Expansion Improved the Physical and Chemical Properties and In Vitro Rumen Digestibility of Buckwheat Straw

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Buckwheat Straw Preparation

2.2. Different Degrees of Expansion Treatment

2.3. Chemical Composition

2.4. Structure

2.4.1. Fourier Transform Infrared Spectroscopy

2.4.2. X-ray Diffraction

2.4.3. Scanning Electron Microscopy

2.5. Mechanical Properties

2.5.1. Dynamic Compression Test on the Texture Properties

2.5.2. Static Compression Test on the Rheological Properties

2.6. In Vitro Rumen Digestibility

2.7. Statistical Analysis

3. Results

3.1. Changes in Chemical Components

3.2. Analysis in Structure

3.2.1. FTIR Spectra

3.2.2. Diffraction Pattern

3.3. Analysis of Mechanical Properties

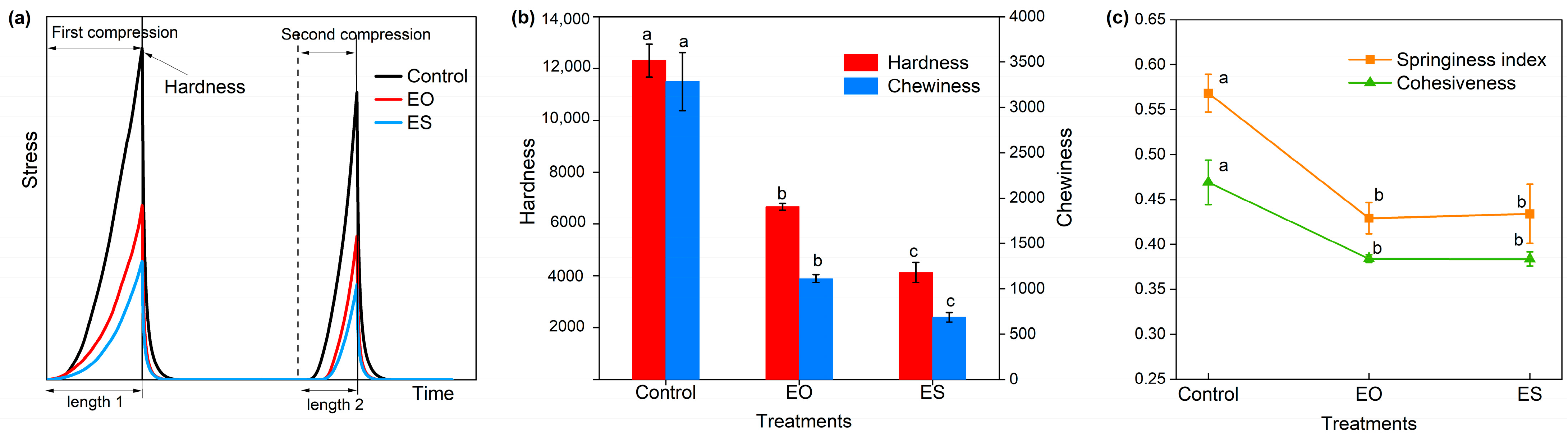

3.3.1. Texture Properties Based on Texture Profile Analysis

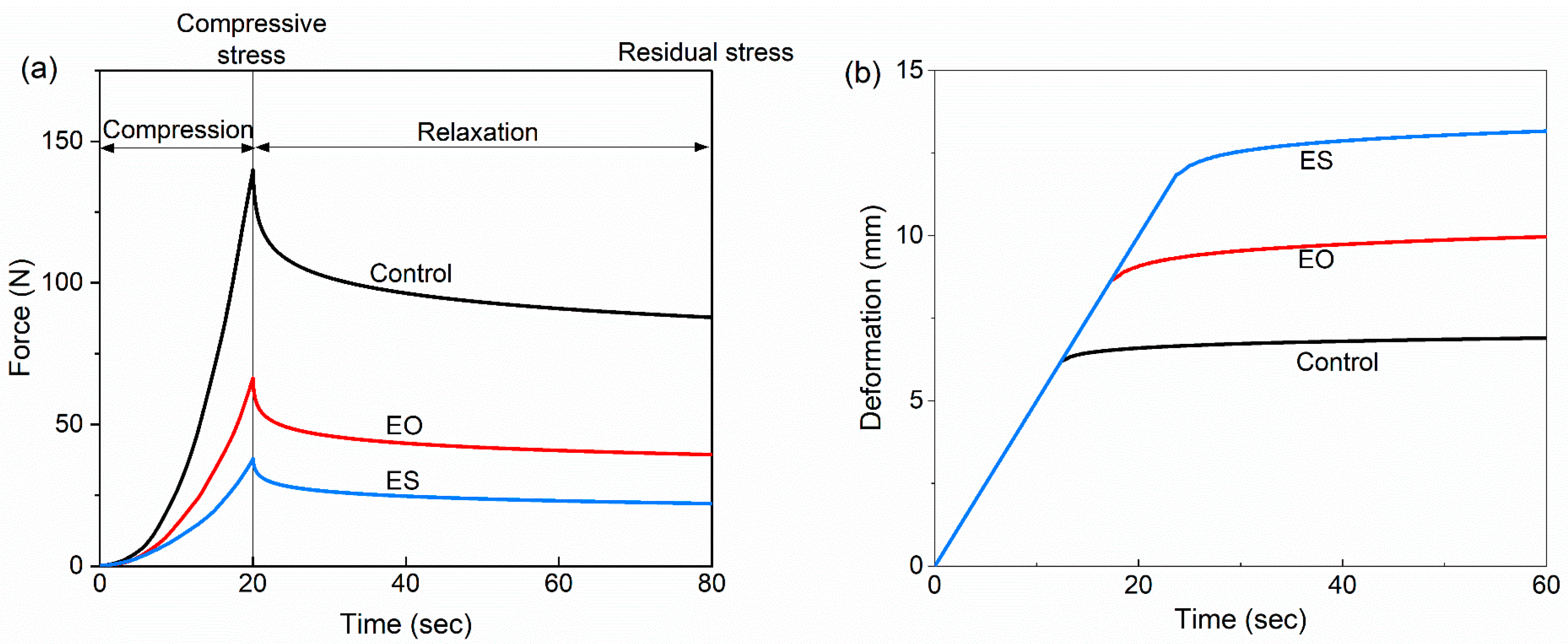

3.3.2. Rheological Properties Based on Stress Relaxation and Creep Tests

3.4. In Vitro Rumen Digestibility

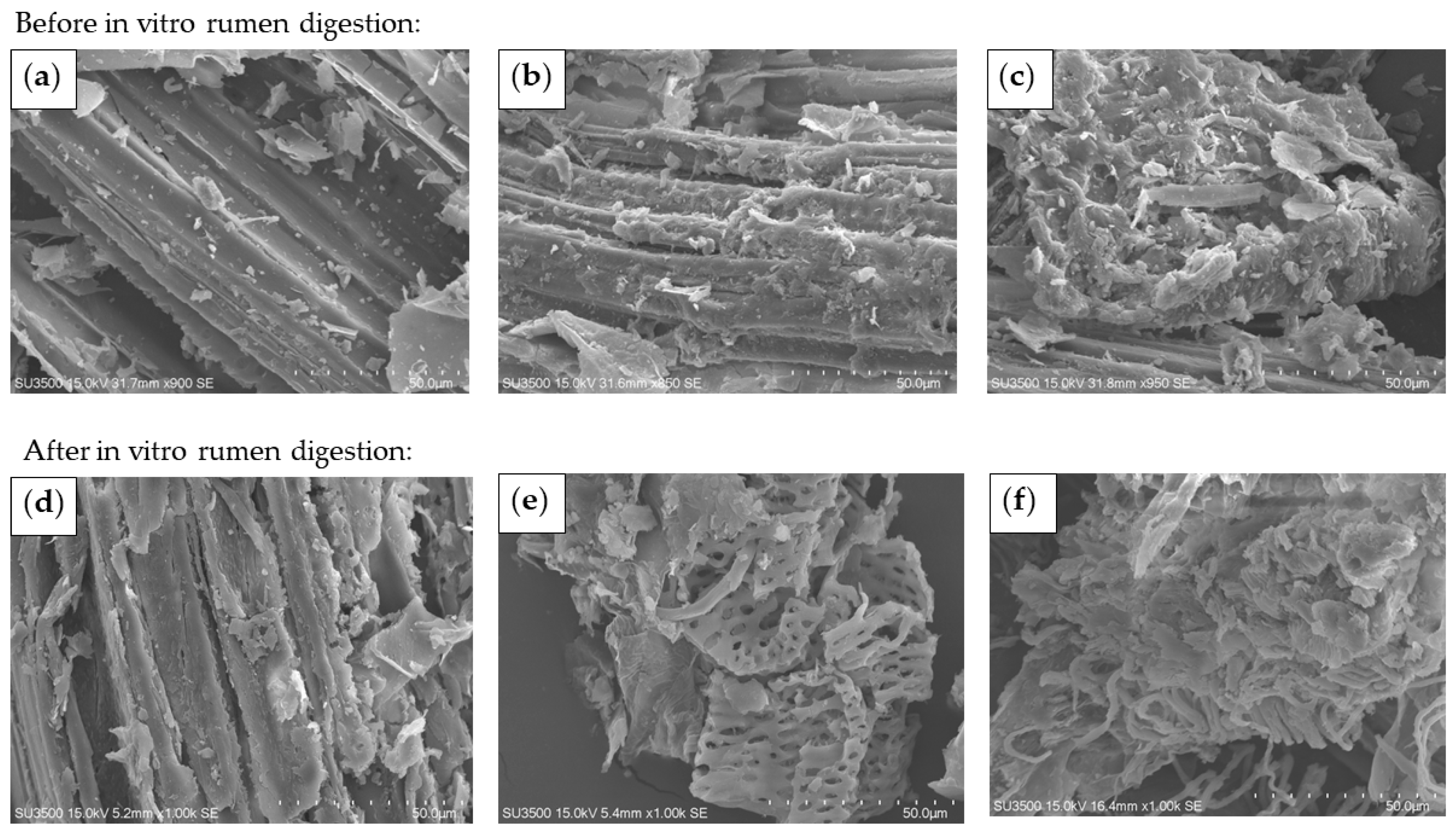

3.5. Changes in Morphological Composition

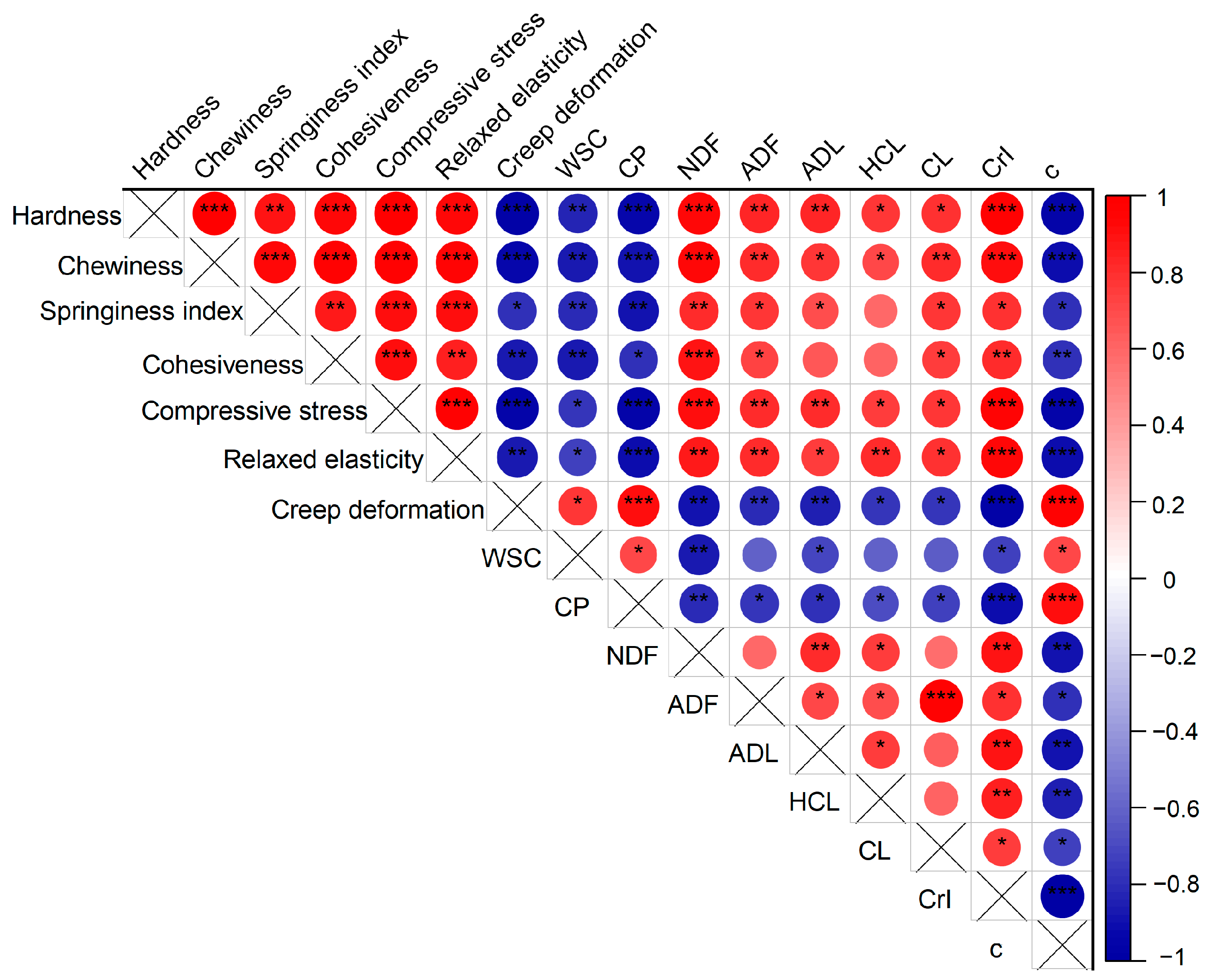

3.6. Correlation of Mechanical Properties, Chemical Characteristics, and Gas Production Rate

4. Discussion

4.1. Changes in Chemical Components

4.2. Analysis in the Chemical Structure

4.3. Analysis of Mechanical Properties

4.4. Analysis of In Vitro Rumen Digestibility

4.5. Correlation Analysis of Mechanical and Chemical Characteristics and Gas Production Efficiency

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nie, D.C.; Yao, L.Y.; Xu, X.K.; Zhang, Z.; Li, Y.L. Promoting corn stover degradation via sequential processing of steam explosion and cellulase/lactic acid bacteria-assisted ensilage. Bioresour. Technol. 2021, 337, 125392. [Google Scholar] [CrossRef]

- Wu, D.; Wei, Z.M.; Mohamed, T.A.; Zheng, G.R.; Qu, F.T.; Wang, F.; Zhao, Y.; Song, C.H. Lignocellulose biomass bioconversion during composting: Mechanism of action of lignocellulase, pretreatment methods and future perspectives. Chemosphere 2022, 286, 131635. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.L.; Chen, X.H.; Gu, Y.; Zhou, X.F. A physicochemical method for increasing methane production from rice straw: Extrusion combined with alkali pretreatment. Appl. Energy 2015, 160, 39–48. [Google Scholar] [CrossRef]

- Souza, M.F.; Devriendt, N.; Willems, B.; Guisson, R.; Biswas, J.K.; Meers, E. Techno-economic Feasibility of Extrusion as a Pretreatment Step for Biogas Production from Grass. Bioenerg. Res. 2022, 15, 1232–1239. [Google Scholar] [CrossRef]

- Guiao, K.S.; Gupta, A.; Tzoganakis, C.; Mekonnen, T.H. Reactive extrusion as a sustainable alternative for the processing and valorization of biomass components. J. Clean. Prod. 2022, 355, 131840. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, M. Extrusion as a pretreatment for lignocellulosic biomass: Fundamentals and applications. Renew. Energy 2017, 114, 1427–1441. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. Influence of Extruder Temperature and Screw Speed on Pretreatment of Corn Stover while Varying Enzymes and Their Ratios. Appl. Biochem. Biotechnol. 2010, 162, 264–279. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Jin, S.Y.; Song, H.D.; Huang, K.; Li, S.; Guan, X.; Wang, Y. Effect of extrusion pretreatment on extraction, quality and antioxidant capacity of oat (Avena sativa L.) bran oil. J. Cereal Sci. 2020, 95, 102972. [Google Scholar] [CrossRef]

- Wang, Z.C.; He, X.J.; Yan, L.M.; Wang, J.P.; Hu, X.L.; Sun, Q.; Zhang, H.R. Enhancing enzymatic hydrolysis of corn stover by twin-screw extrusion pretreatment. Ind. Crops Prod. 2020, 143, 111960. [Google Scholar] [CrossRef]

- Sundaram, V.; Muthukumarappan, K.; Kamireddy, S.R. Effect of ammonia fiber expansion (AFEX (TM)) pretreatment on compression behavior of corn stover, prairie cord grass and switchgrass. Ind. Crops Prod. 2015, 74, 45–54. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Mani, S.; Bi, X.; Zaini, P.; Tabil, L. Binderless pelletization of biomass. In Proceedings of the 2005 ASAE Annual Meeting, Tampa, FL, USA, 17–20 July 2005; p. 1. [Google Scholar]

- Viamajala, S.; McMillan, J.D.; Schell, D.J.; Elander, R.T. Rheology of corn stover slurries at high solids concentrations—Effects of saccharification and particle size. Bioresour. Technol. 2009, 100, 925–934. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.H.; Chen, H.Z. Mechanical property of different corn stover morphological fractions and its correlations with high solids enzymatic hydrolysis by periodic peristalsis. Bioresour. Technol. 2016, 214, 292–302. [Google Scholar] [CrossRef] [PubMed]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- Cai, R.; Cui, X.Y.; Cao, X.H.; Jiang, X.; Wang, R.Z.; Xu, C.C. Crushing combined with high-frequency turning can promote material degradation of sheep manure compost on the Qinghai-Tibet Plateau by improving the microbial metabolic function. J. Environ. Chem. Eng. 2023, 11, 109535. [Google Scholar] [CrossRef]

- Van Soest, P.J. Collaborative Study of Acid-Detergent Fiber and Lignin. J. Assoc. Off. Anal. Chem. 1973, 56, 781–784. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 1990. [Google Scholar]

- Owens, V.N.; Albrecht, K.A.; Muck, R.E.; Duke, S.H. Protein degradation and fermentation characteristics of red clover and alfalfa silage harvested with varying levels of total nonstructural carbohydrates. Crop Sci. 1999, 39, 1873–1880. [Google Scholar] [CrossRef]

- Cai, R.; Zuo, S.S.; Cao, X.H.; Xu, C.C. Carbon and nitrogen transformation mechanism and functional microorganisms of sheep manure composting on the Qinghai-Tibet Plateau under different moisture content. J. Environ. Chem. Eng. 2023, 11, 111341. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Bourne, M.C.; Kenny, J.F.; Barnard, J. Computer-Assisted Readout of Data from Texture Profile Analysis Curves. J. Texture Stud. 1978, 9, 481–494. [Google Scholar] [CrossRef]

- Sozer, N.; Dalgic, A.C. Modelling of rheological characteristics of various spaghetti types. Eur. Food Res. Technol. 2007, 225, 183–190. [Google Scholar] [CrossRef]

- Tilley, J.; Terry, D.R. A two-stage technique for the in vitro digestion of forage crops. Grass Forage Sci. 1963, 18, 104–111. [Google Scholar] [CrossRef]

- France, J.; Dijkstra, J.; Dhanoa, M.S.; Lopez, S.; Bannink, A. Estimating the extent of degradation of ruminant feeds from a description of their gas production profiles observed in vitro: Derivation of models and other mathematical considerations. Br. J. Nutr. 2000, 83, 143–150. [Google Scholar] [CrossRef] [PubMed]

- van Dam, J.E.G.; van den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for production of high density/high performance binderless boards from whole coconut husk—Part 1: Lignin as intrinsic thermosetting binder resin. Ind. Crops Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Lu, X.; Zhang, S. Pretreatment of corn stover with diluted acetic acid for enhancement of acidogenic fermentation. Bioresour. Technol. 2014, 158, 12–18. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Suhag, M.; Dhaka, A. Augmented digestion of lignocellulose by steam explosion, acid and alkaline pretreatment methods: A review. Carbohydr. Polym. 2015, 117, 624–631. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Pang, J.H.; Lu, F.C.; Zhang, X.M.; Che, L.; Xu, F.; Sun, R.C. Application of new expansion pretreatment method on agricultural waste. Part I: Influence of pretreatment on the properties of lignin. Ind. Crops Prod. 2013, 50, 887–895. [Google Scholar] [CrossRef]

- Ma, J.; Yue, H.; Li, H.; Zhang, J.; Liu, G.Q. Selective delignification of poplar wood with a newly isolated white-rot basidiomycete Peniophora incarnata T-7 by submerged fermentation to enhance saccharification. Biotechnol. Biofuels 2021, 14, 1–15. [Google Scholar] [CrossRef]

- Luo, R.H.; Liao, Q.; Xia, A.; Deng, Z.C.; Huang, Y.; Zhu, X.Q.; Zhu, X. Synergistic Treatment of Alkali Lignin via Fungal Coculture for Biofuel Production: Comparison of Physicochemical Properties and Adsorption of Enzymes Used As Catalysts. Front. Energy Res. 2020, 8, 575371. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Lu, M.; Guo, X.; Zhang, H.; Han, L. Integrated chemical and multi-scale structural analyses for the processes of acid pretreatment and enzymatic hydrolysis of corn stover. Carbohydr. Polym. 2016, 141, 1–9. [Google Scholar] [CrossRef]

- Zhai, Q.L.; Li, F.L.; Wang, F.; Feng, J.F.; Jiang, J.C.; Xu, J.M. Ultrafine grinding of poplar biomass: Effect of particle morphology on the liquefaction of biomass for methyl glycosides and phenolics. Cellulose 2019, 26, 3685–3701. [Google Scholar] [CrossRef]

- Chen, X.H.; Zhang, Y.L.; Gu, Y.; Liu, Z.G.; Shen, Z.; Chu, H.Q.; Zhou, X.F. Enhancing methane production from rice straw by extrusion pretreatment. Appl. Energy 2014, 122, 34–41. [Google Scholar] [CrossRef]

- Jacquet, N.; Maniet, G.; Vanderghem, C.; Delvigne, F.; Richel, A. Application of Steam Explosion as Pretreatment on Lignocellulosic Material: A Review. Ind. Eng. Chem. Res. 2015, 54, 2593–2598. [Google Scholar] [CrossRef]

- Hahor, W.; Thongprajukaew, K.; Nuntapong, N.; Saekhow, S.; Rungruangsak-Torrissen, K.; Dumrongrittamatt, T.; Phonchai, A. Partial pretreatment of ingredient mixture effectively improved feed chemical composition, physicochemical properties and in vitro digestibility. Anim. Feed Sci. Technol. 2022, 285, 115216. [Google Scholar] [CrossRef]

- Brummell, D.A.; Dal Cin, V.; Crisosto, C.H.; Labavitch, J.M. Cell wall metabolism during maturation, ripening and senescence of peach fruit. J. Exp. Bot. 2004, 55, 2029–2039. [Google Scholar] [CrossRef] [PubMed]

- Selig, M.J.; Viamajala, S.; Decker, S.R.; Tucker, M.P.; Himmel, M.E.; Vinzant, T.B. Deposition of lignin droplets produced during dilute acid pretreatment of maize stems retards enzymatic hydrolysis of cellulose. Biotechnol. Prog. 2007, 23, 1333–1339. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.Z.; Liu, Z.H. Steam explosion and its combinatorial pretreatment refining technology of plant biomass to bio-based products. Biotechnol. J. 2015, 10, 866–885. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Li, G.; Zheng, N.; Wang, J.; Yu, Z. Steam explosion enhances digestibility and fermentation of corn stover by facilitating ruminal microbial colonization. Bioresour. Technol. 2018, 253, 244–251. [Google Scholar] [CrossRef]

- He, L.W.; Meng, Q.X.; Li, D.Y.; Wang, F.; Ren, L.P. Effect of steam explosion on gas production kinetics and rumen fermentation profiles of three common straws. Ital. J. Anim. Sci. 2015, 14, 4076. [Google Scholar] [CrossRef][Green Version]

- Hussain, S.; Liu, T.; Iqbal, N.; Brestic, M.; Pang, T.; Mumtaz, M.; Shafiq, I.; Li, S.X.; Wang, L.; Gao, Y.; et al. Effects of lignin, cellulose, hemicellulose, sucrose and monosaccharide carbohydrates on soybean physical stem strength and yield in intercropping. Photochem. Photobiol. Sci. 2020, 19, 462–472. [Google Scholar] [CrossRef]

- Zhao, D.Q.; Luan, Y.T.; Xia, X.; Shi, W.B.; Tang, Y.H.; Tao, J. Lignin provides mechanical support to herbaceous peony (Pall.) stems. Hortic. Res. 2020, 7, 213. [Google Scholar] [CrossRef]

- Li, Q.; Fu, C.F.; Liang, C.L.; Ni, X.J.; Zhao, X.H.; Chen, M.; Ou, L.J. Crop Lodging and The Roles of Lignin, Cellulose, and Hemicellulose in Lodging Resistance. Agronomy 2022, 12, 1795. [Google Scholar] [CrossRef]

- Burgert, I. Exploring the micromechanical design of plant cell walls. Am. J. Bot. 2006, 93, 1391–1401. [Google Scholar] [CrossRef] [PubMed]

- Roberts, K.M.; Lavenson, D.M.; Tozzi, E.J.; McCarthy, M.J.; Jeoh, T. The effects of water interactions in cellulose suspensions on mass transfer and saccharification efficiency at high solids loadings. Cellulose 2011, 18, 759–773. [Google Scholar] [CrossRef]

- Pihlajaniemi, V.; Sipponen, M.H.; Liimatainen, H.; Sirvio, J.A.; Nyyssola, A.; Laakso, S. Weighing the factors behind enzymatic hydrolyzability of pretreated lignocellulose. Green Chem. 2016, 18, 1295–1305. [Google Scholar] [CrossRef]

- Shen, F.; Sun, S.; Zhang, X.; Yang, J.R.; Qiu, M.; Qi, X.H. Mechanochemical-assisted production of 5-hydroxymethylfurfural from high concentration of cellulose. Cellulose 2020, 27, 3013–3023. [Google Scholar] [CrossRef]

- Cai, R.; Zuo, S.S.; Cao, X.H.; Jiang, X.; Xu, C.C. Effects of turning frequency on fermentation efficiency and microbial community metabolic function of sheep manure composting on the Qinghai-Tibet Plateau. Bioresour. Bioprocess. 2023, 10, 53. [Google Scholar] [CrossRef]

| Items (g/kg DM) | Control | EO | ES | SEM 1 | p-Value 2 |

|---|---|---|---|---|---|

| Neutral detergent fiber (NDF) | 735.8 a | 705.8 b | 688.6 c | 7.01 | <0.001 |

| Acidity detergent fiber (ADF) | 584.7 a | 554.9 b | 542.9 b | 6.93 | 0.004 |

| Lignin | 84.9 a | 81.9 a | 76.5 b | 1.39 | 0.007 |

| Cellulose (CL) | 498.0 | 472.3 | 463.7 | 6.87 | 0.086 |

| Hemicellulose (HCL) | 154.1 a | 151.5 ab | 145.7 b | 1.36 | 0.017 |

| Water-soluble carbohydrate (WSC) | 16.7 b | 21.5 a | 21.6 a | 0.94 | 0.017 |

| Crude protein (CP) | 32.1 c | 39.5 b | 43.7 a | 1.71 | <0.001 |

| Crude ash | 92.9 | 96.8 | 95.5 | 1.31 | 0.541 |

| Treatment 1 | Y 2 (mL/g DM) | B 3 (mL/g DM) | c 4 (h−1) | L 5 (h) | ||

|---|---|---|---|---|---|---|

| B1 | B2 | c1 | c2 | |||

| Control | 170.1 | 172.64 | 172.64 | 0.0398 | 0.0398 | 0.2038 |

| EO | 180.1 | 153.65 | 78.96 | 0.0523 | 0.0044 | / |

| ES | 178.2 | 123.54 | 75.67 | 0.0697 | 0.0139 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.; Zuo, S.; Lin, Y.; Cai, R.; Yang, F.; Wang, X.; Xu, C. Expansion Improved the Physical and Chemical Properties and In Vitro Rumen Digestibility of Buckwheat Straw. Animals 2024, 14, 29. https://doi.org/10.3390/ani14010029

Cao X, Zuo S, Lin Y, Cai R, Yang F, Wang X, Xu C. Expansion Improved the Physical and Chemical Properties and In Vitro Rumen Digestibility of Buckwheat Straw. Animals. 2024; 14(1):29. https://doi.org/10.3390/ani14010029

Chicago/Turabian StyleCao, Xiaohui, Sasa Zuo, Yanli Lin, Rui Cai, Fuyu Yang, Xuekai Wang, and Chuncheng Xu. 2024. "Expansion Improved the Physical and Chemical Properties and In Vitro Rumen Digestibility of Buckwheat Straw" Animals 14, no. 1: 29. https://doi.org/10.3390/ani14010029

APA StyleCao, X., Zuo, S., Lin, Y., Cai, R., Yang, F., Wang, X., & Xu, C. (2024). Expansion Improved the Physical and Chemical Properties and In Vitro Rumen Digestibility of Buckwheat Straw. Animals, 14(1), 29. https://doi.org/10.3390/ani14010029