Investigation of Geological Anomalies at Pile Foundation Location in Urban Karst Areas Using Single Borehole Radar

Abstract

1. Introduction

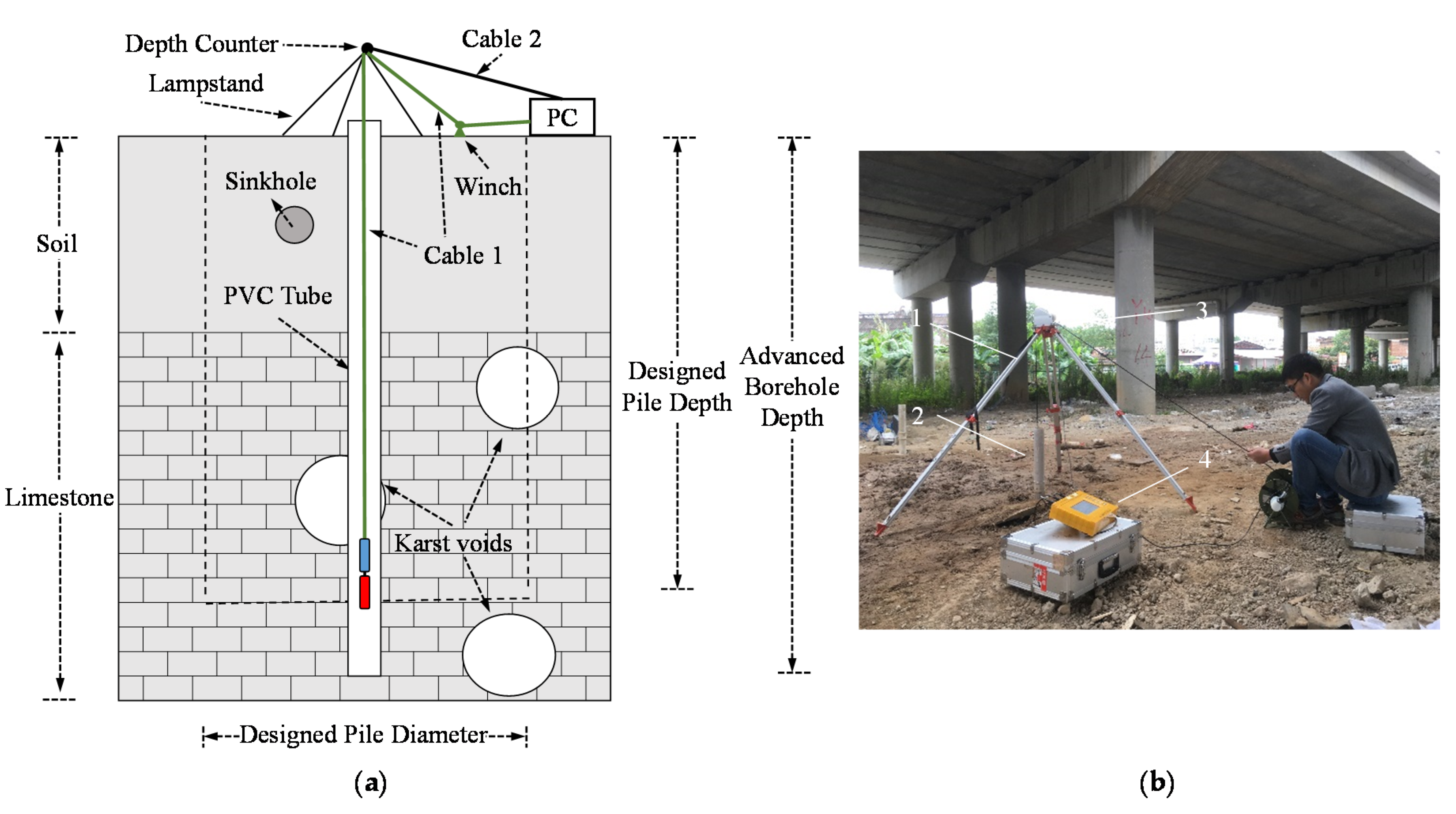

2. Single Borehole Radar Detection

2.1. Detection Object

2.2. Single Borehole GPR Prototype System

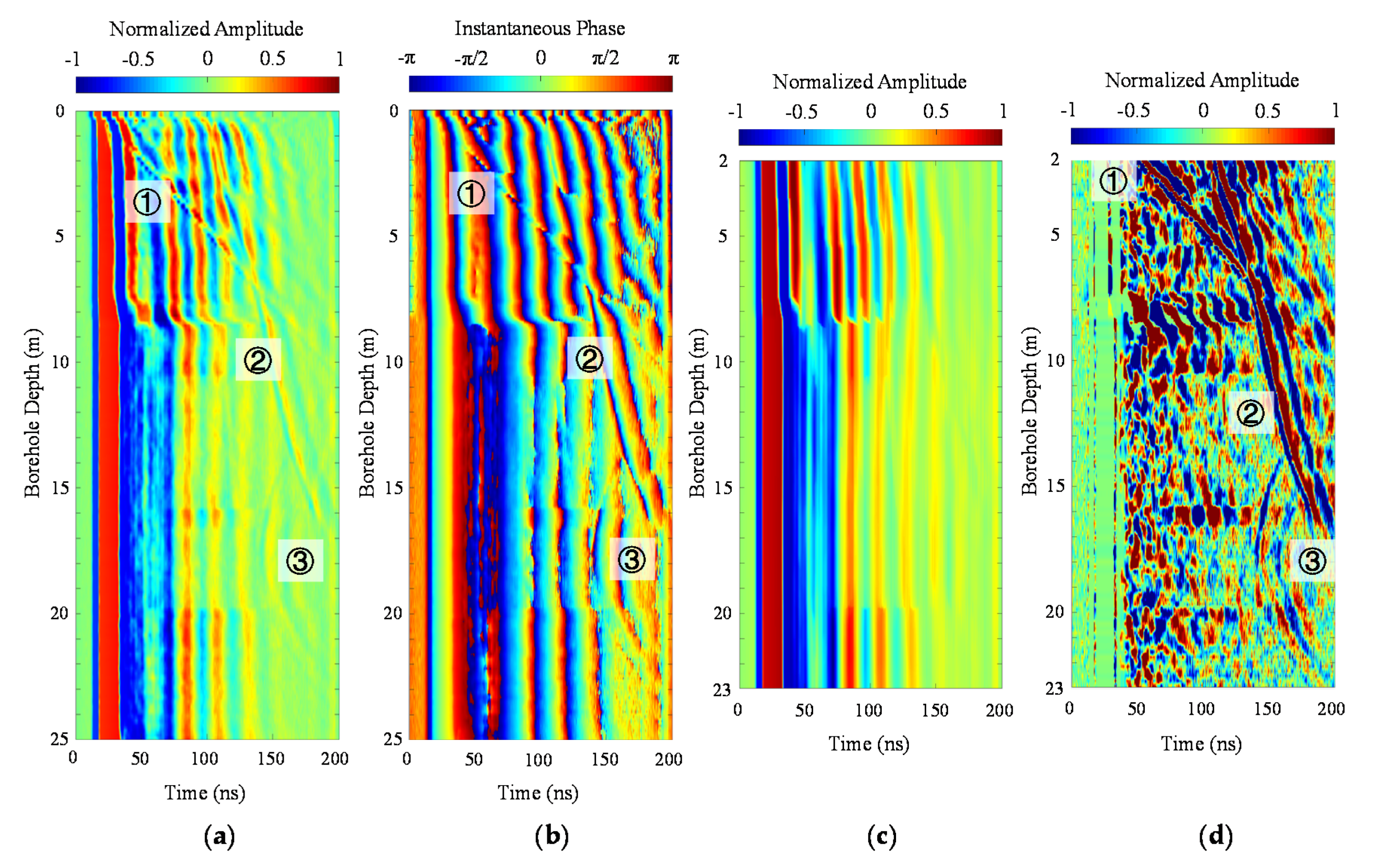

2.3. Signal Analysis

- (a)

- Taking the test signal at one depth sx(t) as an example, a new set of sequences can be formed by reading the test signals of 2N + 1 channels at adjacent depths (sx-N(t), sx-N+1(t)… sx+N(t)).

- (b)

- For every point at time sx(tn), the amplitudes of the test signals of 2N + 1 channels (sx-N(tn), sx-N+1(tn)… sx+N(tn)) are reordered. The median sxm(tn) replaces the original amplitude sx(tn) in the test signal sx(t).

- (c)

- Repeat steps (a) and (b) for all the recordings. A new wave can be obtained as a Pm(t, x) profile after median filtering, which consists of the direct wave and waves in the borehole.

- (d)

- The wave profiles Pr(t, x) can be calculated as Pr(t, x) = P(t, x) − Pm(t, x), which mainly contain the reflected waves from the geological structure.

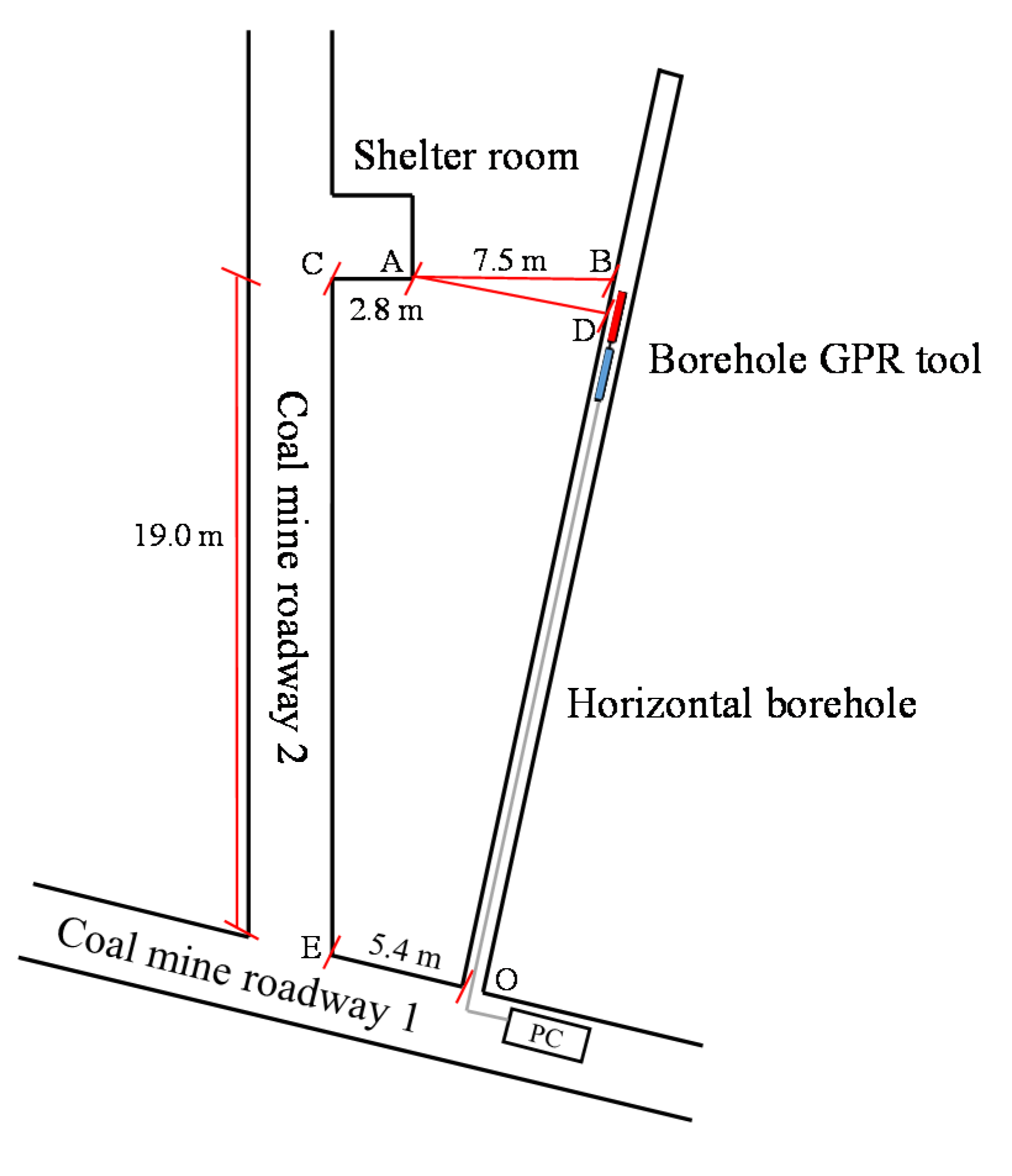

3. Validation by a Controlled Experiment

3.1. Experiment Setting

3.2. Results

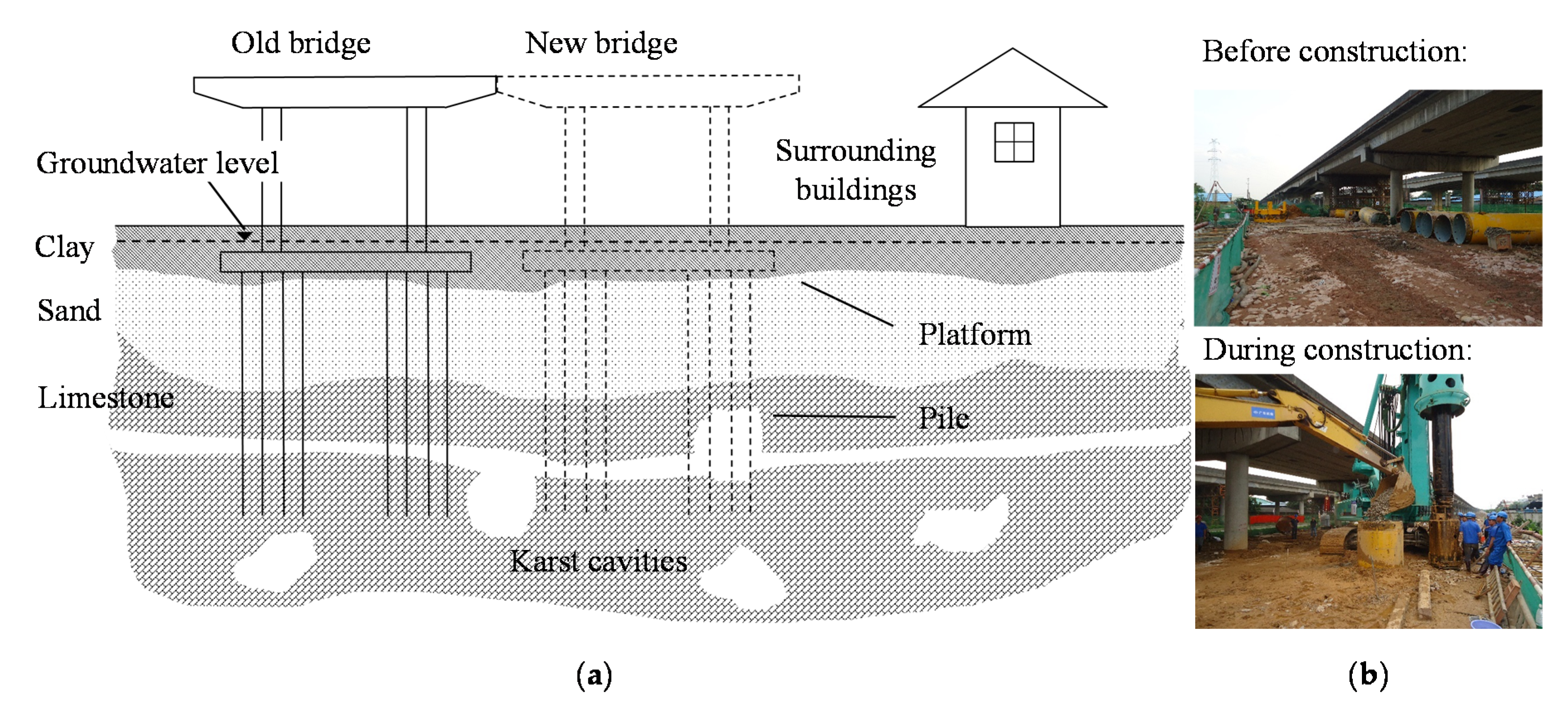

4. Field Test

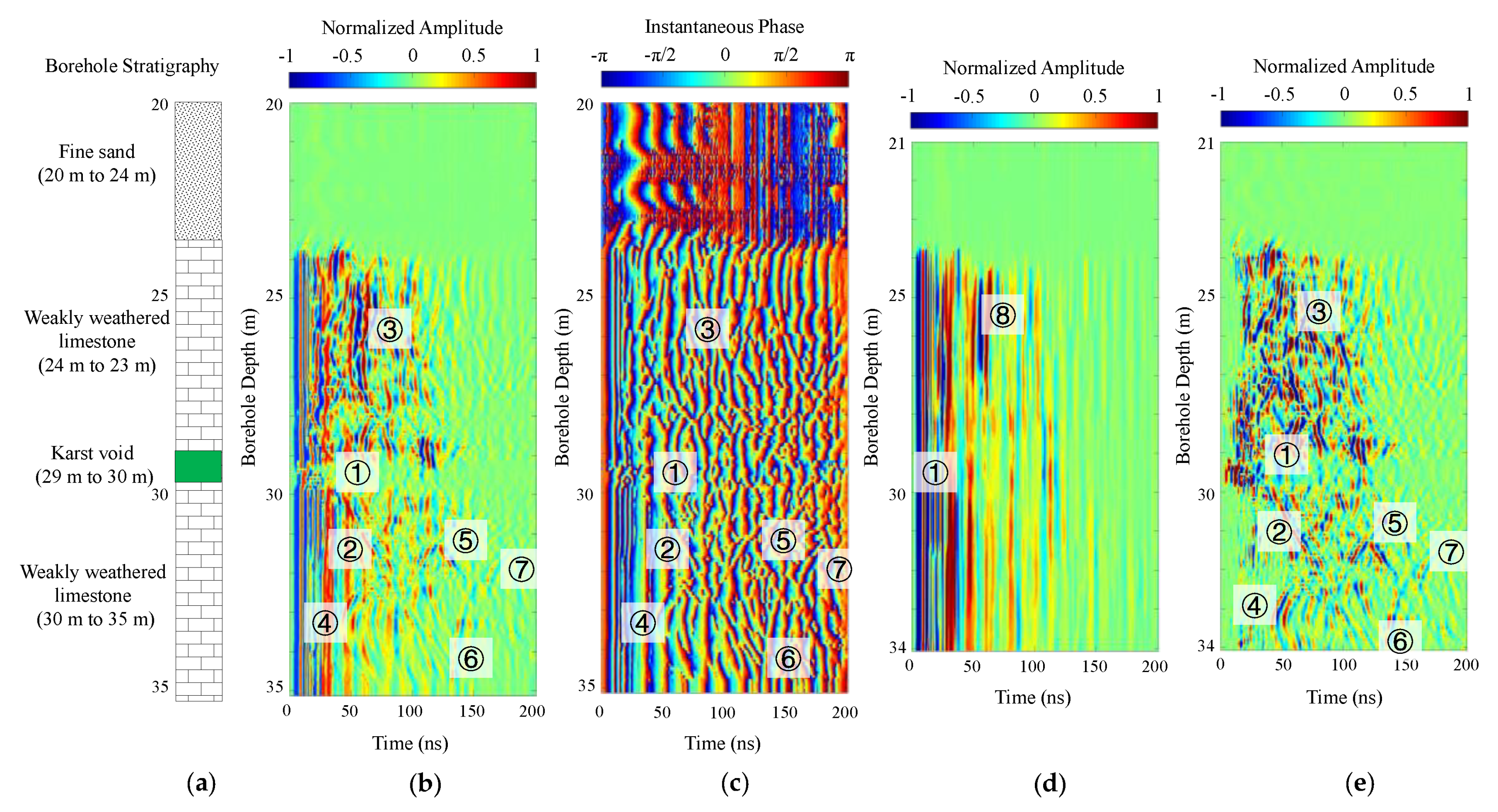

4.1. Scenario 1: Karst Voids

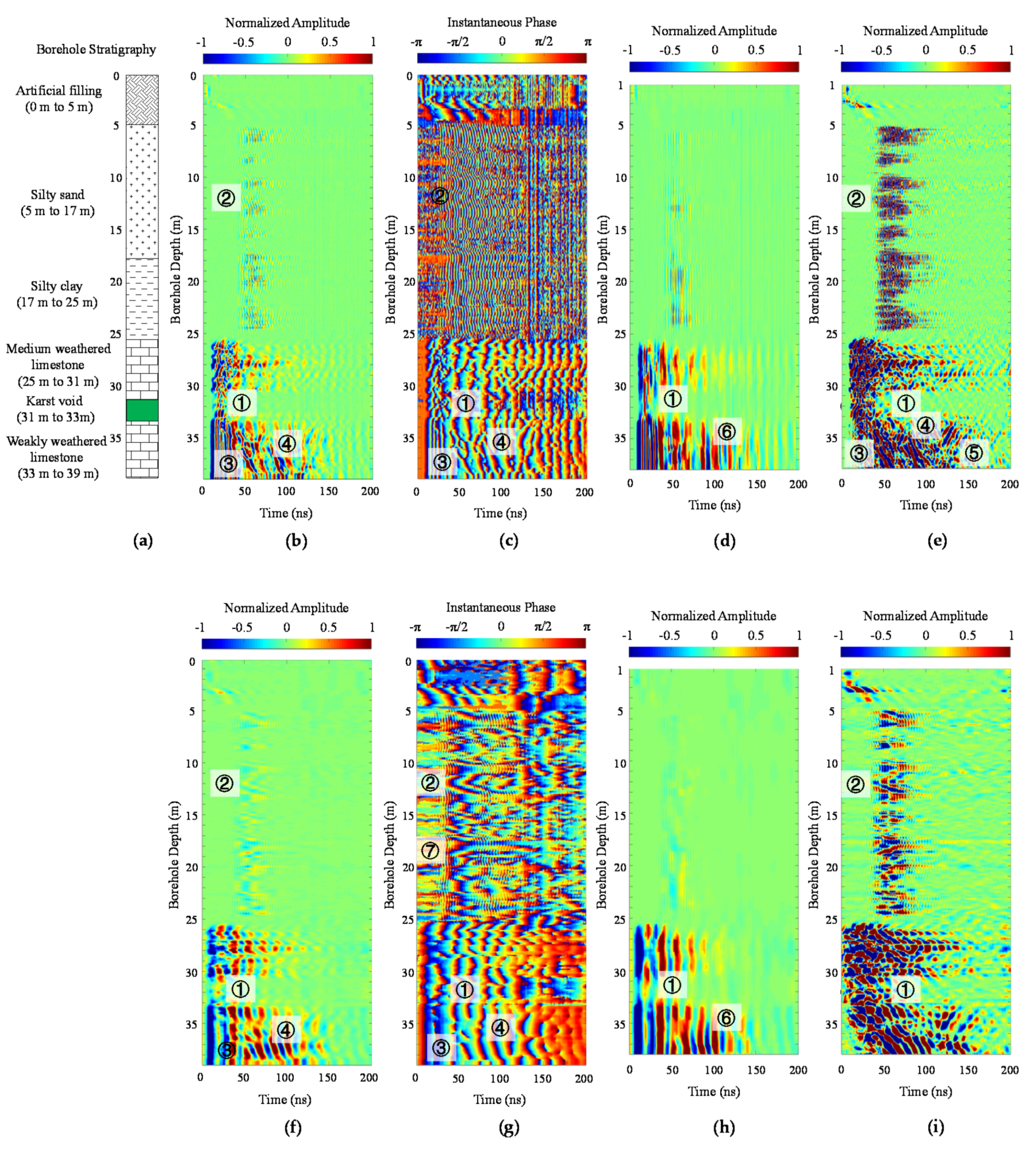

4.2. Scenario 2: Sinkhole

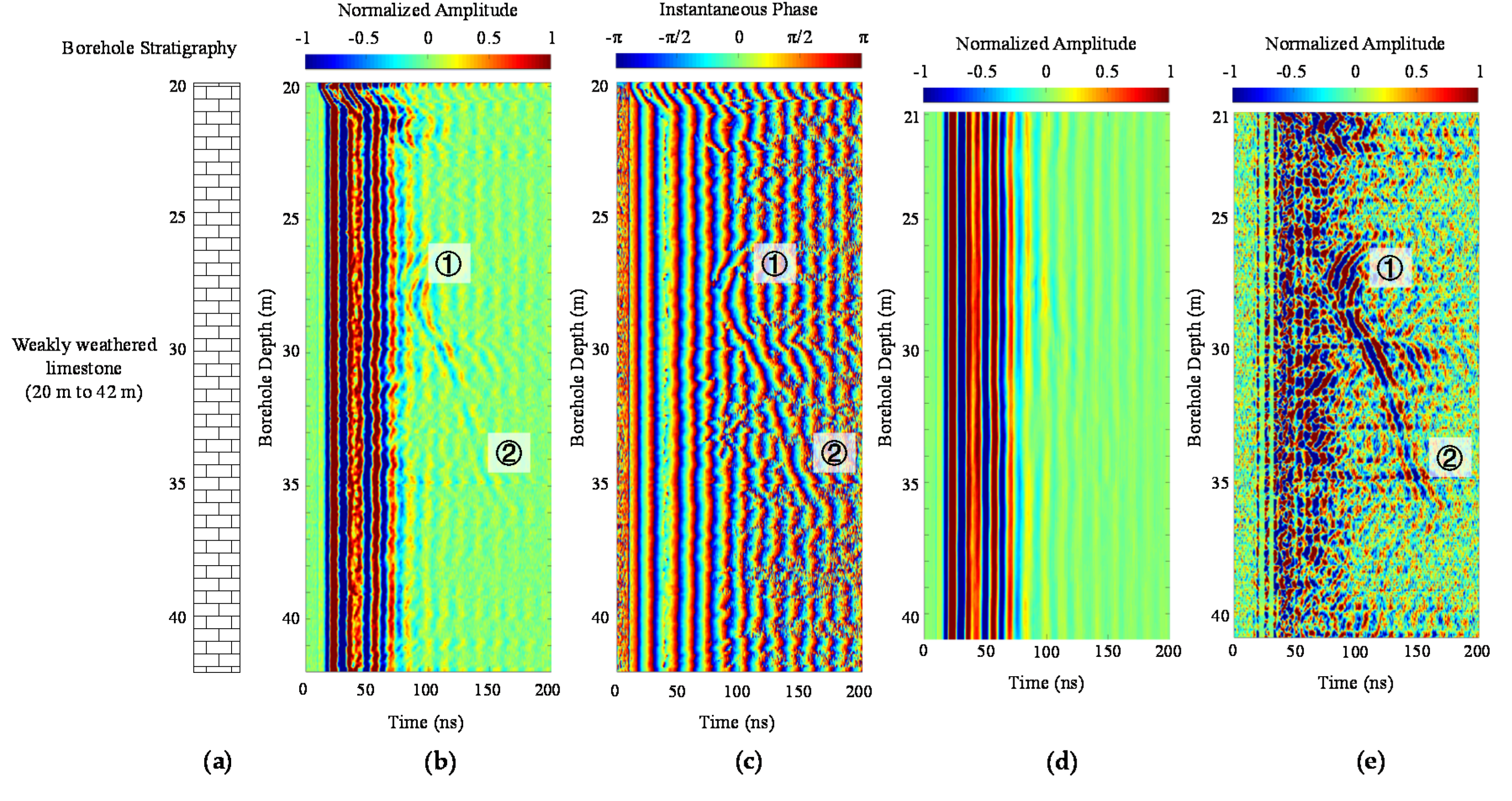

4.3. Scenario 3: Rock Fracture

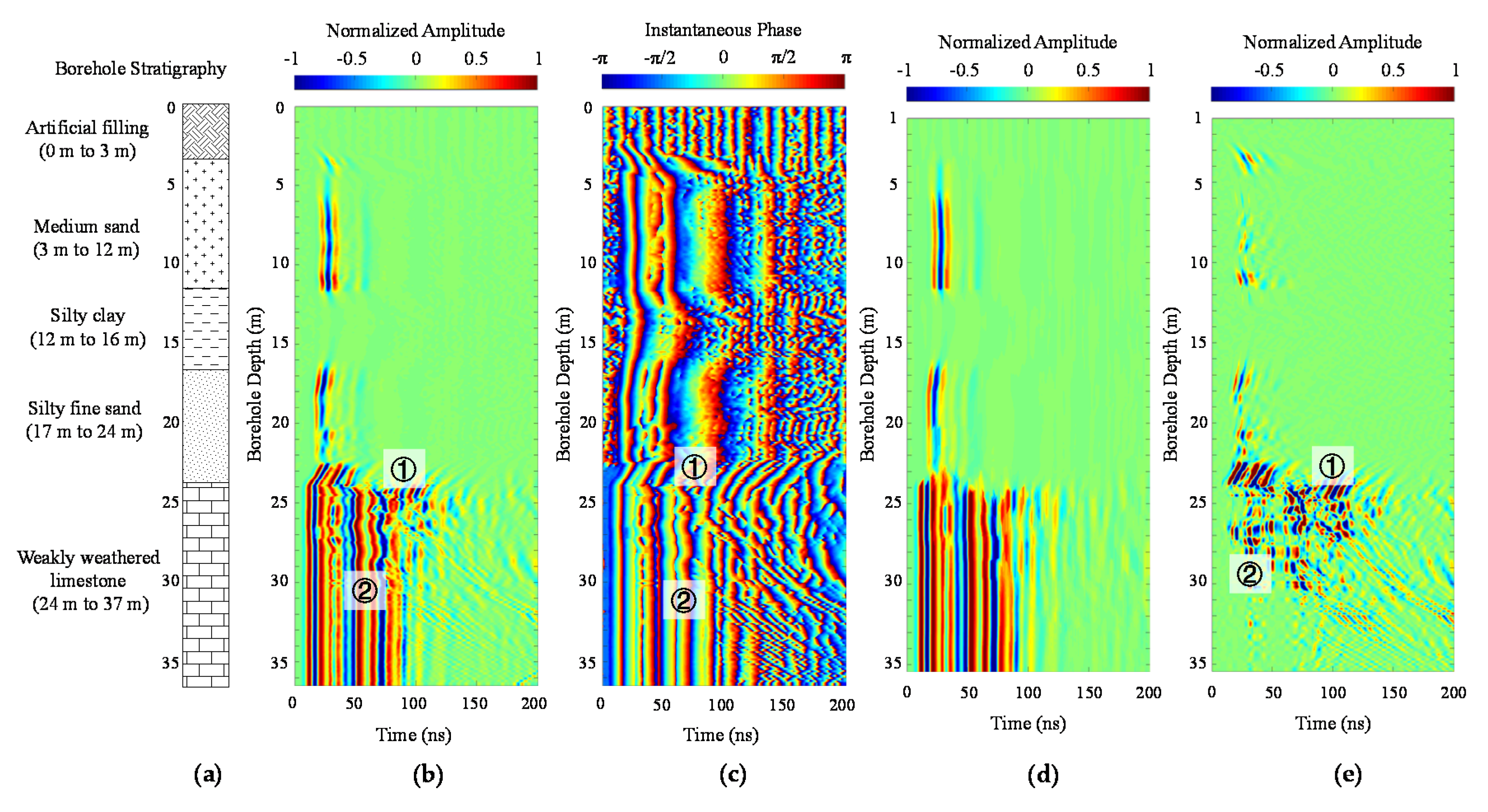

4.4. Scenario 4: Integrated Bedrock

5. Discussion

5.1. Remediation of Karst Voids

5.2. Construction Methods

5.3. Strengths and Weaknesses of Single Borehole Radar Detection

6. Conclusions

- Karst geological anomalies significantly affect the bearing capacity and construction of piles. To detect karst voids at pile locations, a single borehole GPR prototype with a near offset (30 cm) and a small diameter (36 mm) was developed for engineering application of imaging karst anomalies with high resolution. Instantaneous phase analysis by Hilbert transform was employed as an effective way to make low energy reflection visible, and medium filtering was used to differentiate weak reflection from borehole background noise.

- A controlled single borehole GPR experiment was conducted in a mining horizontal borehole to demonstrate the applicability of the prototype and the advantages of the signal analysis methods. The experiment results show three typical reflection events in the detection of karst anomalies at pile locations: (a) a linear event intersecting a borehole corresponds to a soil–rock interface or rock fracture that crosses the borehole; (b) a linear event outside a borehole corresponds to a linear rock fracture outside the borehole; and (c) a hyperbolic reflection indicates point sharped karst voids or sinkholes.

- Single borehole GPR detection was applied in a freeway bridge extension project located in an urban karst area. The results show that the high-frequency signal decays rapidly in the soil and at the infill depth range of karst voids. The direct EM wave event is discontinued and irregular in the depth range of weathered rock. The EM wave velocity can be identified based on the slope of the linear fracture crossing the borehole. The location of the surrounding karst voids can be estimated by the velocity and arrival time of the hyperbolic reflection. Phase reversal can be observed if the void is filled by water or saturated soil.

- Borehole reverberation of noise signals inside the borehole was observed in the detection of a sinkhole. Band-pass filtering was applied to remove the high-frequency ringing noise. The velocity estimation can be used to determine if the event real diffraction or an artifact. The identification of a sinkhole needs to consider the geological setting of the upper bedrock. If there is a karst void beneath a weathered and fractured upper bedrock layer, the enlargement of the borehole in the soil range likely suggests soil loss and a developing sinkhole.

- The remediation of karst voids and the construction method of piles were designed based on the investigation results. Potential sinkholes were remedied by compaction grouting before the pile construction. A construction strategy of rotary bored piling with real-time and permanent steel casing was employed in the piles where multiple karst voids and sinkholes were identified. The construction feedback demonstrates that single borehole radar detection is effective for the investigation of anomalies at pile locations in urban karst areas.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, S. The Theory and Method of Geological Prediction for the Disaster Source of Water and Mud Inrush in Tunnels; China Science Publishing: Beijing, China, 2015. [Google Scholar]

- Li, S.; Liu, B.; Sun, H.; Nie, L.; Zhong, S.; Su, M.; Li, X.; Xu, Z. State of art and trends of advanced geological prediction in tunnel construction. Chin. J. Rock Mech. Eng. 2014, 33, 1090–1113. [Google Scholar]

- Li, S.; Liu, B.; Xu, X.; Nie, L.; Liu, Z.; Song, J.; Sun, H.; Chen, L.; Fan, K. An overview of ahead geological prospecting in tunneling. Tunnel. Undergr. Space Technol. 2017, 63, 69–94. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Zhang, M.; Hu, W.; Bai, Y.; Huang, B. A laboratory investigation of steel to fly ash-based geopolymer paste bonding behavior after exposure to elevated temperatures. Constr. Build. Mater. 2020, 254, 119267. [Google Scholar] [CrossRef]

- Shen, D.; Shi, Z.; Peng, M.; Zhang, L.M.; Jiang, M. Longevity analysis of landslide dams. Landslides 2020. [Google Scholar] [CrossRef]

- Zajc, M.; Celarc, B.; Gosar, A. Structural-geological and karst feature investigations of the limestone-flysch thrust-fault contact using low-frequency ground penetrating radar (Adria-Dinarides thrust zone, SW Slovenia). Environ. Earth Sci. 2015, 73, 1–13. [Google Scholar] [CrossRef]

- Angelis, D.; Tsourlos, P.; Tsokas, G.; Vargemezis, G.; Zacharopoulou, G.; Power, C. Combined application of GPR and ERT for the assessment of a wall structure at the Heptapyrgion fortress (Thessaloniki, Greece). J. Appl. Geophys. 2018, 152, 208–220. [Google Scholar] [CrossRef]

- Xia, J. Estimation of near-surface shear-wave velocities and quality factors using multichannel analysis of surface-wave methods. J. Appl. Geophys. 2014, 103, 140–151. [Google Scholar] [CrossRef]

- Ivanov, J.; Miller, R.D.; Lacombe, P.; Johnson, C.D.; Lane, J.W. Delineating a shallow fault zone and dipping bedrock strata using multichannal analysis of surface waves with a land streamer. Geophysics 2006, 71, A39–A42. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Z.; Li, S.; Fan, K.; Nie, L.; Zhang, X. An improved Time-Lapse resistivity tomography to monitor and estimate the impact on the groundwater system induced by tunnel excavation. Tunnel. Undergr. Space Technol. 2017, 66, 107–120. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Z.; Li, S.; Nie, L.; Su, M.; Sun, H.; Fan, K.; Zhang, K.; Pang, Y. Comprehensive surface geophysical investigation of karst caves ahead of the tunnel face: A case study in the Xiaoheyan section of the water supply project from Songhua River, Jilin, China. J. Appl. Geophys. 2017, 144, 37–49. [Google Scholar]

- Sun, H.; Li, X.; Li, S.; Qi, Z.; Su, M.; Xue, Y. Multi-component and multi-array TEM detection in karst tunnels. J. Geophys. Eng. 2012, 9, 359–373. [Google Scholar] [CrossRef]

- Li, S.; Sun, H.; Lu, X.S.; Li, X. Three-dimensional modeling of transient electromagnetic responses of water-bearing structures in front of a tunnel face. J. Environ. Eng. Geophys. 2014, 19, 13–32. [Google Scholar] [CrossRef]

- Tran, K.T.; McVay, M.; Faraone, M.; Horhota, D. Sinkhole detection using 2D full seismic waveform tomography Sinkhole detection by FWI. Geophysics 2013, 78, R175–R183. [Google Scholar] [CrossRef]

- Steeples, D.; Knapp, R.; McElwee, C. Seismic reflection investigations of sinkholes beneath Interstate Highway 70 in Kansas. Geophysics 1986, 51, 295–301. [Google Scholar] [CrossRef]

- Hiltunen, D.; Cramer, B. Application of seismic refraction tomography in karst terrane. J. Geotech. Geoenviron. Eng. 2008, 134, 938–948. [Google Scholar] [CrossRef]

- Liu, L.; Shi, Z.; Peng, M.; Liu, C.; Tao, F.; Liu, C. Numerical modeling for karst cavity sonar detection beneath bored cast in situ pile using 3D staggered grid finite difference method. Tunn. Undergr. Space. Tech. 2018, 82, 50–65. [Google Scholar] [CrossRef]

- Musil, M.; Maurer, H.R.; Green, A.G. Discrete tomography and joint inversion for loosely connected or unconnected physical properties: Application to crosshole seismic and georadar data sets. Geophys. J. Int. 2003, 153, 389–402. [Google Scholar] [CrossRef]

- Liu, L.; Shi, Z.; Peng, M.; Tsoflias, G.P.; Liu, C.; Tao, F.; Liu, C.S. A borehole multifrequency acoustic wave system for karst detection near piles. J. Appl. Geophys. 2020, 177, 104051. [Google Scholar] [CrossRef]

- Zhong, S.; Wang, C.; Wu, L.; Wu, Y.H.; Wang, Q.Y. Borehole radar response characteristics of point unfavorable geo-bodies: Forward simulation on its geometric effect. Rock Soil Mech. 2011, 32, 1583–1588. [Google Scholar]

- Zhong, S.; Wang, C.; Wu, L.; Tang, X.; Wang, Q. Borehole radar response characteristics of point unfavorable geo-bodies: Forward simulation of its surrounding rock and filling condition. Rock Soil Mech. 2012, 33, 1191–1195. [Google Scholar]

- Ma, C.; Zhao, Q.; Ran, L.; Chang, X. Numerical Study of Borehole Radar for Cliff Imaging. J. Environ. Eng. Geophys. 2014, 19, 269–276. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, Q.; Wang, L.; Liu, S. Modeling borehole radar by finite-difference time-domain in conductive sandstone. J. Environ. Eng. Geophys. 2015, 20, 19–29. [Google Scholar] [CrossRef]

- Ebihara, S. Directional borehole radar with dipole antenna array using optical modulators. IEEE Trans. Geosci. Remote Sens. 2004, 42, 45–58. [Google Scholar] [CrossRef]

- Qin, H.; Vrugt, J.; Xie, X.; Zhou, Y. Improved characterization of underground structure defects from two-stage Bayesian inversion using crosshole GPR data. Automa. Constr. 2018, 95, 233–244. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, F.; Li, S.; Liu, L.; Li, Y.; Xu, X.; Liu, Z.; Zhang, Q. Full waveform inversion based on inequality constraint for cross-hole radar. J. Appli. Geophys. 2019, 162, 118–127. [Google Scholar] [CrossRef]

- Li, Y.; L, S.; Liu, B.; Nie, L.; Zhang, F.; Xu, L.; Wang, C. Forward simulation and complex signal analysis of borehole radar detection for underground adverse geological bodies. Rock Soil Mech. 2017, 38, 300–308. [Google Scholar]

- Alperovich, L.; Eppelbaum, L.; Zheludev, V.; Dumoulin, J.; Soldovieri, F.; Proto, M.; Proto, M.; Loperte, A. A new combined wavelet methodology applied to GPR and ERT data in the Montagnole experiment (French Alps). J. Geophys. Eng. 2013, 14, 1–17. [Google Scholar]

- Taner, M.; Koehler, F.; Sheriff, R. Complex seismic trace analysis. Geophysics 1979, 44, 1041–1063. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Shi, Z.; Peng, M.; Tsoflias, G.P. Investigation of Geological Anomalies at Pile Foundation Location in Urban Karst Areas Using Single Borehole Radar. Geosciences 2020, 10, 232. https://doi.org/10.3390/geosciences10060232

Liu L, Shi Z, Peng M, Tsoflias GP. Investigation of Geological Anomalies at Pile Foundation Location in Urban Karst Areas Using Single Borehole Radar. Geosciences. 2020; 10(6):232. https://doi.org/10.3390/geosciences10060232

Chicago/Turabian StyleLiu, Liu, Zhenming Shi, Ming Peng, and Georgios P. Tsoflias. 2020. "Investigation of Geological Anomalies at Pile Foundation Location in Urban Karst Areas Using Single Borehole Radar" Geosciences 10, no. 6: 232. https://doi.org/10.3390/geosciences10060232

APA StyleLiu, L., Shi, Z., Peng, M., & Tsoflias, G. P. (2020). Investigation of Geological Anomalies at Pile Foundation Location in Urban Karst Areas Using Single Borehole Radar. Geosciences, 10(6), 232. https://doi.org/10.3390/geosciences10060232