Simple Summary

Well-informed consumers demand world markets increase production transparence and adhere to sustainable fish husbandry practices. The Peruvian grunt inhabiting the rocky shores of American Southern Pacific has a high commercial value but its wild population is being harvested unsustainably. The cultivation of this grunt could alleviate fishing pressure on its natural population. Therefore, a bioeconomic insight would allow researchers to gauge cultivation bottlenecks and optimize processes as well as assess the transfer viability to the private sector. This study analyzes the economic feasibility of recirculating aquaculture systems (RAS) in Peruvian grunt farming using field data from previous technological developments. The sensitivity analysis shows that the economic outcome of this grunt aquaculture using photovoltaic solar panels and a 15-month production cycle results in a profitable investment for a farm size of about 400 K/yr. Likewise, a similar profitable exploitation can be achieved by shortening the production cycle to 12 months. These achievements would enable the know-how transference to entrepreneurial initiatives in the semi-desert region of southern Peru and northern Chile.

Abstract

The Peruvian grunt Anisotremus scapularis is one of the most appreciated fish in Peruvian national markets. However, its reduced and irregular fishery is a paradigm of illegal, unreported, and unregulated fishing (IUU) in the Peruvian–Chilean coastal region. An important technological advancement has been achieved in the last decade in capture, management, nutrition, and broodstock maintenance to boost pilot experiences on the aquaculture of this species. Therefore, it is pertinent to evaluate the economic viability of this candidate species to identify cultivation bottlenecks, optimize the process, and assess the transfer feasibility of the technical know-how to interest groups. In this study, we performed a sensitivity analysis to assess how market price and production size should make its commercialization profitable. We show that the use of photovoltaic solar panels and a raw production cycle of 15 months enables profitability at a ~400 k unit farm size at a commercial market price of 6.67 USD/kg, i.e., B/C = USD 1.14. Both, time to market and market price exerted the highest influence on the value of grunt farms; whereas, a reduction of the production cycle to 12 months by seed selection, optimized rearing conditions, and nutritional diets also provides a profitable investment, i.e., NPV = USD 287,054 with an IRR = 23.71% at a discount rate of 10% and B/C = USD 1.15. These scenarios pave the way for the transfer of technological know-how to entrepreneurial initiatives in the economically depressed coastal region of the Atacama Desert.

1. Introduction

The fishery sector has had a significant 1.3% contribution to the Peruvian GDP (gross domestic product) in the last decade [https://snp.org.pe/la-pesca-en-cifras/ (accessed on 14 July 2024)]. However, extractive fisheries exhibited a downward trend over the past decades mainly due to overfishing, pollution, and climate change [1]. Such stagnation of wild fisheries is fueling the development of aquaculture (growing systems and candidate species) [2], which has become the world’s fastest growing food production sector [3]. Nevertheless, pending environmental issues such as sustainable production practices and certification systems are still far from complete [4].

Growing interest exists in aquaculture in the semi-desert coastal region of southern Peru and northern Chile because of its economic and nutritional potential. The Peruvian Department of Tacna is located at the head of the Atacama Desert on the Pacific coast of South America. Its coastline extends from the “Concordia” line between Peru and Chile (18°21′08″ S, 70°22′39″ O) to the beaches of Punta Huaca Luna on its northern border with the Moquegua Department (17°11′33.8496″ S, 70°55′58.1304″ W). The Tacna coastal area is characterized by sandy shores and shallow waters [5] and, also, by more oxygenated and protective shores where a large variety of rocky fishes dwell [6,7]. While the highest landings for human consumption in Peru correspond to jack mackerel (Trachurus murphyi), tuna (Sarda chiliensis chiliensis), and “perico” (Coryphaena hippurus), some other species are in high demand in southern Peru, i.e., “cabrilla” (Hemanthias peruanus), the Peruvian croaker (Cilus gilberti), the Peruvian grunt (Anisotremus scapularis), the conger (Genypterus maculatus), and the swordfish (Xiphias gladius) [8].

The predominant economic activity on the coasts of Tacna is artisanal fishing with around 1040 fishermen (2.4% of the total national) with 34% share fishing on croaker (Cilus gilberti), lorna (Sciaena deliciosa), grunt (A. scapularis), mollusks (e.g., Dosidicus gigas, Octopus mimus, Argopecten purpuratus), crustaceans (Cryphiops caementarius), and echinoderms (Patallus mollis), for first sale in local markets and direct human consumption [5]. The processing and transformation sector of hydrobiological resources mainly exploit sea urchin eggs (Loxechinus albus), flying fish eggs (Cypselurus heterurus), and anchovy (Engraulis ringens) [8]. The annual consumption of hydrobiological products in the Tacna Region in 2021 (fresh, frozen, canned fish and shellfish) was 14.3 kg/capita [9], a ratio well below the national average of 17.3 kg/capita.

The Peruvian grunt Anisotremus scapularis is one of the most appreciated species in national markets and is locally known as “chita”, “sargo”, snorer “roncador”, or “corcovado” (Figure 1).

Figure 1.

Adult specimen (60 cm in length) of the Peruvian grunt Anisotremus scapularis.

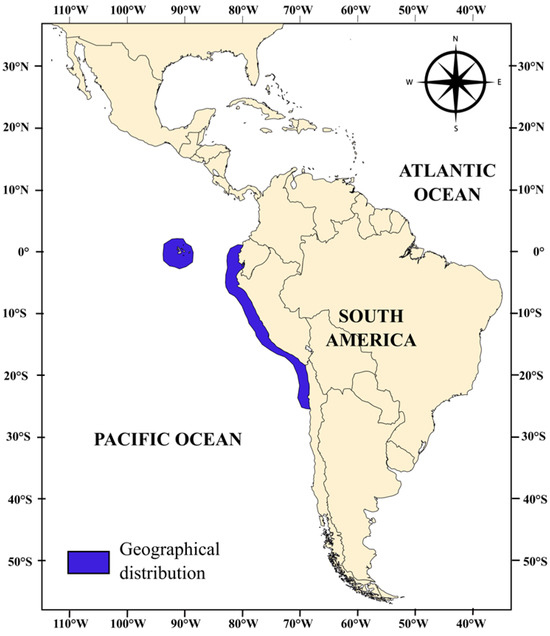

This grunt is one of the six species of the genus Anisotremus (Actinopterygii, Perciformes, Haemulidae) so far reported in Peruvian waters [10]. It is distributed along the coasts of Ecuador, Peru, and Chile, from Manta (Ecuador) to Antofagasta and Cocos Island (Chile) (Figure 2) in rocky areas down to 25 m in depth [11,12].

Figure 2.

Distribution of Anisotremus scapularis [Tschudi, 1846, https://www.marinespecies.org/aphia.php?p=taxdetails&id=279622 (accessed on 5 August 2024)] in the Pacific south.

The adult grunt has a robust body, a convex head, and a small, low, and terminal mouth and reaches 80 cm in length and 7.5 kg in weight (Figure 1). Grunt juveniles are omnivorous, feeding on macroalgae and minor invertebrates, especially copepods, and aggregate in large schools in marine rocky shores and intertidal pools. Bentho-pelagic adults are lonelier and dwell on sandy bottoms; they euryphage on green and red algae as well as invertebrates such as amphipods, caprellids, ophiuroids, echiurids, polyplacophorous mollusks (e.g., Chiton cumingsi), and bivalves (e.g., Semimytilus algosus) [13].

The fishery of Peruvian grunt employs artisanal gears such as string, seine, curtain, and spinel. Landings of this grunt showed a high inter-annual variability, ranging 119–144 GMT (gross metric tons) in the period of 2017–2021. Those figures indicate that the Peruvian grunt fishery is one of the smallest and most irregular among Peruvian artisanal fisheries (Table 1). This shortage has affected the most vulnerable economic stratum made up of artisanal fishermen from small ports and coves in southern Peru. This subsector englobes seasonal coastal professionals and occasional low-expertise fishermen from the highlands with a very precarious economy [14]. The shortage of grunt due to overexploitation (not fully evaluated yet) has not only impacted the species’ abundance but also the consumer habits and the economic wealth of the tertiary sector [https://saludconlupa.com/medio-ambiente/pescadores-en-peru-enfrentan-a-los-ilegales-nos-hemos-organizado-para-trabajar-la-chita-pese-a-los-peligros/ (accessed on 7 August 2024)]. Altogether, the local scarcity of this species and its irregular commercialization in national markets make it a paradigm of illegal, unreported, and unregulated fishing (IUU) [15].

Table 1.

Landings of main rocky coast fishes from Peru in the period of 2017–2021 (in gross metric tons).

The grunt market value and its organoleptic excellence, together with the decline of its fishery, prompted a research project in October 2014 in southern Peru to develop the technological know-how for grunt aquaculture [16]. Eventually, the successful outcome of that initiative would boost the grunt local production as well as alleviate the harvesting pressure on its wild Pacific population. Thereafter, technologies for capture, management, nutrition, and broodstock maintenance were developed in the last decade [16,17,18,19,20].

In parallel to that zootechnical advancement, it is crucial to evaluate the economic viability of this grunt as an aquaculture candidate. Bioeconomic models are key tools for assessing the economic viability of aquaculture systems. These models allow for integrating biological factors such as growth and mortality rates with financial costs and market prices. In particular, horizontally integrated systems, which combine fish, mollusks, and macroalgae, have proven to be economically viable under certain scenarios and can help optimize productivity and reduce environmental impacts [21,22]. Most studies highlight the importance of operational costs and bioeconomic approaches, with differences between species requiring tailored approaches.

Therefore, the aim of this work is to perform a sensitivity analysis to assess the economic viability of Peruvian grunt farming in Vila—Vila, Tacna (Peru). Our null hypothesis considers that if simulated sea bream aquaculture is economically viable, then it is feasible to start a process of transferring the accumulated knowledge of its cultivation to potential entrepreneurs. In other words, this sensitivity analysis would allow us to gauge cultivation bottlenecks and optimizable processes to determine the economic potential of the incipient grunt aquaculture and its transfer viability to the private sector using escalated cultivation systems (e.g., sea cages) [23]. Notably, this area shares a common environmental setup with the rest of the desert coastal region of southern Peru and northern Chile where grunt aquaculture would find its natural niche.

2. Materials and Methods

Once the background knowledge on the cultivation of this species is achieved, the sensitivity analysis performed herein aims to portray the economic outcome of mass culturing the Peruvian grunt in a RAS system under different energy sources, farm sizes, and growth cycle spans. This research was carried out in 2022 at Escuela de Ingeniería Pesquera of University Jorge Basadre Grohmann (UNJBG, Tacna, Peru) using experimental data collected on this species since 2014 at the Morro Sama Aquaculture Center (CAMOSA) of the National Fisheries Development Fund (FONDEPES, Peru) (17°59′39.7″ S, 70°52′59.1″ W). All animal procedures and handling, as described in previous studies, e.g., [16], were carried out according to the Peruvian law#30407 «Law on Animal Protection and Welfare» governed by the Ministry of Agriculture and Irrigation (MINAGRI, Peru) [https://www.leyes.congreso.gob.pe/Documentos/Leyes/30407.pdf (accessed on 7 July 2024)].

2.1. Environmental Setup

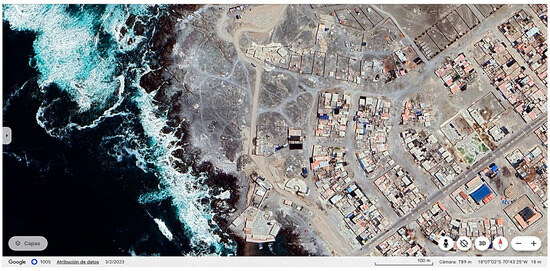

The fishing village of Vila—Vila where the Coastal Marine Laboratory of UNJBG is located (Sama, Tacna, Peru) is the environmental setting with the hatchery facility employed to assess the economic viability of the incipient Peruvian grunt aquaculture (Figure 3). Given that the real area allocated for aquaculture exploitation is owned by farmers or by academia, its cost is not included in this economic assessment. Source data to calculate the initial investment, operation costs, and maintenance costs were funded by the UNJBG—CANON research contract “Investigación y desarrollo de las tecnologías de cultivo de peces marinos de importancia económica: corvina (Cilus gilberti) y sargo (Anisotremus scapularis) en la región Tacna” (Rectoral Resolution No. 3780-2014-UNJBG) and its scientific publications [16,17,18,19,20,24].

Figure 3.

The environmental setup and location of the Coastal Marine Laboratory of Vila—Vila (Tacna, Peru) (Source: Coastal Marine Laboratory Satellite View [https://www.google.com/maps/place/Vila+Vila+Beach/@-18.1144445,-70.7278606,810m/data=!3m1!1e3!4m5!3m4!1s0x91453fd7f507c05b:0x6bf8ebfcbdca8f6c!8m2!3d-18.1172591!4d-70.7264604?hl=es-ES (accessed on 7 July 2024)].

2.2. Structure of the Culture

The experimental facilities evaluated consisted of 3–20 fiberglass circular tanks implemented to maintain all life phases of the Peruvian grunt under controlled conditions. Those facilities include a RAS system with 100% water recirculation per hour and equipped with water quality controls for an optimal adaptation of the grunt broodstock, i.e., 18–19 °C temperature and 6.55 mg/L of dissolved oxygen [16]. Seawater inflow through pipelines had a multi-filtering system to guarantee water quality supply to culture tanks. The indoor facility evaluated was protected from direct sunlight in order to minimize evaporation and to maintain a cooler temperature than outside.

2.3. Biological Material

Peruvian grunt larvae as well as feedstuff were supplied by the Coastal Marine Laboratory of UNJBG according to the feeding protocols developed for the whole life cycle management of this species [19]. The feed conversion ratio (FCR) used in this simulation was 1.8; an FCR of 1.8 is a promising figure for a candidate species optimally fed since 2016. The initial culture of grunt larvae was enforced at an average density of 30 larvae/L. Grunt fry used in current calculations averaged 3.80 ± 0.31 cm in fork length and 0.53 ± 0.22 g in live weight and were cultured in seven tanks of 47 m3 of volume (Table S1). Grunt juveniles 1+ in those tanks ranged 5–10 cm in fork length and averaged 20.00 ± 0.09 g in live weight; their culture averaged 10 kg/m3 (470 kg/tank) with density ranging from 0.6 kg/m3 (282 kg/tank) at day 1 of cultivation to 15 kg/m3 (705 kg/tank) at day 75 of cultivation (Table S1). Grunt juveniles 2+ averaged 15.46 ± 1.01 cm in fork length (range 12–16 cm) and 160.00 ± 35.01 g in live weight; their culture was enforced at an average density of 20 kg/m3 in fifteen tanks of 81 m3 of volume (Table S2). The commercial size of post-fattening adult grunts was >20 cm in fork length with an average live weight of 300.00 ± 65.62 g; their culture density was enforced at 26 kg/m3 in twenty circular tanks of 84 m3 of volume (Table S3).

2.4. Sensitivity Analysis

The production output of aquacultured organisms is constrained by costs incurred from the initial investment, the management practices, and the production process [2]. Capital budgeting is an appropriate approach for assessing the economic feasibility of the current Peruvian grunt farming system. For this species, a sensitivity analysis was developed herein to assess the weight of variable inputs on the final benefit-to-cost ratio (B/C). The initial investment costs included civil work facilities, administrative equipment, cultivation equipment, and machinery (Table S4). Variable costs comprised tank preparation before stocking (salt, fungicide, etc.), fingerling, feed, energy, repair and maintenance, sludge discharge, veterinary services, and labor (Table S5). The working capital was calculated on a 15-month production cycle (Table S6) following the official labor costs of the country. Fixed costs consisted of depreciation of equipment and replacement costs whenever the useful life of the equipment was shorter than the evaluation horizon (Table S7). Total production costs and revenues were expressed in USD (applied exchange rate: USD 1.00 equaled PEN 3.75 as of 1 December 2024) (Table S8). The final product was a Peruvian grunt of ~300 g of live weight (according to customers’ preferred serving size) after a 15-month production cycle and the commercial scenario comprised local fish markets of the Tacna Department (Table S9).

The indicators applied to the economic evaluation were the net present value (NPV), i.e., the difference between the present value of cash inflows and the present value of cash outflows over 10 years; the internal rate of return (IRR), i.e., the return estimated from the investment; and the benefit–cost ratio (B/C), i.e., a profitability index that measures the projected capital inflow (benefits) on the investment (costs). The NPV was determined as the sum of funds flow as updated at a previously calculated discount rate, using the mathematical formula

where I0 is the initial investment; Fn is the net flow in period t; t, is the project horizon (in yr); i, is the discount rate applied [25].

Profitability ratios are financial calculations to assess profitability upon costs and earnings for a specific time period [26]. The profitability ratios employed herein were the internal rate of return (IRR) and the benefit–cost ratio (B/C). The internal rate of return (IRR) is the annual rate of growth at which the updated value of the net funds flow (NPV) equals zero, and it was calculated as

The benefit–cost ratio (B/C) as a profitability indicator that summarizes the overall value for money of this project was calculated as the result of dividing the updated value of the benefit stream by the updated value of the cost stream at a previously determined update rate. B/C < 1 indicates loss, a B/C = 1 indicates break-even, and a B/C > 1 indicates profit [27]. Herein, B/C was calculated as

where Bn is the net profit in period t, and Cn is the net cost in period t.

3. Results and Discussion

Diversification in aquaculture is relevant for coastal communities experiencing the backlash of declining wild fisheries [https://ec.europa.eu/archives/commission_2010-2014/damanaki/headlines/press-releases/2012/09/20120913_en.htm (accessed on 17 May 2024)]. Most studies in this field agree that the profitability of aquaculture candidates depends significantly on local factors, such as labor costs, environmental regulations, access to markets, and a commercial value of the resource [28,29]. The Peruvian grunt (Anisotremus scapularis) is a species of growing interest in marine aquaculture due to a high demand for it in local markets and its ability to adapt to farming conditions. However, the economic evaluation of its farming still faces challenges related to production costs, integration into sustainable systems, and access to competitive markets.

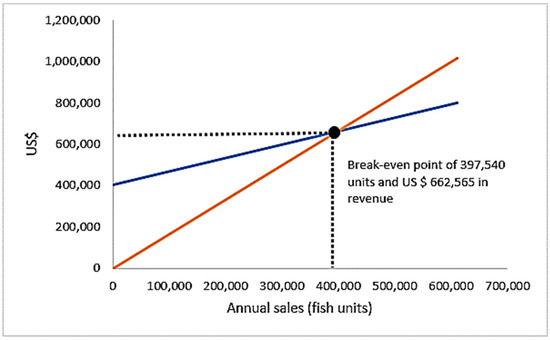

The sensitivity analysis performed herein on the potentiality of Peruvian grunt aquaculture indicates the break-even point of grunt production (B/C = 1) at 397,540 grunt units. In terms of production, this implies that a ~400 k unit farm size at a commercial market price of 6.67 USD/kg provides profitable exploitation (B/C = USD 1.14). Nevertheless, a similar outcome can be achieved by shortening the productive life cycle to 12 months, i.e., NPV = USD 287,054 with an IRR = 23.71% at a discount rate of 10% and B/C = USD 1.15.

3.1. Initial Investment

The initial investment included the acquisition of tangible or intangible assets as necessary to initiate the cultivation system. In the calculation with photovoltaic solar panels, the fixed investment amounted to USD 234,376 (Table S4). The working capital amounted to USD 162,765 (Table S6) as calculated for 15 months until the grunt production was commercialized and is now linked to the estimated production of the grunt. This capital allowed for daily operations and current expenses to be covered without cash flow shortage in the short term, thereby guaranteeing food purchase and operating expenses in the face of unexpected situations.

3.2. Costs

In order to evaluate the economic profitability, the evaluation horizon comprised a life period of 10 years for the main assets. These costs amounted to USD 54,896 (Table 2).

Table 2.

Fixed costs upon average Peruvian labor costs, which are invariant with production and were afforded irrespective of the volume of products, services, or the income generation.

The variable costs were mainly caused by the purchase of larvae, the feeding costs, and the occasional electrical supply to complement the photovoltaic energy. Therefore, these costs depend on production, i.e., on the grunt culture escalation (Table S5). Similar findings have been reported from tilapia production in Lake Victoria [30] as well as in a study of cost drivers in US aquaculture where the cost of feed and fish seed were among the highest in all aquaculture production systems [31]. Also, horizontally integrated systems have been evaluated in temperate and warm waters, highlighting that efficient nutrient and resource management is essential to increasing economic returns [28]. This pattern is repeated in intensive and semi-intensive aquaculture systems, regardless of the geographic region. Notably, feed and energy costs stand out as the main factors affecting profitability in marine aquaculture systems. These costs represent up to 60% of total operating expenses in integrated systems [28], which could also apply to Peruvian grunt farming given that its diet requires high-quality feed to ensure optimal growth and quality of the final product.

The production costs encompass all the resources and activities required during the production process and refer to the set of expenses and disbursements necessary to produce this grunt or to provide services. They include the fixed costs and the variable costs, which altogether amounted to USD 111,754 in year 1 and SD 98,966 in year 10 (Table S8). The depreciation of fixed assets is defined as the loss of their value over their useful lifespan. Those assets depreciating before the ten-year horizon were replaced one year after the loss of their useful life (Table S7).

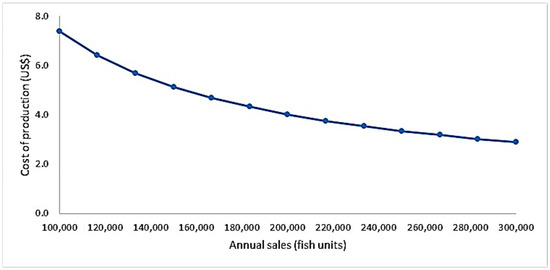

A progressive reduction in production costs was observed with the increase in the production scale, i.e., current simulations indicate that annual sales >300,000 grunt units reduced production costs below 3 USD/unit (Figure 4).

Figure 4.

Aggregated cost of production per grunt unit as a function of farm size (annual sales).

3.3. Economic Indicators

In order to establish the cash flow in the evaluation horizon, we first present the detail of the income flow from the sale of the grunt with a commercial weight of 300 g/specimen and a 10% natural mortality (Table S9). Thereafter, we show the cash flow employed to estimate the NPV (Table S10). A negative net present value (NPV) in USD was obtained upon the cash flow expected to be generated during the useful life of the project in both situations, i.e., without photovoltaic solar panels (NPV = −USD 258,716) and with them (NPV = −USD 86,758) (Table 3). Likewise, the internal rate of return (IRR) of −3% was obtained without photovoltaic solar panels, which suggests that grunt production with electrical supply would not generate enough income to achieve an acceptable profit at the discount rate applied. The use of photovoltaic solar panels improved the situation significantly with the IRR becoming positive (7%) despite the NPV still being negative.

Table 3.

Internal rate of return with or without photovoltaic solar panels.

The benefit–cost ratio (B/C) as a measure that allows for comparing the benefit expected with the costs incurred, indicates the absence of profit under both situations, i.e., either without solar panels (USD 0.25) or with them (USD 0.95), with neither of them reaching the expected profitability in relation to the opportunity cost (Table 3).

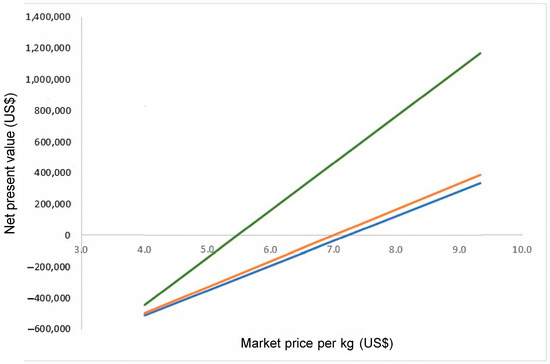

The sensitivity analysis indicates the break-even point of grunt production (B/C = 1) at 397,540 grunt units (Figure 5). In terms of production, this implies that a ~400 k unit farm size at a commercial market price of 6.67 USD/kg provides a clearly profitable exploitation (B/C = USD 1.14) (Figure 6).

Figure 5.

Sensitivity analysis indicating the break-even point of grunt production (B/C = 1) at 397,540 grunt units.

Figure 6.

Net present value (USD; 10-year horizon) per market price (USD/kg) for a farm size of 160 K (blue), 200 K (orange), and 400 K (green) grunt units.

The initial proposal to cultivate the Peruvian grunt without photovoltaic solar panels assumed a production cycle of 15 months after the cultivation protocol was designed for the Peruvian croaker Cilus gilberti [32]. However, as indicated above, the economic indicators of profitability were all negative, even with the implementation of photovoltaic solar panels. Under the latter, a minimum farm size threshold of ~400 k units provides clear profitability which can also be achieved by shortening the production cycle. This can be achieved by selecting high-growth rate seeds, e.g., as shown in mussels [33], environmental optimization, and balanced nutritional diets for all life stages. For instance, the reduction of the production cycle to 12 months would result in a profitable investment, i.e., NPV = USD 287,054 with an IRR = 23.71% at a discount rate of 10% and B/C = USD 1.15.

Some previous sensitivity studies prioritize long-term environmental sustainability by incorporating social and environmental variables, while others focus on maximizing immediate financial returns [29,34]. For instance, the systems evaluated in Israel and France [28] showed significant differences in initial investment and expected returns depending on the emphasis on sustainability or short-term performance. Strategies range from reducing initial costs through vertical integration to diversifying into premium products, such as organic foods. In the case of sea bream, these strategies need to be combined to address both market challenges and production costs.

4. Conclusions

The effective transition from overharvested wild fisheries to aquaculture requires explicit benefits to local communities and limited disruption of existing social patterns [35]. The current pioneering assessment of the economic profitability of the cultivation of the Peruvian grunt has been carried out on real data from an open circulation culture system, employing larvae supply from an experimental pilot laboratory as well as live and concentrated food supply. There are opportunities to reduce production costs, such as using alternate offshore wind energy coupled with marine cage aquaculture. The sensitivity analysis aimed to analyze how much the farm size should be increased to make grunt production profitable. Based on current information on costs and benefits, inshore open system production of Peruvian grunt using solar panels and a 15-month production cycle is profitable above a critical farm size of 400 K/yr. Time to market and market price also had a great influence on the value of grunt farms. Therefore, focusing efforts on optimizing grunt growth rates and developing markets for the added value of farmed grunt products could substantially increase farm values. This scenario paves the way for the transfer of technological know-how to new entrepreneurs in the economically depressed coastal region of the Atacama Desert.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/ani15010048/s1, Table S1: Characteristics of cultivation tanks for Peruvian grunt fry and juveniles 1+; Table S2: Characteristics of cultivation tanks for Peruvian grunt juveniles 2+; Table S3: Characteristics of cultivation tanks for Peruvian grunt adults (fattening period); Table S4: Broken-down initial investment (USD) on Peruvian grunt production as computed on photovoltaic solar panels; Table S5: Variable costs (USD) for the Peruvian grunt calculated on a 10-year horizon; Table S6: Working capital (USD) for a 15-month production cycle of Peruvian grunt in a RAS system; Table S7: Depreciation of fixed assets (USD) with replacement one year after the loss of their useful life; Table S8: Total production costs (USD) comprising fixed costs and variable costs as calculated on a 10-year horizon; Table S9: Grunt sales and income flow (USD) for a specimen weight of 300 g/unit at 15 months and 10% mortality, of a commercial production of 43 K for local fish markets; Table S10: Net cash flow (USD) on a 10-year evaluation horizon implementing photovoltaic solar panels as power supply.

Author Contributions

Conceptualization, experimental design and culture management, L.A.E.-R., J.I.H. and R.P.-V.; data analyses Y.L.P.C.; data curation, interpretation of results, and first draft P.P. and Y.L.P.C.; manuscript review and editing, P.P.; funding acquisition and projects administration, L.A.E.-R. and P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Universidad Nacional Jorge Basadre Grohmann through the CANON contract “Investigación y desarrollo de las tecnologías de cultivo de peces marinos de importancia económica: corvina (Cilus gilberti) y sargo (Anisotremus scapularis) en la región Tacna” (Resolución Rectoral N° 3780-2014-UN/JBG)”. This article was carried out in the framework of the International Cooperation Network SEASOS (Euro-Latin Symbiosis for Sustainable Aquaculture) funded by program FORCYT (OEI-UE 2021-2023) and the Latin American Agro-Aquaculture Network (SIBIOLAT). The APC was funded by SEASOS.

Institutional Review Board Statement

The cultivation trials that gave rise to the biological and economic data used in this study were carried out between October 2014 and May 2019, well before the establishment of the UNJBG Ethics Committee on 11 February 2021, following the approval of the Regulations of the Institutional Ethics Committee (CEI-UNJBG), in accordance with the Resolution from University Council No. #17140-2021-UNJBG Jorge Basadre Grohmann.

Informed Consent Statement

All animal procedures and handling, as described in the experimental studies mentioned in this study, were carried out according to Peruvian law#30407 «Law on Animal Protection and Welfare» governing by The Ministry of Agriculture and Irrigation (MINAGRI) [https://www.leyes.congreso.gob.pe/Documentos/Leyes/30407.pdf (accessed on 7 July 2024)].

Data Availability Statement

Data are provided either within the article or in Supplementary Materials. Further technical data can be accessed upon request made to the corresponding author.

Acknowledgments

The authors express their gratitude to Fondo Nacional de Desarrollo Pesquero (FONDEPES, Peru) for the rearing facilities provided in the Centro de Acuicultura de Morro Sama (CAMOSA, Sama, Tacna, Peru), to the OPI Staff (Oficina de Proxectos Internacionais) from Universidade de Vigo (Vigo, Spain) to the OEI Staff (Organización de Estados Iberoamericanos, Educación Superior y Ciencia), as well as to the Technical Staff from UNJBG and FONDEPES for their invaluable technical help during the experimentation.

Conflicts of Interest

Jordan I. Huanacuni is an employee of the company Finfish Aquaculture—Sociedad Anónima Cerrada, CP. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Lester, S.E.; Gentry, R.R.; Kappel, C.V.; White, C.; Gaines, S.D. Opinion: Offshore aquaculture in the United States: Untapped potential in need of smart policy. Proc. Natl. Acad. Sci. USA 2018, 115, 7162–7165. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Naylor, R.L.; Hardy, R.W.; Buschmann, A.H.; Bush, S.R.; Cao, L.; Klinger, D.H.; Little, D.C.; Lubchenco, J.; Shumway, S.E.; Troell, M. A 20-year retrospective review of global aquaculture. Nature 2021, 591, 551–563. [Google Scholar] [CrossRef]

- FAO. The State of World Fisheries and Aquaculture: Sustainability in Action; FAO Book Series: Rome, Italy, 2020; 244p. [Google Scholar] [CrossRef]

- Bush, S.; Belton, B.; Hall, D.; Vandergeest, P.; Murray, F.J.; Ponte, S.; Oosterveer, P.; Islam, M.S.; Mol, A.P.; Hatanaka, M. Certify sustainable aquaculture? Science 2013, 341, 1067–1068. [Google Scholar] [CrossRef] [PubMed]

- Coronel Flores, N. Diagnóstico de las actividades pesqueras en la región Tacna, periodo 1998–2007. Cienc. Desarro. 2019, 12, 63–66. [Google Scholar] [CrossRef]

- Romero Camarena, M. Lista Actualizada de los Peces Marinos (Chondrichthyes y Osteichthyes) Registrados en Perú (Océano Pacífico Suroriental); Ministerio del Ambiente de Perú–MINAM: Lima, Peru, 2017. [CrossRef]

- Lavallée, D.; Julien, M.; Béarez, P.; Bolaños, A.; Carré, M.; Chevalier, A.; Delabarde, T.; Fontugne, M.; Rodríguez-Loredo, C.; Klaric, L.; et al. Quebrada de los burros: Los primeros pescadores del litoral pacífico en el extremo sur peruano. Chungará 2011, 43, 333–351. [Google Scholar] [CrossRef]

- Ministerio de la Producción del Perú. Anuario Estadístico Pesquero y Acuícola; PRODUCE: Lima, Peru, 2022; Available online: https://m.inei.gob.pe/estadisticas/indice-tematico/economia/ (accessed on 2 May 2024).

- Diario Correo. Tacna: Personas Consumen Solo 14.3 Kilos de Pescado al Año; Diario Correo: Tacna, Peru, 2021; Available online: https://diariocorreo.pe/edicion/tacna/tacna-personas-consumen-solo-143-kilos-de-pescado-al-ano-noticia/ (accessed on 15 February 2024).

- IMARPE. Protocol for larval culture of Peruvian grunt Anisotremus scapularis under laboratory conditions. Inf. Inst. Mar Perú 2021, 48, 20–24. Available online: https://hdl.handle.net/20.500.12958/3534 (accessed on 14 October 2024).

- Chirichigno, N.; Cornejo, R. Catálogo Comentado de los Peces Marinos del Perú; IMARPE: Callao, Peru, 2001; 314p, Available online: https://es.scribd.com/document/495245489/Chirichigno-Cornejo-2001 (accessed on 13 March 2024).

- Méndez-Abarca, F.; Pepe-Victoriano, R. Peces Marinos del Norte de Chile: Guía para la Identificación y Mantención en Cautiverio; Fundación Reino Animal & ONG por la Conservación de la Vida Salvaje: Arica, Chile, 2020; 79p. [Google Scholar]

- Medina, M.; Araya, M.; Vega, C. Alimentación y relaciones tróficas de peces costeros de la zona norte de Chile. Investig. Mar. 2004, 32, 33–47. [Google Scholar] [CrossRef]

- Soto, D.; Quiñones, R. Cambio Climático, Pesca y Acuicultura en América Latina: Potenciales Impactos y Desafíos Para la Adaptación; Taller FAO/Centro de Investigación Oceanográfica en el Pacífico Sur Oriental (COPAS), Universidad de Concepción, Concepción, Chile; FAO Actas de Pesca y Acuicultura 29; Departamento de Pesca y Acuicultura, FAO: Roma, Italy, 2013; 335p, Available online: https://www.fao.org/4/i3356s/i3356s00.htm (accessed on 7 January 2024).

- Petrossian, G.A. Preventing illegal, unreported and unregulated (IUU) fishing: A situational approach. Biol. Conserv. 2015, 189, 39–48. [Google Scholar] [CrossRef]

- Espinoza-Ramos, L.A.; Chilli-Layme, V.F.; Pepe-Victoriano, R.G.; Pino-Choqueapaza, J.; Contreras-Mamani, Z. Captura, acondicionamiento y primer desove de sargo Anisotremus scapularis en la Región Tacna. Cienc. Desarro. 2019, 25, 68–74. [Google Scholar] [CrossRef]

- Espinoza-Ramos, L. Efecto de la Densidad y el Tiempo de Transporte en la Sobrevivencia de Juveniles de Sargo (Anisotremus scapularis). Ph.D. Thesis, Universidad Nacional Jorge Basadre Grohmann, Tacna, Peru, 2019. Available online: https://alicia.concytec.gob.pe/vufind/Record/UNJB_4c4811b8cfad026c9604665d656cdc85 (accessed on 13 October 2023).

- Espinoza-Ramos, L.A.; Pepe-Victoriano, R.; Huanacuni, J.I.; Nande, M. Effect of transportation time and stocking density on seawater quality and survival of Anisotremus scapularis (Perciformes: Haemulidae). J. World Aquacult. Soc. 2022, 53, 1042–1050. [Google Scholar] [CrossRef]

- Espinoza-Ramos, L.A.; Quispe-Mayta, J.M.; Chili-Layme, V.; Nande, M. Effect of stocking density on growth, feed efficiency, and survival in Peruvian Grunt Anisotremus scapularis (Tschudi, 1846): From fingerlings to juveniles. Aquac. J. 2022, 2, 13–22. [Google Scholar] [CrossRef]

- Huanacuni, J.I.; Espinoza-Ramos, L.A. Producción de alimento vivo para la investigación en acuicultura de peces marinos en la UNJBG, Tacna. Cienc. Desarro. 2019, 17, 82–86. [Google Scholar] [CrossRef]

- Bunting, S.W.; Little, D.C. Urban Aquaculture. In Annotated Bibliography on Urban Agriculture; Bruinsma, W., Hertog, W., Eds.; ETC-RUAF Foundation: Leusden, The Netherlands, 2003; pp. 446–467. Available online: https://ruaf.org/document/annotated-bibliography-on-urban-agriculture/ (accessed on 2 September 2024).

- Whitmarsh, D.; Cook, E.J.; Black, K.D. Searching for sustainability in aquaculture: Economic prospects for integrated systems. Mar. Policy 2006, 30, 293–298. [Google Scholar] [CrossRef]

- Burg, S.W.K.V.D.; Duijn, A.P.V.; Bartelings, H.; Krimpen, M.M.V.; Poelman, M. The economic feasibility of seaweed production in the North Sea. Aquacult. Econ. Manag. 2016, 20, 235–252. [Google Scholar] [CrossRef]

- Gomes-dos-Santos, A.; Nande, M.; Espinoza-Ramos, L.A.; Pepe-Victoriano, R.G.; Contreras-Mamani, Z.; Huanacuni, J.I.; Quispe-Mayta, J.M.; Fernández-Cárdenas, C.P.; Froufe, E.; Castro, L.F.C. Constructing the mitochondrial genome of the Peruvian grunt Anisotremus scapularis Tschudi, 1846 (Lutjaniformes: Haemulidae) using RNA-seq data. Mitochondr. DNA Part B Resources 2020, 5, 1921–1923. [Google Scholar] [CrossRef]

- Kay, R.D.; Edwards, W.M.; Duffy, P.A. Farm Management, 9th ed.; McGraw-Hill: New York, NY, USA, 2020; 35p. [Google Scholar]

- Magni, C.A. Average internal rate of return and investment decisions: A new perspective. Eng. Econ. 2013, 1, 37–41. Available online: https://www.tandfonline.com/doi/abs/10.1080/00137911003791856 (accessed on 15 September 2024).

- Olaoye, O.J.; Ashley-Dejo, S.S.; Fakoya, E.O.; Ikeweinwe, N.B.; Alegbeleye, W.O.; Ashaolu, F.O.; Adelaja, O.A. Assessment of socio-economic analysis of fish farming in Oyo State, Nigeria. Glob. J. Sci. Front. Res. 2013, 13, 197–208. Available online: https://catalog.ihsn.org/citations/64159 (accessed on 14 October 2024).

- Bunting, S.W.; Shpigel, M. Evaluating the economic potential of horizontally integrated land-based marine aquaculture. Aquaculture 2009, 294, 43–51. [Google Scholar] [CrossRef]

- Schuhbauer, A.; Sumaila, U.R. Economic viability and small-scale fisheries: A review. Ecol. Econ. 2016, 124, 69–75. [Google Scholar] [CrossRef]

- Musa, S.; Aura, C.M.; Okechi, J.K. Economic analysis of tilapia cage culture in Lake Victoria using different cage volumes. J. Appli. Aquac. 2021, 34, 674–692. [Google Scholar] [CrossRef]

- Engle, C.R.; Kumar, G.; van Senten, J. Cost drivers and profitability of U.S. pond, raceway, and RAS aquaculture. J. World Aquac. Soc. 2020, 51, 847–873. [Google Scholar] [CrossRef]

- Ramírez, P. Cultivo de la Corvina Chilena Como Alternativa Productiva Para la Región del Biobio. Ph.D. Thesis, Facultad de Ingeniería–Universidad Católica de la Santísima Concepción, Concepción, Chile, 2017. Available online: https://tesis.ucsc.cl/handle/25022009/3467 (accessed on 25 March 2024).

- Díaz-Puente, B.; Miñambres, M.; Rosón, G.; Aghzar, A.; Presa, P. Genetic decoupling of spat origin from hatchery to harvest of Mytilus galloprovincialis cultured in suspension. Aquaculture 2016, 460, 124–135. [Google Scholar] [CrossRef]

- Bunting, S.W. Appropriation of environmental goods and services by aquaculture: A reassessment employing the ecological footprint methodology and implications for horizontal integration. Aquac. Res. 2001, 32, 605–609. [Google Scholar] [CrossRef]

- Rubino, M.C.; Stoffle, R.W. Who will control the blue revolution? Economic and social feasibility of Caribbean Crab Mariculture. Hum. Organ. 1990, 49, 386–394. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).