Carbon Footprint Assessment of Dairy Milk and Grana Padano PDO Cheese and Improvement Scenarios: A Case Study in the Po Valley (Italy)

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. System Description

2.2. Life Cycle Assessment

2.3. Goal and Scope

2.4. Functional Unit

2.5. System Boundaries and Allocation

2.6. Life Cycle Inventory

2.7. Primary Data

2.8. Emissions

2.9. Secondary Data

2.10. Impact Assessment

2.11. Statistical Analysis

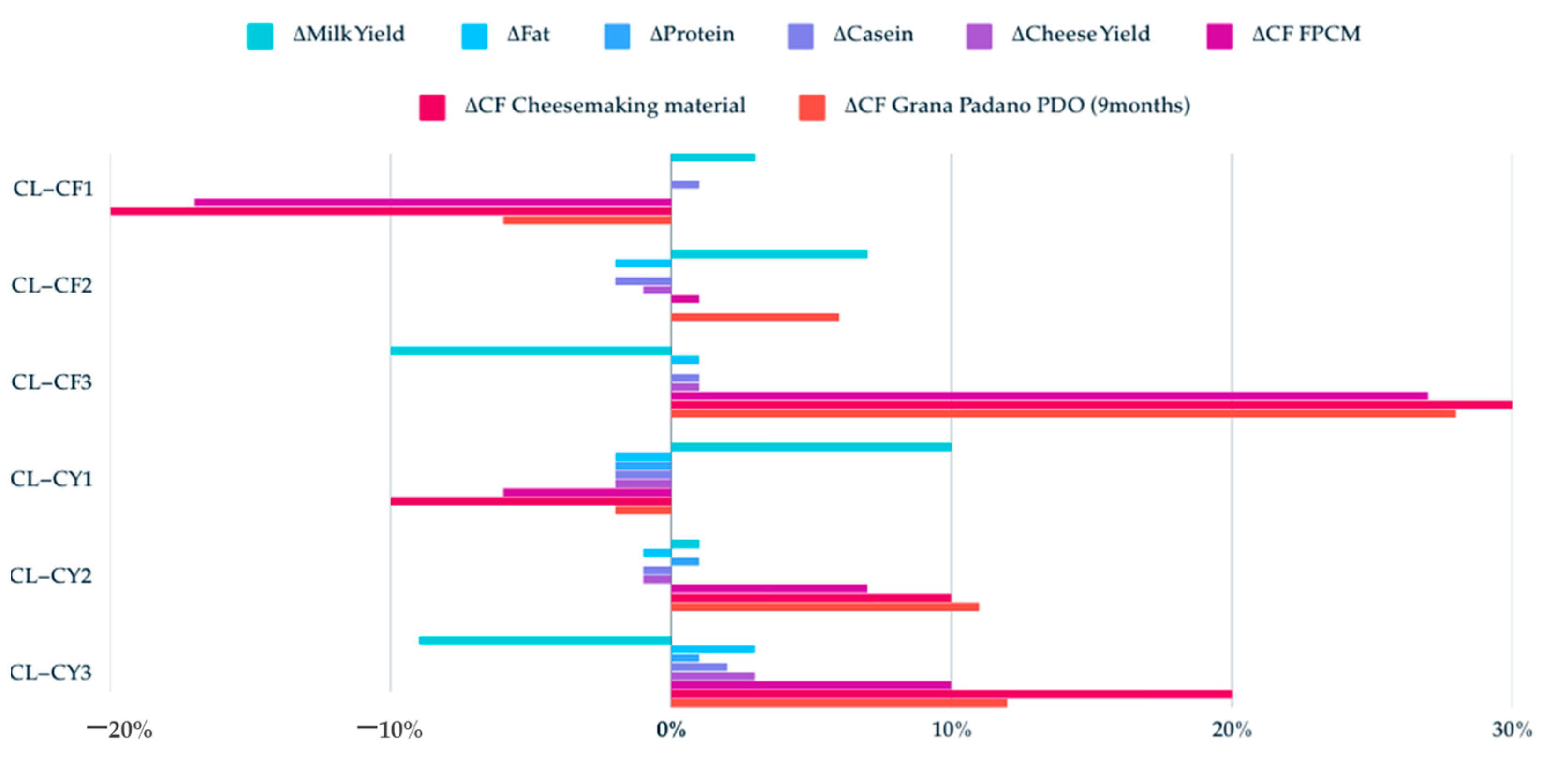

3. Results

3.1. Farm Description

3.2. Cheese Yield Clusters

3.3. Milk Carbon Footprint Clusters

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Daugstad, K.; Rønningen, K.; Skar, B. Agriculture as an Upholder of Cultural Heritage? Conceptualizations and Value Judgements—A Norwegian Perspective in International Context. J. Rural. Stud. 2006, 22, 67–81. [Google Scholar] [CrossRef]

- Gillespie, S.; van den Bold Gillespie, M.S.; van den Bold, M. Agriculture, Food Systems, and Nutrition: Meeting the Challenge. Glob. Chall. 2017, 1, 1600002. [Google Scholar] [CrossRef] [PubMed]

- Gerber, P.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C. Tackling Climate Change Through Livestock: A Global Assessment of Emissions and Mitigation Opportunities; FAO: Rome, Italy, 2013. [Google Scholar]

- Rojas-Downing, M.M.; Nejadhashemi, A.P.; Harrigan, T.; Woznicki, S.A. Climate Change and Livestock: Impacts, Adaptation, and Mitigation. Clim. Risk Manag. 2017, 16, 145–163. [Google Scholar] [CrossRef]

- Mazzetto, A.M.; Falconer, S.; Ledgard, S. Mapping the Carbon Footprint of Milk Production from Cattle: A Systematic Review. J. Dairy Sci. 2022, 105, 9713–9725. [Google Scholar] [CrossRef]

- van Loon, M.P.; Vonk, W.J.; Hijbeek, R.; van Ittersum, M.K.; ten Berge, H.F.M. Circularity Indicators and Their Relation with Nutrient Use Efficiency in Agriculture and Food Systems. Agric. Syst. 2023, 207, 103610. [Google Scholar] [CrossRef]

- van Loon, M.P.; Hijbeek, R.; Vonk, W.J.; Oenema, J. Nutrient Cycling on Dairy Farms in the Netherlands: The Role of Farm Structure, Management and Trade-Offs. Resour. Conserv. Recycl. 2024, 211, 107875. [Google Scholar] [CrossRef]

- Connor, E.E. Invited Review: Improving Feed Efficiency in Dairy Production: Challenges and Possibilities*. Animal 2015, 9, 395–408. [Google Scholar] [CrossRef]

- Dijkstra, J.; Bannink, A.; Bosma, P.M.; Lantinga, E.A.; Reijs, J.W. Modeling the Effect of Nutritional Strategies for Dairy Cows on the Composition of Excreta Nitrogen. Front. Sustain. Food Syst. 2018, 2, 364746. [Google Scholar] [CrossRef]

- Tamminga, S. Nutrition Management of Dairy Cows as a Contribution to Pollution Control. J. Dairy Sci. 1992, 75, 345–357. [Google Scholar] [CrossRef]

- Børsting, C.F.; Kristensen, T.; Misciattelli, L.; Hvelplund, T.; Weisbjerg, M.R. Reducing Nitrogen Surplus from Dairy Farms. Effects of Feeding and Management. Livest. Prod. Sci. 2003, 83, 165–178. [Google Scholar] [CrossRef]

- Kebreab, E.; Strathe, A.; Fadel, J.; Moraes, L.; France, J. Impact of Dietary Manipulation on Nutrient Flows and Greenhouse Gas Emissions in Cattle. Revista Brasileira de Zootecnia 2010, 39, 458–464. [Google Scholar] [CrossRef]

- Atzori, A.S.; Valsecchi, C.; Manca, E.; Masoero, F.; Cannas, A.; Gallo, A. Assessment of Feed and Economic Efficiency of Dairy Farms Based on Multivariate Aggregation of Partial Indicators Measured on Field. J. Dairy Sci. 2021, 104, 12679–12692. [Google Scholar] [CrossRef] [PubMed]

- Flaten, O.; Koesling, M.; Hansen, S.; Veidal, A. Links between Profitability, Nitrogen Surplus, Greenhouse Gas Emissions, and Energy Intensity on Organic and Conventional Dairy Farms. Agroecol. Sustain. Food Syst. 2019, 43, 957–983. [Google Scholar] [CrossRef]

- Jayasundara, S.; Worden, D.; Weersink, A.; Wright, T.; VanderZaag, A.; Gordon, R.; Wagner-Riddle, C. Improving Farm Profitability Also Reduces the Carbon Footprint of Milk Production in Intensive Dairy Production Systems. J. Clean. Prod. 2019, 229, 1018–1028. [Google Scholar] [CrossRef]

- Mezzetti, M.; Passamonti, M.M.; Dall’Asta, M.; Bertoni, G.; Trevisi, E.; Ajmone Marsan, P. Emerging Parameters Justifying a Revised Quality Concept for Cow Milk. Foods 2024, 13, 1650. [Google Scholar] [CrossRef]

- Sonesson, U.; Davis, J.; Flysjö, A.; Gustavsson, J.; Witthöft, C. Protein Quality as Functional Unit—A Methodological Framework for Inclusion in Life Cycle Assessment of Food. J. Clean. Prod. 2017, 140, 470–478. [Google Scholar] [CrossRef]

- March, M.D.; Hargreaves, P.R.; Sykes, A.J.; Rees, R.M. Effect of Nutritional Variation and LCA Methodology on the Carbon Footprint of Milk Production From Holstein Friesian Dairy Cows. Front. Sustain. Food Syst. 2021, 5, 588158. [Google Scholar] [CrossRef]

- Mclaren, S.; Berardy, A.; Henderson, A.; Holden, N.; Huppertz, T.; Jolliet, O.; De Camillis, C.; Renouf, M.; Ru-Gani, B.; Saarinen, M. Integration of Environment and Nutrition in Life Cycle Assessment of Food Items: Opportunities and Challenges; FAO: Rome, Italy, 2021. [Google Scholar] [CrossRef]

- Consorzio del Grana Padano Disciplinare Produzione Grana Padano DOP. 2019. Available online: https://www.granapadano.it/public/file/Disciplinare-produzione-Grana-PadanoDOPNov19-38346.pdf (accessed on 1 February 2025).

- Rencricca, G.; Froldi, F.; Moschini, M.; Trevisan, M.; Ghnimi, S.; Lamastra, L. The Environmental Impact of Permanent Meadows-Based Farms: A Comparison among Different Dairy Farm Management Systems of an Italian Cheese. Sustain. Prod. Consum. 2023, 37, 53–64. [Google Scholar] [CrossRef]

- Froldi, F.; Lamastra, L.; Trevisan, M.; Moschini, M. Climate Change and Photochemical Ozone Creation Potential Impact Indicators of Cow Milk: A Comparison of Different Scenarios for a Diet Assessment. Animals 2024, 14, 1725. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bava, L.; Zucali, M.; D’Imporzano, G.; Adani, F.; Tamburini, A.; Sandrucci, A. Improvements to Dairy Farms for Environmental Sustainability in Grana Padano and Parmigiano Reggiano Production Systems. Ital. J. Anim. Sci. 2019, 18, 1035–1048. [Google Scholar] [CrossRef]

- Bava, L.; Bacenetti, J.; Gislon, G.; Pellegrino, L.; D’Incecco, P.; Sandrucci, A.; Tamburini, A.; Fiala, M.; Zucali, M. Impact Assessment of Traditional Food Manufacturing: The Case of Grana Padano Cheese. Sci. Total Environ. 2018, 626, 1200–1209. [Google Scholar] [CrossRef] [PubMed]

- Gislon, G.; Ferrero, F.; Bava, L.; Borreani, G.; Prà, A.D.; Pacchioli, M.T.; Sandrucci, A.; Zucali, M.; Tabacco, E. Forage Systems and Sustainability of Milk Production: Feed Efficiency, Environmental Impacts and Soil Carbon Stocks. J. Clean. Prod. 2020, 260, 121012. [Google Scholar] [CrossRef]

- Froldi, F.; Lamastra, L.; Corrado, S.; Moschini, M. Carbon Footprint of Raw Milk for Direct Human Consumption Produced in Po Valley: Data Input Uncertainties and Effect on Output Variance. Environ. Chall. 2022, 8, 100536. [Google Scholar] [CrossRef]

- EC Commission Regulation (EU) No 794/2011 of 8 August 2011 Approving Amendments to the Specification for a Name Entered in the Register of Protected Designations of Origin and Protected Geographical Indications (Parmigiano Reggiano (PDO). 2011. Available online: https://eur-lex.europa.eu/eli/reg/2011/794/oj/eng (accessed on 1 February 2025).

- ISO 14040: 2006; Environmental Management–Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044: 2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006; ISBN 5935522004.

- ISO 14067: 2018; The LCA Methodology Was Applied in Accordance with the ISO 14040 and 14044 Guidelines, as Well as the ISO 14067 Standard for Determining the Carbon Footprint. International Organization for Standardization: Geneva, Switzerland, 2018; p. 46.

- IDF. A Common Carbon Footprint Approach for the Dairy Sector; IDF: Brussels, Belgium, 2015. [Google Scholar]

- Masotti, F.; Stroppa, A. Calcolo Della Resa Di Caseificazione a Grana Padano Mediante Una Formula Di Previsione: Applicazione in Un Caseificio Di Piccole Dimensioni. Scienza E Tecnica Lattiero-Casearia 2006, 57, 2. [Google Scholar]

- González-García, S.; Castanheira, É.G.; Dias, A.C.; Arroja, L. Environmental Performance of a Portuguese Mature Cheese-Making Dairy Mill. J. Clean. Prod. 2013, 41, 65–73. [Google Scholar] [CrossRef]

- Calamari, L. Razio-Best Software Di Razionamento e Formulazione Mangimi. Available online: https://digilander.libero.it/luigicalamari/Razbest/Manuale/Manuale-52CD.htm (accessed on 13 February 2025).

- IPCC. Chapter 10—Emissions from Livestock and Manure Management. In Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- IPCC. Chapter 11: N2O Emissions from Managed Soils, and CO2 Emissions from Lime and Urea Application. In Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Durlinger, B.; Tyszler, M.; Scholten, J.; Broekema, R.; Blonk, H.; Schenck, R.; Huizen, D. Agri-Footprint; A Life Cycle Inventory Database Covering Food and Feed Production and Processing. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector, San Francisco, CA, USA, 8–10 October 2014. [Google Scholar]

- Recchioni, M.; Mathieux, F.; Goralczyk, M.; Schau, E.M. ILCD Data Network and ELCD Database: Current Use and Further Needs for Supporting Environmental Footprint and Life Cycle Indicator Projects; Publications Office of the European Union: Luxembourg, 2012. [Google Scholar] [CrossRef]

- Masson-Delmotte, V.; Zhai, P.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; Matthews, J.B.R.; Berger, S.; Huang, M.; Yelekçi, O.; Yu, R.; et al. IPCC, 2021: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, MA, USA, 2021. [Google Scholar]

- R Core Team. A Language and Environment for Statistical Computing; R Core Team: Vienna, Austria, 2024. [Google Scholar]

- Soares, B.B.; Alves, E.C.; De Almeida Neto, J.A.; Rodrigues, L.B. Environmental Impact of Cheese Production. In Environmental Impact of Agro-Food Industry and Food Consumption; Academic Press: Cambridge, MA, USA, 2021; pp. 169–187. [Google Scholar] [CrossRef]

- Pirlo, G.; Lolli, S. Environmental Impact of Milk Production from Samples of Organic and Conventional Farms in Lombardy (Italy). J. Clean. Prod. 2019, 211, 962–971. [Google Scholar] [CrossRef]

- Zucali, M.; Tamburini, A.; Sandrucci, A.; Bava, L. Global Warming and Mitigation Potential of Milk and Meat Production in Lombardy (Italy). J. Clean. Prod. 2017, 153, 474–482. [Google Scholar] [CrossRef]

- Rossi, C.; Grossi, G.; Lacetera, N.; Vitali, A. Carbon Footprint and Carbon Sink of a Local Italian Dairy Supply Chain. Dairy 2024, 5, 201–216. [Google Scholar] [CrossRef]

- Fantin, V.; Buttol, P.; Pergreffi, R.; Masoni, P. Life Cycle Assessment of Italian High Quality Milk Production. A Comparison with an EPD Study. J. Clean. Prod. 2012, 28, 150–159. [Google Scholar] [CrossRef]

- Froldi, F.; Lamastra, L.; Trevisan, M.; Mambretti, D.; Moschini, M. Environmental Impacts of Cow’s Milk in Northern Italy: Effects of Farming Performance. J. Clean. Prod. 2022, 363, 132600. [Google Scholar] [CrossRef]

- Mazzetto, A.; Falconer, S.; Ledgard, S. Mapping the Carbon Footprint of Milk for Dairy Cows. 2022. Available online: https://ucanr.edu/sites/programteams/files/347129.pdf (accessed on 1 February 2025).

- Gislon, G.; Bava, L.; Bisutti, V.; Tamburini, A.; Brasca, M. Bovine Beta Casein Polymorphism and Environmental Sustainability of Cheese Production: The Case of Grana Padano PDO and Mozzarella Cheese. Sustain. Prod. Consum. 2023, 35, 85–94. [Google Scholar] [CrossRef]

- Castellani, V.; Proserpio, C.; Ravaglia, P.; Gianelli, L.; Froldi, F.; Moschini Consorzio di Tutela del Formaggio Grana Padano, M.; Boldini, A.; Stroppa, A. Regole per Categoria Di Prodotto (RCP) per Il Formaggio Grana Padano DOP Organizzazione Proponente Consorzio Di Tutela Del Formaggio Grana Padano (CTFGP). 2022. Available online: https://www.mase.gov.it/sites/default/files/archivio/allegati/impronta_ambientale/rcp_grana_padano_v_1_0.pdf (accessed on 1 February 2025).

- Canellada, F.; Laca, A.; Laca, A.; Díaz, M. Environmental Impact of Cheese Production: A Case Study of a Small-Scale Factory in Southern Europe and Global Overview of Carbon Footprint. Sci. Total Environ. 2018, 635, 167–177. [Google Scholar] [CrossRef] [PubMed]

- Cipolat-Gotet, C.; Cecchinato, A.; De Marchi, M.; Bittante, G. Factors Affecting Variation of Different Measures of Cheese Yield and Milk Nutrient Recovery from an Individual Model Cheese-Manufacturing Process. J. Dairy Sci. 2013, 96, 7952–7965. [Google Scholar] [CrossRef]

- Guinee, T.P.; Mulholland, E.O.; Kelly, J.; Callaghan, D.J.O. Effect of Protein-to-Fat Ratio of Milk on the Composition, Manufacturing Efficiency, and Yield of Cheddar Cheese. J. Dairy Sci. 2007, 90, 110–123. [Google Scholar] [CrossRef]

- Cipolat-Gotet, C.; Cecchinato, A.; Malacarne, M.; Bittante, G.; Summer, A. Variations in Milk Protein Fractions Affect the Efficiency of the Cheese-Making Process. J. Dairy Sci. 2018, 101, 8788–8804. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bovo, M.; Giannone, C.; Santolini, E.; Tassinari, P.; Guarino, M. Reducing Life Cycle Environmental Impacts of Milk Production through Precision Livestock Farming. Sustain. Prod. Consum. 2024, 51, 303–314. [Google Scholar] [CrossRef]

- Wilkinson, J.; Garnsworthy, P. Impact of Diet and Fertility on Greenhouse Gas Emissions and Nitrogen Efficiency of Milk Production. Livestock 2017, 22, 140–144. [Google Scholar] [CrossRef]

- Korver, S. Genetic Aspects of Feed Intake and Feed Efficiency in Dairy Cattle: A Review. Livest. Prod. Sci. 1988, 20, 1–13. [Google Scholar] [CrossRef]

- Herzog, A.; Winckler, C.; Zollitsch, W. In Pursuit of Sustainability in Dairy Farming: A Review of Interdependent Effects of Animal Welfare Improvement and Environmental Impact Mitigation. Agric. Ecosyst. Environ. 2018, 267, 174–187. [Google Scholar] [CrossRef]

- Llonch, P.; Haskell, M.J.; Dewhurst, R.J.; Turner, S.P. Current Available Strategies to Mitigate Greenhouse Gas Emissions in Livestock Systems: An Animal Welfare Perspective. Animal 2017, 11, 274–284. [Google Scholar] [CrossRef] [PubMed]

- Saarinen, M.; Fogelholm, M.; Tahvonen, R.; Kurppa, S. Taking Nutrition into Account within the Life Cycle Assessment of Food Products. J. Clean. Prod. 2017, 149, 828–844. [Google Scholar] [CrossRef]

- McAuliffe, G.A.; Takahashi, T.; Lee, M.R.F. Applications of Nutritional Functional Units in Commodity-Level Life Cycle Assessment (LCA) of Agri-Food Systems. Int. J. Life Cycle Assess. 2020, 25, 208–221. [Google Scholar] [CrossRef]

- Nijdam, D.; Rood, T.; Westhoek, H. The Price of Protein: Review of Land Use and Carbon Footprints from Life Cycle Assessments of Animal Food Products and Their Substitutes. Food Policy 2012, 37, 760–770. [Google Scholar] [CrossRef]

- Gaillac, R.; Marbach, S. The Carbon Footprint of Meat and Dairy Proteins: A Practical Perspective to Guide Low Carbon Footprint Dietary Choices. J. Clean. Prod. 2021, 321, 128766. [Google Scholar] [CrossRef]

- Samoré, A.B.; Canavesi, F.; Rossoni, A.; Bagnato, A. Genetics of Casein Content in Brown Swiss and Italian Holstein Dairy Cattle Breeds. Ital. J. Anim. Sci. 2012, 11, 36. [Google Scholar] [CrossRef]

- Schopen, G.C.B.; Heck, J.M.L.; Bovenhuis, H.; Visker, M.H.P.W.; Van Valenberg, H.J.F.; Van Arendonk, J.A.M. Genetic Parameters for Major Milk Proteins in Dutch Holstein-Friesians. J. Dairy Sci. 2009, 92, 1182–1191. [Google Scholar] [CrossRef]

- Bijl, E.; van Valenberg, H.J.F.; Huppertz, T.; van Hooijdonk, A.C.M. Protein, Casein, and Micellar Salts in Milk: Current Content and Historical Perspectives. J. Dairy Sci. 2013, 96, 5455–5464. [Google Scholar] [CrossRef]

- ANAFIBJ. Schede Di Calcolo Indici Firsona e Jersey; ANAFIBJ: Cremona, Italy, 2024. [Google Scholar]

- Powell, J.M.; Gourley, C.J.P.; Rotz, C.A.; Weaver, D.M. Nitrogen Use Efficiency: A Potential Performance Indicator and Policy Tool for Dairy Farms. Environ. Sci. Policy 2010, 13, 217–228. [Google Scholar] [CrossRef]

- White, R.R. Increasing Energy and Protein Use Efficiency Improves Opportunities to Decrease Land Use, Water Use, and Greenhouse Gas Emissions from Dairy Production. Agric. Syst. 2016, 146, 20–29. [Google Scholar] [CrossRef]

- Brito, A.F.; Silva, L.H.P. Symposium Review: Comparisons of Feed and Milk Nitrogen Efficiency and Carbon Emissions in Organic versus Conventional Dairy Production Systems. J. Dairy Sci. 2020, 103, 5726–5739. [Google Scholar] [CrossRef]

| Item | Unit | CL-CY1 1 (n = 6) | CL-CY2 (n = 6) | CL-CY3 (n = 6) | p-Value |

|---|---|---|---|---|---|

| Carbon footprint: | |||||

| CF 2 milk | kg CO2eq/kg FPCM 3 | 1.30 ± 0.08 | 1.47 ± 0.04 | 1.52 ± 0.19 | 0.296 |

| Feed purchased | kg CO2eq/kg FPCM | 0.40 ± 0.04 | 0.45 ± 0.03 | 0.46 ± 0.10 | 0.581 |

| Feed production | kg CO2eq/kg FPCM | 0.07 ± 0.02 | 0.08 ± 0.01 | 0.08 ± 0.04 | 0.493 |

| Resource use | kg CO2eq/kg FPCM | 0.06 ± 0.01 | 0.10 ± 0.01 | 0.13 ± 0.03 | 0.064 |

| Enteric emissions | kg CO2eq/kg FPCM | 0.48 ± 0.02 | 0.48 ± 0.02 | 0.50 ± 0.07 | 0.960 |

| Manure emissions | kg CO2eq/kg FPCM | 0.29 ± 0.05 | 0.36 ± 0.05 | 0.36 ± 0.07 | 0.612 |

| CF cheesemaking material | kg CO2eq/kg milk | 0.09 ± 0.01 | 0.11 ± 0.003 | 0.12 ± 0.02 | 0.182 |

| CF fat | kg CO2eq/kg milk | 0.05 ± 0.003 | 0.06 ± 0.002 | 0.06 ± 0.01 | 0.220 |

| CF protein | kg CO2eq/kg milk | 0.04 ± 0.003 | 0.05 ± 0.001 | 0.05 ± 0.01 | 0.182 |

| CF cheesemaking material | kg CO2eq/kg cheesemaking material | 71.29 ± 4.62 | 79.94 ± 2.50 | 82.91 ± 10.40 | 0.296 |

| CF fat | kg CO2eq/kg fat | 33.55 ± 2.13 | 38.02 ± 1.07 | 38.61 ± 4.71 | 0.250 |

| CF protein | kg CO2eq/kg protein | 37.75 ± 2.49 | 41.91 ± 1.46 | 44.30 ± 5.69 | 0.347 |

| CF GP | kg CO2eq/1 kg GP PDO 4 9 months | 17.63 ± 0.00 a | 20.03 ± 0.00 ab | 20.28 ± 0.00 b | <0.001 |

| Milk production: | |||||

| Milk production | kg/d | 31.42 ± 0.78 a | 28.86 ± 1.02 ab | 25.79 ± 2.17 b | 0.035 |

| FPCM production | kg/d | 30.86 ± 0.74 a | 28.67 ± 1.03 ab | 26.13 ± 2.10 b | 0.039 |

| Meat sold | t live weight/y | 55.64 ± 14.43 | 29.76 ± 7.05 | 39.87 ± 12.00 | 0.414 |

| AF 5 milk | % | 86.02 ± 1.96 | 88.32 ± 1.53 | 85.67 ± 1.29 | 0.778 |

| AF meat | % | 13.98 ± 1.96 | 11.68 ± 1.53 | 14.33 ± 1.29 | 0.778 |

| Cheesemaking material | % | 7.19 ± 0.01 a | 7.31 ± 0.02 ab | 7.49 ± 0.06 b | <0.001 |

| Fat | % | 3.80 ± 0.01 a | 3.83 ± 0.02 a | 4.00 ± 0.03 b | 0.002 |

| Protein | % | 3.38 ± 0.01 a | 3.48 ± 0.03 b | 3.50 ± 0.03 b | 0.007 |

| Caseine | % | 2.60 ± 0.02 | 2.62 ± 0.04 | 2.68 ± 0.04 | 0.421 |

| Fat/caseine ratio | % | 1.46 ± 0.01 | 1.46 ± 0.03 | 1.49 ± 0.02 | 0.281 |

| Cheese Yield 7 | kg GP/100 kg milk in vat | 9.36 ± 0.02 a | 9.49 ± 0.02 ab | 9.79 ± 0.08 b | <0.001 |

| Cluster herd composition | |||||

| Lactating cow | n° AU 6 | 200.00 ± 31.87 | 139.67 ± 18.40 | 161.33 ± 37.72 | 0.341 |

| Heifers | n° AU | 120.13 ± 21.20 | 86.40 ± 17.16 | 104.03 ± 30.13 | 0.520 |

| Dry cow | n° AU | 34.33 ± 6.35 | 26.33 ± 3.66 | 23.33 ± 4.40 | 0.310 |

| Herd size | n° AU | 354.47 ± 58.76 | 252.40 ± 38.39 | 288.70 ± 71.54 | 0.359 |

| Stocking rate | AU/ha | 3.25 ± 0.30 | 3.65 ± 0.73 | 3.62 ± 0.53 | 0.612 |

| Herd productivity | AU/kg FPCM | 0.0002 ± 0.00001 | 0.0002 ± 0.00001 | 0.0002 ± 0.00003 | 0.097 |

| CH4 enteric fermentation | kg/kg FPCM | 0.02 ± 0.0005 | 0.02 ± 0.001 | 0.02 ± 0.002 | 0.065 |

| Feeding strategy: | |||||

| DMI lactating cow | kg/d | 23.14 ± 0.72 | 24.16 ± 1.29 | 22.29 ± 0.85 | 0.778 |

| DMI heifers | kg/d | 7.56 ± 0.64 | 7.74 ± 0.41 | 6.51 ± 0.50 | 0.140 |

| DMI dry cow | kg/d | 11.80 ± 0.67 | 8.33 ± 1.31 | 10.45 ± 0.64 | 0.058 |

| Herd level feed use intensity | kg DMI herd/kg FPCM | 1.03 ± 0.04 | 1.14 ± 0.04 | 1.18 ± 0.10 | 0.144 |

| FE 7 | kg FPCM/kg DMI | 1.34 ± 0.04 | 1.20 ± 0.05 | 1.17 ± 0.09 | 0.144 |

| DE 8 lactating cow | %DM | 67.40 ± 1.15 | 63.97 ± 0.40 | 65.72 ± 1.70 | 0.081 |

| DE heifers | %DM | 60.79 ± 1.05 | 62.66 ± 0.85 | 62.00 ± 1.26 | 0.459 |

| DE dry cow | %DM | 60.32 ± 1.29 | 56.42 ± 1.89 | 58.88 ± 1.53 | 0.394 |

| Nex 9 total herd | kg/kg FPCM | 0.02 ± 0.001 | 0.02 ± 0.001 | 0.02 ± 0.002 | 0.994 |

| N efficiency lactating cow | % | 33.41 ± 1.93 | 30.36 ± 1.31 | 29.02 ± 2.13 | 0.414 |

| Manure management: | |||||

| Slurry | m3/kg FPCM | 0.002 ± 0.0003 a | 0.002 ± 0.0003 ab | 0.003 ± 0.0004 b | 0.028 |

| Manure | m3/kg FPCM | 0.001 ± 0.0003 | 0.002 ± 0.001 | 0.002 ± 0.001 | 0.523 |

| N at field | kg y/ha | 243.85 ± 20.63 | 262.71 ± 52.88 | 252.45 ± 42.05 | 0.884 |

| N at field | kg/kg FPCM | 0.012 ± 0.001 | 0.012 ± 0.0005 | 0.014 ± 0.002 | 0.587 |

| CH4 storage emissions | kg/kg FPCM | 0.005 ± 0.0005 | 0.004 ± 0.0002 | 0.005 ± 0.001 | 0.399 |

| N2O storage and spreading emissions | kg/kg FPCM | 0.0004 ± 0.00002 | 0.0004 ± 0.00002 | 0.0004 ± 0.0001 | 0.386 |

| Energy and fuel consumption: | |||||

| Energy consumption | kWh/kg FPCM | 0.04 ± 0.01 | 0.03 ± 0.01 | 0.05 ± 0.01 | 0.523 |

| Renewable energy consumption | kWh/kg FPCM | 0.003 ± 0.003 | 0.01 ± 0.005 | 0.06 ± 0.06 | 0.777 |

| LPG 10 | m3/kg FPCM | 0.0005 ± 0.0002 | 0.002 ± 0.001 | 0.002 ± 0.002 | 0.243 |

| Diesel consumed at farm | L/kg FPCM | 0.01 ± 0.001 | 0.01 ± 0.002 | 0.02 ± 0.005 | 0.368 |

| Diesel consumed to crop production | L y/ha | 294.26 ± 12.77 | 289.37 ± 36.22 | 320.46 ± 26.68 | 0.581 |

| Diesel consumed to crop production | L/kg FPCM | 0.01 ± 0.002 | 0.02 ± 0.002 | 0.02 ± 0.01 | 0.927 |

| Bedding materials | kg/kg FPCM | 0.04 ± 0.01 | 0.13 ± 0.05 | 0.18 ± 0.08 | 0.343 |

| Purchased feeds: | |||||

| Milk powder | kg DM/kg FPCM | 0.001 ± 0.0004 a | 0.0001 ± 0.0001 b | 0.0004 ± 0.0003 ab | 0.033 |

| Total hay | kg DM/kg FPCM | 0.03 ± 0.02 | 0.08 ± 0.03 | 0.03 ± 0.02 | 0.412 |

| Hay | kg DM/kg FPCM | 0.02 ± 0.01 | 0.07 ± 0.03 | 0.02 ± 0.01 | 0.232 |

| Alfalfa hay | kg DM/kg FPCM | 0.01 ± 0.01 | 0.01 ± 0.01 | 0.02 ± 0.01 | 0.821 |

| Starch meals | kg DM/kg FPCM | 0.07 ± 0.02 | 0.11 ± 0.02 | 0.09 ± 0.04 | 0.390 |

| Protein meals | kg DM/kg FPCM | 0.05 ± 0.03 | 0.02 ± 0.02 | 0.02 ± 0.02 | 0.473 |

| Concentrate | kg DM/kg FPCM | 0.11 ± 0.05 | 0.19 ± 0.03 | 0.21 ± 0.03 | 0.325 |

| Road transport | kg DM/km | 121.19 ± 46.03 | 334.93 ± 158.92 | 114.65 ± 37.50 | 0.205 |

| Agronomic management: | |||||

| Total land | ha | 108.29 ± 15.76 | 96.50 ± 34.23 | 79.12 ± 12.72 | 0.364 |

| Land self-feedproduction | % ha | 96.71 ± 1.79 | 89.61 ± 8.75 | 90.28 ± 6.76 | 0.875 |

| Land occupation | m2/kg FPCM y | 0.50 ± 0.04 | 0.59 ± 0.14 | 0.85 ± 0.43 | 0.864 |

| Feed self-sufficiency | % DM | 72.18 ± 3.90 | 60.84 ± 4.15 | 66.41 ± 6.59 | 0.312 |

| Total silage | kg DM/kg FPCM | 0.46 ± 0.05 | 0.43 ± 0.06 | 0.68 ± 0.21 | 0.641 |

| Corn silage | kg DM/kg FPCM | 0.39 ± 0.04 | 0.36 ± 0.08 | 0.64 ± 0.23 | 0.738 |

| Other silage | kg DM/kg FPCM | 0.07 ± 0.05 | 0.07 ± 0.03 | 0.04 ± 0.03 | 0.825 |

| Total hay | kg DM/kg FPCM | 0.23 ± 0.05 | 0.26 ± 0.05 | 0.28 ± 0.15 | 0.587 |

| Hay | kg DM/kg FPCM | 0.02 ± 0.01 a | 0.11 ± 0.02 b | 0.04 ± 0.02 a | 0.019 |

| Alfalfa hay | kg DM/kg FPCM | 0.21 ± 0.05 | 0.15 ± 0.05 | 0.25 ± 0.15 | 0.520 |

| N synthesis fertilization | kg/kg FPCM | 0.01 ± 0.001 | 0.004 ± 0.001 | 0.01 ± 0.003 | 0.587 |

| P synthesis fertilization | kg/kg FPCM | 0.0001 ± 0.0001 | 0.00 ± 0.00 | 0.001 ± 0.001 | 0.364 |

| Pesticides | g AI 11/kg FPCM | 0.05 ± 0.01 | 0.05 ± 0.01 | 0.11 ± 0.03 | 0.242 |

| Item | Unit | CL-CF1 (n = 6) | CL-CF2 (n = 6) | CL-CF3 (n = 6) | p-Value |

|---|---|---|---|---|---|

| Carbon footprint: | |||||

| CF 1 milk | kg CO2eq/kg FPCM 2 | 1.14 ± 0.05 a | 1.40 ± 0.02 ab | 1.75 ± 0.10 b | <0.001 |

| Feed purchased | kg CO2eq/kg FPCM | 0.34 ± 0.08 | 0.41 ± 0.03 | 0.55 ± 0.04 | 0.065 |

| Feed production | kg CO2eq/kg FPCM | 0.05 ± 0.01 | 0.08 ± 0.01 | 0.11 ± 0.04 | 0.158 |

| Resource use | kg CO2eq/kg FPCM | 0.06 ± 0.01 a | 0.08 ± 0.01 ab | 0.15 ± 0.03 b | 0.032 |

| Enteric emissions | kg CO2eq/kg FPCM | 0.43 ± 0.04 | 0.50 ± 0.01 | 0.53 ± 0.05 | 0.242 |

| Manure emissions | kg CO2eq/kg FPCM | 0.26 ± 0.07 | 0.34 ± 0.02 | 0.41 ± 0.05 | 0.085 |

| CF cheesemaking material | kg CO2eq/kg milk | 0.08 ± 0.003 a | 0.10 ± 0.002 ab | 0.13 ± 0.01 b | <0.001 |

| CF fat | kg CO2eq/kg milk | 0.04 ± 0.002 a | 0.05 ± 0.001 ab | 0.07 ± 0.01 b | <0.001 |

| CF protein | kg CO2eq/kg milk | 0.04 ± 0.001 a | 0.05 ± 0.001 ab | 0.06 ± 0.004 b | <0.001 |

| CF cheesemaking material | kg CO2eq/kg cheesemaking material | 62.35 ± 2.67 a | 76.21 ± 0.90 ab | 95.57 ± 5.57 b | <0.001 |

| CF fat | kg CO2eq/kg fat | 29.33 ± 1.20 a | 36.10 ± 0.44 ab | 44.75 ± 2.34 b | <0.001 |

| CF protein | kg CO2eq/kg protein | 33.02 ± 1.48 a | 40.11 ± 0.56 ab | 50.82 ± 3.24 b | <0.001 |

| CF GP | kg CO2eq/1 kg GP PDO 3 9 months | 16.96 ± 0.00 a | 19.12 ± 0.00 ab | 23.07 ± 0.00 b | <0.001 |

| Milk production: | |||||

| Milk production | kg/d | 29.42 ± 1.25 | 30.78 ± 1.00 | 25.87 ± 2.09 | 0.082 |

| FPCM production | kg/d | 29.32 ± 1.10 | 30.45 ± 0.96 | 25.89 ± 1.97 | 0.104 |

| Meat sold | t live weight/y | 60.21 ± 16.44 | 37.66 ± 6.59 | 27.456 ± 6.66 | 0.312 |

| AF 4 milk | % | 85.19 ± 1.80 | 88.17 ± 1.63 | 86.65 ± 1.37 | 0.717 |

| AF meat | % | 14.81 ± 1.80 | 11.83 ± 1.63 | 13.35 ± 1.37 | 0.717 |

| Cheesemaking material | % | 7.34 ± 0.07 | 7.27 ± 0.04 | 7.39 ± 0.08 | 0.523 |

| Fat | % | 3.89 ± 0.04 | 3.82 ± 0.02 | 3.92 ± 0.05 | 0.342 |

| Protein | % | 3.45 ± 0.03 | 3.44 ± 0.03 | 3.46 ± 0.04 | 0.884 |

| Caseine | % | 2.66 ± 0.03 | 2.58 ± 0.03 | 2.67 ± 0.05 | 0.205 |

| Fat/caseine ratio | % | 1.46 ± 0.01 | 1.48 ± 0.02 | 1.47 ± 0.03 | 0.476 |

| Cheese Yield 5 | kg GP/100 kg milk in vat | 9.56 ± 0.09 | 9.45 ± 0.04 | 9.64 ± 0.11 | 0.399 |

| Cluster herd composition | |||||

| Lactating cow | n° AU 6 | 202.83 ± 42.43 | 165.33 ± 9.78 | 132.83 ± 27.91 | 0.392 |

| Heifers | n° AU | 125.80 ± 32.40 | 104.60 ± 13.94 | 80.17 ± 17.70 | 0.459 |

| Dry cow | n° AU | 31.00 ± 7.43 | 29.83 ± 2.24 | 23.17 ± 4.32 | 0.412 |

| Herd size | n° AU | 359.63 ± 80.79 | 299.77 ± 25.54 | 236.17 ± 49.11 | 0.366 |

| Stocking rate | AU/ha | 3.74 ± 0.31 | 3.23 ± 0.70 | 3.55 ± 0.56 | 0.587 |

| Herd productivity | AU/kg FPCM | 0.0002 ± 0.00001 | 0.0002 ± 0.00001 | 0.0002 ± 0.00003 | 0.172 |

| CH4 enteric fermentation | kg/kg FPCM | 0.02 ± 0.001 a | 0.02 ± 0.001 ab | 0.02 ± 0.002 b | 0.030 |

| Feeding strategy: | |||||

| DMI lactating cow | kg/d | 22.53 ± 0.61 | 25.01 ± 1.14 | 22.05 ± 0.76 | 0.097 |

| DMI heifers | kg/d | 6.39 ± 0.19 a | 8.15 ± 0.50 b | 7.27 ± 0.64 ab | 0.034 |

| DMI dry cow | kg/d | 11.00 ± 0.57 | 9.02 ± 1.61 | 10.56 ± 0.67 | 0.796 |

| Herd level feed use intensity | kg DMI herd/kg FPCM | 1.01 ± 0.04 | 1.12 ± 0.04 | 1.22 ± 0.10 | 0.135 |

| FE 7 | kg FPCM/kg DMI | 1.31 ± 0.06 | 1.22 ± 0.05 | 1.17 ± 0.09 | 0.402 |

| DE 8 lactating cow | %DM | 65.55 ± 1.21 | 65.17 ± 1.19 | 66.37 ± 1.59 | 0.805 |

| DE heifers | %DM | 61.73 ± 1.32 | 61.40 ± 0.77 | 62.32 ± 1.16 | 0.751 |

| DE dry cow | %DM | 61.43 ± 1.21 a | 55.90 ± 1.71 b | 58.28 ± 1.29 ab | 0.027 |

| Nex 9 total herd | kg/kg FPCM | 0.02 ± 0.001 a | 0.02 ± 0.0004 ab | 0.02 ± 0.002 b | 0.030 |

| N efficiency lactating cow | % | 33.33 ± 1.94 | 30.60 ± 0.87 | 28.85 ± 2.34 | 0.421 |

| Manure management: | |||||

| Slurry | m3/kg FPCM | 0.002 ± 0.0004 | 0.002 ± 0.0003 | 0.003 ± 0.0004 | 0.166 |

| Manure | m3/kg FPCM | 0.002 ± 0.0004 | 0.001 ± 0.0005 | 0.003 ± 0.001 | 0.414 |

| N at field | kg y/ha | 259.46 ± 27.29 | 232.25 ± 49.87 | 267.30 ± 40.73 | 0.567 |

| kg/kg FPCM | 0.01 ± 0.001 a | 0.01 ± 0.0004 ab | 0.01 ± 0.002 b | 0.019 | |

| CH4 storage emissions | kg/kg FPCM | 0.004 ± 0.001 | 0.004 ± 0.0002 | 0.01 ± 0.0004 | 0.209 |

| N2O storage and spreading emissions | kg/kg FPCM | 0.0003 ± 0.00003 a | 0.0004 ± 0.00002 ab | 0.0005 ± 0.00004 b | 0.035 |

| Energy and fuel consumption: | |||||

| Energy consumption | kWh/kg FPCM | 0.04 ± 0.01 | 0.04 ± 0.01 | 0.04 ± 0.01 | 0.796 |

| Renewable energy consumption | kWh/kg FPCM | 0.06 ± 0.06 | 0.01 ± 0.01 | 0.00 ± 0.00 | 0.170 |

| % total energy consumption | 17.88 ± 15.47 | 19.42 ± 9.29 | 0.00 ± 0.00 | 0.170 | |

| LPG 10 | m3/kg FPCM | 0.0001 ± 0.0001 a | 0.002 ± 0.001 b | 0.003 ± 0.001 ab | 0.025 |

| Diesel consumed at farm | L/kg FPCM | 0.01 ± 0.003 | 0.01 ± 0.002 | 0.01 ± 0.005 | 0.641 |

| Diesel consumed to crop production | L y/ha | 296.08 ± 19.84 | 284.24 ± 23.09 | 323.77 ± 34.75 | 0.717 |

| Diesel consumed to crop production | L/kg FPCM | 0.01 ± 0.002 | 0.02 ± 0.002 | 0.03 ± 0.01 | 0.278 |

| Bedding materials | kg/kg FPCM | 0.02 ± 0.01 a | 0.06 ± 0.01 ab | 0.26 ± 0.07 b | 0.0014 |

| Purchased feeds: | |||||

| Milk powder | kg DM/kg FPCM | 0.0006 ± 0.0003 | 0.0005 ± 0.0004 | 0.0008 ± 0.0005 | 0.751 |

| Total hay | kg DM/kg FPCM | 0.003 ± 0.003 | 0.05 ± 0.02 | 0.09 ± 0.03 | 0.080 |

| Hay | kg DM/kg FPCM | 0.003 ± 0.003 | 0.04 ± 0.02 | 0.06 ± 0.03 | 0.086 |

| Alfalfa hay | kg DM/kg FPCM | 0.00 ± 0.00 a | 0.01 ± 0.01 ab | 0.03 ± 0.01 b | 0.048 |

| Starch meals | kg DM/kg FPCM | 0.06 ± 0.03 | 0.10 ± 0.02 | 0.11 ± 0.03 | 0.310 |

| Protein meals | kg DM/kg FPCM | 0.002 ± 0.002 | 0.02 ± 0.02 | 0.06 ± 0.03 | 0.301 |

| Concentrate | kg DM/kg FPCM | 0.19 ± 0.05 | 0.18 ± 0.04 | 0.14 ± 0.04 | 0.796 |

| Road transport | kg DM/km | 117.72 ± 36.66 | 268.56 ± 173.50 | 184.49 ± 36.54 | 0.505 |

| Agronomic management: | |||||

| Total land | ha | 91.69 ± 17.38 | 117.96 ± 30.06 | 74.27 ± 16.40 | 0.554 |

| Land self-feedproduction | % total land | 97.35 ± 1.92 | 88.97 ± 8.61 | 90.28 ± 6.76 | 0.624 |

| Land occupation | m2/kg FPCM y | 0.44 ± 0.03 | 0.63 ± 0.13 | 0.87 ± 0.42 | 0.653 |

| Feed self-sufficiency | % DM | 71.93 ± 3.70 | 66.00 ± 3.12 | 61.49 ± 7.37 | 0.268 |

| Total silage | kg DM/kg FPCM | 0.50 ± 0.04 | 0.44 ± 0.06 | 0.63 ± 0.23 | 0.834 |

| Corn silage | kg DM/kg FPCM | 0.42 ± 0.05 | 0.39 ± 0.05 | 0.58 ± 0.24 | 0.960 |

| Other silage | kg DM/kg FPCM | 0.08 ± 0.05 | 0.05 ± 0.03 | 0.06 ± 0.04 | 0.937 |

| Total hay | kg DM/kg FPCM | 0.17 ± 0.04 | 0.28 ± 0.06 | 0.31 ± 0.14 | 0.459 |

| Hay | kg DM/kg FPCM | 0.04 ± 0.02 | 0.08 ± 0.03 | 0.05 ± 0.03 | 0.320 |

| Alfalfa hay | kg DM/kg FPCM | 0.13 ± 0.03 | 0.20 ± 0.06 | 0.26 ± 0.15 | 0.738 |

| N synthesis fertilization | kg/kg FPCM | 0.004 ± 0.001 | 0.005 ± 0.001 | 0.007 ± 0.003 | 0.612 |

| P synthesis fertilization | kg/kg FPCM | 0.001 ± 0.001 | 0.0001 ± 0.0001 | 0.00 ± 0.00 | 0.364 |

| Pesticides | g AI 11/kg FPCM | 0.07 ± 0.02 | 0.06 ± 0.01 | 0.08 ± 0.03 | 0.977 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferronato, G.; Tobanelli, N.; Bani, P.; Cattaneo, L. Carbon Footprint Assessment of Dairy Milk and Grana Padano PDO Cheese and Improvement Scenarios: A Case Study in the Po Valley (Italy). Animals 2025, 15, 811. https://doi.org/10.3390/ani15060811

Ferronato G, Tobanelli N, Bani P, Cattaneo L. Carbon Footprint Assessment of Dairy Milk and Grana Padano PDO Cheese and Improvement Scenarios: A Case Study in the Po Valley (Italy). Animals. 2025; 15(6):811. https://doi.org/10.3390/ani15060811

Chicago/Turabian StyleFerronato, Giulia, Noemi Tobanelli, Paolo Bani, and Luca Cattaneo. 2025. "Carbon Footprint Assessment of Dairy Milk and Grana Padano PDO Cheese and Improvement Scenarios: A Case Study in the Po Valley (Italy)" Animals 15, no. 6: 811. https://doi.org/10.3390/ani15060811

APA StyleFerronato, G., Tobanelli, N., Bani, P., & Cattaneo, L. (2025). Carbon Footprint Assessment of Dairy Milk and Grana Padano PDO Cheese and Improvement Scenarios: A Case Study in the Po Valley (Italy). Animals, 15(6), 811. https://doi.org/10.3390/ani15060811