1. Introduction

Domestic dishwashers have become indispensable appliances in many households, enabling more efficient cleaning of dishes compared to hand dishwashing while consuming fewer resources such as energy and water [

1]. Although dishwashers may harbor numerous microorganisms [

2], automatic dishwashing has been shown to provide a safe means to reduce pathogens on contaminated dishes, thus contributing to the control of foodborne diseases [

3]. However, the constant decrease in cleaning temperatures to achieve a better energy efficiency might hamper the antimicrobial efficacy and consumer behaviors such as improper loading and insufficient cleaning and sanitization of the dishwasher might contribute to the presence and persistence of contaminants, although these effects still lack proper scientific evidence [

4].

Despite the presence of different microbial colonizers, microbial contamination of dishes after dishwashing is generally assumed to be very low [

2]. Nevertheless, research suggests that lower temperatures (i.e., below 50 °C) can lead to higher bacterial diversity and potentially insufficient microbial reduction [

3]. Both cleaning and antimicrobial effectiveness depend on the interplay of mechanical action, temperature, detergent composition, and cycle duration [

3,

5]. Recent studies have specifically examined the impact of dishwashing detergents on cleaning efficacy, especially in shorter cycles, supporting this concept. As predicted by Sinner’s principle, it has been shown that a decrease in process time can be compensated by better detergent chemistry at a constant temperature, leading to a comparable cleaning efficacy [

6]. However, it remains unclear whether this effect can also be achieved in terms of the reduction in and removal of microorganisms. Similar to certain stains (e.g., tea) that are not removed but rather bleached, a reduction in microbial cells on a dish surface can be achieved by inactivating the cells rather than removing them by physico-chemical means. Since this combination of removal and inactivation is likely driven by all four factors of Sinner’s principle, it is worthwhile considering the role of each factor, especially at lower temperatures. Although systematic investigations have been conducted previously, data on the behavior of market detergents, especially with regard to shorter cycles, are lacking. This gap is of particular importance, as automatic dishwashing plays a crucial role in controlling the risk of infection in the domestic environment, ensuring the removal of pathogens after handling high-risk foods, such as raw poultry, thereby breaking potential chains of infection [

7]. The emphasis on lower energy consumption in the development of household appliances has led to a situation where relying on temperature alone to achieve an adequate reduction in microbial cells on contaminated dishes is insufficient. Unlike sterilization or most medical device reprocessing procedures, temperature alone cannot guarantee effectiveness, making simpler mathematical models, such as the A0 concept [

8], unsuitable for describing the complex interactives of dishwasher cycle profiles (which include various heating phases and periods of constant temperatures during the main wash and rinse cycles). This complexity calls for more sophisticated approaches. Interestingly, initial attempts to link the combined effects of time, temperature, and chemistry on microbial reduction have already been made in the context of domestic dishwashing and laundering, which might serve as a base for further concepts to be developed [

9,

10].

In the current study, we use a freely programmable standard household dishwasher to investigate the hygiene efficacy of cycles with different durations at temperatures representative of the lower end of current market offerings. By using a high-tier market detergent, the standard detergent for normative testing of dishwasher efficacy, and water alone, we aim to develop a comprehensive understanding of the hygiene efficacy of automated dishwashing processes, particularly in relation to shorter cycles and lower temperatures. In addition to providing new systematic data on microbial reduction in domestic dishwashing with regard to time, temperature, and chemistry, this study seeks to delineate the hygienic boundaries of domestic dishwashing, which has traditionally been focused on energy-saving considerations. By introducing a mathematical model to link the antimicrobial efficacy of both low- and high-performing automatic dishwashing detergents to the cycle profiles of the dishwasher, we also aim to contribute to a general understanding of the interplay between all factors of Sinner’s principle, thereby paving the way for future efforts to balance hygiene and sustainability.

4. Discussion

The antimicrobial performance of an automatic dishwashing process is crucial for reducing the risk of foodborne infections in domestic settings, as hand dishwashing often fails to deliver significant reductions in foodborne pathogens on dishes and other food-contact surfaces [

15]. Although studies conducted in consumers’ homes suggest that the level of contamination found on cleaned items after dishwashing is very low [

2], it has been shown that the microbial reduction achievable in a domestic dishwasher depends on several factors, including technical parameters like cycle duration and temperatures in both the main wash and rinse phases, as well as the choice of detergents [

3,

14]. In this context, the impact of activated oxygen bleach has been investigated [

14], while the impact of detergent performance per se remains unclear. It must, however, be assumed that cleaning performance plays a major role in determining the antimicrobial efficacy of dishwashing, since the physical removal of microbial cells, even if they are not inactivated or killed, will contribute to the decontamination of hard surfaces [

5].

Sinner’s principle [

16] applies to automatic dishwashing as it does to any other cleaning processes, indicating that the roles of time and temperature must be considered alongside the chemical effects of detergents. Mechanical action can be considered as a constant factor due to the similar principles that are applied in virtually all domestic dishwashers. Like in other domestic appliances, the strive for lower energy consumption has led to a regulatory framework that strongly favors long cycles at relatively low temperatures, referred to as “eco” cycles [

1]. However, these longer cycles are not always accepted by consumers due to their duration [

17]. Consequently, discussions have emerged regarding the suitability of short cycles, as alternative sustainable programs, which have shorter durations while maintaining low energy consumption levels [

18]. According to Sinner’s principle, a decrease in time and/or temperature can be compensated by the increased use of chemistry or mechanics; however, adjustments to the latter are limited since the operational mechanics of a dishwasher cannot be easily changed. Tewes et al. demonstrated that market detergents could achieve cleaning performance in some short cycles that is comparable to that of longer “eco” cycles [

6]. Unfortunately, a study on laundering showed that Sinner’s principle has some limitations in terms of its adaptability to the antimicrobial efficacy of cleaning processes, mainly because temperature is a crucial factor for inactivating microbial cells [

19]. Therefore, this study investigated the hygiene efficacy of automatic dishwashing processes for domestic applications, focusing on potential boundaries of short cycles and the impact of different detergent formulations. Since the chemical compositions of market detergents are not available to the public, it was not possible to comprehensively analyze the impact of specific ingredients.

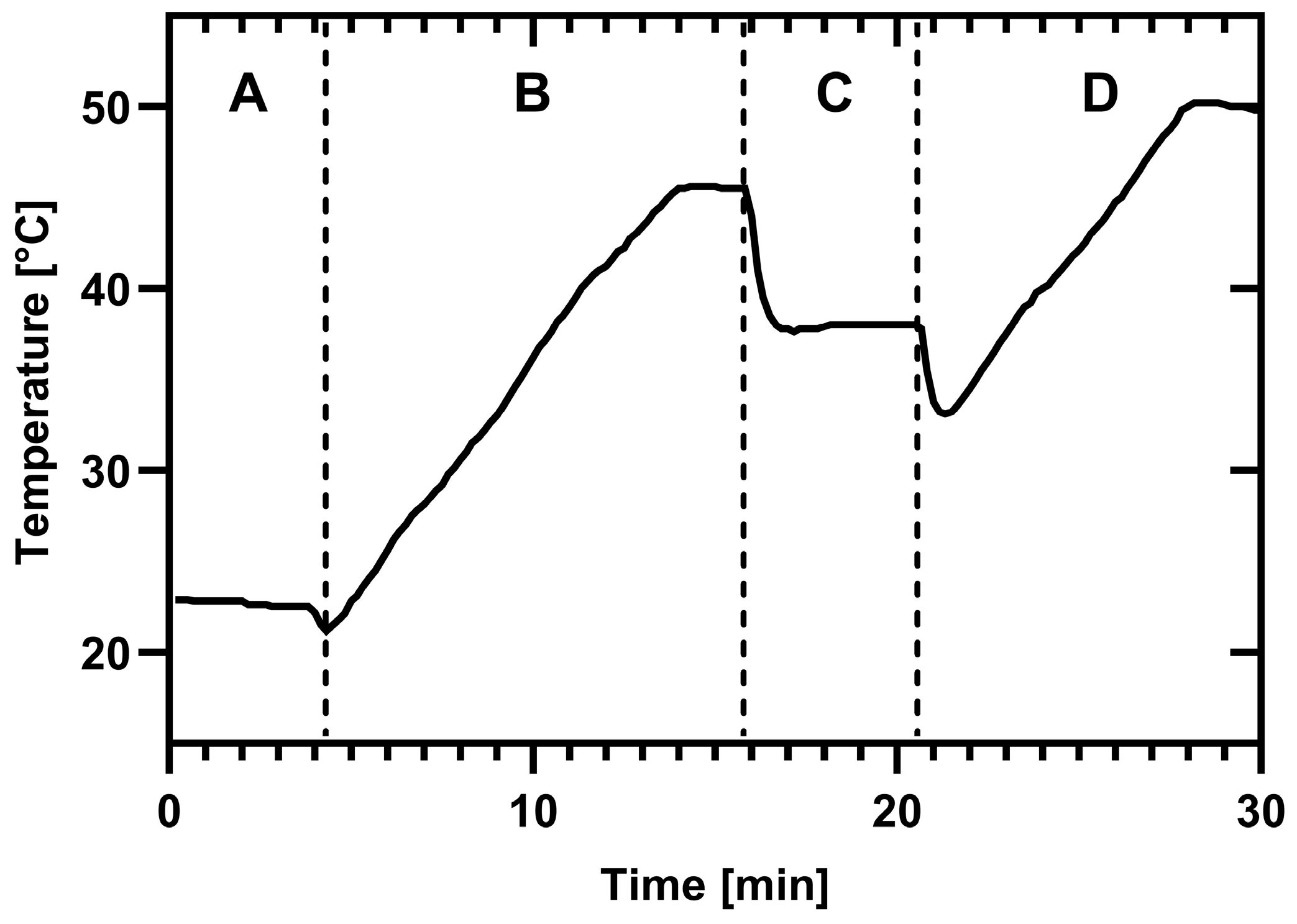

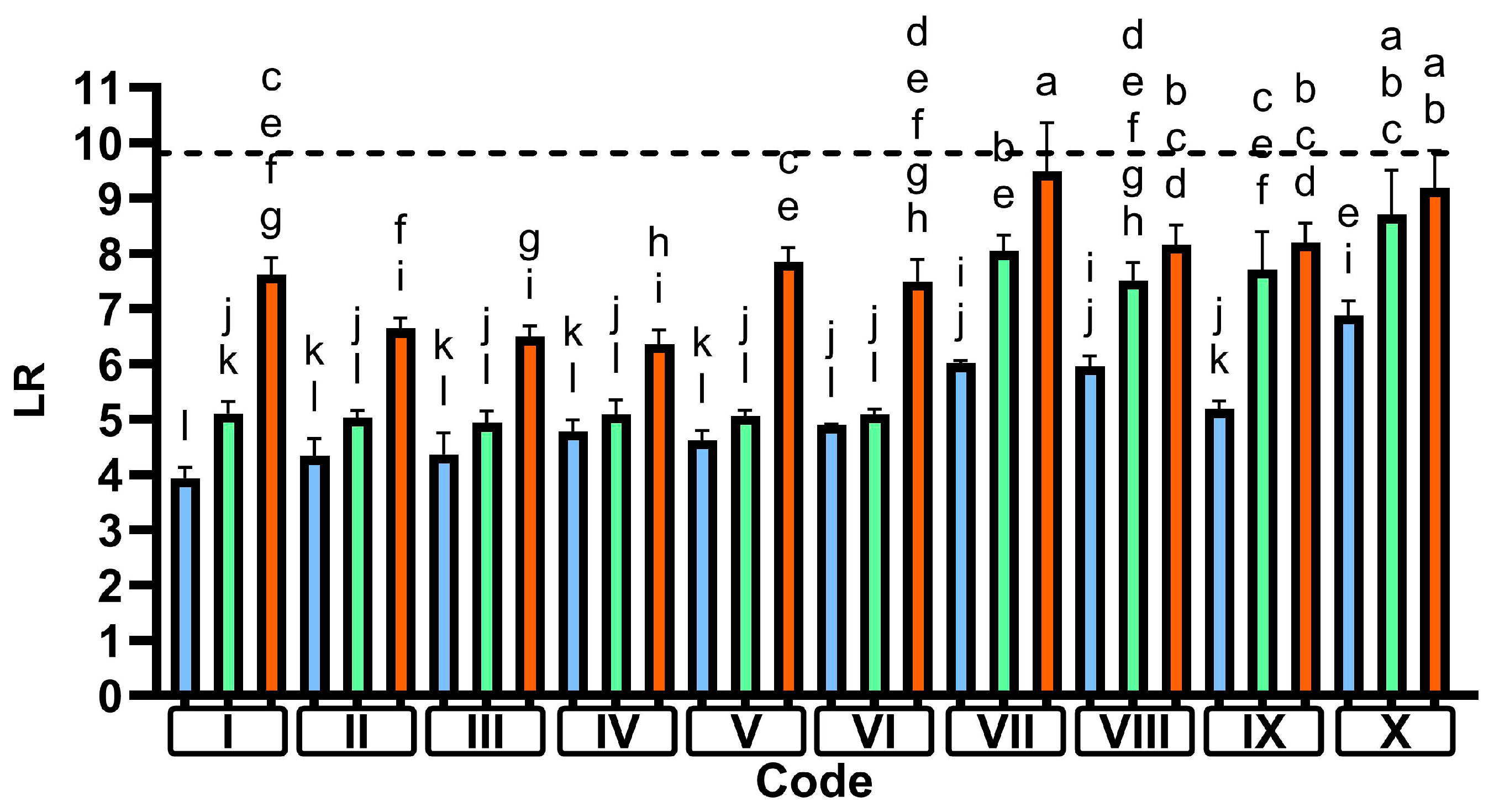

In general, our findings suggest a good hygiene efficacy for the investigated dishwashing processes with an LR of >5 of both tested detergents, even at low temperatures in very short cycles. This might be, at least partly, explained by the fact that the dishwashing process can be assumed to be effective at removing the matrix of bovine albumin, mucin, and cornstarch (according to IEC 63331 [

13]) from hard surfaces, thereby also removing most of the microbial cells embedded in this matrix [

6]. However, our results also show that a considerable number of cells remain on the surfaces, necessitating either more stringent removal methods or inactivation. This can be achieved through the use of a more potent detergent, which can deliver up to a 2.5 log higher reduction under the same cycle conditions, or by increasing the cycle time and/or temperature (

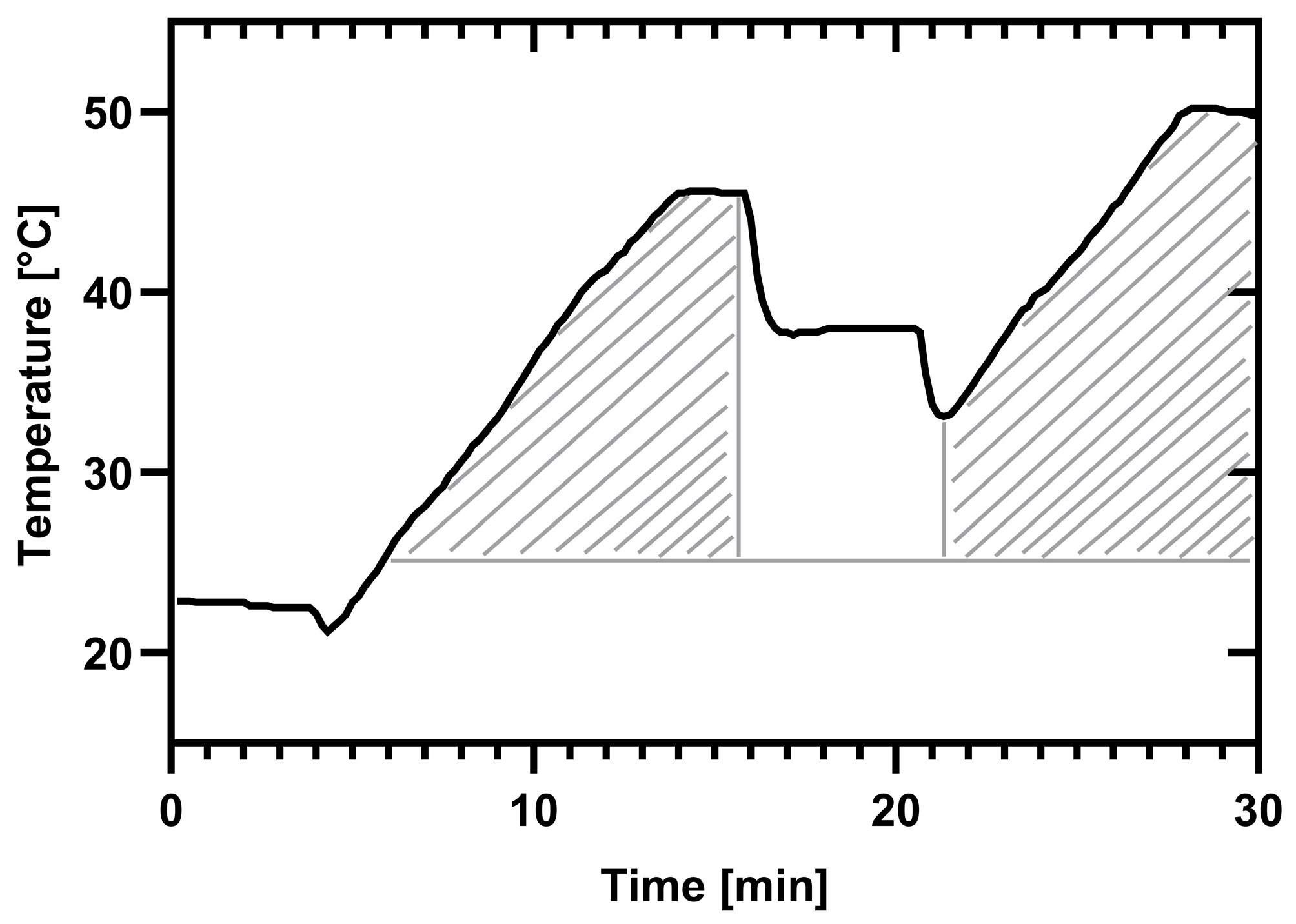

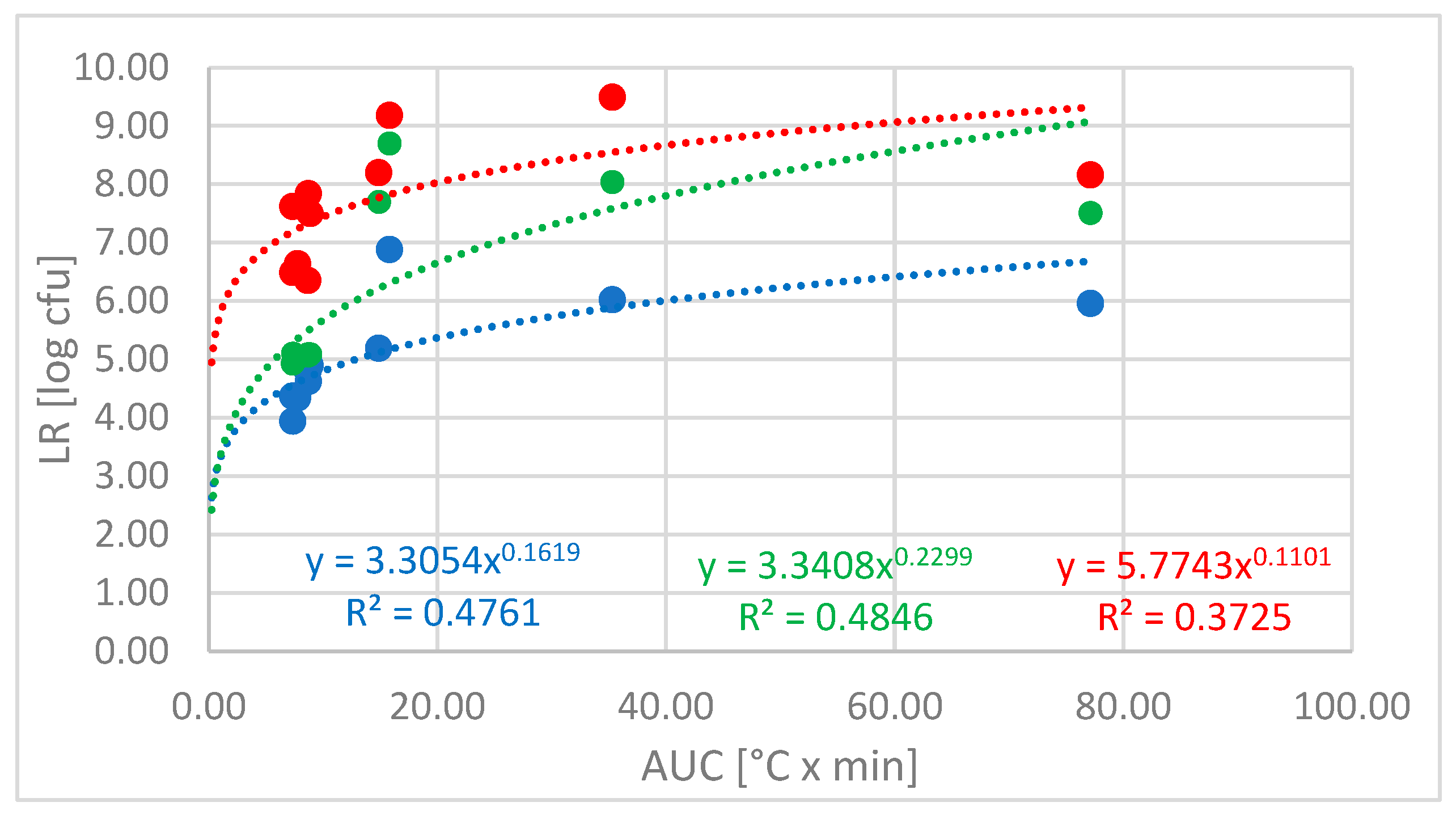

Figure 3). This correlation network is clearly visualized in

Figure 5, where the hygiene performance of the standard detergent resembles that of water at AUCs of <10. At higher AUCs, the differences are less pronounced, suggesting a bigger impact of time and/or temperature. Moreover, this figure suggests that while the use of a detergent enhances the hygiene performance across all cycle profiles, the antimicrobial impact of a high-performing formulation is more pronounced at low AUCs (i.e., in shorter cycles). Using the AUC as the independent variable appears to be more suitable than simply comparing the LR to the maximum temperature reached in the main wash and rinse, as differentiation is not well represented for cycles between 45 °C and 50 °C (Code IV and VI). Nonetheless,

Figure S2 clearly indicates high antimicrobial efficacy in cycles with a maximum temperature (T

max) of ≥60 °C, regardless of the detergent used, and decreased hygiene performance in the cycle with the lowest main wash temperature (30 °C), although this effect is less pronounced for the market detergent. While the AUC is a concept that has been successfully applied to calculate the antimicrobial efficacy of heat-based disinfection in medical devices (A

0 concept; [

8]), our data suggest a more complex interaction among time, temperature, and chemical factors that collectively influence the hygiene efficacy of dishwashing processes. In this context, the detergent appears to have a greater impact on antimicrobial efficacy during the main wash compared to the rinse phase, as illustrated in

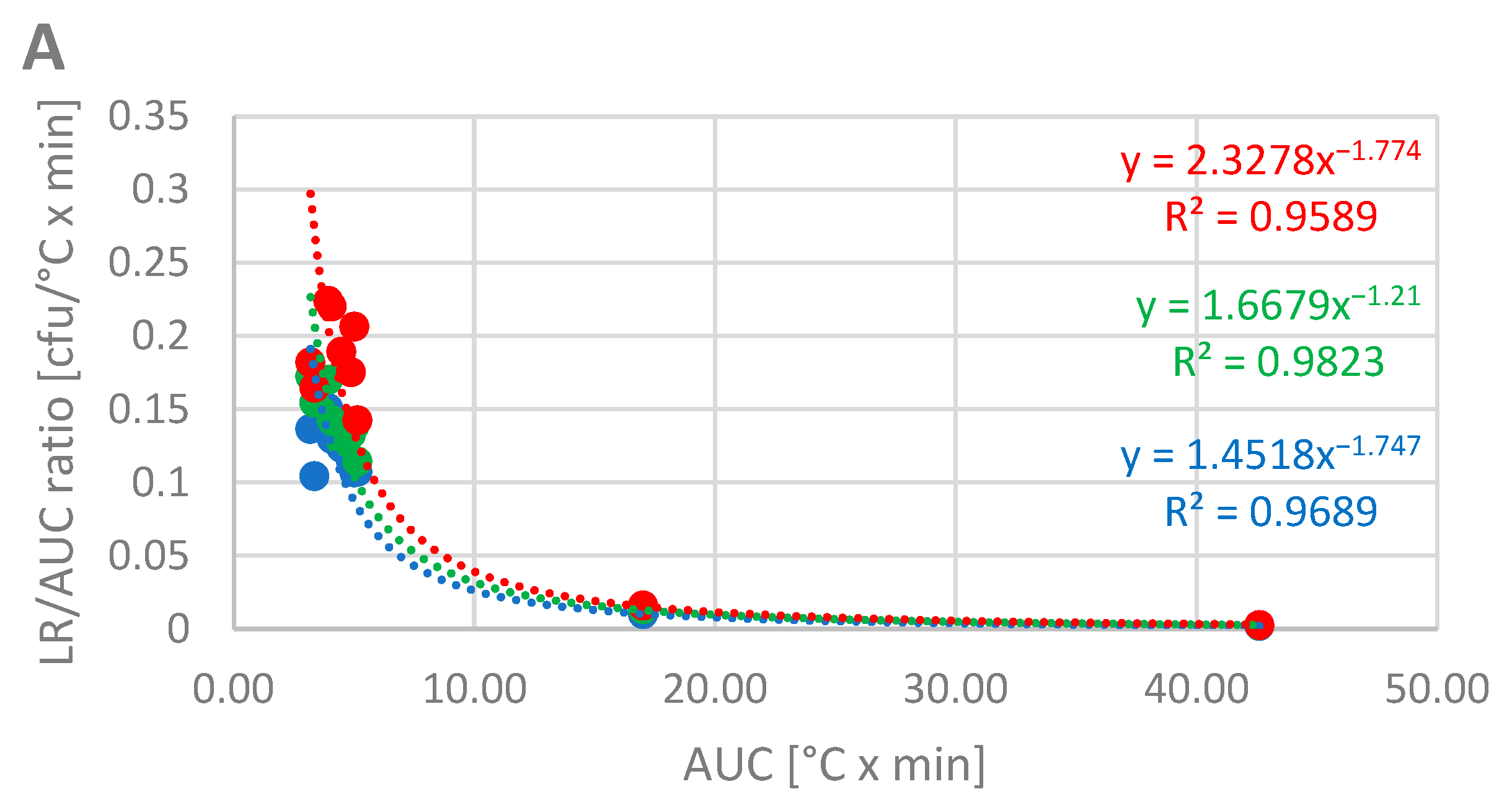

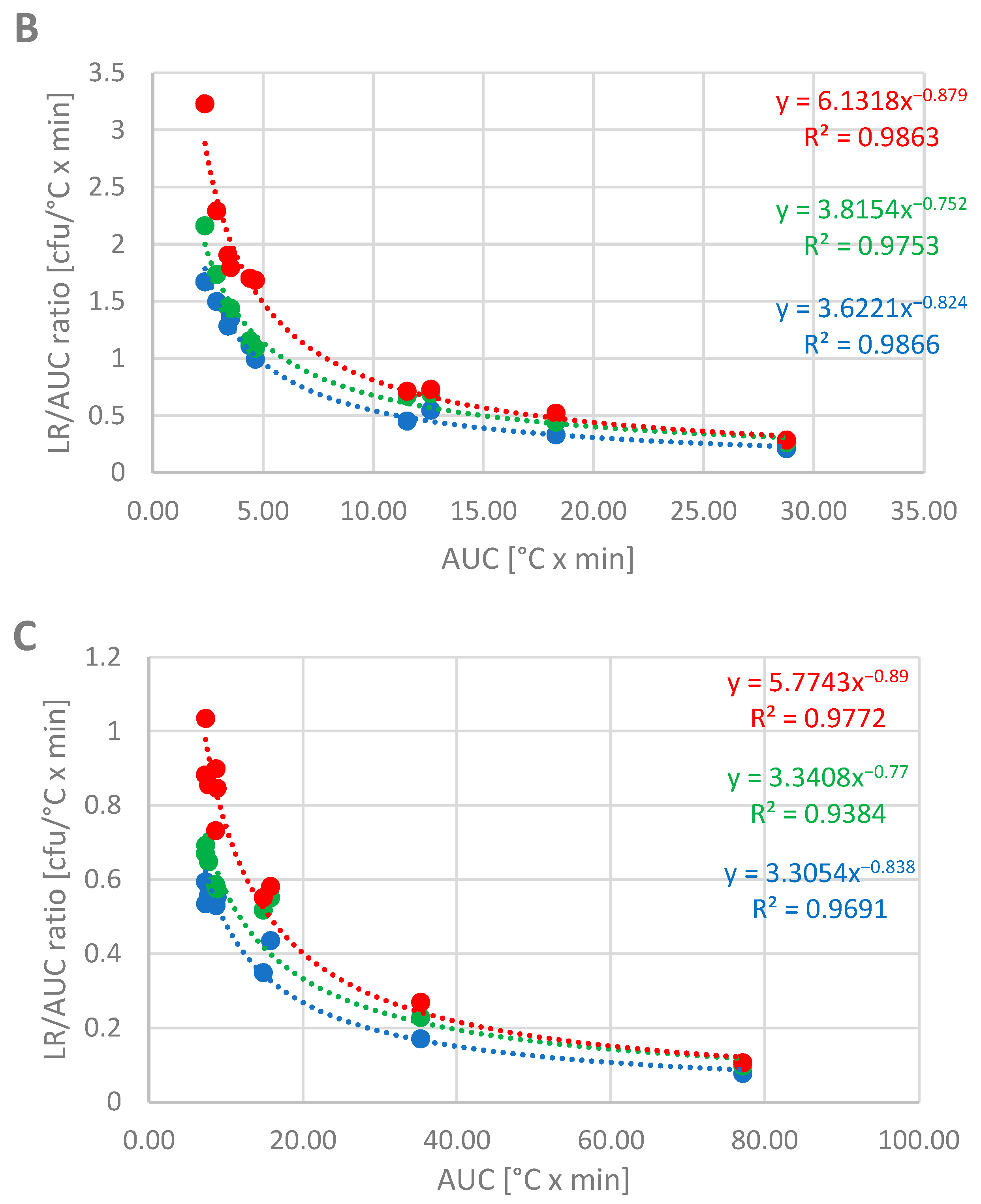

Figure 6. Plotting the LR/AUC ratio against the AUCs of the total cycle, the main wash, and the rinse reveals that the LR of different detergents or water varies with AUCs in the main wash but not in the rinse. This phenomenon can be explained by the absence of detergent in the rinse. Furthermore, this analysis shows that the additional impact of an AUC increase in the rinse on the antimicrobial efficacy is less significant than that of an AUC increase in the main wash, especially when a market detergent is used.

As specified in the standard IEC 63331, the efficacy tests focused on

Micrococcus luteus, a strain known for its differential response to various antimicrobial impacts, thus representing a “worst case scenario” [

13,

14]. However, it is important to understand how other microorganisms, particularly kitchen-relevant strains, react in the dishwasher in order to assess potential infection risks due to insufficiently decontaminated dishes. So, we tested a range of strains representing both Gram-positive and Gram-negative bacteria, as well as important food pathogens.

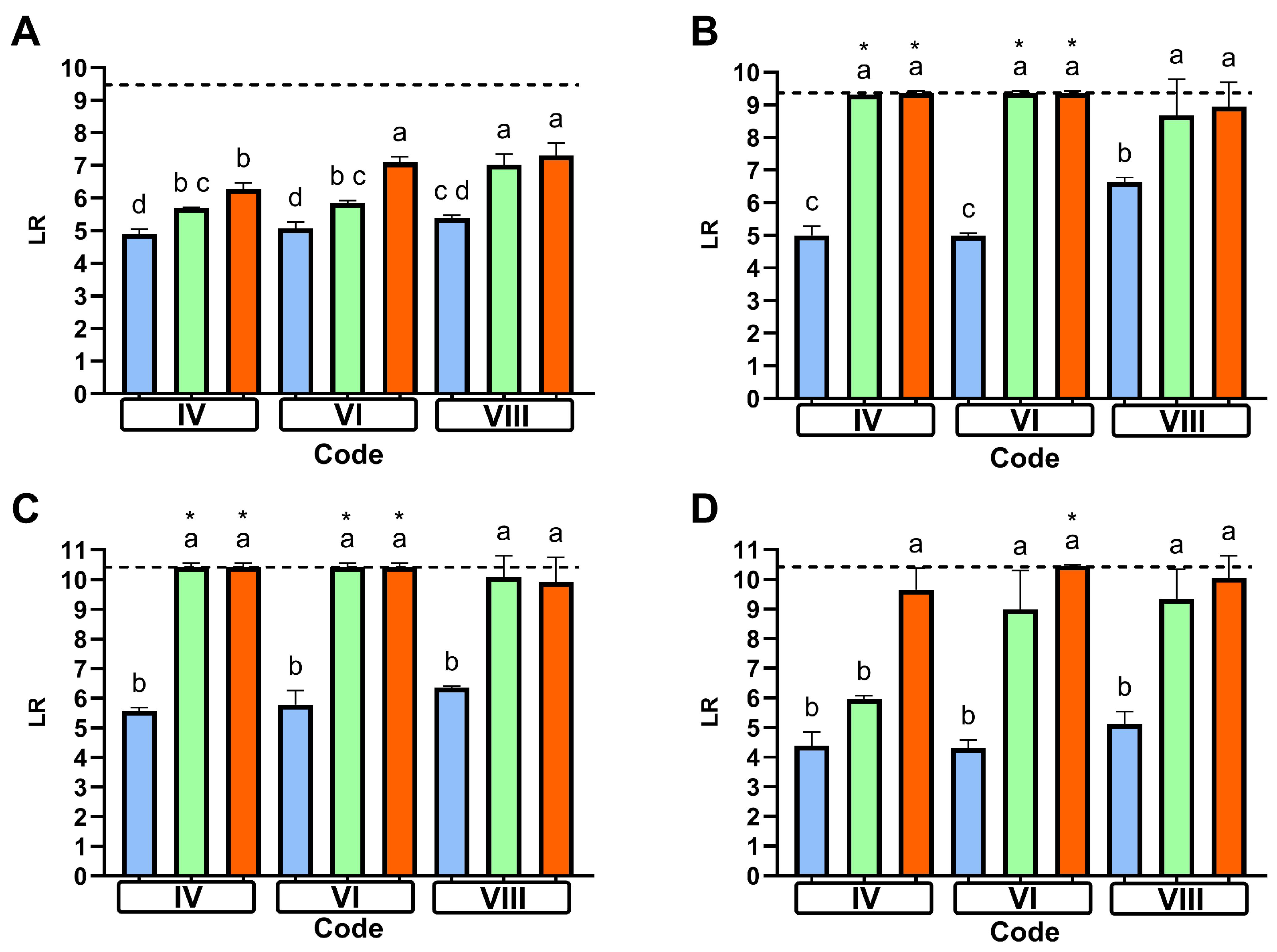

Only selected cycles were tested using these strains, including a typical eco-cycle (code VIII) and two short cycles (codes IV and VI), one of which had a lower main wash temperature (code IV) than the other. Main wash temperatures of 45 °C and 50 °C were chosen based on our data (

Figure 3) and findings from a recent study by Brands et al. [

14], which suggest these temperatures might represent a “critical threshold” where microbial reduction in domestic dishwashing could decline.

A drop in antimicrobial performance of the market detergent between 50 °C (code VI) and 45 °C (code IV) was observed in tests using

E. faecium. In contrast, this effect was not seen with

S. aureus or

S. enterica, although the log reduction of the standard detergent significantly decreased when temperature was lowered from 50 °C to 45 °C. In this regard, the tests with

M. luteus suggest that the temperature-related performance drop with the standard detergent might occur already between 60 °C and 50 °C (

Figure 3, codes VI and VIII). For

E. coli, a slight (but not significant) decrease in antimicrobial performance could be observed between 50 °C and 45 °C for the standard detergent. This is in line with the findings of Brands et al., who observed similar effects with

M. luteus and

E. faecium when using an IEC standard detergent [

14].

Overall, it can be concluded that the main wash temperature has a considerable effect on the antimicrobial performance of an automatic dishwashing process, depending on the performance level of the detergent and the investigated test strain. Data suggest that the critical temperature for short cycles may be below 60 °C or 50 °C when using low- or high-performance detergents, respectively. The antimicrobial impact of a detergent is highest at low AUC values, indicating that shorter cycles require an additional chemical component to achieve better hygiene efficacy. Interestingly, only market detergents seem capable of compensating for the lack of antimicrobial efficacy in short cycles, while in longer cycles, even low-performing products can enhance hygiene efficacy. This discrepancy might be attributed to the varying cleaning efficacy of the detergents, which has been shown to differ significantly in short cycles [

6]. However, this hypothesis cannot be fully answered within the scope of this study and requires further investigation.

It is important to note that our findings regarding antimicrobial efficacy do not allow for definitive conclusions about potential infection risks, as more information would be needed to make such assessments. Likewise, it is not possible to define a specific log reduction that should be achieved during the dishwashing process. Developing such recommendations would require data on microbial species and counts on dishes, their infectious doses, and exposure scenarios. Nevertheless, when compared to other standardized methods that evaluate disinfection efficacy, such as those used in washing machines [

20], which require a log reduction of >7, it can be inferred that short cycles in domestic dishwashers deliver sufficient antimicrobial efficacy at temperatures greater than or equal to 50 °C when using highly pathogenic strains such as

M. luteus and

E. faecium, whereas 45 °C is sufficient when more kitchen-relevant strains such as

E. coli,

S. aureus, and

S. enterica are considered. This, however, must be considered a general recommendation that requires more comprehensive investigations into the impact of different detergent ingredients on antimicrobial performance. Likewise, long-term effects on microbial contamination in domestic dishwashers have not been considered, but might pose a problem, depending on the cycles used, thus requiring further research.

5. Conclusions

Short cycles in domestic dishwashers are effective in reducing the microbial load on contaminated dishes as LRs of >5 were observed in cycles with main wash and rinse temperatures around 50 °C, respectively, even in the absence of detergent. When using a market detergent, an LR of >7 can be achieved in programs with a main wash temperature of ≥50 °C. Interestingly, the range around 45 °C appears to be a critical temperature threshold for the standard germ M. luteus, as more germs survived the dishwasher cycle than in ranges >50 and <40 °C. The exact cause of this phenomenon could not be precisely determined in the course of these experiments, which is why the focus of a future study could be on determining this temperature threshold.

Overall, the presence of detergents increased hygiene efficiency compared to water alone. In some specific codes, the performance with the market detergent was similar to the reference detergent. This includes codes that had either main wash temperatures > 50 °C or a dishwashing cycle duration longer than 90 min. In contrast, all investigated foodborne pathogens showed no significant difference between the market and the reference detergent. Only S. aureus was able to persist at 45 °C in the presence of the reference detergent.

Considering the AUC of a cycle temperature profile, it is possible to roughly predict the LR that can be achieved in a domestic dishwasher when using only water or a different type of detergent. This predictive capability might serve as a versatile tool for the hygiene performance attainable with specific dishwashing cycles, or for setting limits for temperature profiles to ensure the safe reprocessing of contaminated dishes while optimizing energy efficiency.