Two-Stage Geothermal Well Clustering for Oil-to-Water Conversion on Mature Oil Fields

Abstract

:1. Introduction

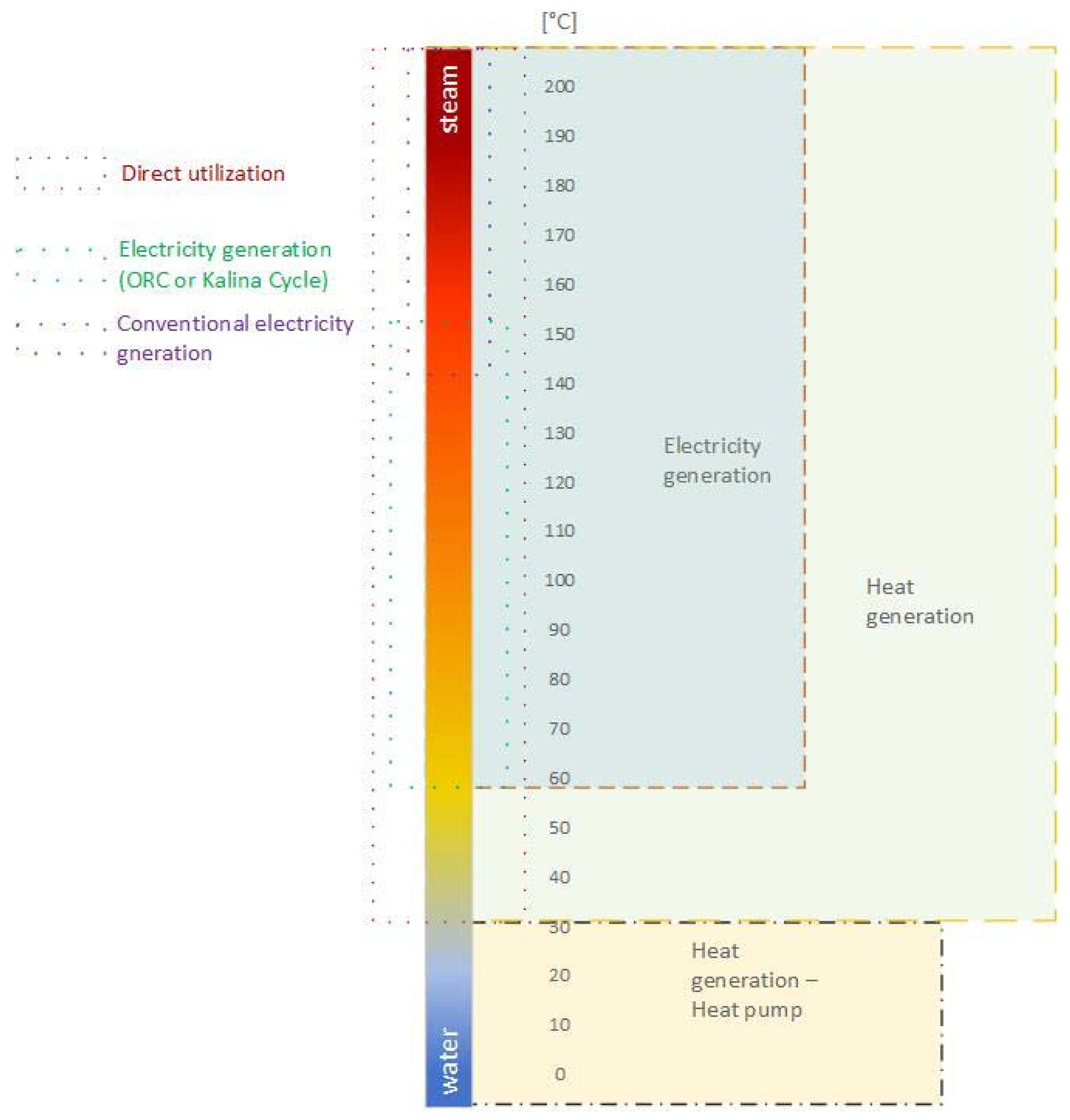

2. Background

2.1. Developed Scenarios

- Scenario 1—“Do nothing”

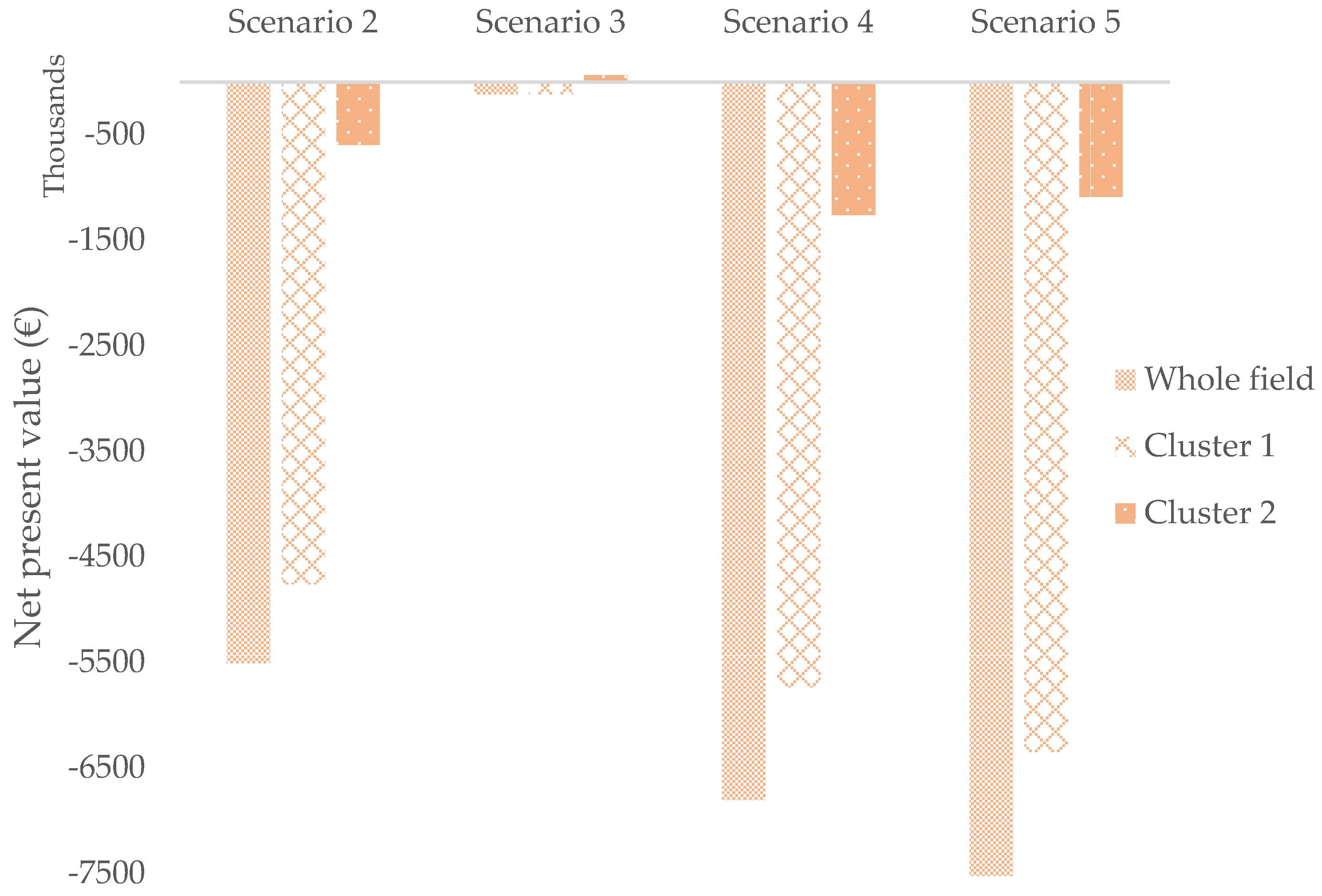

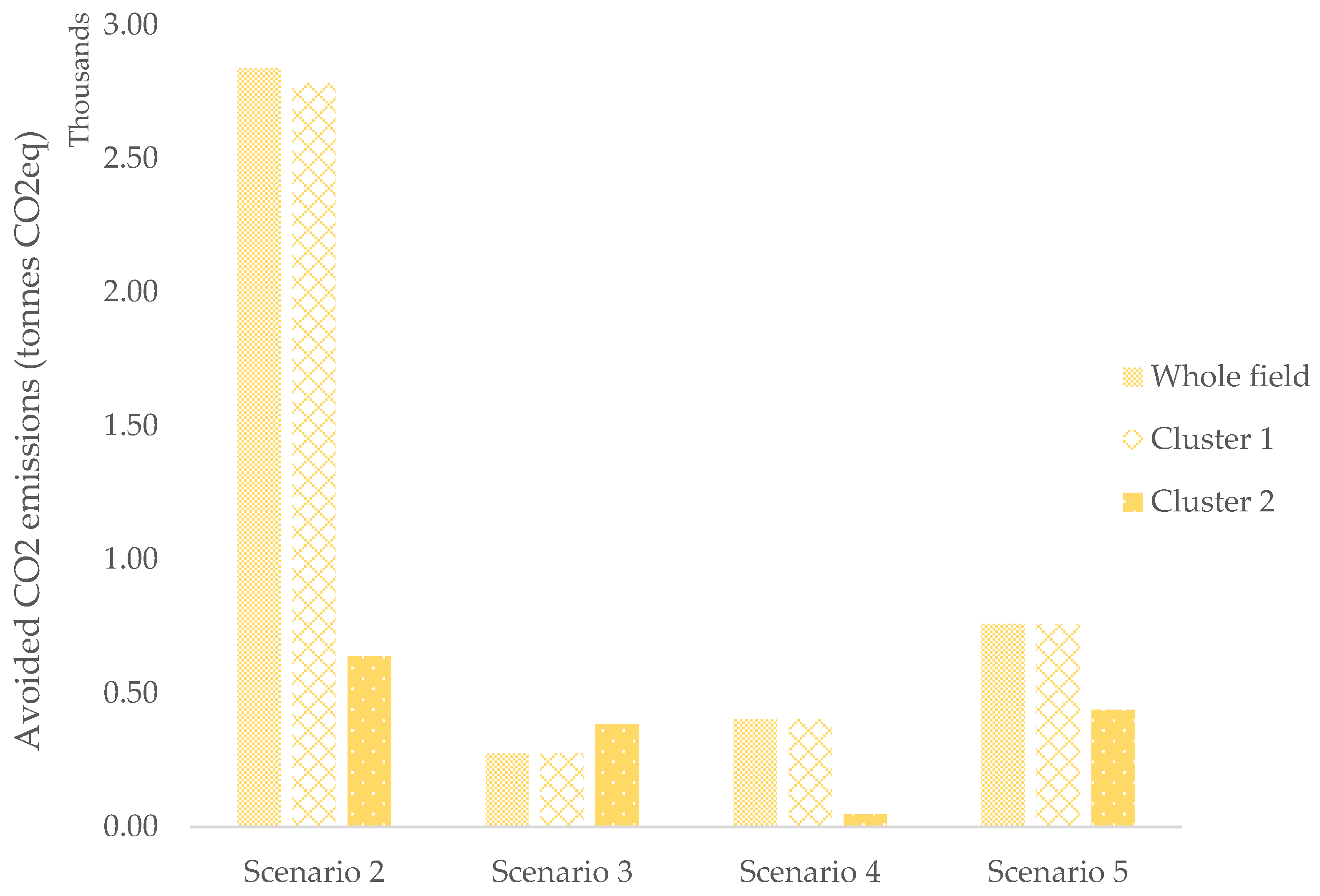

- Scenario 2—“Heat doublets”

- Scenario 3—“Heat via BHE”

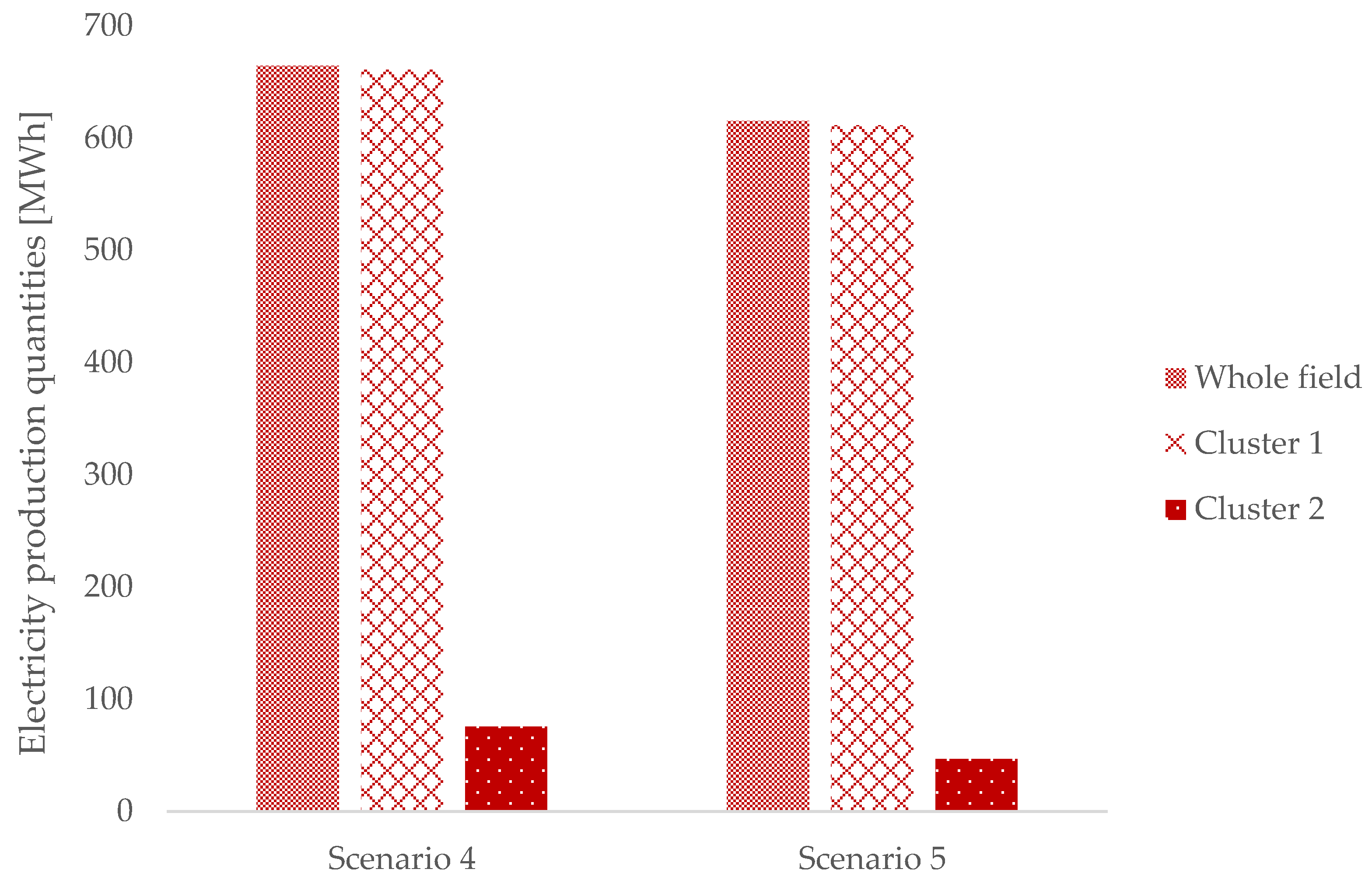

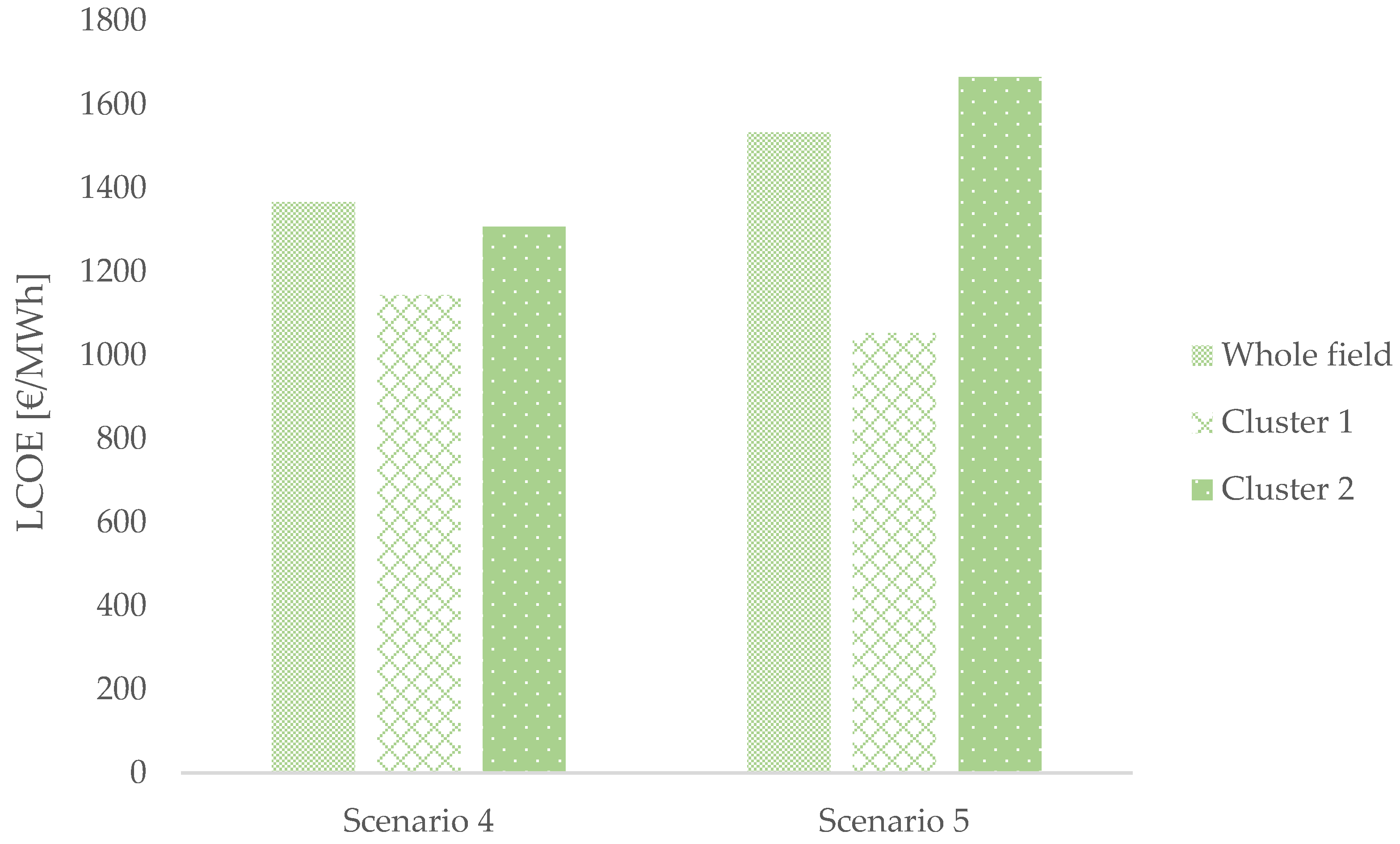

- Scenario 4—“ORC power production”

- Scenario 5—“Combined power and heat”

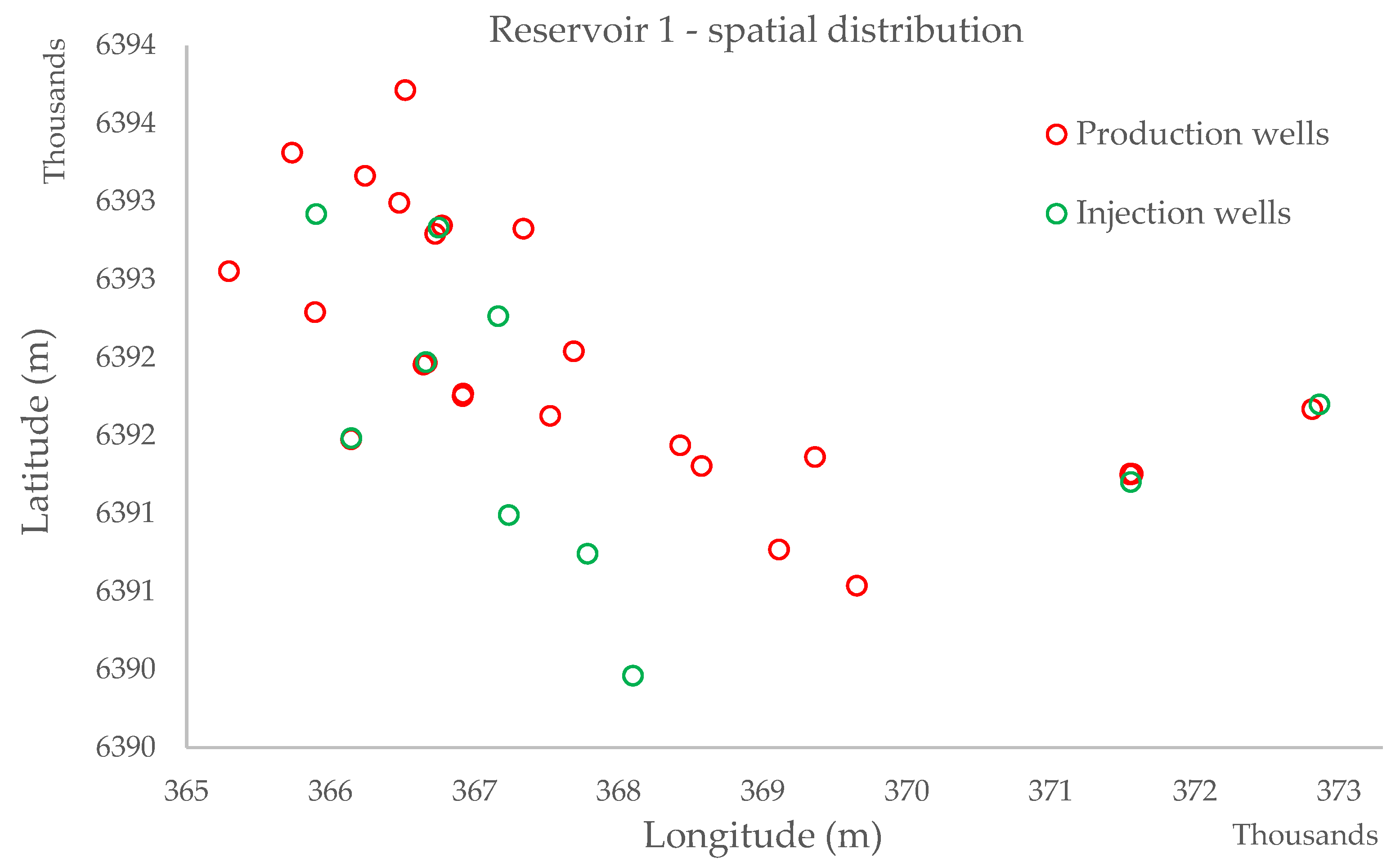

2.2. Input Data

3. Materials and Methods

3.1. Temperature Clustering

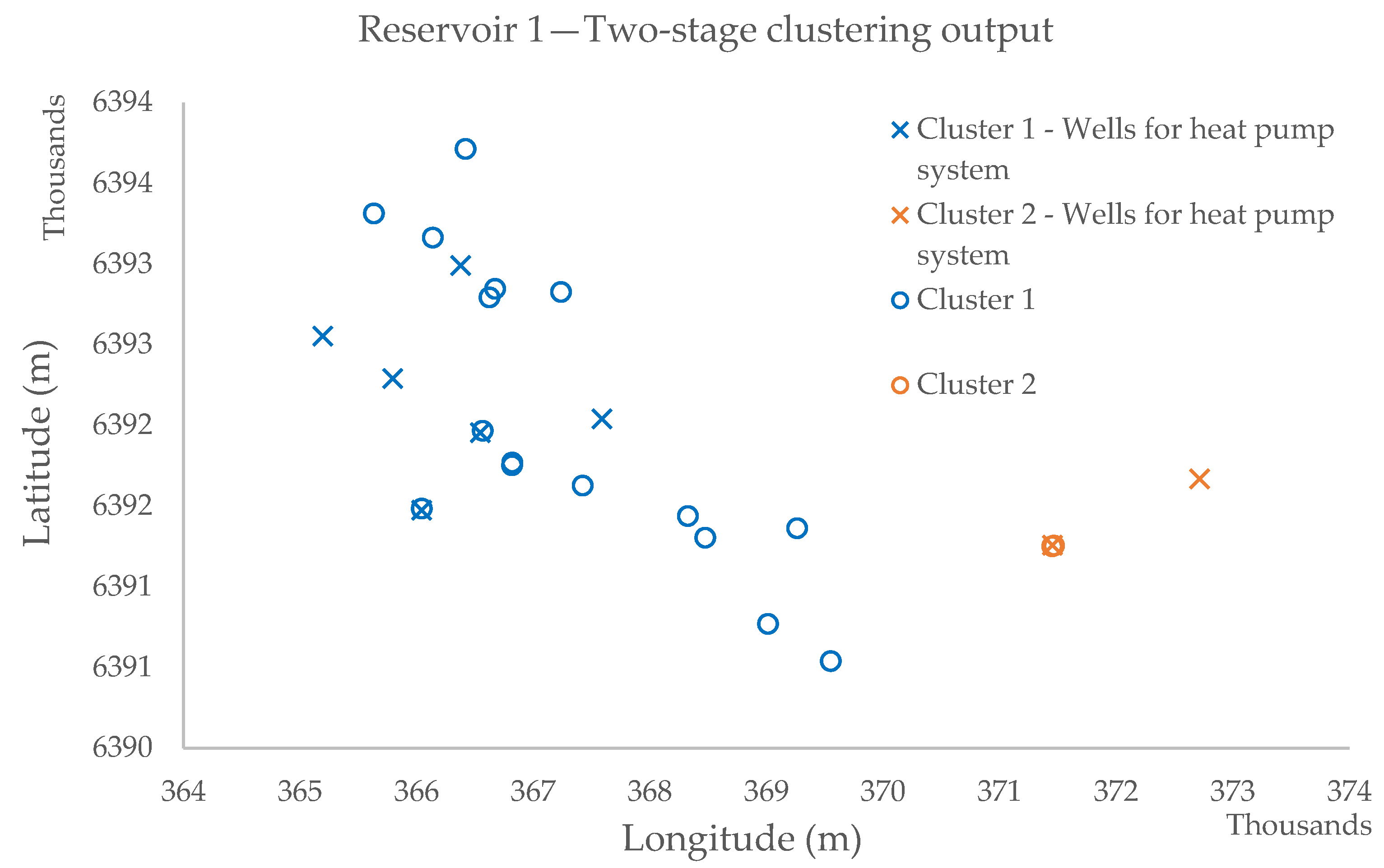

3.2. Spatial Clustering

- Epsilon, as the maximum distance between two data points for one to be considered as in the neighbourhood;

- Minimum samples, as the number of data points (or total weight) in a neighbourhood for a point to be recognized as a core point and includes the point itself;

- Metric, as the metric used when calculating the distance between instances in the array.

3.3. Outputs

3.3.1. Energy Production Quantities

- DT—temperature difference on primary side of dedicated heat exchanger;

- —net ORC power plant efficiency as function of geothermal brine extraction temperature (circulating fluid temperature in case of BHE) and .

3.3.2. Levelized Cost of Energy

3.3.3. Net Present Value

3.3.4. Avoided Emissions

4. Case Study

4.1. Modelling of the Heat Production Scenarios

4.2. Modelling of the Electricity Production Scenarios

4.3. Environmental and Economic Input Parameters

5. Results

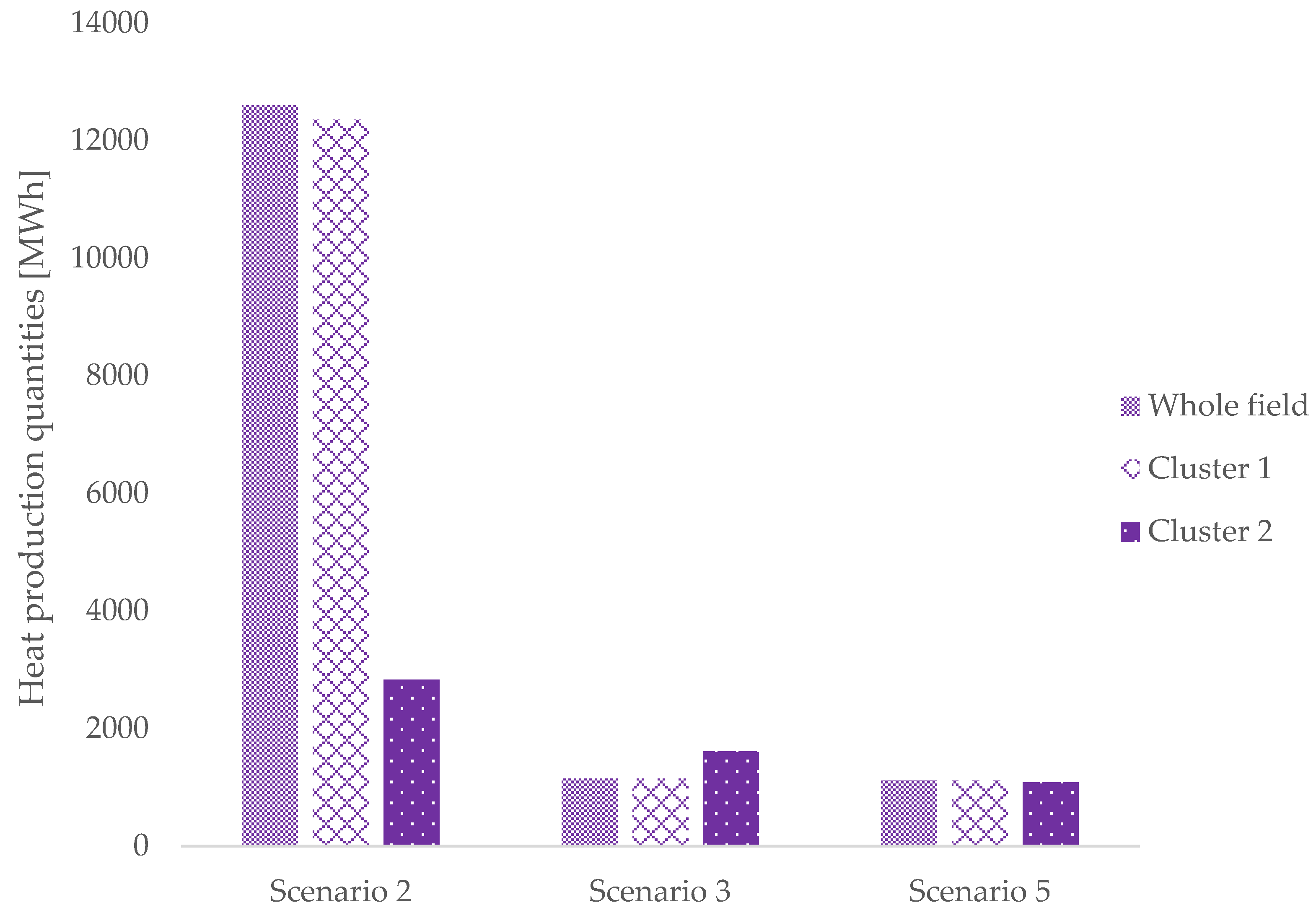

- Whole field—18 production wells;

- Cluster 1—16 production wells;

- Cluster 2—2 production wells.

5.1. Calculated Input Values

5.2. Methodology Outputs

6. Discussion

6.1. Economic Results

6.2. Environmental Results

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Source | Case | Working Fluid | Depth (m) | Bottomhole Temperature (°C) | Outlet Temperature from BHE (°C) | Temperature Ratio |

|---|---|---|---|---|---|---|

| [57] | Simulation | R–C318 | 5950 | 165.00 | 100.38 | 0.608 |

| [58] | Real | Isobutane | 1050 | 154.70 | 75.95 | 0.491 |

| Real | Isobutane | 1050 | 154.70 | 76.37 | 0.494 | |

| Real | Isobutane | 1050 | 154.70 | 74.51 | 0.482 | |

| Real | Isobutane | 1050 | 154.70 | 71.21 | 0.460 | |

| Real | Propane | 1050 | 154.70 | 77.75 | 0.503 | |

| Real | Propane | 1050 | 154.70 | 76.10 | 0.492 | |

| Real | Propane | 1050 | 154.70 | 73.61 | 0.476 | |

| Real | Isopentane | 1050 | 154.70 | 81.97 | 0.530 | |

| Real | Isopentane | 1050 | 154.70 | 81.72 | 0.528 | |

| Real | Isopentane | 1050 | 154.70 | 80.71 | 0.522 | |

| Real | Butane | 1050 | 154.70 | 78.51 | 0.507 | |

| Real | Butane | 1050 | 154.70 | 77.54 | 0.501 | |

| Real | Butane | 1050 | 154.70 | 74.48 | 0.481 | |

| [59] | Stimulation | Water | 5593 | 350.00 | 84.00 | 0.240 |

| [24] | Stimulation | Decafluoro-Butene | 1909 | 295.50 | 150.00 | 0.508 |

| [60] | Real | Water | 6800 | 211.48 | 130.00 | 0.615 |

| Real | Water | 6000 | 186.60 | 130.00 | 0.697 | |

| Real | Water | 4900 | 152.39 | 130.00 | 0.853 | |

| [61] | Real | Water | 2295 | 73.00 | 43.00 | 0.589 |

| [62] | Stimulation | Water | 3950 | 105.70 | 68.00 | 0.643 |

| Stimulation | Water | 3950 | 105.70 | 86.60 | 0.816 | |

| Stimulation | Water | 3950 | 105.70 | 53.00 | 0.501 | |

| [63] | Stimulation | Water | 2340 | 73.18 | 19.90 | 0.272 |

| [64] | Real | Water | 1000 | 185.00 | 128.00 | 0.692 |

| [65] | Stimulation | Water | 4423 | 159.80 | 138.00 | 0.864 |

| [28] | Stimulation | 1800 | 54.00 | 24.19 | 0.448 | |

| Stimulation | Water | 1800 | 54.00 | 18.43 | 0.341 | |

| Stimulation | R134a | 1800 | 54.00 | 27.30 | 0.506 | |

| Stimulation | R152a | 1800 | 54.00 | 27.69 | 0.513 | |

| Stimulation | R227ea | 1800 | 54.00 | 27.65 | 0.512 | |

| Stimulation | R245fa | 1800 | 54.00 | 26.48 | 0.490 | |

| Stimulation | R1234ze | 1800 | 54.00 | 27.85 | 0.516 | |

| Stimulation | R600a | 1800 | 54.00 | 28.92 | 0.536 | |

| Stimulation | Pentane | 1800 | 54.00 | 28.09 | 0.520 | |

| [66] | Stimulation | Water | 4000 | 180.00 | 129.88 | 0.722 |

| Stimulation | Water | 4000 | 180.00 | 129.28 | 0.718 | |

| Stimulation | Water | 4000 | 180.00 | 128.93 | 0.716 | |

| Stimulation | Water | 4000 | 180.00 | 128.96 | 0.716 | |

| Stimulation | Water | 4000 | 180.00 | 128.50 | 0.714 | |

| Stimulation | Water | 4000 | 180.00 | 128.35 | 0.713 | |

| Stimulation | Water | 4000 | 180.00 | 128.22 | 0.712 | |

| Stimulation | Water | 4000 | 180.00 | 128.11 | 0.712 | |

| Stimulation | Water | 4000 | 180.00 | 128.01 | 0.711 | |

| Stimulation | Water | 4000 | 180.00 | 127.92 | 0.711 |

References

- Caulk, R.A.; Tomac, I. Reuse of abandoned oil and gas wells for geothermal energy production. Renew. Energy 2017, 112, 388–397. [Google Scholar] [CrossRef] [Green Version]

- Alimonti, C.; Soldo, E. Study of geothermal power generation from a very deep pil weel with a wellbore heat exchanger. Renew. Sustain. Energy Rev. 2016, 86, 292–301. [Google Scholar] [CrossRef]

- Alimonti, C.; Falcone, G.; Liu, X. Potential for Harnessing the Heat from a Mature High-Pressure-High- Temperature Oil Field in Italy Case Study: The Villafortuna—Trecate Oil Field. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Abuaisha, M.S. Enhanced Geothermal Systems: Permeability Enhancement through Hydraulic Fracturing in a Poro-Thermoelastic Framework; University of Grenoble: Grenoble, France, 2014. [Google Scholar]

- Karvounis, D.C. Simulations of enhanced geothermal systems with an adaptive hierarchical fracture representation. Ph.D. Thesis, ETH Zurich, Zürich, Switzerland, 2013. [Google Scholar]

- Le Lous, M.; Larroque, F.; Dupuy, A.; Moignard, A. Thermal performance of a deep borehole heat exchanger: Insights from a synthetic coupled heat and flow model. Geothermics 2015, 57, 157–172. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Shatri, M.S.; Putra, Z.A.; Zaini, J.; Caesarendra, W.; Sasmito, A.P. Geothermal energy extraction using abandoned oil and gas wells: Techno-economic and policy review. Int. J. Energy Res. 2021. [Google Scholar] [CrossRef]

- Singh, H.; Falcone, G.; Volle, A.; Guillon, L. Harnessing geothermal energy from mature onshore oil fields, the Wytch Farm case study. Work. Geotherm. Reserv. Eng. 2017, 17, 13–15. [Google Scholar]

- Akhmadullin, I. Utilization of co-produced water from oil production, energy generation case. In Proceedings of the SPE Health, Safety, Security, Environment & Social Responsibility Conference, New Orleans, LA, USA, 18–20 April 2017. [Google Scholar]

- Xin, S.; Liang, H.; Hu, B.; Li, K. Electrical power generation from low temperature co-produced geothermal resources at Huabei oilfield. In Proceedings of the Thirty-Seventh Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 30 January–1 February 2012. [Google Scholar]

- Westphal, D.; Ruud, W. Economic appraisal and scoping of geothermal energy extraction projects using depleted hydrocarbon wells. Energy Strateg. Rev. 2018, 22, 348–364. [Google Scholar] [CrossRef]

- Davis, A.P.; Michaelides, E.E. Geothermal power production from abandoned oil wells. Energy 2009, 34, 866–872. [Google Scholar] [CrossRef]

- Wang, K.; Wu, X. Extension of oil well economic life by simultaneous production of oil and electricity. In Proceedings of the Society of Petroleum Engineers—SPE Oklahoma City Oil and Gas Symposium 2019, OKOG 2019, Oklahoma City, OK, USA, 9–10 April 2019. [Google Scholar]

- Noorollahi, Y.; Pourarshad, M.; Jalilinasabady, S.; Yousefi, H. Numerical simulation of power production from abandoned oil wellsin Ahwaz oil field in southern Iran. Geothermics 2015, 55, 16–23. [Google Scholar] [CrossRef]

- Macenić, M.; Kurevija, T. Revitalization of abandoned oil and gas wells for a geothermal heat exploitation by means of closed circulation: Case study of the deep dry well Pčelić-1. Interpretation 2018, 6, SB1–SB9. [Google Scholar] [CrossRef]

- Ziabakhsh-Ganji, Z.; Nick, H.M.; Bruhn, D.F. Investigation of the synergy potential of oil and geothermal energy froma fluvial oil reservior. J. Pet. Sci. Eng. 2019, 181, 106–195. [Google Scholar] [CrossRef]

- Liu, X.; Falcone, G.; Alimonti, C. A systematic study of harnessing low-temperature geothermal energy. Energy 2018, 142, 346–355. [Google Scholar] [CrossRef] [Green Version]

- Mehmood, A.; Yao, J.; Fan, D.; Bongole, K.; Liu, J.; Zhang, X. Potential for heat production by retrofitting abandoned gas wells into geothermal wells. PLoS ONE 2019, 14, e0220128. [Google Scholar] [CrossRef] [Green Version]

- Toth, A.N.; Szucs, P.; Pap, J.; Nyikos, A.; Fenerty, D.K. Converting Abandoned Hungarian Oil and Gas wells into Geothermal Sources. In Proceedings of the 43rd Workoshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 12–14 February 2018. [Google Scholar]

- Syarifudin, M.; Octavius, F.; Maurice, K. Feasibility of Geothermal Energy Extraction from non-activated petroleum wells in Arun field. In Proceedings of the 5th ITB Internation Geothermal Workshop, Bandung, Indonesia, 28 March–2 April 2016. [Google Scholar]

- Al-Mahrouqi, J.; Falcone, G. An Expanded Matrix to Scope the Technical and Economic Feasibility of Waste Heat Recovery from Mature Hydrocarbon Fields. In Proceedings of the PROCEEDINGS Geothermal Reservoir Engineering Stanford University, Stanford, CA, USA, 10–12 February 2020; Volume 3, pp. 1–16. [Google Scholar]

- Soldo, E.; Alimonti, C. From an Oilfield to a Geothermal One: Use of a Selection Matrix to Choose Between Two Extraction Technologies. In Proceedings of the World Geothermal Congress, Kyushu-Tohoku, Japan, 28 May–10 June 2000; pp. 19–25. [Google Scholar]

- Kaplanoglu, M.A.; Baba, A.; Akkurt, G.G. Use of abandoned oil wells in geothermal systems in Turkey. Geomech. Geophys. Geo-Energ. Geo-Resour. 2020, 6, 10. [Google Scholar] [CrossRef]

- Alimonti, C.; Soldo, E.; Berardi, D.; Bocchetti, D. A matrix method to select the more suitable extraction technology for the Campi Flegri geothermal area (Italy). In Proceedings of the European Geothermal Congress 2016, Strasbourg, France, 19–24 September 2016; p. 10. [Google Scholar]

- Alimonti, C.; Soldo, E.; Berardi, D.; Bocchetti, D. A comparison between energy conversion systems for a power plant in Campi Flegrei geothermal district based on a WellBore Heat eXchanger. In Proceedings of the European Geothermal Congress 2016, Strasbourg, France, 19–24 September 2016; pp. 19–24. [Google Scholar]

- Franco, A.; Villani, M. Optimal design of binary cycle power plants for water-dominated, medium-temperature geothermal fields. Geothermics 2009, 38, 379–391. [Google Scholar] [CrossRef] [Green Version]

- Kharseh, M.; Al-Khawaja, M.J.; Hassani, F. Utilization of oil wells for electricity generation: Performance and economics. Energy 2015, 90, 1–7. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, C.; Li, G.; Guo, X.; Wang, G.; Shi, Y.; Peng, C. Performance analysis of a downhole coaxial heat exchanger geothermal system with various working fluids. Appl. Therm. Eng. 2019, 163, 13. [Google Scholar] [CrossRef]

- Templeton, J.D.; Ghoreishi-Madiseh, S.A.; Hassani, F.; Al-Khawaja, M.J. Abandoned petroleum wells as sustainable sources of geothermal energy. Energy 2014, 70, 366–373. [Google Scholar] [CrossRef]

- Soldo, E.; Alimonti, C.; Scrocca, D. Geothermal Repurposing of Depleted Oil and Gas Wells in Italy. Multidiscip. Digit. Publ. Inst. Proc. 2020, 58, 9. [Google Scholar] [CrossRef]

- Gudmundsson, J.S.; Freeston, D.H.; Lienau, P.J. Lindal Diagram. Trans. Geotherm. Resour. Counc. 1985, 9, 15–19. [Google Scholar]

- Jusoh, N.A. Decommiccioning Cost Estimation Study; Universiti Teknologi Petronas: Perak, Malaysia, 2014. [Google Scholar]

- Reyes, A.G. Abondoned Oil and Gas Wells: A Reconnaissance Study of an Unconventional Geothermal Resource; GNS Science: Lower Hutt, New Zealand, 2007. [Google Scholar]

- Alimonti, C.; Soldo, E.; Bocceti, D.; Berardi, D. The Wellbore Heat Exchangers: A Technical Review. Renew. Energy 2018, 123, 353–381. [Google Scholar] [CrossRef]

- Sanyal, S.K.; Butler, S.J. Geothermal Power Capacity from Petroleum Wells—Some Case Histories of Assessment. In Proceedings of the World Geothermal Congress 2010, Bali, Indonesia, 25–29 April 2010. [Google Scholar]

- Johnson, L.A.; Walker, E.D. Oil production waste stream, a source of electrical power. In Proceedings of the Thirty-Fifht Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 1–3 February 2010. [Google Scholar]

- Van Erdeweghe, S.; Van Bael, J.; Laenen, B.; William, D. Comparison of series/parallel configuration for a low-T geothermal CHP plant, coupled to thermal networks. Renew. Energy 2017, 111, 494–505. [Google Scholar] [CrossRef]

- Abramov, A. Optimization of well pad design and drilling—Well clustering. Pet. Explor. Dev. 2019, 46, 614–620. [Google Scholar] [CrossRef]

- Jones, M.C. Implications of Geothermal Energy Production via Geopressured Gas Wells in Texas: Merging Conceptual Understanding of Hydrocarbon Production and Geothermal Systems; University of Texas at Austin: Austin, TX, USA, 2016. [Google Scholar]

- Maklin, C. DBSCAN Python Example: The Optimal Value for Epsilon (EPS). Available online: https://towardsdatascience.com/machine-learning-clustering-dbscan-determine-the-optimal-value-for-epsilon-eps-python-example-3100091cfbc (accessed on 10 February 2021).

- Sharma, A. How Does DBSCAN Clustering Work? DBSCAN Clustering for ML. Available online: https://www.analyticsvidhya.com/blog/2020/09/how-dbscan-clustering-works/ (accessed on 10 February 2021).

- tec-science.com. Final Temperature of Mixtures (Richmann’s Law). Available online: https://www.tec-science.com/thermodynamics/temperature/richmanns-law-of-final-temperature-of-mixtures-mixing-fluids/ (accessed on 10 February 2021).

- Mixing of Fluids Having Different Densities—Pipelines, Piping and Fluid Mechanics Engineering. Available online: https://www.eng-tips.com/threadminder.cfm?pid=378 (accessed on 10 February 2021).

- Rule of Mixtures Calculator for Specific Heat Capacity. Available online: https://thermtest.com/thermal-resources/rule-of-mixtures (accessed on 10 February 2021).

- Trullenque, G.; Genter, A.; Leiss, B.; Wagner, B.; Bouchet, R.; Léoutre, E.; Malnar, B.; Bär, K.; Rajšl, I. Upscaling of EGS in Different Geological Conditions: A European Perspective. In Proceedings of the 43rd Workshop on Geothermal Reservoir Engineering Stanford University, Stanford, CA, USA, 12–14 February 2018; pp. 1–10. [Google Scholar]

- Short, W.; Packey, D.; Holt, T. A manual for the economic evaluation of energy efficiency and renewable energy technologies. Renew. Energy 1995, 95, 73–81. [Google Scholar] [CrossRef]

- Pumps, N.R. How to Read a Pump Curve. Available online: https://www.northridgepumps.com/ (accessed on 16 February 2021).

- Fetoui, I. ESP Design—Hand Calculations. Available online: https://production-technology.org/esp-design-hand-calculations/ (accessed on 26 February 2021).

- Schlumberger REDA Electric Submersible Pump Systems Technology Catalog 2017, 360. Available online: https://www.slb.com/-/media/files/al/catalog/artificial-lift-esp-technology-catalog.ashx (accessed on 29 February 2021).

- The Engineering Toolbox Darcy-Weisbach Pressure and Major Head Loss Equation. Available online: https://www.engineeringtoolbox.com/darcy-weisbach-equation-d_646.html (accessed on 29 February 2021).

- ENTSO-E Data View—Transmission. Available online: http://dataview.ofsted.gov.uk/#/Tab/?percentageType=1&remit=3&deprivation=0&providerType=7&judgement=1&provisionType=0&year=2013-08-31&areaType=1®ionId=0&similarDate=2013-08-31®ionOne=0®ionTwo=0&eightRegions=false&tabName=LocalAuthorityFocus&_=13 (accessed on 1 March 2021).

- Eurostat Database—Eurostat. Available online: http://ec.europa.eu/eurostat/data/database (accessed on 1 March 2021).

- International Energy Agency Data Overview—IEA. Available online: https://www.iea.org/data-and-statistics (accessed on 1 March 2021).

- The Statistical Office of European Union. Available online: https://ec.europa.eu/eurostat/ (accessed on 1 March 2021).

- Sigfússon, B.; Uihlein, A. 2015 JRC Geothermal Energy Status Report; EUR 27623; Publications Office of the European Union: Luxembourg, 2015. [Google Scholar]

- Sigfusson, B.; Uihlein, A. 2014 JRC Geothermal Energy Status Report; EUR 26985; Publications Office of the European Union: Luxembourg, 2015. [Google Scholar]

- Alimonti, C.; Berardi, D.; Bocchetti, D.; Soldo, E. Coupling of energy conversion systems and wellbore het exchanger in a depleted oil well. Geotherm. Energy 2016, 4, 17. [Google Scholar] [CrossRef] [Green Version]

- Immanuel, L.G.; Almas, G.S.F.U.; Dimas, T.M. Experimental Desing of Wellbore Heat Exchanger in Binary Optimization for Low—Medium Enthalpy to Utillize Non-Sefl Discharge Wells in Indonesia. In Proceedings of the 43rd Workshop om Geothermal Reservoir Engineering, Stanford, CA, USA, 12–14 February 2018; p. 8. [Google Scholar]

- Nalla, G.; Shook, G.M.; Mines, G.L.; Bloomfield, K.K. Parametric sensitivity study of operating and design variables in wellbore heat exchangers. In Proceedings of the Twenty-Ninth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 26–28 January 2004. [Google Scholar]

- Wright, N.M.; Bennett, N.S. Geothermal energy from abandoned oil and gas wells using water in combination with a closed wellbore. Appl. Therm. Eng. 2015, 89, 908–915. [Google Scholar] [CrossRef]

- Kohl, T.; Brenni, R.; Eugster, W. System performance of a deep borehole heat exchanger. Geothermics 2002, 31, 687–708. [Google Scholar] [CrossRef]

- Kujawa, T.; Nowak, W.; Atachel, A.A. Utilization of existing deep geological wells for acquisitions of geothermal energy. Energy 2006, 31, 650–664. [Google Scholar] [CrossRef]

- Sliwa, T.; Gonet, A.; Sapinska-Sliwa, A.; Knez, D.; Juzuit, Z. Applicability of Borehole R-1 as BHE for Heating of a Gas Well. In Proceedings of the Proceedings World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015; p. 10. [Google Scholar]

- Alimonti, C.; Soldo, E.; Moroni, E. Evaluation of geothermal energy production using a WellBore Heat eXchanger in the reservoirs of Vampi Flegri and Ischia Island. In Proceedings of the European Geothermal Congress 2016, Strasbourg, France, 19–24 September 2016; p. 6. [Google Scholar]

- Noorollahi, Y.; Yousefi, H.; Pourarshad, M. Three Dimensional Modeling of Heat Extraction from Abandoned Oil Well for Applicatioin in Sugarcane Industry in Ahvaz—Southern Iran. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015; p. 11. [Google Scholar]

- Bu, X.; Ma, W.; Li, H. Geothermal energy production utilizing abandoned oil and gas wells. Renew. Energy 2012, 41, 80–85. [Google Scholar] [CrossRef]

| Input Data |

|---|

| Well name |

| Longitude |

| Latitude |

| Well temperature |

| Temperature loss through gathering lines |

| Oil production |

| Water production |

| Bottomhole pressure |

| Density of oil |

| Density of geothermal fluid |

| Specific heat capacity of oil |

| Specific heat capacity of geothermal fluid |

| Well depth |

| Yearly thermal drawdown |

| Yearly thermal water-cut increment |

| Water-cut |

| Production pump installed |

| Temperature loss along the wellbore |

| Reservoir temperature at the well depth |

| Downtime of the plant |

| Outlet temperature of the plant |

| Input Data | Value | Unit |

|---|---|---|

| Overall fluid flow | 0.042332 | |

| Average wellhead temperature of considered wells | 55.67 | °C |

| Average temperature loss through gathering lines | 1.23 | °C |

| Reservoir pressure gradient | 0.0874 | bar/m |

| Density of produced oil | 850 | |

| Density of geothermal water | 1014 | |

| Specific heat capacity of geothermal water | 3914 | J/kg °C |

| Yearly thermal dropdown | 0.5 | % |

| Average reservoir water-cut production | 84.22 | % |

| Yearly water-cut increment | 0.15 | % |

| Minimum number of well required for the spatial clustering | 4 | - |

| Scenario 2 | Scenario 3 | |||||||

| Input Data | Value | Unit | Input Data | Value | Unit | Input Data | Value | Unit |

| Downtime | 10 | % | Downtime | 10 | % | Circulating fluid flow | 0.004 | /s |

| Outlet temperature | 70 | °C | Outlet temperature | 70 | °C | Efficiency of surface heat exchanger | 100 | % |

| Efficiency of heat exchanger | 100 | % | Well depth | 3500 | m | Temperature ratio | 0.718 | - |

| Specific heat capacity of circulating fluid | 4187 | J/kg °C | Density of circulating fluid | 1000 | ||||

| Temperature loss from the gathering system to the plant | 1 | °C | Yearly thermal dropdown of the wellbore | 0.5 | % | Temperature loss along the wellbore | 4 | °C |

| Geothermal gradient of the well | 0.033 | °C/m | ||||||

| Scenario 5 | ||||||||

| Input Data | Value | Unit | Input Data | Value | Unit | Input Data | Value | Unit |

| Type of building | Public building | - | Temperature loss from the gathering system to the plant | 1 | °C | Pipeline temperature coefficient | 0.94 | - |

| Required inside temperature | 19 | °C | Building surface | 12,000 | Thermal pinch-point in heat exchanger | 1.5 | °C | |

| Outdoor non-heating temperature of the pivot point | 20 | °C | Minimum water temperature of the pivot point | 20 | °C | Specific heat capacity of the cold loop fluid | 4180 | J/kg °C |

| Outdoor non-heating temperature | 17 | °C | Maximum flow in the cold loop | 30 | /h | Density of the cold loop fluid | 1000 | |

| Minimum water temperature | 35 | °C | Minimum flow in the cold loop | 10 | /h | |||

| Scenario 4 | Scenario 5 | ||||

|---|---|---|---|---|---|

| Input Data | Value | Unit | Input Data | Value | Unit |

| Downtime | 10 | % | Downtime | 10 | % |

| Outlet temperature | 70 | °C | Outlet temperature | 70 | °C |

| Temperature loss from the gathering system to the power plant | 1 | °C | Temperature loss from the gathering system to the power plant | 1 | °C |

| Pipeline temperature coefficient | 0.94 | - | |||

| Input Data | Value | Unit | |||

|---|---|---|---|---|---|

| Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 | ||

| Effective tax rate | 30 | % | |||

| Inflation rate | 2.3 | % | |||

| Discount rate | 6.5 | % | |||

| Electricity market price (average) | - | - | 0.03628 | 0.03628 | €/kWh |

| Electricity selling price | - | - | 0.065 | 0.065 | €/kWh |

| Heat selling price | 0.045 | 0.045 | - | - | €/kWh |

| Lifetime of the project | 20 | years | |||

| Input Data | Value | Unit |

|---|---|---|

| Share of coal in total fossil fuel electricity generation | 23 | % |

| Share of oil in total fossil fuel electricity generation | 12 | % |

| Share of natural gas in total fossil fuel electricity generation | 65 | % |

| Share of coal in total fossil fuel heat generation | 7 | % |

| Share of oil in total fossil fuel heat generation | 11 | % |

| Share of natural gas in total fossil fuel heat generation | 82 | % |

| Well Name | Wellhead Temperature (°C) | Number of End-Uses | Cluster Number |

|---|---|---|---|

| Well 1 | 22 | 1 | 1 |

| Well 2 | 23 | 1 | 1 |

| Well 3 | 23 | 1 | 2 |

| Well 4 | 25.3 | 1 | 2 |

| Well 5 | 27 | 1 | 1 |

| Well 6 | 27 | 1 | 1 |

| Well 7 | 29 | 1 | 1 |

| Well 8 | 32 | 1 | 1 |

| Well 9 | 39 | 1 | 1 |

| Well 10 | 47.6 | 1 | 1 |

| Well 11 | 49.3 | 1 | 1 |

| Well 12 | 52.8 | 1 | 1 |

| Well 13 | 54.5 | 1 | 1 |

| Well 14 | 55 | 1 | 1 |

| Well 15 | 60 | 2 | 1 |

| Well 16 | 61.15 | 2 | 1 |

| Well 17 | 68.8 | 2 | 1 |

| Well 18 | 74 | 2 | 1 |

| Well 19 | 74.95 | 2 | 2 |

| Well 20 | 75 | 2 | 2 |

| Well 21 | 78 | 2 | 1 |

| Well 22 | 81.5 | 2 | 1 |

| Well 23 | 83.6 | 2 | 1 |

| Well 24 | 92 | 2 | 1 |

| Well 25 | 95 | 2 | 1 |

| Well 26 | 97 | 2 | 1 |

| Input Data | Value | Unit |

|---|---|---|

| Outlet temperature from the plant in Scenario 2 | 50 | °C |

| Outlet temperature from the plant in Scenario 4 | 47 | °C |

| Outlet temperature from the plant in Scenario 5 | 47 | °C |

| Calculated Value | Unit | Whole Field | Cluster 1 | Cluster 2 |

|---|---|---|---|---|

| Wellhead temperature | °C | 81.16 | 82.10 | 72.93 |

| Specific heat capacity of geothermal water | J/kg °C | 3904.49 | 3906.12 | 3890.20 |

| Density of geothermal water | 1012.35 | 1011.38 | 1020.79 | |

| Total geothermal water flow | 0.0406 | 0.0364 | 0.0042 |

| Calculated Value | Unit | Whole Field | Cluster 1 | Cluster 2 |

|---|---|---|---|---|

| Wellhead temperature | °C | 78.93 | 78.93 | 82.44 |

| Calculated Value | Unit | Whole Field | Cluster 1 | Cluster 2 |

|---|---|---|---|---|

| Wellhead temperature | °C | 84.48 | 85.96 | 72.93 |

| Specific heat capacity of geothermal water | J/kg °C | 3900.69 | 3902.03 | 3890.20 |

| Density of geothermal water | 1012.30 | 1011.22 | 1020.79 | |

| Total geothermal water flow | 0.0366 | 0.0325 | 0.0042 | |

| Thermal efficiency of the ORC plant | % | 4.40 | 4.44 | 2.35 |

| Calculated Value | Unit | Whole Field | Cluster 1 | Cluster 2 |

|---|---|---|---|---|

| Wellhead temperature | °C | 84.48 | 85.96 | 72.93 |

| Specific heat capacity of geothermal water | J/kg °C | 3900.69 | 3902.03 | 3890.20 |

| Density of geothermal water | 1012.30 | 1011.22 | 1020.79 | |

| Total geothermal water flow | 0.0366 | 0.0325 | 0.0042 | |

| Thermal efficiency of the ORC plant | % | 4.40 | 4.44 | 2.35 |

| Available fluid for the electricity generation | 0.0307 | 0.0271 | 0.0006 |

| Input Data | Value | Unit | |||||

|---|---|---|---|---|---|---|---|

| Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 | ||||

| Whole field | CAPEX | ORC | - | - | 5667.48 | 5566.87 | €/kW |

| Heat | 449.26 | 2340.47 | - | 385.14 | |||

| OPEX (average) | 0.0906 | 0.0121 | 1.0217 | 0.3147 | €/kWh | ||

| Cluster 1 | CAPEX | ORC | - | - | 6333.58 | 5469.57 | €/kW |

| Heat | 440.83 | 2340.47 | - | 380.72 | |||

| OPEX (average) | 0.0733 | 0.8337 | 0.0121 | 0.2713 | €/kWh | ||

| Cluster 2 | CAPEX | ORC | - | - | 6710.21 | 5714.34 | €/kW |

| Heat | 392.69 | 1511.67 | - | 367.37 | |||

| OPEX (average) | 0.0396 | 0.0086 | 1.2715 | 0.0780 | €/kWh | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hranić, J.; Raos, S.; Leoutre, E.; Rajšl, I. Two-Stage Geothermal Well Clustering for Oil-to-Water Conversion on Mature Oil Fields. Geosciences 2021, 11, 470. https://doi.org/10.3390/geosciences11110470

Hranić J, Raos S, Leoutre E, Rajšl I. Two-Stage Geothermal Well Clustering for Oil-to-Water Conversion on Mature Oil Fields. Geosciences. 2021; 11(11):470. https://doi.org/10.3390/geosciences11110470

Chicago/Turabian StyleHranić, Josipa, Sara Raos, Eric Leoutre, and Ivan Rajšl. 2021. "Two-Stage Geothermal Well Clustering for Oil-to-Water Conversion on Mature Oil Fields" Geosciences 11, no. 11: 470. https://doi.org/10.3390/geosciences11110470

APA StyleHranić, J., Raos, S., Leoutre, E., & Rajšl, I. (2021). Two-Stage Geothermal Well Clustering for Oil-to-Water Conversion on Mature Oil Fields. Geosciences, 11(11), 470. https://doi.org/10.3390/geosciences11110470