Analysis of High Force Voice Coil Motors for Magnetic Levitation

Abstract

:1. Introduction

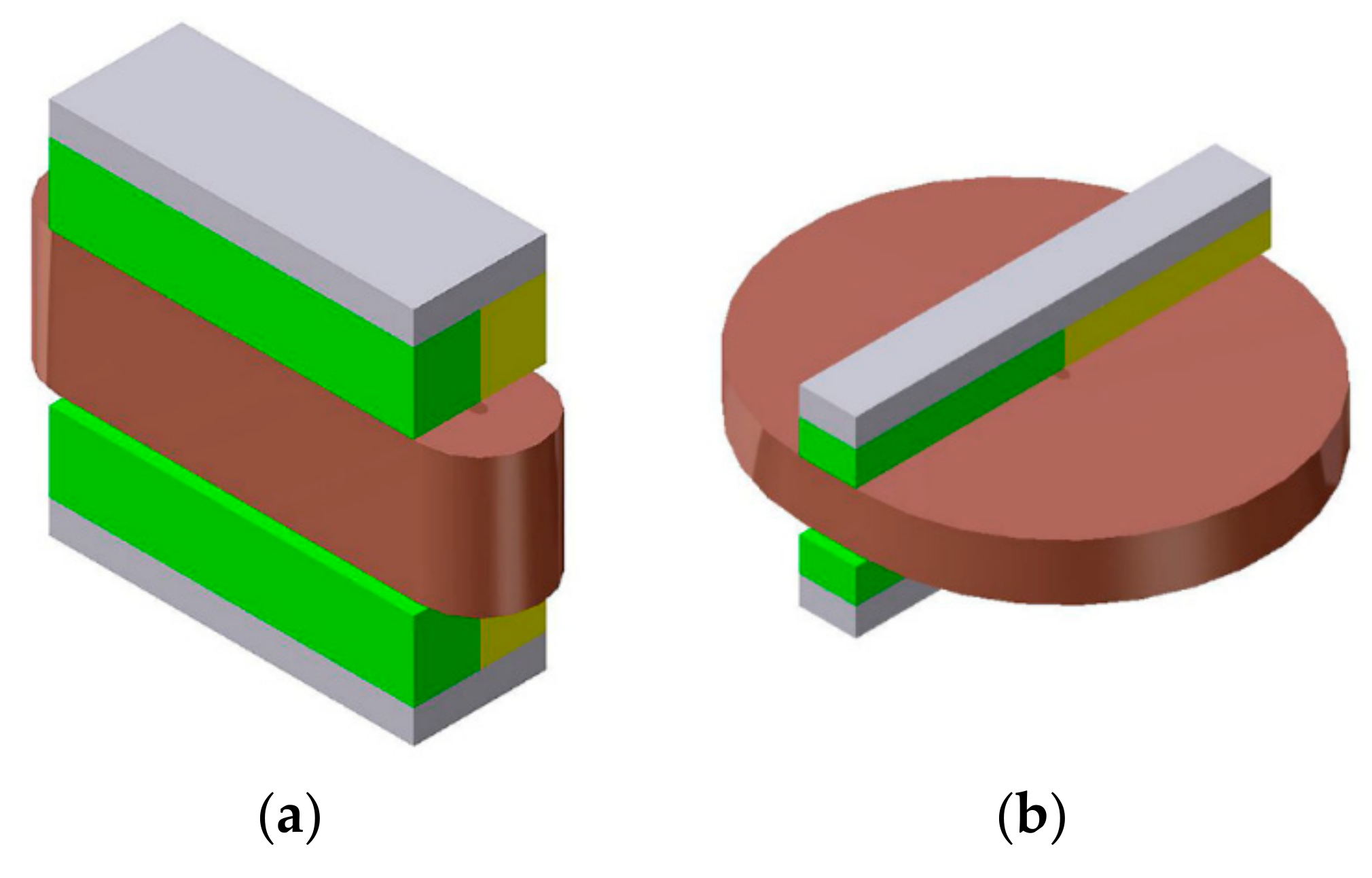

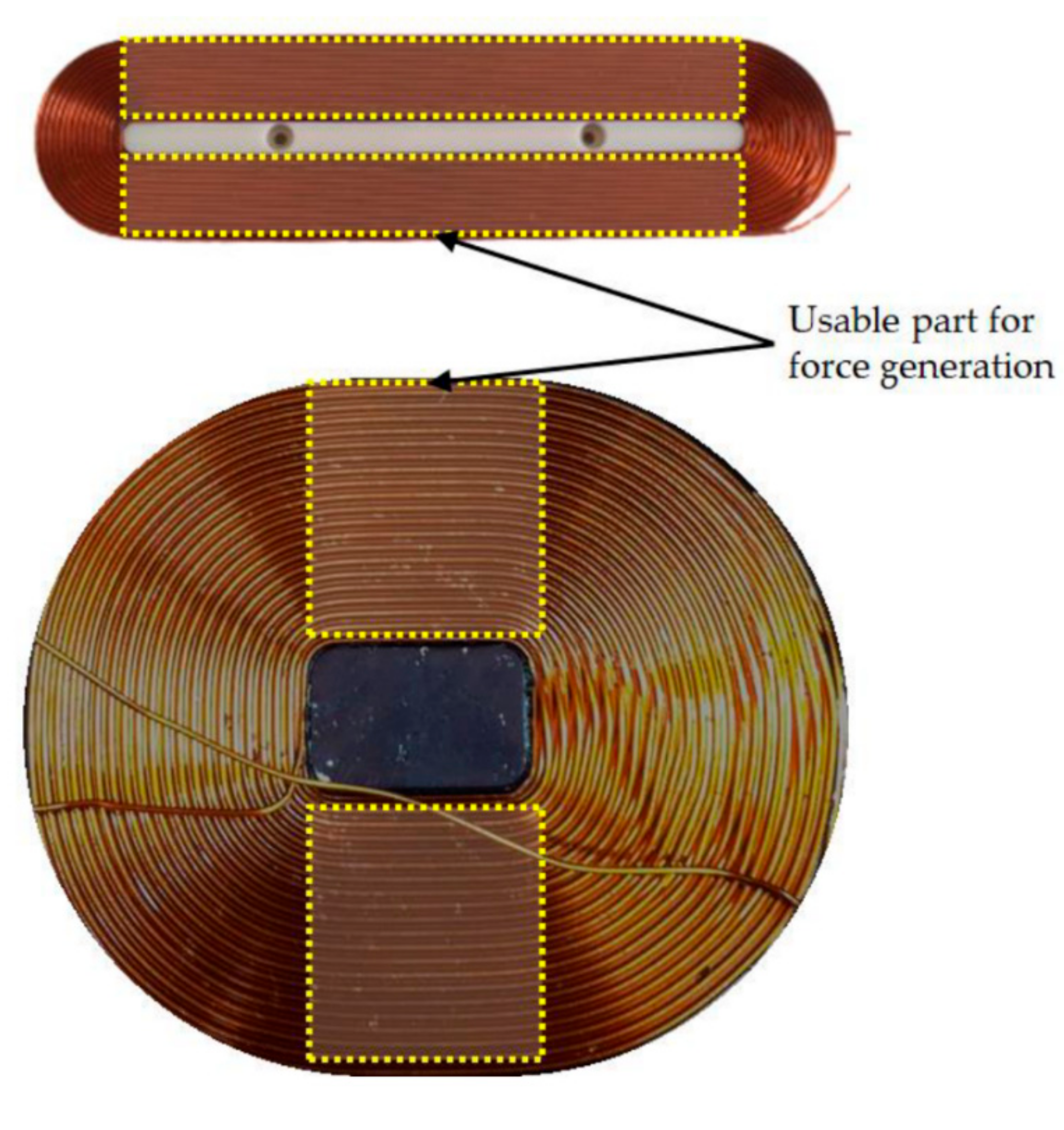

2. Structure of VCMs

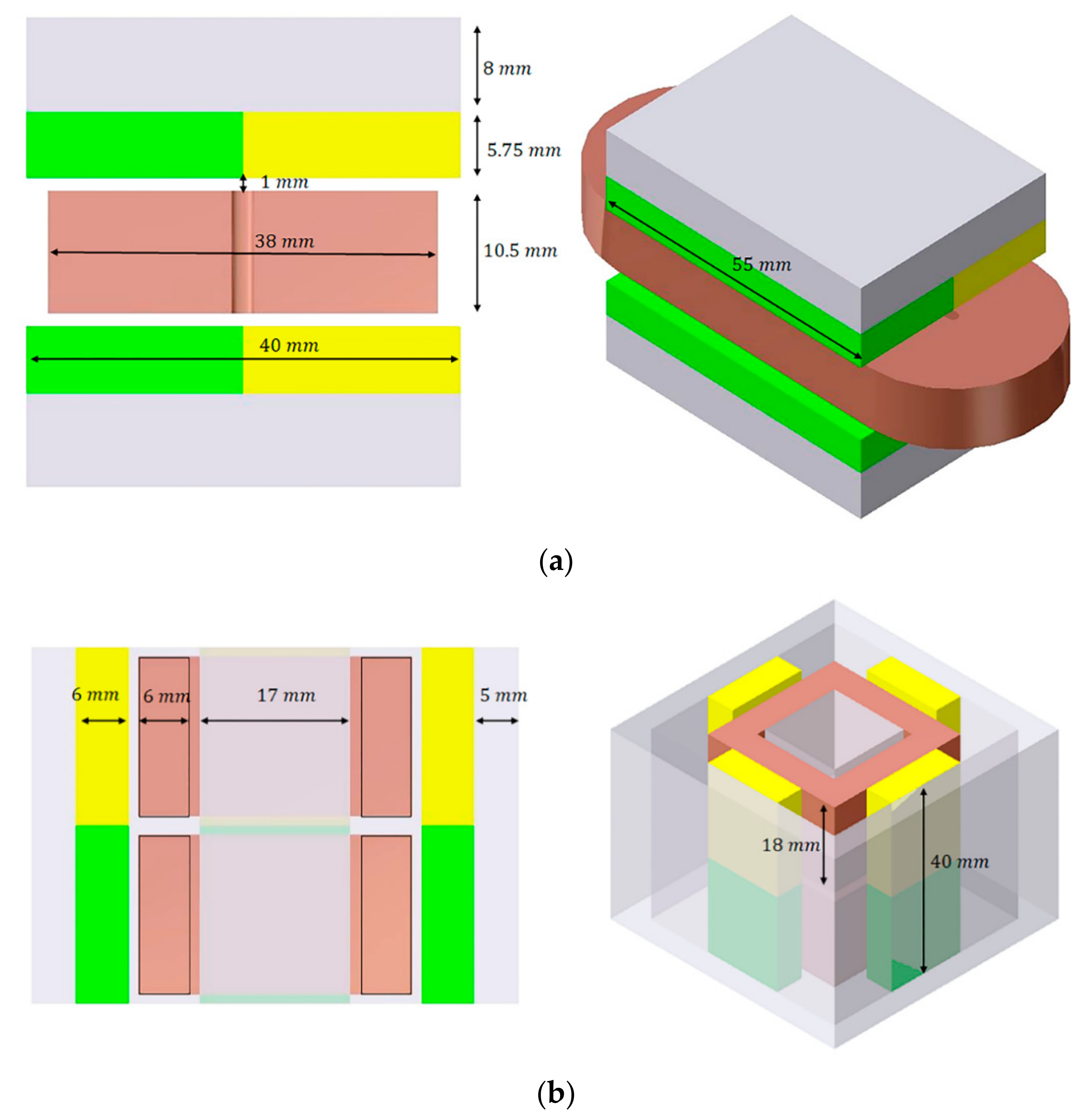

3. Analysis

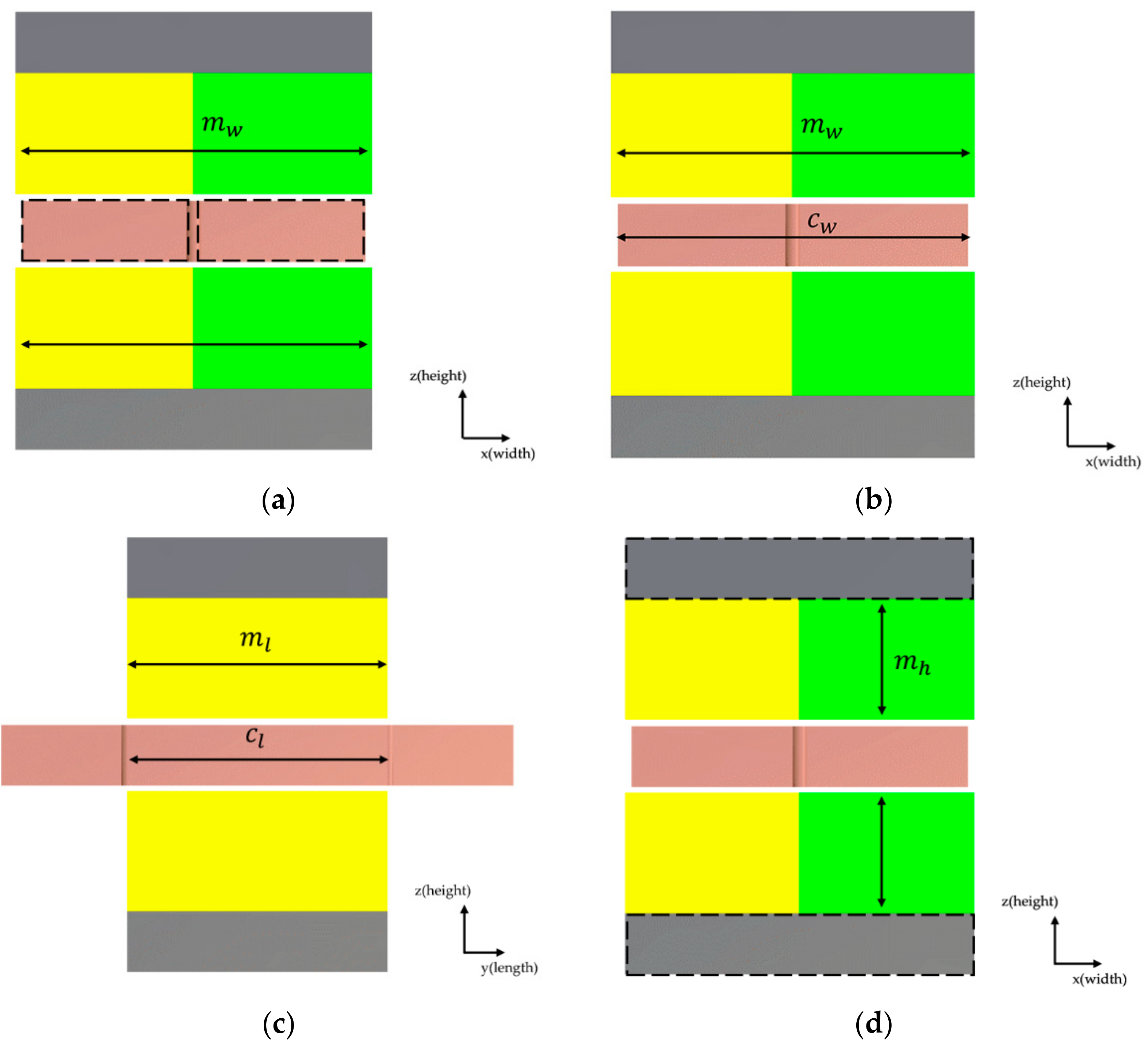

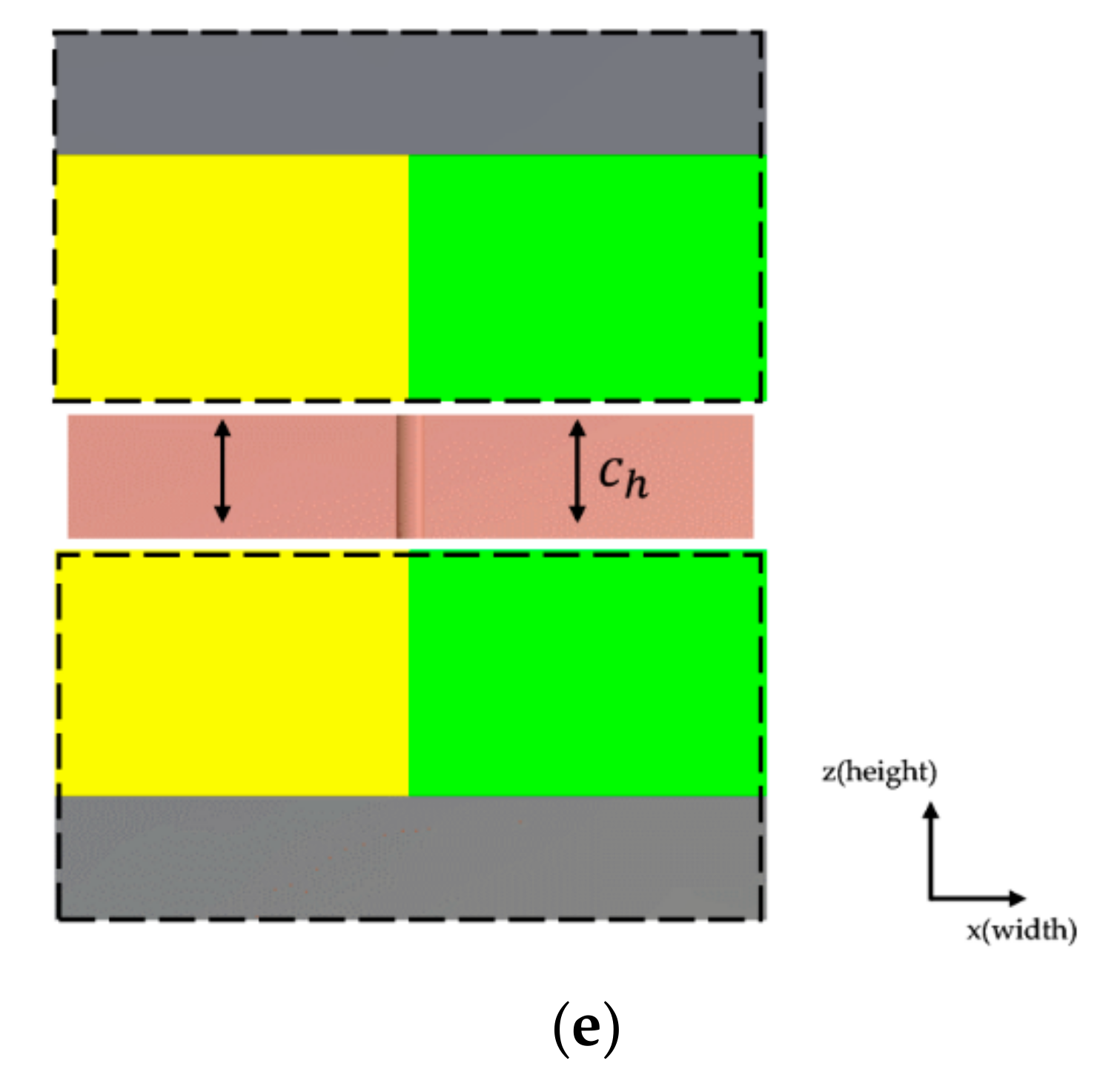

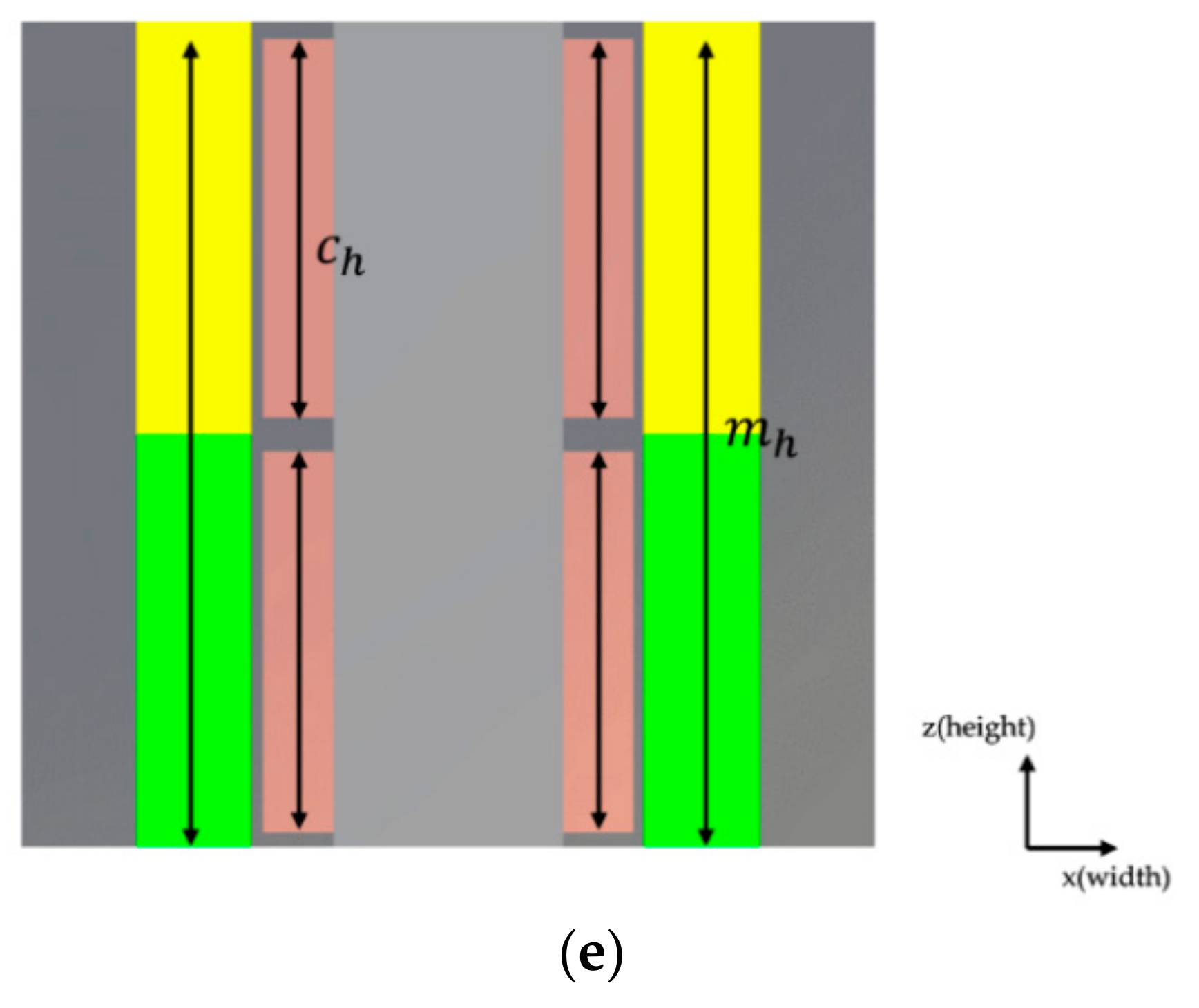

3.1. Design Parameters

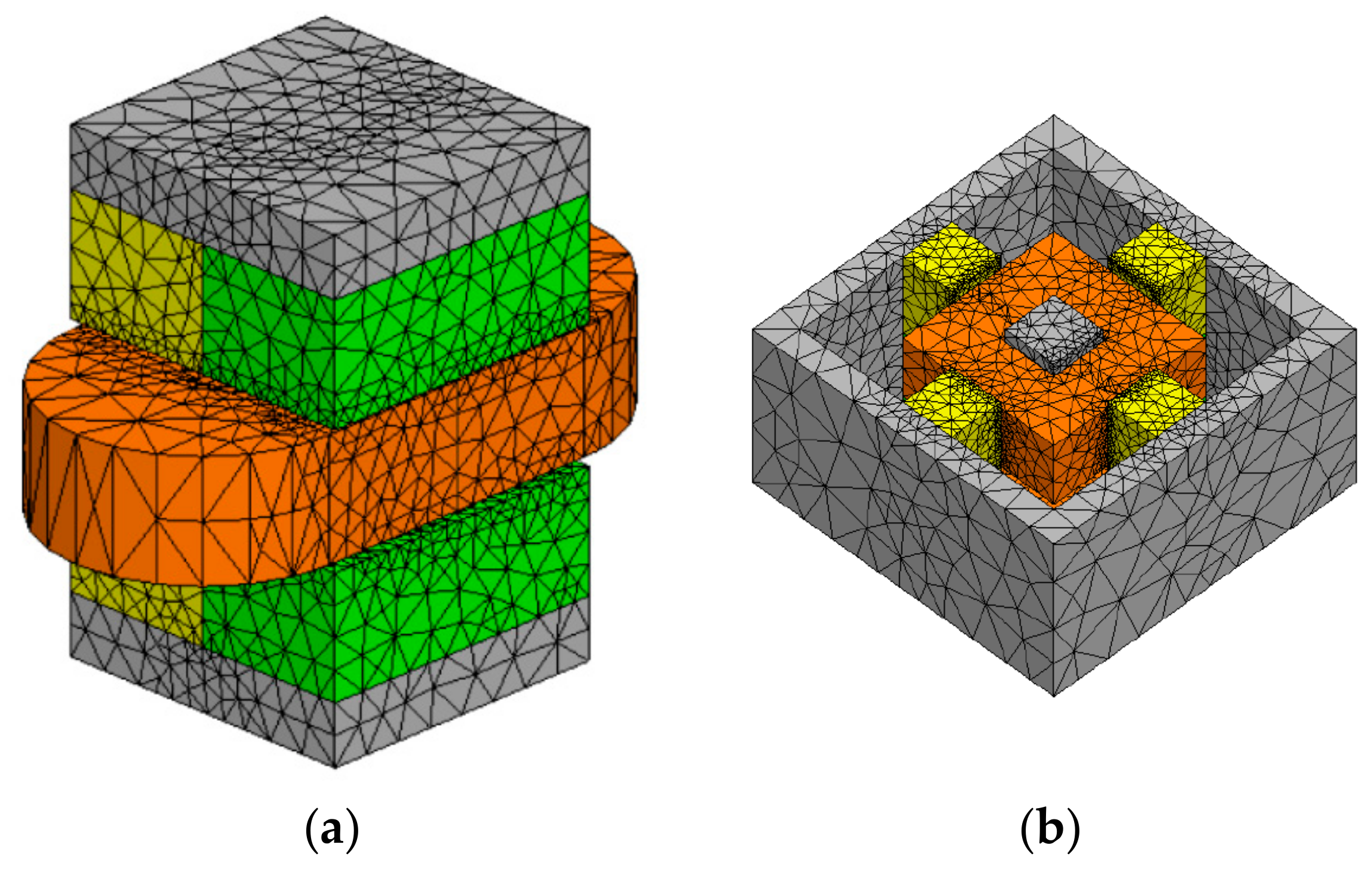

3.2. The FEM Model

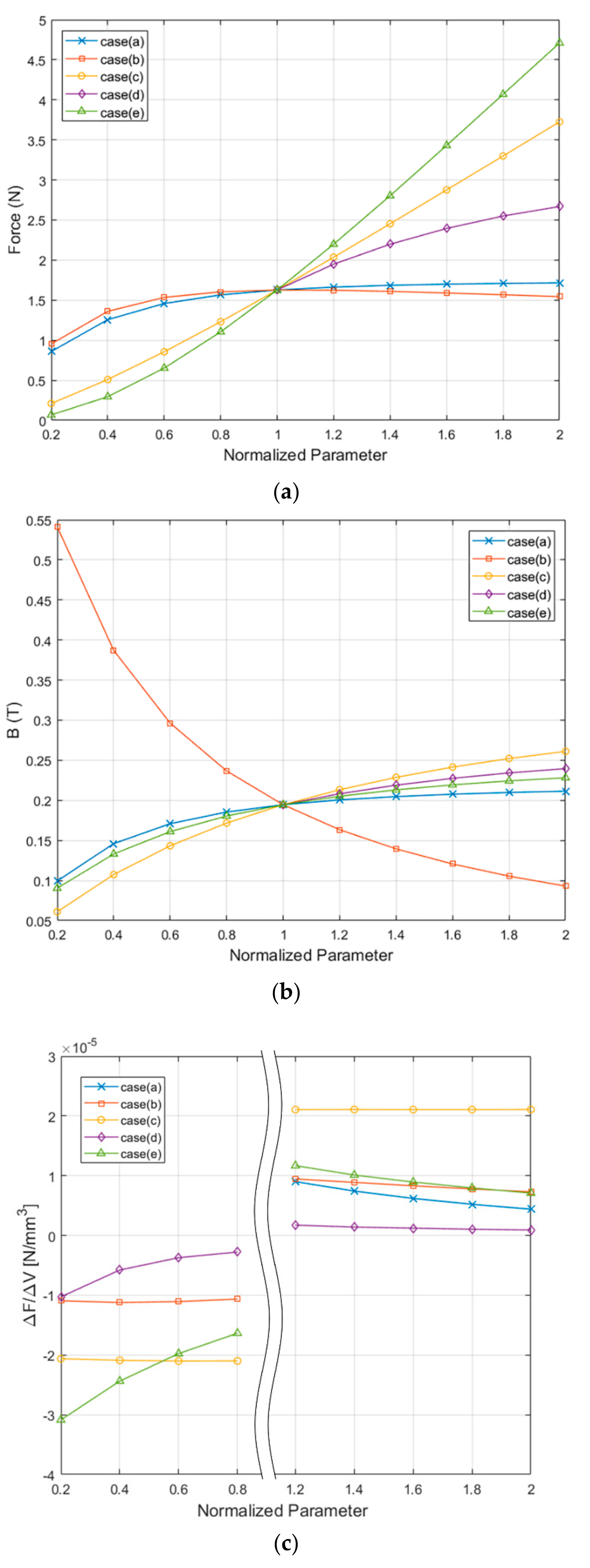

3.3. Results

4. VCM Designs for a Maglev Positioning Device

5. Conclusions

- An increase in force can be attempted by increasing the VCM volume. However, the efficiency of an increase in force differs depending on the method and direction of the volume increase and the type of VCM.

- The HVCM’s force increased significantly when the volume increased in the width and the length direction. However, the most efficient method of enhancing force consisted of increasing the volume in the lengthwise direction while maintaining a certain ratio between the width and length in consideration of the coil fabrication.

- The VVCM’s force increased significantly when the volume increased in the width and height directions. The total length of the coil increases when the VVCM width increases, and the number of coil turns increases when the VVCM height increases.

- Two VCMs could efficiently increase the volume with appropriate direction, after selecting an appropriate thickness for the magnet and coil and setting the magnet’s size to be no larger than that of the coil.

Author Contributions

Funding

Conflicts of Interest

References

- Gao, W.; Arai, Y.; Shibuya, A.; Kiyono, S.; Park, C.H. Measurement of multi-degree-of-freedom error motions of a precision linear air-bearing stage. Precis. Eng. 2006, 30, 96–103. [Google Scholar] [CrossRef]

- Ro, S.K.; Kim, S.; Kwak, Y.; Park, C.H. A linear air bearing stage with active magnetic preloads for ultraprecise. Precis. Eng. 2010, 34, 186–194. [Google Scholar] [CrossRef]

- Ro, S.K.; Park, J.K. A compact ultra-precision air bearing stage with 3-DOF planar motions using electromagnetic motors. Int. J. Precis. Eng. Manuf. 2011, 12, 115–119. [Google Scholar] [CrossRef]

- Peijnenburg, A.T.A.; Vermeulen, J.P.M.; van Eijk Ro, J. Magnetic levitation systems compared to conventional bearing systems. Microelectron. Eng. 2006, 83, 1372–1375. [Google Scholar] [CrossRef]

- Kim, W.J.; Trumper, D.L. High-precision magnetic levitation stage for photolithography. Precis. Eng. 1998, 22, 66–77. [Google Scholar] [CrossRef]

- Jansen, J.W.; van Lierop, C.M.M.; Lomonova, E.A.; Vandenput, A.J. Magnetically levitated planar actuator with moving magnets. IEEE Trans. Ind. Appl. 2008, 44, 1108–1115. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Teo, T.J.; Pang, C.K. Design and modeling of a six-degree-of-freedom magnetically levitated positioner using square coils and 1-D halbach arrays. IEEE Trans. Ind. Electron. 2017, 64, 440–450. [Google Scholar] [CrossRef]

- Hollis, R.L.; Salcudean, S.E.; Allan, A.P. A six-degree-of-freedom magnetically levitated variable compliance fine-motion wrist: Design, modeling, and control. IEEE Trans. Robot. Autom. 1991, 7, 320–332. [Google Scholar] [CrossRef]

- Verma, S.; Shakir, H.; Kim, W.J. Novel Electromagnetic Actuation Scheme for Multiaxis Nanopositioning. IEEE Trans. Magn. 2006, 42, 2052–2062. [Google Scholar] [CrossRef]

- Kim, W.J.; Verma, S.; Shakir, H. Design and precision construction of novel magnetic-levitation-based multi-axis nanoscale positioning systems. Precis. Eng. 2007, 31, 337–350. [Google Scholar] [CrossRef]

- Zhang, Z.; Menq, C. Six-Axis Magnetic Levitation and Motion Control. Ieee Trans. Robot. 2007, 23, 196–205. [Google Scholar] [CrossRef]

- Ahn, D.; Kim, H.; Choi, K.; Choi, Y.M.; Lim, J.Y. Design process of square column-shaped voice coil motor design for magnetic levitation stage. Int. J. Appl. Electromagn. Mech. 2019, 1, 1–24. [Google Scholar] [CrossRef]

- Choi, Y.M.; Gweon, D.G. A High-precision dual-servo stage using halbach linear active magnetic bearings. IEEE/ASME Trans. Mechatron. 2011, 16, 925–931. [Google Scholar] [CrossRef]

- Kim, M.; Jeong, J.H.; Kim, H.; Gweon, D.G. A six-degree-of-freedom magnetic levitation fine stage for a high-precision and high-acceleration dual-servo stage. Smart Mater. Struct. 2015, 24, 105022. [Google Scholar] [CrossRef]

- John, S.; Sirohi, J.; Wang, G.; Wereley, N.M. Comparison of Piezoelectric, Magnetostrictive, and Electrostrictive Hybrid Hydraulic actuators. J. Intell. Mater. Syst. Struct. 2007, 18, 1035–1048. [Google Scholar] [CrossRef]

- Vrijsen, N.H.; Jansen, J.W.; Lomonova, E.A. Comparison of linear voice coil and reluctance actuators for high-precision applications. In Proceedings of the 14th International Power Electronics and Motion Control Conference, Ohrid, North Macedonia, 6–8 September 2010; Volume 22, pp. 29–36. [Google Scholar]

- Choi, Y.M.; Ahn, D.; Gweon, D.G.; Lee, M.G. Design of a rectangular-type voice coil actuator for frame vibration compensation. J. Magn. 2016, 21, 348–355. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Wang, S. Topological shape optimization of permanent magnet in voice coil motor using level set method. IEEE Trans. Magn. 2012, 48, 931–934. [Google Scholar] [CrossRef]

- Choi, Y.M.; Lee, M.G.; Gweon, D.G.; Jeong, J. A new magnetic bearing using Halbach magnet arrays for a magnetic levitation stage. Rev. Sci. Instrum. 2009, 80, 45106. [Google Scholar]

- Kim, M.H.; Kim, H.Y.; Kim, H.C.; Ahn, D.; Gweon, D. Design and Control of a 6-DOF Active Vibration Isolation System Using a Halbach Magnet Array. IEEE/ASME Trans. Mechatron. 2016, 21, 2185–2196. [Google Scholar] [CrossRef]

- Dong, L.; Chen, J.; Zhang, C.; Wu, D.; Yu, G.; Liu, Q. Design and comparison of three-type VCMs for nano-positioning system. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications, Hefei, China, 5–7 June 2016. [Google Scholar]

- Janssen, J.L.G.; Paulides, J.J.H.; Encica, L.; Lomonova, E. High-performance moving-coil actuators with double-sided PM arrays: A design comparison. In Proceedings of the International Conference on Electrical Machines and Systems, Incheon, Korea, 10–13 October 2010. [Google Scholar]

| Expansion Direction | Case | Parameters | Description | Normalized Dimension (mm) | Variation (mm) |

|---|---|---|---|---|---|

| x(width) | a | mw | Magnet width | 52 | 52–104 |

| b | cw | Coil width | 50 | 10–100 | |

| mw | Magnet width | 52 | 10.4–104 | ||

| y(length) | c | cl | Coil length | 50 | 10–100 |

| ml | Magnet length | 50 | 10–100 | ||

| z(height) | d | mh | Magnet height | 20 | 4–40 |

| e | ch | Coil height | 20 | 4–40 |

| Expansion Direction | Case | Parameters | Description | Normalized Dimension (mm) | Variation (mm) |

|---|---|---|---|---|---|

| x, y(width) | a | mt | Magnet thickness | 20 | 4–40 |

| b | ct | Coil thickness | 20 | 4–40 | |

| c | mw | Magnet width | 20 | 4–40 | |

| cw | Coil width | 20 | 4–40 | ||

| z(height) | d | mh | Magnet height | 52 | 52–104 |

| e | ch | Coil height | 24 | 4–49 | |

| mh | Magnet height | 52 | 52–104 |

| Grade | Remanence (T) | Coercive Force (kA/m) |

|---|---|---|

| N-45M | 1.35 | 876 |

| HVCM | VVCM | |

|---|---|---|

| Given space for VCM design (mm × mm × mm) | 90 × 50 × 40 | 55 × 55 × 40 |

| Force constant (N/A) | 17.71 | 19.31 |

| Electrical resistance (Ω) | 4.50 | 2.73 |

| Coil diameter without sheath (mm) | 0.5 | 0.5 |

| Number of coil turns | 368 | 420 |

| Moving mass (g) | 471 | 530 |

| Horizontal Force Generation | Vertical Force Generation | |

|---|---|---|

| Given Space for VCM Design (mm × mm × mm) | 90 × 50 × 40 | 55 × 55 × 40 |

| HVCM (N/A) | 17.71 | 5.98 |

| VVCM (N/A) | 10.23 | 9.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-Y.; Ahn, D. Analysis of High Force Voice Coil Motors for Magnetic Levitation. Actuators 2020, 9, 133. https://doi.org/10.3390/act9040133

Kim J-Y, Ahn D. Analysis of High Force Voice Coil Motors for Magnetic Levitation. Actuators. 2020; 9(4):133. https://doi.org/10.3390/act9040133

Chicago/Turabian StyleKim, Jae-Yeol, and Dahoon Ahn. 2020. "Analysis of High Force Voice Coil Motors for Magnetic Levitation" Actuators 9, no. 4: 133. https://doi.org/10.3390/act9040133

APA StyleKim, J.-Y., & Ahn, D. (2020). Analysis of High Force Voice Coil Motors for Magnetic Levitation. Actuators, 9(4), 133. https://doi.org/10.3390/act9040133