Microfluidic Jetting Deformation and Pinching-off Mechanism in Capillary Tubes by Using Traveling Surface Acoustic Waves

Abstract

1. Introduction

2. Materials and Methods

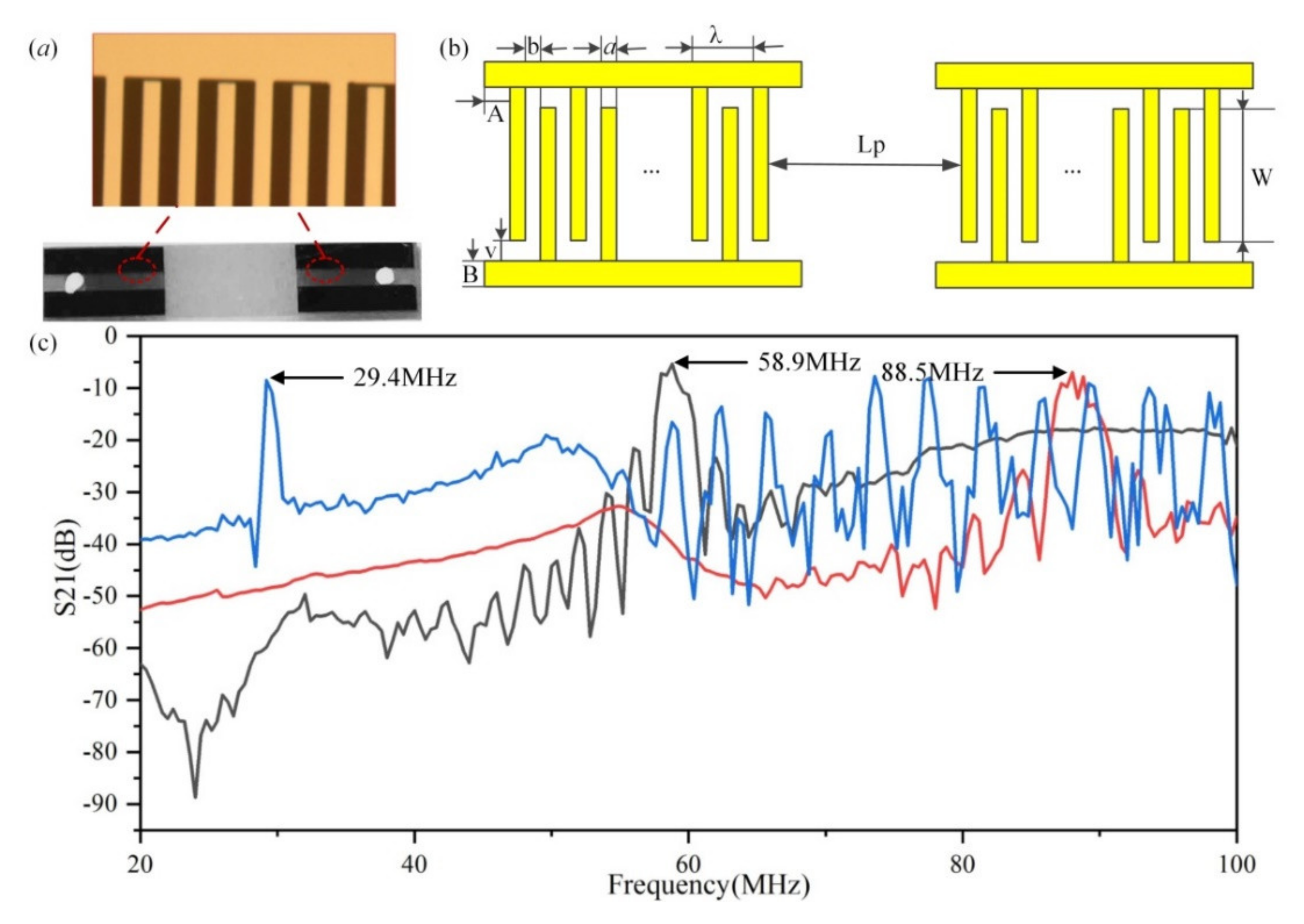

2.1. SAW Device Fabrication

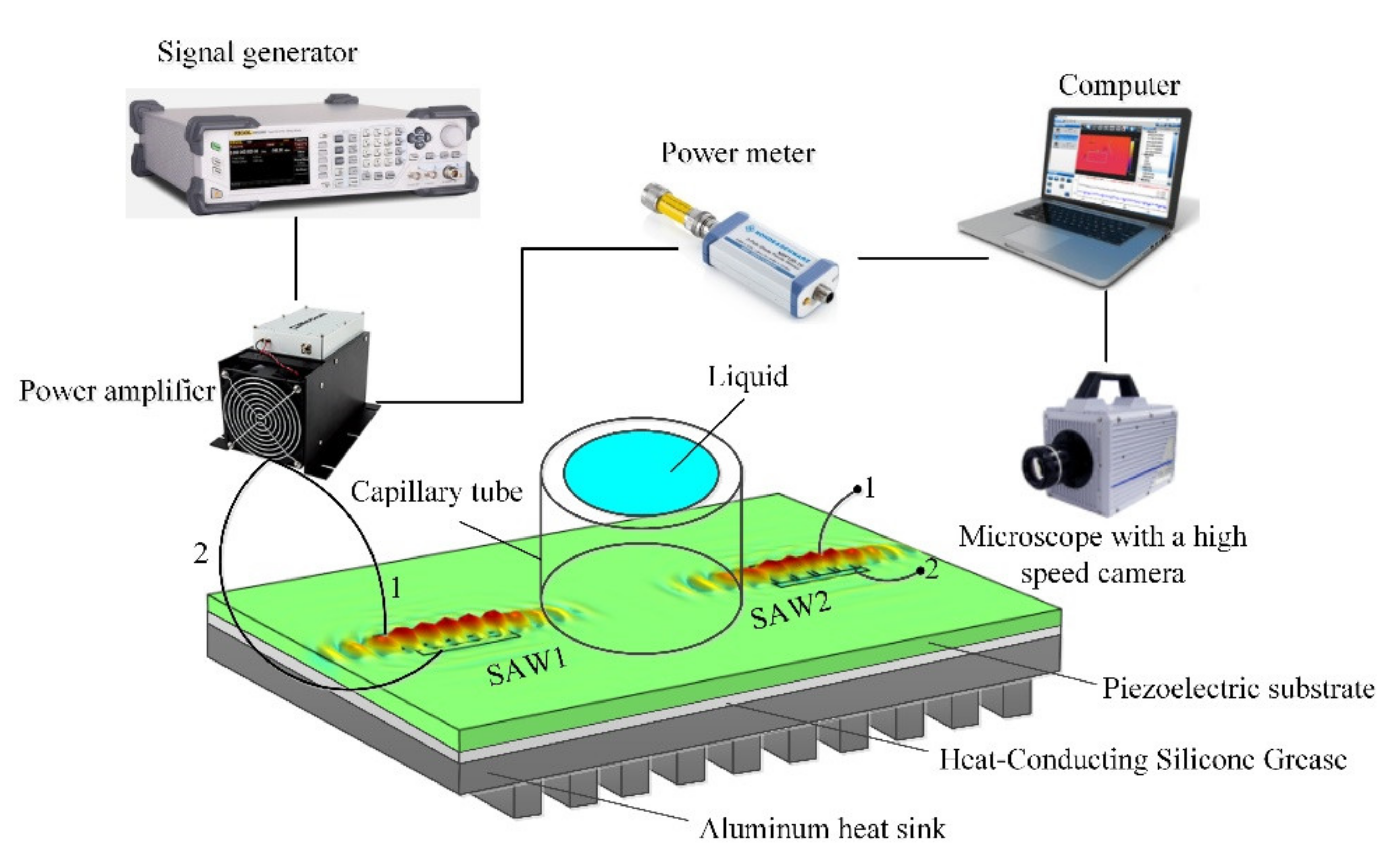

2.2. Experimental Setup

3. Results and Discussion

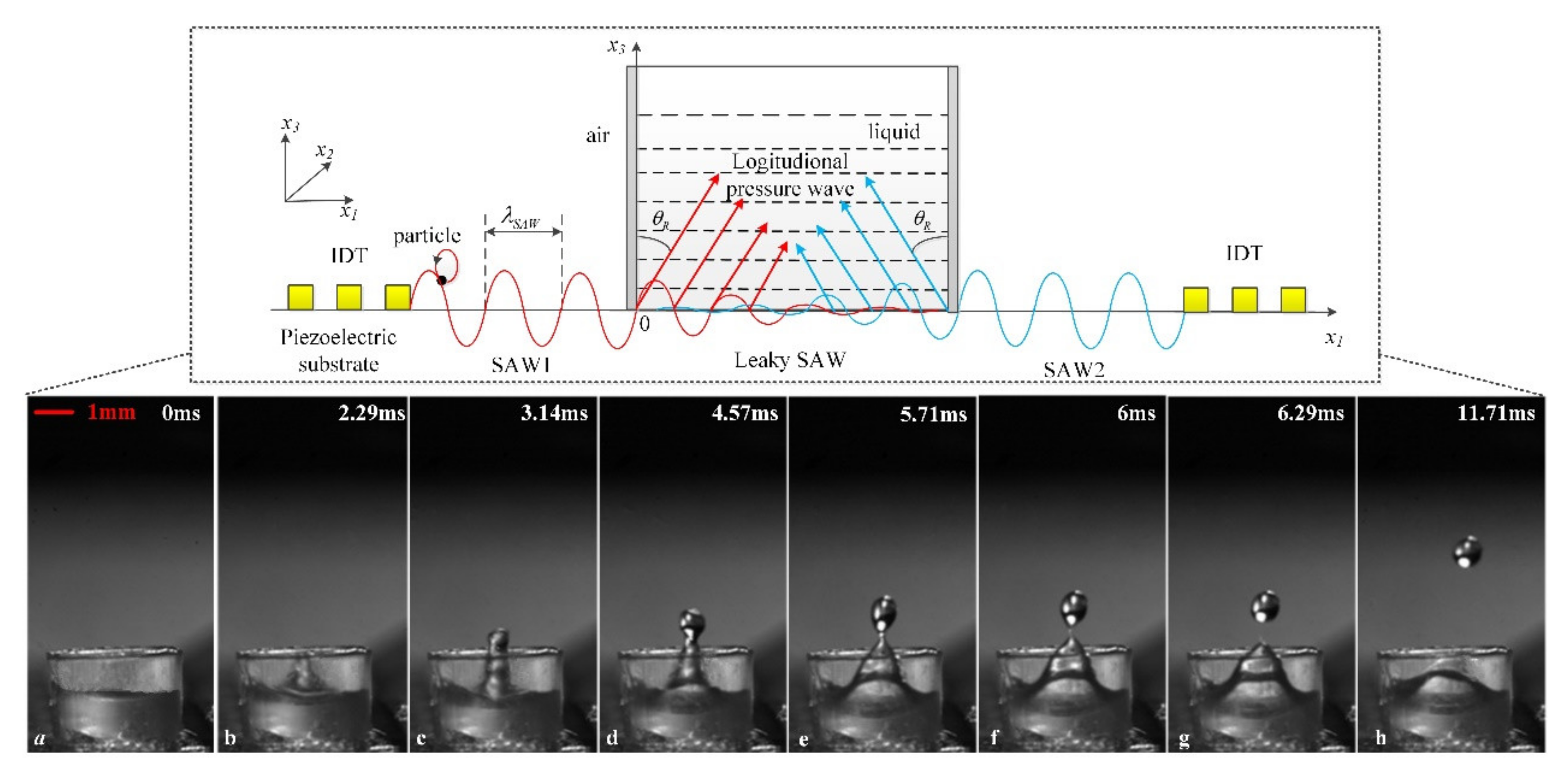

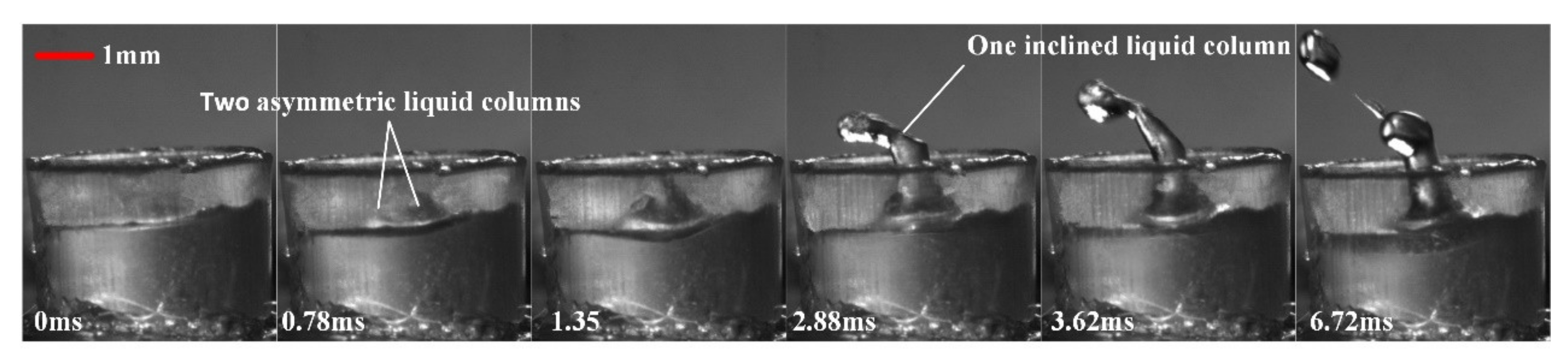

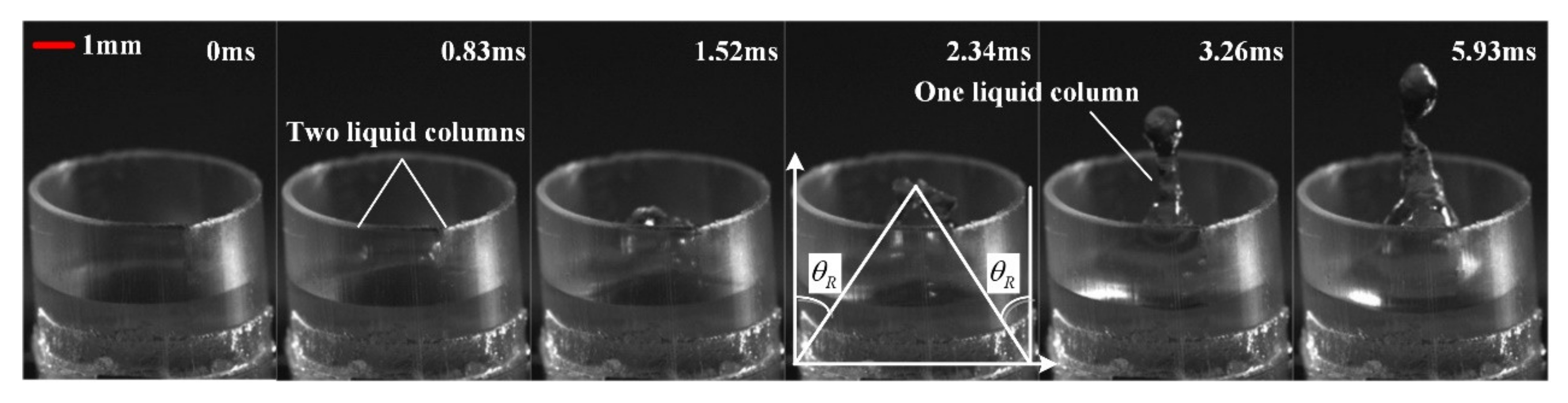

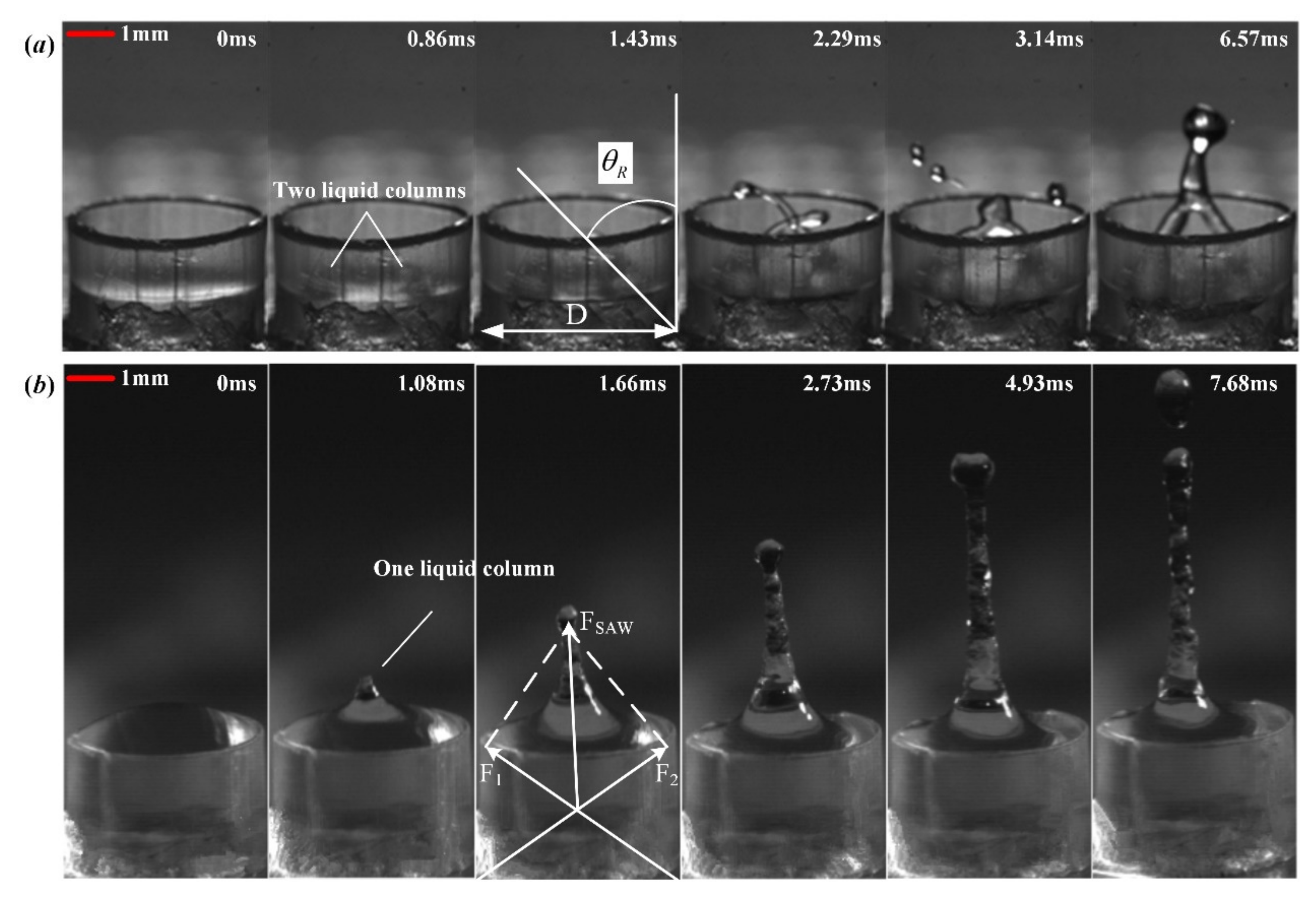

3.1. Droplet Jetting Mechanism in Vertical Capillary Tube

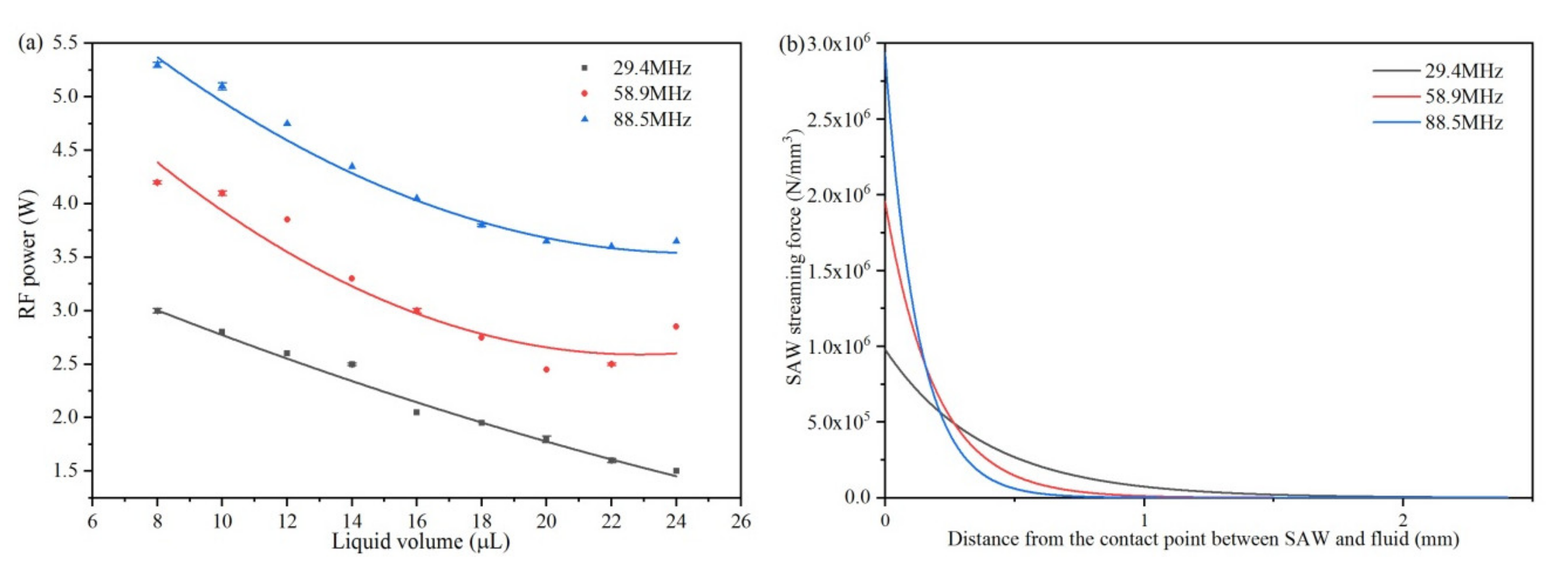

3.2. Single Droplet Jetting Condition

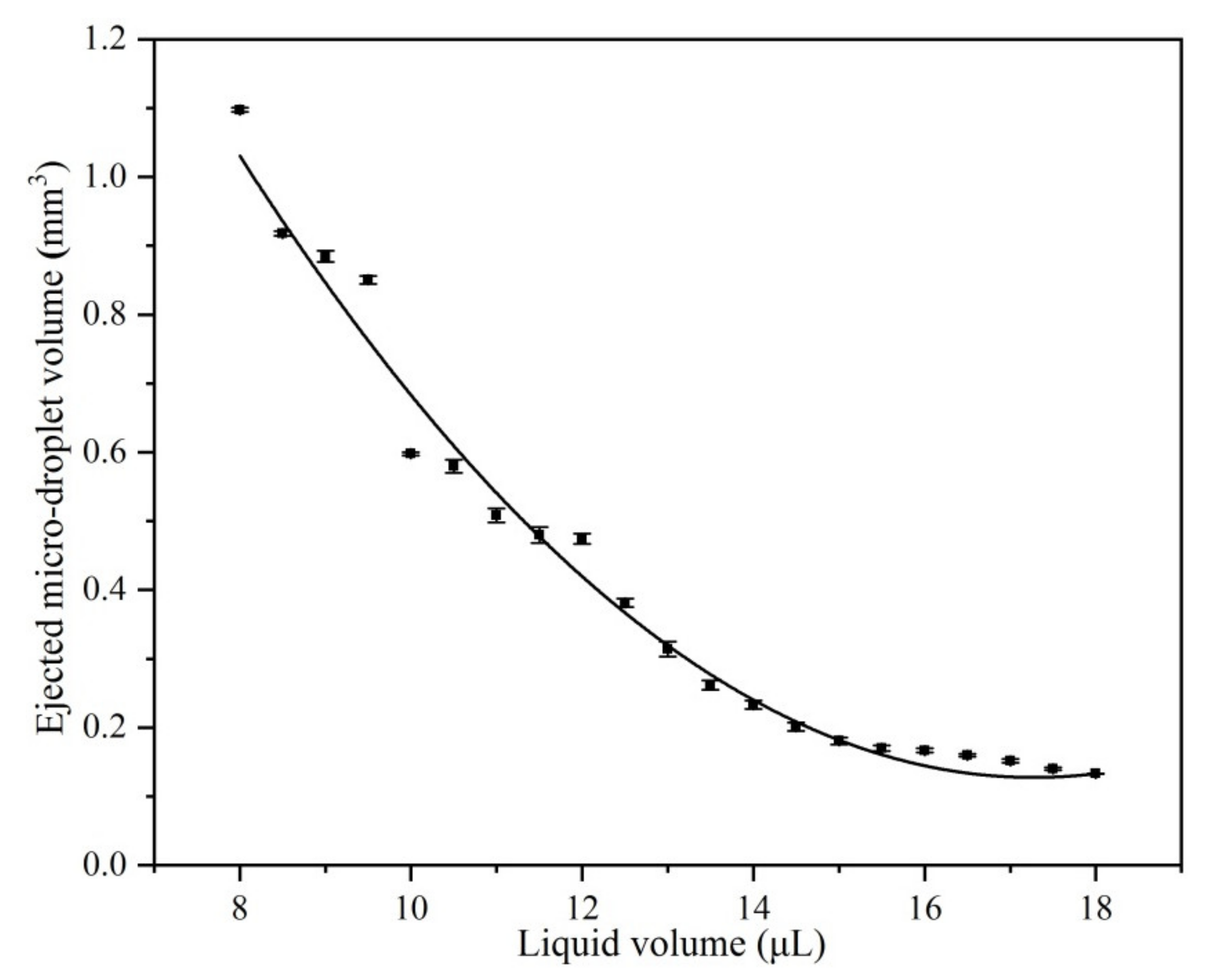

3.3. Analysis of Jetting Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hoath, S.D.; Harlen, O.G.; Hutchings, I.M. Jetting behavior of polymer solutions in drop-on-demand inkjet printing. J. Rheol. 2012, 56, 1109–1127. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, G. The influence of fluid viscosity of fluid jetting dispensing. In Proceedings of the 2007 International Symposium on High Density packaging and Microsystem Integration, Shanghai, China, 26–28 June 2007; pp. 1–4. [Google Scholar]

- Barron, J.A.; Young, H.D.; Dlott, D.D.; Darfler, M.M.; Krizman, D.B.; Ringeisen, B.R. Printing of protein microarrays via a capillary-free fluid jetting mechanism. Proteomics 2005, 5, 4138–4144. [Google Scholar] [CrossRef]

- Zohar, R.; Sagi, D.; Sadowski, B. Jet print apparatus and method for printed circuit board manufacturing. U.S. Patent 6,754,551, 22 June 2004. [Google Scholar]

- Xie, D.; Zhang, H.; Shu, X.; Xiao, J.; Cao, S. Multi-materials drop-on-demand inkjet technology based on pneumatic diaphragm actuator. Sci. China Technol. Sci. 2010, 53, 1605–1611. [Google Scholar] [CrossRef]

- Karri, B.; Avila, S.R.G.; Loke, Y.C.; O’Shea, S.J.; Klaseboer, E.; Khoo, B.C.; Ohl, C.D. High-speed jetting and spray formation from bubble collapse. Phys. Rev. E 2012, 85, 015303. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.G.; Lee, E.; Song, K.; Hur, S. Dynamics of the piezoelectric driven ink jetting. In Proceedings of the 71st Annual Meeting of the APS Division of Fluid Dynamics, Atlanta, GA, USA, 18–20 November 2018. [Google Scholar]

- Luo, Z.; Wang, X.; Wang, L.; Sun, D.; Li, Z. Drop-on-demand electromagnetic printing of metallic droplets. Mater. Lett. 2017, 188, 184–187. [Google Scholar] [CrossRef]

- Silverbrook, K. Micro electro-mechanical system for jetting of fluids. U.S. Patent 6,299,300, 10 September 2001. [Google Scholar]

- Tanaka, H.; Mizuno, Y.; Nakamura, K. Jetting of small droplet from microplate using focused ultrasound. Jpn. J. Appl. Phys. 2017, 56, 087202. [Google Scholar] [CrossRef]

- Shilton, R.J.; Travagliati, M.; Beltram, F.; Cecchini, M. Nanoliter-droplet acoustic streaming via ultra high frequency surface acoustic waves. Adv. Mater. 2014, 26, 4941–4946. [Google Scholar] [CrossRef]

- Ding, X.; Lin, S.C.S.; Kiraly, B.; Yue, H.; Li, S.; Chiang, K.I.; Huang, T.J. On-chip manipulation of single microparticles, cells, and organisms using surface acoustic waves. Proc. Natl. Acad. Sci. USA 2012, 109, 11105–11109. [Google Scholar] [CrossRef]

- Schmid, L.; Wixforth, A.; Weitz, D.A.; Franke, T. Novel surface acoustic wave (SAW)-driven closed PDMS flow chamber. Microfluid. Nanofluid. 2012, 12, 229–235. [Google Scholar] [CrossRef]

- Tan, M.K.; Friend, J.R.; Yeo, L.Y. Interfacial jetting phenomena induced by focused surface vibrations. Phys. Rev. Lett. 2009, 103, 024501. [Google Scholar] [CrossRef]

- Ju, J.; Yamagata, Y.; Ohmori, H.; Higuchi, T. High-frequency surface acoustic wave atomizer. Sens. Actuators A-Phys. 2008, 145, 437–441. [Google Scholar] [CrossRef]

- Qi, A.; Yeo, L.Y.; Friend, J.R. Interfacial destabilization and atomization driven by surface acoustic waves. Phys. Fluids 2008, 20, 074103. [Google Scholar] [CrossRef]

- Yeo, L.Y.; Friend, J.R. Surface acoustic wave microfluidics. Annu. Rev. Fluid Mech. 2014, 46, 379–406. [Google Scholar] [CrossRef]

- Shiokawa, S.; Matsui, Y.; Ueda, T. Study on SAW streaming and its application to fluid devices. Jpn. J. Appl. Phys. 1990, 29, 137. [Google Scholar] [CrossRef]

- Bourquin, Y.; Wilson, R.; Zhang, Y.; Reboud, J.; Cooper, J.M. Phononic crystals for shaping fluids. Adv. Mater. 2011, 23, 1458–1462. [Google Scholar] [CrossRef] [PubMed]

- Darmawan, M.; Byun, D. Focused surface acoustic wave induced jet formation on superhydrophobic surfaces. Microfluid. Nanofluid. 2015, 18, 1107–1114. [Google Scholar] [CrossRef]

- Castro, J.O.; Ramesan, S.; Rezk, A.R.; Yeo, L.Y. Continuous tuneable droplet jetting via pulsed surface acoustic wave jetting. Soft Matter 2018, 14, 5721–5727. [Google Scholar] [CrossRef]

- Nakanishi, H.; Nakamura, H.; Goto, R. High-electromechanical-coupling-coefficient surface acoustic wave resonator on Ta2O5/Al/LiNbO3 structure. Jpn. J. Appl. Phys. 2010, 49, 07HD21. [Google Scholar] [CrossRef]

- Nakahata, H.; Higaki, K.; Hachigo, A.; Shikata, S.; Fujimori, N.; Takahashi, Y.; Kajihara, T.; Yamamoto, Y. High frequency surface acoustic wave filter using ZnO/diamond/Si structure. Jpn. J. Appl. Phys. 1994, 33, 324. [Google Scholar] [CrossRef]

- Hassanizadeh, S.M.; Celia, M.A.; Dahle, H.K. Dynamic effect in the capillary pressure–saturation relationship and its impacts on unsaturated flow. Vadose Zone J. 2002, 1, 38–57. [Google Scholar] [CrossRef]

- Alghane, M.; Fu, Y.Q.; Chen, B.X.; Li, Y.; Desmulliez, M.P.Y.; Walton, A.J. Frequency effect on streaming phenomenon induced by Rayleigh surface acoustic wave in microdroplets. J. Appl. Phys. 2012, 112, 084902. [Google Scholar] [CrossRef]

| Frequency (MHz) | Liquid Volume (μL) | PD (W) | Rj (mm) | Uj (m/s) | We | rj (mm) | vj (m/s) |

|---|---|---|---|---|---|---|---|

| 29.4 | 8 | 3 | 0.4313 | 0.2139 | 0.2736 | 0.6400 | 0.1683 |

| 29.4 | 10 | 2.6 | 0.3813 | 0.2746 | 0.3988 | 0.5227 | 0.1254 |

| 29.4 | 12 | 2.05 | 0.3625 | 0.1888 | 0.1793 | 0.4836 | 0.1609 |

| 29.4 | 14 | 1.8 | 0.3438 | 0.2082 | 0.2066 | 0.3823 | 0.0924 |

| 29.4 | 16 | 1.5 | 0.3063 | 0.2552 | 0.2766 | 0.3414 | 0.1336 |

| 29.4 | 18 | 1.4 | 0.2813 | 0.1856 | 0.1343 | 0.3167 | 0.0689 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Y.; Hu, H.; Chen, J.; Zhang, P. Microfluidic Jetting Deformation and Pinching-off Mechanism in Capillary Tubes by Using Traveling Surface Acoustic Waves. Actuators 2020, 9, 5. https://doi.org/10.3390/act9010005

Lei Y, Hu H, Chen J, Zhang P. Microfluidic Jetting Deformation and Pinching-off Mechanism in Capillary Tubes by Using Traveling Surface Acoustic Waves. Actuators. 2020; 9(1):5. https://doi.org/10.3390/act9010005

Chicago/Turabian StyleLei, Yulin, Hong Hu, Jian Chen, and Peng Zhang. 2020. "Microfluidic Jetting Deformation and Pinching-off Mechanism in Capillary Tubes by Using Traveling Surface Acoustic Waves" Actuators 9, no. 1: 5. https://doi.org/10.3390/act9010005

APA StyleLei, Y., Hu, H., Chen, J., & Zhang, P. (2020). Microfluidic Jetting Deformation and Pinching-off Mechanism in Capillary Tubes by Using Traveling Surface Acoustic Waves. Actuators, 9(1), 5. https://doi.org/10.3390/act9010005