A Survey of Italian Dairy Farmers’ Propensity for Precision Livestock Farming Tools

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Farm Selection and Data Collection

2.2. Statistical Analyses

3. Results

3.1. General Information about the Surveyed Farms

3.2. Information on the Parameters Measured on the Dairy Farms

3.3. Distribution and Interest in Technologies Based on Categories

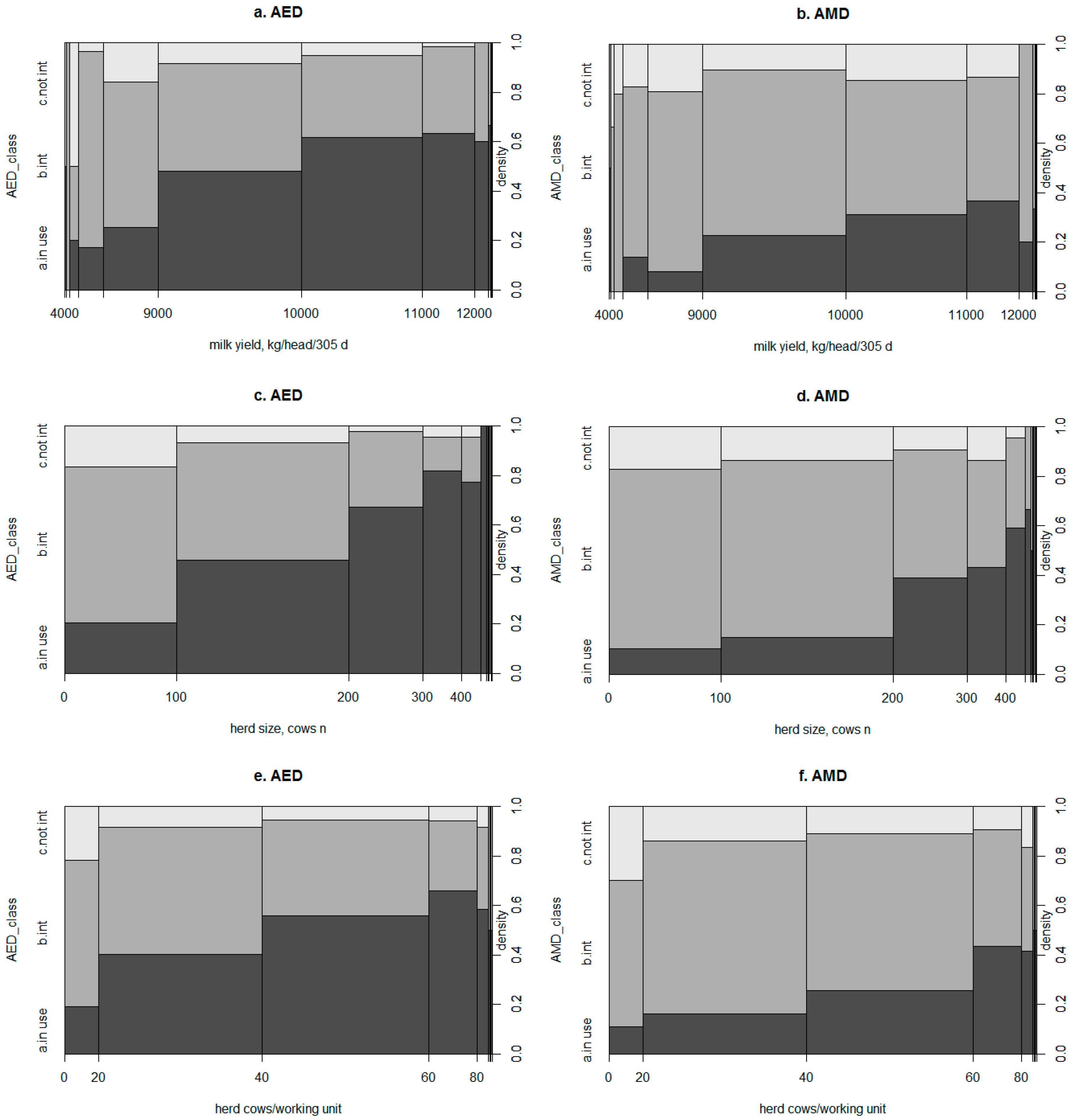

3.4. Prediction of the Presence of a Tool in the Farm Based on General Information

3.5. Criteria Considered in Evaluating Possible Investment in PLF

3.6. Prediction of the Presence of a Tool in the Farm Based on Criteria and Motivation Scores

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Berckmans, D. General introduction to precision livestock farming. Anim. Front. 2017, 7, 6–11. [Google Scholar] [CrossRef]

- Hartung, J.; Banhazi, T.; Vranken, E.; Guarino, M. European farmers’ experiences with precision livestock farming systems. Anim. Front. 2017, 7, 38–44. [Google Scholar] [CrossRef]

- Steeneveld, W.; Tauer, L.W.; Hogeveen, H.; Lansink, A.G.J.M.O. Comparing technical efficiency of farms with an automatic milking system and a conventional milking system. J. Dairy Sci. 2012, 95, 7391–7398. [Google Scholar] [CrossRef]

- Jacobs, J.A.; Siegford, M. Invited review: The impact of automatic milking systems on dairy cow management, behavior, health, and welfare. J. Dairy Sci. 2012, 95, 2227–2247. [Google Scholar] [CrossRef]

- Tse, C.; Barkema, H.W.; DeVries, T.J.; Rushen, J.; Pajor, E.A. Effect of transitioning to automatic milking systems on producers’ perceptions of farm management and cow health in the Canadian dairy industry. J. Dairy Sci. 2017, 100, 2404–2414. [Google Scholar] [CrossRef]

- Abeni, F.; Calamari, L.; Calza, F.; Speroni, M.; Bertoni, G.; Pirlo, G. Welfare assessment based on metabolic and endocrine aspects in primiparous cows milked in a parlor or with an automatic milking system. J. Dairy Sci. 2005, 88, 3542–3552. [Google Scholar] [CrossRef]

- Abeni, F.; Degano, L.; Calza, F.; Giangiacomo, R.; Pirlo, G. Milk quality and automatic milking: Fat globule size, natural creaming, and lipolysis. J. Dairy Sci. 2005, 88, 3519–3529. [Google Scholar] [CrossRef]

- Abeni, F.; Terzano, M.G.; Speroni, M.; Migliorati, L.; Capelletti, M.; Calza, F.; Bianchi, L.; Pirlo, G. Evaluation of milk enzymes and electrolytes, plasma metabolites, and oxidative status in twin cows milked in an automatic milking system or twice daily in a conventional milking parlor. J. Dairy Sci. 2008, 91, 3372–3384. [Google Scholar] [CrossRef]

- Caja, G.; Castro-Costa, A.; Knight, C.H. Engineering to support wellbeing of dairy animals. J. Dairy Res. 2016, 83, 136–147. [Google Scholar] [CrossRef]

- Abeni, F.; Galli, A. Monitoring cow activity and rumination time for an early detection of heat stress in dairy cow. Int. J. Biometeorol. 2017, 61, 417–425. [Google Scholar] [CrossRef]

- Stevenson, J.S.; Hill, S.L.; Nebel, R.L.; DeJarnette, J.M. Ovulation timing and conception risk after automated activity monitoring in lactating dairy cows. J. Dairy Sci. 2014, 97, 4296–4308. [Google Scholar] [CrossRef]

- Sauls, J.A.; Voelz, B.E.; Hill, S.L.; Mendonça, L.G.D.; Stevenson, J.S. Increasing estrus expression in the lactating dairy cow. J. Dairy Sci. 2017, 100, 807–820. [Google Scholar] [CrossRef]

- Silper, B.F.; Madureira, A.M.L.; Kaur, M.; Burnett, T.A.; Cerri, R.L.A. Short communication: Comparison of estrus characteristics in Holstein heifers by 2 activity monitoring systems. J. Dairy Sci. 2015, 98, 3158–3165. [Google Scholar] [CrossRef]

- Steeneveld, W.; Vernooij, J.C.M.; Hogeveen, H. Effect of sensor systems for cow management on milk production, somatic cell count, and reproduction. J. Dairy Sci. 2015, 98, 3896–3905. [Google Scholar] [CrossRef]

- Steeneveld, W.; Hogeveen, H.; Lansink, A.G.J.M.O. Economic consequences of investing in sensor systems on dairy farms. Comput. Electron. Agric. 2015, 119, 33–39. [Google Scholar] [CrossRef]

- Rutten, C.J.; Steeneveld, W.; Inchaisri, C.; Hogeveen, H. An ex ante analysis on the use of activity meters for automated estrus detection: To invest or not to invest? J. Dairy Sci. 2014, 97, 6869–6887. [Google Scholar] [CrossRef]

- Borchers, M.R.; Bewley, J.M. An assessment of producer precision dairy farming technology use, prepurchase considerations, and usefulness. J. Dairy Sci. 2015, 98, 4198–4205. [Google Scholar] [CrossRef]

- Giordano, J.O. Use of Technologies in Reproductive Management: Economics of Automated Activity Monitoring Systems for Detection of Estrus. In Proceedings of the Western Dairy Management Conference, Reno, NV, USA, 3–5 March 2015; Dairy Conferences LLC: Manhattan, KS, USA, 2015; pp. 51–66. [Google Scholar]

- Dolecheck, K.A.; Heersche, G., Jr.; Bewley, J.M. Retention payoff–based cost per day open regression equations: Application in a user-friendly decision support tool for investment analysis of automated estrus detection technologies. J. Dairy Sci. 2016, 99, 10182–10193. [Google Scholar] [CrossRef]

- Bewley, J.M.; Russell, R.A.; Dolecheck, K.A.; Borchers, M.R.; Stone, A.E.; Wadsworth, B.A.; Mayo, L.M.; Tsai, I.-C. Precision Dairy Monitoring Opportunities, Limitations, and Considerations. In Proceedings of the Western Dairy Management Conference, Reno, NV, USA, 3–5 March 2015. [Google Scholar]

- CLAL. Available online: http://www.clal.it/?section=consegne_reg_it&year=2016#LOM (accessed on 31 August 2017).

- AIA. Available online: http://bollettino.aia.it/Contenuti.aspx?CD_GruppoStampe=RS&CD_Specie=C4 (accessed on 31 August 2017).

- Neves, R.C.; LeBlanc, S.J. Reproductive management practices and performance of Canadian dairy herds using automated activity-monitoring systems. J. Dairy Sci. 2015, 98, 2801–2811. [Google Scholar] [CrossRef]

- Likert, R. A technique for the measurement of attitudes. Arch. Psychol. 1932, 22, 1–55. [Google Scholar]

- Scheaffer, R.L.; Mendenhall, W.I.I.I.; Ott, R.L. Elementary Survey Sampling, 6th ed.; Thomson Higher Education: Belmont, CA, USA, 2006. [Google Scholar]

- Fox, J.; Weisberg, S. An R Companion to Applied Regression, 2nd ed.; R package version 2.1–2; Sage: Thousand Oaks, CA, USA, 2011. [Google Scholar]

- Everitt, B.S.; Hothorn, T. A Handbook of Statistical Analyses Using R, 2nd ed.; Chapman & Hall/CRC-Taylor & Francis Group: Boca Raton, FL, USA, 2010; ISBN 978-1-4200-7933-3. [Google Scholar]

- Radtke, A.; Ambraß, S.; Zerbe, S.; Tonon, G.; Fontana, V.; Ammer, C. Traditional coppice forest management drives the invasion of Ailanthus altissima and Robinia pseudoacacia into deciduous forests. For. Ecol. Manag. 2013, 291, 308–317. [Google Scholar] [CrossRef]

- Gargiulo, J.I.; Eastwood, C.R.; Garcia, S.C.; Lyons, N.A. Dairy farmers with larger herd sizes adopt more precision dairy technologies. J. Dairy Sci. 2018, 101, 5466–5473. [Google Scholar] [CrossRef]

- Rutten, C.J.; Velthuis, A.G.J.; Steeneveld, W.; Hogeveen, H. Invited review: Sensors to support health management on dairy farm. J. Dairy Sci. 2013, 98, 1928–1952. [Google Scholar] [CrossRef] [PubMed]

- Van Hertem, T.; Rooijakkers, L.; Berckmans, D.; Peña Fernández, A.; Norton, T.; Berckmans, D.; Vranken, E. Appropriate data visualisation is key to Precision Livestock Farming acceptance. Comput. Electron. Agric. 2017, 138, 1–10. [Google Scholar] [CrossRef]

- Van Hertem, T.; Maltz, E.; Antler, A.; Romanini, C.E.B.; Viazzi, S.; Bahr, C.; Schlageter-Tello, A.; Lokhorst, C.; Berckmans, D.; Halachmi, I. Lameness detection based on multivariate continuous sensing of milk yield, rumination, and neck activity. J. Dairy Sci. 2013, 96, 4286–4298. [Google Scholar] [CrossRef] [PubMed]

- Bewley, J.; Palmer, R.W.; Jackson-Smith, D.B. Modeling milk production and labor efficiency in modernized Wisconsin dairy herds. J. Dairy Sci. 2001, 84, 705–716. [Google Scholar] [CrossRef]

- Steeneveld, W.; Hogeveen, H. Characterization of Dutch dairy farms using sensor systems for cow management. J. Dairy Sci. 2015, 98, 709–717. [Google Scholar] [CrossRef]

- Hostiou, N.; Fagon, J.; Chauvat, S.; Turlot, A.; Kling-Eveillard, F.; Boivin, X.; Allain, C. Impact of precision livestock farming on work and human-animal interactions on dairy farms. A review. Biotechnol. Agron. Soc. Environ. 2017, 21, 268–275. Available online: http://www.pressesagro.be/base/index.php/base/issue/view/436 (accessed on 19 January 2018).

- Lawson, L.G.; Pedersen, S.M.; Sørensen, C.G.; Pesonen, L.; Fountas, S.; Werner, A.; Oudshoorn, F.W.; Herold, L.; Chatzinikos, T.; Kirketerp, I.M.; et al. A four nation survey of farm information management and advanced farming systems: A descriptive analysis of survey responses. Comput. Electron. Agric. 2011, 77, 7–20. [Google Scholar] [CrossRef]

- Van De Gucht, T.; Saeys, W.; Van Nuffel, A.; Pluym, L.; Piccart, K.; Lauwers, L.; Vangeyte, J.; Van Weyenberg, S. Farmers’ preferences for automatic lameness-detection systems in dairy cattle. J. Dairy Sci. 2017, 100, 5746–5757. [Google Scholar] [CrossRef]

| Item | Mean | Standard Deviation | Median | 1st Quartile | 3rd Quartile |

|---|---|---|---|---|---|

| Land owned by farmers, ha | 96.2 | 89.7 | 70.0 | 42.0 | 115.0 |

| Herd size (dry + lactating cows), n | 188.7 | 137.0 | 154 | 98 | 239 |

| Herd size variation from the previous year, % | 1.10 | 12.22 | 2.21 | −2.89 | 6.57 |

| Herd average 305-day milk yield, kg/cow | 9827.3 | 1346.5 | 9870 | 9121 | 10,599 |

| Total employed workers, n | 4.3 | 2.2 | 4.0 | 3.0 | 5.0 |

| Cows per working unit, n | 43.3 | 19.1 | 42.3 | 30.6 | 53.8 |

| Parameter | Using | Interested in | Not interested in | No Answer |

|---|---|---|---|---|

| a. Technologies for automatic estrus detection and animal well-being monitoring | ||||

| Leg activity (pedometer) | 34.5 (169) * | 37.6 (184) | 22.7 (111) | 5.3 (26) |

| Neck activity (activity meter) | 29.0 (142) | 41.4 (203) | 25.5 (125) | 4.1 (20) |

| Hoof health/locomotion problems | 0.2 (1) | 50.2 (246) | 49.2 (241) | 0.4 (2) |

| Milk progesterone | 0.2 (1) | 47.8 (234) | 51.2 (251) | 0.8 (4) |

| Calving alert | 1.0 (5) | 31.4 (154) | 58.8 (288) | 8.8 (43) |

| Animal position | 3.3 (16) | 25.7 (126) | 68.4 (335) | 2.7 (13) |

| Animal location | 0.4 (2) | 13.1 (64) | 85.1 (417) | 1.4 (7) |

| Body temperature, heart, and breathing rate | 0.4 (2) | 22.5 (110) | 76.5 (375) | 0.6 (3) |

| b. Technologies for automatic monitoring of feeding behavior and metabolic problems | ||||

| Rumination and cow activity | 14.5 (71) | 58.4 (286) | 23.3 (114) | 3.9 (19) |

| Chewing activity | 0.4 (2) | 41.6 (204) | 57.6 (282) | 0.4 (2) |

| Rumen pH | 0.2 (1) | 32.9 (161) | 66.5 (326) | 0.4 (2) |

| Body condition score (BCS) | 0.2 (1) | 31 (152) | 68.6 (336) | 0.2 (1) |

| Body weight (BW) | 1.0 (5) | 26.9 (132) | 71.8 (352) | 0.2 (1) |

| Rumen temperature | 0.2 (1) | 24.9 (122) | 74.9 (367) | 0.0 (0) |

| Milk beta-hydroxybutyrate (BHB) | 0.6 (3) | 63.3 (310) | 34.7 (170) | 1.4 (7) |

| Milk urea | 0.4 (2) | 44.1 (216) | 54.7 (268) | 0.8 (4) |

| Methane emissions | 0.0 (0) | 10.4 (51) | 89.6 (439) | 0.0 (0) |

| c. Technologies for automatic MY, milk quality, and mastitis detection | ||||

| Daily milk yield | 39.4 (193) | 46.7 (229) | 9.2 (45) | 4.7 (23) |

| Milk somatic cell count (SCC) | 1.0 (5) | 81.6 (400) | 16.5 (81) | 0.8 (4) |

| Milk electrical conductivity (EC) | 23.3 (114) | 44.1 (216) | 32.0 (157) | 0.6 (3) |

| Milk components (e.g., fat, protein, SCC) | 1.8 (9) | 51.8 (254) | 45.1 (221) | 1.2 (6) |

| Milk color | 3.3 (16) | 40.0 (196) | 55.7 (273) | 1.0 (5) |

| Milk lactate dehydrogenase (LDH) | 0.2 (3) | 41.0 (201) | 58.8 (288) | 0.2 (1) |

| Milk temperature | 1.6 (8) | 36.7 (180) | 60.8 (298) | 0.8 (4) |

| Variable | β Estimate | SE | p-Value | Odds Ratio | 95% CI |

|---|---|---|---|---|---|

| Automated estrus detection (AED) | |||||

| (Intercept) | −3.48800 | 0.88260 | <0.001 | 0.0306 | 0.0052–0.1659 |

| Farmer’s age (class 1 to 5) | −0.15480 | 0.08805 | 0.079 | 0.8566 | 0.7198–1.0173 |

| Own farmland (ha) | 0.00539 | 0.00218 | 0.013 | 1.0054 | 1.0013–1.0099 |

| Herd size (no. of dairy cows) | 0.00423 | 0.00135 | 0.002 | 1.0042 | 1.0016–1.0070 |

| Herd average 305 day MY (kg/cow) | 0.00027 | 0.00008 | 0.001 | 1.0003 | 1.0001–1.0004 |

| Automated milk yield recording (AMYR) | |||||

| (Intercept) | −3.36500 | 0.82210 | <0.001 | 0.0346 | 0.0066–0.1672 |

| Land owned by farmers (ha) | 0.00505 | 0.00204 | 0.013 | 1.0051 | 1.0012–1.0093 |

| Herd size (no. of dairy cows) | 0.00526 | 0.00131 | <0.001 | 1.0053 | 1.0027–1.0079 |

| Herd average 305 day MY (kg/cow) | 0.00015 | 0.00008 | 0.081 | 1.0001 | 1.0000–1.0003 |

| Automated mastitis detection (AMD) | |||||

| (Intercept) | −1.68968 | 0.36779 | <0.001 | 0.1846 | 0.0879–0.3729 |

| Farmer’s age (classes 1 to 5) | −0.20208 | 0.09958 | 0.042 | 0.817 | 0.6718–0.9935 |

| Herd size (no. of dairy cows) | 0.00554 | 0.00089 | <0.001 | 1.0056 | 1.0039–1.0074 |

| Variable | β Estimate | SE | p-Value | Odds Ratio | 95% CI |

|---|---|---|---|---|---|

| Automated estrus detection (AED) | |||||

| (Intercept) | 0.31410 | 0.91245 | 0.731 | 1.3690 | 0.2185–8.3691 |

| Farmer’s age | −0.14623 | 0.08348 | 0.080 | 0.8640 | 0.7325–1.0167 |

| Benefit-to-cost ratio | 0.31144 | 0.15348 | 0.042 | 1.3654 | 1.0162–1.8596 |

| Third party opinions on tool performance | 0.13922 | 0.08506 | 0.102 | 1.1494 | 0.9737–1.3599 |

| The user-friendly degree of the new tool | 0.23100 | 0.09097 | 0.011 | 1.2599 | 1.0569–1.5115 |

| Time needed for information and data management | −0.23370 | 0.09760 | 0.017 | 0.7916 | 0.6496–0.9543 |

| Improvement of estrus and health monitoring | −0.37110 | 0.17316 | 0.032 | 0.6900 | 0.4869–0.9653 |

| Automated milk yield recording (AMYR) | |||||

| (Intercept) | −0.30732 | 0.43749 | 0.482 | 0.7354 | 0.3095–1.7338 |

| Third party opinions on tool performance | 0.18046 | 0.08225 | 0.028 | 1.1978 | 1.0209–1.4102 |

| Time needed for information and data management | −0.17403 | 0.08270 | 0.035 | 0.8403 | 0.7130–0.9877 |

| Automated mastitis detection (AMD) | |||||

| (Intercept) | −3.01592 | 1.08641 | 0.006 | 0.0490 | 0.0047–0.3454 |

| Farmer’s age | −0.17291 | 0.09641 | 0.073 | 0.8412 | 0.6960–1.0166 |

| Benefit-to-cost ratio | 0.51180 | 0.22292 | 0.022 | 1.6683 | 1.1081–2.6796 |

| Total investment cost | −0.18976 | 0.10894 | 0.082 | 0.8272 | 0.6680–1.0255 |

| Third party opinions on tool performance | 0.22645 | 0.10287 | 0.028 | 1.2541 | 1.0277–1.5393 |

| The user-friendly degree of the new tool | 0.17373 | 0.11113 | 0.118 | 1.1897 | 0.9643–1.4936 |

| Time needed for information and data management | −0.18919 | 0.10619 | 0.075 | 0.8276 | 0.6729–1.0242 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abeni, F.; Petrera, F.; Galli, A. A Survey of Italian Dairy Farmers’ Propensity for Precision Livestock Farming Tools. Animals 2019, 9, 202. https://doi.org/10.3390/ani9050202

Abeni F, Petrera F, Galli A. A Survey of Italian Dairy Farmers’ Propensity for Precision Livestock Farming Tools. Animals. 2019; 9(5):202. https://doi.org/10.3390/ani9050202

Chicago/Turabian StyleAbeni, Fabio, Francesca Petrera, and Andrea Galli. 2019. "A Survey of Italian Dairy Farmers’ Propensity for Precision Livestock Farming Tools" Animals 9, no. 5: 202. https://doi.org/10.3390/ani9050202

APA StyleAbeni, F., Petrera, F., & Galli, A. (2019). A Survey of Italian Dairy Farmers’ Propensity for Precision Livestock Farming Tools. Animals, 9(5), 202. https://doi.org/10.3390/ani9050202