Laboratory Evaluation of Mechanical Properties of Draupne Shale Relevant for CO2 Seal Integrity

Abstract

1. Introduction

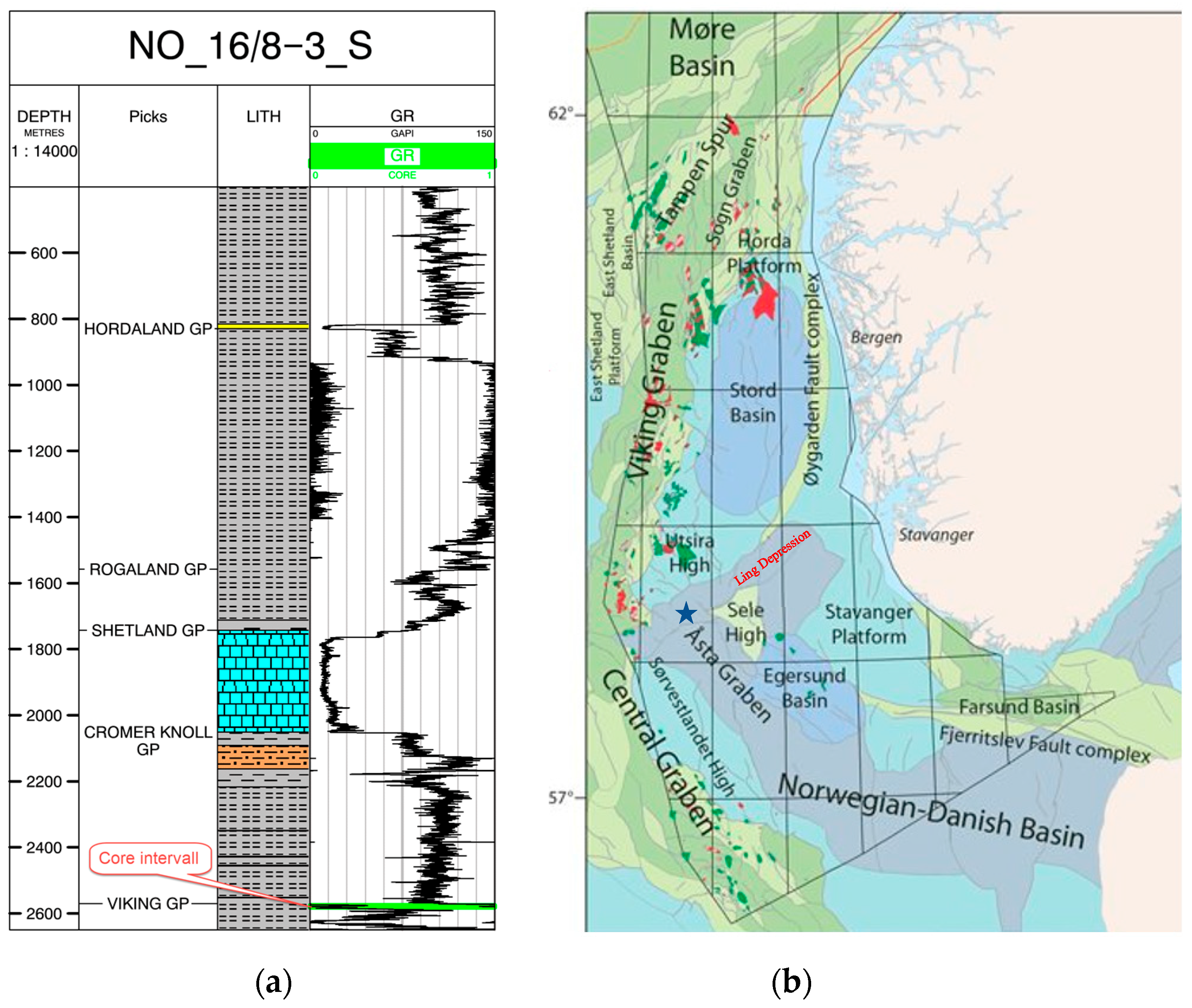

2. Material

2.1. Geological Setting

2.2. Index Properties

3. Method

3.1. Sample Preparation

3.2. Oedometer Testing

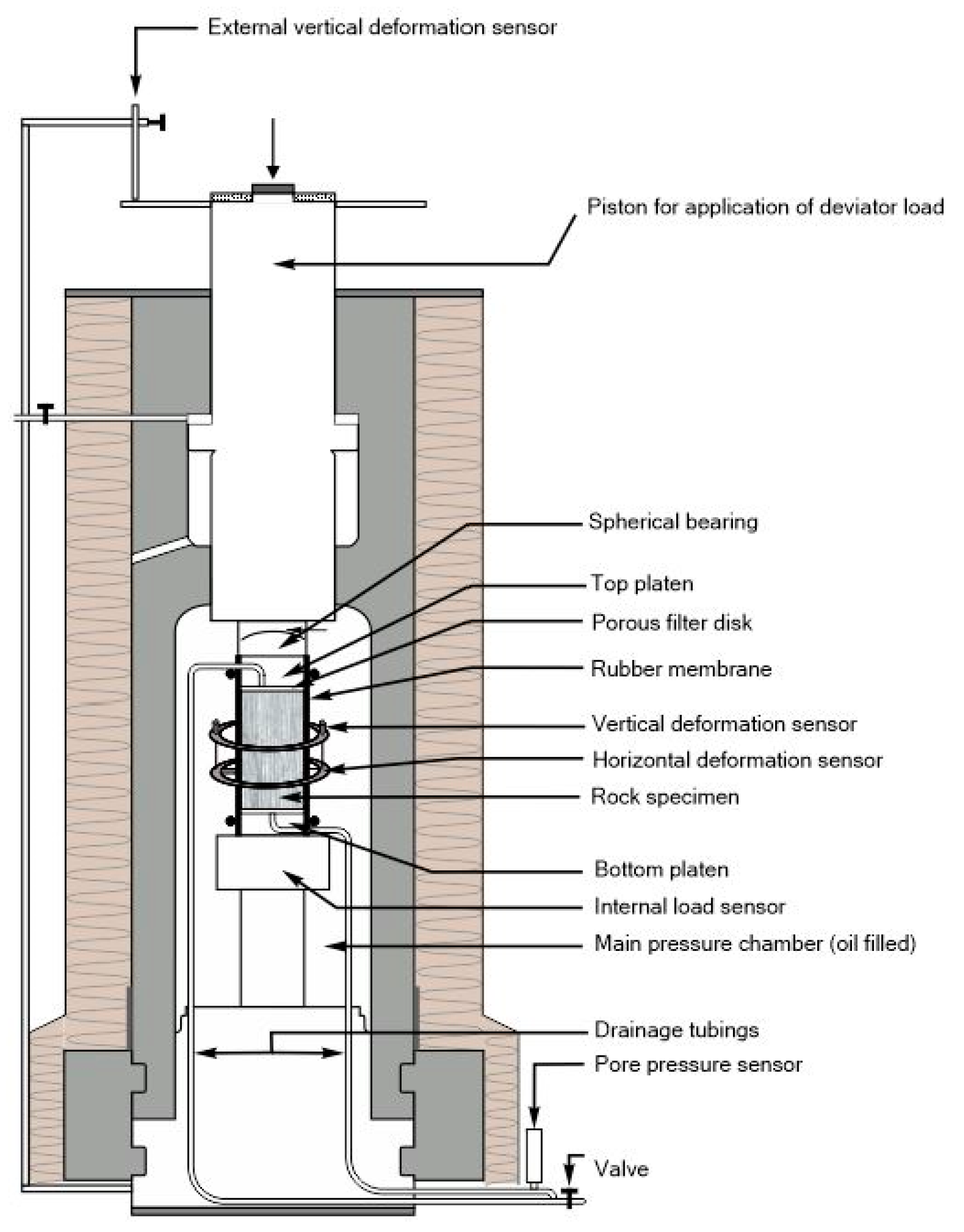

3.3. Triaxial Testing

3.4. Strain Rates

3.5. Triaxial Test Procedure

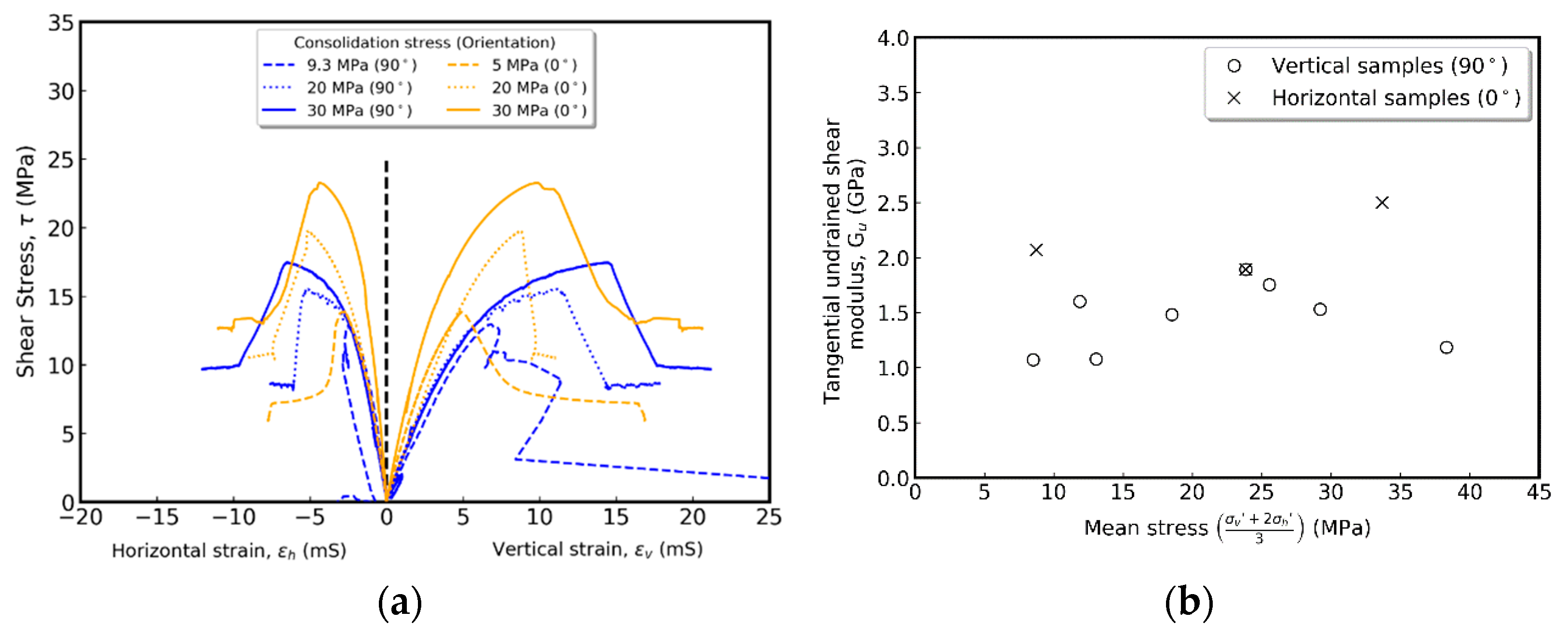

- One vertical and one horizontal sample (tests 7 and 11) were isotropically loaded under drained conditions to determine the bulk modulus. Both samples were loaded using a constant stress rate. Using five times higher stress rate for the horizontal sample (0.05 MPa/h compared to 0.01 MPa/h) resulted in approximately equal vertical strain rates in the two tests (5 × 10−10 s−1), reflecting the anisotropy in permeability given in Table 1. Secant bulk modulus was calculated as the ratio of change in effective isotropic change over a change in volumetric strain (εVOL = εV + 2*εH).

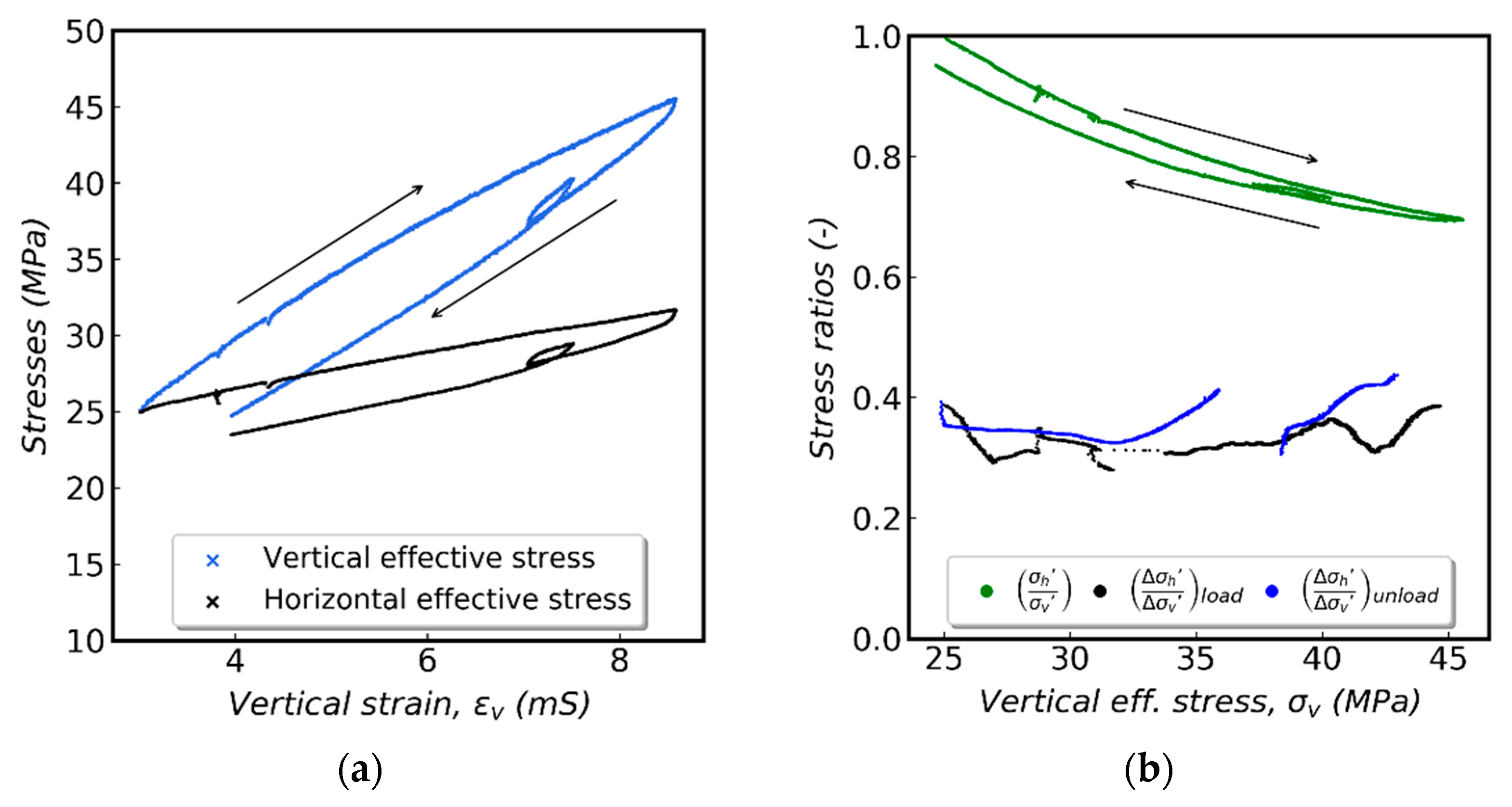

- For test 8, a drained uniaxial strain loading (“k0 loading”) phase was included for estimation of the constrained modulus (M) as the ratio between the change in effective vertical stress and resulting vertical strain. With constant pore pressure, the total vertical stress was increased to give a vertical strain rate of 5 × 10−9 s−1, while the confining pressure was adjusted to prevent horizontal deformation. Uniaxial strain loading was started from an effective isotropic stress of 23.9 MPa and continued until an effective vertical stress of 45.5 MPa was reached.

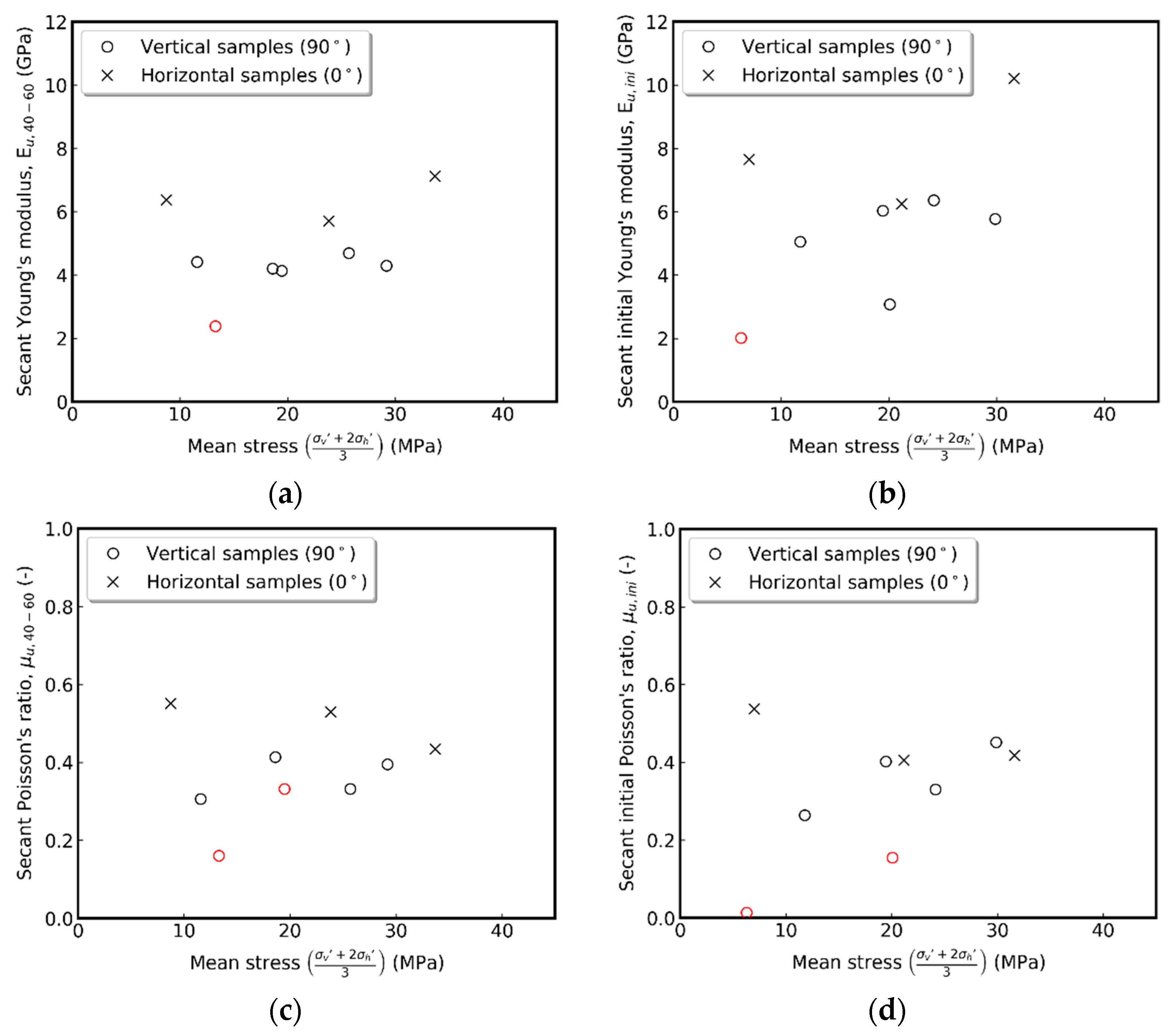

- Finally, for test 7 the initial phase of shearing was conducted under drained conditions for the assessment of the drained stiffness. Using a low strain rate and open drainage valves, axial loading was continued until 0.1% vertical strain had been reached. At this point, shearing was reversed and unloaded almost back to isotropic stress conditions. Secant-drained Young’s modulus was estimated from both loading and unloading as the ratio between effective vertical stress change and change in vertical strain. Similarly, Poisson’s ratio was calculated from loading and unloading as the change in horizontal strain over the change in vertical strain.

4. Experimental Results

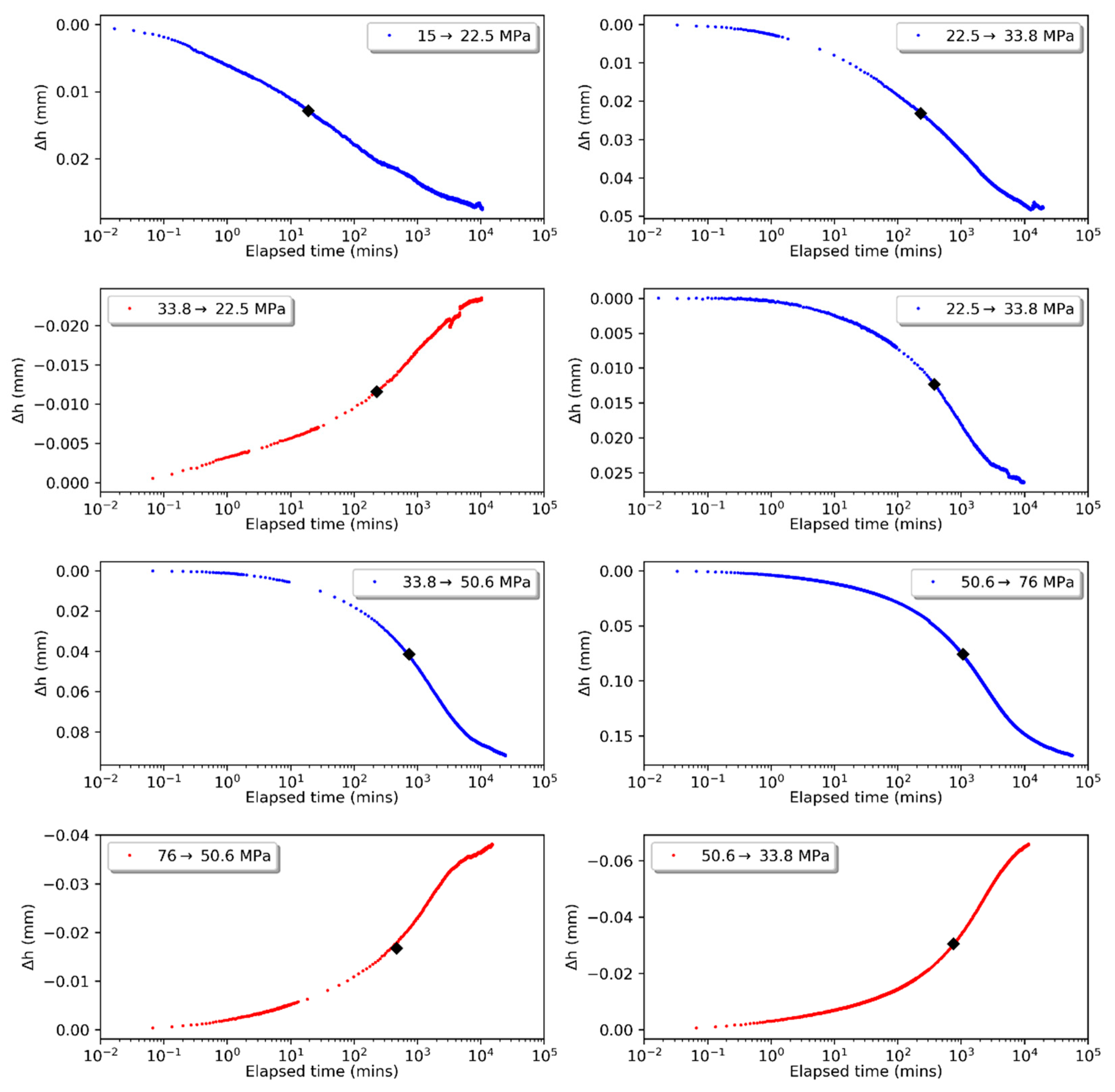

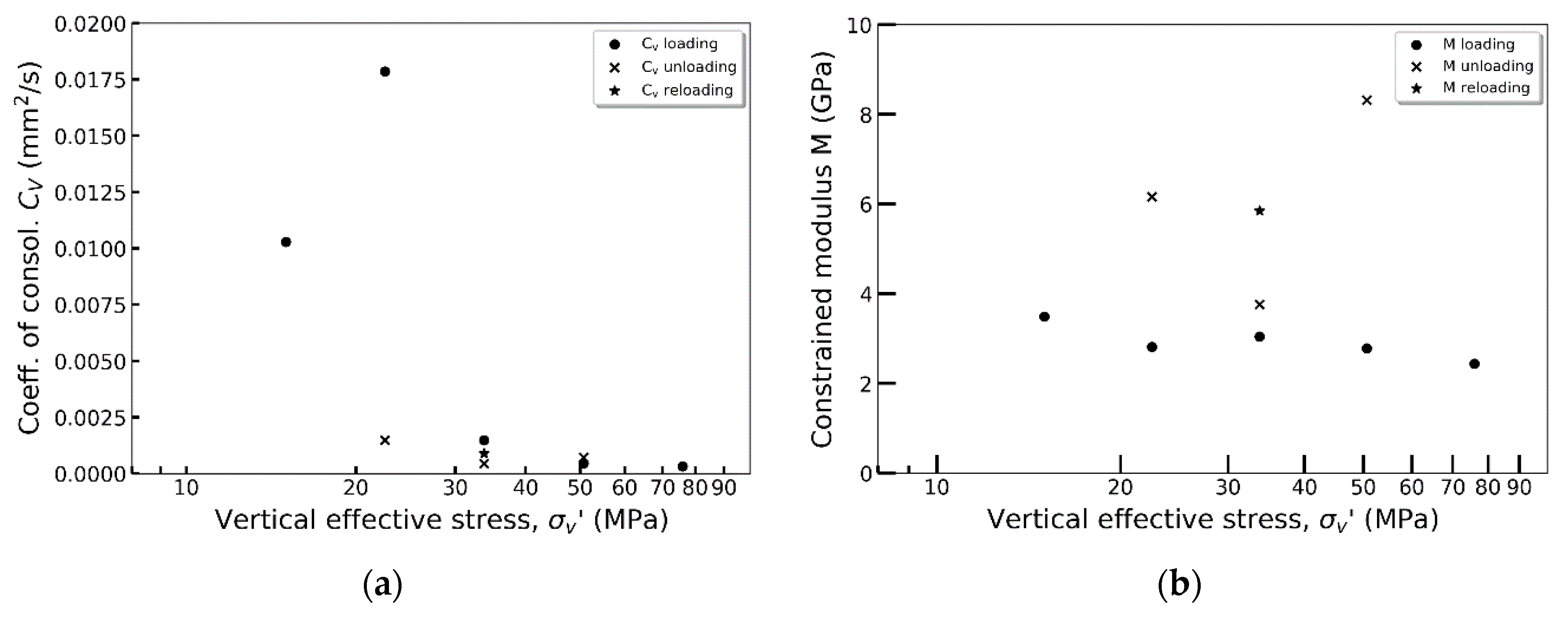

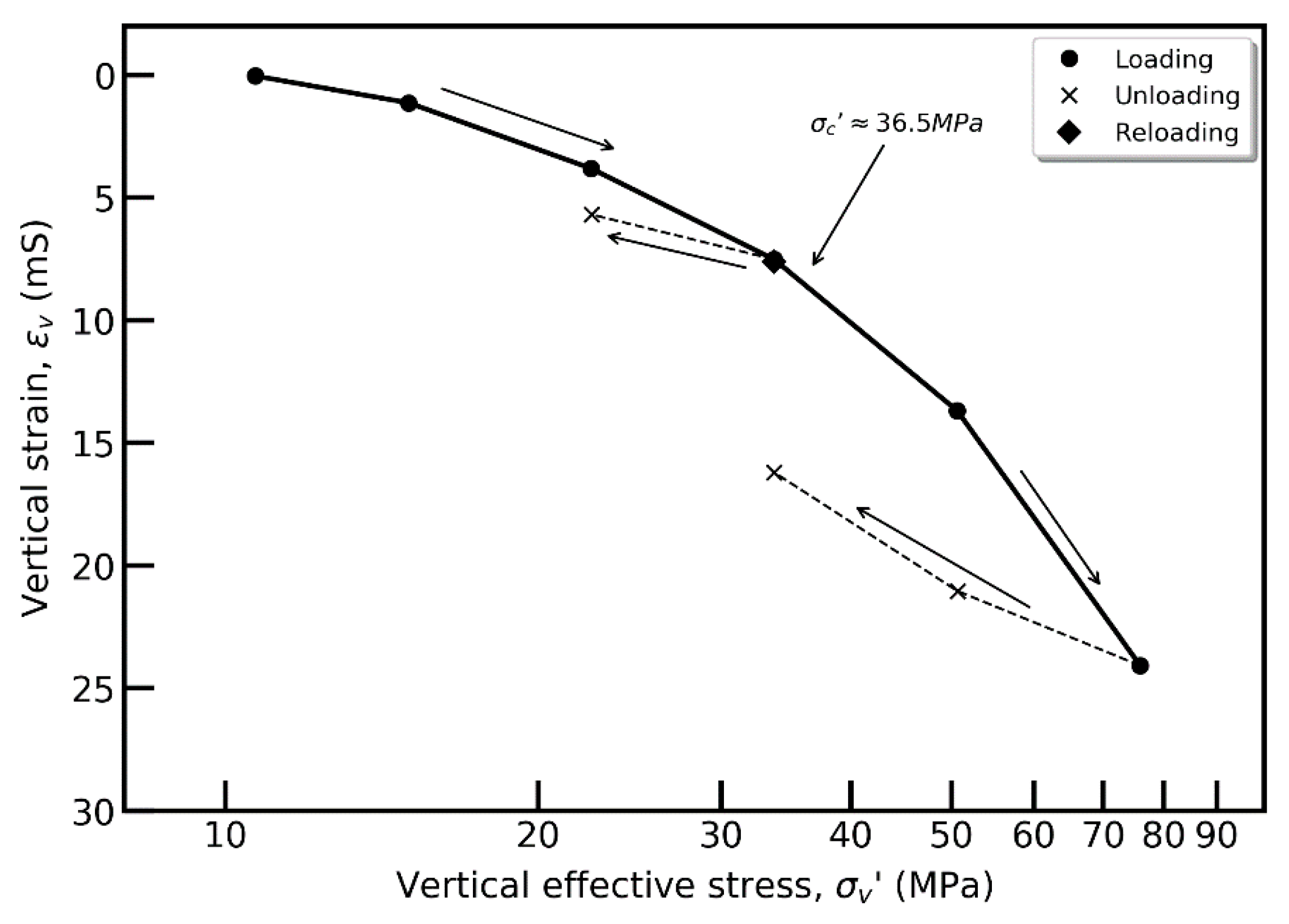

4.1. Oedometer

4.2. Triaxial Testing-Consolidation

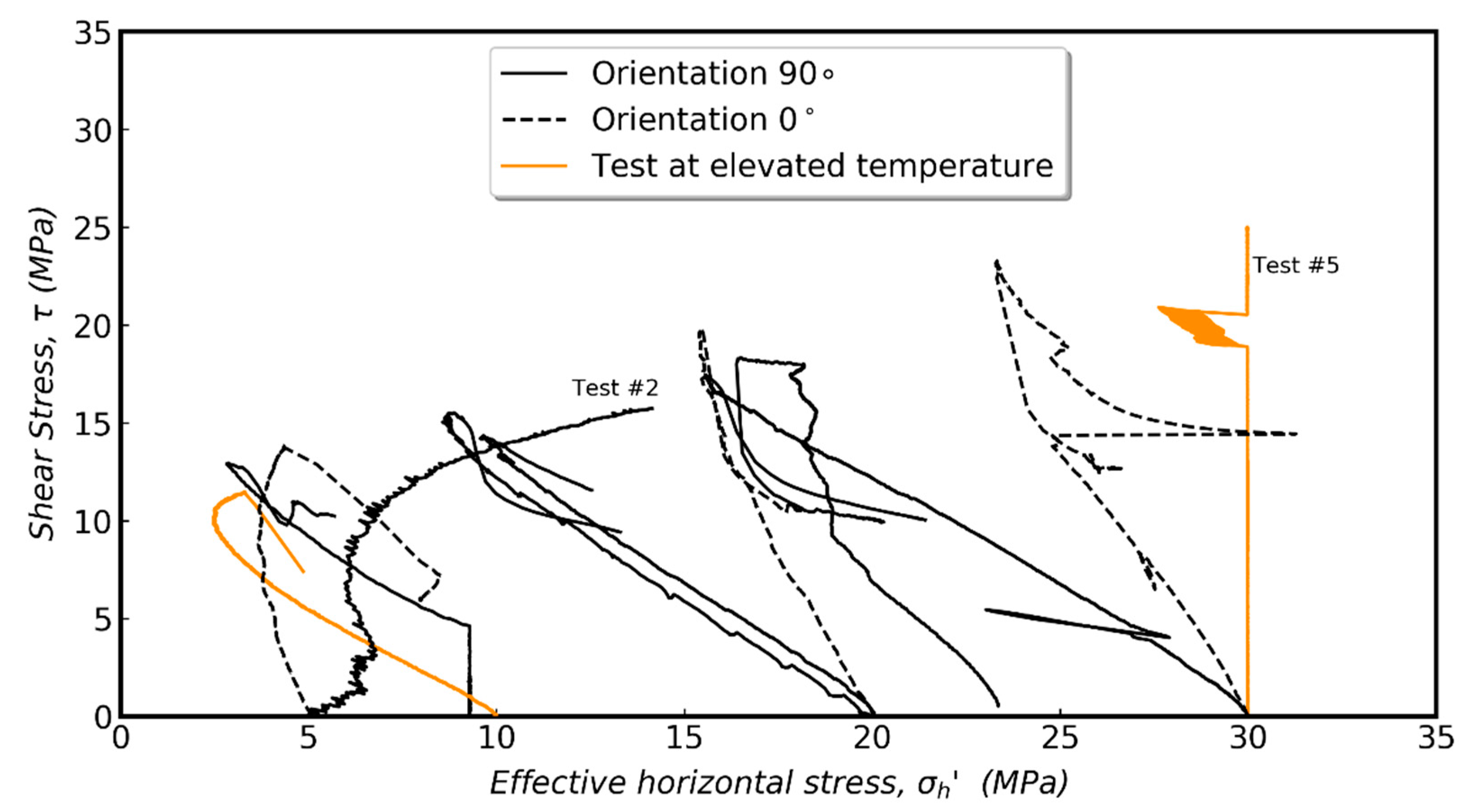

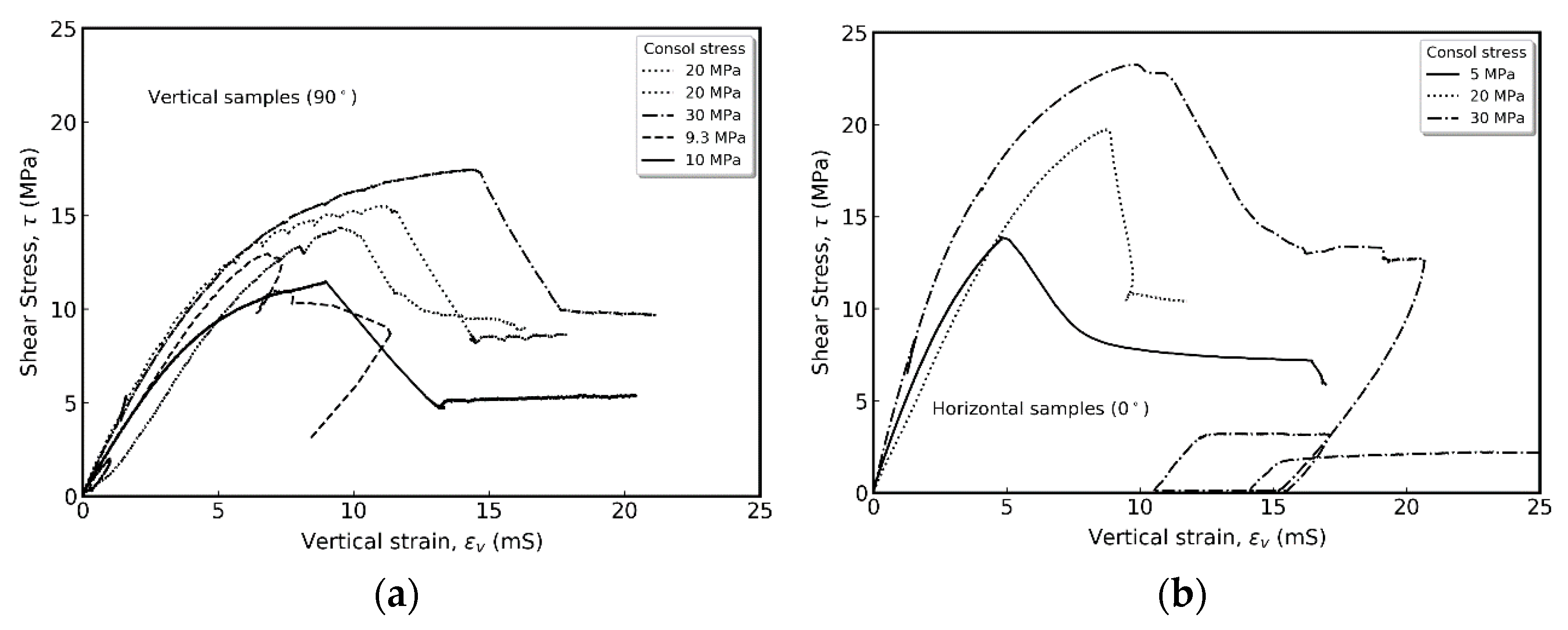

4.3. Triaxial Testing-Shearing

4.3.1. Elastic Parameters

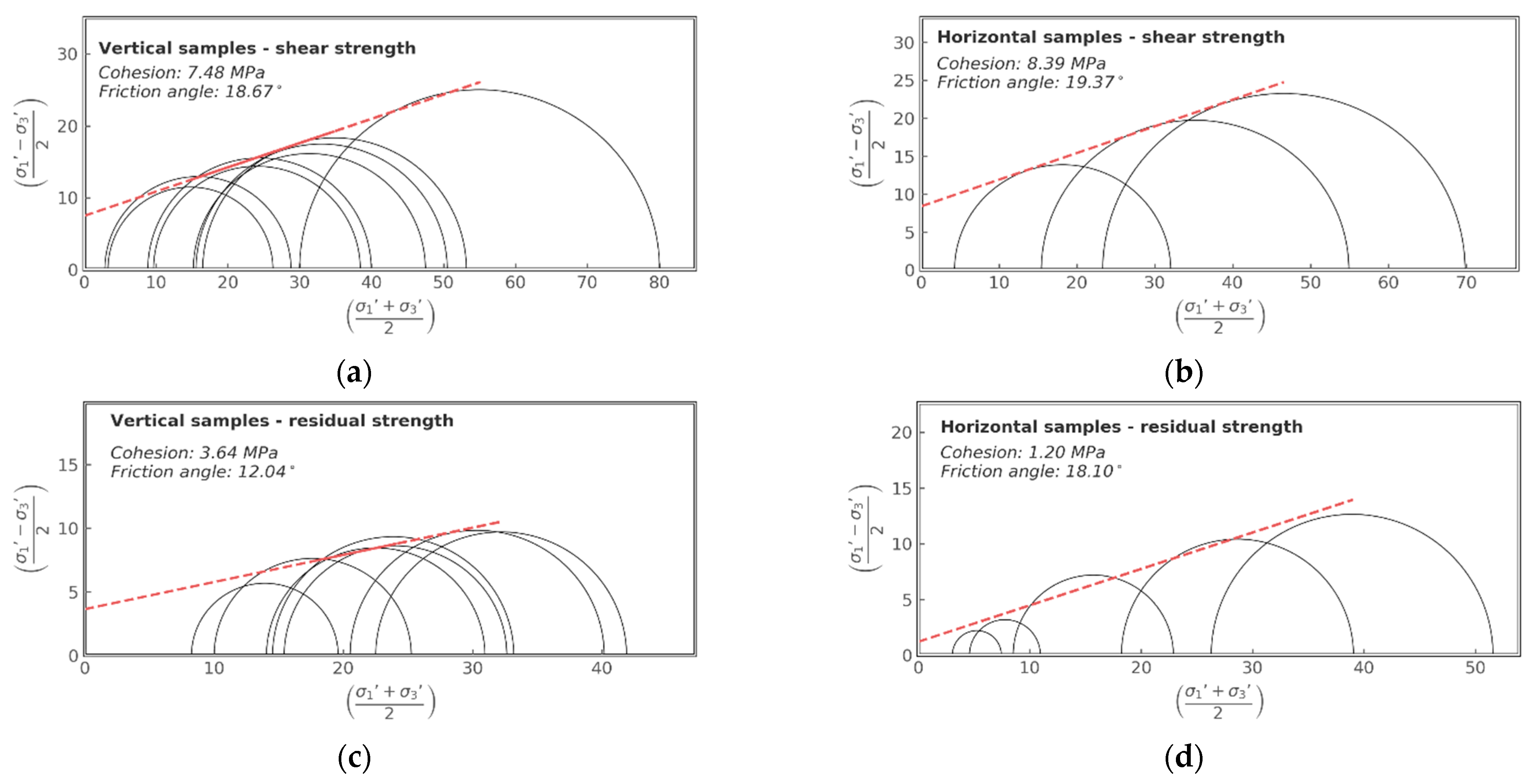

4.3.2. Intact and Residual Strength

5. Discussion

6. Conclusions

- For the intact vertical samples, an apparent cohesion of 7.5 MPa and a friction angle of 18.7° were estimated based on constructed Mohr Coulomb failure envelope. Relatively similar values were found for the horizontal samples (cohesion 8.4 MPa and friction 19.4°). In terms of residual strength, the constructed failure envelopes showed a significant reduction in cohesion, whereas the reduction in friction angles was less significant. Both intact and residual strengths are important in the operational design of CO2 injection operations to avoid fracture creation or reactivation of pre-existing weakness planes.

- Secant-undrained Young’s modulus measured between 40 and 60% of peak stress was between 4.2 and 4.7 GPa for vertical samples and 5.7–7.1 GPa for horizontal samples. The average secant Poisson’s ratios for samples of both principal directions were close to 0.5.

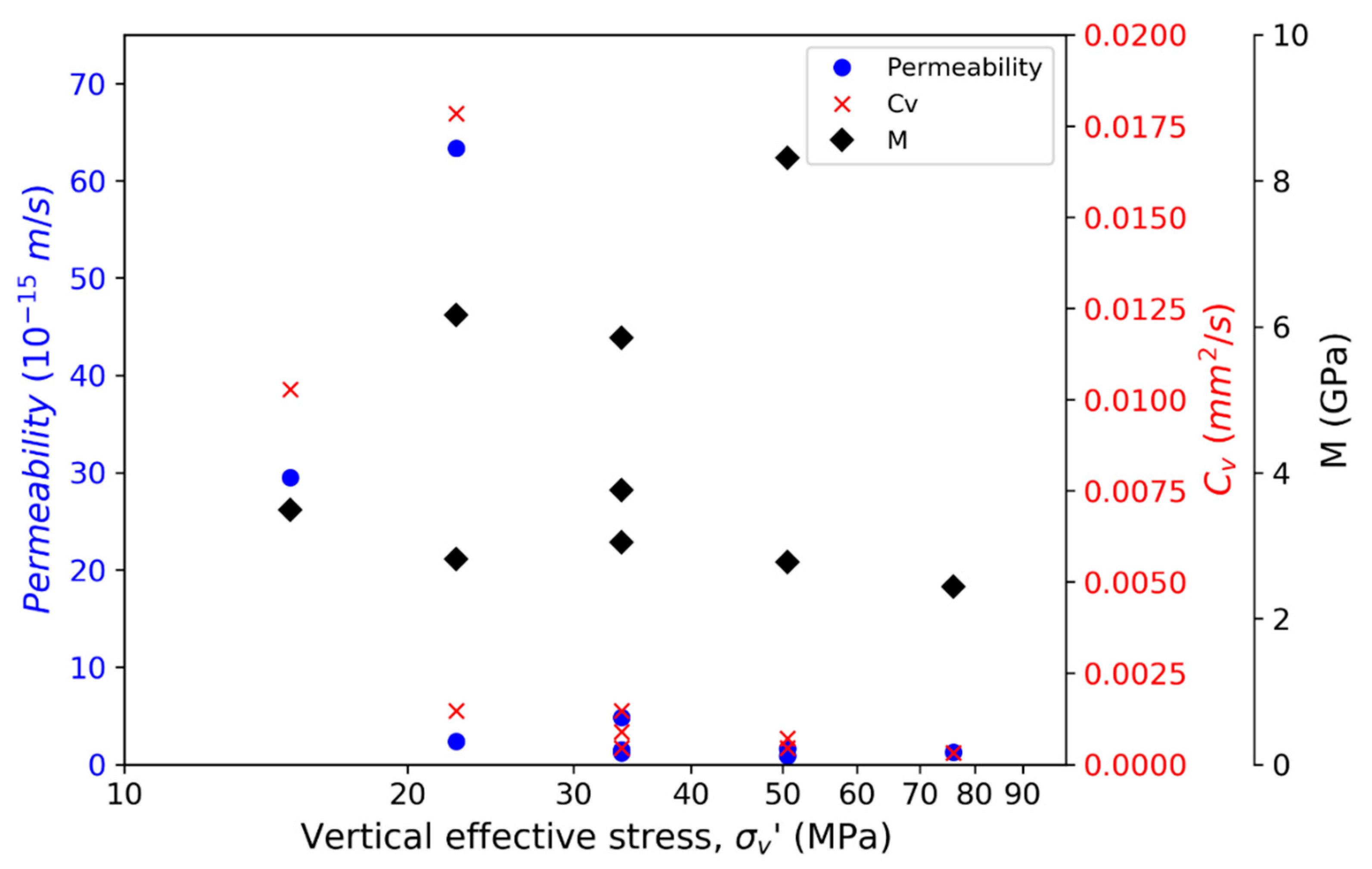

- Whereas the measured constrained modulus from oedometer testing showed little or no stress dependency, the coefficient of consolidation decreased with increasing effective vertical stress. Hydraulic permeability estimated from constrained modulus and coefficient of consolidation therefore also decreased with increasing effective vertical stress. Increasing effective vertical stress from 33 to 75 MPa caused a reduction in hydraulic permeability of around 15%.

- The apparent pre-consolidation stress determined from oedometer incremental loading was 36.5 MPa. Consequently, the tested Draupne shale is considered normally consolidated to lightly overconsolidated. The measured undrained strength from triaxial testing normalized against the effective vertical consolidation stress correlated quite well with overconsolidation ratio following the SHANSEP normalization procedure developed for clays.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rutqvist, J. The geomechanics of CO2 storage in deep sedimentary formations. Geotech. Geol. Eng. 2012, 30, 525–551. [Google Scholar] [CrossRef]

- Bachu, S. CO2 storage in geological media: Role, means, status and barriers to deployment. Prog. Energy Combust. Sci. 2008, 34, 254–273. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Schlömer, S.; Krooss, B.M.; Littke, R. Gas breakthrough experiments on pelitic rocks: Comparative study with N2, Co2 and Ch4. Geofluids 2004, 4, 61–80. [Google Scholar] [CrossRef]

- Li, S.; Dong, M.; Li, Z.; Huang, S.; Qing, H.; Nickel, E. Gas breakthrough pressure for hydrocarbon reservoir seal rocks: Implications for the security of long-term CO2 storage in the Weyburn field. Geofluids 2005, 5, 326–334. [Google Scholar] [CrossRef]

- Springer, N.; Lindgren, H. Caprock properties of the nordland shale recovered from the 15/9-A11 Well, the Sleipner Area. In Proceedings of the Greenhouse Gas Technology Conference 2006 (GHGT-8), Trondeim, Norway, 19–22 June 2006; pp. 1–6. [Google Scholar]

- Bergmo, P.E.S.; Grimstad, A.-A.; Lindeberg, E. Simultaneous CO2 injection and water production to optimise aquifer storage capacity. Int. J. Greenh. Gas Control 2011, 5, 555–564. [Google Scholar] [CrossRef]

- Espinoza, D.N.; Santamarina, J.C. CO2 breakthrough—Caprock sealing efficiency and integrity for carbon geological storage. Int. J. Greenh. Gas Control 2017, 66, 218–222. [Google Scholar] [CrossRef]

- Orlic, B. Some geomechanical aspects of geological CO2 sequestration. KSCE J. Civ. Eng. 2009, 13, 225–232. [Google Scholar] [CrossRef]

- Rutqvist, J.; Tsang, C.-F. A study of caprock hydromechanical changes associated with CO2-injection into a brine formation. Environ. Earth Sci. 2002, 42, 296–305. [Google Scholar] [CrossRef]

- Hawkes, C.D.; McLellan, P.J.; Zimmer, U.; Bachu, S. Geomechanical factors affecting geological storage of CO2 in depleted oil and gas reservoirs: Risks and mechanisms. In Proceedings of the 6th North America Rock Mechanics Symposium (NARMS) 2004, Houston, TX, USA, 7–9 June 2004. [Google Scholar]

- Bao, J.; Hou, Z.; Fang, Y.; Ren, H.; Lin, G. Uncertainty quantification for evaluating impacts of caprock and reservoir properties on pressure buildup and ground surface displacement during geological CO2 sequestration. Greenh. Gases Sci. Technol. 2013, 3, 338–358. [Google Scholar] [CrossRef]

- Newell, P.; Yoon, H.; Martinez, M.; Bishop, J.; Bryant, S. Investigation of the influence of geomechanical and hydrogeological properties on surface uplift at In Salah. J. Pet. Sci. Eng. 2017, 155, 34–45. [Google Scholar] [CrossRef]

- Gutierrez, M.; Nygård, R.; Høeg, K.; Berre, T. Normalized undrained shear strength of clay shales. Eng. Geol. 2008, 99, 31–39. [Google Scholar] [CrossRef]

- Fjaer, E.; Holt, R.M.; Horsrud, P.; Raaen, A.M.; Risnes, R. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Giger, S.B.; Ewy, R.T.; Favero, V.; Stankovic, R.; Keller, L.M. Consolidated-undrained triaxial testing of Opalinus Clay: Results and method validation. Géoméch. Energy Environ. 2018, 14, 16–28. [Google Scholar] [CrossRef]

- Minardi, A.; Giger, S.B.; Ewy, R.T.; Stankovic, R.; Stenebråten, J.; Soldal, M.; Rosone, M.; Ferrari, A.; Laloui, L. Benchmark study of undrained triaxial testing of Opalinus Clay shale: Results and implications for robust testing. Geomech. Energy Environ. 2001, 25, 100210. [Google Scholar] [CrossRef]

- Favero, V.; Ferrari, A.; Laloui, L. Anisotropic behaviour of Opalinus Clay through consolidated and drained triaxial testing in saturated conditions. Rock Mech. Rock Eng. 2018, 51, 1305–1319. [Google Scholar] [CrossRef]

- Giger, S.; Ewy, R.; Stankovic, R. Consolidated-undrained triaxial test results of Opalinus Clay and comparison with caprock Shales. In Advances in Laboratory Testing and Modelling of Soils and Shales (ATMSS); Springer: Cham, Switzerland, 2017; pp. 330–337. [Google Scholar]

- Gutierrez, M.; Katsuki, D.; Tutuncu, A. Determination of the continuous stress-dependent permeability, compressibility and poroelasticity of shale. Mar. Pet. Geol. 2015, 68, 614–628. [Google Scholar] [CrossRef]

- Islam, A.; Skalle, P. An experimental investigation of shale mechanical properties through drained and undrained test mechanisms. Rock Mech. Rock Eng. 2013, 46, 1391–1413. [Google Scholar] [CrossRef]

- Nygård, R.; Gutierrez, M.; Bratli, R.K.; Høeg, K. Brittle–ductile transition, shear failure and leakage in shales and mudrocks. Mar. Pet. Geol. 2006, 23, 201–212. [Google Scholar] [CrossRef]

- Valès, F.; Minh, D.N.; Gharbi, H.; Rejeb, A. Experimental study of the influence of the degree of saturation on physical and mechanical properties in Tournemire shale (France). Appl. Clay Sci. 2004, 26, 197–207. [Google Scholar] [CrossRef]

- Wild, K.M.; Barla, M.; Turinetti, G.; Amann, F. A multi-stage triaxial testing procedure for low permeable geomaterials applied to Opalinus Clay. J. Rock Mech. Geotech. Eng. 2017, 9, 519–530. [Google Scholar] [CrossRef]

- Gabrielsen, R.H.; Skurtveit, E.; Faleide, J.I. Caprock integrity of the Draupne Formation, Ling Depression, North Sea, Norway. Nor. J. Geol. 2020, 100. [Google Scholar] [CrossRef]

- Bohloli, B.; Soldal, M.; Smith, H.; Skurtveit, E.; Choi, J.C.; Sauvin, G. Frictional Properties and Seismogenic Potential of Caprock Shales. Energies 2020, 13, 6275. [Google Scholar] [CrossRef]

- Grande, L.; Griffith, L.; Park, J.; Choi, J.; Bjørnarå, T.; Sauvin, G.; Mondol, N. Acoustic emission testing of shales for evaluation of microseismic monitoring of North Sea CO2 storage sites. In Proceedings of the EAGE 2020 Annual Conference & Exhibition Online 2020, Houten, The Netherlands, 8–11 December 2020. [Google Scholar]

- Zadeh, K.; Mohammad; Mondol, N.H.; Jahren, J. Velocity anisotropy of upper jurassic organic-rich shales, Norwegian continental shelf. Geophysics 2017, 82. [Google Scholar] [CrossRef]

- Skurtveit, E.; Grande, L.; Ogebule, O.Y.; Gabrielsen, R.H.; Faleide, J.I.; Mondol, N.H.; Maurer, R.; Horsrud, P. Mechanical Testing and Sealing Capacity of the Upper Jurassic Draupne Formation, North Sea. In Proceedings of the 49th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 29 June–1 July 2015. [Google Scholar]

- Smith, H. Engineering Parameters of Draupne Shale—Characterization of Fractured Samples and Integration with Mechanical Tests. Master’s Thesis, University of Oslo, Oslo, Norway, 2019. [Google Scholar]

- Dewhurst, D.N.; Siggins, A.F. Impact of fabric, microcracks and stress field on shale anisotropy. Geophys. J. Int. 2006, 165, 135–148. [Google Scholar] [CrossRef]

- Dewhurst, D.; Siggins, A.F.; Sarout, J.; Raven, M.D.; Nordgård-Bolås, H.M. Geomechanical and ultrasonic characterization of a Norwegian Sea shale. Geophysics 2011, 76, WA101–WA111. [Google Scholar] [CrossRef]

- Sarout, J.; Guéguen, Y. Anisotropy of elastic wave velocities in deformed shales: Part 2—Modeling results. Geophysics 2008, 73, D91–D103. [Google Scholar] [CrossRef]

- Færseth, B.R.; Gabrielsen, R.H.; Hurich, C.A. Influence of basement in structuring of the North Sea basin, offshore Southwest Norway. Nor. Geol. Tidsskr. 1005, 75, 105–119. [Google Scholar]

- Whipp, P.S.; Jackson, C.A.-L.; Gawthorpe, R.L.; Dreyer, T.; Quinn, D.J. Normal fault array evolution above a reactivated rift fabric; a subsurface example from the northern Horda Platform, Norwegian North Sea. Basin Res. 2014, 26, 523–549. [Google Scholar] [CrossRef]

- Faleide, J.I.; Bjørlykke, K.; Gabrielsen, R.H. Geology of the Norwegian continental shelf. In Petroleum Geoscience: From Sedimentary Environments to Rock Physics; Bjorlykke, K., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 467–499. [Google Scholar]

- Underhill, J.R. Jurassic. In Petroleum Geology of the North Sea; Wiley: Hoboken, NJ, USA, 2009; pp. 245–293. [Google Scholar]

- Fossen, H.; Hurich, C.A. The Hardangerfjord Shear Zone in SW Norway and the North Sea: A large-scale low-angle shear zone in the Caledonian crust. J. Geol. Soc. 2005, 162, 675–687. [Google Scholar] [CrossRef]

- Norwegian Petroleum Directorate. Ndp Factmaps. Available online: https://factmaps.npd.no/factmaps/3_0/ (accessed on 12 March 2021).

- Hansen, J.A.; Mondol, N.H.; Fawad, M. Organic content and maturation effects on elastic properties of source rock shales in the Central North Sea. Interpretation 2019, 7, T477–T497. [Google Scholar] [CrossRef]

- Busch, A.; Schweinar, K.; Kampman, N.; Coorn, A.; Pipich, V.; Feoktystov, A.; Leu, L.; Amann-Hildenbrand, A.; Bertier, P. Determining the porosity of mudrocks using methodological pluralism. Geol. Soc. Lond. Spéc. Publ. 2017, 454, 15–38. [Google Scholar] [CrossRef]

- Badics, B.; Avu, A.; Mackie, S. Assessing source rock distribution in Heather and Draupne Formations of the Norwegian North Sea: A workflow using organic geochemical, petrophysical, and seismic character. Interpretation 2015, 3, SV45–SV68. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Jackson, M.L. Soil Chemical Analysis; Prentice-Hall: Englewood Cliffs, NJ, USA, 1958. [Google Scholar]

- Skurtveit, E.; Aker, E.; Soldal, M.; Angeli, M.; Wang, Z. Experimental investigation of CO2 breakthrough and flow mechanisms in shale. Pet. Geosci. 2012, 18, 3–15. [Google Scholar] [CrossRef]

- Ewy, R.T. Shale/claystone response to air and liquid exposure, and implications for handling, sampling and testing. Int. J. Rock Mech. Min. Sci. 2015, 80, 388–401. [Google Scholar] [CrossRef]

- Zadeh, K.; Mohammad; Mondol, N.H.; Jahren, J. Experimental mechanical compaction of sands and sand—Clay mixtures: A study to investigate evolution of rock properties with full control on mineralogy and rock texture. Geophys. Prospect. 2016, 64, 915–941. [Google Scholar] [CrossRef]

- Mondol, N.H.; Bjørlykke, K.; Jahren, J.; Høeg, K. Experimental mechanical compaction of clay mineral aggregates—Changes in physical properties of mudstones during burial. Mar. Pet. Geol. 2007, 24, 289–311. [Google Scholar] [CrossRef]

- Nooraiepour, M.; Mondol, N.H.; Hellevang, H.; Bjørlykke, K. Experimental mechanical compaction of reconstituted shale and mudstone aggregates: Investigation of petrophysical and acoustic properties of SW Barents Sea cap rock sequences. Mar. Pet. Geol. 2017, 80, 265–292. [Google Scholar] [CrossRef]

- Mesri, G.; Hayat, T.M. The coefficient of earth pressure at rest. Can. Geotech. J. 1993, 30, 647–666. [Google Scholar] [CrossRef]

- Casagrande, A. The determination of pre-consolidation load and it’s practical significance. In Proceedings of the International Conference on Soil Mechanics and Foundation Engineering, Harvard, MA, USA, 22–26 June 1936. [Google Scholar]

- Ferrari, A.; Favero, V.; Laloui, L. One-dimensional compression and consolidation of shales. Int. J. Rock Mech. Min. Sci. 2016, 88, 286–300. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; Wiley: New York, NY, USA, 1943. [Google Scholar]

- Casagrande, A.; Fadum, R.E. Notes on Soil Testing for Engineering Purposes; Harvard University: Cambridge, MA, USA, 1940. [Google Scholar]

- ASTM. D2435/D2435m-11(2020) Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Head, K.H. Manual of Soil Laboratory Testing; Volume 3: Effective Stress Tests; Pentech Press: London, UK, 1986. [Google Scholar]

- Blight, G.E. The Effect of Nonuniform Pore Pressures on Laboratory Measurements of the Shear Strength of Soils; ASTM International: West Conshohocken, PA, USA, 2009; p. 173. [Google Scholar]

- Suits, L.D.; Sheahan, T.C.; Berre, T. Triaxial testing of soft rocks. Geotech. Test. J. 2011, 34, 61–75. [Google Scholar] [CrossRef]

- Al-Mhaidib, A.I. Swelling behaviour of expansive shales from the middle region of Saudi Arabia. Geotech. Geol. Eng. 1998, 16, 291–307. [Google Scholar] [CrossRef]

- Crisci, E.; Ferrari, A.; Giger, S.B.; Laloui, L. Hydro-mechanical behaviour of shallow Opalinus Clay shale. Eng. Geol. 2019, 251, 214–227. [Google Scholar] [CrossRef]

- Ewy, R.T. Shale swelling/shrinkage and water content change due to imposed suction and due to direct brine contact. Acta Geotech. 2014, 9, 869–886. [Google Scholar] [CrossRef]

- Mohajerani, M.; Delage, P.; Monfared, M.; Tang, A.; Sulem, J.; Gatmiri, B. Oedometric compression and swelling behaviour of the Callovo-Oxfordian argillite. Int. J. Rock Mech. Min. Sci. 2011, 48, 606–615. [Google Scholar] [CrossRef]

- Skempton, A.W. Horizontal stresses in an Over-Consolidated Eocene Clay. In Selected Papers on Soil Mechanics; Thomas Telford Ltd.: London, UK, 1984; pp. 119–125. [Google Scholar]

- Ong, O.N.; Schmitt, D.R.; Kofman, R.S.; Haug, K. Static and dynamic pressure sensitivity anisotropy of a calcareous shale. Geophys. Prospect. 2016, 64, 875–897. [Google Scholar] [CrossRef]

- Piane, C.D.; Dewhurst, D.; Siggins, A.F.; Raven, M.D. Stress-induced anisotropy in brine saturated shale. Geophys. J. Int. 2011, 184, 897–906. [Google Scholar] [CrossRef]

- Sondergeld, C.H.; Rai, C.S. Elastic anisotropy of shales. Geophysics 2011, 30, 324–331. [Google Scholar] [CrossRef]

- Ladd, C.C.; Foott, R. New design procedure for stability of soft clays: 10F, 3T, 39R. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1974, 11, A220. [Google Scholar] [CrossRef]

- Horsrud, P.; Sønstebø, E.F.; Bøe, R. Mechanical and petrophysical properties of North Sea Shales. Int. J. Rock Mech. Min. Sci. 1998, 35, 1009–1020. [Google Scholar] [CrossRef]

- Okland, D.; Cook, J.M. Bedding-related borehole instability in high-angle wells. In Proceedings of the SPE/ISRM Rock Mechanics in Petroleum Engineering, Trondheim, Norway, 8–9 July 1998. [Google Scholar]

| Mineralogical Composition (wt.%) | |

|---|---|

| Quartz | 19–25 |

| Feldspars | 7–18 |

| Carbonates | 2–7 |

| Pyrite | 3–13 |

| Total clay | 41–53 |

| Total organic content | 6–8 |

| Bulk density (g/cm3) | 2.25 |

| Initial porosity (%) | 15.1 |

| Surface area (m2/g) | 11 ± 1 |

| Cationic exchange cap. (meq/100 g) | 23 |

| Critical pore diameter (nm) | 9 |

| Vertical coeff. of permeability (m/s) | 1.3 × 10−15 |

| Horizontal coeff. of permeability (m/s) | 5.8 × 10−15 |

| Load Steps during Incremental Loading in Oedometer | ||

|---|---|---|

| Load Step | σV′ Start of Load Step (MPa) | σV′ End of Load Step (MPa) |

| 10.7 | 15 |

| 15 | 22.5 |

| 22.5 | 33.75 |

| 33.75 | 22.5 |

| 22.5 | 33.75 |

| 33.75 | 50.63 |

| 50.63 | 75.95 |

| 75.95 | 50.63 |

| 50.63 | 30.75 |

| Test # | Test ID | εv = 0 during Re-Saturation | Drained Isotropic Loading | Uniaxial Strain Loading | Drained Anisotropic Loading | Undrained Shearing | |

|---|---|---|---|---|---|---|---|

| 1 | Vertical plugs | CIU_90_20_A | x | ||||

| 2 | CIU_90_5_A | x | |||||

| 3 | CIU_90_20_B | x | |||||

| 4 | CIU_90_30_A | x | |||||

| 5 | CIDt_90_30_A | ||||||

| 6 | CIUt_90_10_A | x | |||||

| 7 | CIU_90_9.3_A | x | x | x | x | ||

| 8 | UST_90_23.9_A | x | x | x | |||

| 9 | Horizontal plugs | CIU_0_5_A | x | ||||

| 10 | CIU_0_20_A | x | |||||

| 11 | CIU_0_30_A | x | x | x | |||

| Parameter | Vertical Samples | Horizontal Samples | |

|---|---|---|---|

| Oedometer | Coefficient of consolidation (mm2/s) | 0.0003–0.0015 | |

| Constrained modulus, M (GPa) | Loading: 2.5–3.5 | ||

| Unloading: 3.8–8.3 | |||

| Apparent pre-consolidation stress (MPa) | 36.5 | ||

| Triaxial | Bulk modulus, Kb (GPa) | 3.09 | 2.97 |

| Undrained Young’s modulus, Eu (GPa) | 4.2–4.7 | 5.7–7.1 | |

| Undrained Poisson’s ratio, μu | 0.33–0.47 | 0.40–0.54 | |

| Drained Young’s modulus, E (GPa) | Loading: 3.7 | ||

| Drained Young’s modulus, E (GPa) Drained Poisson’s ratio, μ | Unloading: 4.6 | ||

| Loading: 0.14 | |||

| Drained Poisson’s ratio, μ Undrained shear modulus, Gu (GPa) | Unloading: 0.20 | ||

| 1.1–1.9 | 1.4–2.0 | ||

| Apparent cohesion (MPa) | 7.48 | 8.39 | |

| Friction angle (°) | 18.7 | 19.4 | |

| Residual apparent cohesion (MPa) | 3.6 | 1.2 | |

| Residual friction angle (°) | 12.0 | 18.1 |

| Material | a | b | R2 | Source |

|---|---|---|---|---|

| Draupne, Ling depression | 0.51 | 0.72 | 0.95 | Current study |

| “Draupne, North Sea” | 0.49 | 0.65 | 0.99 | [13] |

| “Kimmeridge, Dorset, UK” | 0.47 | 0.66 | 0.99 | [13] |

| “25 different types of shales” | 0.37 | 0.87 | 0.8 | [13] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soldal, M.; Skurtveit, E.; Choi, J.C. Laboratory Evaluation of Mechanical Properties of Draupne Shale Relevant for CO2 Seal Integrity. Geosciences 2021, 11, 244. https://doi.org/10.3390/geosciences11060244

Soldal M, Skurtveit E, Choi JC. Laboratory Evaluation of Mechanical Properties of Draupne Shale Relevant for CO2 Seal Integrity. Geosciences. 2021; 11(6):244. https://doi.org/10.3390/geosciences11060244

Chicago/Turabian StyleSoldal, Magnus, Elin Skurtveit, and Jung Chan Choi. 2021. "Laboratory Evaluation of Mechanical Properties of Draupne Shale Relevant for CO2 Seal Integrity" Geosciences 11, no. 6: 244. https://doi.org/10.3390/geosciences11060244

APA StyleSoldal, M., Skurtveit, E., & Choi, J. C. (2021). Laboratory Evaluation of Mechanical Properties of Draupne Shale Relevant for CO2 Seal Integrity. Geosciences, 11(6), 244. https://doi.org/10.3390/geosciences11060244