydrated Cement Treated Crushed Rock Base (HCTCRB) as a Road Base Material for Western Australian Roads. Ph.D. Thesis, Curtin University, Perth, WA, Australia, 2014. Available online: https://catalogue.curtin.edu.au/permalink/61CUR_INST/1ti2cgm/cdi_ands_rda_oai_ands_org_au_64603 (accessed on 27 March 2025).

- Vuong, B.; Arnold, G. Predicting In-Service Performance of Alternative Pavement Materials for New Zealand Conditions; No. 304; Land Transport New Zealand: Wellington, New Zealand, 2006. [Google Scholar]

| Material | Composition (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | MgO | K2O | SO3 | H2O | LOI * | |

| GGBFS | 31.9 | 13.6 | 1.35 | 45.3 | 0.26 | 6.2 | 0.31 | 2.04 | – | 0.06 |

| Fly ash | 56 | 26.8 | 6.6 | 9.79 | 0.28 | 1.22 | 0.78 | 0.26 | – | 1.59 |

| Solid activator | 28.3 | – | – | – | 29.2 | – | – | – | 42.5 | – |

| Test | Na2O (%) | OPG Content (%) |

|---|---|---|

| UCS | 3 | 2 |

| 6 | 1 | |

| 2 | ||

| 3 | ||

| 9 | 2 | |

| RLT | 6 | 1 |

| 2 | ||

| 3 |

| OPG Content (%) | Resilient Modulus (MPa) | ||

|---|---|---|---|

| Minimum | Maximum | Average | |

| 0 | 170 | 587 | 483 ± 63 |

| 1 | 893 | 1471 | 1151 ± 146 |

| 2 | 1117 | 2028 | 1563 ± 240 |

| 3 | 1757 | 2614 | 2165 ± 174 |

| OPG Content (%) | K1 | K2 | R2 |

|---|---|---|---|

| 1 | 214.18 | 0.2816 | 0.8009 |

| 2 | 185.4 | 0.3554 | 0.8446 |

| 3 | 1136.9 | 0.1074 | 0.2775 |

| Performance | Permanent Strain Rate | Resilient Deformation |

| Stable | Decreasing | Decreasing to constant |

| Unstable | Decreasing to constant | Constant to increasing |

| Failure | Constant to increasing | Increasing |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camarini, G.C.; Abdullah, H.H.; Shahin, M.A. One-Part Geopolymer for Stabilising Crushed Rock Road Base Material. Geosciences 2025, 15, 122. https://doi.org/10.3390/geosciences15040122

Camarini GC, Abdullah HH, Shahin MA. One-Part Geopolymer for Stabilising Crushed Rock Road Base Material. Geosciences. 2025; 15(4):122. https://doi.org/10.3390/geosciences15040122

Chicago/Turabian StyleCamarini, Guilherme C., Hayder H. Abdullah, and Mohamed A. Shahin. 2025. "One-Part Geopolymer for Stabilising Crushed Rock Road Base Material" Geosciences 15, no. 4: 122. https://doi.org/10.3390/geosciences15040122

APA StyleCamarini, G. C., Abdullah, H. H., & Shahin, M. A. (2025). One-Part Geopolymer for Stabilising Crushed Rock Road Base Material. Geosciences, 15(4), 122. https://doi.org/10.3390/geosciences15040122