A Machine Vision-Based Method Optimized for Restoring Broiler Chicken Images Occluded by Feeding and Drinking Equipment

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

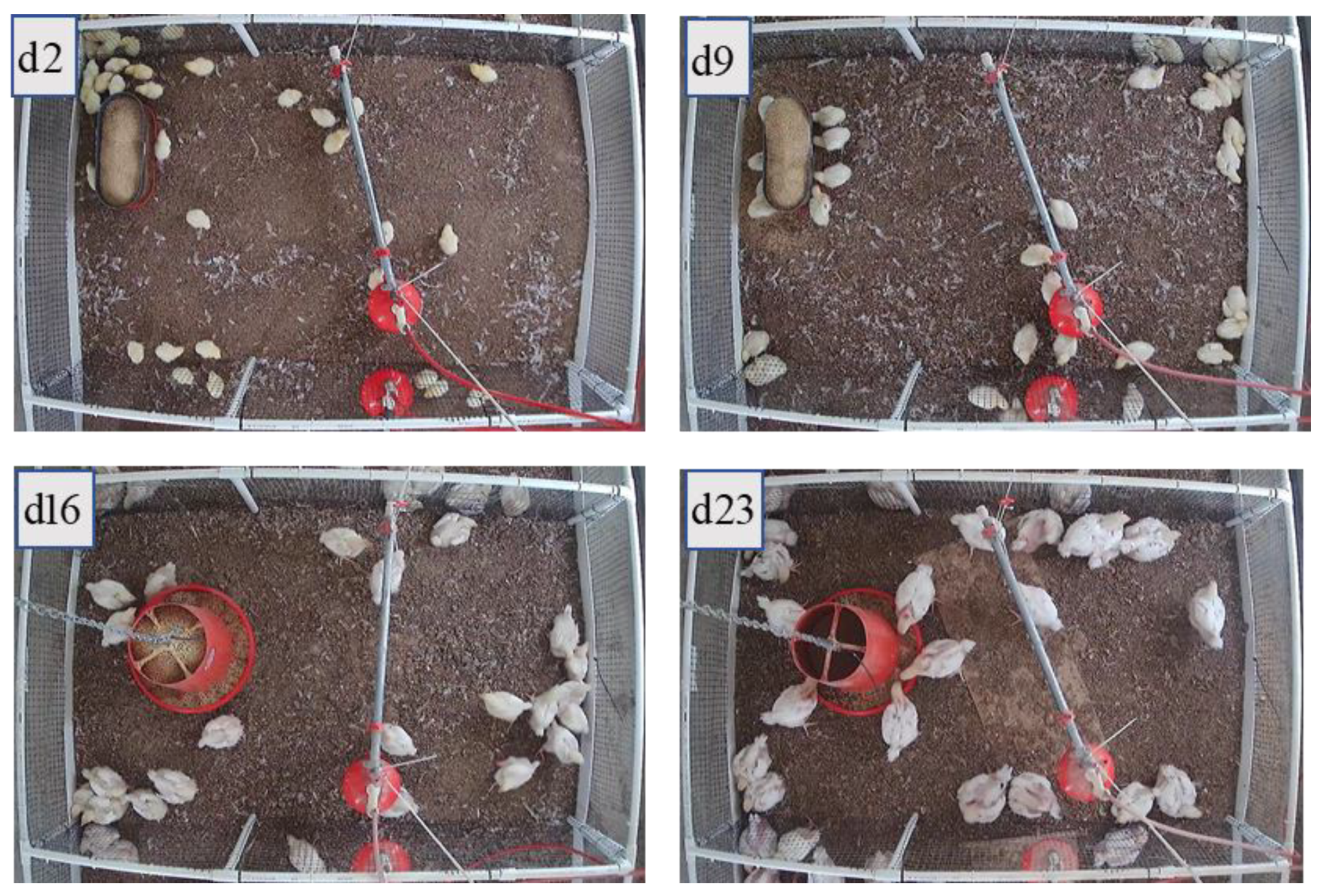

2.1. Experimental Setup and Data Collection

2.2. Method for Target Detection

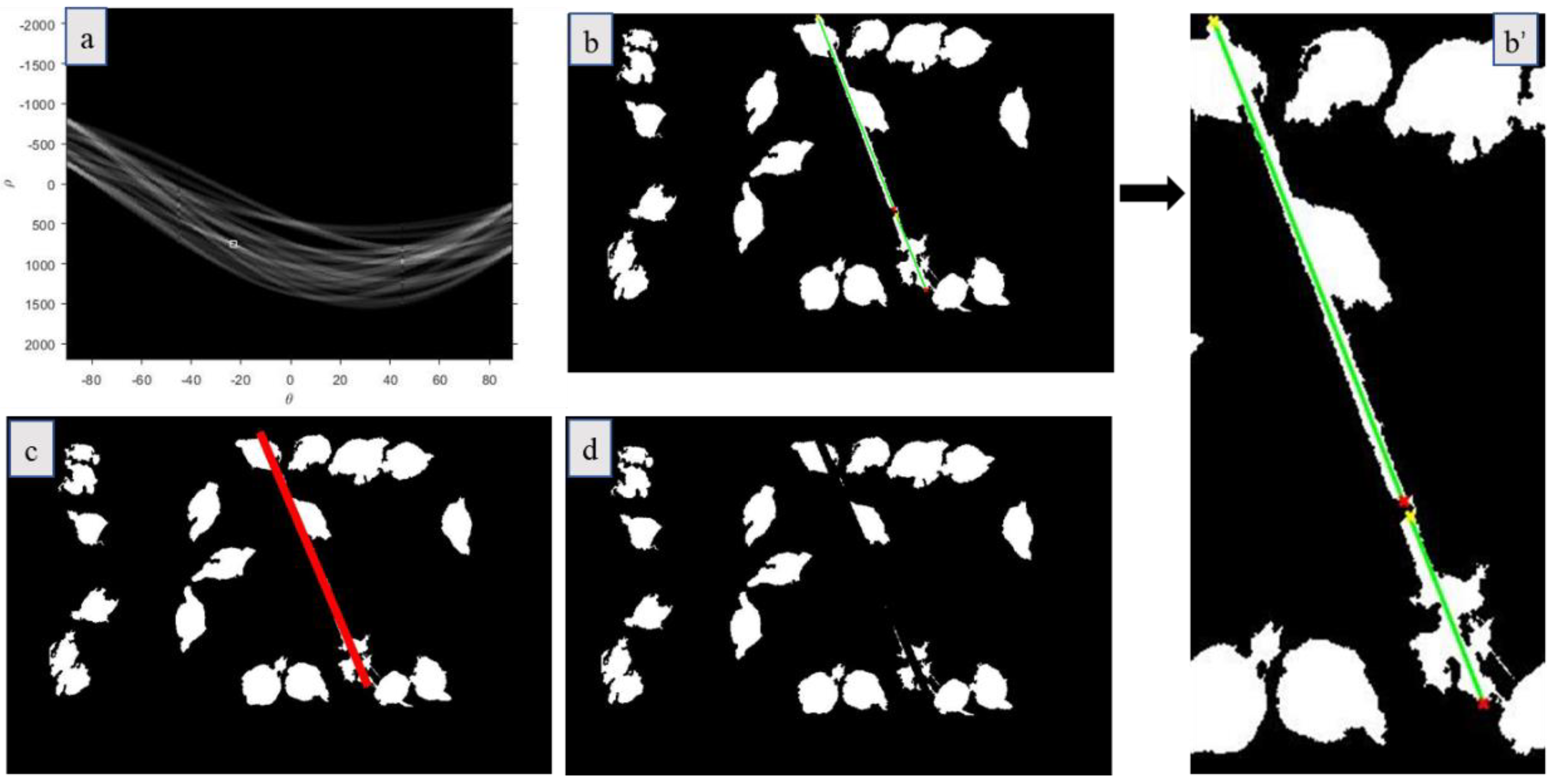

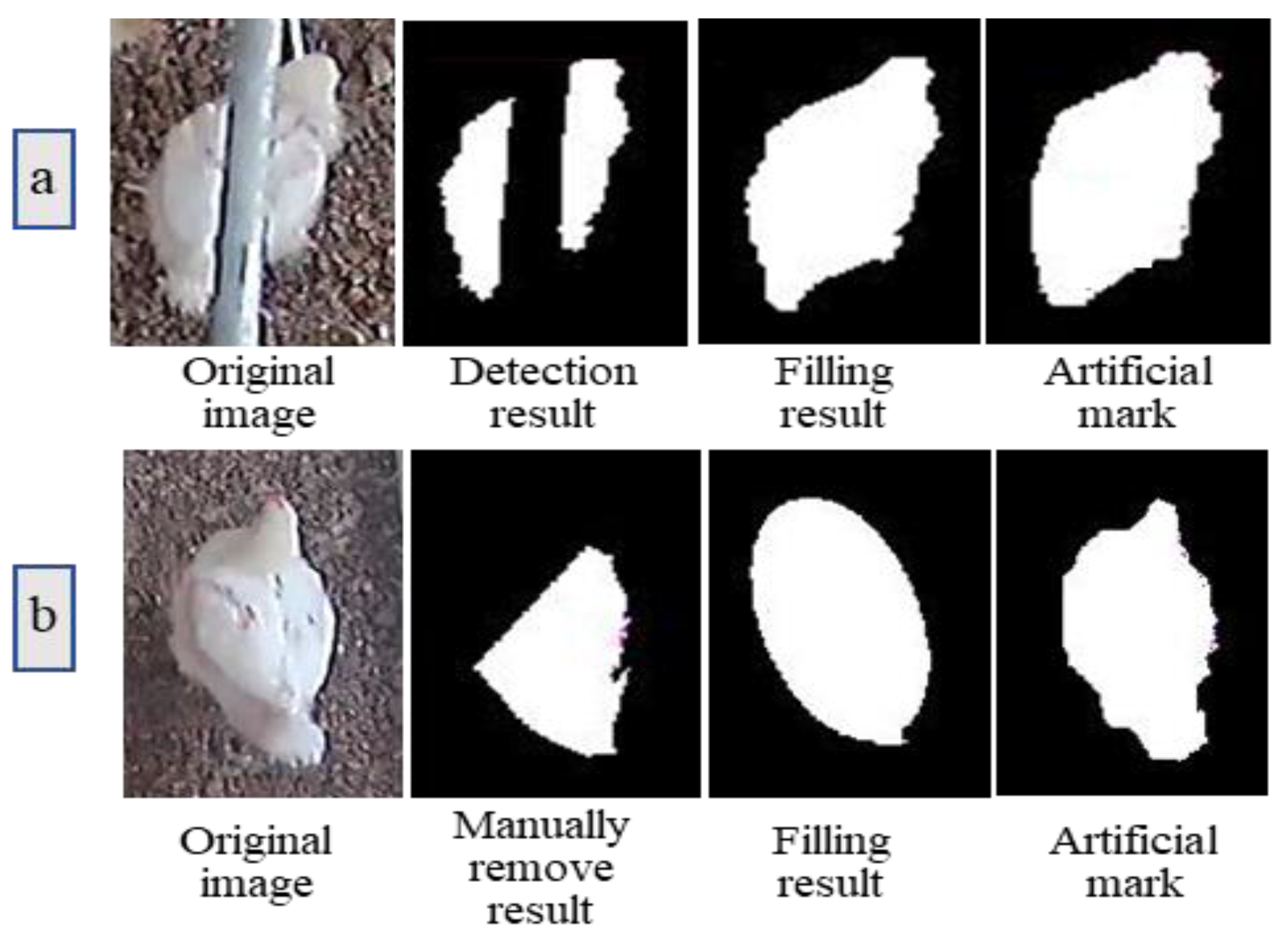

2.3. The Equipment Area Removal

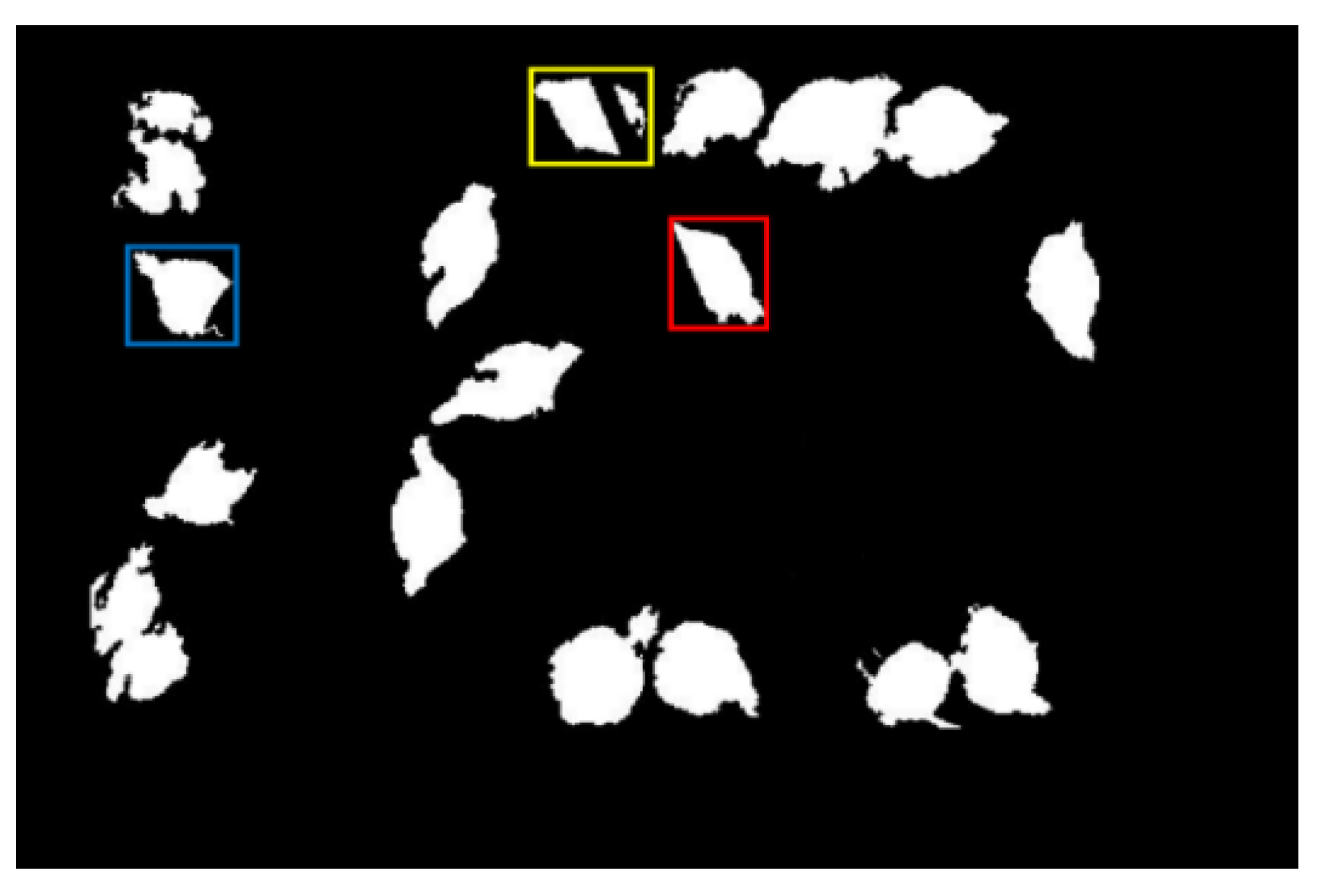

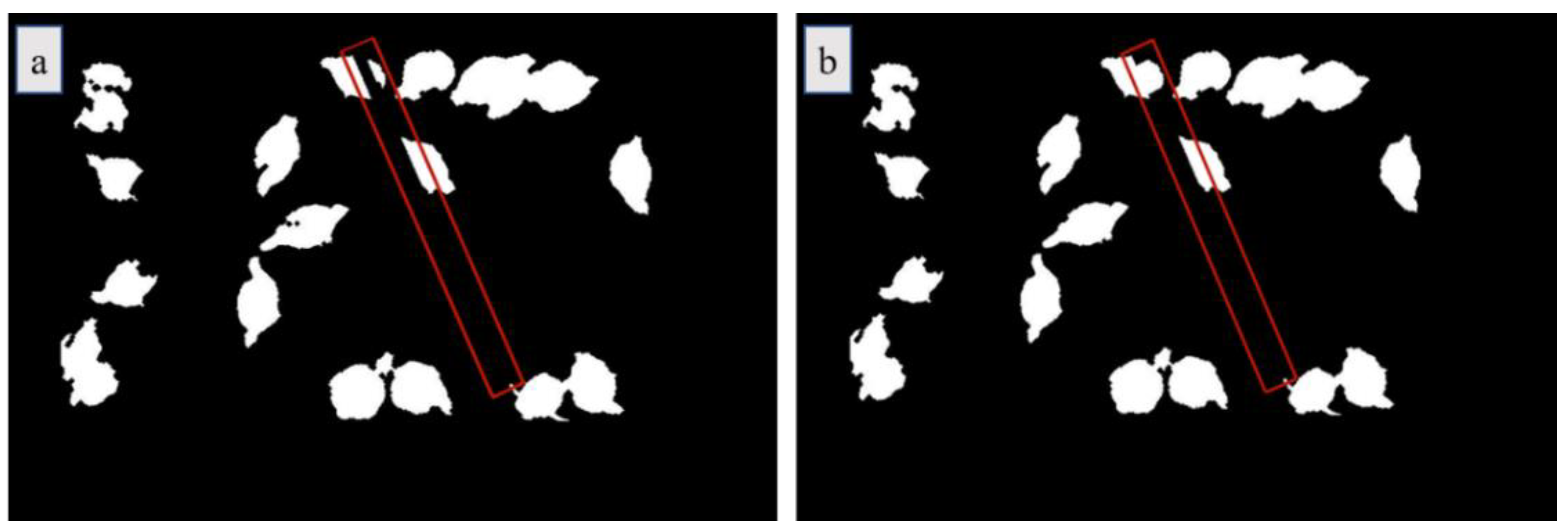

2.4. Equipment Occlusion Detection and Restoration

2.5. Evaluation Criteria and Statistical Analysis

3. Results and Discussion

3.1. Restoration Efficiency for Occluded Area

3.2. Performance of the Restoration Method

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, G.; Zhao, Y.; Purswell, J.L.; Du, Q.; Chesser, G.D., Jr.; Lowe, J.W. Analysis of feeding and drinking behaviors of group-reared broilers via image processing. Comput. Electron. Agric. 2020, 175, 105596. [Google Scholar] [CrossRef]

- Pereira, D.F.; Miyamoto, B.C.; Maia, G.D.; Sales, G.T.; Magalhães, M.M.; Gates, R.S. Machine vision to identify broiler breeder behavior. Comput. Electron. Agric. 2013, 99, 194–199. [Google Scholar] [CrossRef]

- Wang, J.; Wang, N.; Li, L.; Ren, Z. Real-time behavior detection and judgment of egg breeders based on YOLO v3. Neural Comput. Appl. 2020, 32, 5471–5481. [Google Scholar] [CrossRef]

- Li, G.; Ji, B.; Li, B.; Shi, Z.; Zhao, Y.; Dou, Y.; Brocato, J. Assessment of layer pullet drinking behaviors under selectable light colors using convolutional neural network. Comput. Electron. Agric. 2020, 172, 105333. [Google Scholar] [CrossRef]

- Zhuang, X.; Zhang, T. Detection of sick broilers by digital image processing and deep learning. Biosyst. Eng. 2019, 179, 106–116. [Google Scholar] [CrossRef]

- Okinda, C.; Lu, M.; Liu, L.; Nyalala, I.; Muneri, C.; Wang, J.; Zhang, H.; Shen, M. A machine vision system for early detection and prediction of sick birds: A broiler chicken model. Biosyst. Eng. 2019, 188, 229–242. [Google Scholar] [CrossRef]

- Neves, D.P.; Mehdizadeh, S.A.; Tscharke, M.; de Alencar Nääs, I.; Banhazi, T.M. Detection of flock movement and behaviour of broiler chickens at different feeders using image analysis. Inf. Process. Agric. 2015, 2, 177–182. [Google Scholar] [CrossRef]

- Fernandez, A.P.; Norton, T.; Tullo, E.; van Hertem, T.; Youssef, A.; Exadaktylos, V.; Vranken, E.; Guarino, M.; Berckmans, D. Real-time monitoring of broiler flock’s welfare status using camera-based technology. Biosyst. Eng. 2018, 173, 103–114. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, A.K.; Choi, C.H.; Kim, Y.J. Study on image-based flock density evaluation of broiler chicks. J. Korean Inst. Inf. Electron. Commun. Technol. 2019, 12, 373–379. [Google Scholar]

- Mortensen, A.K.; Lisouski, P.; Ahrendt, P. Weight prediction of broiler chickens using 3D computer vision. Comput. Electron. Agric. 2016, 123, 319–326. [Google Scholar] [CrossRef]

- Nakarmi, A.D.; Tang, L.; Xin, H. Automated tracking and behavior quantification of laying hens using 3D computer vision and radio frequency identification technologies. Trans. ASABE 2014, 57, 1455–1472. [Google Scholar]

- Nääs, I.A.; Garcia, R.G.; Caldara, F.R. Infrared thermal image for assessing animal health and welfare. JABB-Online Submiss. Syst. 2014, 2, 66–72. [Google Scholar] [CrossRef]

- Xiong, X.; Lu, M.; Yang, W.; Duan, G.; Yuan, Q.; Shen, M.; Norton, T.; Berckmans, D. An Automatic Head Surface Temperature Extraction Method for Top-View Thermal Image with Individual Broiler. Sensors 2019, 19, 5286. [Google Scholar] [CrossRef]

- Barbin, D.F.; Mastelini, S.M.; Barbon Jr, S.; Campos, G.F.; Barbon, A.P.A.; Shimokomaki, M. Digital image analyses as an alternative tool for chicken quality assessment. Biosyst. Eng. 2016, 144, 85–93. [Google Scholar] [CrossRef]

- Mehdizadeh, S.A.; Neves, D.P.; Tscharke, M.; Nääs, I.A.; Banhazi, T.M. Image analysis method to evaluate beak and head motion of broiler chickens during feeding. Comput. Electron. Agric. 2015, 114, 88–95. [Google Scholar] [CrossRef]

- Xiao, L.; Ding, K.; Gao, Y.; Rao, X. Behavior-induced health condition monitoring of caged chickens using binocular vision. Comput. Electron. Agric. 2019, 156, 254–262. [Google Scholar] [CrossRef]

- Aydin, A. Using 3D vision camera system to automatically assess the level of inactivity in broiler chickens. Comput. Electron. Agric. 2017, 135, 4–10. [Google Scholar] [CrossRef]

- Zaninelli, M.; Redaelli, V.; Luzi, F.; Bontempo, V.; Dell’Orto, V.; Savoini, G. A monitoring system for laying hens that uses a detection sensor based on infrared technology and image pattern recognition. Sensors 2017, 17, 1195. [Google Scholar] [CrossRef]

- Guo, Y.; Chai, L.; Aggrey, S.E.; Oladeinde, A.; Johnson, J.; Zock, G. A Machine Vision-Based Method for Monitoring Broiler Chicken Floor Distribution. Sensors 2020, 20, 3179. [Google Scholar] [CrossRef]

- Lao, F.; Teng, G.; Li, J.; Yu, L.; Li, Z. Behavior recognition method for individual laying hen based on computer vision. Trans. Chin. Soc. Agric. Eng. 2012, 28, 157–163. [Google Scholar]

- Amraei, S.; Abdanan Mehdizadeh, S.; Salari, S. Broiler weight estimation based on machine vision and artificial neural network. Br. Poult. Sci. 2017, 58, 200–205. [Google Scholar] [CrossRef]

- Poursaberi, A.; Wichman, A.; Bahr, C.; Laura, H.Ã.; Pastell, M.; Berckmans, D. Automatic monitoring of turkeys: A vision-based approach to detect and analyse the behaviour of turkeys in transport cages based on ellipse fitting. In Proceedings of the 7th World Congress on Computers in Agriculture Conference Proceedings, Reno, NV, USA, 22–24 June 2009. [Google Scholar]

- Liu, Z.; Liu, X.; Duan, G.; Tan, J. A real-time and precise ellipse detector via edge screening and aggregation. Mach. Vision. Appl. 2020, 31, 1–23. [Google Scholar] [CrossRef]

- Dong, H.; Prasad, D.K.; Chen, I.M. Accurate detection of ellipses with false detection control at video rates using a gradient analysis. Pattern Recogn. 2018, 81, 112–130. [Google Scholar] [CrossRef]

- Aggarwal, N.; Karl, W.C. Line detection in images through regularized Hough transform. IEEE Trans. Image Process. 2006, 15, 582–591. [Google Scholar] [CrossRef]

- Fitzgibbon, A.; Pilu, M.; Fisher, R.B. Direct least square fitting of ellipses. IEEE Trans. Pattern Anal. 1999, 21, 476–480. [Google Scholar] [CrossRef]

- Rosin, P.L. Further five-point fit ellipse fitting. Graph. Model. Image Process. 1999, 61, 245–259. [Google Scholar] [CrossRef]

- Guo, Y.; He, D.; Song, H. Region detection of lesion area of knee based on colour edge detection and bilateral projection. Biosyst. Eng. 2018, 173, 19–31. [Google Scholar] [CrossRef]

| Occlusion Type | d2 | d9 | d16 | d23 | ||||

|---|---|---|---|---|---|---|---|---|

| BFarea/INaera | AFarea/INaera | BFarea/INaera | AFarea/INaera | BFarea/INaera | AFarea/INaera | BFarea/INaera | AFarea/INaera | |

| TA | 0.4357 | 0.9706 | 0.4971 | 0.9687 | 0.6299 | 0.9637 | 0.6747 | 0.9512 |

| OA | 0.4773 | 1.2008 | 0.4518 | 0.9445 | 0.5077 | 1.009 | 0.6962 | 1.1017 |

| Evaluation Indices | Occlusion Type | d2 | d9 | d16 | d23 | Average |

|---|---|---|---|---|---|---|

| OR | TA | 0.7265 a | 0.8240 b | 0.8593 c | 0.8502 c | 0.8150 |

| OA | 0.9106 a | 0.8480 a | 0.8673 a | 0.8834 a | 0.8788 | |

| FPR | TA | 0.0022 a | 0.0076 b | 0.0031 c | 0.0002 d | 0.0032 |

| OA | 0.2963 a | 0.2216 ab | 0.2064 ab | 0.1665 b | 0.2227 | |

| FNR | TA | 0.2735 a | 0.1760 b | 0.1407 c | 0.1498 c | 0.1850 |

| OA | 0.0894 a | 0.1520 a | 0.1327 a | 0.1166 a | 0.1212 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Aggrey, S.E.; Oladeinde, A.; Johnson, J.; Zock, G.; Chai, L. A Machine Vision-Based Method Optimized for Restoring Broiler Chicken Images Occluded by Feeding and Drinking Equipment. Animals 2021, 11, 123. https://doi.org/10.3390/ani11010123

Guo Y, Aggrey SE, Oladeinde A, Johnson J, Zock G, Chai L. A Machine Vision-Based Method Optimized for Restoring Broiler Chicken Images Occluded by Feeding and Drinking Equipment. Animals. 2021; 11(1):123. https://doi.org/10.3390/ani11010123

Chicago/Turabian StyleGuo, Yangyang, Samuel E. Aggrey, Adelumola Oladeinde, Jasmine Johnson, Gregory Zock, and Lilong Chai. 2021. "A Machine Vision-Based Method Optimized for Restoring Broiler Chicken Images Occluded by Feeding and Drinking Equipment" Animals 11, no. 1: 123. https://doi.org/10.3390/ani11010123

APA StyleGuo, Y., Aggrey, S. E., Oladeinde, A., Johnson, J., Zock, G., & Chai, L. (2021). A Machine Vision-Based Method Optimized for Restoring Broiler Chicken Images Occluded by Feeding and Drinking Equipment. Animals, 11(1), 123. https://doi.org/10.3390/ani11010123