Abstract

The present study focused on the petrography and geotechnics of aggregates of two sites around the city of Mongo for their use in construction. The study area is located in central Chad, in the Guéra province, at the eastern and north-western entrance to the city of Mongo. The area corresponds to a crystalline basement, and granitic massifs are abundant. Two deposits were studied: the Mongo massif, closest to the town of the same name, and the Oyo massif at the eastern exit of Mongo. The petrographic analysis showed that the studied materials are granites, light grey in color, composed of 30% quartz, 15% biotite, 20% feldspar, 30% plagioclase and 5% other minerals. From the geotechnical point of view, the materials of the Mongo site are more resistant to wear compared to those of Oyo which are less resistant. According to the results of micro-Deval and Los Angeles tests, the use of aggregates obtained from the Mongo site granites are usable in base courses for T1–T3 traffic admitting an axle of 8 to 10 tons and in surface dressings, contrary to those of Oyo, which are not favorable in road construction.

1. Introduction

From the beginning, man has used natural materials for the construction of his habitat and the development of his environment. From these two first necessities, three great sectors of activity arise today, which are the industries of quarries and building materials, building and public works [1]. Aggregates, due to the importance of their use throughout the world, constitute after air and water, the third substance used by man [2]. Their form, nature and composition are factors that determine the types and properties of concrete [3] and other aggregate-based formulations. The intrinsic qualities of aggregates, especially in terms of resistance to fragmentation, wear or polishing, condition the criteria for re-use. It is thus common to find rocks of crystalline or magmatic origin in the most mechanically stressed parts of structures because their characteristics are often clearly superior to those of rocks of sedimentary origin. For this reason, the construction of buildings, bridges and road infrastructures requires large quantities of good quality materials [4]. Most public bodies and companies build structures with materials whose characteristics are not well known, which very often lead to the ruin or early deterioration of the structures [5].

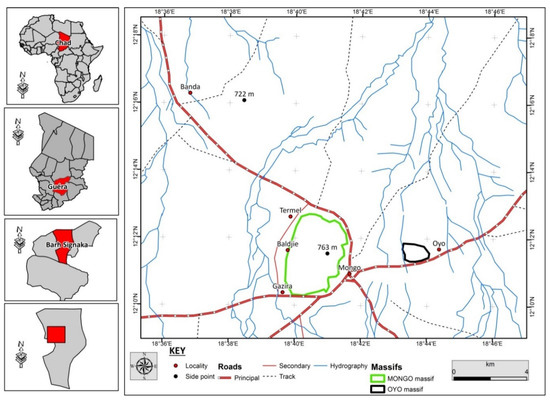

The geological formations in Chad are mostly of sedimentary origin. Locally, patches of plutonic basement are available to be exploited and valorized for high added value uses [6]. The study area is located in the Guéra province between N 12°06′00′′ and 12°18′00′′ latitudes and from E 18°35′00′′ to 18°48′00′′ longitude (Figure 1).

Figure 1.

Detailed location map of the study area, with general location at different scales on the left.

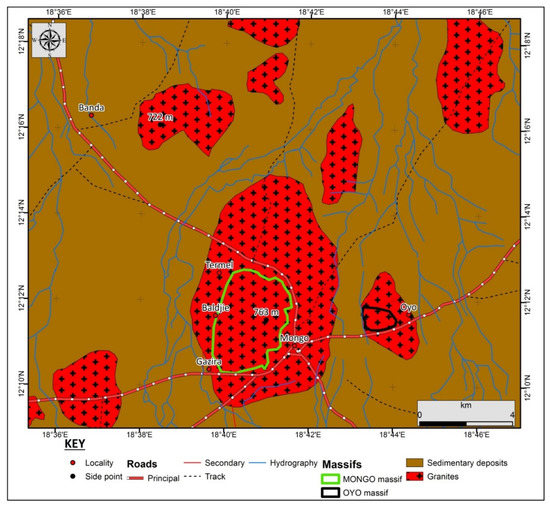

From a geological point of view, the Guéra province in which the town of Mongo is located, is a crystalline basement zone which belongs to the Pan-African Belt of central Africa [7,8,9,10,11,12,13]. The Guéra granitoids have been dated between 560 and 590 Ma [13]. The massifs of the town of Mongo, capital of the Guéra province, which were the subject of this study, are points of this crystalline basement. According to [13] they should correspond to the syntectonic circa 590 Ma biotite granites. On the other hand [12] states that Oyo massif is made of diorite. They constitute sufficiently important massifs to suggest that the resources are abundant for use in the construction industry (Figure 2).

Figure 2.

Geological map of the study area, redrawn after [12].

On the geotechnical level, the studies in Chad have been much more focused on soft materials and foundation engineering, and very little work has been done on the geotechnical characterization of aggregates [14]. The present study uses data obtained by experimentation on ten samples of aggregates taken from the two sites. Such knowledge is necessary to estimate the conditions of use of these materials for construction.

2. Methodology

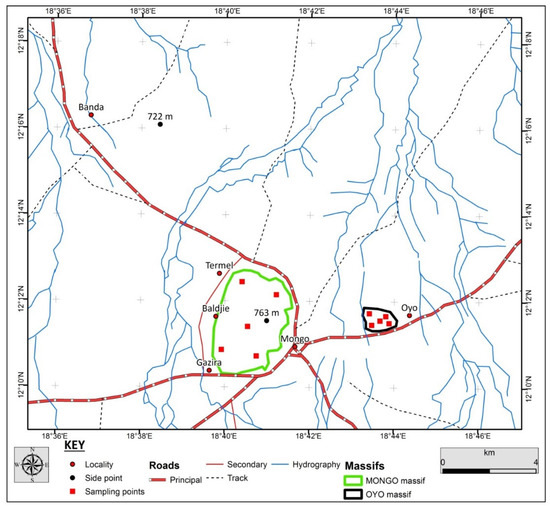

The field work consisted of localizing, petrographic description, data collection and sampling for thin sections and geotechnical tests. To this end, ten samples were taken from two sites, five from the Oyo massif and five from the Mongo massif (Figure 3). The selected points were those located in different areas of the site and present all apparent diversities in terms of shape, color and size of grains. The samples taken were then coded and sent to the Civil Engineering Laboratory in N’Djamena for geotechnical testing.

Figure 3.

Sampling map.

For the mineralogical composition, four samples were taken, i.e., two samples per massif and analyzed at the Geosciences Laboratory of Superficial Formations of the University of Yaoundé I (Yaoundé, Cameroon) after preparation of thin slides of 30 µm thickness.

Physical and geotechnical properties were measured on aggregates obtained by manual crushing of the materials to the granular class 10/14 mm, Geotechnical tests were carried out in accordance with French norms. The geotechnical parameters of the Los Angeles (LA) and micro-Deval coefficients were determined in accordance with French norms. The LA and micro-Deval coefficients are the percentage of the initial aggregate that passes the 1.6 mm sieve after being tumbled together with steel balls in a normalized test. While the Los Angeles test is designed to produce more shock in between the gravels and steel balls, the micro-Deval test privileges wear by friction. The apparent density was determined using the weighing method, and grain density using pycnometry.

3. Results and Discussion

3.1. Geological and Petrographic Characteristics

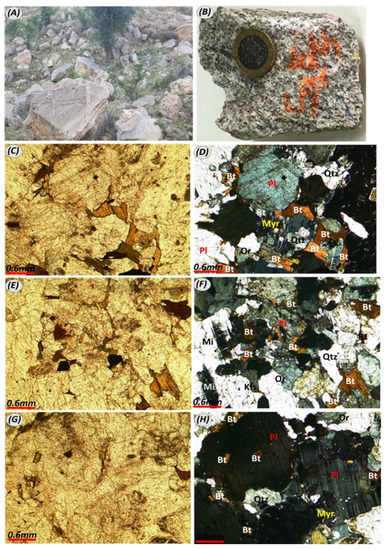

Oyo and Mongo massifs culminates 330 m and 80 m above regional topography, respectively. The granites outcrop as large domes or flagstones, eroded as angular blocks on slopes or residual balls. Colors varies between dark-grey, pinkish-grey and light-grey colors. Oyo and Mongo granites are, on average, coarse-grained and medium-grained, respectively (Figure 4 and Figure 5). Oyo massif shows compositional banding, with dark and light bands (Figure 4A). Rock softening and disaggregation due to surficial weathering is limited in the Mongo massif. In the Oyo massif, we note the abundance of rock degradation products throughout the massif, indicative of a more intense weathering. Accordingly, field observation and satellite imagery show that clean outcrops cover a much larger relative surface in Mongo compared to the Oyo massifs. It should be noted that the samples are taken from unaltered cores of block.

Figure 4.

Oyo massif (A) outcropping conditions (field of view is 10 m wide); (B) hand sample with 2 cm coin; (C–H) thin slide optical microscope views alternatively without or with crossed nicols (left and right) with phase identification indicated (quartz = Qtz, orthose = Or or Kfs, plagioclase = Pl, biotite = Bt, myrmekite intergrowth of quartz and plagioclase = Myr or Mi).

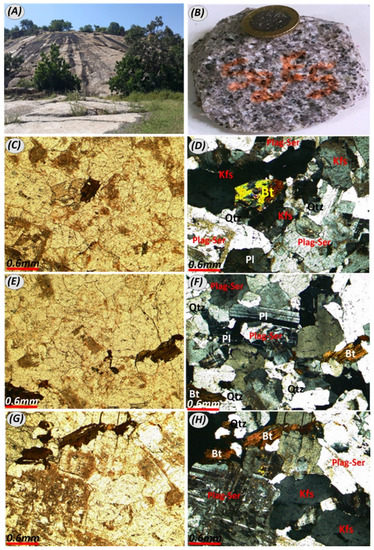

Figure 5.

Mongo massif; (A) outcropping conditions (field of view is 20 m wide); (B) hand sample; (C–H) thin slide optical microscope views alternatively without or with crossed nicols (left and right) with phase identification indicated (quartz = Qtz, orthose = Or or Kfs, biotite = Bt, sericitized plagioclase = Plag-Ser).

From the microscopic point of view, the studied granites present a typical plutonic texture (Figure 4 and Figure 5), characterized by the presence of K feldspar, quartz, plagioclase, biotite and opaque minerals. Plagioclase grains appear sericitized in Mongo massif, indicative of hydrothermal alteration. The estimation of the percentage of minerals was made with the help of the abacus of the relative proportions of minerals in a rock using Michel-Levy chart [15]. The results obtained are presented in Table 1.

Table 1.

Mineralogical mode in percent of the Oyo and Mongo Massif samples.

The results obtained are consistent with the work of [16] on the magmatic formations encountered in the central Chadian massif and those of [17] on the granitoids of the southeast sector of Mongo.

3.2. Geotechnical Characteristics

3.2.1. Physical Parameters

The values of the apparent density of the crushed materials of the Oyo massif are between 1.23 and 1.30 g/cm3, with an average of 1.26 g/cm3. As for the Mongo massif, the values are between 1.26 and 1.38 g/cm3. with an average of 1.29 g/cm3 (Table 2).

Table 2.

Values of bulk densities of the studied samples in g/cm3.

The density values of the solid grains of the crushed aggregates of the Oyo massif are between 2.45 and 2.63 g/cm3, with an average value of 2.55 g/cm3. For the Mongo massif, the values vary from 2.52 to 2.58 g/cm3, with an average of 2.55 g/cm3 (Table 3).

Table 3.

Grain density values of the studied samples in g/cm3.

The solid grain density values of crushed aggregates in the Oyo and Mongo massifs (2.55 g/cm3) are on average equal and close to those of quartz (2.65 g/cm3) and feldspars (2.57–2.75 g/cm3). According to [18], these values are consistent with the mineralogy of granites. The fact that grain densities are more variable in Oyo than Mongo massifs signs the higher heterogeneity already pointed for Oyo. A significantly lower bulk density for Oyo may correspond to a higher porosity linked to weathering and microcracks.

3.2.2. Mechanical Parameters

Micro-Deval Coefficient

The wear resistance is evaluated by the micro-Deval coefficient in the presence of water (MDE). The values of wear resistance of the materials of the Oyo massif (Site 1) are between 27.00 and 66.20%, with an average value of 49.96%. For the Mongo massif, the values obtained are between 7.00 and 16.20%, with an average of 10.88% (Table 4).

Table 4.

Values MDE coefficient in % indicative of the wear resistance of solid grains from the 10/14 mm fraction of the Oyo and Mongo samples.

The results of the micro-Deval coefficient obtained from the crushed granites of the Oyo massif (27–66.20%) are largely superior to those obtained on granites of the same sub-region located at Bonis in Eastern Cameroon (22.70%) [19] and on the migmatitic gneisses of the Okola area, Central Cameroon (22–26%) [20]. This difference could be explained by the petrographic nature, mineral size, degree of alteration and degree of fracturing of the granites.

The data obtained from the Mongo massif are not in agreement with the results of [21], according to which the pyroclastic products of the Takouche-Baleng quarry (Cameroon) present a micro-Deval coefficient of 7%. This discrepancy could be explained by the grain size of the materials studied.

Los Angeles Coefficient

The fragmentation resistance of the aggregates is evaluated by means of the Los Angeles test (LA). The values of resistance to the shocks of the aggregates of the Oyo massif (Site 1) are between 60.24 and 78.94%, with an average of 71.90%. As for the Mongo massif (Site 2) the values obtained are between 25.78 and 51.62%, with an average of 36.41% (Table 5).

Table 5.

Values of the LA coefficient in %, indicative of the resistance to fragmentation of solid grains on the 10/14 mm fraction of the Oyo and Mongo samples.

The materials from Mongo site are more resistant to wear compared to those from Oyo site which have LA > 40% values. According to [22], the Mongo granites have medium impact strength except for sample E1 which has poor strength. The lower strength of the Oyo granites is likely due to the fact that these materials are already subject to significant weathering.

The mechanical properties required for the use of an aggregate in base layer are presented in Table 6. Aggregates obtained from Oyo granites are not suitable for road construction.

Table 6.

Order of magnitude and appreciation of the Los Angeles coefficient (CEBTP, 1984).

To better appreciate the mechanical characteristics of aggregates, the NF P18-545 [23] standard shows the different codes of use (Table 7 and Table 8).

Table 7.

LA and MDE (uncompensated) category codes for foundation, base and binder layers.

Table 8.

Codes of the specified values of the categories for LA and MDE and the LA + MDE compensation of aggregates for sub-base, base and binder layers.

Compliance is warranted if both conditions (LA and MDE) are met simultaneously. These tables indicate that the aggregates of Oyo are in category F and usable only for certain uses, for example, treated with hydraulic binders or subgrade. On the other hand, those of Mongo are in category D (with the rule of the compensation).

Our geotechnical study shows that there is a variation between the mechanical parameters of the aggregates. This variation is mainly due to the grain size, mineralogical composition, degree of cracking and the state of weathering of the rocks.

4. Conclusions

The present study deals with the geotechnical characterization of Oyo and Mongo granites in order to appreciate their use in the construction of various structures. For this purpose, the study was carried out on the petrographic and geotechnical level.

The petrographic study has showed that both massifs are composed of biotitic granites. The Mongo massif is more isotropic and homogeneous with medium grain size, while the Oyo massif is foliated and banded, with coarser grain size. These granites are composed of a plutonic set with massive structure and of granular to porphyroid textures. They outcrop in blocks, balls, domes and slabs.

The geotechnical study reveals that the wear resistance of the materials of the Oyo massif is between 27.00 and 66.20%, with an average value of 49.96%. For the Mongo massif, the values obtained are between 7.00 and 16.20%, with an average of 10.88%. The impact resistance of the aggregates of the Oyo massif is between 60.24 and 78.94%, with an average of 71.90%. As for the Mongo massif, the values obtained are between 25.78 and 51.62%. with an average of 36.41%.

The examination of the results shows that the Mongo granites are indeed usable in the field of civil engineering. On the other hand, the materials obtained from the Oyo granites are not usable in road construction. The study shows that the mineralogical composition, grain size and the degree of weathering influence the quality of the material.

Author Contributions

H.Z.A.-h. designed the study, performed the sampling and wrote the article; P.R. corrected the article and performed submission and revision; M.T.A.D. performed some measurements and interpretations. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by French Embassy in Chad.

Data Availability Statement

All data is presented in the manuscript.

Acknowledgments

We acknowledge the comments of two anonymous reviewers, providing an incentive for significant improvement of the initial submission. This paper was written during a stay of the first author in Aix-en-Provence, funded by the French Embassy in N’Djamena, Chad, for which we are particularly grateful.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Martaud, T. Evaluation Environnementale de la Production de Granulats Naturels en Exploitation de Carrière—Indicateurs, Modèles et Outils. Ph.D. Thesis, Orléans University, Orléans, France, 2008; 213p. [Google Scholar]

- Boufedah, B.A. Influence de la Granularité (Classe Granulaire 4/22.4) sur les Caractéristiques des Granulats et sur les Propriétés des Bétons Ordinaires. Master’s Thesis, Constantine University, Constantine, Algeria, 2011; 85p. [Google Scholar]

- Dreux, G. Nouveau Guide du Béton; Eyrolles: Paris, France, 1978. [Google Scholar]

- Makhaly, B.; Babacar, D.; Oumar, K. Etude comparative des caractéristiques des bétons hydrauliques et des bétons bitumineux à base de granulats de basaltes de Diack et de quartzites de Bakel. Rev. CAMES-Sci. Appliquées L’ingénieur 2014, 1, 57–64. [Google Scholar]

- Vouffo, M.; Kamga, D.T.; Codjo, L.Z.; Moussa, S.; Amba, J.C.; Ngapgue, F. Physical characterization of granite alteration products for use in civil engineering. Electron. J. Geotech. Eng. 2018, 23, 301–313. [Google Scholar]

- Al-Hadj, H.Z. Caractérisation Géotechnique des Granites de la Région du Ouaddaï en vue de leur Utilisation en Génie Civil. Master’s Thesis, Dschang University, Dschang, Cameroon, 2014; 72p. [Google Scholar]

- Bessoles, B.; Trompette, R. Géologie de l’Afrique: La Chaine Panafricaine Zone Mobile d’Afrique Centrale (Partie Sud) et Zone Mobile Soudanaise; Mémoire du Bureau de Recherches Géologiques et Minières: Orléans, France, 1980; Volume 92, 394p. [Google Scholar]

- Abdelsalam, M.G.; Abdel-Rahman, E.-S.M.; El-Faki, E.F.M.; Al-Hur, B.; El-Bashier, F.R.M.; Stern, R.J.; Thurmond, A.K. Neoproterozoic deformation in the northeastern part of the Saharan Metacraton, northern Sudan. Precambrian Res. 2003, 123, 203–221. [Google Scholar]

- Toteu, S.F.; Penaye, J.; Djomani, P.Y. Geodynamic evolution of the Pan-African belt in Central Africa with special reference to Cameroon. Can. J. Earth Sci. 2004, 41, 73–85. [Google Scholar] [CrossRef]

- Penaye, J.; Kroner, A.; Toteu, S.F.; Van Schmus, W.R.; Doumnang, J.C. Evolution of the Mayo-Kebbi region as revealed by zircon dating: An early (Ca. 740Ma) Pan African magmatic arc in south western Chad. J. Afr. Earth Sci. 2006, 44, 530–542. [Google Scholar] [CrossRef]

- Ngako, V.; Affaton, P.; Njonfang, E. Pan-African tectonics in north-western Cameroon: Implication for the history of western Gondwana. Gondwana Res. 2008, 14, 509–522. [Google Scholar] [CrossRef]

- Isseini, M.; Hamit, A.; Abderamane, M. The tectonic and geological framework of the Mongo area, a segment of the Pan-African Guéra Massif in Central Chad: Evidences from field observations and remote sensing. Rev. Sci. Tchad 2013, 1, 4–12. [Google Scholar]

- Shellnutt, J.G.; Pham, N.H.T.; Yeh, M.W.; Lee, T.Y. Two series of Ediacaran collision-related granites in the Guéra Massif, South-Central Chad: Tectono-magmatic constraints on the terminal collision of the eastern Central African Orogenic Belt. Precambrian Res. 2020, 347, 105823. [Google Scholar] [CrossRef]

- Al-hadj, H.Z.; Maurice, K.; Bozabe, R.K. Geotechnical Interattraction of Granites from Ouaddai Region (East-Chad) for Use in Civil Engineering. Elixir Civil Eng. 2019, 137, 53938–53942. [Google Scholar]

- Lof, P. Elsevier’s Mineral and Rock Table; Elsevier Science Publishers B.V.: Amsterdam, The Netherlands, 1982. [Google Scholar]

- Vincent, P.M. Extraction du Zircon dans un Granite Intrusif Porphyroïde en Provenance du District de Mongo n°R6-2 (Coupure Géologique d’Am Timan-Ouest); Direction des Mines et de la Géologie: Brazzaville, Congo Republic, 1956. [Google Scholar]

- Issaka, A. Etude Pétrographique et Structurale des Granitoïdes du Secteur Sud-Est de Mongo (Abou-Telfan/Tchad). Master’s Thesis, N’gaoundéré University, N’gaoundéré, Cameroon, 2011; 58p. [Google Scholar]

- Anonymous. Mémento des Mines et Carrières: Aide-Mémoire de L’exploitant; Nouvelle édition N°3; Société de l’Industrie Minéralogique: Paris, France, 1997; 531p. [Google Scholar]

- Nzabakurikiza, A.; Onana, V.; Ngo’oZe, A.; Ndzié, A.T.; Ekodeck, G.E. Geological, geotechnical, and mechanical characterization of lateritic gravels from Eastern Cameroon for road construction purposes. Bull. Eng. Geol. Environ. 2017, 76, 1549–1562. [Google Scholar] [CrossRef]

- Bekon, N. Caractérisation Géotechnique et Mécanique des Produits D’altération des Gneiss Migmatiques de la Zone d’Okola (Centre Cameroun). Master’s Thesis, Yaoundé University, Yaoundé, Cameroon, 2012; 73p. [Google Scholar]

- Vouffo, M.; Kamga, D.T.; Ngapgué, F.; Kemtchou, F.H. Mechanical Characterization of Pyroclastic Products for Use in Civil Engineering Works. IOSR J. Mech. Civ. Eng. 2020, 17, 35–43. [Google Scholar]

- CEBTP. Guide Pratique de Dimensionnement des Chaussées Pour les Pays Tropicaux; Centre D’expertise du Bâtiment et des Travaux Publics: Saint-Rémy-lès-Chevreuse, France, 1984; 155p. [Google Scholar]

- Norme Française NF-P-18-545: Granulats-Eléments de Définition, Conformité et Codification. 2011. Available online: https://www.legifrance.gouv.fr/eli/ordonnance/2010/12/17/2010-1579/jo/texte (accessed on 25 June 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).