Predicting the Net Energy Partition Patterns of Growing Pigs Based on Different Nutrients

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment 1

2.1.1. Experimental Design and Diets

2.1.2. Experimental Management and Sample Collection

2.1.3. Chemical Analysis

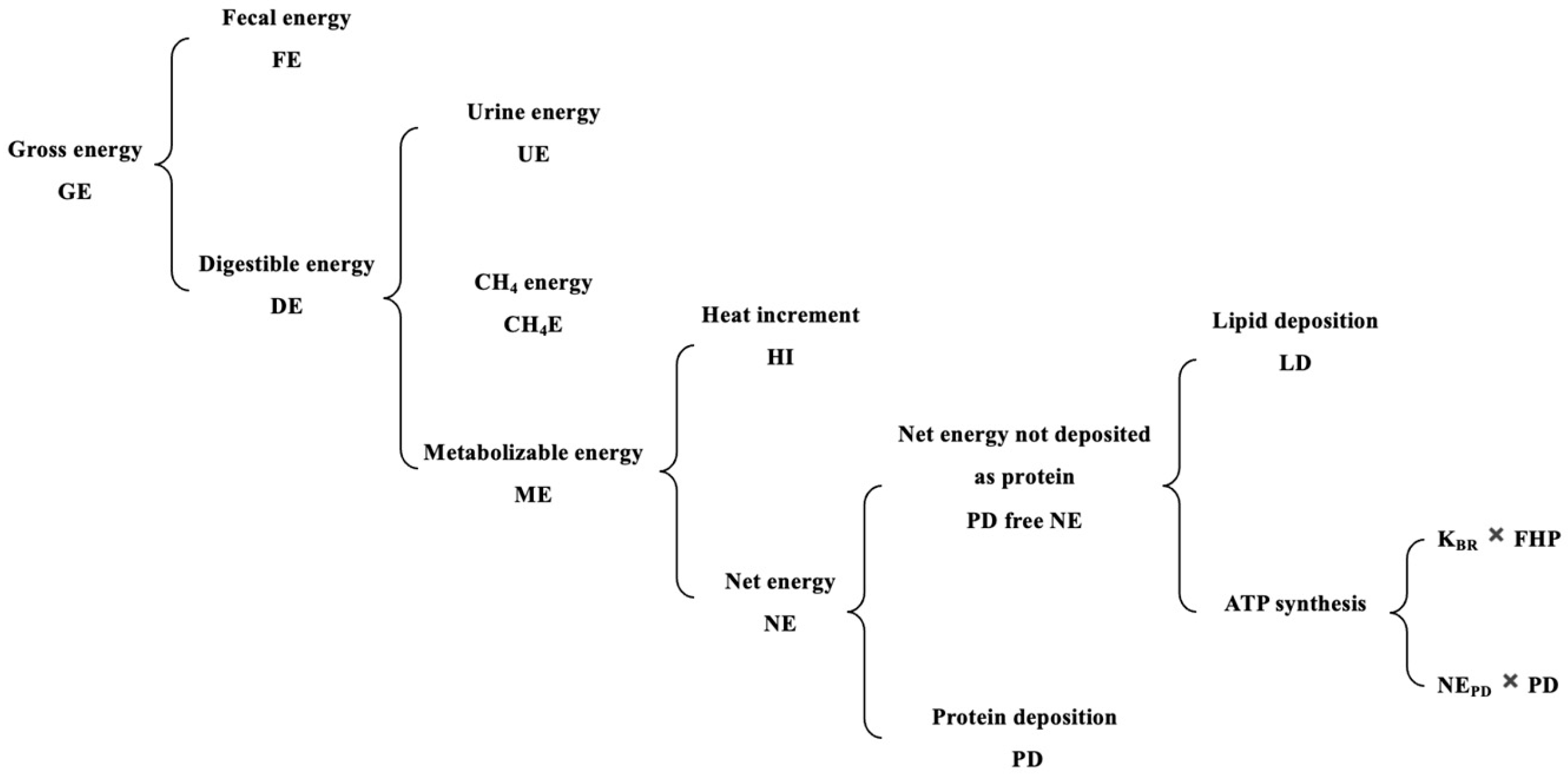

2.1.4. Calculations

2.1.5. Statistical Analysis

2.2. Experiment 2

2.2.1. Data Sources

2.2.2. Statistical Analysis

3. Results

3.1. Experiment 1

3.1.1. Nutrient Digestibility and Nitrogen Balance of Experimental Diets

3.1.2. Energy Balance of Experimental Diets

3.1.3. Energy Values and Energetic Efficiencies of Nutrients

3.2. Experiment 2

4. Discussion

4.1. Nutrient Digestibility and Nitrogen Balance of Experimental Diets

4.2. Energy Balance of Experimental Diets

4.3. Energy Values and Energetic Efficiencies of Nutrients

4.4. Correlation Analysis and Prediction Equations for PD and LD Based on Nutrient Characteristics of Different Ingredients

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADF | Acid detergent fiber |

| AIC | Akaike Information Criterion |

| ATTD | Apparent total tract digestibility |

| BIC | Bayesian Information Criterion |

| BW | Body weight |

| CH4E | Methane energy |

| CP | Crude protein |

| DE | Digestible energy |

| dj | Efficiency of using GE for DE |

| DDGS | Corn distillers dried grains with soluble |

| DM | Dry matter |

| DM intake | Dry matter intake |

| EE | Ether extract |

| FE | Fecal energy |

| FHP | Fasting heat production |

| GE | Gross energy |

| HI | Heat increment |

| HP | Heat production |

| KBR | Efficiency of using body reserves for ATP synthesis |

| kj | Efficiency of using ME for PD-free NE |

| LD | Lipid deposition |

| ME | Metabolizable energy |

| MEI | Metabolizable energy intake |

| MEm | Metabolizable energy for maintenance |

| mj | Efficiency of using DE for ME |

| NDF | Neutral detergent fiber |

| NE | Net energy |

| NEPD | Additional energy required for PD |

| OM | Organic matter |

| PD | Protein deposition |

| PD-free NE | Net energy not deposited as protein |

| pj | Efficiency of using ME for PD |

| RE | Retention energy |

| RMSE | Root mean square error |

| RQ | Respiratory quotient |

| THP | Total heat production |

| UE | Urine energy |

References

- Noblet, J. Net energy evaluation of feeds and determination of net energy requirements for pigs. Rev. Bras. Zootecn. 2007, 36, 277–284. [Google Scholar] [CrossRef]

- Noblet, J.; Fortune, H.; Shi, X.S.; Dubois, S. Prediction of net energy value of feeds for growing pigs. J. Anim. Sci. 1994, 72, 344–354. [Google Scholar] [CrossRef] [PubMed]

- Brown, J.; Livesey, G.; Roe, M.; Faulks, R.; Poppitt, S.; Wilkinson, J.; Elia, M. Metabolizable energy of high non-starch polysaccharide-maintenance and weight-reducing diets in men: Experimental appraisal of assessment systems. J. Nutr. 1998, 128, 986–995. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Yin, F.G.; Bo, M.J.; Li, T.J.; Huang, R.L. Study on digestibility of starch from oat, wheat, buckwheat and sweet potato in intestinal tract of growing pigs by feeding semi-single diet. Res. Agric. Mod. 2009, 30, 501–504. [Google Scholar]

- Oates, C.G. Towards an understanding of starch granule structure and hydrolysis. Trends Food Sci. Technol. 1997, 8, 375–382. [Google Scholar] [CrossRef]

- Zhao, J.B.; Song, X.M.; Li, Z.C.; Liu, L. Effects of different starch types on available energy and nutrient digestibility in growing pigs. Chin. J. Anim. Nutr. 2021, 33, 1330–1338. [Google Scholar]

- Black, J.L. Modelling energy metabolism in the pig—Critical evaluation of a simple reference model. In Modelling Growth in the Pig; Moughan, P.J., Mwa, V., Visser-Reynevel, M.I., Eds.; Wageningen Press: Wageningen, The Netherlands, 1995. [Google Scholar]

- NRC. Nutrient Requirements of Swine, 11th ed.; National Academy Press: Washington, DC, USA, 2012. [Google Scholar]

- Sauvant, D.; Perez, J.M.; Tran, G. Tables of Composition and Nutritional Value of Feed Materials: Pigs, Poultry, Cattle, Sheep, Goats, Rabbits, Horses and Fish; INRA Editions: Paris, France, 2002. [Google Scholar]

- Birkett, S.; de Lange, K. Limitations of conventional models and a conceptual framework for a nutrient flow representation of energy utilization by animals. Br. J. Nutr. 2001, 86, 647–659. [Google Scholar] [CrossRef]

- van Milgen, J.; Noblet, J.; Dubois, S. Energetic efficiency of starch, protein and lipid utilization in growing pigs. J. Nutr. 2001, 131, 1309–1318. [Google Scholar] [CrossRef]

- Elia, M.; Livesey, G. Energy expenditure and fuel selection in biological systems: The theory and practice of calculations based on indirect calorimetry and tracer methods. World Rev. Nutr. Diet. 1992, 70, 68–131. [Google Scholar]

- van Milgen, J.; Quiniou, N.; Noblet, J. Modelling the relation between energy intake and protein and lipid deposition in growing pigs. Anim. Sci. 2000, 71, 119–130. [Google Scholar] [CrossRef]

- Noblet, J.; Perez, J.M. Prediction of digestibility of nutrients and energy values of pig diets from chemical-analysis. J. Anim. Sci. 1993, 71, 3389–3398. [Google Scholar] [CrossRef] [PubMed]

- Quiniou, N.; Noblet, J. Effect of the dietary net energy concentration on feed intake and performance of growing-finishing pigs housed individually. J. Anim. Sci. 2012, 90, 4362–4372. [Google Scholar] [CrossRef] [PubMed]

- Adeola, O. Digestion and balance techniques in pigs. In Swine Nutrition, 2nd ed.; Lewis, A.J., Southern, L.L., Eds.; CRC Press: Washington, DC, USA, 2001; pp. 903–916. [Google Scholar]

- AOAC International. Official Methods of Analysis of AOAC International, 18th ed.; Hortwitz, W., Latimer, G.W., Jr., Eds.; AOAC Int.: Gaithersburg, MD, USA, 2007. [Google Scholar]

- Thiex, N.J.; Anderson, S.; Gildemeister, B. Crude fat, diethyl ether extraction, in feed, cereal grain, and forage (Randall/Soxtec/submersion method): Collaborative study. J. AOAC Int. 2003, 86, 88–898. [Google Scholar] [CrossRef]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Brouwer, E. Report of sub-committee on constants and factors. In European Association for Animal Production Publication; Blaxter, K., Ed.; Energy Metabolism Academic Press: London, UK, 1965; pp. 441–443. [Google Scholar]

- Wang, L.; Zeng, Z.C.; Hu, Q.L.; Wang, L.; Shi, H.W.; Lai, C.H.; Zhang, S. Determination and prediction of the available energy and amino acids digestibility of full-fat soybean fed to growing pigs. J. Anim. Sci. 2023, 101, 305–320. [Google Scholar] [CrossRef]

- Kies, A.K.; Moughan, P.J.; Smith, W.C. The apparent and true ileal digestibility of nitrogen and amino-acids in lactic casein for the growing-pig. Anim. Feed Sci. Technol. 1986, 16, 169–178. [Google Scholar] [CrossRef]

- Libao-Mercado, A.J.; Yin, Y.; van Eys, J.; de Lange, C.F.M. True ileal amino acid digestibility and endogenous ileal amino acid losses in growing pigs fed wheat shorts- or casein-based diets. J. Anim. Sci. 2006, 84, 1351–1361. [Google Scholar] [CrossRef]

- Myrie, S.B.; Bertolo, R.F.; Sauer, W.C.; Ball, R.O. Effect of common antinutritive factors and fibrous feedstuffs in pig diets on amino acid digestibilities with special emphasis on threonine. J. Anim. Sci. 2008, 86, 609–619. [Google Scholar] [CrossRef]

- El Kaoutari, A.; Armougom, F.; Gordon, J.I.; Raoult, D.; Henrissat, B. The abundance and variety of carbohydrate-active enzymes in the human gut microbiota. Nat. Rev. Microbiol. 2013, 11, 497–504. [Google Scholar] [CrossRef]

- Cervantes-Pahm, S.K.; Stein, H.H. Effect of dietary soybean oil and soybean protein concentration on the concentration of digestible amino acids in soybean products fed to growing pigs. J. Anim. Sci. 2008, 86, 1841–1849. [Google Scholar] [CrossRef]

- Kil, D.Y.; Ji, F.; Stewart, L.L.; Hinson, R.B.; Beaulieu, A.D.; Allee, G.L.; Patience, J.F.; Pettigrew, J.E.; Stein, H.H. Net energy of soybean oil and choice white grease in diets fed to growing and finishing pigs. J. Anim. Sci. 2011, 89, 448–459. [Google Scholar] [CrossRef]

- Peyraud, J.L.; Verite, R.; Delaby, L. Nitrogen excretion by dairy cows: Effect of the diet and of the level of production. Fourrages. 1995, 142, 131–144. [Google Scholar]

- Noblet, J.; Henry, Y.; Dubois, S. Effect of protein and lysine levels in the diet on body gain composition and energy-utilization in growing-pigs. J. Anim. Sci. 1987, 65, 717–726. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.J. The Study on Available Energy of Individual Components Indifferent Carbohydrates Sources in Growing Pigs. Ph.D. Thesis, China Agricultural University, Beijing, China, 2013. [Google Scholar]

- Li, D.F.; Qiao, S.Y.; Chen, D.W.; Wu, D.; Jiang, Z.Y.; Liu, Z.H.; Che, L.Q.; Yang, F.Y.; Xiong, B.H.; Liu, L.; et al. Nutrient Requirements of Swine in China; China Agriculture Press: Beijing, China, 2020. [Google Scholar]

- Fujita, S.; Dreyer, H.C.; Drummond, M.J.; Glynn, E.L.; Cadenas, J.G.; Yoshizawa, F.; Volpi, E.; Rasmussen, B.B. Nutrient signalling in the regulation of human muscle protein synthesis. J. Physiol. 2007, 582, 813–823. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.F.; Liu, D.W.; Wang, F.L.; Li, D.F. Estimation of the net energy requirements for maintenance in growing and finishing pigs. J. Anim. Sci. 2014, 92, 2987–2995. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.Q. Net Energy Prediction of Common High-Fiber Ingredients in Growing Pigs. Ph.D. Thesis, China Agricultural University, Beijing, China, 2021. [Google Scholar]

- Li, Z.C.; Li, Y.K.; Lyu, Z.Q.; Liu, H.; Zhao, J.B.; Nobel, J.; Wang, F.L.; Lai, C.H.; Li, D.F. Net energy of corn, soybean meal and rapeseed meal in growing pigs. J. Anim. Sci. Biotechnol. 2017, 8, 44. [Google Scholar] [CrossRef]

- Noblet, J.; van Milgen, J. Energy value of pig feeds: Effect of pig body weight and energy evaluation system. J. Anim. Sci. 2004, 82, E229–E238. [Google Scholar]

- Reeds, P.J.; Fuller, M.F.; Cadenhead, A.; Lobley, G.E.; McDonald, J.D. Effects of changes in the intakes of protein and non-protein energy on whole-body protein-turnover in growing-pigs. Br. J. Nutr. 1981, 45, 539–546. [Google Scholar] [CrossRef]

- Roth, F.X.; Gotterbarm, G.G.; Windisch, W.; Kirchgessner, M. Influence of dietary level of dispensable amino acids on nitrogen balance and whole-body protein turnover in growing pigs. J. Anim. Physiol. Anim. Nutr. 1999, 81, 232–238. [Google Scholar]

- Anguita, M.; Canibe, N.; Perez, J.F.; Jensen, B.B. Influence of the amount of dietary fiber on the available energy from hindgut fermentation in growing pigs: Use of cannulated pigs and in vitro fermentation. J. Anim. Sci. 2006, 84, 2766–2778. [Google Scholar] [CrossRef]

- Wiseman, J.; Cole, D.J.A.; Hardy, B. The dietary energy values of soybean oil, tallow and their blends for growing finishing pigs. Anim. Prod. 1990, 50, 513–518. [Google Scholar]

- Kerr, B.J.; Weber, T.E.; Dozier, W.A.; Kidd, M.T. Digestible and metabolizable energy content of crude glycerin originating from different sources in nursery pigs. J. Anim. Sci. 2009, 87, 4042–4049. [Google Scholar] [CrossRef] [PubMed]

- Rijnen, M.M.J.A.; Verstegen, M.W.A.; Heetkamp, M.J.W.; Schrama, J.W. Effects of two different dietary fermentable carbohydrates on activity and heat production in group-housed growing pigs. J. Anim. Sci. 2003, 81, 1210–1219. [Google Scholar] [CrossRef] [PubMed]

- May, R.; Bell, J. Digestible and metabolizable energy values of some feeds for growing pig. Can. J. Anim. Sci. 1971, 51, 271–278. [Google Scholar] [CrossRef]

- Lange, C.F.M. Efficiency of utilization of energy from protein and fiber in the pig—A case for NE systems. In Proceedings of the Midwest Swine Nutrition Conference, Indianapolis, IN, USA, 4 September 2008. [Google Scholar]

| Items | Diets | |||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | |

| Ingredient, % | ||||||

| Corn | 72.90 | 51.44 | 51.44 | 51.44 | 68.75 | 64.39 |

| Soybean meal | 23.20 | 16.37 | 16.37 | 16.37 | 21.88 | 20.49 |

| Corn starch | - | 27.00 | - | - | - | - |

| Pea starch | - | - | 27.00 | - | - | - |

| Tapioca starch | - | - | - | 27.00 | - | - |

| Soybean oil | - | - | - | - | 5.00 | - |

| Casein | - | - | - | - | - | 11.80 |

| Dicalcium phosphate | 0.85 | 1.00 | 1.00 | 1.00 | 0.90 | 0.80 |

| L-lysine-HCl | 0.50 | 0.96 | 0.96 | 0.96 | 0.73 | - |

| DL-methionine | 0.09 | 0.23 | 0.23 | 0.23 | 0.12 | 0.05 |

| L-threonine | 0.10 | 0.25 | 0.25 | 0.25 | 0.13 | 0.01 |

| L-tryptophan | 0.04 | 0.08 | 0.08 | 0.08 | 0.05 | 0.04 |

| L-valine | 0.01 | 0.21 | 0.21 | 0.21 | 0.05 | 0.01 |

| Salt | 0.21 | 0.26 | 0.26 | 0.26 | 0.29 | 0.31 |

| Limestone | 1.10 | 1.20 | 1.20 | 1.20 | 1.10 | 1.10 |

| Premix 1 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Nutrient levels 2 | ||||||

| DM | 85.99 | 85.91 | 86.23 | 85.83 | 87.74 | 85.09 |

| Ash | 4.36 | 4.18 | 4.23 | 4.13 | 4.41 | 4.23 |

| EE | 2.90 | 2.05 | 2.01 | 2.03 | 6.92 | 2.50 |

| NDF | 11.14 | 7.83 | 7.40 | 7.28 | 9.81 | 9.67 |

| ADF | 4.03 | 2.70 | 2.29 | 2.47 | 3.27 | 3.07 |

| CP | 16.31 | 12.35 | 12.08 | 12.19 | 16.03 | 23.58 |

| GE, MJ/kg | 17.53 | 17.09 | 17.15 | 17.22 | 18.33 | 17.84 |

| Lys/ME, g/Mcal | 2.41 | 2.39 | 2.42 | 2.39 | 2.48 | 3.41 |

| Lysine | 0.99 | 1.01 | 1.01 | 1.01 | 1.07 | 1.44 |

| Methionine + cysteine | 0.58 | 0.57 | 0.57 | 0.57 | 0.58 | 0.82 |

| Threonine | 0.61 | 0.60 | 0.60 | 0.60 | 0.61 | 0.87 |

| Tryptophan | 0.18 | 0.17 | 0.17 | 0.17 | 0.18 | 0.31 |

| Valine | 0.67 | 0.67 | 0.67 | 0.67 | 0.67 | 1.25 |

| Variables | Definitions | Units |

|---|---|---|

| NEi | net energy of experimental diet | MJ/kg DM |

| MEi | metabolizable energy of experimental diet | MJ/kg DM |

| HI | heat increment | kJ/kg BW0.6/d |

| REi | retention energy of experimental diet | kJ/kg BW0.6/d |

| THP | total heat production | kJ/kg BW0.6/d |

| PDi | protein deposition of experimental diet | kJ/kg BW0.6/d |

| PD-free NEi | net energy not deposited as protein of experimental diet | kJ/kg BW0.6/d |

| LDi | lipid deposition of experimental diet | kJ/kg BW0.6/d |

| Variables | Definitions | Units |

|---|---|---|

| energy valuej | energy value of nutrients | MJ/kg DM |

| energy valuetest | energy value of test diet (T2–T6 diets) | MJ/kg DM |

| energy valuebasal | energy value of basal diet (T1 diet) | MJ/kg DM |

| r0 | the energy-supplying fractions (consisting of corn and soybean meal) in the basal diet | % |

| r1 | the proportion of the basal ingredients in the test diet | % |

| r2 | the proportion of the tested nutrients in the test diet | % |

| GEj | gross energy of nutrients | MJ/kg DM |

| DEj | digestible energy of nutrients | MJ/kg DM |

| dj | efficiency of using GE for DE of nutrients | - |

| MEj | metabolizable energy of nutrients | MJ/kg DM |

| mj | efficiency of using DE for ME of nutrients | - |

| PDj | protein deposition of nutrients | kJ/kg BW0.6/d |

| pj | efficiency of using ME for PD of nutrients | - |

| PD-free NEj | net energy not deposited as protein of nutrients | kJ/kg BW0.6/d |

| kj | efficiency of using ME for PD-free NE of nutrients | - |

| LDj | lipid deposition of nutrients | kJ/kg BW0.6/d |

| KBR | the efficiency of using body reserves for ATP synthesis | - |

| FHP | fasting heat production | kJ/kg BW0.6/d |

| NEPD | the additional energy required for PD | - |

| Ingredients | Nutrient Characteristics (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| GE, MJ/kg | CP | EE | Starch | NDF | ADF | Ash | PD, kJ/kg BW0.6/d | LD, kJ/kg BW0.6/d | |

| Peanut meal | 19.17 | 52.63 | 1.90 | 15.23 | 18.87 | 7.43 | 6.85 | 1339.02 | 456.01 |

| Soybean meal | 19.17 | 52.97 | 0.88 | 3.50 | 15.00 | 6.68 | 7.07 | 1385.60 | 7.60 |

| Soybean meal | 19.47 | 51.23 | 2.10 | 3.50 | 17.55 | 7.76 | 6.41 | 1361.60 | 5.95 |

| Soybean meal | 19.29 | 50.25 | 1.28 | 3.50 | 19.73 | 9.17 | 6.56 | 1277.60 | 3.60 |

| Soybean meal | 19.12 | 49.25 | 0.93 | 3.50 | 17.46 | 7.40 | 6.83 | 1337.60 | 35.60 |

| Soybean meal | 19.50 | 48.52 | 1.20 | 0.00 | 17.08 | 9.96 | 6.21 | 1195.06 | 5.59 |

| Soybean meal | 19.21 | 48.02 | 1.25 | 3.50 | 15.73 | 7.74 | 6.27 | 1321.60 | 15.60 |

| Cottonseed meal | 17.99 | 46.43 | 0.27 | 1.80 | 33.02 | 15.35 | 6.28 | 1098.74 | 31.13 |

| Rapeseed meal | 19.54 | 42.36 | 1.08 | 0.00 | 30.75 | 20.7 | 6.97 | 1530.06 | 115.59 |

| Rapeseed meal | 19.37 | 41.83 | 1.68 | 2.26 | 39.83 | 24.79 | 9.14 | 730.25 | 98.34 |

| Rapeseed meal | 19.60 | 41.03 | 1.71 | 3.12 | 30.84 | 20.04 | 7.22 | 694.35 | 75.26 |

| Rapeseed meal | 19.47 | 39.92 | 2.58 | 3.02 | 37.27 | 21.50 | 8.24 | 637.94 | 98.34 |

| Rapeseed cake | 20.56 | 39.75 | 6.55 | 4.43 | 32.34 | 21.75 | 6.94 | 689.22 | 31.67 |

| Rapeseed cake | 21.33 | 39.23 | 9.52 | 0.00 | 36.98 | 22.84 | 6.41 | 815.06 | 0.00 |

| Rapeseed meal | 18.11 | 38.23 | 1.02 | 3.58 | 25.88 | 15.64 | 6.54 | 750.02 | 26.01 |

| Rapeseed cake | 21.35 | 37.70 | 11.27 | 2.95 | 41.00 | 24.18 | 7.49 | 196.91 | 642.69 |

| Sunflower meal | 19.13 | 32.49 | 1.93 | 4.91 | 43.51 | 28.97 | 8.51 | 475.60 | 19.34 |

| DDGS | 20.16 | 26.95 | 10.58 | 3.97 | 39.93 | 12.23 | 4.99 | 406.98 | 706.00 |

| Corn gluten feed | 18.58 | 23.05 | 2.34 | 14.85 | 42.27 | 12.70 | 5.70 | 437.40 | 241.23 |

| Corn germ meal | 19.31 | 21.53 | 2.07 | 19.54 | 50.30 | 14.38 | 1.85 | 342.26 | 453.53 |

| Full-fat rice bran | 20.61 | 15.30 | 16.04 | 32.92 | 17.78 | 7.38 | 8.11 | 343.12 | 809.09 |

| Corn | 18.84 | 8.71 | 4.06 | 74.19 | 10.22 | 1.35 | 1.51 | 193.08 | 1011.87 |

| Corn | 18.79 | 8.77 | 3.74 | 74.19 | 10.85 | 2.32 | 1.67 | 206.40 | 904.02 |

| Corn | 18.53 | 8.61 | 3.68 | 74.28 | 9.82 | 1.07 | 2.05 | 181.71 | 1006.61 |

| Corn | 18.76 | 8.54 | 3.75 | 74.64 | 10.36 | 2.08 | 1.77 | 182.66 | 1002.06 |

| Corn | 18.71 | 9.51 | 3.86 | 71.93 | 10.94 | 2.10 | 1.7 | 233.37 | 1016.11 |

| Corn | 18.74 | 9.34 | 3.62 | 71.90 | 10.93 | 1.96 | 1.47 | 195.13 | 1027.26 |

| Corn | 16.37 | 7.60 | 3.32 | 66.44 | 13.06 | 2.83 | 1.13 | 197.74 | 965.94 |

| Corn | 16.02 | 8.31 | 2.16 | 61.03 | 7.21 | 1.58 | 1.06 | 112.75 | 76.43 |

| Corn | 16.02 | 8.31 | 2.16 | 61.03 | 7.21 | 1.58 | 1.06 | 112.16 | 311.06 |

| Corn | 16.02 | 8.31 | 2.16 | 61.03 | 7.21 | 1.58 | 1.06 | 360.91 | 540.67 |

| Wheat | 16.48 | 13.76 | 1.59 | 60.78 | 12.38 | 3.15 | 1.67 | 350.26 | 761.66 |

| Wheat | 16.19 | 14.51 | 1.76 | 50.85 | 13.30 | 2.31 | 1.78 | 367.67 | 712.84 |

| Husked millet | 17.11 | 14.27 | 1.23 | 65.16 | 8.29 | 1.56 | 1.21 | 410.03 | 970.96 |

| Millet | 17.49 | 12.17 | 1.88 | 51.34 | 22.74 | 11.07 | 2.34 | 330.46 | 733.66 |

| Naked oat | 17.06 | 15.31 | 3.68 | 59.30 | 12.73 | 3.14 | 1.83 | 398.22 | 796.43 |

| Sorghum | 16.42 | 10.13 | 2.79 | 61.66 | 11.37 | 3.78 | 1.55 | 210.80 | 828.66 |

| Barley | 16.21 | 9.68 | 1.63 | 54.43 | 24.68 | 6.62 | 2.38 | 276.23 | 806.95 |

| Unpolished rice | 15.88 | 9.99 | 1.56 | 70.81 | 10.26 | 1.68 | 1.15 | 276.45 | 974.32 |

| Partially husked barley | 16.33 | 9.95 | 1.89 | 58.35 | 20.78 | 2.98 | 1.67 | 281.87 | 895.34 |

| Soybean oil | 0.00 | 0.35 | 93.65 | 0.00 | 0.00 | 0.00 | 3.24 | 8.12 | 2823.49 |

| Soybean oil | 0.00 | 0.35 | 94.65 | 0.00 | 1.13 | 0.00 | 0.00 | 65.08 | 3728.48 |

| Poultry oil | 0.00 | 0.00 | 91.40 | 0.00 | 0.00 | 0.00 | 3.20 | 6.77 | 3008.14 |

| Linseed oil | 0.00 | 0.00 | 91.00 | 0.00 | 0.00 | 0.00 | 2.70 | 7.66 | 3208.03 |

| Fish oil | 0.00 | 0.00 | 86.90 | 0.00 | 0.00 | 0.00 | 2.10 | 86.77 | 3158.47 |

| Corn oil | 0.00 | 0.00 | 88.30 | 0.00 | 0.00 | 0.00 | 3.20 | 6.77 | 3208.05 |

| Palm oil | 0.00 | 0.00 | 91.50 | 0.00 | 0.00 | 0.00 | 4.00 | 66.77 | 3158.11 |

| Items | Diets | SEM | p-Value | |||||

|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | |||

| BW, kg | 30.66 | 30.63 | 29.69 | 29.62 | 30.64 | 30.72 | 0.28 | 0.76 |

| DM intake, g/d | 935 | 897 | 884 | 878 | 874 | 889 | 21.28 | 0.95 |

| Apparent digestibility/% | ||||||||

| GE | 87.28 b | 91.23 a | 90.97 a | 91.59 a | 88.89 ab | 88.98 ab | 0.38 | <0.01 |

| OM | 87.19 b | 91.51 a | 91.27 a | 91.82 a | 88.91 ab | 88.96 ab | 0.41 | <0.01 |

| CP | 86.90 | 88.68 | 87.74 | 89.26 | 86.26 | 90.01 | 0.47 | 0.16 |

| EE | 54.75 b | 54.60 b | 53.70 b | 50.39 b | 79.47 a | 52.60 b | 2.11 | <0.01 |

| NDF | 54.87 | 56.85 | 55.60 | 54.62 | 56.15 | 50.91 | 1.11 | 0.74 |

| ADF | 48.13 | 47.90 | 43.94 | 51.83 | 45.99 | 39.22 | 1.45 | 0.20 |

| Nitrogen balance/(g/d) | ||||||||

| Nitrogen intake | 28.38 b | 20.63 d | 19.83 d | 19.96 d | 25.57 c | 39.39 a | 1.30 | <0.01 |

| Fecal nitrogen | 3.71 a | 2.32 b | 2.43 b | 2.13 b | 3.52 a | 3.94 a | 0.16 | <0.01 |

| Urinal nitrogen | 4.44 b | 3.69 b | 3.12 b | 3.43 b | 3.68 b | 8.34 a | 0.38 | <0.01 |

| Nitrogen retention | 20.22 b | 14.62 c | 14.27 c | 14.40 c | 18.37 b | 27.11 a | 0.89 | <0.01 |

| Net protein availability, % | 0.71 a | 0.71 a | 0.72 a | 0.72 a | 0.72 a | 0.69 b | 0.02 | <0.01 |

| Items | Diets | SEM | p-Value | |||||

|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | |||

| Energy balance, kJ/kg BW0.6/d | ||||||||

| MEI | 2066.73 | 2036.18 | 2018.06 | 2039.59 | 2027.80 | 2013.16 | 30.53 | 0.64 |

| THP | 1176.64 | 1150.69 | 1173.54 | 1168.28 | 1093.23 | 1112.11 | 39.03 | 0.06 |

| FHP | 853.09 | 854.36 | 827.46 | 823.37 | 834.21 | 847.62 | 48.16 | 0.96 |

| Total RE | 890.09 | 885.49 | 844.52 | 871.31 | 934.57 | 901.05 | 53.13 | 0.54 |

| PD | 386.42b | 279.48c | 278.27c | 281.00c | 351.86b | 518.03a | 16.57 | <0.01 |

| LD | 503.66a | 606.01a | 566.25a | 590.30a | 582.71a | 383.02b | 17.44 | <0.01 |

| RQ | 1.03 | 1.03 | 1.03 | 1.04 | 1.01 | 1.01 | - | - |

| Fasted RQ | 0.83 | 0.81 | 0.81 | 0.81 | 0.82 | 0.83 | - | - |

| Energy values, MJ/kg DM | ||||||||

| DE | 17.79b | 18.15ab | 18.09ab | 18.38ab | 18.57a | 18.66a | 0.07 | <0.01 |

| ME | 17.23b | 17.68ab | 17.45b | 17.72ab | 18.07a | 17.69ab | 0.07 | <0.01 |

| NE | 14.50b | 15.13ab | 14.49b | 14.78ab | 15.76a | 15.43ab | 0.13 | <0.01 |

| Energy utilization, % | ||||||||

| ME/DE | 97.00a | 97.20a | 96.60a | 96.40a | 97.00a | 94.80b | 0.74 | <0.01 |

| NE/ME | 84.20 | 85.60 | 83.00 | 83.40 | 87.00 | 87.40 | 2.31 | 0.11 |

| Items | Basal | Corn Starch | Pea Starch | Tapioca Starch | Soybean Oil | Casein | SEM |

|---|---|---|---|---|---|---|---|

| Utilization efficiency of energy | |||||||

| dj | 0.87 | 0.99 | 0.99 | 1.00 | 0.96 | 0.95 | 0.01 |

| mj | 0.97 | 0.99 | 0.95 | 0.95 | 0.99 | 0.88 | 0.01 |

| pj | 0.19 | 0.05 | 0.05 | 0.05 | 0.12 | 0.51 | 0.03 |

| kj | 0.81 | 0.88 | 0.80 | 0.86 | 0.95 | 0.68 | 0.02 |

| NEPD | 0.35 | ||||||

| KBR | 0.96 | ||||||

| Energy values, MJ/kg DM | |||||||

| GE | 18.36 | 16.13 | 16.30 | 17.02 | 37.97 | 20.20 | 1.43 |

| DE | 16.02 | 16.03 | 16.06 | 17.07 | 36.49 | 19.18 | 1.39 |

| ME | 15.52 | 15.77 | 15.37 | 16.34 | 36.16 | 16.89 | 1.42 |

| NE | 14.50 | 15.06 | 14.37 | 15.22 | 34.03 | 16.22 | 1.80 |

| Multiple Regression Equations | R2 | RMSE | AIC | BIC | Validation R2 |

|---|---|---|---|---|---|

| PD = −23.37 + 23.50 × CP | 0.87 | 173.36 | 373.09 | 376.08 | 0.78 |

| PD = 37.56 + 28.98 × CP − 24.51 × ADF | 0.96 | 105.45 | 346.89 | 350.48 | 0.77 |

| PD = 48.64 + 29.64 × CP − 23.77 × ADF − 7.77 × Ash | 0.96 | 106.99 | 349.54 | 353.48 | 0.77 |

| PD = 364.36 − 18.44 × GE + 29.10 × CP − 3.79 × EE − 21.37 × ADF | 0.96 | 105.15 | 350.66 | 354.65 | 0.80 |

| PD = 509.27 − 17.47 × GE + 26.61 × CP − 5.41 × EE − 2.01 × Starch − 24.37 × ADF | 0.96 | 106.18 | 353.56 | 357.28 | 0.79 |

| PD = 640.63 − 17.12 × GE + 24.56 × CP − 6.88 × EE − 3.36 × Starch − 2.49 × NDF − 21.91 × ADF | 0.96 | 108.06 | 357.21 | 360.29 | 0.80 |

| PD = 643.11 − 18.60 × GE + 24.54 × CP − 7.02 × EE − 3.13 × Starch − 2.21 × NDF − 22.21 × ADF + 3.45 × Ash | 0.96 | 110.66 | 361.60 | 363.59 | 0.80 |

| LD = 3106.14 − 141.09 × GE | 0.88 | 359.68 | 413.96 | 416.95 | 0.88 |

| LD = 1.25 + 35.15 × EE + 11.46 × Starch | 0.96 | 199.62 | 382.62 | 386.21 | 0.97 |

| LD = −200.77 + 37.34 × EE + 13.10 × Starch + 6.37 × NDF | 0.97 | 193.09 | 382.61 | 386.54 | 0.97 |

| LD = −1276.12 + 16.77 × CP + 49.36 × EE + 24.81 × Starch + 15.65 × NDF | 0.97 | 183.93 | 381.97 | 385.96 | 0.97 |

| LD = −1503.50 + 21.58 × CP + 51.98 × EE + 26.30 × Starch + 26.81 × NDF − 23.87 × ADF | 0.98 | 172.85 | 380.85 | 384.57 | 0.97 |

| LD = −1424.08 − 5.51 × GE + 21.91 × CP + 51.11 × EE + 26.46 × Starch + 26.91 × NDF − 22.82 × ADF | 0.98 | 176.67 | 384.74 | 387.82 | 0.97 |

| LD = −1413.85 − 11.61 × GE + 21.86 × CP + 50.55 × EE + 27.41 × Starch + 28.06 × NDF − 24.06 × ADF + 14.23 × Ash | 0.98 | 180.37 | 388.96 | 390.95 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, W.; Zeng, Z.; Shi, H.; Wang, L.; Liu, S.; Dong, X.; Wang, T.; Lai, C.; Zhang, S. Predicting the Net Energy Partition Patterns of Growing Pigs Based on Different Nutrients. Animals 2025, 15, 2464. https://doi.org/10.3390/ani15162464

Gao W, Zeng Z, Shi H, Wang L, Liu S, Dong X, Wang T, Lai C, Zhang S. Predicting the Net Energy Partition Patterns of Growing Pigs Based on Different Nutrients. Animals. 2025; 15(16):2464. https://doi.org/10.3390/ani15162464

Chicago/Turabian StyleGao, Wenjun, Zhengcheng Zeng, Huangwei Shi, Lu Wang, Shijie Liu, Xinwei Dong, Tenghao Wang, Changhua Lai, and Shuai Zhang. 2025. "Predicting the Net Energy Partition Patterns of Growing Pigs Based on Different Nutrients" Animals 15, no. 16: 2464. https://doi.org/10.3390/ani15162464

APA StyleGao, W., Zeng, Z., Shi, H., Wang, L., Liu, S., Dong, X., Wang, T., Lai, C., & Zhang, S. (2025). Predicting the Net Energy Partition Patterns of Growing Pigs Based on Different Nutrients. Animals, 15(16), 2464. https://doi.org/10.3390/ani15162464