Sizing Milking Groups in Small Cow Dairies of Mediterranean Countries

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Preliminary Assumptions

2.2. Milking Extraction Time (Milk Flow Time)

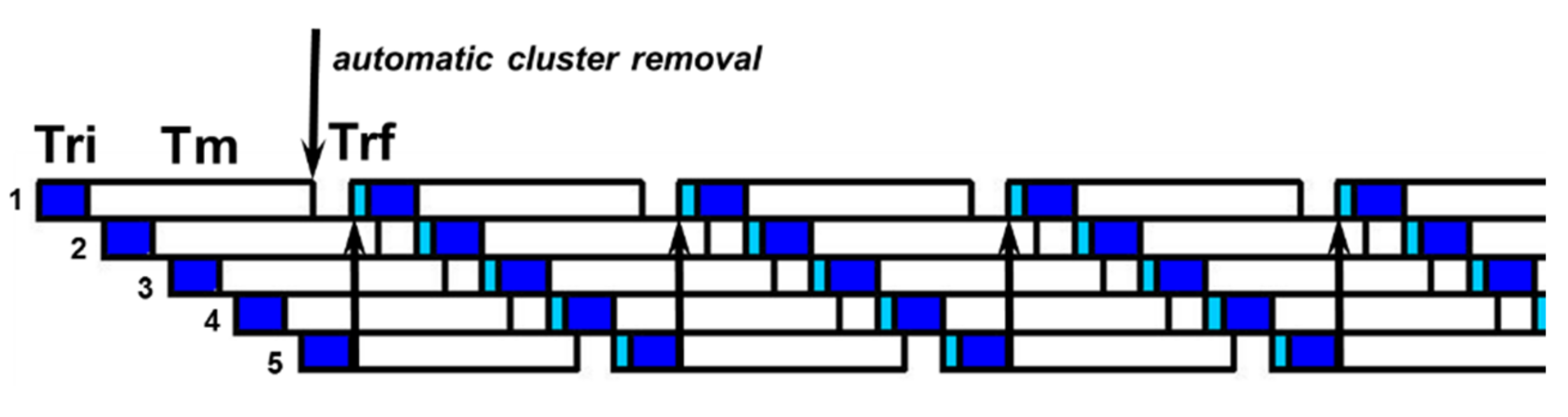

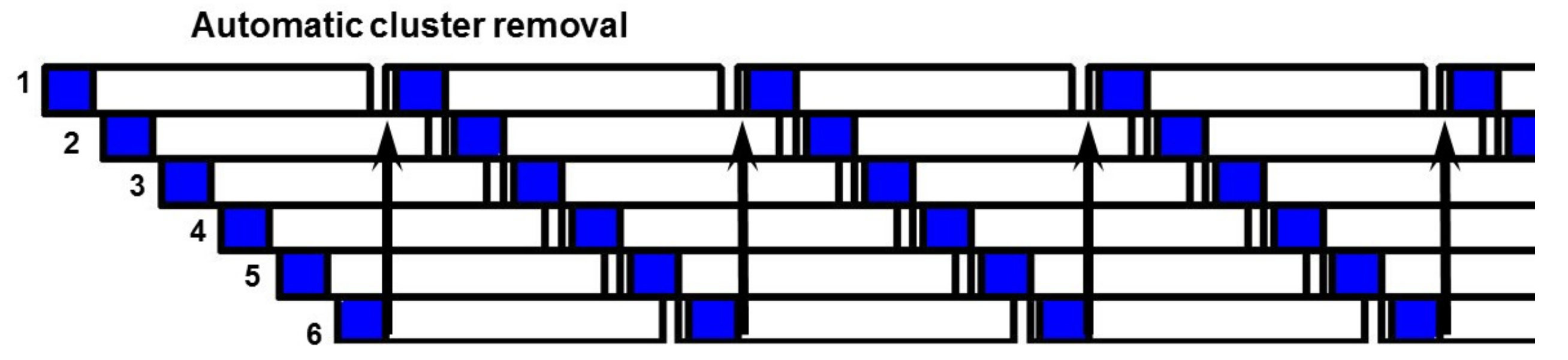

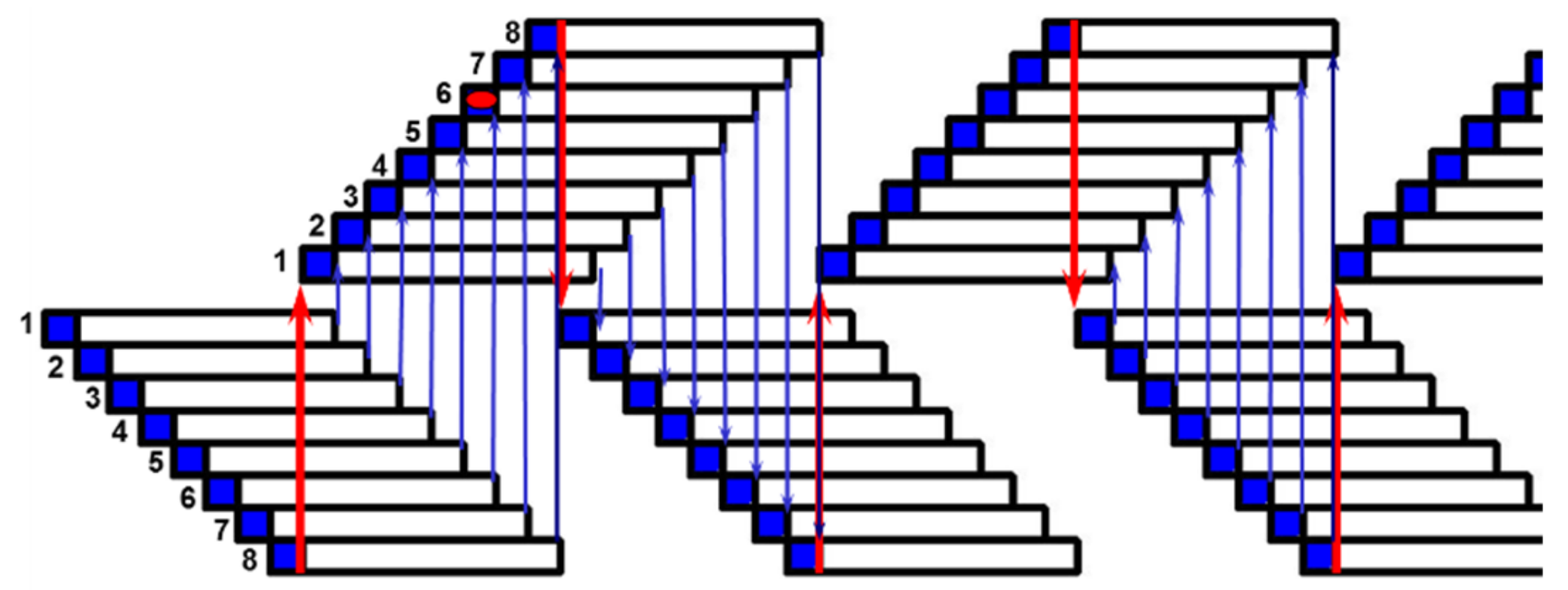

2.3. Milking Routine: Definitions

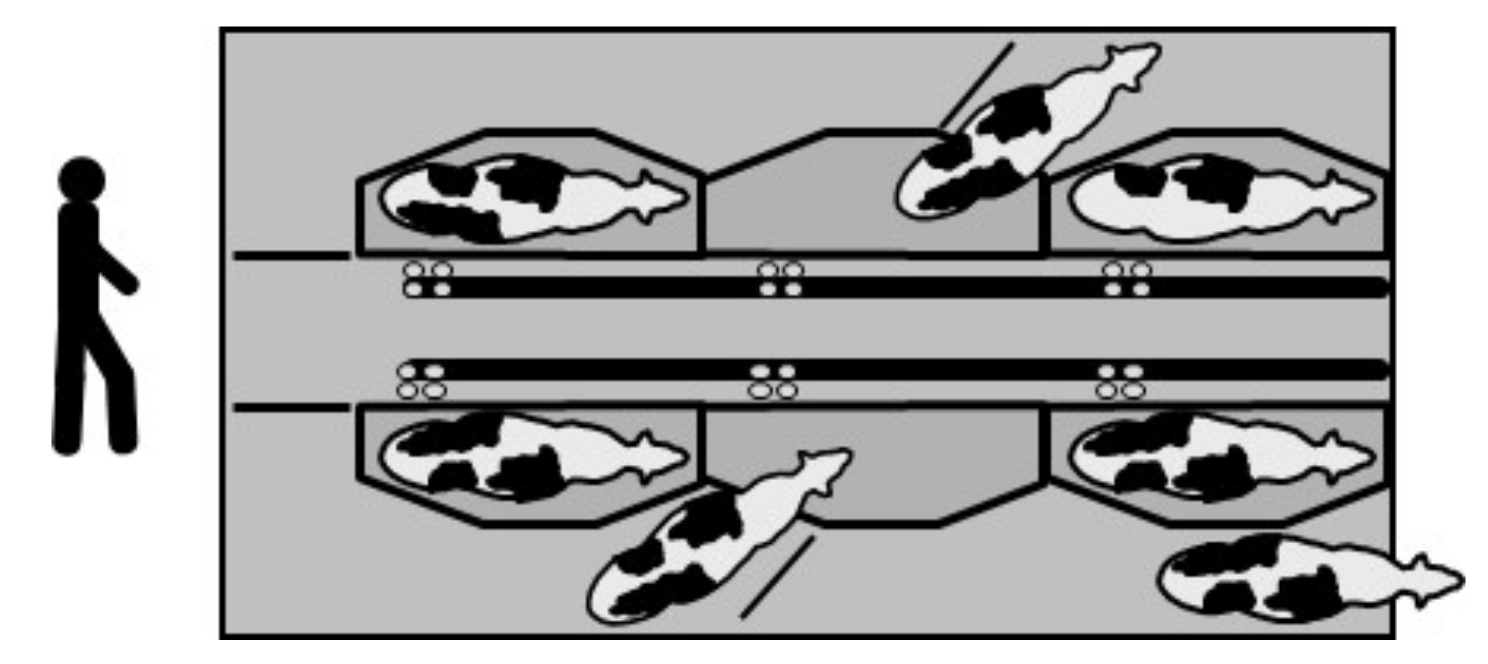

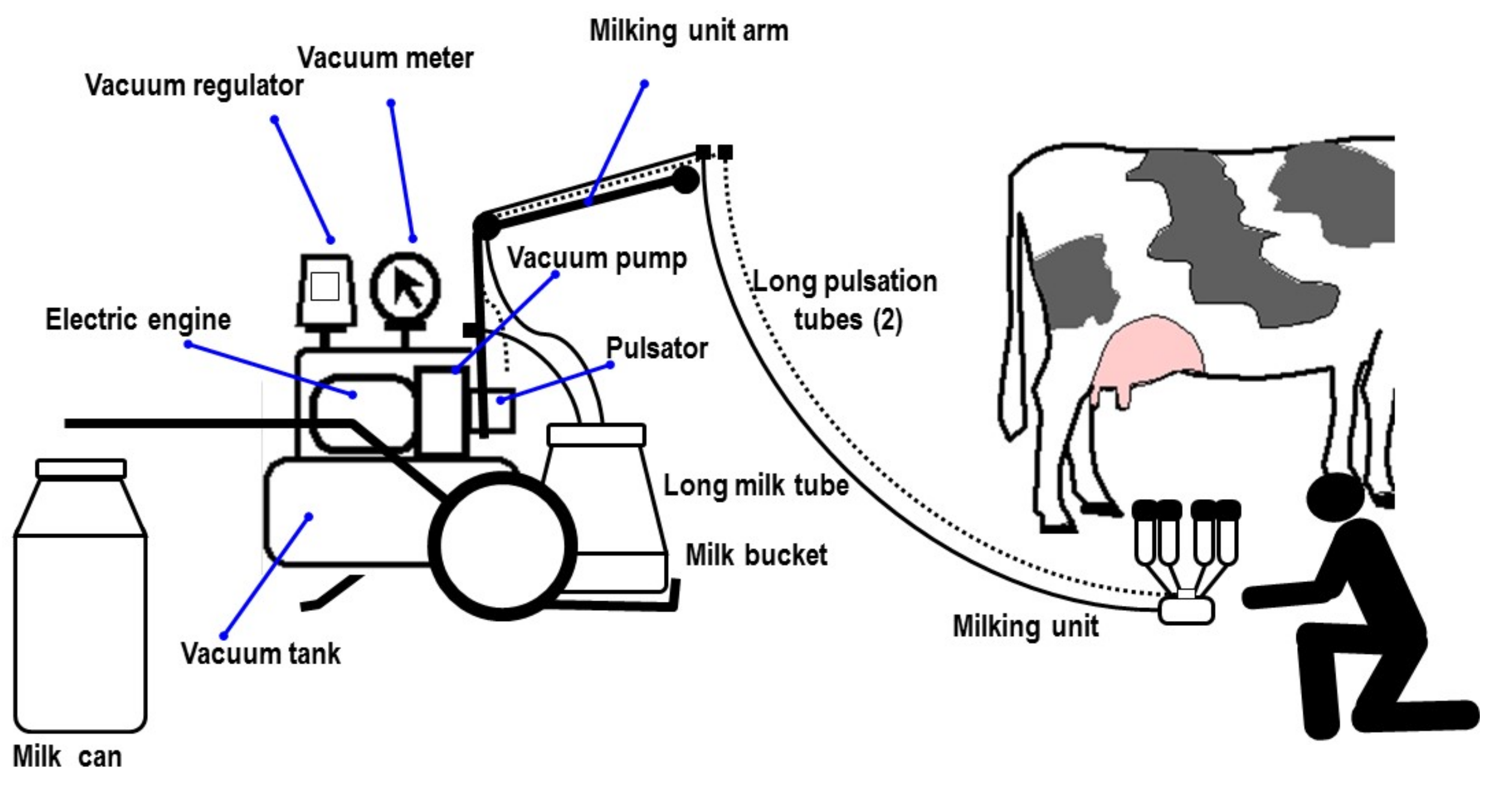

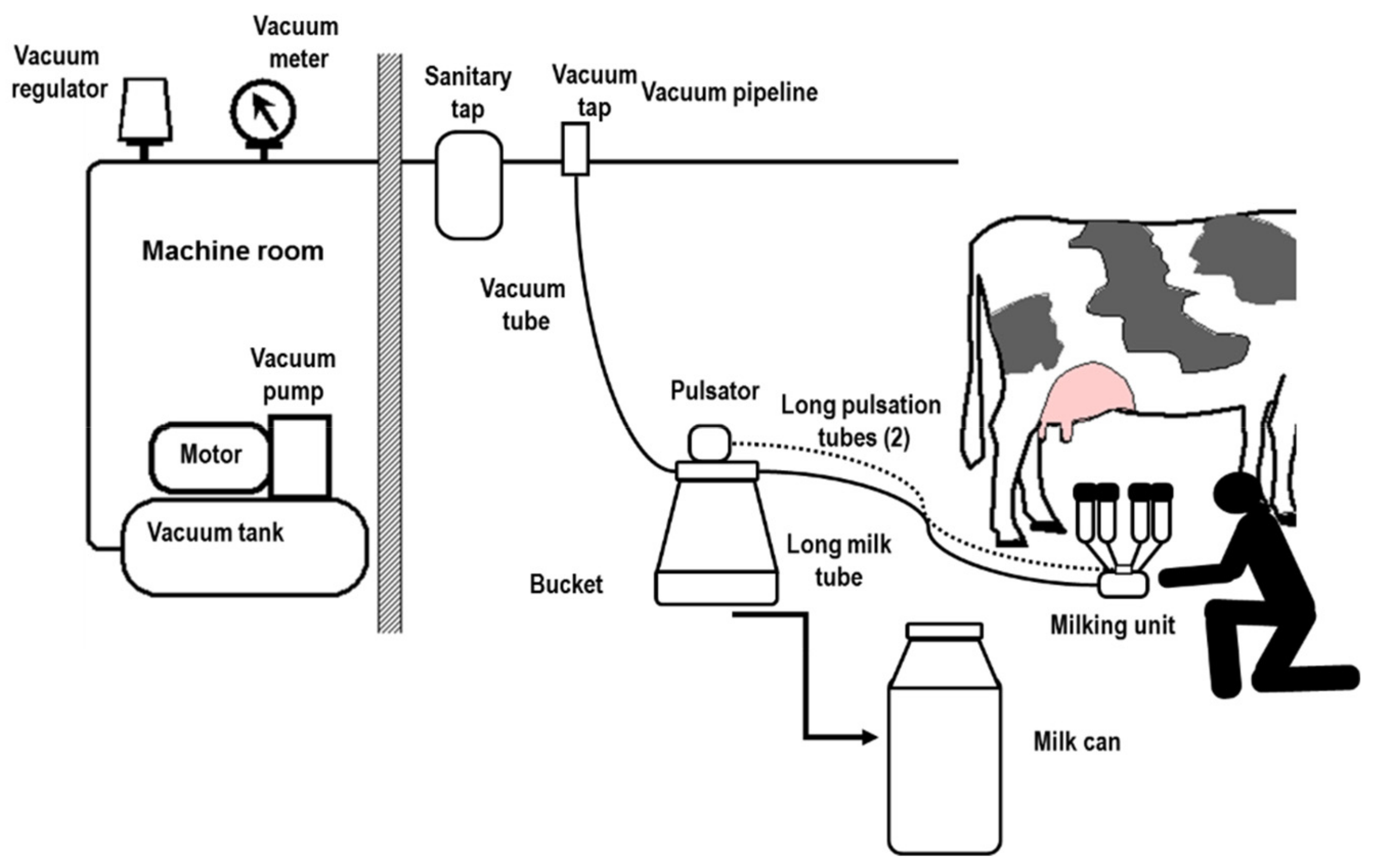

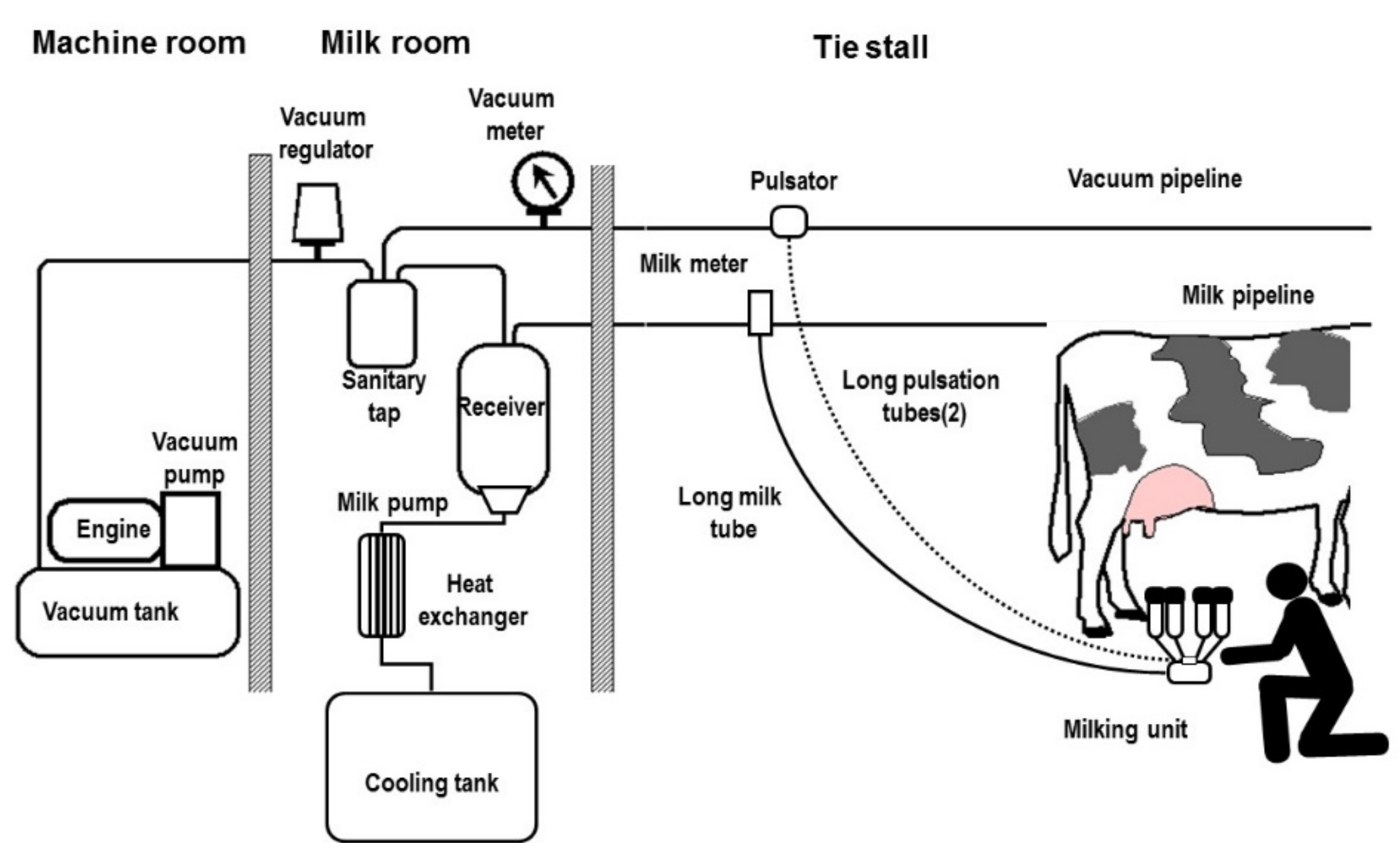

2.4. Inspected Milking Systems: Tethering Cows

2.5. Inspected Milking Systems: Little Parlors

2.5.1. Tandem (Side-Opening) and Autotandem

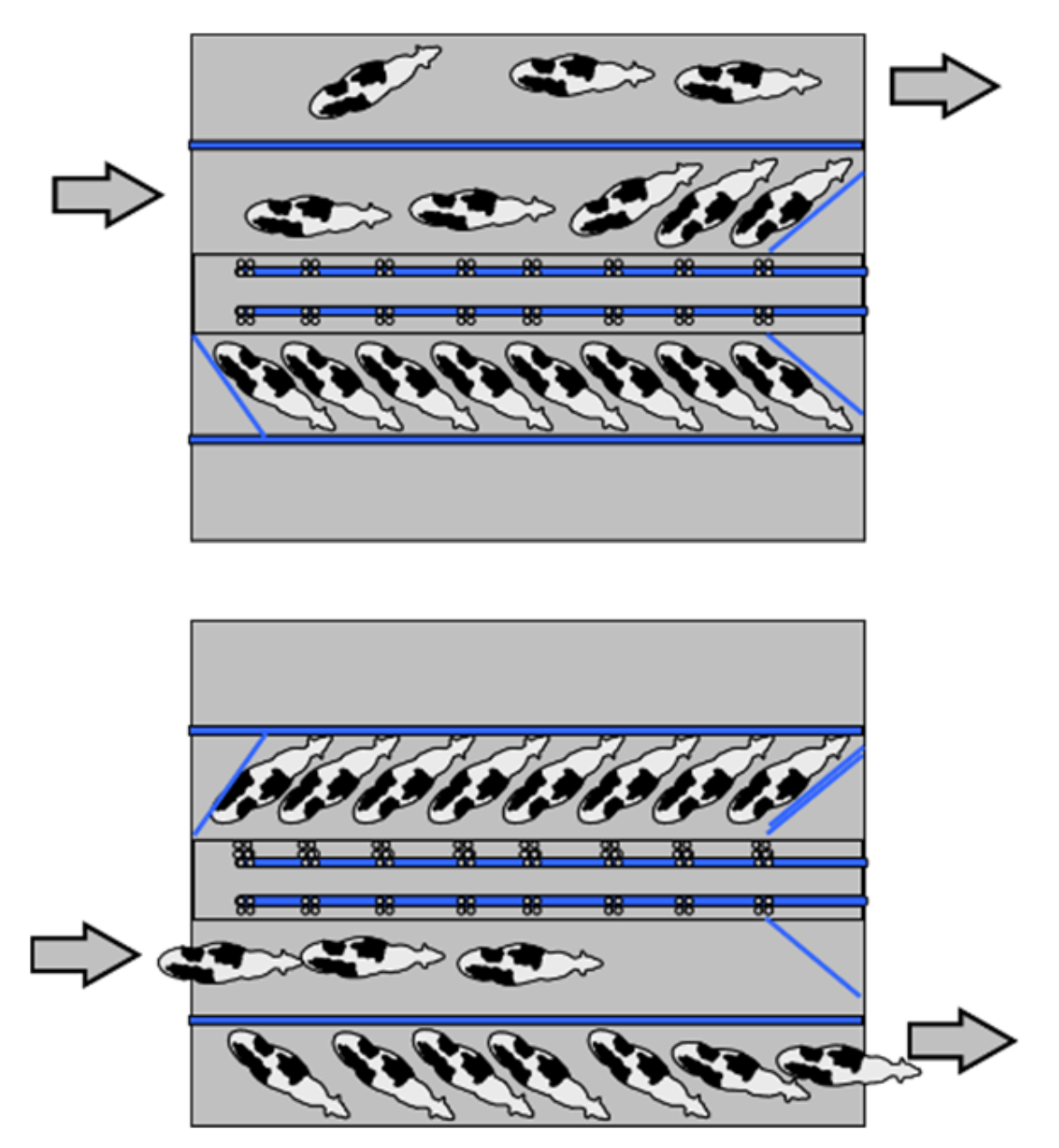

2.5.2. Herringbone

2.5.3. Parallel

2.6. Study of the Models

2.7. Data Elaboration

3. Results

3.1. Tie-Stalls

3.1.1. Trolley

3.1.2. Bucket

3.1.3. Milk-Line

3.2. Parlor

3.2.1. Autotandem (Side-Open) with Automatic Milking Cluster Removal

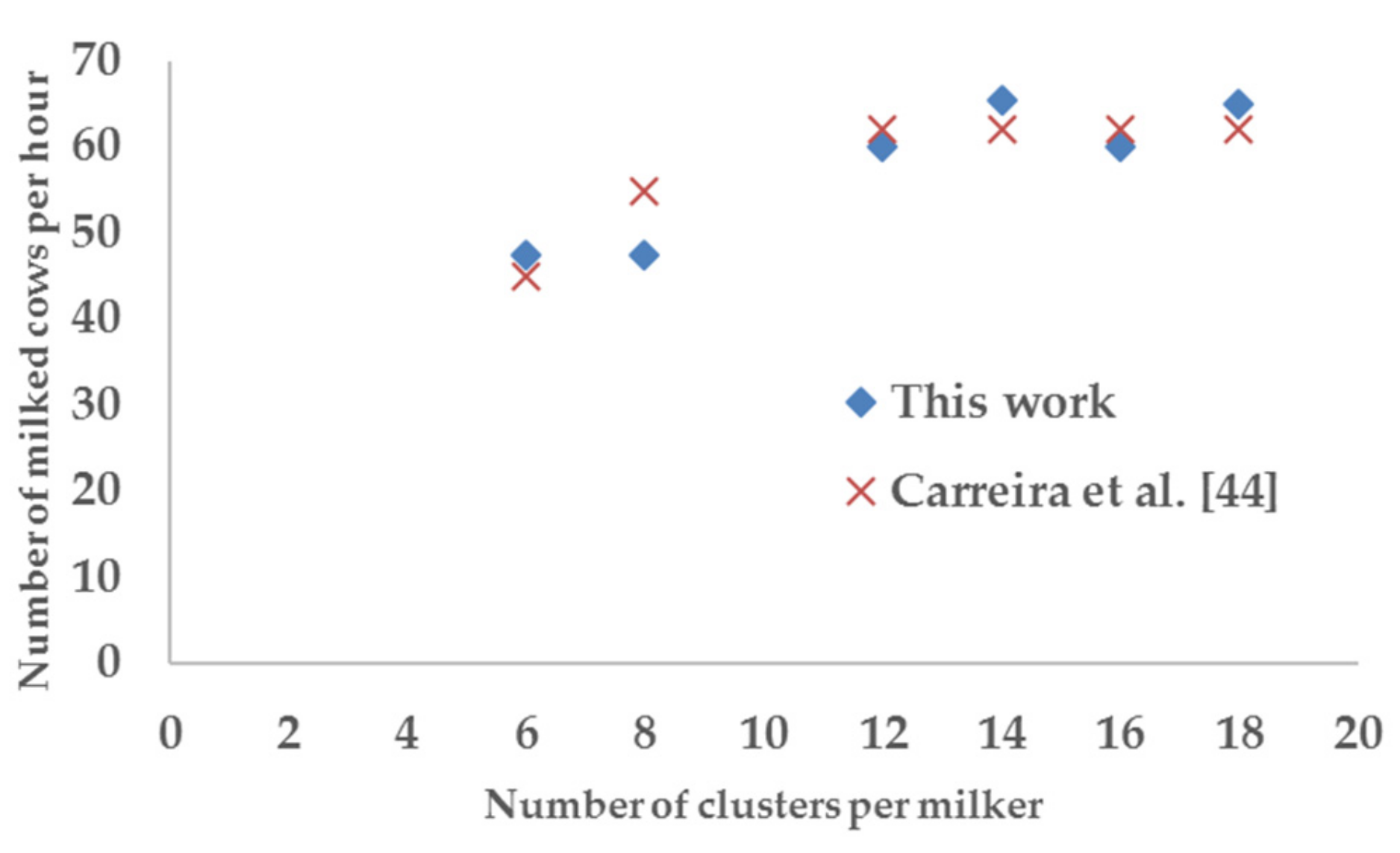

3.2.2. Herringbone and Parallel Parlors

3.3. The Examined Dairy Farms

3.3.1. Tie-Stall Dairy Farms

3.3.2. Dairy Farms with Parlors

3.3.3. Differences in the Observed Routines

4. Discussion

4.1. Tie-Stall

4.2. Herringbone and Parallel Parlors

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Burks, T.F.; Turner, L.W.; Gates, R.S.; Bridges, T.C.; Crist, W.L. A stochastic simulation model for predicting cow throughputs in dairy parlors. Trans. ASAE 1998, 41, 1789–1797. [Google Scholar] [CrossRef]

- Bickert, W.G.; Speicher, J.A.; Armstrong, D.V. Milking systems for large herds. J. Dairy Sci. 1974, 57, 369–377. [Google Scholar] [CrossRef]

- Armstrong, D.V.; Quick, A.J. Time and motion to measure milking parlor performance. J. Dairy Sci. 1984, 69, 1169–1177. [Google Scholar] [CrossRef]

- Blake, R.W.; Mcdaniel, B.T. Relationships among rates of milk flow, machine time, udder conformation, and management aspects of milking efficiency: A review. J. Dairy Sci. 1978, 61, 363–378. [Google Scholar] [CrossRef]

- Smith, J.F.; Armstrong, D.V.; Gamroth, M.J. Labor management considerations in selecting milking parlor type & size. In Proceedings of the Western Dairy Management Conference, Las Vegas, NV, USA, 13–15 March 1997; pp. 43–49. [Google Scholar]

- Thomas, C.V.; DeLorenzo, M.A.; Bray, D.R. Prediction of individual cow milking time for milking parlor simulation models. J. Dairy Sci. 1993, 76, 2184–2194. [Google Scholar] [CrossRef]

- Chang, W.; Barry, M.C.; Jones, L.R.; Merrill, W.G. A computerized milking parlor evaluation system. J. Dairy Sci. 1992, 75, 2578–2586. [Google Scholar] [CrossRef]

- Chang, W.; Streeter, D.H.; Jones, L.R. An object-oriented model for simulating milking parlor operations. J. Dairy Sci. 1994, 77, 84–93. [Google Scholar] [CrossRef]

- Thomas, C.V.; DeLorenzo, M.A.; Bray, D.R. A network simulation model of large herringbone and parallel milking parlors. J. Dairy Sci. 1996, 79, 1960–1971. [Google Scholar] [CrossRef]

- Price, D.R.; Heathington, K.W.; Peart, R.M. Computer simulation of dairy milking parlors. Trans. Amer. Soc. Agr. Eng. 1972, 15, 317–319. [Google Scholar] [CrossRef]

- Micke, C.F.; Appleman, R.D. Simulating herringbone and side-opening milking parlor operations. J. Dairy Sci. 1973, 56, 1063–1069. [Google Scholar] [CrossRef]

- Bickert, W.G.; Gerrish, J.B.; Hurt, J.H. Simulated milking rates in various semi-automatic milking parlors. Trans. Am. Soc. Agric. Eng. 1972, 15, 482–489. [Google Scholar] [CrossRef]

- Wagner, A.; Palmer, R.W.; Bewley, J.; Jackson-Smith, D.B. Producer satisfaction, efficiency, and investment cost factors of different milking systems. J. Dairy Sci. 2001, 84, 1890–1898. [Google Scholar] [CrossRef]

- Thomas, C.V.; DeLorenzo, M.A.; Bray, D.R.; Weldon, R.N.; Bucklin, R.A.; Martin, J.G., III. A stochastic economic analysis of large herringbone and parallel milking parlors. J. Dairy Sci. 1997, 80, 2418–2428. [Google Scholar] [CrossRef]

- Blowey, R.; Edmondson, P. The milking routine and its effect on mastitis. In Mastitis Control in Dairy Herds, Chapter 6; Farming Press Books: Ipswich, UK, 1995; pp. 83–86. [Google Scholar]

- Baines, J.R. The role of machine milking in quality milk production and ensuring dairy cow welfare. Cattle Pract. 2010, 18, 48–52. [Google Scholar]

- Smith, J.F.; Armstrong, D.V.; Gamroth, M.J.; Harner, J., III. Factors affecting milking parlor efficiency and operator walking distance. Appl. Eng. Agric. 1998, 14, 643–650. [Google Scholar] [CrossRef]

- Hamann, J.; Dodd, F.H. Milking routines. In Machine Milking and Lactation, Chapter 3; Bramley, A.J., Dodd, F.H., Mein, G.A., Bramley, J.A., Eds.; Insight Books: Berkshire, UK, 1992; pp. 69–96. [Google Scholar]

- Reneau, J.K.; Farnsworth, R.J.; Johnson, D.G. Practical milking routines. In Proceedings of the National Mastitis Council Regional Meeting, East Lansing, MI, USA, 18 August 1994; pp. 22–32. [Google Scholar]

- Nitzan, R.; Bruckental, I.; Bar Shira, Z.; Maltz, E.; Halachmi, I. Stochastic models for simulating parallel, rotary, and side-opening milking parlors. J. Dairy Sci. 2006, 89, 4462–4472. [Google Scholar] [CrossRef]

- Hatem, M.; Samer, M.; Grimm, H.; Doluschitz, R.; Jungbluth, T. An expert system for planning and designing corral systems and their concrete constructions for dairy farms in hot climates. In Proceedings of the CIGR Workshop Section II: “Animal Housing in Hot Climates”, CIGR Working Group 13 & China Agricultural University, Chongqing, China, 22–25 October 2009. [Google Scholar]

- Armstrong, D.V.; Gamroth, M.J.; Smith, J.F. Milking Parlor Performance. In Proceedings of the Western Dairy Management Conference, Las Vegas, NV, USA, 4–6 April 2001; pp. 7–12. [Google Scholar]

- Krumm, A.; Hartmut, G.; Ordloff, D. Working times and milking capacity in Swingover Parlours. Landtechnik 2004, 6, 42–343. [Google Scholar]

- Herd, D.; Seufert, H. Work organization in large parallel or herringbone milking Parlours. Landtechnik 2007, 2, 110–111. [Google Scholar]

- Smith, J.F.; Armstrong, D.V.; Gamroth, M.J.; Martin, J.G. Planning the milking center in expanding dairies. J. Dairy Sci. 1997, 80, 1866–1871. [Google Scholar] [CrossRef]

- Graeme, A.M.; Reinemann, D.J. Machine Milking; CreateSpace: Scotts Valley, CA, USA, 2014; Volume 1, ISBN 1517603110. [Google Scholar]

- Marnet, P.G. Milking procedures and facilities. In Milk and Dairy Products in Human Nutrition: Production, Composition and Health; Young, W., Park, G., Haenlein, F.W., Eds.; John Wiley and Sons: Hoboken, NJ, USA, 2013; pp. 46–64. [Google Scholar] [CrossRef]

- Douphrate, D.I.; Hagevoort, G.R.; Nonnenmann, M.W.; Kolstrup, C.L.; Reynolds, S.J.; Jakob, M.; Kinsel, M. The dairy industry: A brief description of production practices, trends, and farm characteristics around the world. J. Agromedicine 2013, 18, 187–197. [Google Scholar] [CrossRef]

- Sturaro, E.; Marchiori, E.; Cocca, G.; Penasa, M.; Ramanzin, M.; Bittante, G. Dairy systems in mountainous areas: Farm animal biodiversity, milk production and destination, and land use. Livest. Sci. 2013, 158, 157–168. [Google Scholar] [CrossRef]

- Petersen, M.L.; Hansen, B.; Young, W.; Miller, K.P. Rates of milk flow and milking times resulting from selection for milk yield. J. Dairy Sci. 1986, 69, 556–563. [Google Scholar] [CrossRef]

- Markos, H.G.; Touchberry, R.W. Heritability of rates of milk flow and time required to milk. J. Dairy Sci. 1970, 53, 188–194. [Google Scholar] [CrossRef]

- Appleman, R.D.; Micke, C.F. Relationships of milking systems to adequacy of milking. J. Dairy Sci. 1973, 56, 1450–1458. [Google Scholar] [CrossRef]

- Touchberry, R.W.; Markos, H. G Variations in the time required to milk cows. J. Dairy Sci. 1970, 53, 176–187. [Google Scholar] [CrossRef]

- Tamburini, A.; Sandrucci, A.; Nicoletti, C.; Zanini, L. Milking procedures and milk ejection in Italian Brown cows. Ital. J. Anim. Sci. 2007, 6 Suppl. 1, 478–480. [Google Scholar] [CrossRef]

- Raussi, S. Human-cattle interactions in group housing. Appl. Anim. Behav. Sci. 2003, 80, 245–262. [Google Scholar] [CrossRef]

- Vanbergue, E.; Peyraud, J.L.; Ferlay, A.; Miranda, G.; Martin, P.; Hurtaud, C. Effects of feeding level, type of forage and milking time on milk lipolytic system in dairy cows. Livest. Sci. 2018, 217, 116–126. [Google Scholar] [CrossRef]

- Bachman, K.C.; Hayen, M.J.; Morse, D.; Wilcox, C.J. Effect of pregnancy, milk yield, and somatic cell count on bovine milk fat hydrolysis. J. Dairy Sci. 1988, 71, 925–931. [Google Scholar] [CrossRef]

- Peychev, K.; Georgiev, D.; Dineva, G.; Dimova, V. Structure-time analysis and development of dairy cows machine milking models in “Herringbone” milking parlors. Bulg. J. Agric. Sci. 2019, 25, 196–200. [Google Scholar]

- Smith, J.F.; Harner, J., III; Armstrong, D.V.; Fuhrmann, T.; Gamroth, M.J.; Brouk, M.J.; Reid, D.A.; Bray, D. Selecting and managing your milking facility. In Proceedings of the VI Western Dairy Management Conference, Reno, NV, USA, 12–14 March 2003; pp. 119–131. [Google Scholar]

- CRPA (Centro Ricerche Produzioni Animali). Strutture, Attrezzature e Impianti Per Vacche Da Latte; L’Informatore Agrario: Verona, Italy, 2002; ISBN 8872201705. [Google Scholar]

- Rasmussen, M.D. Influence of switch level of automatic cluster removers on milking performance and udder health. J. Dairy Res. 1993, 60, 287–297. [Google Scholar] [CrossRef] [PubMed]

- Carreira, X.C.; Marino, R.A.; Perez-Cancio, X.; Fernandez, M.E. Design of algorithms for evaluating the efficiency of labour and variability of some group milking parlour parameters. Livest. Sci. 2013, 151, 252–263. [Google Scholar] [CrossRef]

- Boettcher, P. Breeding for improvement of functional traits in dairy cattle. Ital. J. Anim. Sci. 2005, 4, 7–16. [Google Scholar] [CrossRef]

- Hamann, J.; Osteras, O.; Mayntz, M.; Woyke, W. Functional parameters of milking units with regard to teat tissue treatment. In Teat Tissue Reactions to Machine Milking and New Infection Risk; Bulletin of the IDF (International Dairy Federation) No. 297/1994; IDF: Brussels, Belgium, 1994; pp. 23–34. [Google Scholar]

- Chambliss, R.L., Jr. Labor and Capital Requirements in Herringbone and other Elevated Stall Milking Parlors; Virginia Agricultural Experiment Station, Virginia Polytechnic Institute: Blacksburg, VA, USA, 1962; p. 46. [Google Scholar]

| Simbol | Unit | Meaning | Further Information |

|---|---|---|---|

| Nc | n | Number of milked cows | |

| Tm | min | Milk extraction (or flow) time | 6–8 min |

| Tri | s | Early (initial) routine | Animal entry (Ten); bucket, trolley, or cluster positioning (Tpos), pre-dipping (Tpre), foremilk inspecting (Tfor), udder preparation (Tup), teat cups attach (Tatt) |

| Trf | s | Ending (final) routine | Teat cups removal (Trem), post-dipping (Tpost), bucket or tank empting (Tempt), relocation of the mobile parts of the milking system (Trr), animal exit (Tex) |

| Tr | s | Milking routine | 30–180 s |

| Td | s | Downtime | Unproductive time due to unpredictable events (always present and split among Tri, Trf and Trr) |

| Tc | s | Milker’s time for milking each cow | Tc is always higher than, or equal to, the milking routine Tr |

| Ng | n | Number of stalls | Only in parlor |

| Ng | n | Number of milking groups | |

| Tmw | s | Milker waiting time | Unproductive routine time (for example due to the absence of the milking cluster removal |

| Task | Time (s) | Routine Time (s) | Routine Time (min) | ||||

|---|---|---|---|---|---|---|---|

| Input Data | Trolley | Bucket | Trolley | Bucket | Trolley | Bucket | |

| Bucket or trolley positioning | Tpos | 10 | 28 | Tri = 67 + 8 * | Tri = 85 + 10 * | Tri = 1.25 | Tri = 1.58 |

| Pre-dipping | Tpre | 15 | 15 | ||||

| Foremilk inspection | Tfor | 8 | 8 | ||||

| Udder preparation | Tup | 20 | 20 | ||||

| Teat cups attach | Tatt | 14 | 14 | ||||

| Teat cups removal | Trem | 25 | 25 | Trf = 84 + 16 * | Trf = 84 + 10 * | ||

| Post-dipping | Tpost | 9 | 9 | Trf = 1.67 | Trf = 1.57 | ||

| Bucket or container empting | Tempt | 20 | 50 | ||||

| Relocation of trolley | Trr | 30 | 0 | ||||

| Downtimes * | Td | 24 | 20 | ||||

| Time (s) | Routine Time (s) | Routine Time (min) | |||||

|---|---|---|---|---|---|---|---|

| Task | Input data | NOACR 1 | YESACR 2 | NOACR | YESACR | NOACR | YESACR |

| Milking group positioning | Tpos | 23 | 15 | Tri = 80 + 10 * | Tri = 72 + 6 * | Tri = 1.5 | Tri = 1.3 |

| Pre-dipping | Tpre | 15 | 15 | ||||

| Foremilk inspecting | Tfor | 8 | 8 | ||||

| Udder preparation | Tup | 20 | 20 | ||||

| Teat cups attach | Tatt | 14 | 14 | ||||

| Teat cups removal | Trem | 25 | - | Trf = 49 + 5 * | Trf = 21 + 6 * | Trf = 0.9 | Trf = 0.45 |

| Post-dipping | Tpost | 9 | 9 | ||||

| Group removal | Tempt | 15 | 12 | ||||

| Downtimes * | Td | 15 | 12 | ||||

| Routine Time (min) | Trolley | Bucket | Milk-Line NOACR | Milk-Line YESACR |

|---|---|---|---|---|

| Tri | 1.25 | 1.58 | 1.50 | 1.30 |

| Trf | 1.03 | 1.57 | 0.90 | 0.45 |

| Time (s) | Routine Time (s) | ||||||

|---|---|---|---|---|---|---|---|

| Task | Input Data | Auto Tandem | Herring Bone | Parallel | Auto Tandem | Herring Bone | Parallel |

| Animal entry | Ten | 15 | 8 | 6 | Tri = 53 + 10 * | Tri = 40 + 6 * | Tri = 38 + 4 * |

| Pre-dipping | Tpre | 15 | 9 | 9 | |||

| Foremilk inspecting | Tfor | 6 | 6 | 6 | |||

| Udder preparation | Tup | 7 | 7 | 7 | |||

| Teat cups attach | Tatt | 10 | 10 | 10 | |||

| Post-dipping | Tpost | 7 | 7 | 7 | Trf = 9 + 4 * | Trf = 9 + 5 * | Trf = 9 + 4 * |

| Animal exit | Tex | 2 | 2 | 2 | |||

| Downtimes * | Td | 14 * | 11 * | 8 * | |||

| Routine Time (min) | Auto Tandem | Herring Bone | Parallel |

|---|---|---|---|

| Tri | 1.05 | 0.77 | 0.7 |

| Trf | 0.22 | 0.23 | 0.22 |

| Trolley | Bucket | Milk-Line NOACR | Milk-Line YESACR | |||||

|---|---|---|---|---|---|---|---|---|

| Dairy Farm Data | Average | SD | Average | SD | Average | SD | Average | SD |

| lactating cows (n) | 24.7 | 2.52 | 34.3 | 6.0 | 35.0 | 8.89 | 50 | - |

| milk flow time average (min) | 6.4 | 0.12 | 6.7 | 0.17 | 6.9 | 0.10 | 7.1 | - |

| milk flow time min (min) | 5.5 | 0.12 | 5.4 | 0.30 | 5.8 | 0.17 | 6.8 | - |

| milk flow time max (min) | 7.1 | 0.12 | 7.2 | 0.06 | 7.6 | 0.06 | 7.6 | - |

| Autotandem | Herringbone | Parallel | ||||

|---|---|---|---|---|---|---|

| Dairy Farm Data | Mean | SD | Mean | SD | Mean | SD |

| lactating cows (n) | 98.5 | 4.95 | 111.7 | 10.41 | 121.4 | 7.40 |

| milk flow time average (min) | 7.2 | 0.07 | 6.8 | 0.06 | 7.0 | 0.03 |

| milk flow time min (min) | 5.9 | 0.10 | 6.3 | 0.04 | 6.5 | 0.02 |

| milk flow time max (min) | 8.1 | 0.07 | 7.4 | 0.06 | 7.5 | 0.20 |

| Origin | ss | df | Ms | F | p-Value | |

|---|---|---|---|---|---|---|

| Correct model | Tri | 7.169 a | 6 | 1.195 | 131.464 | 0.000 |

| Trf | 22.204 b | 6 | 3.701 | 282.077 | 0.000 | |

| Intercept | Tri | 64.386 | 1 | 64.386 | 7083.875 | 0.000 |

| Trf | 28.773 | 1 | 28.773 | 2193.215 | 0.000 | |

| Milking system | Tri | 7.169 | 6 | 1.1948 | 131.464 | 0.000 |

| Trf | 22.204 | 6 | 3.701 | 282.076 | 0.000 | |

| Tri | Trf | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Milk_System | Test | Subset | Milk_System | Title | Subset | |||||||

| N | 1 | 2 | 3 | 4 | 5 | N | 1 | 2 | 3 | 4 | ||

| Parallel | 15 | 0.70 | Parallel | 15 | 0.23 | |||||||

| Herringbone | 9 | 0.75 | Herringbone | 9 | 0.25 | |||||||

| Autotandem | 6 | 1.01 | Autotandem | 6 | 0.27 | 0.27 | ||||||

| Trolley | 9 | 1.26 | Milk-line YESACR | 3 | 0.45 | |||||||

| Milk-line YESACR | 3 | 1.30 | 1.30 | Milk-line NOACR | 9 | 0.94 | ||||||

| Milk-line NOACR | 9 | 1.46 | 1.46 | Bucket | 9 | 1.57 | ||||||

| Bucket | 9 | 1.59 | Trolley | 9 | 1.68 | |||||||

| Sign. | 0.97 | 1.00 | 0.98 | 0.05 | 0.12 | Sign. | 0.99 | 0.07 | 1.00 | 0.61 | ||

| Milking System | Tm = 6 min | Tm = 8 min | ||||||

|---|---|---|---|---|---|---|---|---|

| Tr | Tc | Ng | Nc | Tr | Tc | Ng | Nc | |

| Trolley | 2.91 | 8.91 | 2 | 13.46 | 2.91 | 10.91 | 2 | 5.50 |

| Bucket | 3.15 | 4.58 | 2 | 26.23 | 3.15 | 3.72 | 3 | 16.14 |

| NOACR Milk-line | 2.40 | 2.80 | 3 | 21.43 | 2.40 | 2.60 | 4 | 23.08 |

| YESACR Milk-line | 1.75 | 1.55 | 5 | 34.29 | 1.75 | 1.63 | 6 | 34.29 |

| Tm = 6 min | Tm = 8 min | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Parlor Type | Tr | Tc | Ng | Ns | Nc | Tr | Tc | Ng | Ns | Nc |

| Autotandem | 1.27 | 1.27 | 6 | (3 + 3) | 47.4 | 1.27 | 1.27 | 8 | (4 + 4) | 47.4 |

| Herringbone | 1.00 | 1.00 | 12 | (6 + 6) | 60.0 | 1.00 | 1.00 | 16 | (8 + 8) | 60.0 |

| Herringbone with swing-over | 1.00 | 1.00 | 6 | (6 + 6) | 60.0 | 1.00 | 1.00 | 8 | (8 + 8) | 60.0 |

| Parallel | 0.92 | 0.92 | 14 | (7 + 7) | 65.5 | 0.92 | 0.92 | 18 | (9 + 9) | 65.5 |

| Parallel with swing-over | 0.92 | 0.92 | 7 | (7 + 7) | 65.5 | 0.92 | 0.92 | 9 | (9 + 9) | 65.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calvo, A.; Airoldi, G. Sizing Milking Groups in Small Cow Dairies of Mediterranean Countries. Animals 2020, 10, 795. https://doi.org/10.3390/ani10050795

Calvo A, Airoldi G. Sizing Milking Groups in Small Cow Dairies of Mediterranean Countries. Animals. 2020; 10(5):795. https://doi.org/10.3390/ani10050795

Chicago/Turabian StyleCalvo, Angela, and Gianfranco Airoldi. 2020. "Sizing Milking Groups in Small Cow Dairies of Mediterranean Countries" Animals 10, no. 5: 795. https://doi.org/10.3390/ani10050795

APA StyleCalvo, A., & Airoldi, G. (2020). Sizing Milking Groups in Small Cow Dairies of Mediterranean Countries. Animals, 10(5), 795. https://doi.org/10.3390/ani10050795