Precision Livestock Farming in Swine Welfare: A Review for Swine Practitioners

Abstract

:Simple Summary

Abstract

1. Introduction

2. Precision Livestock Farming: An Overview

2.1. Sensors and Animal Recognition

2.1.1. Cameras (2D and 3D)—Behavior and Physiology

2.1.2. Microphones—Sound

2.1.3. Thermistors and Infrared Imaging—Temperature

2.1.4. Accelerometers—Motion Tracking

2.2. Livestock Identification

2.2.1. Radio Frequency Identification (RFID)

2.2.2. Optical Character Recognition

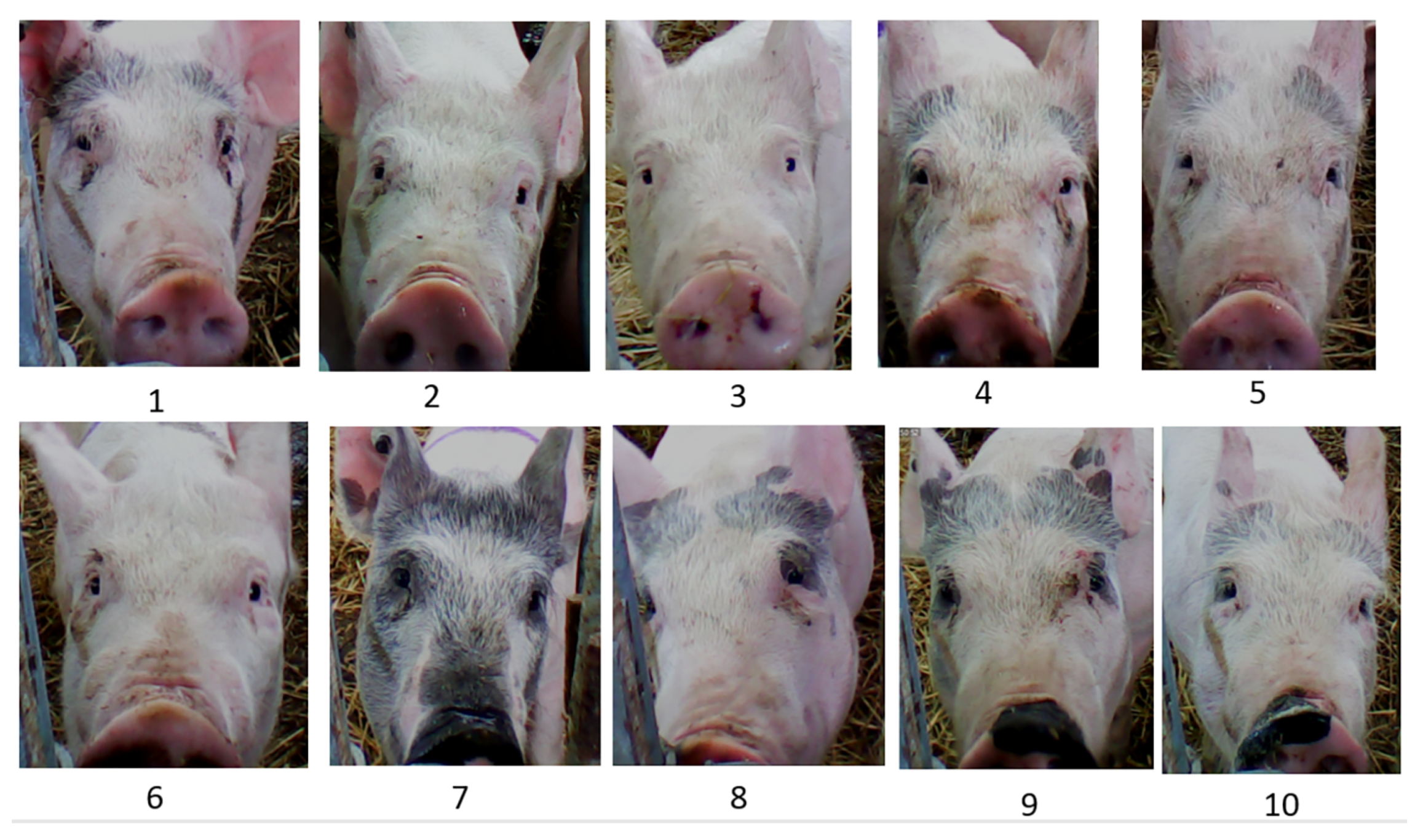

2.2.3. Facial Recognition

2.3. Hardware and Software Comparison Summary

2.4. Mobile Applications, WiFi and Bluetooth

2.5. Precision Livestock Farming Technology Design and Implementation

3. Welfare Challenges in the Swine Industry

3.1. Lameness

3.2. Body Condition

3.3. Prolapse Syndrome

3.4. Welfare at the Group Level

4. Summary of Remote Monitoring Technology Applications for Swine

4.1. Lameness and Mobility

4.2. Pen Level Activity Monitoring—Nursery and Grower Pigs

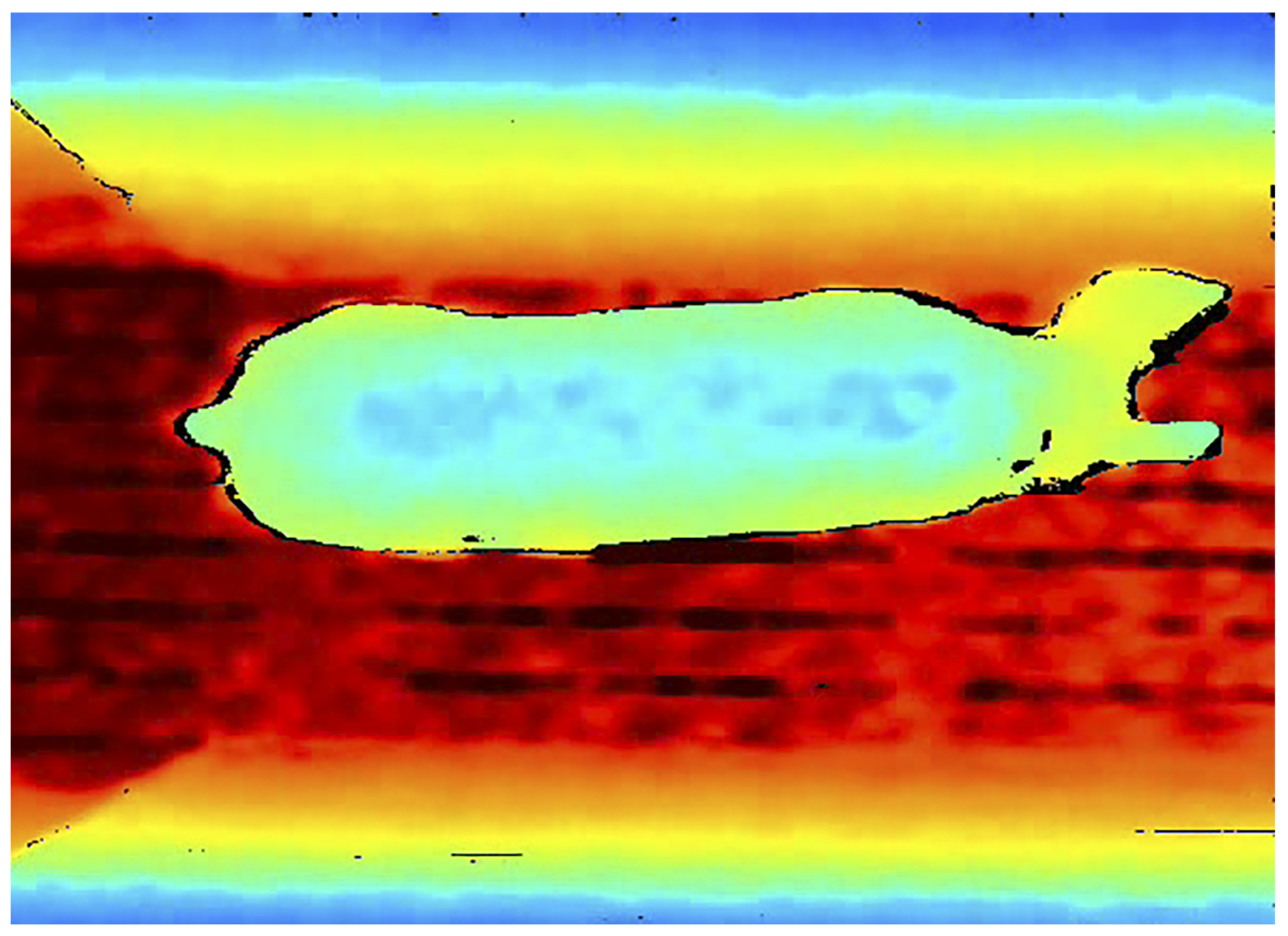

4.2.1. Infrared Thermography

4.2.2. Sound Detection

4.2.3. Live Weight, Body Condition and Physiology

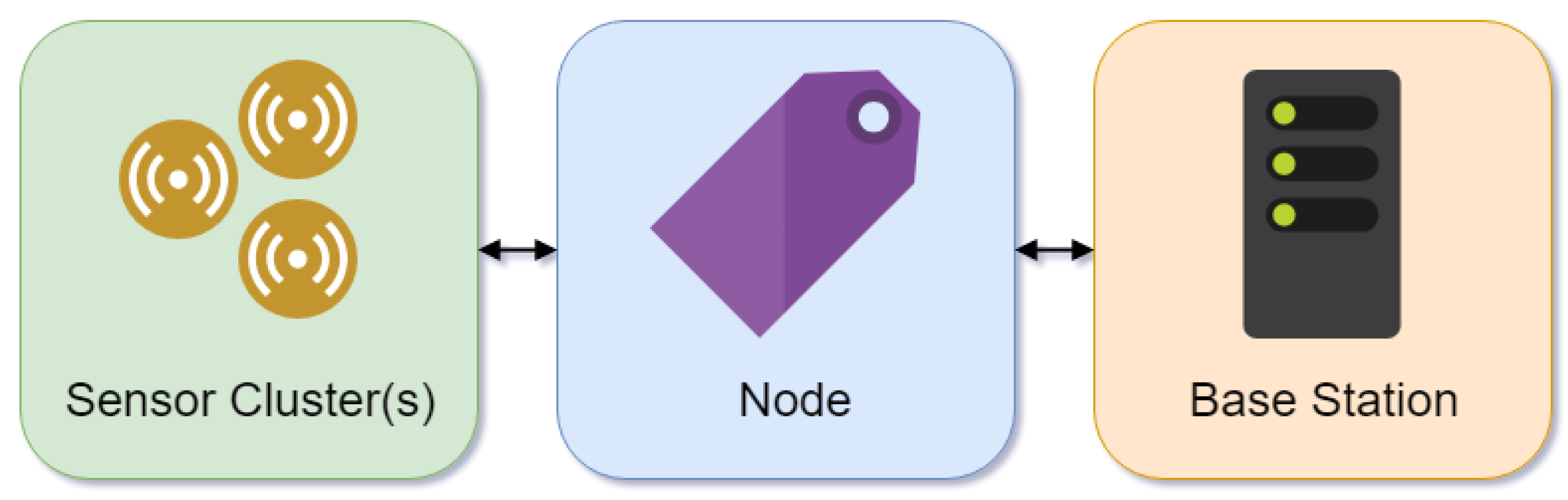

4.2.4. Wireless Sensor Networks

5. Precision Livestock Farming—Practitioner and Consultant

5.1. A Technical Role of Swine Practitioners

5.2. Robustness of Sensors

6. Limitations and Opportunities

6.1. Data Rights, Transparency and Traceability

6.2. Stakeholder Advocacy and Collaboration

6.3. Emerging Technological Integration

6.4. Opportunities

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| 2D | Two Dimensional |

| 3D | Three Dimensional |

| AASV | American Association of Swine Veterinarians |

| CSIA | Common Swine Industry Audit |

| PQA Plus | Pork Quality Assurance Plus |

| LED | Light Emitting Diode |

| LF | Low Frequency |

| Massive MIMO | Massive Multiple Input Multiple Output |

| PLF | Precision Livestock Farming |

| QR Code | Quick Response Code |

| RFID | Radio Frequency Identification |

| TOF | Time of Flight |

| UHF | Ultra High Frequency |

| WSN | Wireless Sensor Network |

References

- Food and Agriculture Organization (FAO). The State of Food and Agriculture: Livestock in Balance; FAO: Roman, Italy, 2009; p. 180. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Garnett, T. Food security and sustainable intensification. Philos. Trans. R. Soc. B Biol. Sci. 2014, 369, 20120273. [Google Scholar] [CrossRef]

- Scholten, M.C.; De Boer, I.J.; Gremmen, B.; Lokhorst, C. Livestock Farming with Care: Towards sustainable production of animal-source food. NJAS Wagening. J. Life Sci. 2013, 66, 3–5. [Google Scholar] [CrossRef]

- Broom, D.M. Animal Welfare: An Aspect of Care, Sustainability, and Food Quality Required by the Public. J. Vet. Med. Educ. 2010, 37, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Pairis-Garcia, M. Mitigating and Managing Pain in Swine Production; American Association of Swine Veterinarians: New Orleans, LA, USA, 2016; pp. 14–17. [Google Scholar] [CrossRef]

- Knauer, M.T.; Baitinger, D.J. The sow body condition caliper. Appl. Eng. Agric. 2015, 31, 175–178. [Google Scholar] [CrossRef]

- Whay, H.R.; Main, D.C.; Green, L.E.; Webster, A.J. Assessment of the welfare of dairy cattle using animal-based measurements: Direct observations and investigation of farm records. Vet. Rec. 2003, 153, 197–202. [Google Scholar] [CrossRef] [PubMed]

- Pittman, J.S. Sow Prolapse Syndrome. In Proceedings of the ISU—James D. McKean Swine Disease Conference, Ames, IA, USA, 3–4 November 2016; pp. 45–58. [Google Scholar]

- Dawkins, M.S.; Roberts, S.J.; Cain, R.J.; Nickson, T.; Donnelly, C.A. Early warning of footpad dermatitis and hockburn in broiler chicken flocks using optical flow, bodyweight and water consumption. Vet. Rec. 2017, 180, 499. [Google Scholar] [CrossRef] [PubMed]

- Van Hertem, T.; Lague, S.; Vranken, E. Objective sustainability assessment by Precision Livestock Farming. In Proceedings of the 166th EAAE Seminar on Sustainability in the Agri-Food Sector, Galaway, Ireland, 30–31 August 2018. [Google Scholar] [CrossRef]

- Hostiou, N.; Fagon, J.; Chauvat, S.; Turlot, A.; Kling-Eveillard, F.; Boivin, X.; Allain, C. Impact of precision livestock farming on work and human-animal interactions on dairy farms. A review. Biotechnol. Agron. Soc. Environ. 2017, 21, 268–275. [Google Scholar]

- Matthews, S.G.; Miller, A.L.; PlÖtz, T.; Kyriazakis, I. Automated tracking to measure behavioural changes in pigs for health and welfare monitoring. Sci. Rep. 2017, 7, 17582. [Google Scholar] [CrossRef] [PubMed]

- Nasirahmadi, A.; Edwards, S.A.; Matheson, S.M.; Sturm, B. Using automated image analysis in pig behavioural research: Assessment of the influence of enrichment substrate provision on lying behaviour. Appl. Anim. Behav. Sci. 2017, 196, 30–35. [Google Scholar] [CrossRef]

- Halachmi, I.; Guarino, M.; Bewley, J.; Pastell, M. Smart Animal Agriculture: Application of Real-Time Sensors to Improve Animal Well-Being and Production. Annu. Rev. Anim. Biosci. 2019, 7. [Google Scholar] [CrossRef]

- Berckmans, D. Precision livestock farming technologies for welfare management in intensive livestock systems. Rev. Sci. Tech. 2014. [Google Scholar] [CrossRef]

- Hostetler, C.; Stokes, A.; Becton, L. NATIONAL PORK BOARD Request for Proposals General Call 2018 Writing Research Proposals for the NPB The National Pork Board Is Soliciting Research Proposals Dealing with These Categories; NATIONAL PORK BOARD: Ames, IA, USA, 2018; pp. 1–19. [Google Scholar]

- Neethirajan, S. Recent advances in wearable sensors for animal health management. Sens. Bio-Sens. Res. 2017, 12, 15–29. [Google Scholar] [CrossRef]

- De Montis, A.; Modica, G.; Arcidiacono, C. Aginformatics. In Encyclopedia of Big Data, AG2017 ed.; Schintler, L.A., McNeely, C.L., Eds.; Springer: New York, NY, USA, 2017; pp. 1–4. [Google Scholar] [CrossRef]

- DeShazer, J.A.; Moran, P.; Onyango, C.M.; Randall, J.M.; Schofield, C.P. Imaging Systems to iMprove Stockmanship in Pig Production; AFRC Institute of Engineering Research: Bedfordshire, UK, 1988. [Google Scholar]

- Banhazi, T.M.; Lehr, H.; Black, J.L.; Crabtree, H.; Schofield, P.; Tscharke, M.; Berckmans, D. Precision Livestock Farming: An international review of scientific and commercial aspects. Int. J. Agric. Biol. Eng. 2012, 5, 1–9. [Google Scholar]

- Puri, M.; Solanki, A.; Padawer, T.; Tipparaju, S.M.; Moreno, W.A.; Pathak, Y. Introduction to Artificial Neural Network (ANN) as a Predictive Tool for Drug Design, Discovery, Delivery, and Disposition: Basic Concepts and Modeling. Basic Concepts and Modeling; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 3–13. [Google Scholar] [CrossRef]

- Guarino, M.; Norton, T.; Berckmans, D.; Vranken, E.; Berckmans, D. A blueprint for developing and applying precision livestock farming tools: A key output of the EU-PLF project. Anim. Front. 2017, 7, 12. [Google Scholar] [CrossRef]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.J. Big Data in Smart Farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Guarino, M.; Sartori, L.; González, L.A.; Marinello, F. On-barn pig weight estimation based on body measurements by a Kinect v1 depth camera. Comput. Electron. Agric. 2018, 148, 29–36. [Google Scholar] [CrossRef]

- Vandermeulen, J.; Bahr, C.; Tullo, E.; Fontana, I.; Ott, S.; Kashiha, M.; Guarino, M.; Moons, C.P.H.; Tuyttens, F.A.M.; Niewold, T.A.; et al. Discerning pig screams in production environments. PLoS ONE 2015, 10, 1–15. [Google Scholar] [CrossRef]

- Kashiha, M.A.; Bahr, C.; Ott, S.; Moons, C.P.H.; Niewold, T.A.; Tuyttens, F.; Berckmans, D. Automatic monitoring of pig locomotion using image analysis. Livest. Sci. 2014, 159, 141–148. [Google Scholar] [CrossRef]

- Kongsro, J. Estimation of pig weight using a Microsoft Kinect prototype imaging system. Comput. Electron. Agric. 2014, 109, 32–35. [Google Scholar] [CrossRef]

- Kollis, K.; Phang, C.S.; Banhazi, T.M.; Searle, S.J. Weight estimation using image analysis and statistical modelling: A preliminary study. Appl. Eng. Agric. 2007, 23, 91–96. [Google Scholar] [CrossRef]

- Tscharke, M.; Banhazi, T.M. Review of methods to determine weight, size and composition of livestock from images. Aust. J. Multi-Discip. Eng. 2011, 8388. [Google Scholar] [CrossRef]

- Lee, J.; Jin, L.; Park, D.; Chung, Y. Automatic recognition of aggressive behavior in pigs using a kinect depth sensor. Sensors 2016, 16, 631. [Google Scholar] [CrossRef]

- Stavrakakis, S.; Li, W.; Guy, J.H.; Morgan, G.; Ushaw, G.; Johnson, G.R.; Edwards, S.A. Validity of the Microsoft Kinect sensor for assessment of normal walking patterns in pigs. Comput. Electron. Agric. 2015, 117, 1–7. [Google Scholar] [CrossRef]

- Lao, F.; Brown-Brandl, T.; Stinn, J.P.; Liu, K.; Teng, G.; Xin, H. Automatic recognition of lactating sow behaviors through depth image processing. Comput. Electron. Agric. 2016, 125, 56–62. [Google Scholar] [CrossRef]

- Marchant, J.; Schofield, C.; White, R. Pig growth and conformation monitoring using image analysis. Anim. Sci. 1999, 68, 141–150. [Google Scholar] [CrossRef]

- DeBoer, S.P.; Garner, J.P.; Lay, D.C.; Eicher, S.D.; Lucas, J.R.; Marchant-Forde, J.N. Does the presence of a human affect the preference of enrichment items in young, isolated pigs? Appl. Anim. Behav. Sci. 2013, 143, 96–103. [Google Scholar] [CrossRef]

- Wang, K.; Guo, H.; Ma, Q.; Su, W.; Chen, L.; Zhu, D. A portable and automatic Xtion-based measurement system for pig body size. Comput. Electron. Agric. 2018, 148, 291–298. [Google Scholar] [CrossRef]

- Mittek, M.; Psota, E.; Carlson, J.; Pérez, L.; Vision, T.S.I.C. Tracking of group-housed pigs using multi-ellipsoid expectation maximisation. IET 2017, 121–128. [Google Scholar] [CrossRef]

- Spoliansky, R.; Edan, Y.; Parmet, Y.; Halachmi, I. Development of automatic body condition scoring using a low-cost 3-dimensional Kinect camera. J. Dairy Sci. 2016, 99, 7714–7725. [Google Scholar] [CrossRef]

- Kim, J.; Choi, Y.; Ju, M.; Sa, J.; Chung, Y.; Park, D.; Kim, H. Lying-Pig Detection using Depth Information. In Proceedings of the International Conference Algorithms Computer Systms—ICACS ’17, Jeju Island, Korea, 10–13 August 2017; pp. 40–43. [Google Scholar] [CrossRef]

- Schön, P.C.; Puppe, B.; Manteuffel, G. Linear prediction coding analysis and self-organizing feature map as tools to classify stress calls of domestic pigs ( Sus scrofa ). J. Acoust. Soc. Am. 2002, 110, 1425–1431. [Google Scholar] [CrossRef]

- Manteuffel, C.; Hartung, E.; Schmidt, M.; Hoffmann, G.; Schon, P.C. Online detection and localisation of piglet crushing using vocalisation analysis and context data. Comput. Electron. Agric. 2017, 135, 108–114. [Google Scholar] [CrossRef]

- Silva, M.; Ferrari, S.; Costa, A.; Aerts, J.M.; Guarino, M.; Berckmans, D. Cough localization for the detection of respiratory diseases in pig houses. Comput. Electron. Agric. 2008, 64, 286–292. [Google Scholar] [CrossRef]

- Sellier, N.; Guettier, E.; Staub, C.; Sellier, N.; Guettier, E.; Staub, C. A review of methods to measure animal body temperature in precision farming. Am. J. Agric. Sci. Technol. 2014, 2, 74–99. [Google Scholar] [CrossRef]

- Salles, M.S.V.; da Silva, S.C.; Salles, F.A.; Roma, L.C.; El Faro, L.; Bustos Mac Lean, P.A.; Lins de Oliveira, C.E.; Martello, L.S. Mapping the body surface temperature of cattle by infrared thermography. J. Therm. Biol. 2016, 62, 63–69. [Google Scholar] [CrossRef]

- Stewart, M.; Webster, J.R.; Schaefer, A.L.; Cook, N.J.; Scott, S.L. Infrared thermography as a non-invasive tool to study animal welfare. Anim. Welf. 2005, 14, 319–325. [Google Scholar] [CrossRef]

- Soerensen, D.D.; Pedersen, L.J. Infrared skin temperature measurements for monitoring health in pigs: A review. Acta Vet. Scand. 2015, 57. [Google Scholar] [CrossRef]

- Brown-Brandl, T.M.; Maselyne, J.; Adrion, F.; Kapun, A.; Hessel, E.; Saeys, W.; Van Nuffel, A.; Gallmann, E. Comparing three different passive RFID systems for behaviour monitoring in grow-finish pigs. In Proceedings of the Precision Livestock Farming ’17, Nantes, France, 12–14 September 2017; pp. 622–629. [Google Scholar]

- Hansen, M.F.; Smith, M.L.; Smith, L.N.; Salter, M.G.; Baxter, E.M.; Farish, M.; Grieve, B. Towards on-farm pig face recognition using convolutional neural networks. Comput. Ind. 2018, 98, 145–152. [Google Scholar] [CrossRef]

- Ariff, M.H.; Ismarani, I.; Shamsuddin, N. RFID based systematic livestock health management system. In Proceedings of the 2014 IEEE Conference on Systems Process Control (ICSPC), Kuala Lumpur, Malaysia, 12–14 December 2014; pp. 111–116. [Google Scholar]

- Förschner, A.; Adrion, F.; Gallmann, E. Practical test and evaluation of optimized UHF ear tags for behavior monitoring of fattening pigs. In Proceedings of the 10 th International Livestock Environment Symposium (ILES X), Omaha, NE, USA, 25–27 September 2018; pp. 1–8. [Google Scholar]

- Maselyne, J.; Saeys, W.; Van Nuffel, A. Review: Quantifying animal feeding behaviour with a focus on pigs. Physiol. Behav. 2015, 138, 37–51. [Google Scholar] [CrossRef]

- Cornou, C.; Vinther, J.; Kristensen, A. Automatic detection of oestrus and health disorders using data from electronic sow feeders. Livest. Sci. 2008, 118, 262–271. [Google Scholar] [CrossRef]

- Adrion, F.; Kapun, A.; Holland, E.M.; Staiger, M.; Löb, P.; Gallmann, E. Novel approach to determine the influence of pig and cattle ears on the performance of passive UHF-RFID ear tags. Comput. Electron. Agric. 2017, 140, 168–179. [Google Scholar] [CrossRef]

- Sales, G.; Green, A.; Gates, R.; Brown-Brandl, T.; Eigenberg, R. Quantifying detection performance of a passive low-frequency RFID system in an environmental preference chamber for laying hens. Comput. Electron. Agric. 2015, 114, 261–268. [Google Scholar] [CrossRef]

- Brown-Brandl, T. Understanding Heat Stress in Beef Cattle. Rev. Bras. Zootec. 2018, 47. [Google Scholar] [CrossRef]

- Mittek, M.; Psota, E.T.; Pérez, L.C.; Schmidt, T.; Mote, B. Health Monitoring of Group-Housed Pigs using Depth-Enabled Multi-Object Tracking. In Proceedings of the International Conference of Pattern Recognition, Roma, Italy, 24–26 February 2016. [Google Scholar]

- Lancaster, L.; Psota, E.; Mote, B.; Perez, L.; Fricke, L.; Mittek, M.; Kett, L.; Schmidt, T. Evaluation of a Novel Computer Vision Systems’ Ability to Continuously Identify and Track the Activities of Newly Weaned Pigs. J. Anim. Sci. 2012, 96, 69–70. [Google Scholar] [CrossRef]

- AL-Allaf, O.N.A. Review of Face Detection Systems Based Artificial Neural Networks Algorithms. Int. J. Multimed. Appl. 2014, 6, 1–16. [Google Scholar] [CrossRef]

- Wada, N.; Shinya, M.; Shiraishi, M. [Short Paper] Pig Face Recognition Using Eigenspace Method. ITE Trans. Media Technol. Appl. 2013, 1, 328–332. [Google Scholar] [CrossRef]

- Smith, D.; Lyle, S.; Berry, A. Internet of Animal Health Things (Opportunities and Challenges); Technical Report; Cambridge Service Alliance: Cambridge, UK, 2015. [Google Scholar] [CrossRef]

- Kay, S.M. Fundamentals of Statistical Signal Processing: Estimation Theory; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 1993. [Google Scholar]

- Society of Automotive Engineers. Potential Failure Mode and Effects Analysis in Design (Design FMEA), Potential Failure Mode and Effects Analysis in Manufacturing and Assembly Processes (Process FMEA); Technical Report; Society of Automotive Engineers: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Veissier, I.; Butterworth, A.; Bock, B.; Roe, E. European approaches to ensure good animal welfare. Appl. Anim. Behav. Sci. 2008, 113, 279–297. [Google Scholar] [CrossRef]

- Dewey, C.E.; Friendship, R.M.; Wilson, M.R. Clinical and postmortem examination of sows culled for lameness. Can. Vet. J. 1993, 34, 555–556. [Google Scholar]

- Heinonen, M.; Peltoniemi, O.; Valros, A. Impact of lameness and claw lesions in sows on health and production. Livest. Sci. 2013, 156, 2–9. [Google Scholar] [CrossRef]

- Anil, S.S.; Anil, L.; Deen, J. Effect of lameness on sow longevity. J. Am. Vet. Med. Assoc. 2009, 235, 734–738. [Google Scholar] [CrossRef]

- Pluym, L.M.; Maes, D.; Vangeyte, J.; Mertens, K.; Baert, J.; Van Weyenberg, S.; Millet, S.; Van Nuffel, A. Development of a system for automatic measurements of force and visual stance variables for objective lameness detection in sows: SowSIS. Biosyst. Eng. 2013, 116, 64–74. [Google Scholar] [CrossRef]

- Ison, S.H.; Clutton, R.E.; Di Giminiani, P.; Rutherford, K.M.D. A Review of Pain Assessment in Pigs. Front. Vet. Sci. 2016, 3, 108. [Google Scholar] [CrossRef] [PubMed]

- Anil, L.; Anil, S.S.; Deen, J.; Baidoo, S.K.; Walker, R.D. Effect of group size and structure on the welfare and performance of pregnant sows in pens with electronic sow feeders. Can. J. Vet. Res. 2006, 70, 128–136. [Google Scholar] [PubMed]

- Courboulay, V.; Foubert, C. Testing different methods to evaluate pig welfare on farm. Anim. Welf. 2007, 16, 193–196. [Google Scholar]

- Davies, P.R.; Morrow, W.E.; Miller, D.C.; Deen, J. Epidemiologic study of decubital ulcers in sows. J. Am. Vet. Med. Assoc. 1996, 208, 1058–1062. [Google Scholar]

- Knauer, M.; Stalder, K.J.; Karriker, L.; Baas, T.J.; Johnson, C.; Serenius, T.; Layman, L.; McKean, J.D. A descriptive survey of lesions from cull sows harvested at two Midwestern U.S. facilities. Prev. Vet. Med. 2007, 82, 198–212. [Google Scholar] [CrossRef]

- Randall, L.; Green, M.; Chagunda, M.; Mason, C.; Archer, S.; Green, L.; Huxley, J. Low body condition predisposes cattle to lameness: An 8-year study of one dairy herd. J. Dairy Sci. 2015, 98, 3766–3777. [Google Scholar] [CrossRef]

- Knauer, M.; Stalder, K.; Baas, T.; Johnson, C.; Karriker, L. Physical Conditions of Cull Sows Associated with On-Farm Production Records. Open J. Vet. Med. 2012, 2, 137–150. [Google Scholar] [CrossRef]

- Millman, S.T. Sickness behaviour and its relevance to animal welfare assessment at the group level. Anim. Welf. 2007, 16, 123–125. [Google Scholar]

- Cook, N.J.; Bench, C.A.; Schaefer, A.L. Infrared Thermography and Behaviour Information for Identification of Biologically Important States in Animals. U.S. Patent 9,955,672, 1 May 2018. [Google Scholar]

- Valros, A. Tail biting. Adv. Pig Welf. 2017, 137–166. [Google Scholar] [CrossRef]

- D’Eath, R.B.; Arnott, G.; Turner, S.P.; Jensen, T.; Lahrmann, H.P.; Busch, M.E.; Niemi, J.K.; Lawrence, A.B.; Sandøe, P. Injurious tail biting in pigs: How can it be controlled in existing systems without tail docking? Animal 2014, 8, 1479–1497. [Google Scholar] [CrossRef]

- Marques, B.M.F.; Bernardi, M.L.; Coelho, C.F.; Almeida, M.; Morales, O.E.; Mores, T.J.; Borowski, S.M.; Barcellos, D.E. Influence of tail biting on weight gain, lesions and condemnations at slaughter of liinishing pigs. Pesquisa Veterinaria Brasileira 2012, 32, 967–974. [Google Scholar] [CrossRef]

- Ala-Kurikka, E.; Heinonen, M.; Mustonen, K.; Peltoniemi, O.; Raekallio, M.; Vainio, O.; Valros, A. Behavior changes associated with lameness in sows. Appl. Anim. Behav. Sci. 2017, 193, 15–20. [Google Scholar] [CrossRef]

- Mohling, C.M.; Johnson, A.K.; Coetzee, J.F.; Abell, C.E.; Karriker, L.A.; Stalder, K.J.; Tyler, H.D.; Millman, S.T. Evaluation of mechanical and thermal nociception as objective tools to measure painful and nonpainful lameness phases in multiparous sows1. J. Anim. Sci. 2014, 92, 3073–3081. [Google Scholar] [CrossRef] [PubMed]

- Meijer, E.; Bertholle, C.P.; Oosterlinck, M.; van der Staay, F.J.; Back, W.; van Nes, A. Pressure mat analysis of the longitudinal development of pig locomotion in growing pigs after weaning. BMC Vet. Res. 2014, 10, 37. [Google Scholar] [CrossRef] [PubMed]

- de Carvalho, V.C.; de Alencar Nääs, I.; Mollo Neto, M.; de Souza, S.R.L. Measurement of pig claw pressure distribution. Biosyst. Eng. 2009, 103, 357–363. [Google Scholar] [CrossRef]

- Sun, G.; Fitzgerald, R.F.; Stalder, K.J.; Karriker, L.A.; Johnson, A.K.; Hoff, S.J. Development of an embedded microcomputer-based force plate system for measuring sow weight distribution and detection of lameness. Appl. Eng. Agric. 2011, 27, 475–482. [Google Scholar] [CrossRef]

- Conte, S.; Bergeron, R.; Gonyou, H.; Brown, J.; Rioja-Lang, F.C.; Connor, L.; Devillers, N. Measure and characterization of lameness in gestating sows using force plate, kinematic, and accelerometer methods. J. Anim. Sci. 2014, 92, 5693–5703. [Google Scholar] [CrossRef]

- Karriker, L.A.; Abell, C.E.; Pairis-Garcia, M.D.; Holt, W.A.; Sun, G.; Coetzee, J.F.; Johnson, A.K.; Hoff, S.J.; Stalder, K.J. Validation of A lameness model in sows using physiological and mechanical measurements. J. Anim. Sci. 2013, 91, 130–136. [Google Scholar] [CrossRef] [PubMed]

- Scheel, C.; Traulsen, I.; Auer, W.; Müller, K.; Stamer, E.; Krieter, J. Detecting lameness in sows from ear tag-sampled acceleration data using wavelets. Animal 2017, 1–8. [Google Scholar] [CrossRef]

- Grégoire, J.; Bergeron, R.; D’Allaire, S.; Meunier-Salaün, M.C.; Devillers, N. Assessment of lameness in sows using gait, footprints, postural behaviour and foot lesion analysis. Animal 2013, 7, 1163–1173. [Google Scholar] [CrossRef]

- Van Hertem, T.; Viazzi, S.; Steensels, M.; Maltz, E.; Antler, A.; Alchanatis, V.; Schlageter-Tello, A.A.; Lokhorst, K.; Romanini, E.C.; Bahr, C.; et al. Automatic lameness detection based on consecutive 3D-video recordings. Biosyst. Eng. 2014, 119, 108–116. [Google Scholar] [CrossRef]

- Van Hertem, T.; Schlageter Tello, A.; Viazzi, S.; Steensels, M.; Bahr, C.; Romanini, C.E.B.; Lokhorst, K.; Maltz, E.; Halachmi, I.; Berckmans, D. Implementation of an automatic 3D vision monitor for dairy cow locomotion in a commercial farm. Biosyst. Eng. 2018, 173, 166–175. [Google Scholar] [CrossRef]

- Ringgenberg, N.; Bergeron, R.; Devillers, N. Validation of accelerometers to automatically record sow postures and stepping behaviour. Appl. Anim. Behav. Sci. 2010, 128, 37–44. [Google Scholar] [CrossRef]

- Traulsen, I.; Scheel, C.; Auer, W.; Burfeind, O.; Krieter, J. Using acceleration data to automatically detect the onset of farrowing in sows. Sensors (Switzerland) 2018, 18, 170. [Google Scholar] [CrossRef] [PubMed]

- Traulsen, I.; Breitenberger, S.; Auer, W.; Stamer, E.; Müller, K.; Krieter, J. Automatic detection of lameness in gestating group-housed sows using positioning and acceleration measurements. Animal 2016, 10, 970–977. [Google Scholar] [CrossRef]

- Marcon, M.; Melot, G.; Courboulay, V.; Boulot, S.; Rousseliere, Y. Monitoring the sows’ level of activity through communicating accelerometer placed on earing tag. Journales Recherche Porcine 2017, 49, 171–172. [Google Scholar]

- Ott, S.; Moons, C.P.H.; Kashiha, M.A.; Bahr, C.; Tuyttens, F.A.M.; Berckmans, D.; Niewold, T.A. Automated video analysis of pig activity at pen level highly correlates to human observations of behavioural activities. Livest. Sci. 2014, 160, 132–137. [Google Scholar] [CrossRef]

- Kashiha, M.A.; Bahr, C.; Ott, S.; Moons, C.P.H.; Niewold, T.A.; Ödberg, F.O.; Berckmans, D. Automatic identification of marked pigs in a pen using image pattern recognition. In Pattern Recognition and Image Analysis; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2013; 7887 LNCS; pp. 205–212. [Google Scholar] [CrossRef]

- Oczak, M.; Viazzi, S.; Ismayilova, G.; Sonoda, L.T.; Roulston, N.; Fels, M.; Bahr, C.; Hartung, J.; Guarino, M.; Berckmans, D.; et al. Classification of aggressive behaviour in pigs by activity index and multilayer feed forward neural network. Biosyst. Eng. 2014, 119, 89–97. [Google Scholar] [CrossRef]

- Viazzi, S.; Ismayilova, G.; Oczak, M.; Sonoda, L.T.; Fels, M.; Guarino, M.; Vranken, E.; Hartung, J.; Bahr, C.; Berckmans, D. Image feature extraction for classification of aggressive interactions among pigs. Comput. Electron. Agric. 2014, 104, 57–62. [Google Scholar] [CrossRef]

- Lahrmann, H.P.; Hansen, C.F.; D’Eath, R.; Busch, M.E.; Forkman, B. Tail posture predicts tail biting outbreaks at pen level in weaner pigs. Appl. Anim. Behav. Sci. 2018, 200, 29–35. [Google Scholar] [CrossRef]

- Lancaster, J.M. Utilization of Depth—Enabled Identification and Tracking System to Identify and Track Individual Pigs and Analyse Individual Pig Activity. Ph.D. Thesis, University of Nebraska, Lincoln, NE, USA, 2018. [Google Scholar]

- Shao, B.; Xin, H. A real-time computer vision assessment and control of thermal comfort for group-housed pigs. Comput. Electron. Agric. 2008, 62, 15–21. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Richter, U.; Hensel, O.; Edwards, S.; Sturm, B. Using machine vision for investigation of changes in pig group lying patterns. Comput. Electron. Agric. 2015, 119, 184–190. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Sturm, B.; Olsson, A.C.; Jeppsson, K.H.; Müller, S.; Edwards, S.; Hensel, O. Automatic scoring of lateral and sternal lying posture in grouped pigs using image processing and Support Vector Machine. Comput. Electron. Agric. 2019, 156, 475–481. [Google Scholar] [CrossRef]

- D’Eath, R.B.; Jack, M.; Futro, A.; Talbot, D.; Zhu, Q.; Barclay, D.; Baxter, E.M. Automatic early warning of tail biting in pigs: 3D cameras can detect lowered tail posture before an outbreak. PLoS ONE 2018, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Metzner, M.; Sauter-Louis, C.; Seemueller, A.; Petzl, W.; Klee, W. Infrared thermography of the udder surface of dairy cattle: Characteristics, methods, and correlation with rectal temperature. Vet. J. 2014, 199, 57–62. [Google Scholar] [CrossRef]

- Alsaaod, M.; Syring, C.; Dietrich, J.; Doherr, M.G.; Gujan, T.; Steiner, A. A field trial of infrared thermography as a non-invasive diagnostic tool for early detection of digital dermatitis in dairy cows. Vet. J. 2014, 199, 281–285. [Google Scholar] [CrossRef]

- Alsaaod, M.; Syring, C.; Luternauer, M.; Doherr, M.; Steiner, A. Effect of routine claw trimming on claw temperature in dairy cows measured by infrared thermography. J. Dairy Sci. 2015, 98, 2381–2388. [Google Scholar] [CrossRef]

- Harris-Bridge, G.; Young, L.; Handel, I.; Farish, M.; Mason, C.; Mitchell, M.A.; Haskell, M.J. The use of infrared thermography for detecting digital dermatitis in dairy cattle: What is the best measure of temperature and foot location to use? Vet. J. 2018, 237, 26–33. [Google Scholar] [CrossRef]

- Schaefer, A.L.; Cook, N.J.; Bench, C.; Chabot, J.B.; Colyn, J.; Liu, T.; Okine, E.K.; Stewart, M.; Webster, J.R. The non-invasive and automated detection of bovine respiratory disease onset in receiver calves using infrared thermography. Res. Vet. Sci. 2012, 93, 928–935. [Google Scholar] [CrossRef]

- Cook, N.J.; Chabot, B.; Lui, T.; Bench, C.J.; Schaefer, A.L. Infrared thermography detects febrile and behavioural responses to vaccination of weaned piglets. Animal 2015, 9, 339–346. [Google Scholar] [CrossRef]

- Ferrari, S.; Costa, A.; Guarino, M. Heat stress assessment by swine related vocalizations. Livest. Sci. 2013, 151, 29–34. [Google Scholar] [CrossRef]

- Ferrari, S.; Silva, M.; Guarino, M.; Aerts, J.M.; Berckmans, D. Cough sound analysis to identify respiratory infection in pigs. Comput. Electron. Agric. 2008, 64, 318–325. [Google Scholar] [CrossRef]

- Exadaktylos, V.; Silva, M.; Aerts, J.M.; Taylor, C.J.; Berckmans, D. Real-time recognition of sick pig cough sounds. Comput. Electron. Agric. 2008, 63, 207–214. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Winter, P.; Walker, L. Walk-through weighing of pigs using machine vision and an artificial neural network. Biosyst. Eng. 2008, 100, 117–125. [Google Scholar] [CrossRef]

- Condotta, I.C.; Brown-Brandl, T.M.; Silva-Miranda, K.O.; Stinn, J.P. Evaluation of a depth sensor for mass estimation of growing and finishing pigs. Biosyst. Eng. 2018, 173, 11–18. [Google Scholar] [CrossRef]

- Khanji, M.S.; Llorente, C.; Falceto, M.V.; Bonastre, C.; Mitjana, O.; Tejedor, M.T. Using body measurements to estimate body weight in gilts. Can. J. Anim. Sci. 2018, 98, 362–367. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, D.; Guo, H.; Ma, Q.; Su, W.; Su, Y. Automated calculation of heart girth measurement in pigs using body surface point clouds. Comput. Electron. Agric. 2019, 156, 565–573. [Google Scholar] [CrossRef]

- Molapo, N.A.; Malekian, R.; Nair, L. Real-Time Livestock Tracking System with Integration of Sensors and Beacon Navigation. Wirel. Pers. Commun. 2019, 104, 853–879. [Google Scholar] [CrossRef]

- Cairns, W.J. Wireless Asset Management; World Intellectual Property Organization: Geneva, Switzerland, 2016. [Google Scholar]

- O’Donnel, L. Agosto Deploys Iot Solution to Help Farmer Remotely Monitor Livestock. Available online: https://www.crn.com/news/internet-of-things/300095681/connected-pigs-google-partner-agosto-deploys-\iot-solution-to-help-farmers-remotely-monitor-livestock.htm (accessed on 19 March 2019).

- Zimmerman, J.J.; Karriker, L.A.; Ramirez, A.; Schwartz, K.J.; Stevenson, G.W. Diseases of Swine, 10th ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2010. [Google Scholar]

- Rutten, S.; Deen, J. Benchmarking: Sow productivity and PigCHAMP. In Proceedings of the Allen D. Leman Swine Conference, Minneapolis, MN, USA, 17 September 2005; pp. 166–171. [Google Scholar]

- PigCHAMP. Summary Reports 2016—US; Technical Report; PigChamp, Inc.: Ames, IA, USA, 2016. [Google Scholar]

- Maselyne, J.; Adriaens, I.; Huybrechts, T.; De Ketelaere, B.; Millet, S.; Vangeyte, J.; Van Nuffel, A.; Saeys, W. Measuring the drinking behaviour of individual pigs housed in group using radio frequency identification (RFID). Animal 2016, 10, 1557–1566. [Google Scholar] [CrossRef]

- Shepherd, M.; Turner, J.A.; Small, B.; Wheeler, D. Priorities for science to overcome hurdles thwarting the full promise of the ‘digital agriculture’ revolution. J. Sci. Food Agric. 2018. [Google Scholar] [CrossRef]

- Halachmi, I.; Guarino, M. Editorial: Precision livestock farming: A ‘per animal’ approach using advanced monitoring technologies. Animal 2016, 10, 1482–1483. [Google Scholar] [CrossRef] [PubMed]

- Conte, S.; Bergeron, R.; Gonyou, H.; Brown, J.; Rioja-Lang, F.C.; Connor, M.L.; Devillers, N. Use of an analgesic to identify pain-related indicators of lameness in sows. Livest. Sci. 2015, 180, 203–208. [Google Scholar] [CrossRef]

- Arcidiacono, C.; Porto, S.M.; Mancino, M.; Cascone, G. Development of a threshold-based classifier for real-time recognition of cow feeding and standing behavioural activities from accelerometer data. Comput. Electron. Agric. 2017, 134, 124–134. [Google Scholar] [CrossRef]

- Norton, T.; Berckmans, D. Developing precision livestock farming tools for precision dairy farming. Anim. Front. 2017, 7, 18. [Google Scholar] [CrossRef]

- Grandin, T. Animal welfare and society concerns finding the missing link. MESC 2014, 98, 461–469. [Google Scholar] [CrossRef]

- Lin, J.; Shen, Z.; Zhang, A.; Chai, Y. Blockchain and IoT based Food Traceability for Smart Agriculture. In Proceedings of the 3rd International Conference on Crowd Science and Engineering—ICCSE’18, Singapore, 28–31 July 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Hay, S.I.; George, D.B.; Moyes, C.L.; Brownstein, J.S. Big Data Opportunities for Global Infectious Disease Surveillance. PLoS Med. 2013, 10, e1001413. [Google Scholar] [CrossRef] [PubMed]

- Adams-Progar, A.; Fink, G.; Walker, E.; Llewellyn, D. Security and Privacy Issues in the Internet of Cows. In Security and Privacy in Cyber-Physical Systems: Foundations, Principles, and Applications; Song, H., Fink, G.A., Jeschke, S., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; Chapter 18; pp. 375–398. [Google Scholar] [CrossRef]

- Zhou, W.; Jia, Y.; Peng, A.; Zhang, Y.; Liu, P. The Effect of IoT New Features on Security and Privacy: New Threats, Existing Solutions, and Challenges Yet to Be Solved. IEEE Internet Things J. 2018, PP, 1. [Google Scholar] [CrossRef]

- McInerney, J. Animal Welfare, Economics and Policy. Report to Department of Environment, Food and Rural Affairs; Technical Report; Animal Welfare, Economics and Policy: London, UK, 2004. [Google Scholar]

- Jonathan, P.; Kerr, G.; Sullivan, J.P. A critical review of consumer wearables, mobile applications and equipment for providing biofeedback, monitoring stress and sleep in physically active populations. Front. Physiol. 2018, 9, 743. [Google Scholar] [CrossRef]

- Ivanschitz, R.; Korn, D. Digital Transformation and Jobs: Building a Cloud for Everyone Digital Transformation and Jobs. Univ. Miami Inter-Am. Law Rev. 2017, 49. Available online: https://repository.law.miami.edu/umialr/vol49/iss1/4 (accessed on 20 January 2018).

- Larsson, E.G.; Van der Perre, L. Massive MIMO for 5G. Available online: https://futurenetworks.ieee.org/tech-focus/march-2017/massive-mimo-for-5g (accessed on 21 March 2019).

- Wang, F.K.; Horng, T.S.; Peng, K.C.; Jau, J.K.; Li, J.Y.; Chen, C.C. Single-antenna doppler radars using self and mutual injection locking for vital sign detection with random body movement cancellation. IEEE Trans. Microw. Theory Tech. 2011, 59, 3577–3587. [Google Scholar] [CrossRef]

- Turner, S.P.; Roehe, R.; D’Eath, R.B.; Ison, S.H.; Farish, M.; Jack, M.C.; Lundeheim, N.; Rydhmer, L.; Lawrence, A.B. Genetic validation of postmixing skin injuries in pigs as an indicator of aggressiveness and the relationship with injuries under more stable social conditions. J. Anim. Sci. 2009, 87, 3076–3082. [Google Scholar] [CrossRef] [PubMed]

- Wurtz, K.E.; Siegford, J.M.; Ernst, C.W.; Raney, N.E.; Steibel, J.P.; Bates, R.O. Genome-wide association analyses of lesion counts in group-housed pigs. Anim. Genet. 2018, 49, 628–631. [Google Scholar] [CrossRef] [PubMed]

- Werkheiser, I. Precision Livestock Farming and Farmers’ Duties to Livestock. J. Agric. Environ. Ethics 2018, 1–15. [Google Scholar] [CrossRef]

- Röös, E.; Garnett, T.; Patel, M.; Little, D.; Smith, P.; Bajželj, B. Greedy or needy? Land use and climate impacts of food in 2050 under different livestock futures. Glob. Environ. Chang. 2017, 47, 1–12. [Google Scholar] [CrossRef]

| Hardware Comparisons | |||

|---|---|---|---|

| Sensor Device and Manufacturer examples | Features | Fallbacks | Applications |

| Cameras | |||

| 2D (RGB) — Lorax — eYenamic® 3D (RGBD) — Microsoft Kinect® — Intel Realsense® — eYegrow® | — Useful for fine positional and color variational data — High precision and lots of data — Remote sensing (non-invasive) — Fast readings (usually 15–60fps) — Individual or group can be analyzed | — Requires filtering to obtain useful information — Performance is dependent on lighting conditions — May require protective covers against environmental elements | — Optical character recognition — Feature extraction — Motion detection — Topology extraction — Animal distribution and activity |

| Thermometers | |||

| Infrared Imaging (IR) — FLIR® — FLUKE® — TESTO 875® | — Useful for biological process observation and night vision — High performance in low visibility settings — Remote sensing (non-invasive) — Fast readings (usually 15–60fps) | — Expensive (Mid hundreds to several thousands per unit) — Environmental factors affect readings | — Remote temperature sensing — Low light imaging — Physiological responses (individualized and group) |

| Thermistors — Integrated in wearable sensors | — Useful for temperature fluctuations — Inexpensive | — Slow to sense changes — Not an off the shelf system | — Contact temperature sensing — Physiological responses |

| Microphones | |||

| — Soundtalks® — PCM Monitor® | — Useful for sound/frequency fluctuations —Immediate readings — Inexpensive | — Easily corrupted by noise | — Monitoring periodic physiological process (in pens and/or barns) — Auditory classification |

| Accelerometers | |||

| Exmples of WSN — Remote Insights® — Smartbow® | — Useful for motion tracking — Near instantaneous readings — Embedded into wearable sensors used in wireless sensor networks (WSN) | — Requires external processing to obtain displacement and velocity data —Information is relative (not absolute) — Fragile (can break with sow behavior) | — Motion detection/observation (i.e., walking, nesting behavior) —Positional state tracking (i.e., lying, standing) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benjamin, M.; Yik, S. Precision Livestock Farming in Swine Welfare: A Review for Swine Practitioners. Animals 2019, 9, 133. https://doi.org/10.3390/ani9040133

Benjamin M, Yik S. Precision Livestock Farming in Swine Welfare: A Review for Swine Practitioners. Animals. 2019; 9(4):133. https://doi.org/10.3390/ani9040133

Chicago/Turabian StyleBenjamin, Madonna, and Steven Yik. 2019. "Precision Livestock Farming in Swine Welfare: A Review for Swine Practitioners" Animals 9, no. 4: 133. https://doi.org/10.3390/ani9040133

APA StyleBenjamin, M., & Yik, S. (2019). Precision Livestock Farming in Swine Welfare: A Review for Swine Practitioners. Animals, 9(4), 133. https://doi.org/10.3390/ani9040133