Development of Value-Added Butter by Incorporating Whey Protein Hydrolysate-Encapsulated Probiotics

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Spray-Dried Conjugated WPH-MD Probiotic Encapsulant

2.1.1. Cell Harvesting of BB12 and LA5 for the Preparation of Concentrated Bacterial Cell Suspensions

2.1.2. Preparation of Conjugated WPH-MD Probiotic Solution for Spray-Drying Process

2.1.3. Spray-Drying of the Conjugated WPH-MD Probiotic Solution for the Probiotic Encapsulant Powder Preparation

2.2. Preparation of Value-Added Salted and Unsalted Butter Variants by Adding Encapsulated Probiotics

2.2.1. Butter Sample Preparation under Laboratory Conditions

2.2.2. Incorporation of WPH-MD Probiotic Encapsulant in the Butter Grains to Develop Probiotic Butter Variants

2.3. Physicochemical Characterization of 0.1% and 1% Salted and Unsalted Encapsulated Probiotic Butter Variants

2.3.1. Experimental Design

2.3.2. Enumeration of the Viable Probiotic Counts

2.3.3. Physicochemical Analysis to Assess the Influence of the WPH-MD Probiotic Encapsulant on the Butter Properties

Effect of WPH-MD Probiotic Encapsulant on the Rheological Properties of Butter Variants

Effect of WPH-MD Probiotic Encapsulant on the Textural Properties of Butter Variants

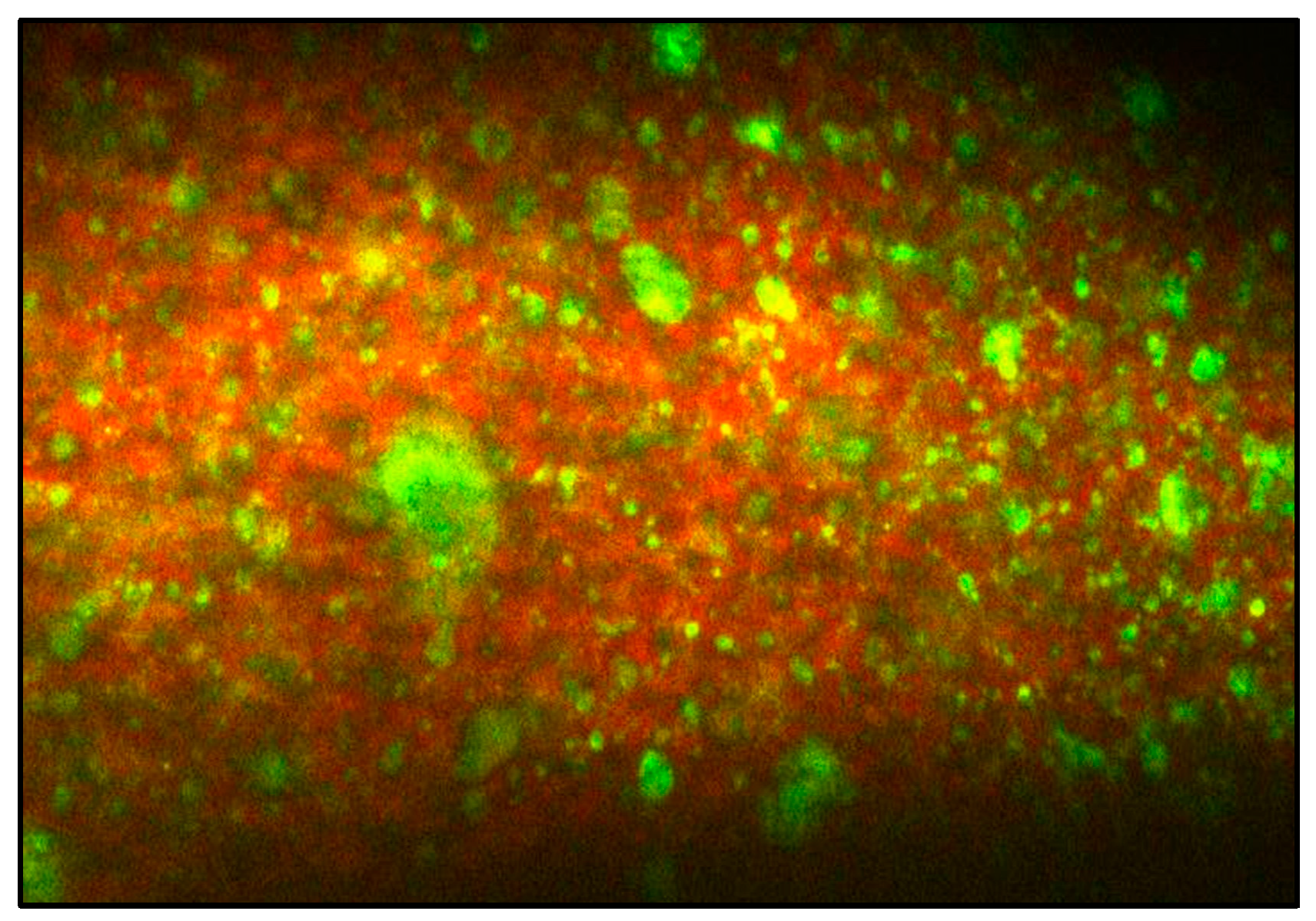

2.4. Interaction of WPH-MD Probiotic Encapsulant with the Butter Matrix through Confocal Laser Scanning Microscopy

2.5. Storage Studies of Salted and Unsalted WPH-MD Probiotic Butter Samples at Refrigerated Conditions 4 °C

2.5.1. Experimental Design

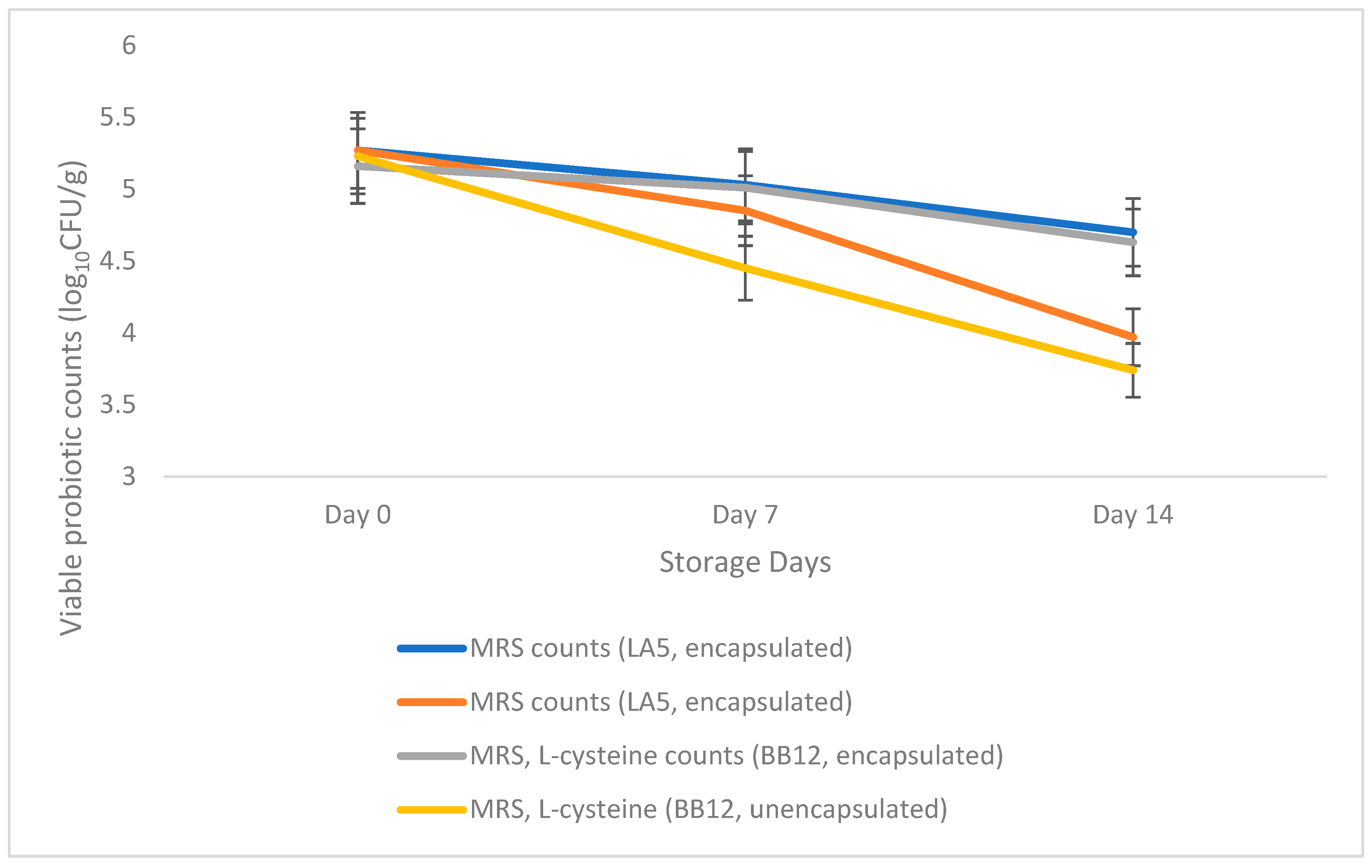

2.5.2. Probiotics Viability of Butter Samples during Storage

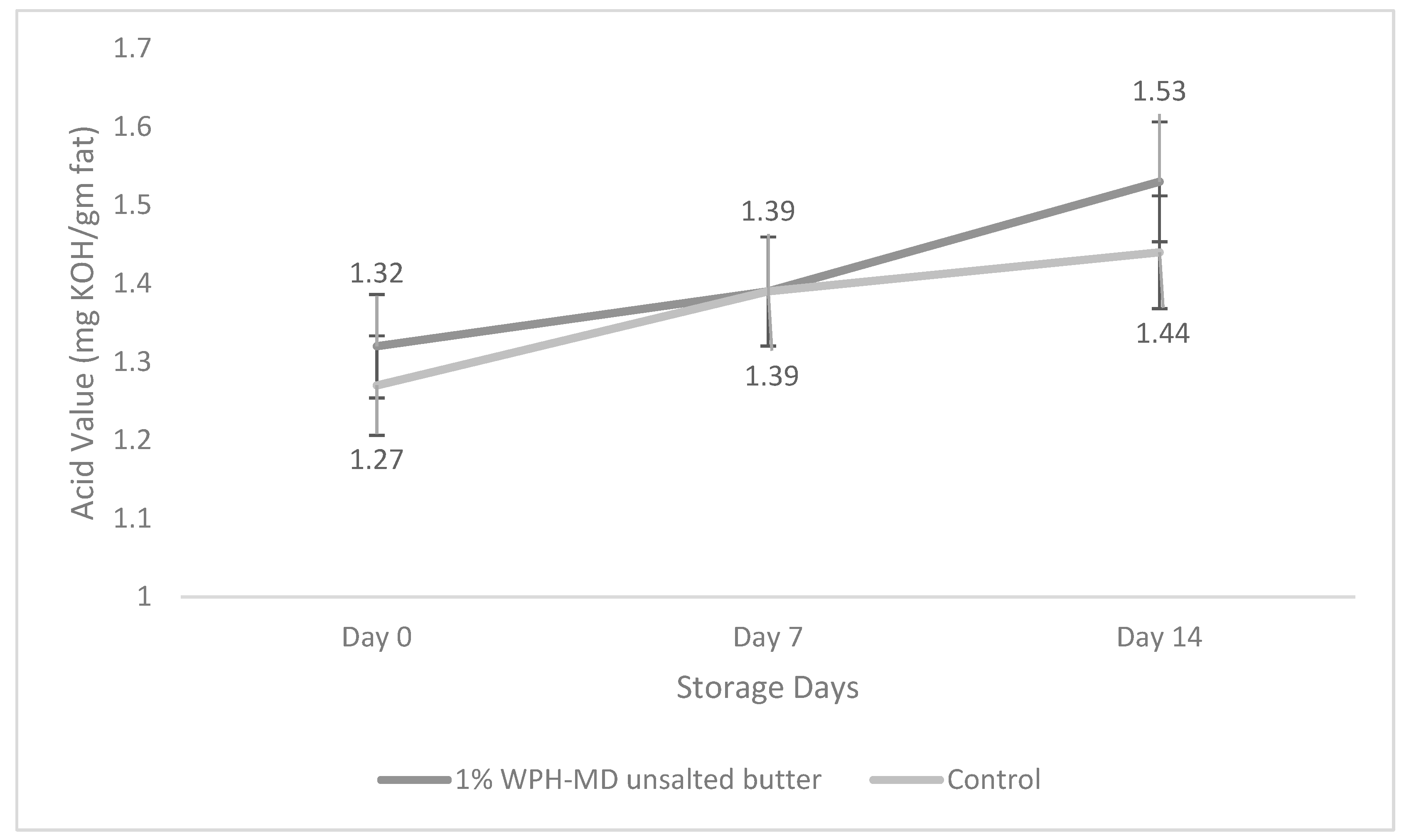

2.5.3. Impact of WPH-MD Probiotic Encapsulant on the Acid Value of Fatty Acids Present in Butter during Storage

- N—Normality of KOH

- V—Volume of KOH

- W—Weight of the sample

2.5.4. Impact of WPH-MD Probiotic Encapsulant on the Textural Properties (Hardness) of Butter during Storage

2.6. Statistical Analysis

3. Results and Discussion

3.1. Viable Probiotic Counts in Salted and Unsalted Butter Variants with the Incorporation of WPH-MD Probiotic Encapsulant

3.2. Effect of WPH-MD Probiotic Encapsulant on the Rheological Properties of Butter Variants

3.3. Effect of WPH-MD Probiotic Encapsulant on the Textural Properties of Butter Variants

3.4. Viability of Encapsulated Probiotics in Salted and Unsalted Butter Variants during Refrigerated Storage Conditions:

3.5. Impact of Incorporation of WPH-MD Probiotic Encapsulant on the Acid Value of Salted and Unsalted Butter Variants during Refrigerated Storage Conditions

3.6. Impact of Incorporation of WPH-MD Probiotic Encapsulant on the Textural Properties of Salted and Unsalted Butter Variants during Refrigerated Storage Conditions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bellinazo, P.L.; Vitola, H.R.S.; Cruxen, C.E.d.S.; Braun, C.L.K.; Hackbart, H.C.d.S.; da Silva, W.P.; Fiorentini, Â.M. Probiotic butter: Viability of Lactobacillus casei strains and bixin antioxidant effect (Bixa orellana L.). J. Food Process. Preserv. 2019, 43, e14088. [Google Scholar] [CrossRef]

- Morden Intelligence. Available online: https://www.mordorintelligence.com/industry-reports/united-states-probiotics-market-industry (accessed on 16 April 2023).

- Globe News Wire. Available online: https://www.globenewswire.com/news-release/2021/12/13/2350884/0/en/Probiotics-Market-size-worth-90-57-Billion-Globally-by-2028-at-6-81-CAGR-Verified-Market-Research.html (accessed on 13 December 2021).

- da Silva, M.N.; Tagliapietra, B.L.; dos Santos Richards, N.S.P. Encapsulation, storage viability, and consumer acceptance of probiotic butter. LWT 2021, 139, 110536. [Google Scholar] [CrossRef]

- FAO—Food and Agriculture Organization of the United Nations Codex Standard for Fermented Milks 2001. Evaluation of Health and Nutritional Properties of Probiotics in Food Including Powder Milk with Live Lactic Acid Bacteria; Córdoba, Argentina. Available online: http://www.who.int/foodsafety/publications/fs_management/en/probiotics.pdf?ua=1 (accessed on 10 October 2001).

- Zalán, Z.; Hudáček, J.; Štětina, J.; Chumchalová, J.; Halász, A. Production of organic acids by Lactobacillus strains in three different media. Eur. Food Res. Technol. 2010, 230, 395–404. [Google Scholar] [CrossRef]

- Ferreira, L.; Borges, A.; Gomes, D.; Dias, S.; Pereira, C.; Henriques, M. Adding value and innovation in dairy SMEs: From butter to probiotic butter and buttermilk. J. Food Process. Preserv. 2022, 46, e14867. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Giri, S.K. Probiotic functional foods: Survival of probiotics during processing and storage. J. Funct. Foods 2014, 9, 225–241. [Google Scholar] [CrossRef]

- Abbas, M.S.; Saeed, F.; Afzaal, M.; Jianfeng, L.; Hussain, M.; Ikram, A.; Jabeen, A. Recent trends in encapsulation of probiotics in dairy and beverage: A review. J. Food Process. Preserv. 2022, 46, e16689. [Google Scholar] [CrossRef]

- Yoha, K.S.; Nida, S.; Dutta, S.; Moses, J.A.; Anandharamakrishnan, C. Targeted Delivery of Probiotics: Perspectives on Research and Commercialization. Probiotics Antimicrob. Proteins 2022, 14, 15–48. [Google Scholar] [CrossRef]

- Minj, S.; Anand, S. Development of a spray-dried conjugated whey protein hydrolysate powder with entrapped probiotics. J. Dairy Sci. 2022, 105, 2038–2048. [Google Scholar] [CrossRef]

- Erkaya, T.; Ürkek, B.; Doğru, Ü.; Çetin, B.; Şengül, M. Probiotic butter: Stability, free fatty acid composition and some quality parameters during refrigerated storage. Int. Dairy J. 2015, 49, 102–110. [Google Scholar] [CrossRef]

- Ewe, J.A.; Loo, S.Y. Effect of cream fermentation on microbiological, physicochemical and rheological properties of L. helveticus-butter. Food Chem. 2016, 201, 29–36. [Google Scholar] [CrossRef]

- Karakus, M.S.; Akgul, F.Y.; Korkmaz, A.; Atasoy, A.F. Evaluation of fatty acids, free fatty acids and textural properties of butter and sadeyag (anhydrous butter fat) produced from ovine and bovine cream and yoghurt. Int. Dairy J. 2022, 126, 105229. [Google Scholar] [CrossRef]

- Rønholt, S.; Kirkensgaard, J.J.K.; Pedersen, T.B.; Mortensen, K.; Knudsen, J.C. Polymorphism, microstructure and rheology of butter. Effects of cream heat treatment. Food Chem. 2012, 135, 1730–1739. [Google Scholar] [CrossRef]

- Samet-Bali, O.; Ayadi, M.A.; Attia, H. Traditional Tunisian butter: Physicochemical and microbial characteristics and storage stability of the oil fraction. LWT 2009, 42, 899–905. [Google Scholar] [CrossRef]

- Emadzadeh, B.; Razavi, S.M.A.; Schleining, G. Dynamic rheological and textural characteristics of low-calorie pistachio butter. Int. J. Food Prop. 2013, 16, 512–526. [Google Scholar] [CrossRef]

- Rønholt, S.; Mortensen, K.; Knudsen, J.C. The Effective Factors on the Structure of Butter and Other Milk Fat-Based Products. Compr. Rev. Food Sci. Food Saf. 2013, 12, 468–482. [Google Scholar] [CrossRef]

- Klu, Y.A.K.; Chen, J. Effect of peanut butter matrices on the fate of probiotics during simulated gastrointestinal passage. LWT 2015, 62, 983–988. [Google Scholar] [CrossRef]

- Panchal, B.; Truong, T.; Prakash, S.; Bansal, N.; Bhandari, B. Influence of fat globule size, emulsifiers, and cream-aging on microstructure and physical properties of butter. Int. Dairy J. 2021, 117, 105003. [Google Scholar] [CrossRef]

- Possemiers, S.; Marzorati, M.; Verstraete, W.; Van de Wiele, T. Bacteria and chocolate: A successful combination for probiotic delivery. Int. J. Food Microbiol. 2010, 141, 97–103. [Google Scholar] [CrossRef]

- Satapathy, M.; Quereshi, D.; Nguyen, T.T.H.; Pani, D.; Mohanty, B.; Anis, A.; Maji, S.; Kim, D.; Sarkar, P.; Pal, K. Preparation and characterization of cocoa butter and whey protein isolate based emulgels for pharmaceutical and probiotics delivery applications. J. Dispers. Sci. Technol. 2020, 41, 426–440. [Google Scholar] [CrossRef]

- Ruttarattanamongkol, K.; Afizah, M.N.; Rizvi, S.S.H. Stability and rheological properties of corn oil and butter oil emulsions stabilized with texturized whey proteins by supercritical fluid extrusion. J. Food Eng. 2015, 166, 139–147. [Google Scholar] [CrossRef]

- Li, H.; Wu, Y.; Hou, D.; Zhao, S.; Li, D.; Wang, X.; Li, H.; Yu, J. Effects of pre-emulsification with whey protein and high temperature sterilisation on texture, functional characteristics and Maillard reaction products of room temperature stored processed cheese. Int. Dairy J. 2023, 140, 105610. [Google Scholar] [CrossRef]

- Silva, T.; Pires, A.; Gomes, D.; Viegas, J.; Pereira-Dias, S.; Pintado, M.E.; Henriques, M.; Pereira, C.D. Sheep’s Butter and Correspondent Buttermilk Produced with Sweet Cream and Cream Fermented by Aromatic Starter, Kefir and Probiotic Culture. Foods 2023, 12, 331. [Google Scholar] [CrossRef]

- Lin, H.Y.; Tsai, J.C.; Lai, L.S. Effect of salts on the rheology of hydrocolloids from mulberry (Morus alba L.) leaves in concentrated domain. Food Hydrocoll. 2009, 23, 2331–2338. [Google Scholar] [CrossRef]

- Wright, A.J.; Scanlon, M.G.; Hartel, R.W.; Marangoni, A.G. Rheological properties of milkfat and butter. J. Food Sci. 2001, 66, 1056–1071. [Google Scholar] [CrossRef]

- Mahmmodi, P.; Khoshkhoo, Z.; Basti, A.A.; Shotorbani, P.M.; Khanjari, A. Effect of Bunium persicum essential oil, NaCl, Bile Salts, and their combinations on the viability of Lactobacillus acidophilus in probiotic yogurt. Qual. Assur. Saf. Crop. Foods 2021, 13, 37–48. [Google Scholar] [CrossRef]

- Koczon, P.; Gruczynska, E.; Kowalski, B. Changes in the acid value of butter during storage at different temperatures as assessed by standard methods or by FT-IR spectroscopy. Am. J. Food Technol. 2008, 3, 154–163. [Google Scholar] [CrossRef]

- Bendixen, H.A. Acid Values and Acid Ratios as Related to the Keeping Quality of Salted Butter. J. Dairy Sci. 1940, 23, 275–284. [Google Scholar] [CrossRef]

- Chueamchaitrakun, P.; Chompreeda, P.; Haruthaithanasan, V.; Suwonsichon, T.; Kasemsamran, S.; Prinyawiwatkul, W. Sensory descriptive and texture profile analyses of butter cakes made from composite rice flours. Int. J. Food Sci. Technol. 2011, 46, 2358–2365. [Google Scholar] [CrossRef]

| Butter Samples | Viable Probiotic Counts on MRS Plate (LA5) (log10CFU/g) | Viable Probiotic Counts on MRS, L-Cysteine Plate (BB12) (log10CFU/g) |

|---|---|---|

| 0.1% WPH-MD Encapsulated probiotic unsalted butter | aA | aB |

| 1% WPH-MD Encapsulated probiotic unsalted Butter | bA | bB |

| 0.1% WPH-MD Encapsulated probiotic salted Butter | cA | cB |

| 1% WPH-MD Encapsulated probiotic salted Butter | dA | dB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaba, K.; Anand, S.; Syamala, A. Development of Value-Added Butter by Incorporating Whey Protein Hydrolysate-Encapsulated Probiotics. Microorganisms 2023, 11, 1139. https://doi.org/10.3390/microorganisms11051139

Gaba K, Anand S, Syamala A. Development of Value-Added Butter by Incorporating Whey Protein Hydrolysate-Encapsulated Probiotics. Microorganisms. 2023; 11(5):1139. https://doi.org/10.3390/microorganisms11051139

Chicago/Turabian StyleGaba, Kritika, Sanjeev Anand, and Athira Syamala. 2023. "Development of Value-Added Butter by Incorporating Whey Protein Hydrolysate-Encapsulated Probiotics" Microorganisms 11, no. 5: 1139. https://doi.org/10.3390/microorganisms11051139

APA StyleGaba, K., Anand, S., & Syamala, A. (2023). Development of Value-Added Butter by Incorporating Whey Protein Hydrolysate-Encapsulated Probiotics. Microorganisms, 11(5), 1139. https://doi.org/10.3390/microorganisms11051139