Assessment of a Novel Real-Time Bio-Liquor Circulation System for Manure Management and Mitigation of Odor Potential in Swine Farming

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

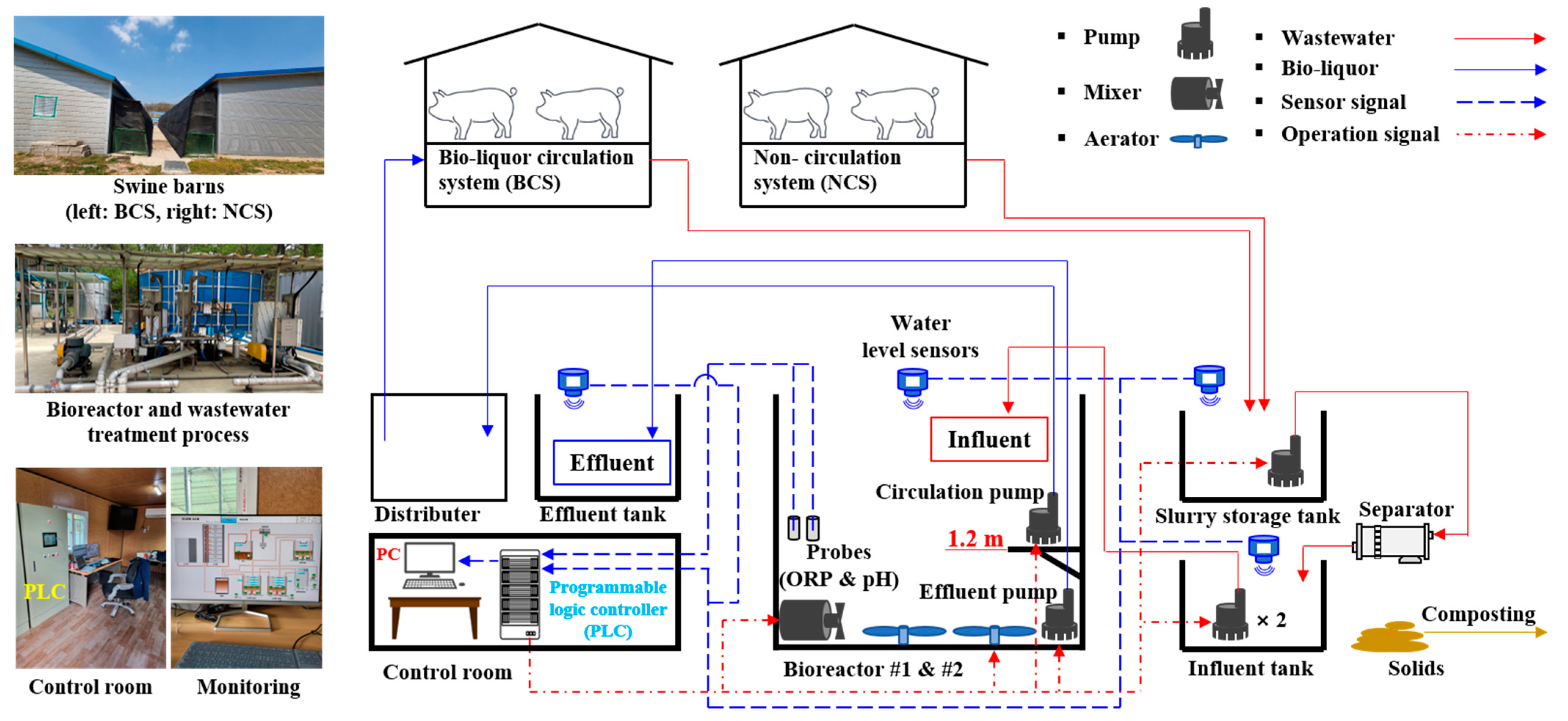

2.1. The Bio-Liquor Circulation Process

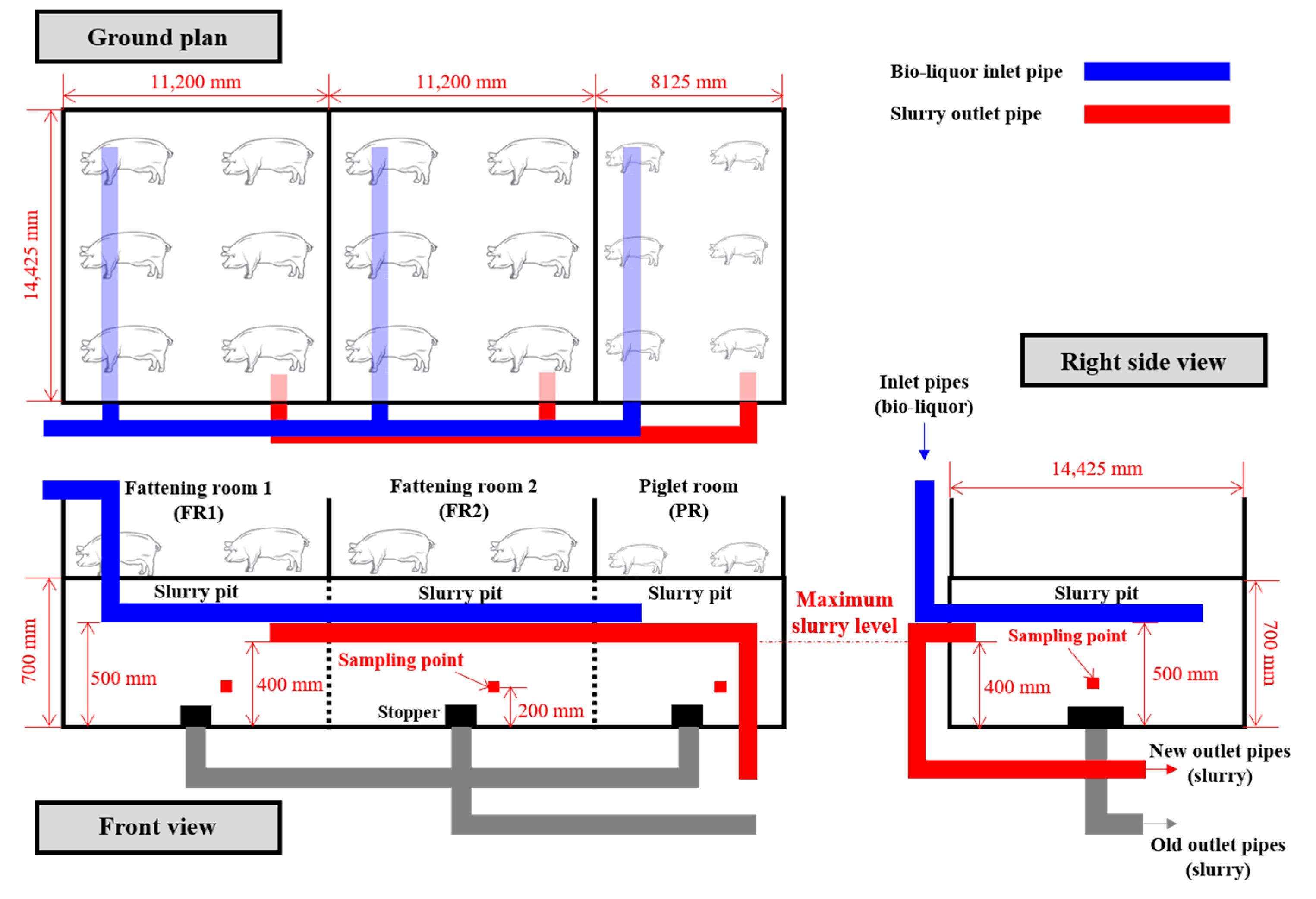

2.1.1. Slurry Pit Remodeling

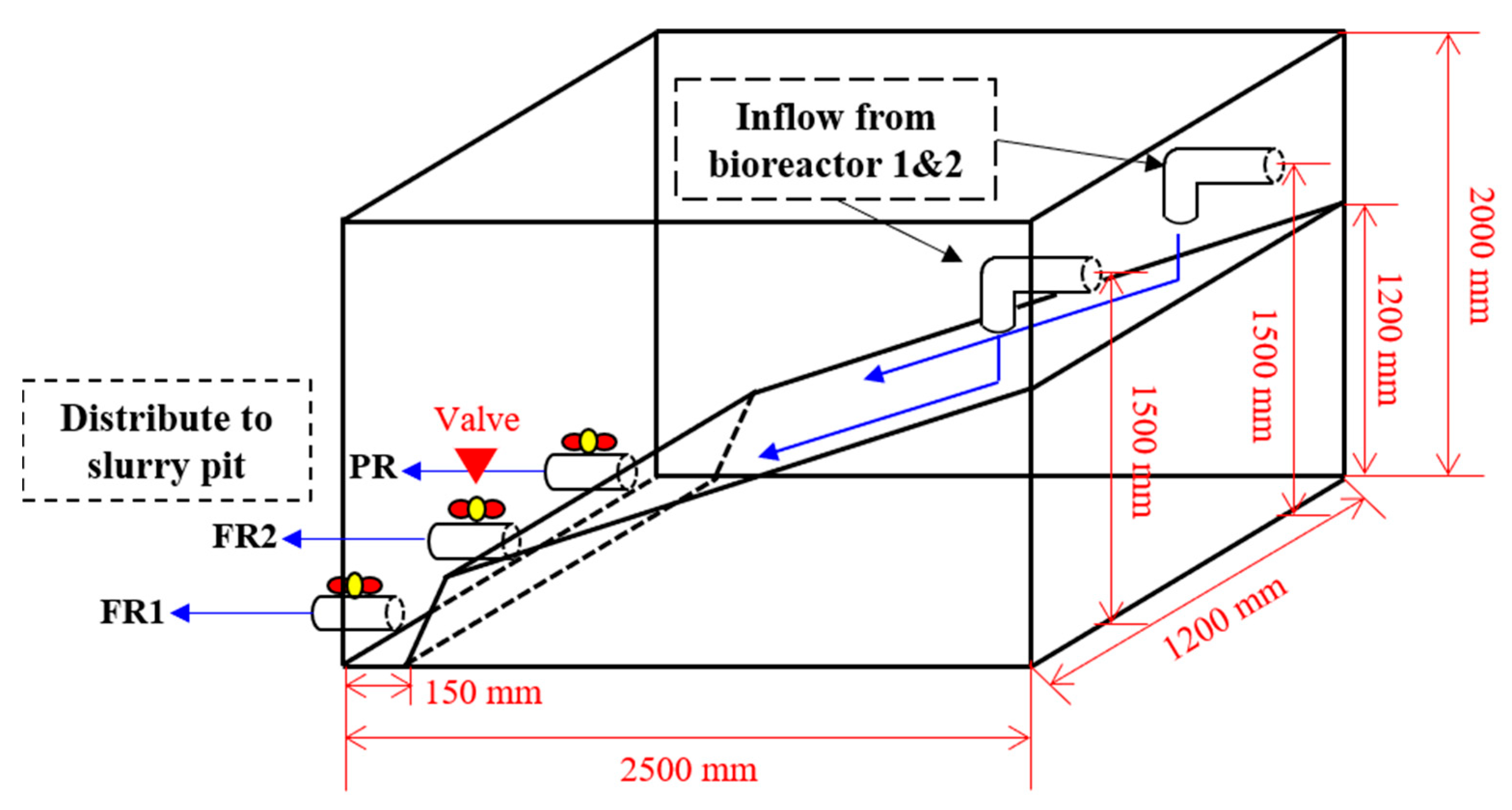

2.1.2. Construction of the Bio-Liquor Distributor

2.1.3. Construction of the Bioreactor and Bio-Liquor Circulation System

2.2. Construction of the Bioreactor and Bio-Liquor Circulation System

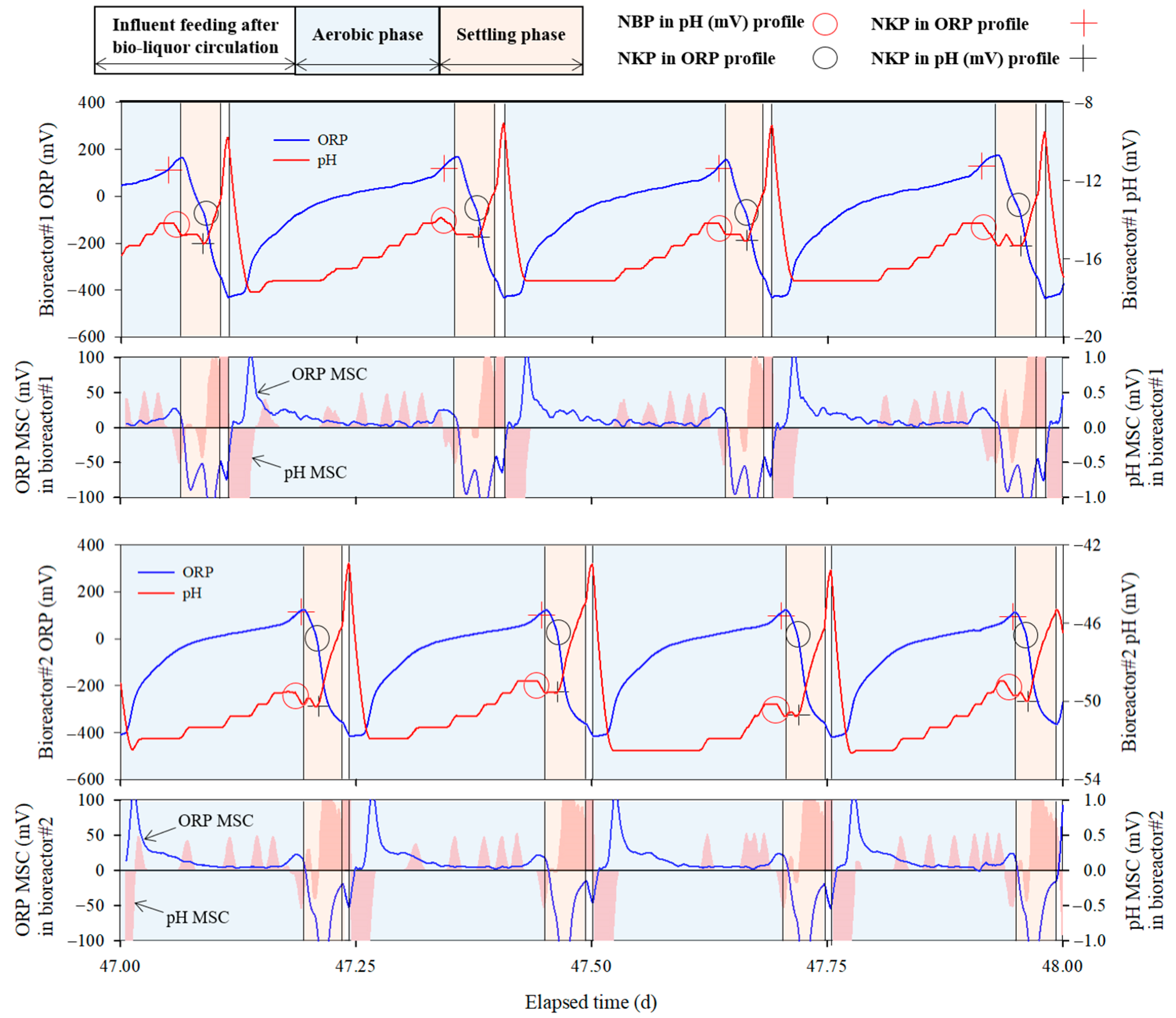

2.2.1. Monitoring System

2.2.2. Operational Algorithm for the Bio-Liquor Circulation System

2.2.3. Operational Conditions

2.3. Temperature Control and Breeding Program in the Swine Barns

2.4. Sampling Procedure

2.5. Analytical Methods

2.6. Calculation of the Methane and Ammonia Emission Potentials of Swine Manure

| Parameters | Reference | Used Factor | Used Value |

|---|---|---|---|

| CH4 | IPCC (2006) [36] | Volatile solids (VS): analyzed value | VS (kg/m3) |

| Bo 1: Market swine characteristics in Western Europe | 0.45 (m3 CH4/kg VS) | ||

| MCF 2: Slurry system, 18 °C | 35 (%) | ||

| CH4 conversion factor of m3 to kg | 0.67 (kg/m3) | ||

| NH3 | Emerson et al. (1975) [37] | pH | measured value |

| Temperature | 18 (°C) |

3. Results and Discussion

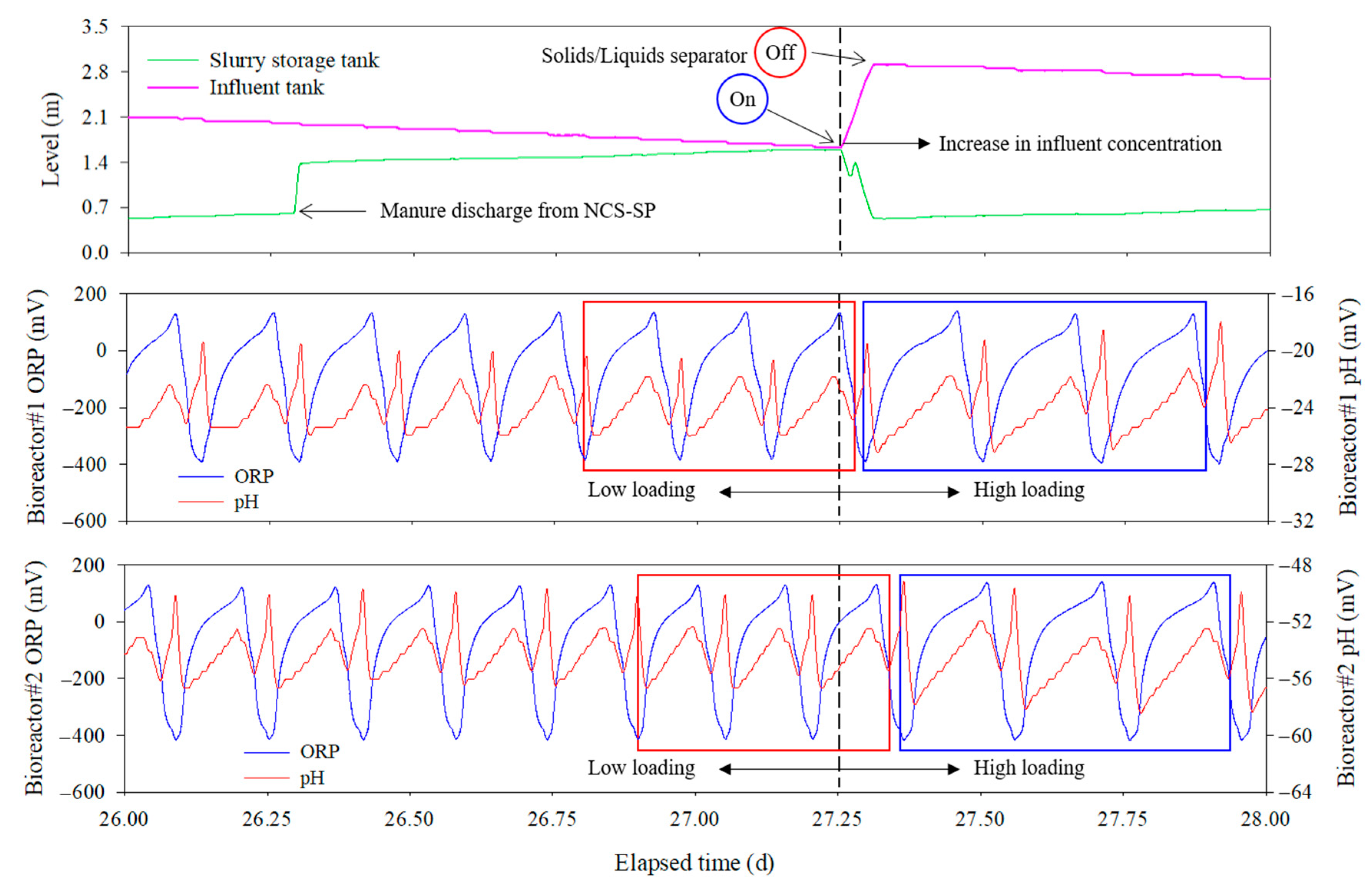

3.1. Real-Time Operation of the Bioreactors

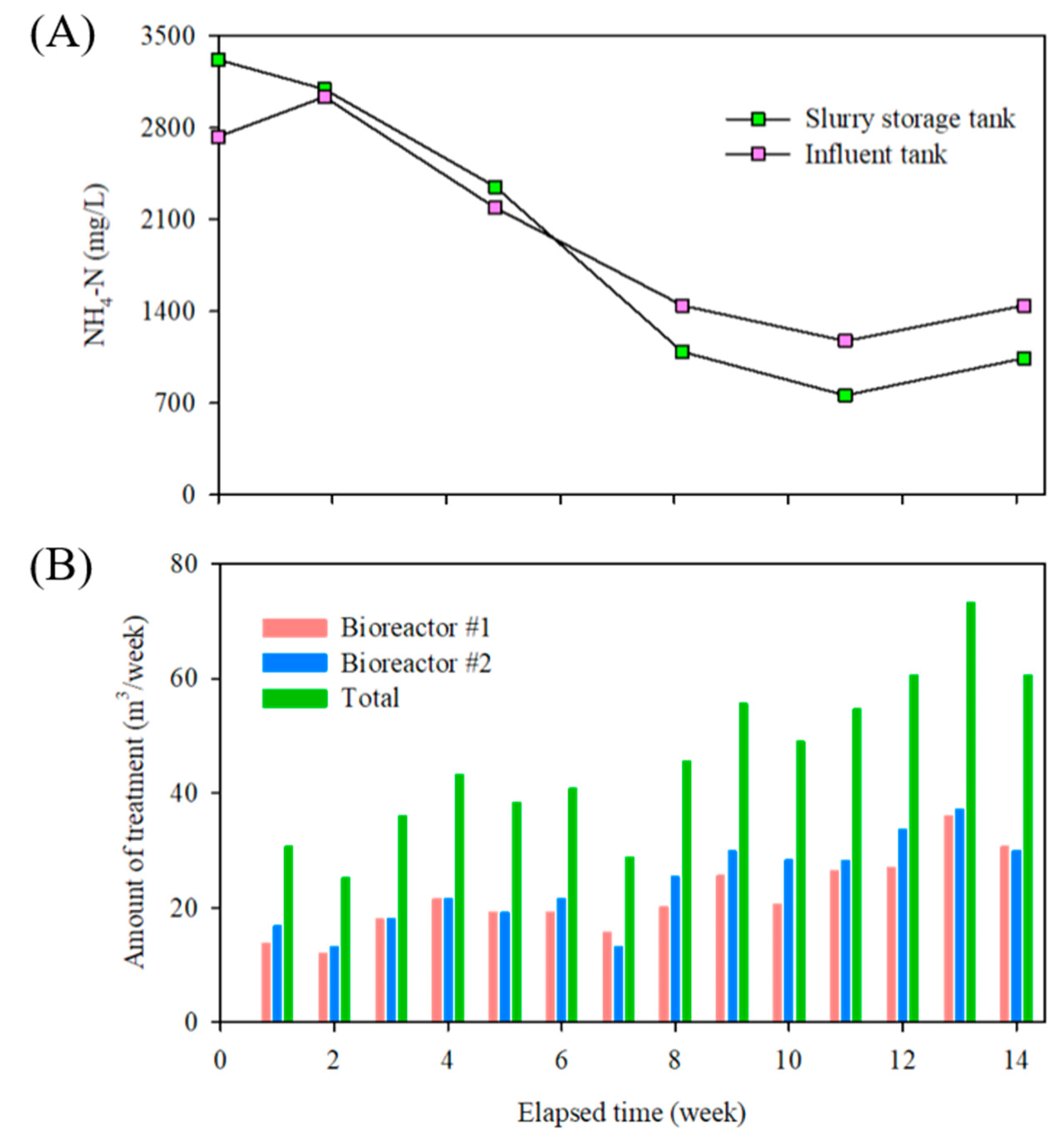

3.2. Quantitative Analysis for Bio-Liquor Circulation

3.3. Changes in Swine Manure Properties in Slurry Pit

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Haro Martí, M.E.; Neibling, W.H.; Chen, L.; Chahine, M. On-farm testing of a zeolite filter to capture ammonia and odors from a dairy manure flushing system. Trans. ASABE 2020, 63, 597–607. [Google Scholar] [CrossRef]

- Keck, M.; Mager, K.; Weber, K.; Keller, M.; Frei, M.; Steiner, B.; Schrade, S. Odour impact from farms with animal husbandry and biogas facilities. Sci. Total Environ. 2018, 645, 1432–1443. [Google Scholar] [CrossRef] [PubMed]

- Conti, C.; Guarino, M.; Bacenetti, J. Measurements techniques and models to assess odor annoyance: A review. Environ. Int. 2020, 134, 105261. [Google Scholar] [CrossRef] [PubMed]

- Van der Heyden, C.; Brusselman, E.; Volcke, E.I.P.; Demeyer, P. Continuous measurements of ammonia, nitrous oxide and methane from air scrubbers at pig housing facilities. J. Environ. Manag. 2016, 181, 163–171. [Google Scholar] [CrossRef]

- Post, P.M.; Hogerwerf, L.; Bokkers, E.A.M.; Baumann, B.; Fischer, P.; Rutledge-Jonker, S.; Hilderink, H.; Hollander, A.; Hoogsteen, M.J.J.; Liebman, A.; et al. Effects of Dutch livestock production on human health and the environment. Sci. Total Environ. 2020, 737, 139702. [Google Scholar] [CrossRef] [PubMed]

- Hanajima, D.; Kuroda, K.; Morishita, K.; Fujita, J.; Maeda, K.; Morioka, R. Key odor components responsible for the impact on olfactory sense during swine feces composting. Bioresour. Technol. 2010, 101, 2306–2310. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xi, J.; Hu, H.; Kang, I. Effects of design parameters on performance and cost analysis of combined ultraviolet-biofilter systems treating gaseous chlorobenzene based on mathematical modeling. Front. Environ. Sci. Eng. 2012, 6, 588–594. [Google Scholar] [CrossRef]

- Dentoni, L.; Capelli, L.; Sironi, S.; Guillot, J.M.; Rossi, A.N. Comparison of different approaches for odour impact assessment: Dispersion modelling (CALPUFF) vs field inspection (CEN/TC 264). Water Sci. Technol. 2013, 68, 1731–1738. [Google Scholar] [CrossRef]

- Han, K.; Vitale, J.; Lee, Y.G.; Ji, I. Measuring the economic value of the negative externality of livestock malodor in South Korea. Int. J. Environ. Res. Public Health 2022, 19, 9475. [Google Scholar] [CrossRef]

- Wang, Y.C.; Han, M.F.; Jia, T.P.; Hu, X.R.; Zhu, H.Q.; Tong, Z.; Lin, Y.T.; Wang, C.; Liu, D.Z.; Peng, Y.Z.; et al. Emissions, measurement, and control of odor in livestock farms: A review. Sci. Total Environ. 2021, 776, 145735. [Google Scholar] [CrossRef]

- Cao, T.; Zheng, Y.; Dong, H. Control of odor emissions from livestock farms: A review. Environ. Res. 2023, 225, 115545. [Google Scholar] [CrossRef] [PubMed]

- Mahin, T.D. Comparison of different approaches used to regulate odours around the world. Water Sci. Technol. 2001, 44, 87–102. [Google Scholar] [CrossRef] [PubMed]

- Both, R. Directive on odour in ambient air: An established system of odour measurement and odour regulation in Germany. Water Sci. Technol. 2001, 44, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Maurer, D.L.; Koziel, J.A.; Harmon, J.D.; Hoff, S.J.; Rieck-Hinz, A.M.; Andersen, D.S. Summary of performance data for technologies to control gaseous, odor, and particulate emissions from livestock operations: Air management practices assessment tool (AMPAT). Data Brief 2016, 7, 1413–1429. [Google Scholar] [CrossRef] [PubMed]

- Rappert, S.; Müller, R. Odor compounds in waste gas emissions from agricultural operations and food industries. Waste Manag. 2005, 25, 887–907. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J. A review of microbiology in swine manure odor control. Agric. Ecosyst. Environ. 2000, 78, 93–106. [Google Scholar] [CrossRef]

- Sunesson, A.L.; Gullberg, J.; Blomquist, G. Airborne chemical compounds on dairy farms. J. Environ. Monit. 2001, 3, 210–216. [Google Scholar] [CrossRef] [PubMed]

- Nahm, K.H. Efficient feed nutrient utilization to reduce pollutants in poultry and swine manure. Crit. Rev. Environ. Sci. Technol. 2002, 32, 1–16. [Google Scholar] [CrossRef]

- Schiffman, S.S.; Bennett, J.L.; Raymer, J.H. Quantification of odors and odorants from swine operations in North Carolina. Agric. Forest Meteorol. 2001, 108, 213–240. [Google Scholar] [CrossRef]

- Van Emous, R.A.; Winkel, A.; Aarnink, A.J.A. Effects of dietary crude protein levels on ammonia emission, litter and manure composition, N losses, and water intake in broiler breeders. Poult. Sci. 2019, 98, 6618–6625. [Google Scholar] [CrossRef]

- Trabue, S.L.; Kerr, B.J.; Scoggin, K.D.; Andersen, D.; van Weelden, M.V. Swine diets impact manure characteristics and gas emissions: Part I protein level. Sci. Total Environ. 2021, 755, 142528. [Google Scholar] [CrossRef] [PubMed]

- Kupper, T.; Häni, C.; Neftel, A.; Kincaid, C.; Bühler, M.; Amon, B.; VanderZaag, A. Ammonia and greenhouse gas emissions from slurry storage—A review. Agric. Ecosyst. Environ. 2020, 300, 106963. [Google Scholar] [CrossRef]

- Overmeyer, V.; Kube, A.; Clemens, J.; Büscher, W.; Trimborn, M. One-time acidification of slurry: What is the most effective acid and treatment strategy? Agronomy 2021, 11, 1319. [Google Scholar] [CrossRef]

- Eriksen, J.; Andersen, A.J.; Poulsen, H.V.; Adamsen, A.P.S.; Petersen, S.O. Sulfur turnover and emissions during storage of cattle slurry: Effects of acidification and sulfur addition. J. Environ. Qual. 2012, 41, 1633–1641. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.J.; Zhu, J. Effectiveness of short-term aeration in treating swine finishing manure to reduce odour generation potential. Agric. Ecosyst. Environ. 2005, 105, 115–125. [Google Scholar] [CrossRef]

- Choi, E.; Kim, J.; Choi, I.; Ahn, H.; Dong, J.I.; Kim, H. Microbial additives in controlling odors from stored swine slurry. Water Air Soil Pollut. 2015, 226, 104. [Google Scholar] [CrossRef]

- Kim, K.Y.; Ko, H.J.; Kim, H.T.; Kim, Y.S.; Roh, Y.M.; Lee, C.M.; Kim, C.N. Odor reduction rate in the confinement pig building by spraying various additives. Bioresour. Technol. 2008, 99, 8464–8469. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.S.; Shim, S.M.; Lee, T.H.; Jeon, T.B.; Won, S.G.; Song, J.I.; Jung, B.D.; Lee, J.J.; Ra, C.S. Optimal parameters of bio-liquor circulation type swine manure management system. Ann. Anim. Resour. Sci. 2019, 30, 133–144. [Google Scholar] [CrossRef]

- Kim, S.S.; Reza, A.; Shim, S.M.; Won, S.G.; Ra, C.S. Development of a real-time controlled bio-liquor circulation system for swine farms: A lab-scale study. Animals 2021, 11, 311. [Google Scholar] [CrossRef]

- Kim, S.S.; Shim, S.M.; Won, S.G.; Kwag, J.H.; Ra, C.S. Real-time control technology for a bio-liquor circulation system in a swine barn with slurry pit: Pilot scale study. Animals 2022, 12, 2941. [Google Scholar] [CrossRef]

- Wi, J.; Lee, S.; Kim, E.; Lee, M.; Koziel, J.A.; Ahn, H. Evaluation of semi-continuous pit manure recharge system performance on mitigation of ammonia and hydrogen sulfide emissions from a swine finishing barn. Atmosphere 2019, 10, 170. [Google Scholar] [CrossRef]

- Wi, J.S.; Lee, S.H.; Kim, E.J.; Lee, M.S.; Koziel, J.A.; Ahn, H.K. Effects of treated manure conditions on ammonia and hydrogen sulfide emissions from a swine finishing barn equipped with semicontinuous pit recharge system in Summer. Atmosphere 2020, 11, 713. [Google Scholar] [CrossRef]

- Ha, D.M.; Kim, D.H. The effect of liquid manure circulation system on the odor reduction of swine farm. J. Agric. Life Sci. 2015, 49, 57–64. [Google Scholar] [CrossRef]

- Jeong, C.H.; Park, M.J.; Jeong, D.W. Reduction of odor from swine manure using soil microorganisms on liquid manure circulation system. KSWST J. Water Treat. 2019, 27, 97–106. [Google Scholar] [CrossRef]

- Ga, C.H.; Ra, C.S. Real-time control of oxic phase using pH (mV)-time profile in swine wastewater treatment. J. Hazard. Mater. 2009, 172, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Eggleston, S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006. [Google Scholar]

- Emerson, K.; Russo, R.C.; Lund, R.E.; Thurston, R.V. Aqueous ammonia equilibrium calculations: Effect of pH and temperature. J. Fish. Res. Board Can. 1975, 32, 2379–2383. [Google Scholar] [CrossRef]

- Ministry of the Environment. National Greenhouse Gas Inventory Report of Korea; Ministry of the Environment: Sejong, Republic of Korea, 2022.

- Won, S.G.; Ra, C.S. Biological nitrogen removal with a real-time control strategy using moving slope changes of pH(mV)- and ORP-time profiles. Water Res. 2011, 45, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Chen, M.; Kishida, N.; Sudo, R. Integrated real-time control strategy for nitrogen removal in swine wastewater treatment using sequencing batch reactors. Water Res. 2004, 38, 3340–3348. [Google Scholar] [CrossRef]

- Kishida, N.; Kim, J.H.; Chen, M.; Sasaki, H.; Sudo, R. Effectiveness of oxidation-reduction potential and pH as monitoring and control parameters for nitrogen removal in swine wastewater treatment by sequencing batch reactors. J. Biosci. Bioeng. 2003, 96, 285–290. [Google Scholar] [CrossRef]

- Tanwar, P.; Nandy, T.; Ukey, P.; Manekar, P. Correlating on-line monitoring parameters, pH, DO and ORP with nutrient removal in an intermittent cyclic process bioreactor system. Bioresour. Technol. 2008, 99, 7630–7635. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, T.; Wang, B.; Xu, Z.; Zhang, L.; Peng, Y. Advanced nitrogen removal of low C/N ratio sewage in an anaerobic/aerobic/anoxic process through enhanced post-endogenous denitrification. Chemosphere 2020, 252, 126624. [Google Scholar] [CrossRef] [PubMed]

- Kuo, W.C.; Parkin, G.F. Characterization of soluble microbial products from anaerobic treatment by molecular weight distribution and nickel-chelating properties. Water Res. 1996, 30, 915–922. [Google Scholar] [CrossRef]

- Li, Y.; Li, A.M.; Xu, J.; Li, W.W.; Yu, H.Q. Formation of soluble microbial products (SMP) by activated sludge at various salinities. Biodegradation 2013, 24, 69–78. [Google Scholar] [CrossRef] [PubMed]

- Keller, J.K.; Weisenhorn, P.B.; Megonigal, J.P. Humic acids as electron acceptors in wetland decomposition. Soil Biol. Biochem. 2009, 41, 1518–1522. [Google Scholar] [CrossRef]

- Blodau, C.; Deppe, M. Humic acid addition lowers methane release in peats of the Mer Bleue bog, Canada. Soil Biol. Biochem. 2012, 52, 96–98. [Google Scholar] [CrossRef]

- Bridgham, S.D.; Cadillo-Quiroz, H.; Keller, J.K.; Zhuang, Q. Methane emissions from wetlands: Biogeochemical, microbial, and modeling perspectives from local to global scales [Review]. Glob. Chang. Biol. 2013, 19, 1325–1346. [Google Scholar] [CrossRef] [PubMed]

- Miller, K.E.; Lai, C.-T.; Friedman, E.S.; Angenent, L.T.; Lipson, D.A. Methane suppression by iron and humic acids in soils of the Arctic Coastal Plain. Soil Boil. Biochem. 2015, 83, 176–183. [Google Scholar] [CrossRef]

- Tan, W.B.; Jia, Y.F.; Huang, C.H.; Zhang, H.; Li, D.; Zhao, X.Y.; Wang, G.; Jiang, J.; Xi, B. Increased suppression of methane production by humic substances in response to warming in anoxic environments. J. Environ. Manag. 2018, 206, 602–606. [Google Scholar] [CrossRef]

- Khadem, A.F.; Azman, S.; Plugge, C.M.; Zeeman, G.; van Lier, J.B.; Stams, A.J.M. Effect of humic acids on the activity of pure and mixed methanogenic cultures. Biomass Bioenerg. 2017, 99, 21–30. [Google Scholar] [CrossRef]

- Wagner, S.; Angenendt, E.; Beletskaya, O.; Zeddies, J. Costs and benefits of ammonia and particulate matter abatement in German agriculture including interactions with greenhouse gas emissions. Agric. Syst. 2015, 141, 58–68. [Google Scholar] [CrossRef]

- Xu, W.; Wu, Q.; Liu, X.; Tang, A.; Dore, A.J.; Heal, M.R. Characteristics of ammonia, acid gases, and PM2.5 for three typical land-use types in the NCP. Environ. Sci. Pollut. Res. Int. 2016, 23, 1158–1172. [Google Scholar] [CrossRef]

| Item | Shape | Area (m2) | Depth (m) | Volume (m3) | |

|---|---|---|---|---|---|

| Total | Working | ||||

| NCS-SP | Rectangular Paralleled pipe | 327.5 | 0.7 | 212.9 | 131.0 |

| BCS-SP | 440.3 | 0.7 | 286.2 | 176.0 | |

| Slurry storage tank | 12.3 | 3.5 | 43.1 | 30.0 | |

| Influent tank | 18.9 | 3.5 | 66.0 | 50.0 | |

| Bioreactor #1 | 16.7 | 3.5 | 58.5 | 40.0 | |

| Bioreactor #2 | 16.7 | 3.5 | 58.5 | 40.0 | |

| Distributer | 2.5 | 1.2 | 3.0 | 2.0 | |

| Effluent tank | Cylindrical | 34.2 | 3.0 | 100.0 | 80.0 |

| Parameters | Bioreactors 1 & 2 | BCS-SP | NCS-SP |

|---|---|---|---|

| Working volume (m3) | 40 | 176.0 | 131.0 |

| Initial condition | Filled with bio-liquor | Full of slurry manure | |

| Manure production (L/d) | - | 652.8 | 489.6 |

| Working volume of slurry pit (m3/head) | - | 2.28 | 2.24 |

| Circulation rate (m3/cycle) | 0.6 | 0.6 | No circulation |

| Circulation rate based on working volume (L/m3/cycle) | 15 | 3.4 | No circulation |

| Aeration rate (m3/min/m3) | 0.1 | - | - |

| Parameters (mg/L) | Mixed Liquor |

|---|---|

| TS 1 | 24,225.0 |

| TVS 2 | 11,795.9 |

| TSS 3 | 18,980.0 |

| TVSS 4 | 9766.7 |

| NH4-N 5 | 83.6 |

| NOX-N 6 | 0.0 |

| TKN 7 | 1066.1 |

| TN 8 | 1066.1 |

| STOC 9 | 1529.1 |

| Parameters | Breeding Room in NCS and BCS | ||

|---|---|---|---|

| FR 1 & 2 | PR | ||

| Temperature (°C) | Max. | 25 | 30 |

| Min. | 20 | 25 | |

| Feed composition | Crude protein (%) | 14–16 | 18–20 |

| Crude fat (%) | 4–5 | 7–8 | |

| Crude fiber (%) | 3–5 | 2.5–5 | |

| Crude ash (%) | 6–7 | 4.5–5 | |

| Calcium (%) | 0.5–0.6 | 0.6–0.7 | |

| Phosphorus (%) | 0.35–0.4 | 0.6–0.65 | |

| Lysine (%) | 0.8–0.9 | 1.45–1.5 | |

| Digestible energy (Mcal/kg) | 2.4–2.46 | 2.45–2.5 | |

| Parameters | NH4-N Loading Rate (g/m3·d) | F/M 1 (Ratio/d) | Circulated Bio-Liquor (mg/L) | |||

|---|---|---|---|---|---|---|

| MLSS 2 | NH4-N | NOX-N | STOC | |||

| Bioreactor 1 | 157.1 ± 43.0 | 9.2 ± 3.8 | 25,185.0 ± 3933.0 | 0.0 ± 0.0 | 0.0 ± 0.0 | 1613.7 ± 75.2 |

| Bioreactor 2 | 192.9 ± 46.3 | 11.0 ± 5.5 | 26,058.3 ± 5795.7 | 0.0 ± 0.0 | 0.0 ± 0.0 | 1640.8 ± 98.2 |

| Parameters | Bioreactor 1 | Bioreactor 2 | Total |

|---|---|---|---|

| Amount of circulation (m3/d) | 3.3 ± 1.1 | 3.6 ± 1.2 | 6.9 ± 2.2 |

| Circulation rate based on slurry pit volume (L/m3/d) | 18.6 ± 6.3 | 20.4 ± 6.6 | 39.0 ± 12.3 |

| Circulation ratio based on manure production (bio-liquor/manure) | 5.0 ± 1.7 | 5.5 ± 1.8 | 10.5 ± 3.3 |

| Parameters | NCS | BCS | Reduction Efficiency (%) |

|---|---|---|---|

| TS (mg/L) | 172,037.5 ± 7548.4 | 50,421.3 ± 708.2 | 70.7 |

| TVS (mg/L) | 124,975.0 ± 3712.3 | 31,220.4 ± 858.4 | 75.0 |

| TSS (mg/L) | 151,597.7 ± 12,810.4 | 40,757.4 ± 1442.1 | 73.1 |

| TVSS (mg/L) | 112,716.7 ± 6976.8 | 28,102.8 ± 409.0 | 75.1 |

| NH4-N (mg/L) | 3061.1 ± 71.3 | 382.4 ± 190.6 | 87.5 |

| TN (mg/L) | 11,956.3 ± 2391.5 | 3710.8 ± 251.2 | 69.0 |

| STOC (mg/L) | 29,292.1 ± 884.2 | 3086.6 ± 432.5 | 89.5 |

| pH | 7.79 ± 0.03 | 7.20 ± 0.06 | - |

| Potential amount of CH4 production (kg/m3) | 13.2 ± 0.4 | 3.3 ± 0.1 | 75.0 |

| Theoretical NH3 emissions (g/m3) | 103.7 ± 4.1 | 5.0 ± 1.2 | 95.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Shim, S.; Won, S.; Ra, C. Assessment of a Novel Real-Time Bio-Liquor Circulation System for Manure Management and Mitigation of Odor Potential in Swine Farming. Animals 2023, 13, 3849. https://doi.org/10.3390/ani13243849

Kim S, Shim S, Won S, Ra C. Assessment of a Novel Real-Time Bio-Liquor Circulation System for Manure Management and Mitigation of Odor Potential in Swine Farming. Animals. 2023; 13(24):3849. https://doi.org/10.3390/ani13243849

Chicago/Turabian StyleKim, Seungsoo, Soomin Shim, Seunggun Won, and Changsix Ra. 2023. "Assessment of a Novel Real-Time Bio-Liquor Circulation System for Manure Management and Mitigation of Odor Potential in Swine Farming" Animals 13, no. 24: 3849. https://doi.org/10.3390/ani13243849

APA StyleKim, S., Shim, S., Won, S., & Ra, C. (2023). Assessment of a Novel Real-Time Bio-Liquor Circulation System for Manure Management and Mitigation of Odor Potential in Swine Farming. Animals, 13(24), 3849. https://doi.org/10.3390/ani13243849