1. Introduction

Soft, mechanically compliant robotic grippers can elastically deform to grasp irregularly shaped organic objects, such as strawberries, small citrus fruits, and mushrooms. In contrast to industrial rigid robotic end effectors that apply point forces on a target, soft grippers can distribute the contact forces over a broader surface area [

1], thereby minimizing contact damage to delicate surfaces and structures. Pneumatic actuation [

2,

3,

4,

5,

6,

7] is commonly used because air is nearly inviscid, and compressed air can be stored and dispensed at precise pressure levels. During operation, the applied pressurized air causes the inflation and deformation of one or more inner cavities (i.e., chambers) embedded in the actuators of the grasping mechanism. These air-driven, soft actuators often have complex geometries and are fabricated from hyperelastic materials, such as synthetic rubbers or silicone polymers [

3], which exhibit nonlinear stress–strain properties, making it difficult to precisely predict the actuator’s behavior. The inherent nonlinearity of the elastomeric material becomes a critical design consideration when developing a soft gripper for commercial applications such as automated harvesting of small horticultural crops.

Various soft, air-driven actuators have been reported in the literature, and they are based on several complementary operating principles [

2,

3,

4,

5,

6,

7,

8,

9,

10]. One of the simplest and earliest actuators is the Pneumatic Artificial Muscle (PAM), where a closed inflatable membrane is inflated with pressurized air to generate a linear and unidirectional axial force [

5]. A variant of the PAM is the McKibben actuator, which surrounds the closed membrane with a braided sleeve [

6,

7]. When pressurized with air, the volume of the tube increases radially while the overall actuator length decreases. It is also possible to introduce a bending motion by adding an inextensible layer along the length of a McKibben actuator. Studies have shown that the bendable McKibben actuator operating under 500 kPa of air pressure can produce a contact force of approximately 42 N [

7]. The PneuNet [

2] is another popular bendable, soft actuator that consists of a series of air chambers connected by a long channel. To control the direction of movement or bending, the stretchable elastomeric structure has one or more surfaces bonded to an inextensible material such as paper, cloth, or fiber mesh. Although visually impressive, the bulky and ultrasoft PneuNet uses low air pressures (e.g., 72 kPa) and thus generates very small contact forces (e.g., 1.4 N) [

2]. In another type of bending actuator, researchers have used a variety of wrapping fiber reinforcements, including Kevlar threads, nylon, and string [

8,

9]. Incorporating fiber reinforcements in semicircular tube-shaped soft actuators, Miron et al. [

8] use an increased air pressure to 275 kPa and created forces in the range of 20 to 28 N.

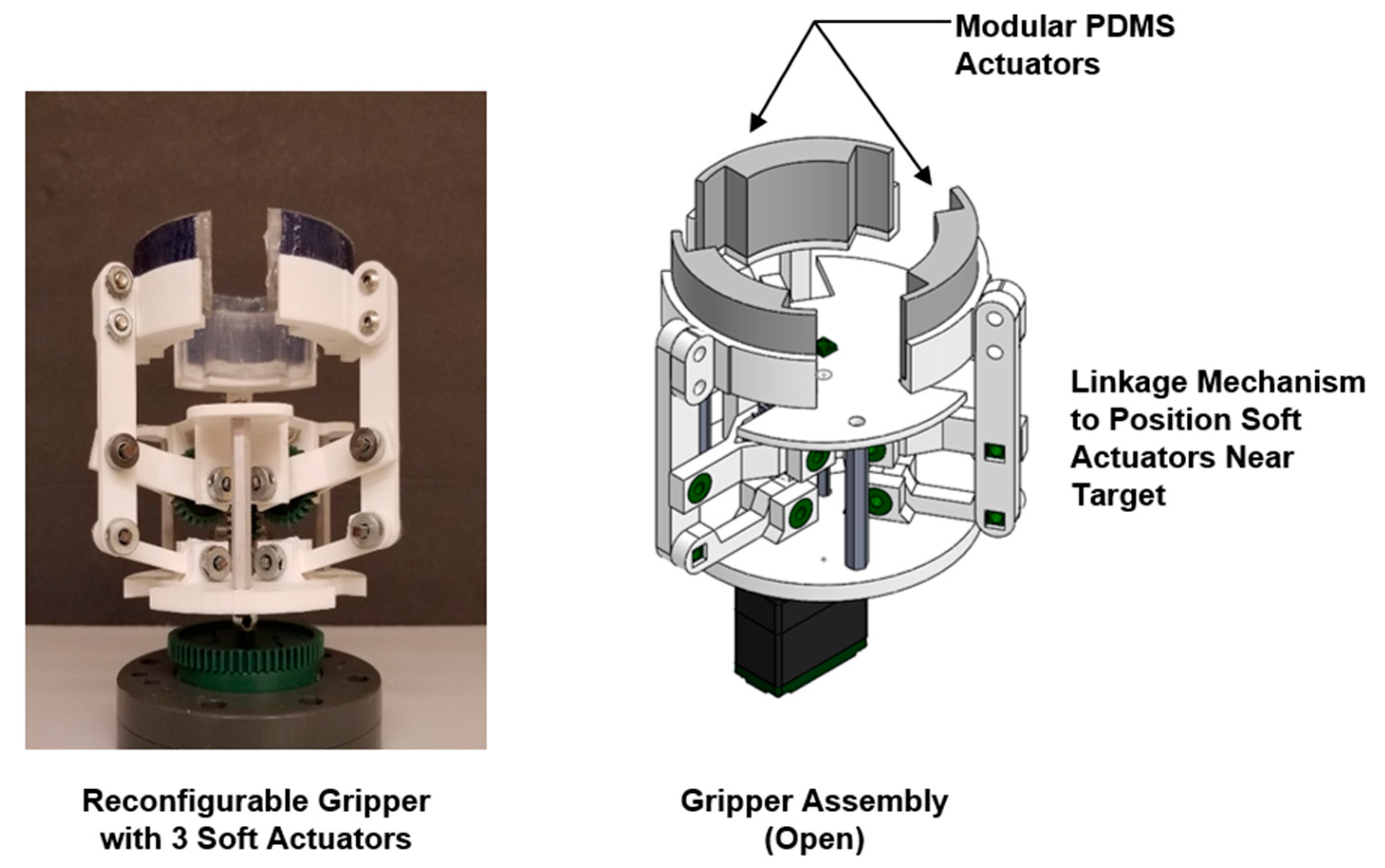

In general, pneumatically-driven expandable, soft actuators are based on the notion of stretchable elastomeric structures with inflatable air cavities that incorporate inextensible walls or surfaces that guide movement, such as active surface deformation or bending motion. Important design considerations include selecting an appropriate elastomeric material with predictable properties, developing a viable geometry for the required movement, restricting the actuator’s degrees-of-freedom (DoF) to achieve the desired contact forces, and ensuring ease of fabrication and reproducibility. The intended application also imposes constraints on the actuator design. For example, many of the biologically inspired soft, bendable actuators [

2,

3,

4,

5,

6] are not suitable for horticultural applications, because the designs incorporate too many DoF and do not take into account spatial constraints imposed by the work environment. To address these practical concerns, the air-driven, soft gripper described in this paper is comprised of three modular hyperelastic polydimethylsiloxane (PDMS) actuators inserted in a closed ring assembly (

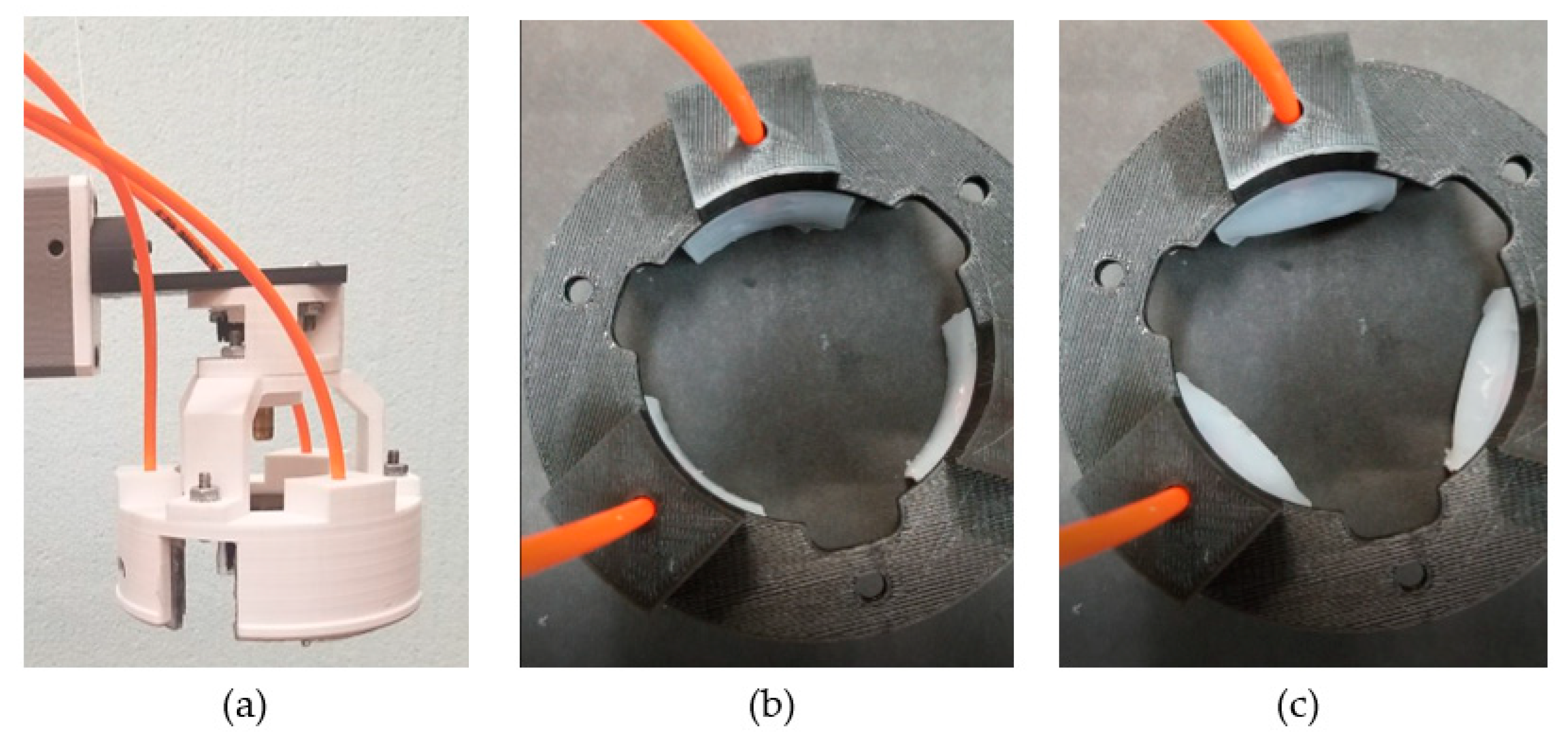

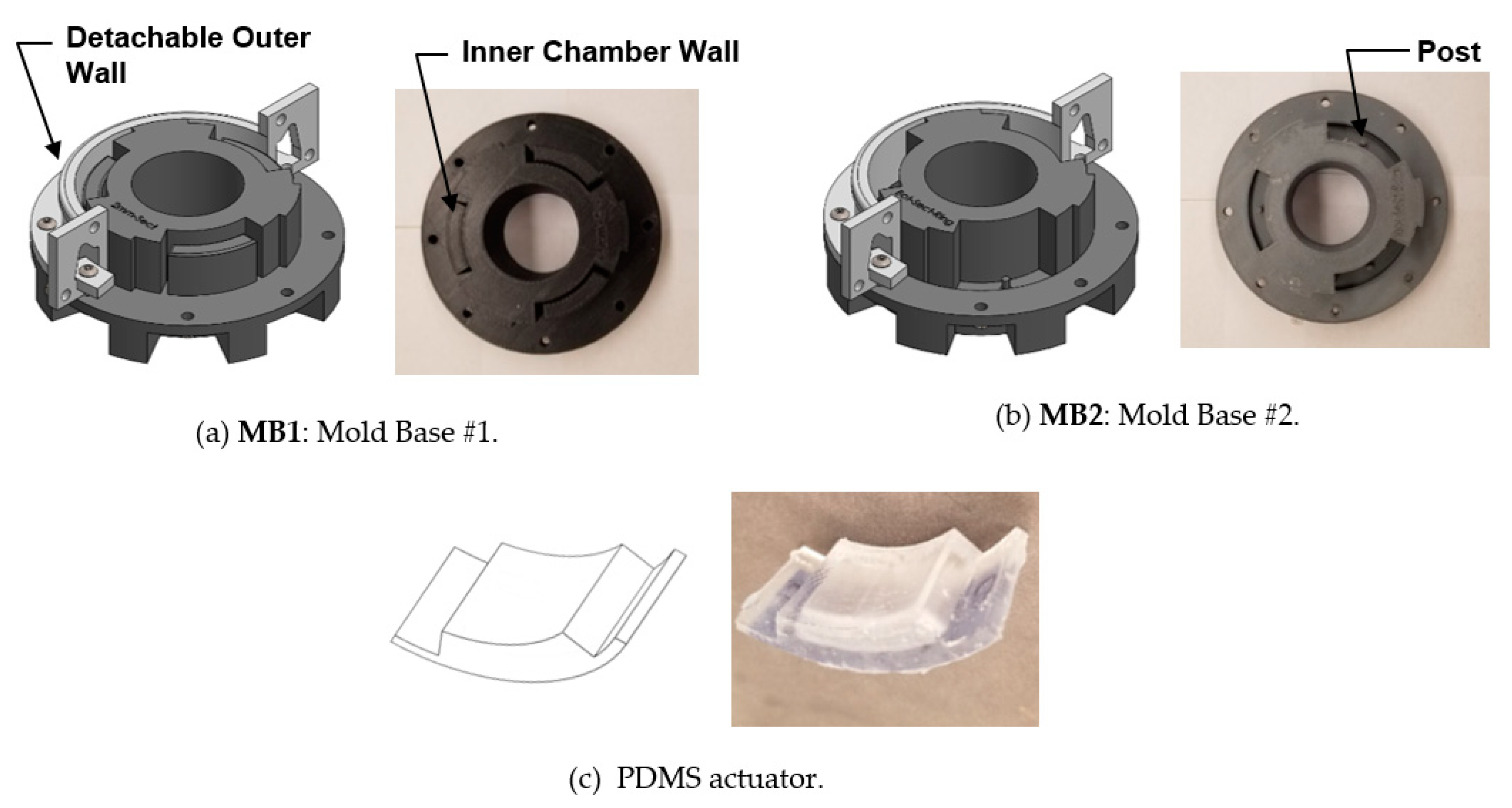

Figure 1).

While a similar closed monolithic design inspired by the mouth of a sea lamprey has been described in the literature [

10], the individual actuators proposed in this work have a scalable modular structure that enable multiple discrete units to be inserted in the gripper assembly or attached to the tips of discrete robotic fingers for controlled “soft touch” applications. To reduce the complexity and ensure that specific design parameters can be directly related to actuator displacement, only a single deformable surface or wall of the elastomeric air chamber is allowed to make contact with the target object. This is achieved, in part, by a rigid housing structure that restricts the material expansion along the desired working surface (

Figure 1b,c). Furthermore, the selected hyperelastic material is polydimethylsiloxane (PDMS). This elastomer in its commercial form (e.g., Sylgard 184) has well-established tensile and shear properties [

11,

12,

13,

14,

15], and it can be easily molded into a variety of shapes using soft-lithography and low-temperature molding processes.

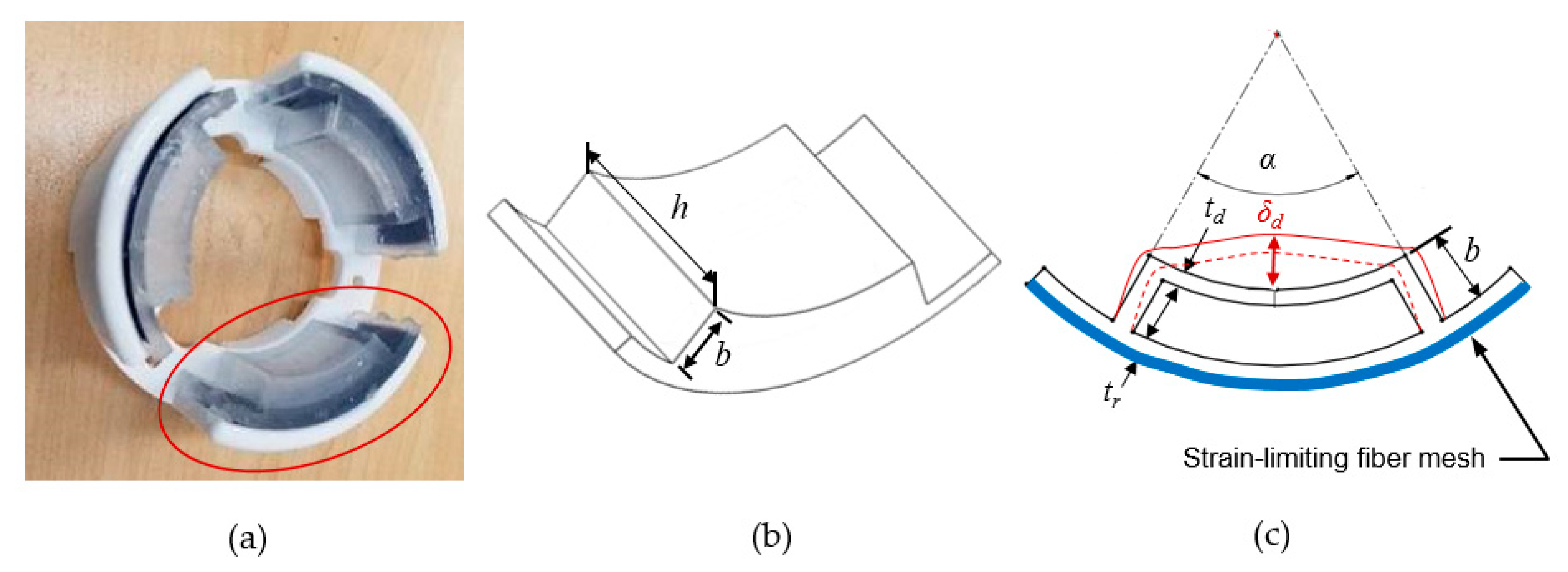

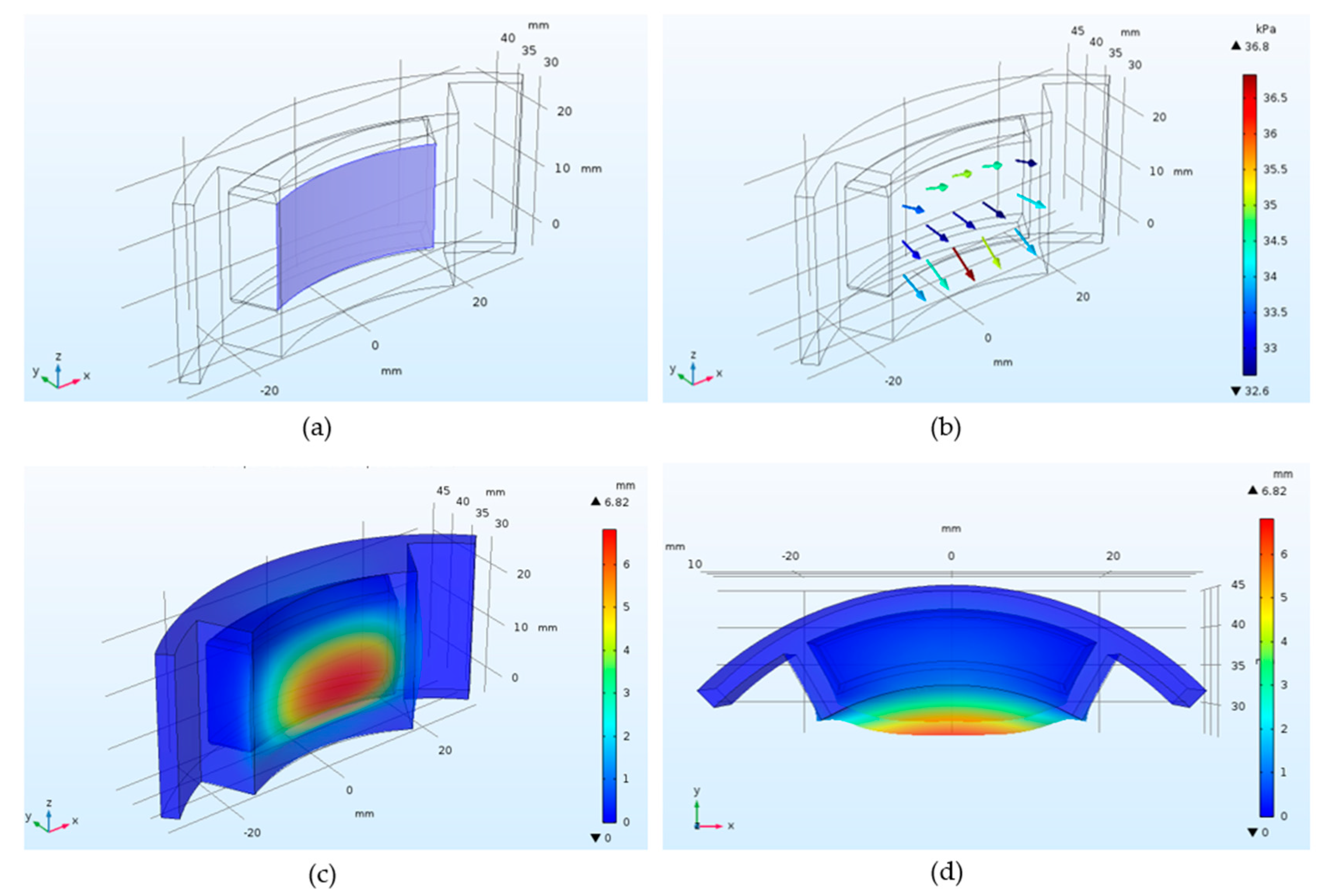

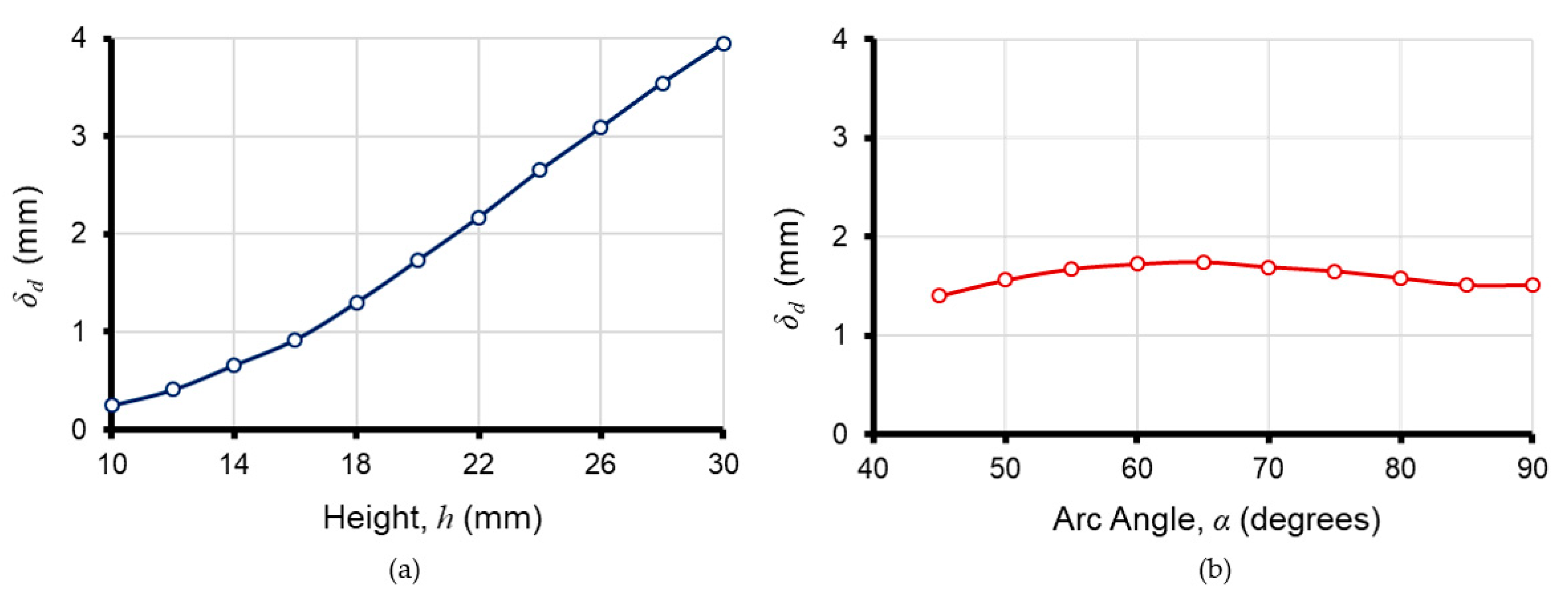

Section 2 introduces the design of the modular elastic actuators embedded in the rigid gripper assembly. The discussion focuses on the key geometric dimensions and role of the selected PDMS elastomer. In addition, a COMSOL simulation study is used to relate key geometric parameters of the expandable surface to expected actuator displacement. The stress–strain behavior of the PDMS device is simulated using the Mooney–Rivlin model for hyperelastic materials [

16,

17]. The multistep soft lithography molding process for fabricating the soft actuators is briefly summarized in

Section 3.

Section 4 describes several experiments used to characterize the prototype performance. Specifically, the physical actuator displacement for three different wall thicknesses and under various applied pressures are investigated. In addition, the measured contact forces, contact area, and slip test payload are acquired for the three selected wall thicknesses. The viability of the soft gripper with PDMS actuators for horticultural harvesting applications is illustrated by gently grasping a variety of mushroom caps. Finally, important design guidelines are summarized and future work is discussed.

4. Experimental Results and Discussion

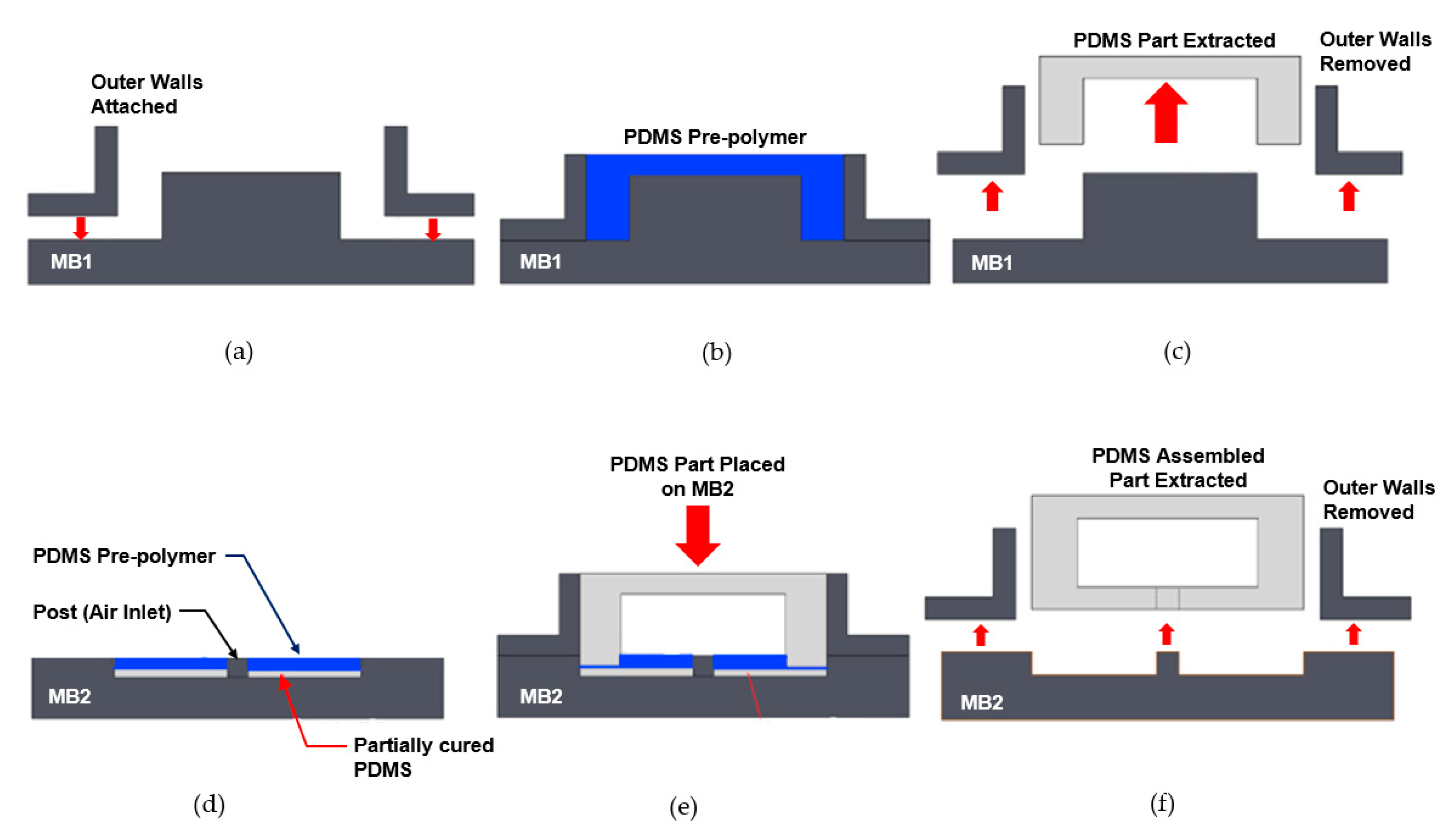

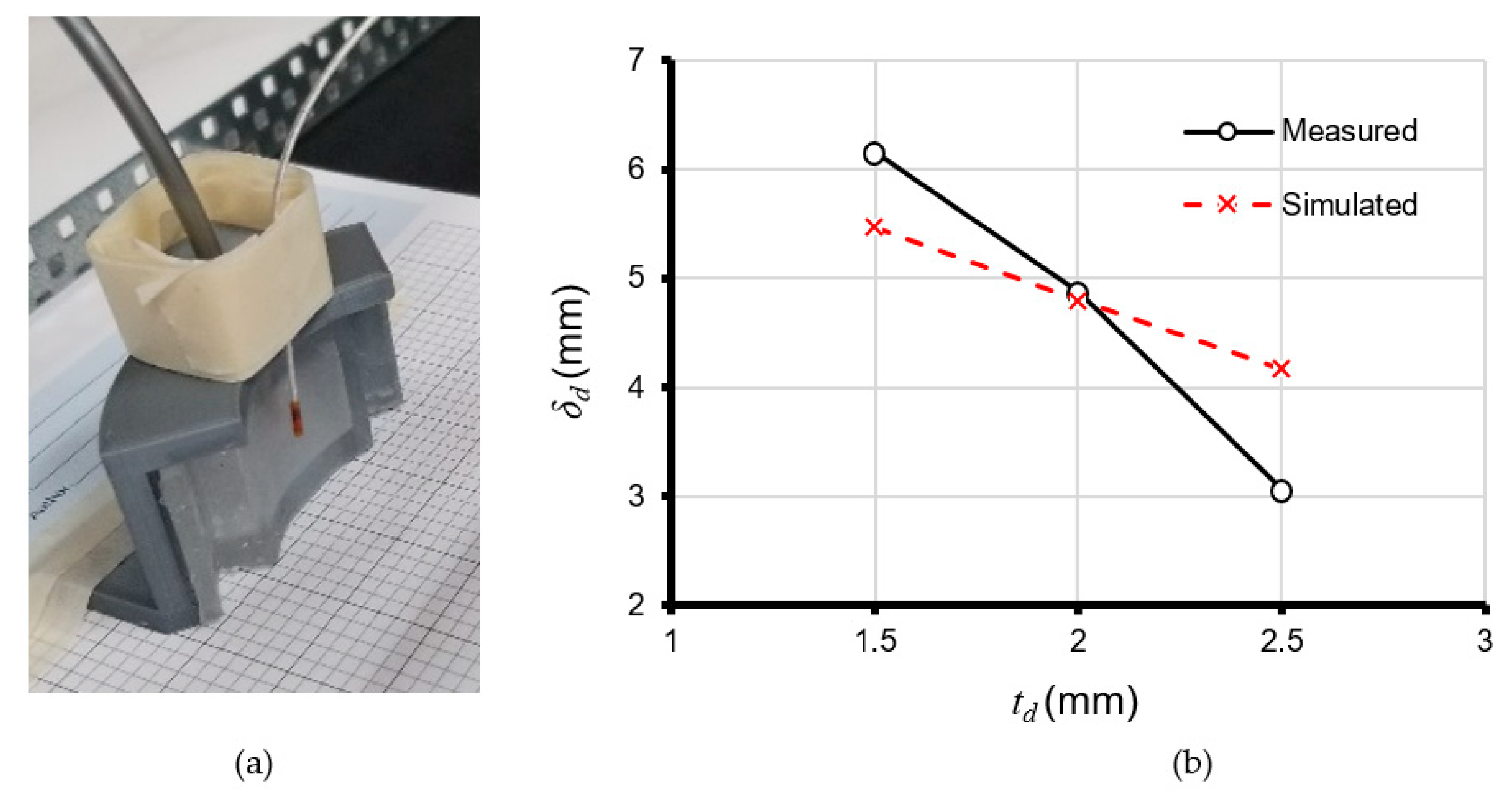

A series of experiments were performed on individual PDMS actuators and the multiactuator gripper assembly. In all cases, the chamber height was fixed at and the arc angle was set at . The tests examined the actuator displacement , contact forces , contact area , and mass payload slippage for three different wall thicknesses . Finally, the viability of the proposed PDMS actuators for grasping and holding fragile objects (i.e., mushroom tops) is briefly explored. Some discrepancies will always exist between experimentally measured values and simulations, due to limitations in fabrication and in-situ measurements. In addition, experiments provide new empirical data whereas simulations do not. Rather, they produce results that are influenced by the conditions implemented within the model.

4.1. Measured Actuator Displacement

The displacement of the actuating surface was measured using a 3D Guidance TrakSTAR system [

24], with an electromagnetic (EM) sensor capable of measuring 6 DOF (

Figure 8a). The measurement values correspond to the distance between the sensor probe and fixed transmitter location. The displacement is, therefore, the change in distance with respect to the initial noninflated actuating surface.

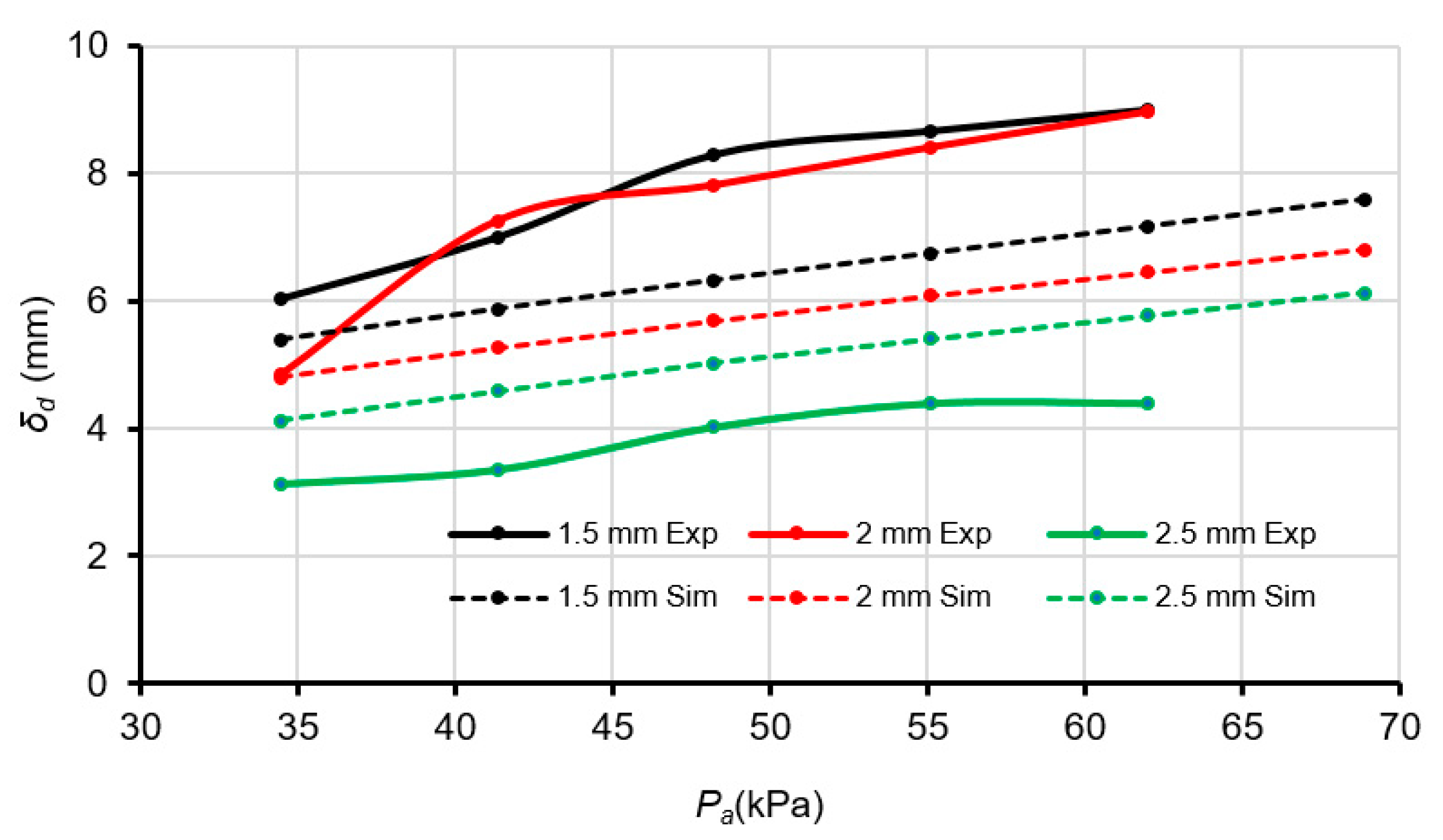

Figure 8b shows both the measured and COMSOL simulated displacements for the three different wall thicknesses when

. Note that the measurement value is the average steady-state displacement over a 0.5 s window. The observed differences in the measured and simulated displacements

are partly the result of limitations in the Mooney–Rivlin hyperelastic model, the theoretical values for the shear and bulk moduli, and the computational limitations imposed by the size of the finite element mesh used in the simulations. The smallest difference occurs at

where

and the largest at

where

. The latter case represents a ~25% error.

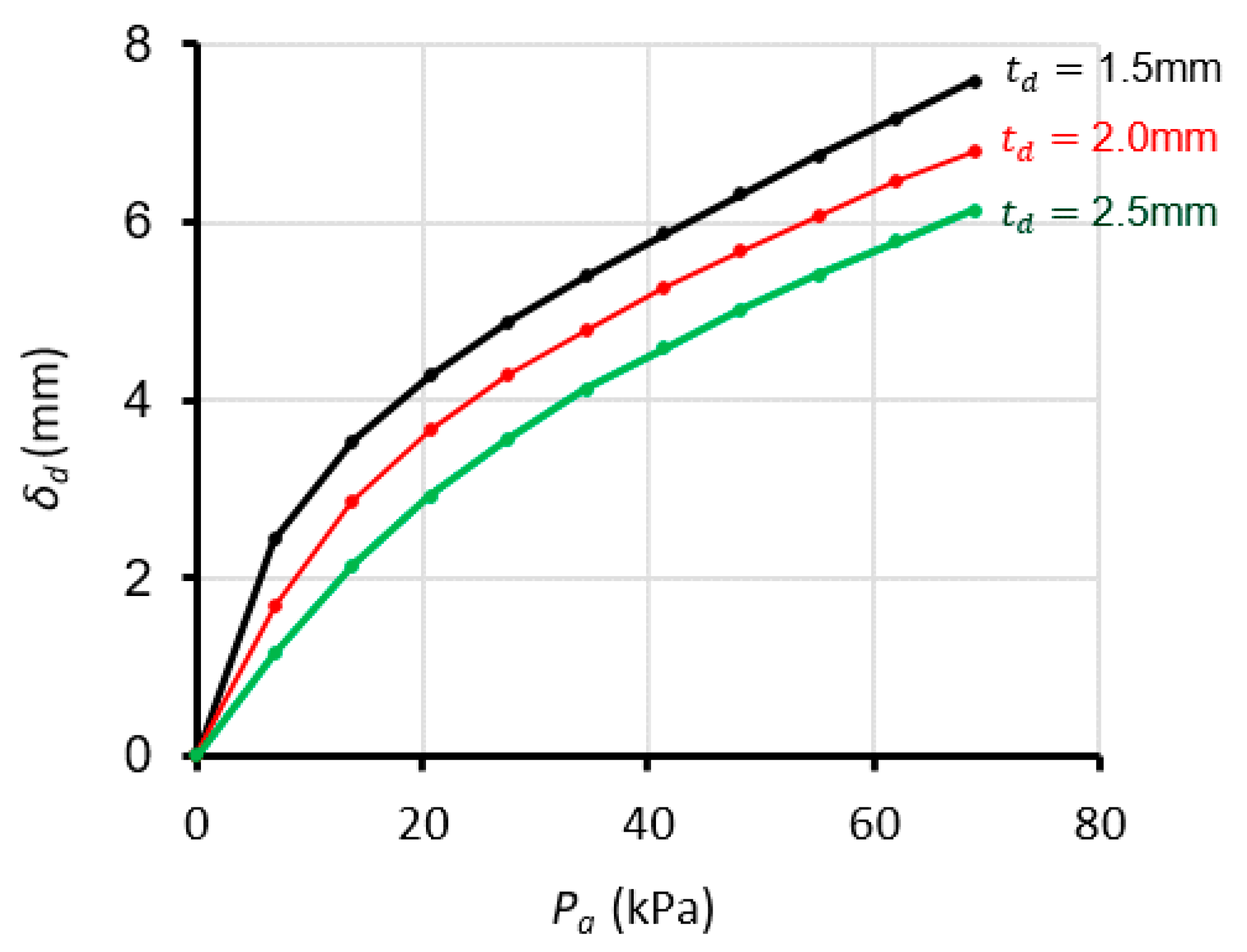

Figure 9 shows the impact of air pressure changes on the displacement of the expandable actuating wall. In these experiments

was varied between 34.47 to 68.94 kPa at 6.89 kPa increments. For each

, the displacement

was measured by averaging three separate actuations over 10 s time trials at a sampling frequency of 120 Hz. Note that this pressure range was selected because

resulted in inaccurate readings due to the limitations of the pressure regulator and gauge used in the experiments. In addition,

caused a number of the fabricated actuators to prematurely rupture. The differences observed between simulated and experimental data may be due, in part, to the Mooney–Rivlin model’s inability to capture larger strains [

25]. However, the simulations still illustrate the general trend of increased actuator displacement with increased air pressure.

4.2. Contact Forces and Impact of Payload

The contact force

generated between the actuating surface and target object can be given by

where

is the contact pressure, and

is the area of contact with the target. The contact pressure for each

was obtained from COMSOL simulations at

. To measure the contact area when the actuator is pressurized, paint was applied to the deformable walls of the soft actuators and then the gripper assembly was used to grasp a Styrofoam sphere (dia. 60 mm). When the target was released it left an imprint of

on the sphere surface that can be measured. The experiments confirm that thicker deformable walls tend to generate greater

and larger

(

Table 2). Contact area is dependent on the geometry of the target, and organic objects like fungi are seldom identical in shape. The simplified contact force formula shown in Equation (3) allows the gripper’s behavior to be approximated.

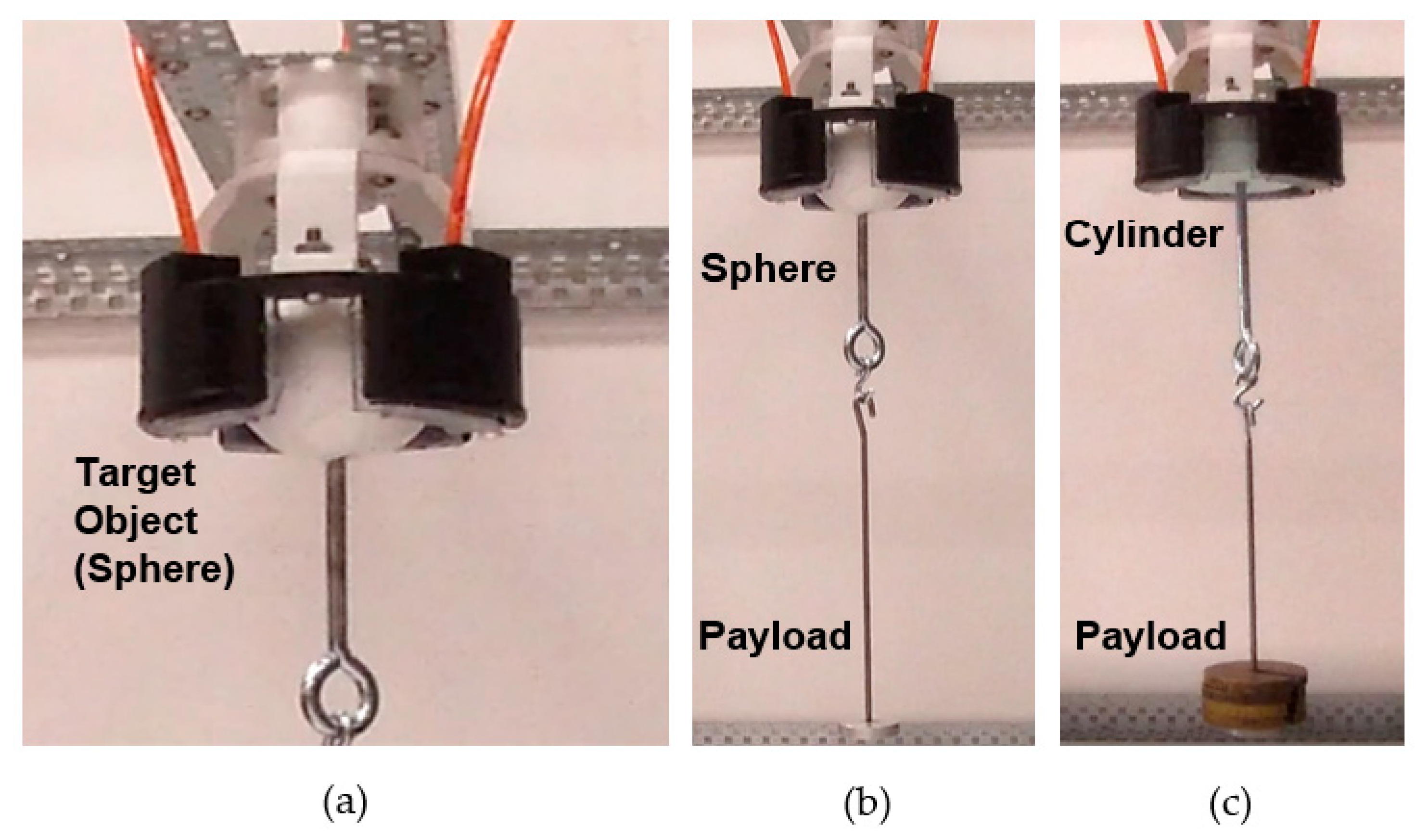

For grasping applications such as horticultural harvesting, it is also important to investigate the grip strength by measuring the payload capabilities of the pneumatic gripper with different actuator wall thicknesses. In this study, a Styrofoam sphere and cylinder with equal diameters were used as the target objects. Each target was modified by attaching a 50 g payload platform that would enable additional weights to be applied in a controlled fashion (

Figure 10). This apparatus created a downward force on the grippers hold on the object and is represented as a slip test payload mass

. The maximum payload of the soft pneumatic gripper (

Table 2) was verified using free weights. Overall, the grippers exhibit roughly double the maximum payload capacity for cylindrical shapes over spheres. At these maximum payloads, and with similar gripper weights of about 76 g, the 1.5, 2, and 2.5 mm gripper variants have respective payload-to-weight ratios of 30, 26, and 18. These results however, appear contrary to an initial assumption that the maximum payload tests would follow the same trend as contact force experiments. The inverse relationship may be the result of changes in surface friction between the thinner inflated elastic actuator and target object. Clearly, the surface effects between the hyperelastic actuator and object need to be explored in greater detail.

4.3. Grasping Organic Objects

Automated robotic systems [

18,

26] are being used to harvest a wide variety of organic horticultural crops, such as delicate fruits, vegetables, and edible fungi. The proposed hyperelastic actuators and soft robotic gripper system are part of an industry driven initiative to explore the use of mechanically compliant end-effectors for gently grasping and holding mushrooms during commercial harvesting operations. Typically, these tasks are performed by traditional robotic systems that use semirigid vacuum cup grippers to twist and pull the individual mushrooms from the growing bed. Unfortunately, mushrooms are delicate fungi that can be easily bruised and damaged by excessive forces during the picking operations. In this regard, the viability of the soft gripper with PDMS actuators for horticultural harvesting applications is explored by gently grasping a variety of mushroom tops. A detailed comparative study between the proposed design and alternative approaches is beyond the scope of the current paper.

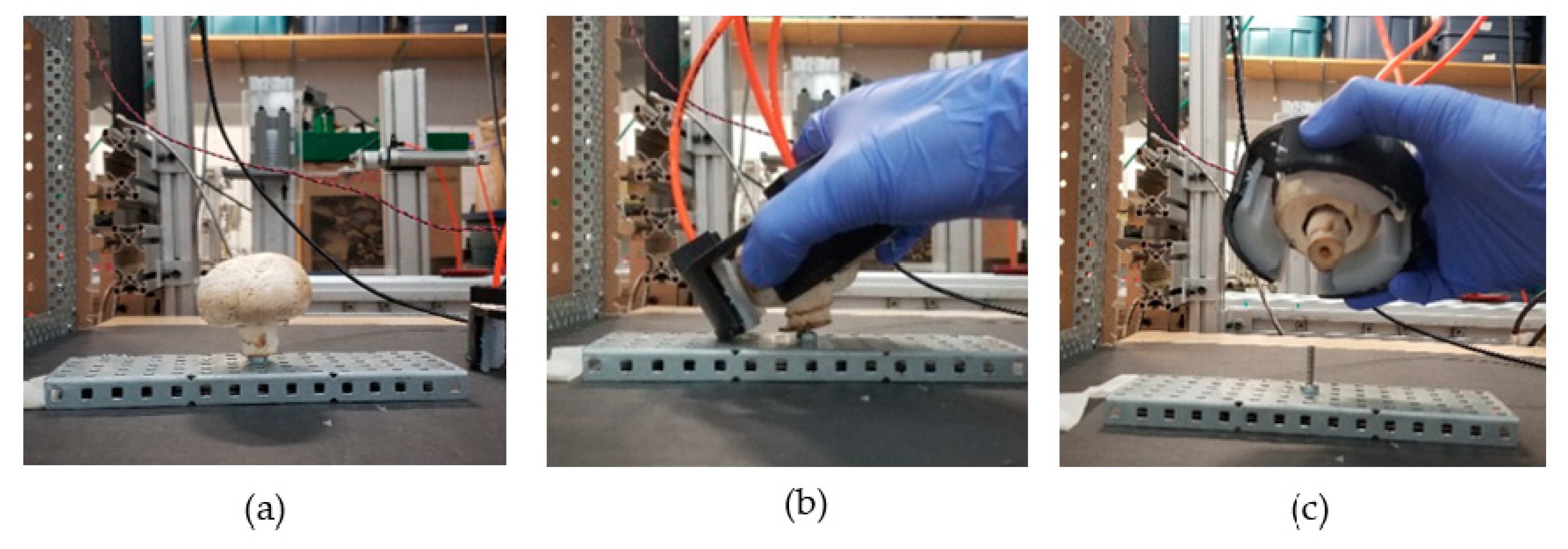

For these preliminary tests, the mushroom specimens were wedged onto a threaded bolt to simulate how they are anchored in the growing bed (

Figure 11). The measures used to evaluate performance correspond to grasping success and damage inflicted. In this context, success was determined by visually inspecting the target mushroom for physical damage (or any disfigurement) after it had been grasped, pulled from the threaded rod, and held for a short period of time by the pneumatic gripper. In addition, dropping the mushroom during the procedure or being unable to make sufficient contact to lift it were considered failures.

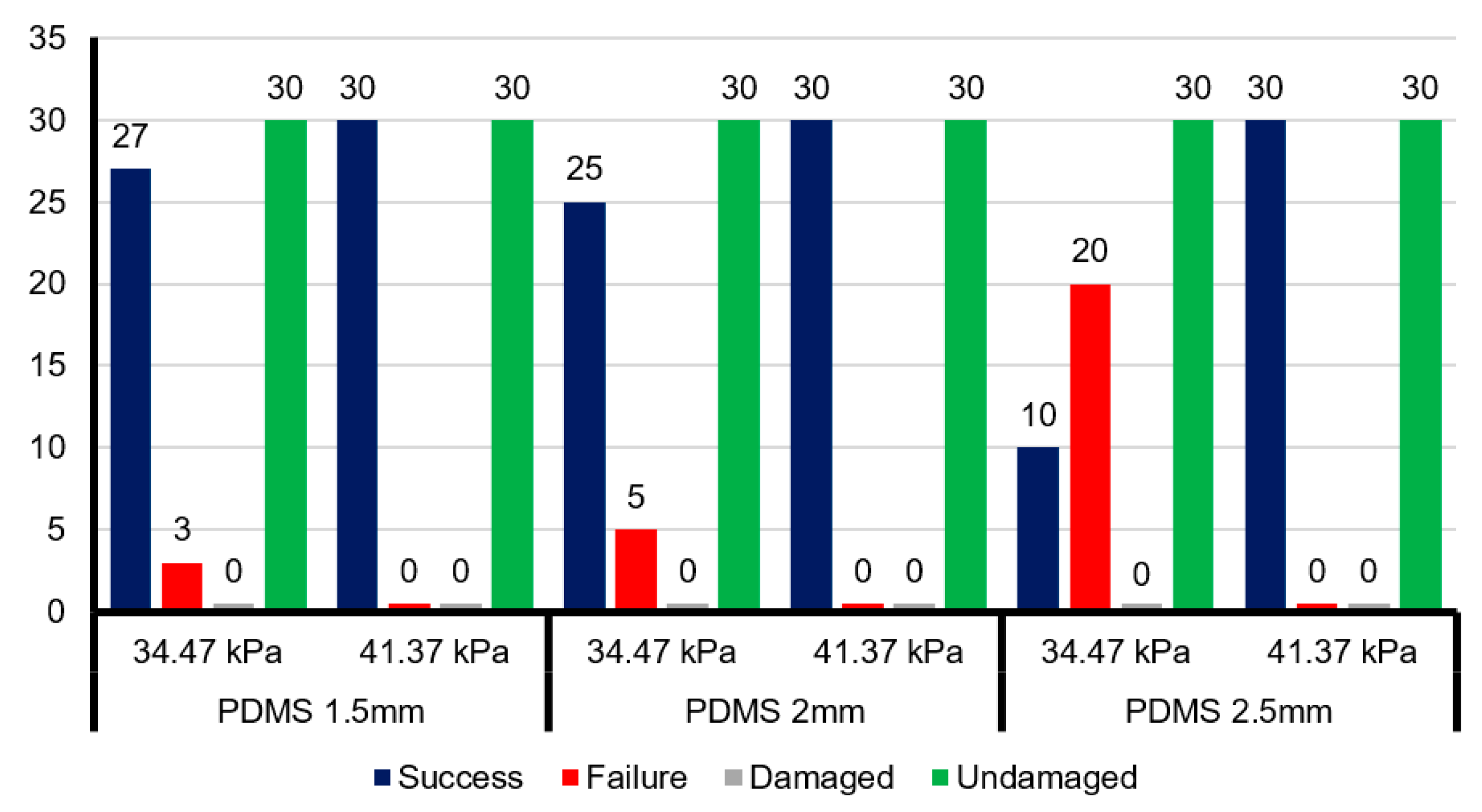

The PDMS soft actuators were assembled in three gripper assemblies with concave wall thicknesses of 1.5, 2.0, and 2.5 mm. For each gripper assembly, two sets of tests were performed with the applied air pressure equal to 34.47 kPa (5 psi) and 41.37 kPa (6 psi), respectively. A single test involved grasping, pulling, and holding 30 organic mushrooms of similar size. The experimental observations of the various soft grippers,

Figure 12, indicate that PDMS actuators with

performed well for both the grasp-and-hold (success/failure) and minimal infliction of surface damage (damaged/undamaged). In contrast, the gripper with soft actuators that had a wall thickness of

failed 2/3rd of the grasp-and-hold tests but still did not produce any significant surface damage on the target mushroom.

Similar tests were also performed using a commercially available vacuum cup gripper for grasping these types of mushrooms. A maximum harvesting success of 37.5% was recorded, with a minimum 0% recorded grasping success for the cups tested. A maximum damage rate of 100% was observed, with a minimum of 12.5%. These cups were provided by the sponsor of the industry-driven project, Vineland Research and Innovation Centre Inc., and are proven to be poorly-suited for a mushroom harvesting application. The proposed soft pneumatic gripper at

was found to have a higher grasping success rate and inflicted less surface damage on the test mushrooms. The maximum harvesting success for the PDMS grippers was recorded as 100%, and in each case the damage rate was 0%. For reference, performance indicators for various harvesting systems list a recorded harvest success rate of 75% and a damage rate of 5% [

18]. Thus, the soft PDMS gripper may be a viable replacement for conventional vacuum cup grippers in terms of grasping success and damage inflicted.

4.4. Discussion

These initial experimental tests confirm that a soft robotic gripper incorporating pneumatically-driven hyperelastic PDMS actuators can successfully grasp and hold light weight delicate objects. In addition, the compact gripper geometry was not affected by gravity in the same manner as the longer soft actuator designs (e.g., PneuNet [

2]), thereby making it suitable for attachment to conventional robotic manipulators with spherical wrists. Furthermore, the COMSOL simulations and experimental tests on the fabricated prototypes suggest that the current gripper design could be easily modified and adapted for a variety of applications, including harvesting horticultural produce. For example, the thickness of the actuator’s deforming wall

could be adjusted for different target loads or target geometries. In addition, the actuator height

can be changed for different target sizes or to change the number of active actuators in the gripper assembly (i.e., more than three). Modifying the arc of the actuator

had minimal impact on the performance, but this parameter can be adjusted to accommodate more or fewer actuators in an assembly. By increasing the number discrete actuators in a larger gripper assembly, it would be possible to increase the number of contact points and grasp larger organic objects. The scalable modular design also permits multiple discrete units to be attached to the tips of discrete robotic fingers for controlled “soft touch” applications (

Figure 13). Application dependent design guidelines are summarized in

Table 3.

5. Conclusions

A scalable modular pneumatic actuator made from PDMS was developed for a soft robotic gripper that can grasp and hold delicate, curved organic objects, such as small fruits and edible fungi. The key design parameters were related to the size of the expandable surface area (h,α) and thickness of the deformable wall structure that makes contact with the target object. The impact of these parameters on actuator displacement were initially explored through COMSOL simulation using the simplified Mooney–Rivlin model of hyperelastic materials. These simple simulations were then used to identify appropriate dimensional parameters for the physical prototype. The actuator prototypes were fabricated using a soft lithography modeling process and inserted into a closed ring gripper assembly for experimental testing. A closed ring configuration was used for the gripper housing in order to constrain the experiments and more clearly relate actuator displacement to measured contact forces, contact areas, and maximum payload capacity prior to slippage. The initial results demonstrated that increasing the thickness of the expanding actuator wall allows the gripper to apply greater contact forces over a broader surface area. However, contrary to expectation, the slip tests showed that the thinnest wall exhibited almost double the payload capacity over the thickest . The results suggest that further studies are required to better understand the contact forces, including friction, between the hyperelastic material and target object. Finally, the viability of the soft gripper for horticultural harvesting applications was illustrated by gently grasping a variety of mushroom tops and monitoring the inflicted surface damage.

The investigative study reported in this paper also showed the limitations of the current computational modeling approach. Specifically, a more realistic hyperelastic material model and comprehensive finite element mesh need to be developed in order to improve the simulation accuracy. In addition, more complex simulations could be performed to model the contact and interaction between the soft grippers and a delicate target structure like the mushroom cap. This would require verified material properties for the various target organic objects.