An IoT-Based Breeding Egg Identification and Coding System for Selection of High-Quality Breeding Geese

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. RFID Module

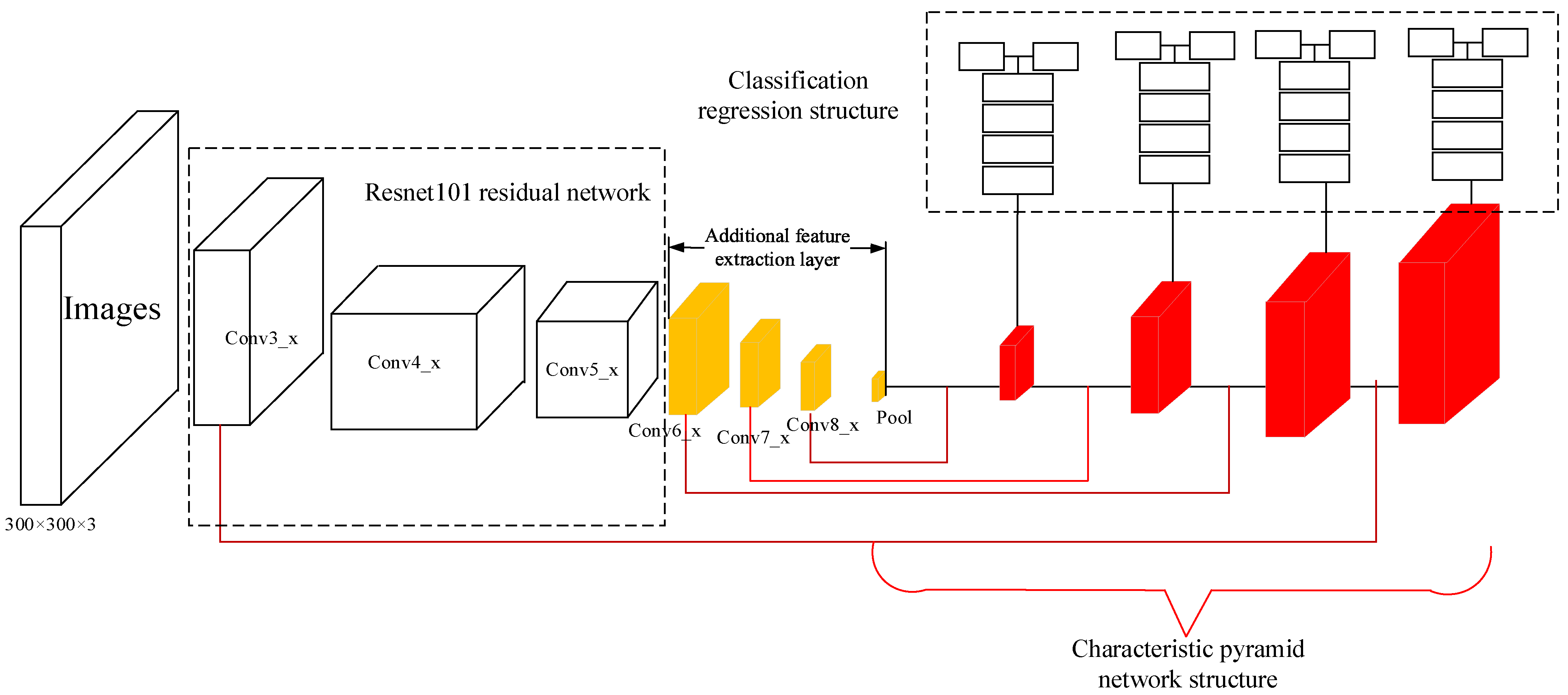

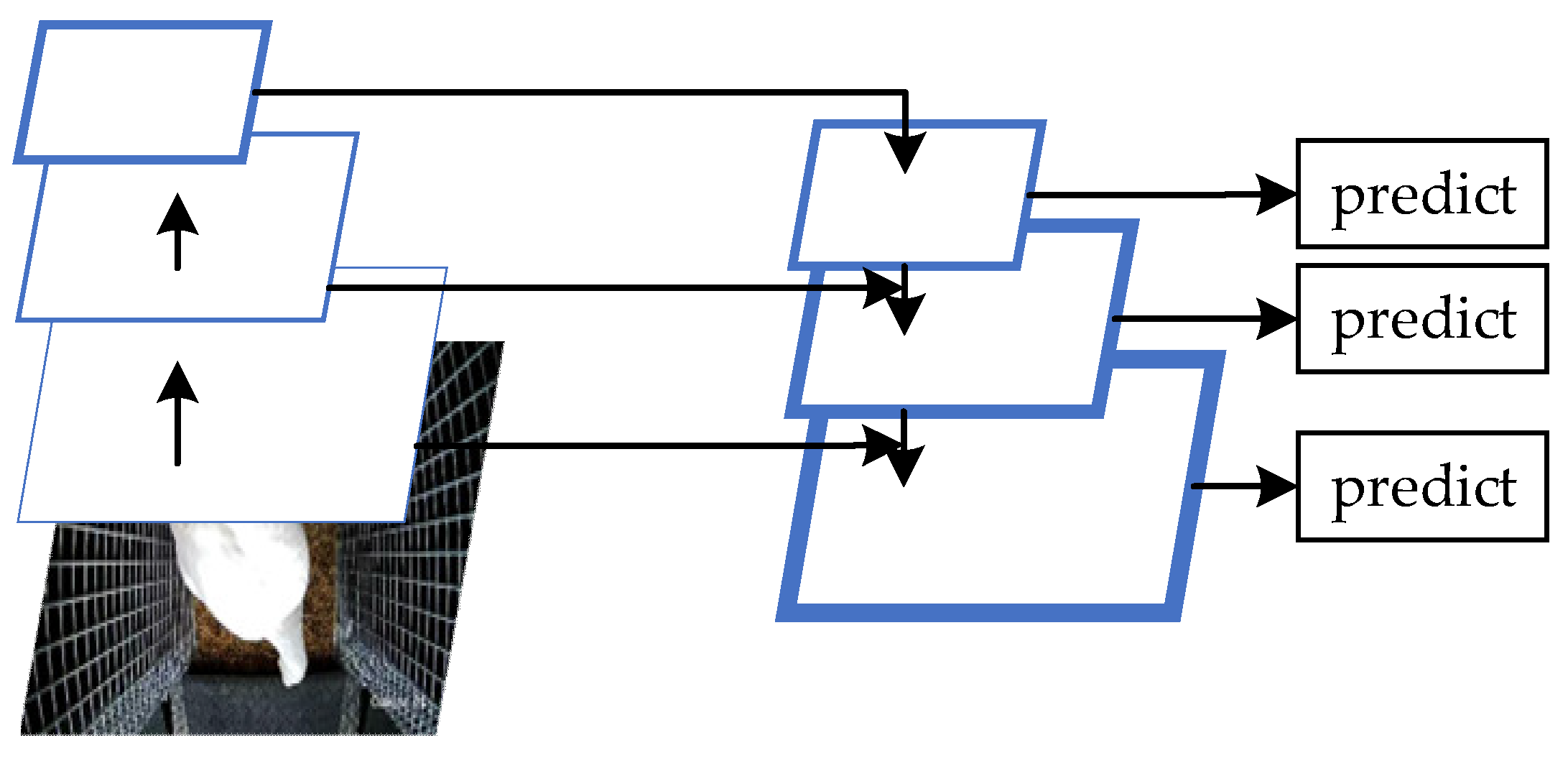

2.2. Target Detection Module

2.3. Transmission Coding Module

3. Results and Discussion

3.1. Characterization Test of Transmission Coding Module

3.2. Comparison of Target Detection Algorithms

3.3. Device Coding Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.F.; Zhu, W.Q.; Chen, K.W.; Xu, W.J.; Song, W. Two maternal origins of Chinese domestic goose. Poult. Sci. 2011, 90, 2705–2710. [Google Scholar] [CrossRef]

- Wang, J.; Hu, X.; Shen, Q. Research on Yangzhou Goose breeding system based on RFID. In Proceedings of the 2015 12th IEEE International Conference on Electronic Measurement & Instruments (ICEMI), Qingdao, China, 16–18 July 2015; pp. 1224–1227. [Google Scholar]

- Shi, Z.; Tian, Y.; Wu, W.; Wang, Z. Controlling reproductive seasonality in the geese: A review. World Poult. Sci. J. 2008, 64, 343–355. [Google Scholar] [CrossRef]

- Liu, G.J.; Chen, Z.F.; Zhao, X.H.; Li, M.Y.; Guo, Z.H. Meta-analysis: Supplementary artificial light and goose reproduction. Anim. Reprod. Sci. 2020, 214, 106278. [Google Scholar] [CrossRef]

- John, T.M.; George, J.C.; Scanes, C.G. Seasonal changes in circulating levels of luteinizing hormone and growth hormone in the migratory Canada goose. Gen. Comp. Endocrinol. 1983, 51, 44–49. [Google Scholar] [CrossRef]

- Luis, R.G.; Loredana, L. The role of RFID in agriculture: Applications, limitations and challenges. Comput. Electron. Agric. 2011, 79, 42–50. [Google Scholar]

- Felix, A.; Anita, K.; Florian, E.; Eva-Maria, H.; Max, S.; Sven, G.; Eva, G. Monitoring trough visits of growing-finishing pigs with UHF-RFID. Comput. Electron. Agric. 2018, 144, 144–153. [Google Scholar]

- Brown-Brandl, T.M.; Adrion, F.; Gallmann, E.; Eigenberg, R. Development and validation of a low-frequency RFID system for monitoring grow-finish pig feeding and drinking behavior. In Proceedings of the 10th International Livestock Environment Symposium (ILES X), Omaha, NE, USA, 25–27 September 2018. [Google Scholar] [CrossRef]

- Maselyne, J.; Saeys, W.; De Ketelaere, B.; Mertens, K.; Vangeyte, J.; Hessel, E.F.; Millet, S.; Van Nuffel, A. Validation of a high-frequency radio frequency identification (HF RFID) system for registering feeding patterns of growing-finishing pigs. Comput. Electron. Agric. 2014, 102, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Campbell, D.L.M.; Hinch, G.N.; Dyall, T.R.; Warin, L.; Little, B.A.; Lee, C. Outdoor stocking density in free-range laying hens: Radio frequency identification of impacts on range use. Animal 2017, 11, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Menzies, D.; Patison, K.P.; Corbet, N.J.; Swain, D.L. Using temporal associations to determine maternal parentage in extensive beef herds. Anim. Prod. Sci. 2018, 58, 943–949. [Google Scholar] [CrossRef]

- Barnes, A.L.; Wickham, S.L.; Admiraal, R.; Miller, D.W.; Collins, T.; Stockman, C.A.; Fleming, P.A. Characterization of inappetent sheep in a feedlot using radio-tracking technology. J. Anim. Sci. 2018, 96, 902–911. [Google Scholar] [CrossRef] [Green Version]

- Doughty, A.K.; Horton, B.J.; Huyen, N.T.D.; Ballagh, C.R.; Corkrey, R.; Hinch, C.N. The influence of lameness and individuality on movement patterns in sheep. Behav. Processes 2018, 151, 34–38. [Google Scholar] [CrossRef]

- Siegford, J.M.; Berezowski, J.; Biswas, S.K.; Daigle, C.L.; Gebhardt-Henrich, S.G.; Hernandez, C.E.; Thurner, S.; Toscano, M.J. Assessing Activity and Location of Individual Laying Hens in Large Groups Using Modern Technology. Animals 2016, 6, 10. [Google Scholar] [CrossRef]

- Burel, C.; Ciszuk, P.; Wiklund, B.S.; Brännäs, E.; Kiessling, A. Note on a method for individual recording of laying performance in groups of hens. Appl. Anim. Behav. Sci. 2002, 77, 167–171. [Google Scholar] [CrossRef]

- Icken, W.; Thurner, S.; Heinrich, A.; Kaiser, A.; Cavero, D.; Wendl, G.; Fries, R.; Schmutz, M.; Preisinger, R. Higher precision level at individual laying performance tests in noncage housing systems. Poult. Sci. 2013, 92, 2276–2282. [Google Scholar] [CrossRef]

- Chien, Y.R.; Chen, Y.X. An RFID-Based Smart Nest Box: An Experimental Study of Laying Performance and Behavior of Individual Hens. Sensors 2018, 18, 859. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.F.; Peng, W.P.; Chen, X. Architecture design of food supply chain traceability system based on internet of things. J. Appl. Sci. 2013, 3, 2848–2852. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, G.Y.; Lu, N.B. Information collection system of crop growth environment based on the Internet of things. Asian Agric. Res. 2013, 5, 148–150. [Google Scholar]

- Voulodimos, A.S.; Patrikakis, C.Z.; Sideridis, A.B.; Ntafis, V.A.; Xylouri, E.M. A complete farm management system based on animal identification using RFID technology. Comput. Electron. Agric. 2010, 70, 380–388. [Google Scholar] [CrossRef]

- Srbinovska, M.; Gavrovski, C.; Dimcev, V.; Krkoleva, A.; Borozan, V. Environmental Parameters Monitoring in Precision Agriculture Using Wireless Sensor Networks. J. Clean. Prod. 2015, 88, 297–307. [Google Scholar] [CrossRef]

- Mois, G.; Folea, S.; Sanislav, T. Analysis of Three IoT-Based Wireless Sensors for Environmental Monitoring. IEEE Trans. Instrum. Meas. 2017, 66, 2056–2064. [Google Scholar] [CrossRef]

- de Souza, R.S.; Lopes, J.L.B.; Geyer, C.F.R.; João, L.D.R.S.; Cardozo, A.A.; Yamin, A.C.; Gadotti, G.I.; Barbosa, J.L.V. Continuous monitoring seed testing equipaments using internet of things. Comput. Electron. Agric. 2019, 158, 122–132. [Google Scholar] [CrossRef]

- Bao, Q.; Yao, Y.; Weng, K.; Zheng, M.; Zhang, Y.; Zhang, Y.; Chen, G.; Xu, Q. Research Note: Comparison on laying behavior and clutch traits among Zhedong white geese (Anser cygnoides), Sichuan white geese (Anser cygnoides), and Hungarian geese (Anser anser). Poult. Sci. 2022, 101, 101594. [Google Scholar] [CrossRef]

- Zhu, H.; Shao, X.; Chen, Z.; Wei, C.; Lei, M.; Ying, S.; Yu, J.; Shi, Z. Induction of out-of-season egg laying by artificial photoperiod in Yangzhou geese and the associated endocrine and molecular regulation mechanisms. Anim. Reprod. Sci. 2017, 180, 127–136. [Google Scholar] [CrossRef]

- Yang, H.M.; Wang, Y.; Wang, Z.Y.; Wang, X.X. Seasonal and photoperiodic regulation of reproductive hormones and related genes in Yangzhou geese. Poult. Sci. 2017, 96, 486–490. [Google Scholar] [CrossRef]

- Wang, C.M.; Chen, L.R.; Lee, S.R.; Jea, Y.S.; Kao, J.Y. Supplementary artificial light to increase egg production of geese under natural lighting conditions. Anim. Reprod. Sci. 2009, 113, 317–321. [Google Scholar] [CrossRef]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the 2014 IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 23–28 June 2014; pp. 580–587. [Google Scholar]

- Girshick, R. Fast R-CNN. In Proceedings of the 2015 IEEE International Conference on Computer Vision (ICCV), Santiago, Chile, 7–13 December 2015; pp. 1440–1448. [Google Scholar]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You only look once: Unified, real-time object detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 779–788. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, faster, stronger. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 6517–6525. [Google Scholar]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. SSD: Single Shot MultiBox Detector. Eur. Conf. Comput. Vis. 2016, 9905, 21–37. [Google Scholar]

| Experience Group | A (°) | B (mm) | C (mm) | (%) |

|---|---|---|---|---|

| 1 | 60 | 75 | 600 | 96 |

| 2 | 30 | 90 | 550 | 96 |

| 3 | 60 | 75 | 500 | 92 |

| 4 | 60 | 82.5 | 550 | 98 |

| 5 | 60 | 82.5 | 550 | 98 |

| 6 | 60 | 82.5 | 550 | 98 |

| 7 | 90 | 75 | 550 | 92 |

| 8 | 60 | 90 | 600 | 98 |

| 9 | 90 | 82.5 | 500 | 98 |

| 10 | 30 | 75 | 550 | 96 |

| 11 | 30 | 82.5 | 600 | 100 |

| 12 | 60 | 90 | 500 | 96 |

| 13 | 60 | 82.5 | 550 | 98 |

| 14 | 30 | 82.5 | 500 | 98 |

| 15 | 60 | 82.5 | 550 | 98 |

| 16 | 90 | 90 | 550 | 96 |

| 17 | 90 | 82.5 | 600 | 98 |

| Models | AP (%) | MAP (%) | Speed (ms) | |

|---|---|---|---|---|

| Breeding Geese | Goose Eggs | |||

| Traditional SSD | 87.41% | 75.81% | 81.61% | 10.2 |

| Improved SSD | 92.58% | 87.94% | 90.26% | 72.8 |

| ID | Number of Collected Goose Eggs | Number of Coded Goose Eggs | Number of Qualified Eggs | Coding Success Rate |

|---|---|---|---|---|

| 1 | 21 | 21 | 21 | 100% |

| 2 | 23 | 23 | 22 | 95.7% |

| 3 | 22 | 22 | 21 | 95.5% |

| 4 | 18 | 18 | 18 | 100% |

| 5 | 19 | 19 | 19 | 100% |

| 6 | 24 | 24 | 23 | 95.8% |

| Average | 21.1 | 21.1 | 20.7 | 97.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Ge, Y.; Yang, T.; Guo, Y.; Yang, J.; Han, J.; Gong, D.; Miao, H. An IoT-Based Breeding Egg Identification and Coding System for Selection of High-Quality Breeding Geese. Animals 2022, 12, 1545. https://doi.org/10.3390/ani12121545

Zhang Y, Ge Y, Yang T, Guo Y, Yang J, Han J, Gong D, Miao H. An IoT-Based Breeding Egg Identification and Coding System for Selection of High-Quality Breeding Geese. Animals. 2022; 12(12):1545. https://doi.org/10.3390/ani12121545

Chicago/Turabian StyleZhang, Yanjun, Yujie Ge, Tian Yang, Yangyang Guo, Jian Yang, Jiawen Han, Daoqing Gong, and Hong Miao. 2022. "An IoT-Based Breeding Egg Identification and Coding System for Selection of High-Quality Breeding Geese" Animals 12, no. 12: 1545. https://doi.org/10.3390/ani12121545

APA StyleZhang, Y., Ge, Y., Yang, T., Guo, Y., Yang, J., Han, J., Gong, D., & Miao, H. (2022). An IoT-Based Breeding Egg Identification and Coding System for Selection of High-Quality Breeding Geese. Animals, 12(12), 1545. https://doi.org/10.3390/ani12121545