Abstract

Chopsticks are a popular tool used every day by 1.5 billion people to pick up pieces of food of different sizes and shapes. Given that the use of chopsticks requires sophisticated muscle control, they are difficult to use for unskilled people. In this study, a chopstick robot that uses a new soft actuator was developed. Firstly, we developed an X-shaped soft actuator and tested its performance. When a voltage was applied to the actuator, the gap in the X shape was reduced by the resulting electrostatic force. Conversely, when the power was turned off, the actuator recovered its original shape owing to the elasticity of its material. We attached the X-shaped soft actuator between the chopsticks. The chopstick robot, controlled by the input voltage, can pick up various objects in the switched-on state and is able to release them when switched off. We tested the performance of the chopstick robot and analyzed the forces acting on the chopsticks. The robot can be used for picking up various objects. Moreover, the X-shaped actuator can be adapted for use in various studies, through different shapes and configurations.

1. Introduction

Chopsticks are a common and simple tool used for picking up food in oriental culture [1,2]. At least 1.5 billion people use chopsticks daily [3]. Chopsticks enable the user to pick up a variety of food pieces in comparison to a fork. Experienced people manipulate their fingers to properly move food with chopsticks, regardless of the size and hardness of the pieces [4,5].

There are several ways to handle chopsticks. Normally, when people use chopsticks, they pass two chopsticks through the space between the thumb and index finger (Figure 1) [2,6]. One stick is caught in the angle between the thumb and the index finger and is supported by the ring finger. The other stick is held between the middle and index fingers and is supported by the thumb. By the movement of the latter stick, the tips of the chopsticks are opened and closed.

Figure 1.

Photographs of moving chopsticks: (a) when the tips of the chopsticks are opened, and (b) when they are closed.

Several studies related to chopsticks have been conducted. Specifically, in regards to the effective use of chopsticks, their mechanism, optimum size, and shape have been studied [2,3,6,7]. Furthermore, virtual chopsticks driven by captured movement of a user’s hand have been demonstrated in a virtual reality system [8]. In addition, by applying the advantages of chopsticks to surgery and other research areas, new devices and techniques have been developed for grasp and transport [9,10,11,12,13].

Although chopsticks constitute a useful tool and have many advantages, they need accurate muscle manipulation [14]. Chopsticks require fine-tuning and adjustment of intrinsic and extrinsic muscles in the hands. Thus, auxiliary devices for chopstick operation have also been developed to improve user performance [15,16]. Moreover, chopstick robots have been developed for the elderly and disabled people who have weak hand muscles.

Chopstick robots are evolving into various driving forms. For instance, there is a way to attach chopsticks to a robot arm. The robot provides meal assistance through a 5-axis horizontal-type robot system and a camera [17,18]. These robots can deliver food with various actions including mixing, stabbing, cutting, separating, and spooning food with chopsticks. Another chopstick robot utilizes a gripper based on the concept of under-actuation and a planar mechanism with 2 degree of freedom (DOF) composed of a combination of 2 four-bar mechanisms [4]. A chopstick robot operated by the fingers of a human-inspired robot hand has also been developed [19]. It has bones, joints, ligaments, and tendons. Thus, it is able to use chopsticks through precise control of the fingers. The robot is also capable of handling chopsticks for grasping various objects.

In this study, we propose a soft chopstick robot that works by directly using a soft actuator to manipulate the chopsticks with minimum effort. Soft robots are used for a variety of applications, such as wearable devices, artificial muscles, and grippers [20,21,22,23]. Typically, robots consist either of rigid and electromechanical parts (e.g., magnet, copper, and steel bearings) or internal combustion engines made of steel and aluminum alloys [24,25,26]. Owing to their composition, conventional robots are fast, accurate, and very powerful. However, they are also substantially heavier and cumbersome. Soft robots, on the other hand, have soft body structures and are composed of flexible materials which can be operated smoothly [24,25,27,28]. Soft robots can also be adjusted in size and are lightweight. Moreover, they have agile mobility, and they show great potential for future applications. For example, soft robot hands can reach any point in a 3D workspace, using a variety of shapes and configurations. They also have a low resistance to compression and carry fragile objects without damaging them [29,30,31,32]. Therefore, soft robots can be used in various forms, such as service robots that interact with humans, exploration robots, and medical robots used in surgery and rehabilitation [24,27,33,34].

Soft actuators are key for soft robots. Electroactive polymers (EAPs) are a novel class of soft actuators. EAPs that activated by electrostatic force can show fast reaction speeds and are compatible with various manufacturing technologies [35]. In general, flexible actuators can be divided into two main categories: electroactive polymer (EAP) actuators driven by electric fields and actuators driven by other stimuli, including optical, thermal and chemical stimuli [36]. In addition, EAP actuators generally include two actuators: dielectric and ionic actuators [37]. In dielectric elastomer actuators, electric field-induced activation is generated by electrostatic attraction between two charged conductive layers applied to the surface of a polymer film [38]. When a voltage potential difference is applied between the two compliant electrodes, it causes compression of thickness and elongation in the region of the polymer film. On the other hand, ionic EAP actuators are driven by the movement of mobile ions within the polymer [36,39]. Small changes in external variables such as electric and magnetic fields, temperature, solvent quality, and pH cause discontinuous changes. Examples of ionic EAPs include polymer electrolyte gels, ionic polymer metal composites (IPMCs), conductive polymers, and bucky gel actuators [36].

Recently, studies are being conducted to improve the thermal stability and mechanical performance of the material for actuators [40]. These studies suggest new process methods for long life, high repeatability, and fast actuators compared to pneumatic and hydraulic actuators [41]. In particular, multilayer dielectric elastomer actuators based on silicone materials and elastomeric electrodes have many advantages in terms of thickness and manufacturing [42]. Further advantages include light weight, easy fabrication, and miniaturization [43].

Many different kinds of polymeric materials have been used for soft actuators—among them, silicone has been widely used for a lot of soft robot parts including actuators [44,45,46,47,48]. Silicone has a high flexibility with an average Young’s modulus of 68.9 kPa, tensile strength at 100% strain, and Poisson’s ratio of 0.499 [49]. Due to its high elasticity, the actuator does not require additional force when it is restored to its original state [50]. Further, since the silicone is harmless to the human body, silicone is widely used for surgical material and in daily necessities [51]. Thus, we use an EAP actuator driven by an electric field.

By using this material, we make X-shaped soft actuators for a chopstick robot. Specifically, the X shape is designed by combining two semi-ellipses with curved surfaces. To control the actuator using an electric field, conductive tapes are attached to the surfaces of the X-shaped silicone. In addition, the X-shaped silicone structure can be recovered after activation due to its elasticity. This paper is organized as follows. Section 2 describes the fabrication method of the X-shaped actuator and the experimental setup. Section 3 shows the operation of the chopstick robot with the X-shaped actuator. We also analyze the force required to move the chopsticks and the force of the X-shaped actuator. The conclusions are summarized in the final chapter.

2. Materials and Methods

2.1. X-shaped Actuator Fabrication

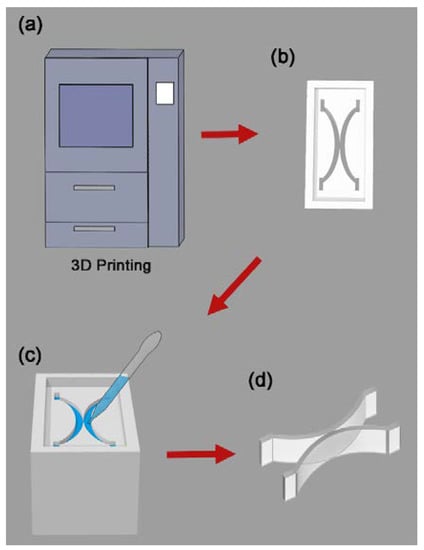

The fabrication mold for the X-shaped actuator was designed using Solidworks software (Dassault Systemes Solidworks Corp., Waltham, MA, USA). The design mold was made of a main part (VisiJet M3 Crystal, 3D Systems Inc., Rock Hill, SC, USA) and supporter (VisiJet S300, 3D Systems Inc., Rock Hill, SC, USA) materials with a 3D printer (ProJet HD3500, 3D systems Inc., Rock Hill, SC, USA) (Figure 2a). After printing, the mold was heated at 60 °C for 6 h in a convection oven (DCF-31-N, Dae Heung Science, Incheon, Korea) to melt the supporter material. Then, the melted supporter was completely removed from the mold and the mold was put in an oil bath of an ultrasonic cleaner (Sae Han Ultrasonic Co., Seoul, Korea) (Figure 2b). After washing and drying, a release agent (Ease release 200, Smooth-On, Inc., East Texas, PA, USA) was sprayed on the mold surface to prevent the silicone from sticking to the mold. The sprayed release agent was dried at 24 °C for 2 h.

Figure 2.

Schematic for X-shaped actuator fabrication: (a) the designed mold was fabricated with a 3D printer, (b) the mold was printed, (c) the silicone mixture was poured into the mold and solidified, and (d) the X-shaped silicone fabrication was completed.

After manufacturing the mold, the silicone was fabricated to create the X-shaped structure. First, Ecoflex 0030 part A (Smooth-On, Inc., East Texas, PA, USA), Ecoflex 0030 part B (Smooth-On, Inc., East Texas, PA, USA), and a platinum silicone cure accelerator (Plat-cat, Smooth-On, Inc., East Texas, PA, USA) were properly mixed in the ratio of 1:1:0.04 following the manufacturer’s guide. The mixture was vacuumed to remove air bubbles. Then, it was slowly poured into the mold and cured at approximately 24 °C for 2 h (Figure 2c). The X-shaped specimen was carefully separated from the mold using tweezers, after solidification (Figure 2d).

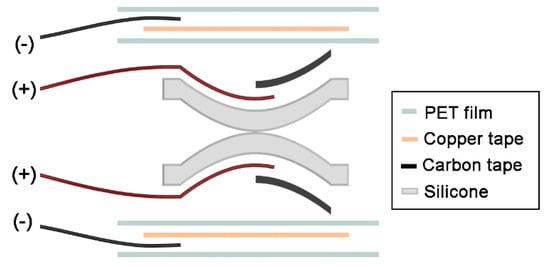

A 2.5 cm × 1 cm carbon conductive adhesive tape (Nisshin EM Co., Ltd., Tokyo, Japan) was attached to the right half of the curved surfaces of silicone with wires (Figure 3). Polyethylene terephthalate (PET) film (Saehan, Paju, Korea) and a copper tape (1181, 3M, Saint Paul, MN, USA) was cut into sizes of 7 cm × 2 cm and 5 cm × 1 cm, respectively. Then, the top and bottom of the copper tape were covered with two PET films. We connected wires to supply input voltage to the copper tapes. Two of these copper tapes with PET films were attached to the top and bottom of the X-shaped silicone.

Figure 3.

X-shaped actuator structure. Carbon tape attached to silicone is connected to the (+) of the input voltage and the surrounding copper tape is connected to the (-) of the input voltage to create an electrostatic force. In between, the two electrodes are blocked with polyethylene terephthalate (PET) films.

2.2. Voltage Input

A high-voltage power supply (MK-200002B, MKPOWER Inc., Seoul, Korea) providing an output of 12 kV was utilized for operating the actuator. Two thick-film resistors (50 MΩ each, Ohmite, Warrenville, IL, USA) were connected between the output pins of this power supply for discharging. For the electrostatic force, the (+) and (-) ports of the high-voltage power supply were connected to the carbon and copper tapes, respectively (Figure 3).

2.3. Chopstick Robot Configuration

The outer PET film of the X-shaped actuator was attached to each chopstick handle. One of the chopsticks was fixed using a stand and the other was free so that it could move according to the movement of the X-shaped actuator. The operation of the chopsticks was recorded using a camera (DSC RX10M3, Sony, Tokyo, Japan; lens: Vario-Sonnnar T*, Zeiss, Oberkochen, Germany).

3. Results

3.1. Motion of X-shaped Actuator

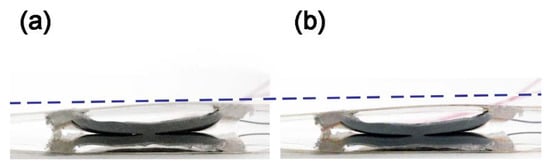

Electrostatic attraction occurs when voltage is applied to the copper and carbon tapes in the X-shaped actuator. For a clear gap comparison between the switched-on and switched-off states, we attached a carbon tape to the whole length of the X-shaped actuator (Figure 4). As a result, the distance between the carbon and copper tapes was reduced, and the total height of the X-shaped actuator was lower. When we placed the X-shaped actuator on the ground and applied the voltage, the gap between the carbon and copper tapes decreased by approximately 5 mm from the original height. By contrast, when the power is turned off, the elasticity of the X-shaped actuator makes it return to the original shape immediately.

Figure 4.

Motion of the X-shaped actuator: (a) its original shape without a voltage input, and (b) its contracted shape when a voltage difference is applied.

3.2. Operation Mechanism of Chopstick Robot

There are two ways to hold the chopsticks to catch objects. The first method is to narrow the gap between the supporting chopstick and the moving chopstick in parallel. The second method corresponds to the use of chopsticks with fingers. The latter type of exercise is to rotate the chopstick around the thumb. Interestingly, the chopstick moves by the movement of the index finger and the middle finger, which are located in front of the thumb. In this method, the gap between the two tips of the chopsticks on the side holding the object is very narrow, but the gap between the two ends of the chopsticks is very wide.

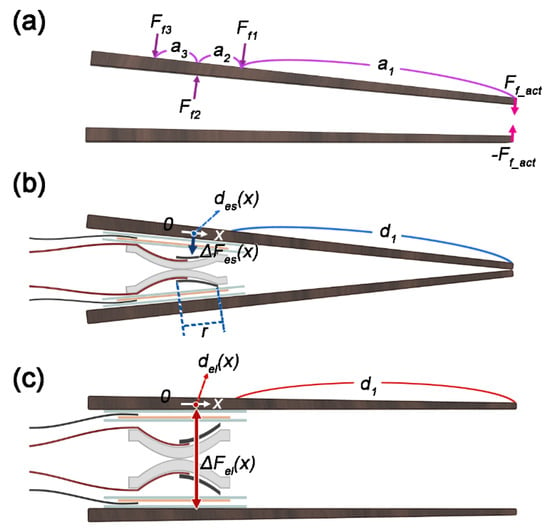

Chepisheva et al. made a soft robotic hand to use chopsticks and proposed a simple chopstick model [19]. In this model, the downward force of the chopsticks takes into account the forces exerted by the distal and proximal phalanges of the index finger, Ff1 and Ff3, respectively (Figure 5a). They also considered Ff2, i.e., the force exerted by the distal phalanx of the thumb; a1, a2, and a3 denote the lengths up to each point of the force. Considering these forces and distances, the force and moment equalities for the chopstick model are expressed as follows:

Figure 5.

Schematics for the chopstick robot operation: (a) the force acting when moving the chopsticks with fingers (Chepisheva et al.’s theory), (b) the chopsticks are closed by electrostatic force, and (c) the chopsticks are opened by elasticity.

In our case, the chopstick robot is operated by electrostatic forces (ΔFes(x)) at certain distances (des(x)) of the X-shaped actuator (Figure 5b). In the switched-off state, the elastic force (ΔFel(x)) at the distances (del(x)), based on the structure and material characteristics of the robot, is used for the recovery of the X-shaped actuator (Figure 5c). Note that des(x) and del(x) denote the distance from the tip of the chopstick to the point at which the elastic force and elasticity act, respectively. The lengths up to each point of the force can be expressed as follows:

where r denotes the equatorial radius of the semi-ellipse structure (Figure 5b) and d1 is the distance from the tip of the chopstick to the end of the actuator. By considering the robot condition, the force and moment equalities for the chopstick model are as follows:

The electrostatic force acts only on the lower half of the semi-ellipse, but the elastic force acts on the entire semi-ellipse. Therefore, the range of the force is doubled.

The electrostatic force acting on the carbon tape of the semi-ellipse structure can be calculated as follows,

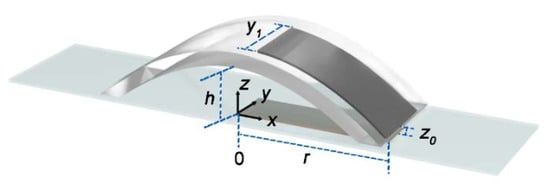

where ε0, Vd, and y1 are the electric permittivity of free space, the voltage difference, and the width of the carbon tape, respectively (Figure 6); z0 denotes a slight gap between the PET film and the lowest point in the X-shaped actuator; and h represents the polar radius. The parameters for calculation are presented in Table 1.

Figure 6.

A schematic of the semi-ellipse in the X-shaped actuator with parameters and coordinate definitions.

Table 1.

Parameters for electrostatic force calculation.

We can calculate the total electrostatic force by substituting the parameters given in Table 1 into Equation (7). The result is 1.01 × 10−2 N.

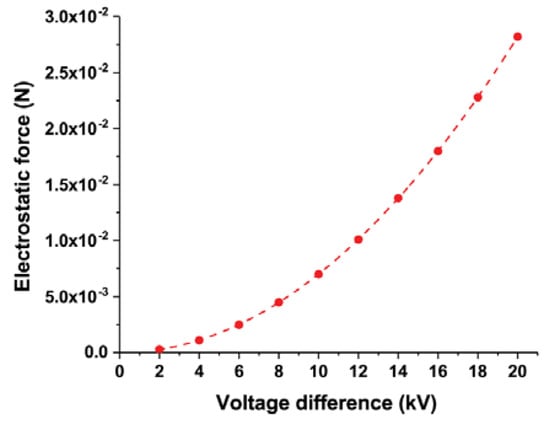

As can be seen in Equation (7), parameters such as the applied voltage difference and the radius and height of the X-shaped actuator have a decisive influence on the electrostatic force. To investigate the effects of these parameters, we performed further calculations.

As the applied voltage difference increases, the electrostatic force sharply increases (Figure 7). Compared to 12 kV, which was the voltage we used for the experiment, the electrostatic force at 6 kV is reduced by one-quarter. Conversely, the electrostatic force is more than doubled at 18 kV.

Figure 7.

Electrostatic force changes due to variation in voltage difference.

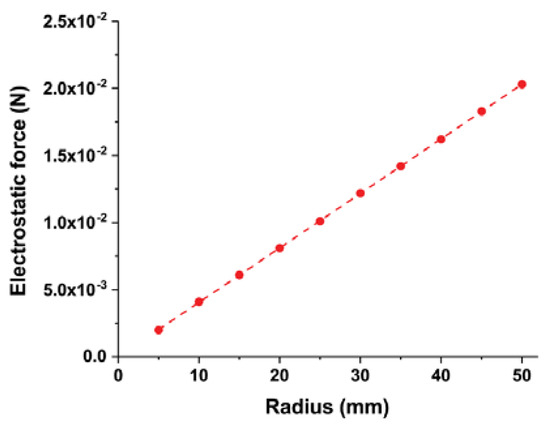

Further, the radius of the X-shaped actuator is proportional to the electrostatic force (Figure 8). When the radius of the X-shaped actuator is reduced by 1 cm, the electrostatic force is reduced by approximately 60.4%. On the other hand, doubling the radius of an X-shaped actuator doubles the electrostatic force.

Figure 8.

Electrostatic force changes due to variation in the radius of the X-shaped actuator (r).

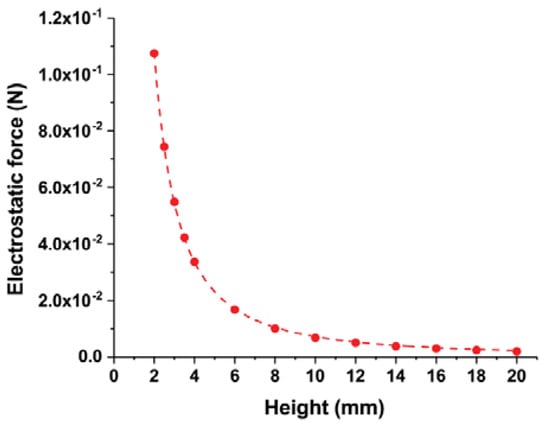

When the height of the X-shaped actuator is increased, the electrostatic force decreases sharply (Figure 9). The height of the actuator is the peak distance between the two electrodes. Halving the height of the X-shaped actuator results in a greater than 3-fold increase in the electrostatic force. Conversely, the electrostatic force is reduced by one-third when the height is doubled.

Figure 9.

Electrostatic force changes due variation in the height of the X-shaped actuator.

3.3. Chopstick Robot Tests with Various Objects

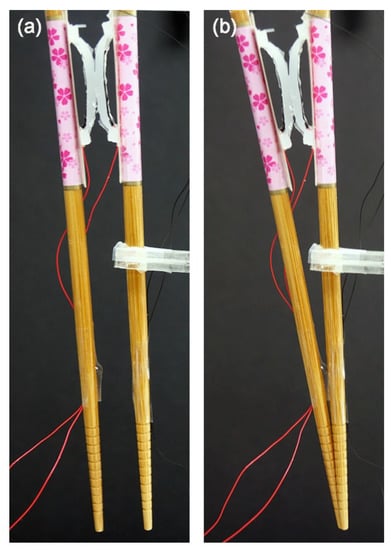

We attached the X-shaped actuator between the chopsticks. When the voltage input was applied to the X-shaped actuator, the gap between the chopsticks became narrower (Figure 10). On the other hand, when the voltage was turned off, the electrostatic attraction disappeared and the elasticity of the actuator resulted in recovery of its original shape. Therefore, it was possible to recover its original shape again. The chopstick robot was closed within 0.9 s and opened within 0.5 s due to the voltage applied.

Figure 10.

Motion of chopstick robot: (a) its original state without a voltage input, and (b) when the chopsticks are closed by the electrostatic force when voltage is supplied.

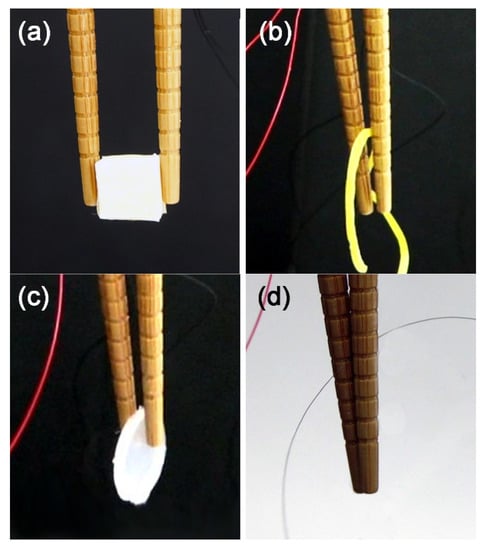

We tested the chopstick robot by attempting to hold various objects (Supplementary Video S1). The robot grasped a 10 mm × 10 mm × 10 mm cube made of paper (Figure 11a). In addition, the robot successfully grasped a rubber band and a silicone plate, with a radius of 10 mm and a thickness of 2 mm, respectively (Figure 11b,c). The chopstick robot holds an object while the power is turned on, and immediately drops it when the power is turned off. It could also pick up a strand of hair (Figure 11d). Moreover, we have carried out hundreds of repeated experiments and the chopstick robot performed well repetitively, without any structural modifications or problems.

Figure 11.

Pictures of the chopstick robot holding various objects: (a) a paper cube, (b) a rubber band, (c) a silicone piece, and (d) a strand of hair.

4. Conclusions

In this study, we designed and manufactured a chopstick robot that uses an X-shaped actuator and is driven by an electrostatic force and elasticity. In order to close the tips of the chopsticks, we utilized an electrostatic force. In order to open the tips of the chopsticks, the elasticity of the X-shaped actuator was utilized. The balance between the opening force and the closing force at the tips is very important for the chopstick robot. If the elasticity of the soft actuator is too strong, the electrostatic force cannot overcome the elastic force and the chopsticks cannot be closed. On the other hand, if the elastic force is too small, the chopsticks cannot return to the original shape immediately. Both the electrostatic force and elastic force were calculated through simple theoretical analysis. We also investigated the effects of the parameters using theoretical calculations. Finally, we demonstrated that the chopstick robot could successfully pick up various objects. The theoretical modeling and simulation to study the dynamics of the X-shaped actuator will be our future work.

The X-shaped actuator can be used to control the distance of two parallel panels. Typically, it can be applied to a gripper that has a mechanism similar to a chopstick. Recently, much research has been conducted aimed at grasping and moving fine and fragile materials without damage in various fields including in semiconductor fabrication. The grasping force of the X-shaped actuator can be controlled depending on the size or shape of the target sample. In particular, if all the gripper parts are replaced with soft materials, they will be able to specialize in carrying small and fragile objects. In addition, the X-shaped actuator can be used as a valve that controls the flow of fluids because it can manage the distance and angle of two parallel panels.

Supplementary Materials

The following are available online at https://www.mdpi.com/2076-0825/9/2/32/s1, Video S1: Chopstick robot driven by soft actuator: a supplementary video showing the motion of the chopstick robot when an electrostatic force is applied in the switched-on state.

Author Contributions

Conceptualization, K.S. and Y.C.; experiment, K.S.; validation, K.S. and Y.C.; writing, K.S. and Y.C.; funding acquisition, Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the KIST flagship program under Project 2E30280 and the Technology Innovation Program for Development of robotic work control technology capable of grasping and manipulating various objects in everyday life environment based on multimodal recognition and using tools funded by the Ministry of Trade, Industry and Energy under grant number 20001856.

Acknowledgments

We gratefully thank Chohee Kim for supporting us with drawing the schematics.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fu, B.X. Asian noodles: History, classification, raw materials, and processing. Food Res. Int. 2008, 41, 888–902. [Google Scholar] [CrossRef]

- Chen, Y.-L. Effects of shape and operation of chopsticks on food-serving performance. Appl. Ergon. 1998, 29, 233–238. [Google Scholar] [CrossRef]

- Chan, T. A study for determining the optimum diameter of chopsticks. Int. J. Ind. Ergon. 1999, 23, 101–105. [Google Scholar] [CrossRef]

- Oka, T.; Matsuura, D.; Sugahara, Y.; Solis, J.; Lindborg, A.-L.; Takeda, Y. Chopstick-type Gripper Mechanism for Meal-Assistance Robot Capable of Adapting to Size and Elasticity of Foods. In Proceedings of the IFToMM Symposium on Mechanism Design for Robotics, Udine, Italy, 31 August 2018; Springer: Udine, Italy; pp. 284–292. [Google Scholar]

- Kim, J.S.; Yeo, I.S.; Kim, S.O.; Kim, K.H. The Effects of Chopstick Action Observational Physical Training on the Improvement of Non-dominant Hands Fine Motor Functions. Int. J. Hum. Mov. Sci. 2012, 6, 143–152. [Google Scholar]

- Hsu, S.-H.; Wu, S.-P. An investigation for determining the optimum length of chopsticks. Appl. Ergon. 1991, 22, 395–400. [Google Scholar] [CrossRef]

- Chen, S.; Liang, J.; Lai, K.; Ting, Y.; Peng, Y.; Hsu, H.; Lai, K.; Su, F. Kinematics Analysis of Chopsticks Manipulation. In Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Munich, Germany, 7–12 September 2009; Springer: Munich, Germany; pp. 410–413. [Google Scholar]

- Kitamura, Y.; Higashi, T.; Masaki, T.; Kishino, F. Virtual Chopsticks: Object Manipulation Using Multiple Exact Interactions. In Proceedings of the IEEE Virtual Reality, Houston, TX, USA, 13–17 March 1999; IEEE: Houston, TX, USA; pp. 198–204. [Google Scholar]

- Joseph, R.A.; Goh, A.C.; Cuevas, S.P.; Donovan, M.A.; Kauffman, M.G.; Salas, N.A.; Miles, B.; Bass, B.L.; Dunkin, B.J. “Chopstick” surgery: A novel technique improves surgeon performance and eliminates arm collision in robotic single-incision laparoscopic surgery. Surg. Endosc. 2010, 24, 1331–1335. [Google Scholar] [CrossRef] [PubMed]

- Ramadan, A.A.; Takubo, T.; Mae, Y.; Oohara, K.; Arai, T. Developmental process of a chopstick-like hybrid-structure two-fingered micromanipulator hand for 3-D manipulation of microscopic objects. IEEE Trans. Ind. Electron. 2009, 56, 1121–1135. [Google Scholar] [CrossRef]

- Colinjivadi, K.S.; Lee, J.-B.; Draper, R. Viable cell handling with high aspect ratio polymer chopstick gripper mounted on a nano precision manipulator. Microsyst. Technol. 2008, 14, 1627–1633. [Google Scholar] [CrossRef]

- Yamasaki, Y.; Tsumugiwa, T.; Yokogawa, R. Grasp and Transport control of a chopsticks-type robot. In Proceedings of the Fourth International Conference on Innovative Computing, Information and Control (ICICIC), Kaohsiung, Taiwan, 7–9 December 2009; IEEE: Kaohsiung, Taiwan; pp. 197–202. [Google Scholar]

- Tanikawa, T.; Arai, T.; Masuda, T. Development of micro manipulation system with two-finger micro hand. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Osaka, Japan, 8 November 1996; IEEE: Osaka, Japan; pp. 850–855. [Google Scholar]

- Pang, J. A Comparative Biomechanical Analysis of Independent Finger Movement–Between Skilled and Unskilled Chopsticks Users. Ph.D. Thesis, University of Massachusetts Lowell, Lowell, MA, USA, 2012. [Google Scholar]

- Lee, Y.-C.; Chen, Y.-L. An auxiliary device for chopsticks operation to improve the food-serving performance. Appl. Ergon. 2008, 39, 737–742. [Google Scholar] [CrossRef]

- Chen, Y.-L.; Lee, Y.-C. Effect of an auxiliary device for chopstick operations on the chopstick-use performance of foreign novices. Neuropsychiatry 2017, 7, 310–315. [Google Scholar] [CrossRef]

- Koshizaki, T.; Masuda, R. Control of a meal assistance robot capable of using chopsticks. In Proceedings of the 41st International Symposium on Robotics (ISR) and 6th German Conference on Robotics (ROBOTIK), Munich, Germany, 7–9 June 2010; VDE: Munich, Germany; pp. 1–6. [Google Scholar]

- Yamazaki, A.; Masuda, R. Autonomous foods handling by chopsticks for meal assistant robot. In Proceedings of the 7th German Conference on Robotics, Munich, Germany, 21–22 May 2012; VDE: Munich, Germany; pp. 1–6. [Google Scholar]

- Chepisheva, M.; Culha, U.; Iida, F. A biologically inspired soft robotic hand using chopsticks for grasping tasks. In International Conference on Simulation of Adaptive Behavior; Springer: Cham, Swizerland, 2016; pp. 195–206. [Google Scholar]

- Liang, X.; Yap, H.K.; Guo, J.; Yeow, R.C.H.; Sun, Y.; Chui, C.K. Design and characterization of a novel fabric-based robotic arm for future wearable robot application. In Proceedings of the IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, China, 5–8 December 2017; pp. 367–372. [Google Scholar]

- Greer, J.D.; Morimoto, T.K.; Okamura, A.M.; Hawkes, E.W. Series pneumatic artificial muscles (sPAMs) and application to a soft continuum robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Singapore, 29 May–3 June 2017. [Google Scholar]

- Lee, C.; Kim, M.; Kim, Y.J.; Hong, N.; Ryu, S.; Kim, H.J.; Kim, S. Soft robot review. Int. J. Control Autom. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mat. 2018, 1707035. [Google Scholar] [CrossRef] [PubMed]

- Laschi, C.; Cianchetti, M. Soft robotics: New perspectives for robot bodyware and control. Front. Bioeng. Biotechnol. 2014, 2, 3. [Google Scholar] [CrossRef] [PubMed]

- Martinez, R.V.; Glavan, A.C.; Keplinger, C.; Oyetibo, A.I.; Whitesides, G.M. Soft actuators and robots that are resistant to mechanical damage. Adv. Funct. Mater. 2014, 24, 3003–3010. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Trivedi, D.; Rahn, C.D.; Kier, W.M.; Walker, I.D. Soft robotics: Biological inspiration, state of the art, and future research. Appl. Bionics Biomech. 2008, 5, 99–117. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467. [Google Scholar] [CrossRef]

- Tian, M.; Xiao, Y.; Wang, X.; Chen, J.; Zhao, W. Design and experimental research of pneumatic soft humanoid robot hand. In Robot Intelligence Technology and Applications 4; Springer: Basel, Switzerland, 2017; pp. 469–478. [Google Scholar]

- Zhou, X.; Majidi, C.; O’Reilly, O.M. Soft hands: An analysis of some gripping mechanisms in soft robot design. Int. J. Solids Struct. 2015, 64, 155–165. [Google Scholar] [CrossRef]

- She, Y.; Li, C.; Cleary, J.; Su, H.-J. Design and fabrication of a soft robotic hand with embedded actuators and sensors. J. Mech. Robot. 2015, 7, 021007. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef]

- Best, C.M.; Wilson, J.P.; Killpack, M.D. Control of a pneumatically actuated, fully inflatable, fabric-based, humanoid robot. In Proceedings of the IEEE-RAS 15th International Conference on Humanoid Robots (Humanoids), Seoul, Korea, 3–5 November 2015; IEEE: Seoul, Korea; pp. 1133–1140. [Google Scholar]

- Tolley, M.T.; Shepherd, R.F.; Mosadegh, B.; Galloway, K.C.; Wehner, M.; Karpelson, M.; Wood, R.J.; Whitesides, G.M. A resilient, untethered soft robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Song, K.; Lee, H.; Cha, Y. A V-Shaped actuator utilizing electrostatic force. Actuators 2018, 7, 30. [Google Scholar] [CrossRef]

- Chen, W.; Zhu, Z. Flexible Actuators; Springer: Singapore, 2015; pp. 381–4110. [Google Scholar]

- Mirfakhrai, T.; Madden, J.D.; Baughman, R.H. Polymer artificial muscles. Mater. Today 2007, 10, 30–38. [Google Scholar] [CrossRef]

- Shankar, R.; Ghosh, T.K.; Spontak, R.J. Dielectric elastomers as next-generation polymeric actuators. Soft Matter 2007, 3, 1116–1129. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Electroactive polymers: Current capabilities and challenges. In Proceedings of the Smart Structures and Materials 2002: Electroactive Polymer Actuators and Devices (EAPAD), San Diego, CA, USA, 11 July 2002; International Society for Optics and Photonics: San Diego, CA, USA; pp. 1–7. [Google Scholar]

- Kong, J.; Tong, Y.; Sun, J.; Wei, Y.; Thitsartarn, W.; Jayven, C.C.Y.; Muiruri, J.K.; Wong, S.Y.; He, C. Electrically conductive PDMS-grafted CNTs-reinforced silicone elastomer. Compos. Sci. Technol. 2 2018, 159, 208–215. [Google Scholar] [CrossRef]

- Rosset, S.; Araromi, O.A.; Schlatter, S.; Shea, H.R. Fabrication process of silicone-based dielectric elastomer actuators. J. Vis. Exp. 2016, 108, e53423. [Google Scholar] [CrossRef]

- Li, Z.; Dong, P.; Shi, T.; Tang, C.; Bian, C.; Chen, H. Elastomeric electrode and casting process for manufacturing multilayer dielectric elastomer actuators. Electroact. Polym. Actuators Devices (EAPAD) XX 2018, 10594, 1059414. [Google Scholar]

- Song, K.; Kim, S.H.; Jin, S.; Kim, S.; Lee, S.; Kim, J.-S.; Park, J.-M.; Cha, Y. Pneumatic actuator and flexible piezoelectric sensor for soft virtual reality glove system. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef]

- Shintake, J.; Sonar, H.; Piskarev, E.; Paik, J.; Floreano, D. Soft pneumatic gelatin actuator for edible robotics. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: Vancouver, BC, Canada; pp. 6221–6226. [Google Scholar]

- Choi, H.R.; Jung, K.; Ryew, S.; Nam, J.-D.; Jeon, J.; Koo, J.C.; Tanie, K. Biomimetic soft actuator: Design, modeling, control, and applications. IEEE-ASME Trans. Mechatron. 2005, 10, 581–593. [Google Scholar] [CrossRef]

- Suzumori, K.; Asaad, S. A novel pneumatic rubber actuator for mobile robot bases. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Osaka, Japan, 8 November 1996; IEEE: Osaka, Japan; pp. 1001–1006. [Google Scholar]

- Phung, H.; Hoang, P.T.; Nguyen, C.T.; Nguyen, T.D.; Jung, H.; Kim, U.; Choi, H.R. Interactive haptic display based on soft actuator and soft sensor. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: Vancouver, BC, Canada; pp. 886–891. [Google Scholar]

- Sun, Y.; Guo, J.; Miller-Jackson, T.M.; Liang, X.; Ang, M.H.; Yeow, R.C.H. Design and fabrication of a shape-morphing soft pneumatic actuator: Soft robotic pad. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: Vancouver, BC, Canada; pp. 6214–6220. [Google Scholar]

- Roche, E.T.; Wohlfarth, R.; Overvelde, J.T.; Vasilyev, N.V.; Pigula, F.A.; Mooney, D.J.; Bertoldi, K.; Walsh, C.J. A bioinspired soft actuated material. Adv. Mater. 2014, 26, 1200–1206. [Google Scholar] [CrossRef]

- Song, K.; Cha, Y. Hemispherical Cell-Inspired Soft Actuator. Front. Bioeng. Biotechnol. 2020, 8, 20. [Google Scholar] [CrossRef] [PubMed]

- Mayne, A.; Bayliss, S.; Barr, P.; Tobin, M.; Buckberry, L. Biologically interfaced porous silicon devices. Phys. Status Solidi (a) 2000, 182, 505–513. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).