The Use of Infrared Thermography for the Monitoring of Udder Teat Stress Caused by Milking Machines

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Animals and Farms

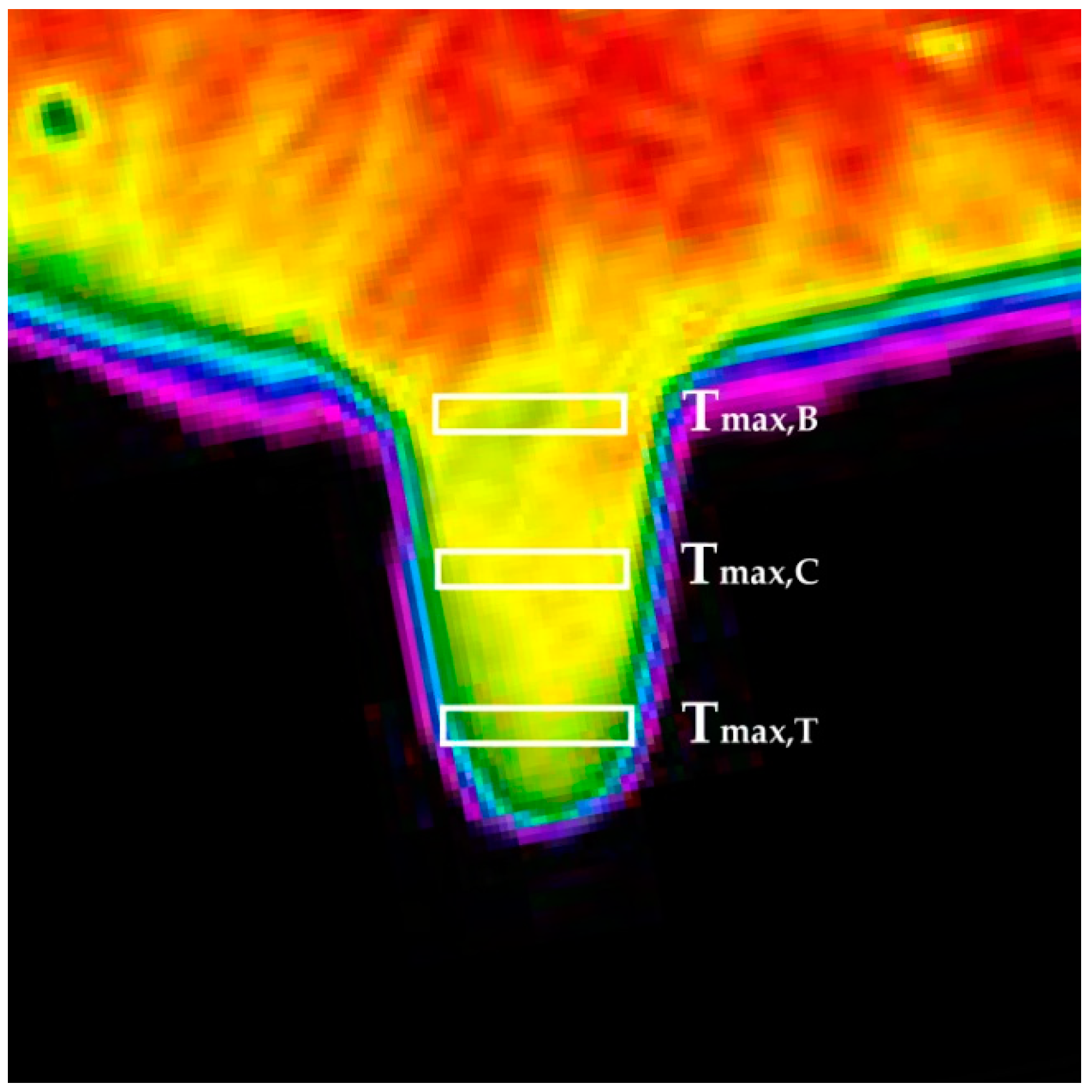

2.2. Thermographic Images Collection

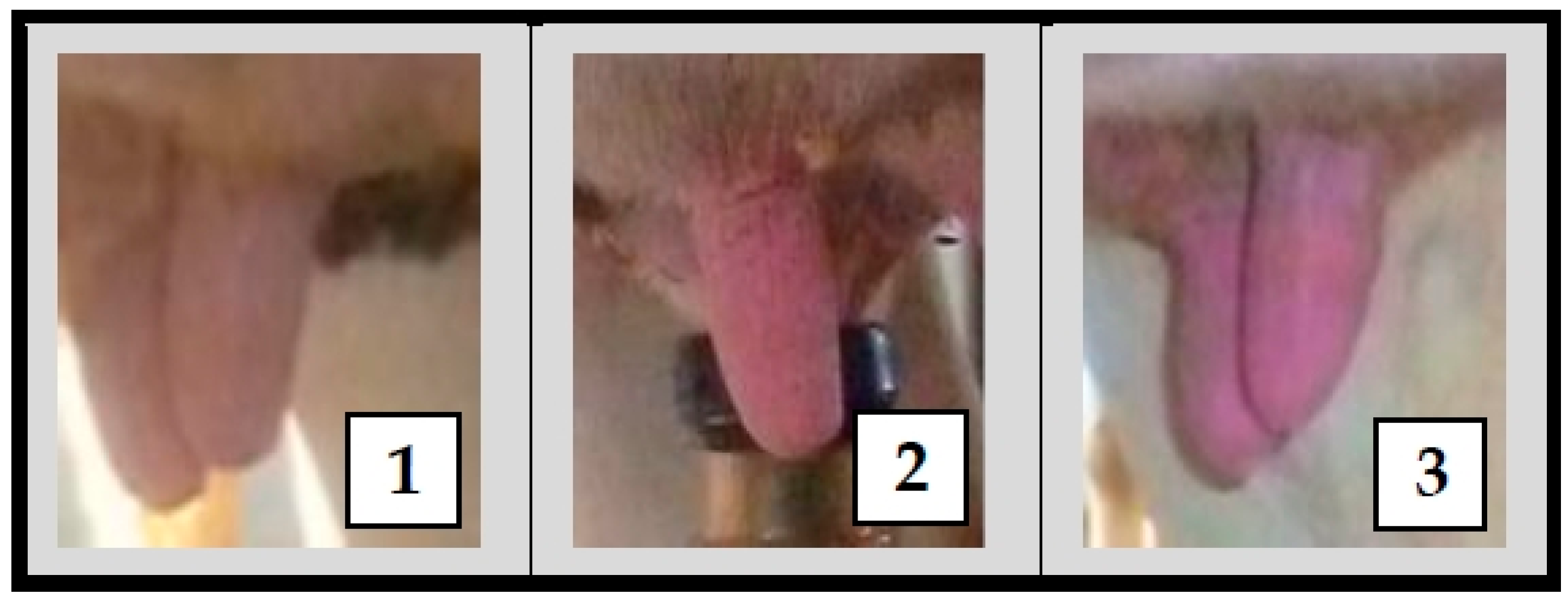

2.3. Digital Pictures Collection and Udder Teat Evaluations

2.4. Statistical Analysis

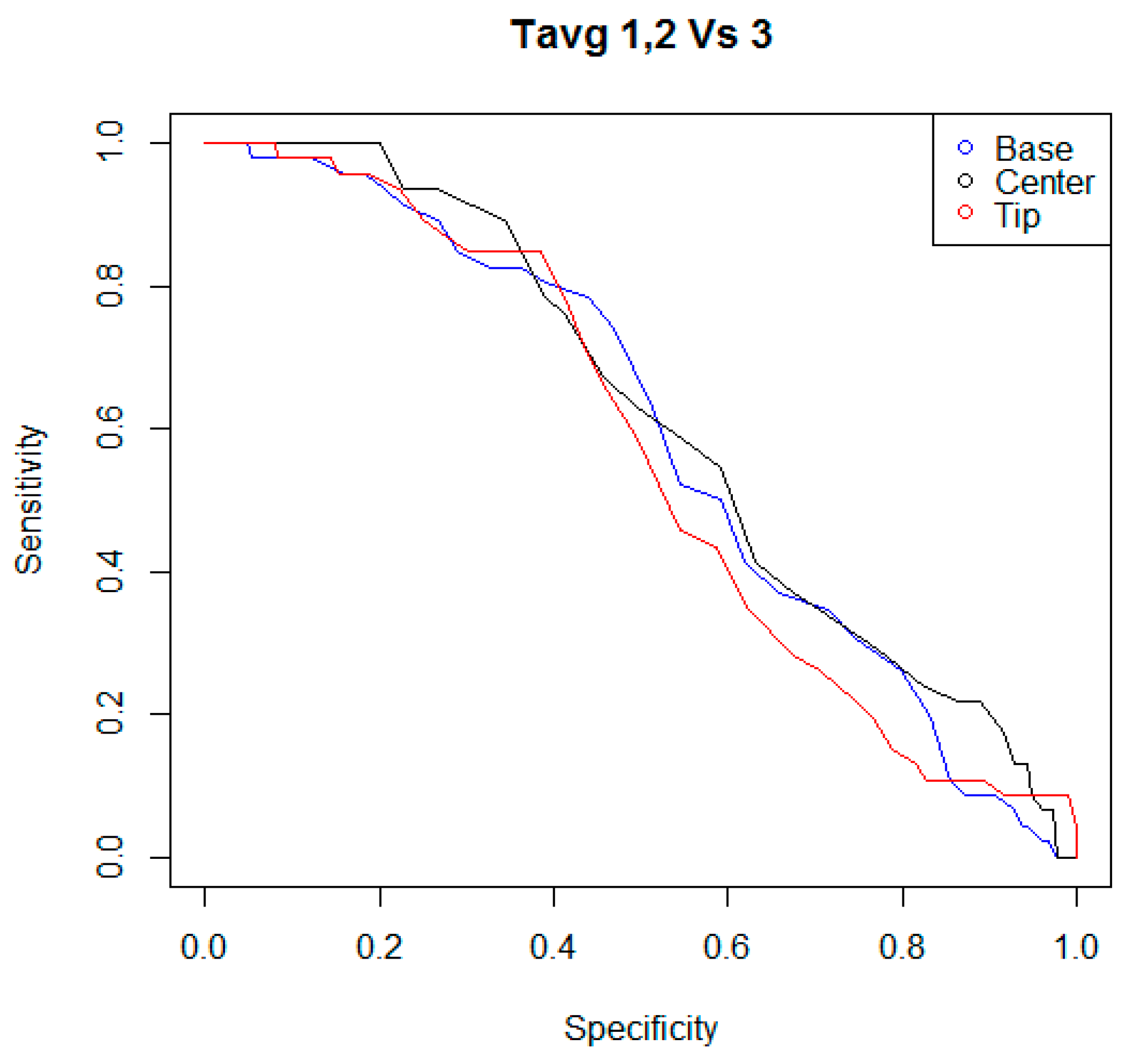

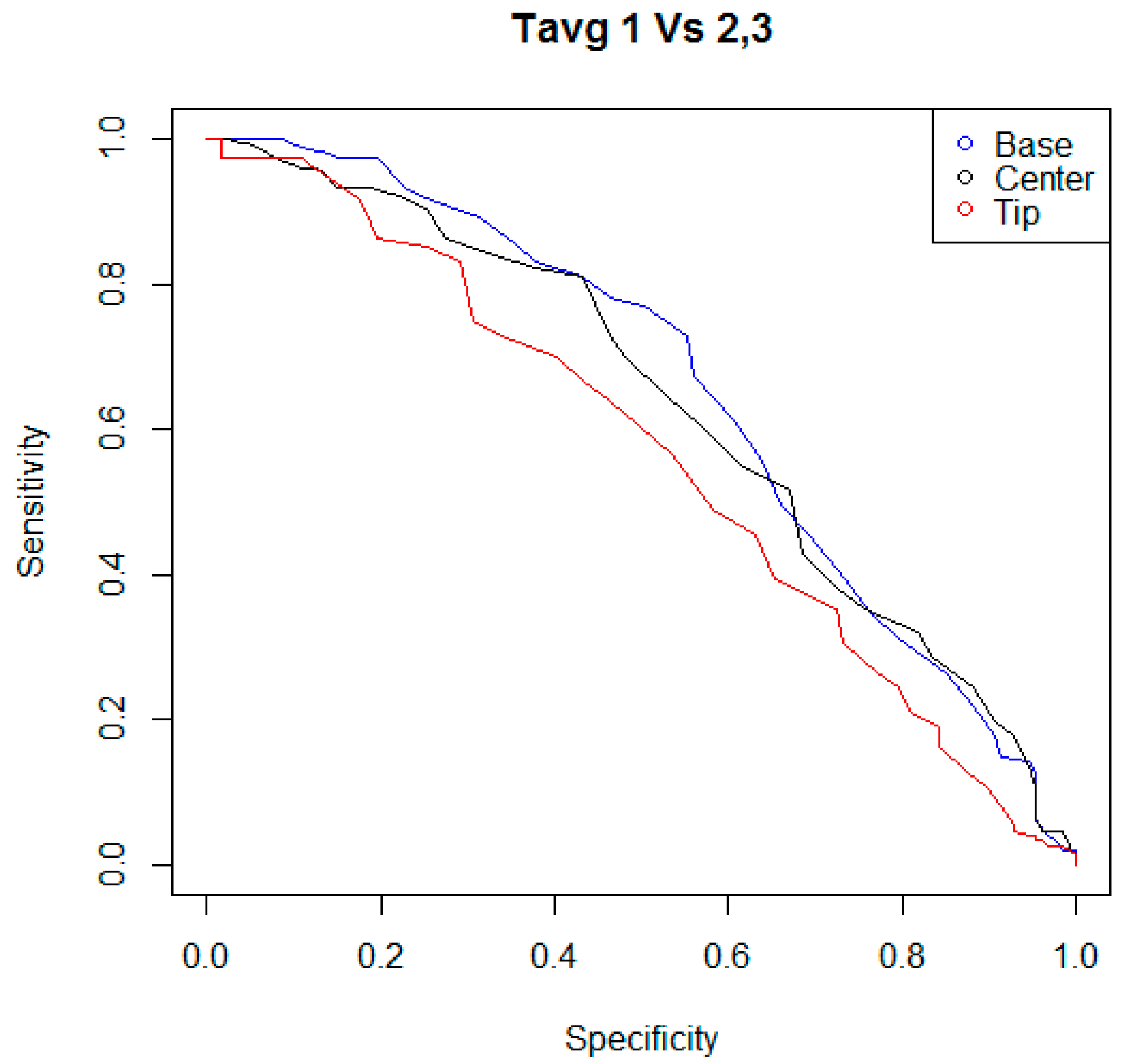

3. Result

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hillerton, J.E.; Ohnstad, I.; Baines, J.R. Relation of cluster performance to postmilking teat condition. In 37th An. Mtg; National Mastitis Council: St Louis, MI, USA, 1998; pp. 75–84. [Google Scholar]

- Hillerton, J.E.; Ohnstad, I.; Baines, J.R.; Leach, K.A. Changes in cow teat tissue created by two types of milking cluster. J. Dairy Res. 2000, 67, 309–317. [Google Scholar] [CrossRef] [PubMed]

- Mein, G.A.; Neijenhuis, F.; Morgan, W.F.; Reinemann, D.J.; Hillerton, J.E.; Baines Ohnstad, J.R.; Rasmussen, M.D.; Timms, L.; Britt, J.S.; Farnsworth, R.; et al. Evaluation of bovine teat condition in commercial dairy herds: 1. Non-infectious factors. In Proceedings of the 2nd International Symposium on Mastitis and Milk Quality, Vancouver, BC, Canada, 13–15 September 2001; pp. 347–351. [Google Scholar]

- Ohnstad, I.; Mein, G.A.; Baines, J.R.; Rasmussen, M.D.; Farnsworth, R.; Pocknee, B.R.; Hemling, T.C.; Hillerton, J.E. Addressing teat condition problems. In Proceedings of the National Mastitis Council Annual Meeting, San Antonio, TX, USA, 21–24 January 2007; pp. 189–199. [Google Scholar]

- Rasmussen, M.D. The relationship between mouthpiece vacuum, teat condition, and udder health. In Proceedings of the 36th Annual Meeting National Mastitis Council, Albuquerque, NM, USA, 16–19 February 1997; pp. 91–96. [Google Scholar]

- Mein, G.A.; Thompson, P.D.; Thompson, P.D. Milking the 30,000-pound herd. J. Dairy Sci. 1993, 76, 3294–3300. [Google Scholar] [CrossRef]

- Rønningen, O.; Reitan, A.D. Influence of static and dynamic teat characteristics and milking time on udder health in Norwegian Red Cattle. J. Dairy Res. 1990, 57, 171–177. [Google Scholar] [CrossRef] [PubMed]

- Hillerton, J.E.; Pankey, J.W.; Pankey, P. Effects of machine milking on teat condition. In Proceedings of the 38th Annual Meeting National Mastitis Council, Arlington, VA, USA, 14–16 February 1999; pp. 202–203. [Google Scholar]

- Council, N.N.M. Guidelines for Evaluating Teat Skin Condition; NMC National Mastitis Council: Verona, WI, USA, 2007. [Google Scholar]

- Isaksson, A.; Lind, O. Teat reactions in cows associated with machine milking. Zentralbl. Veterinarmed. A 1992, 39, 282–288. [Google Scholar] [CrossRef] [PubMed]

- Stampa, F.; Kalchreuter, S.; Brunotte-Schütte, G. Handbuch Mastitis, 2nd ed.; Auflage. Kamlage Verlag GmbH & Co.: Osnabrück, Germany, 2006. [Google Scholar]

- Ordolff, D. Surface temperatures of udder and teats for conventional and automatic milking methods. Kieler Milchwirtsch. Forschungsberichte 2000, 52, 5–10. [Google Scholar]

- Kunc, P.; Knížková, I.; Koubková, M.; Flusser, J.; Doležal, O. Comparison of rubber liners by means of temperature states of teats. Res. Agric. Eng. 2000, 46, 104–107. [Google Scholar]

- Paulrud, C.O.; Clausen, S.; Andersen, P.E.; Rasmussen, M.D. Infrared thermography and ultrasonography to indirectly monitor the influence of liner type and overmilking on teat tissue recovery. Acta Vet. Scand. 2005, 46, 137–147. [Google Scholar] [CrossRef]

- Vegricht, J.; Machálek, A.; Ambroź, P.; Brehme, U.; Rose, S. Milking-related changes of teat temperature caused by various milking machines. Res. Agric. Eng. 2007, 53, 121–125. [Google Scholar] [CrossRef]

- Maldagues, X. Nondestructive Testing Handbook, 3rd ed.; Moore, P., Ed.; The American Society for Nondestructive Testing: Columbus, OH, USA, 2001; Volume 3, Infrared and thermal testing; ISBN 978-1-57117-287-7. [Google Scholar]

- Poikalainen, V.; Praks, J.; Veermäe, I.; Kokin, E. Infrared temperature patterns of cow’s body as an indicator for health control at precision cattle farming. Agron. Res. 2012, 10, 187–194. [Google Scholar]

- Zaninelli, M.; Redaelli, V.; Tirloni, E.; Bernardi, C.; Dell’Orto, V.; Savoini, G. First results of a detection sensor for the monitoring of laying hens reared in a commercial organic egg production farm based on the use of infrared technology. Sensors 2016, 16, 1757. [Google Scholar] [CrossRef]

- Kunc, P.; Knížková, I.; Přikryl, M.; Maloun, J. Infrared Thermography As a Tool To Study the Milking Process: A Review. Agric. Trop. Subtrop. 2007, 40, 29–32. [Google Scholar]

- Kunc, P.; Knizkova, I. (Eds.) The Use of Infrared Thermography in Livestock Production and Veterinary Field. In Infrared Thermography Recent Advances and Future Trends; Bentham Science Publishers: Sharjah, UAE, 2012; pp. 85–101. [Google Scholar]

- Talukder, S.; Kerrisk, K.L.; Ingenhoff, L.; Thomson, P.C.; Garcia, S.C.; Celi, P. Infrared technology for estrus detection and as a predictor of time of ovulation in dairy cows in a pasture-based system. Theriogenology 2017, 81, 925–935. [Google Scholar] [CrossRef] [PubMed]

- Montanholi, Y.R.; Swanson, K.C.; Schenkel, F.S.; McBride, B.W.; Caldwell, T.R.; Miller, S.P. On the determination of residual feed intake and associations of infrared thermography with efficiency and ultrasound traits in beef bulls. Livest. Sci. 2017, 125, 22–30. [Google Scholar] [CrossRef]

- Montanholi, Y.R.; Odongo, N.E.; Swanson, K.C.; Schenkel, F.S.; McBride, B.W.; Miller, S.P. Application of infrared thermography as an indicator of heat and methane production and its use in the study of skin temperature in response to physiological events in dairy cattle (Bos taurus). J. Therm. Biol. 2008, 33, 468–475. [Google Scholar] [CrossRef]

- Weschenfelder, A.V.; Saucier, L.; Maldague, X.; Rocha, L.M.; Schaefer, A.L.; Faucitano, L. Use of infrared ocular thermography to assess physiological conditions of pigs prior to slaughter and predict pork quality variation. Meat Sci. 2013, 95, 616–620. [Google Scholar] [CrossRef] [PubMed]

- Hovinen, M.; Siivonen, J.; Taponen, S.; Hänninen, L.; Pastell, M.; Aisla, A.; Pyörälä, S. Detection of clinical mastitis with the help of a thermal camera. J. Dairy Sci. 2008, 91, 4592–4598. [Google Scholar] [CrossRef] [PubMed]

- Castro-Costa, A.; Caja, G.; Salama, A.A.K.; Rovai, M.; Flores, C.; Aguiló, J. Thermographic variation of the udder of dairy ewes in early lactation and following an Escherichia coli endotoxin intramammary challenge in late lactation. J. Dairy Sci. 2014, 97, 1377–1387. [Google Scholar] [CrossRef]

- McManus, C.; Tanure, C.B.; Peripolli, V.; Seixas, L.; Fischer, V.; Gabbi, A.M.; Menegassi, S.R.O.; Stumpf, M.T.; Kolling, G.J.; Dias, E.; et al. Infrared thermography in animal production: An overview. Comput. Electron. Agric. 2016, 123, 10–16. [Google Scholar] [CrossRef]

- Polat, B.; Colak, A.; Cengiz, M.; Yanmaz, L.E.; Oral, H.; Bastan, A.; Kaya, S.; Hayirli, A. Sensitivity and specificity of infrared thermography in detection of subclinical mastitis in dairy cows. J. Dairy Sci. 2010, 93, 3525–3532. [Google Scholar] [CrossRef]

- Sathiyabarathi, M.; Jeyakumar, S.; Manimaran, A.; Jayaprakash, G.; Pushpadass, H.A.; Sivaram, M.; Ramesha, K.P.; Das, D.N.; Kataktalware, M.A.; Prakash, M.A.; et al. Infrared thermography: A potential noninvasive tool to monitor udder health status in dairy cows. Vet. World 2016, 9, 1075–1081. [Google Scholar] [CrossRef]

- Alsaaod, M.; Syring, C.; Dietrich, J.; Doherr, M.G.; Gujan, T.; Steiner, A. A field trial of infrared thermography as a non-invasive diagnostic tool for early detection of digital dermatitis in dairy cows. Vet. J. 2014, 199, 281–285. [Google Scholar] [CrossRef] [PubMed]

- Alejandro, M.; Romero, G.; Sabater, J.M.; Díaz, J.R. Infrared thermography as a tool to determine teat tissue changes caused by machine milking in Murciano-Granadina goats. Livest. Sci. 2014, 160, 178–185. [Google Scholar] [CrossRef]

- Rose-Meierhöfer, S.; Müller, A.B.; Mittmann, L.; Demba, S.; Entorf, A.C.; Hoffmann, G.; Ammon, C.; Rudovsky, H.J.; Brunsch, R. Effects of quarter individual and conventional milking systems on teat condition. Prev. Vet. Med. 2014, 113, 556–564. [Google Scholar] [CrossRef] [PubMed]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2008; ISBN 3-900051-07-0. [Google Scholar]

- Lindstrom, M.J.; Bates, D.M. Newton-Raphson and EM Algorithms for Linear Mixed-Effects Models for Repeated-Measures Data. J. Am. Stat. Assoc. 1988, 83, 1014–1022. [Google Scholar]

- Barkema, H.W.; Schukken, Y.H.; Lam, T.J.; Galligan, D.T.; Beiboer, M.L.; Brand, A. Estimation of interdependence among quarters of the bovine udder with subclinical mastitis and implications for analysis. J. Dairy Sci. 1997, 80, 1592–1599. [Google Scholar] [CrossRef]

- Sing, T.; Sander, O.; Beerenwinkel, N.; Lengauer, T. ROCR: Visualizing classifier performance in R. Bioinformatics 2005, 21, 3940–3941. [Google Scholar] [CrossRef] [PubMed]

- Kejík, C.; Mašková, A. Thermographic measurements of teat surface temperature during machine milking. Živočišná výroba 1989, 35, 225–230. [Google Scholar]

- Malik, K.; Maskova, A.; Vevoda, J. A thermovision study of the rubber teat cup function. Plast. Rubber 1989, 16, 49–51. [Google Scholar]

- Caruolo, E.V.; Jarman, R.F.; Dickey, D.A. Milk temperature in the claw piece of the milking machine and mammary surface temperature are predictors of internal mammary temperature in goats. Zentralbl. Veterinarmed. A 1990, 37, 61–67. [Google Scholar] [CrossRef]

- Eichel, H. Temperature of teat skin in dairy cows milked in piped milking parlor. Monatsh. Veterinarmed. 1992, 47, 193–195. [Google Scholar]

- Kunc, P.; Knížková, I.; Koubková, M. Teat stress by calf suckling and machine milking. Folia Vet. 2002, 46, 48–49. [Google Scholar]

- Hanusová, J.; Gálik, R.; Bodo, Š.; Kunc, P.; Knážková, I.; Staronová, L. Analysis of quality milking process by thermographic method. Acta Univ. Agric. Silvic. Mendelianae Brun. 2016, 64, 1149–1153. [Google Scholar] [CrossRef]

- Zaninelli, M.; Redaelli, V.; Luzi, F.; Bronzo, V.; Mitchell, M.; Dell’Orto, V.; Bontempo, V.; Cattaneo, D.; Savoini, G. First evaluation of infrared thermography as a tool for the monitoring of udder health status in farms of dairy cows. Sensors 2018, 18, 862. [Google Scholar] [CrossRef] [PubMed]

- Zaninelli, M.; Redaelli, V.; Luzi, F.; Bronzo, V.; Tappella, A.; Mitchell, M.; Dell’Orto, V. Development of a software algorithm working with infrared images and useful for the early detection of mastitis in dairy cows. In Proceedings of the 14th Quantitative InfraRed Thermography Conference, QIRT 2018, Berlin, Germany, 25–29 June 2018; pp. 1–6. [Google Scholar]

| Indicator | Teat Color Change Scale | Mean (°C) | Standard Error | Significance |

|---|---|---|---|---|

| Tavg,B | 1 | 33.92 | 0.09 | p < 0.01 |

| 2 | 34.44 | 0.08 | ||

| 3 | 34.47 | 0.09 | ||

| Tavg,C | 1 | 34.54 | 0.08 | p < 0.01 |

| 2 | 34.90 | 0.08 | ||

| 3 | 35.07 | 0.10 | ||

| Tavg,T | 1 | 34.83 | 0.09 | p = 0.06 |

| 2 | 34.97 | 0.09 | ||

| 3 | 35.19 | 0.14 | ||

| Tmax,B | 1 | 34.62 | 0.10 | p = 0.01 |

| 2 | 35.00 | 0.09 | ||

| 3 | 35.07 | 0.10 | ||

| Tmax,C | 1 | 35.50 | 0.08 | p < 0.01 |

| 2 | 35.96 | 0.08 | ||

| 3 | 36.12 | 0.08 | ||

| Tmax,T | 1 | 36.39 | 0.08 | p < 0.01 |

| 2 | 36.66 | 0.08 | ||

| 3 | 36.97 | 0.10 |

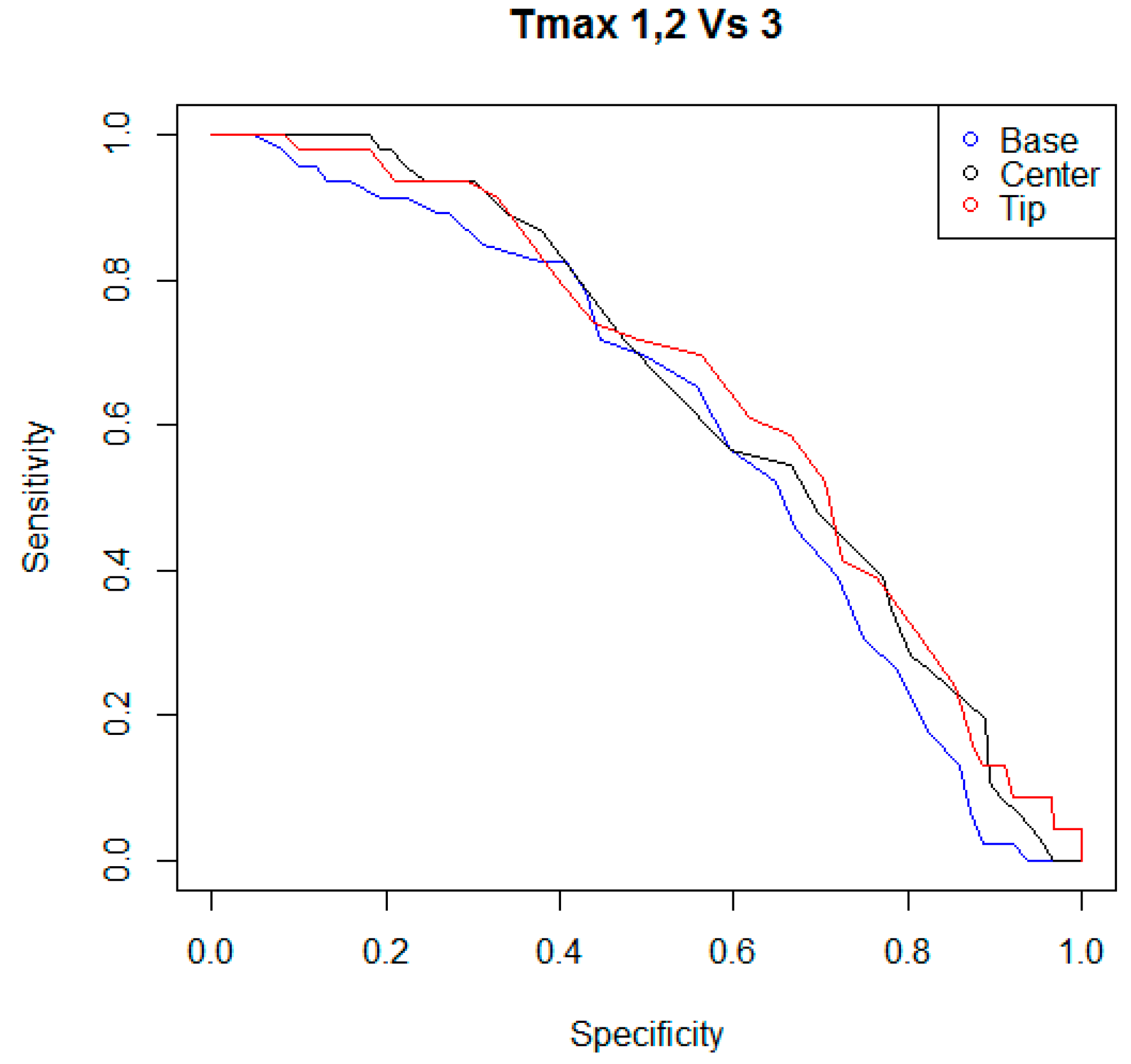

| Color Change Scale Value Used to Classify a Teat Stressed by the Milking Machine | Indicator | AUC (Area) | Sensitivity (%) | Specificity (%) | Cutoff Level (°C) |

|---|---|---|---|---|---|

| 3 | Tavg,B | 0.586 | 52.17 | 54.38 | 34.4 |

| Tavg,C | 0.612 | 54.35 | 59.21 | 35.0 | |

| Tavg,T | 0.559 | 45.65 | 54.39 | 35.1 | |

| Tmax,B | 0.600 | 56.52 | 59.65 | 35.1 | |

| Tmax,C | 0.642 | 56.52 | 59.65 | 36.0 | |

| Tmax,T | 0.657 | 60.87 | 61.84 | 36.8 | |

| 2 and 3 | Tavg,B | 0.651 | 55.78 | 61.78 | 34.4 |

| Tavg,C | 0.630 | 55.10 | 61.42 | 34.9 | |

| Tavg,T | 0.560 | 48,98 | 58.27 | 35.1 | |

| Tmax,B | 0.617 | 55.78 | 61.42 | 35.0 | |

| Tmax,C | 0.652 | 59.86 | 60.63 | 35.9 | |

| Tmax,T | 0.623 | 55.78 | 60.63 | 36.7 |

| Color Change Scale Levels Used to Classify a Teat Stressed by the Milking Machine | Indicator | Teat Status (Not Stressed/Stressed) | Cases (n) | Temperatures (°C, Means ± S.E.) | Significance |

|---|---|---|---|---|---|

| 3 | Tavg,B | not stressed | 228 | 34.17 ± 0.06 | =0.13 |

| stressed | 46 | 34.46 ± 0.10 | |||

| Tavg,C | not stressed | 228 | 34.70 ± 0.06 | <0.05 | |

| stressed | 46 | 35.07 ± 0.10 | |||

| Tavg,T | not stressed | 228 | 34.90 ± 0.07 | =0.11 | |

| stressed | 46 | 35.19 ± 0.14 | |||

| Tmax,B | not stressed | 228 | 34.79 ± 0.07 | =0.14 | |

| stressed | 46 | 35.07 ± 0.10 | |||

| Tmax,C | not stressed | 228 | 35.70 ± 0.06 | =0.01 | |

| stressed | 46 | 36.12 ± 0.09 | |||

| Tmax,T | not stressed | 228 | 36.51 ± 0.06 | <0.01 | |

| stressed | 46 | 36.97 ± 0.10 | |||

| 2 and 3 | Tavg,B | not stressed | 127 | 33.93 ± 0.07 | <0.01 |

| stressed | 147 | 34.46 ± 0.07 | |||

| Tavg,C | not stressed | 127 | 34.54 ± 0.08 | <0.01 | |

| stressed | 147 | 34.95 ± 0.07 | |||

| Tavg,T | not stressed | 127 | 34.83 ± 0.09 | =0.12 | |

| stressed | 147 | 35.04 ± 0.08 | |||

| Tmax,B | not stressed | 127 | 34.62 ± 0.10 | =0.01 | |

| stressed | 147 | 35.02 ± 0.07 | |||

| Tmax,C | not stressed | 127 | 35.50 ± 0.08 | <0.01 | |

| stressed | 147 | 36.01 ± 0.06 | |||

| Tmax,T | not stressed | 127 | 36.39 ± 0.08 | <0.01 | |

| stressed | 147 | 36.76 ± 0.07 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tangorra, F.M.; Redaelli, V.; Luzi, F.; Zaninelli, M. The Use of Infrared Thermography for the Monitoring of Udder Teat Stress Caused by Milking Machines. Animals 2019, 9, 384. https://doi.org/10.3390/ani9060384

Tangorra FM, Redaelli V, Luzi F, Zaninelli M. The Use of Infrared Thermography for the Monitoring of Udder Teat Stress Caused by Milking Machines. Animals. 2019; 9(6):384. https://doi.org/10.3390/ani9060384

Chicago/Turabian StyleTangorra, Francesco Maria, Veronica Redaelli, Fabio Luzi, and Mauro Zaninelli. 2019. "The Use of Infrared Thermography for the Monitoring of Udder Teat Stress Caused by Milking Machines" Animals 9, no. 6: 384. https://doi.org/10.3390/ani9060384

APA StyleTangorra, F. M., Redaelli, V., Luzi, F., & Zaninelli, M. (2019). The Use of Infrared Thermography for the Monitoring of Udder Teat Stress Caused by Milking Machines. Animals, 9(6), 384. https://doi.org/10.3390/ani9060384