Recycling-Oriented Design in Soft Robotics

Abstract

1. Introduction

2. Recycling Cycles

3. Actions in the Primary Cycle

3.1. Casting Processes

3.2. Additive Production Processes

4. Actions in the Secondary Cycle

4.1. Material

4.2. Modularity

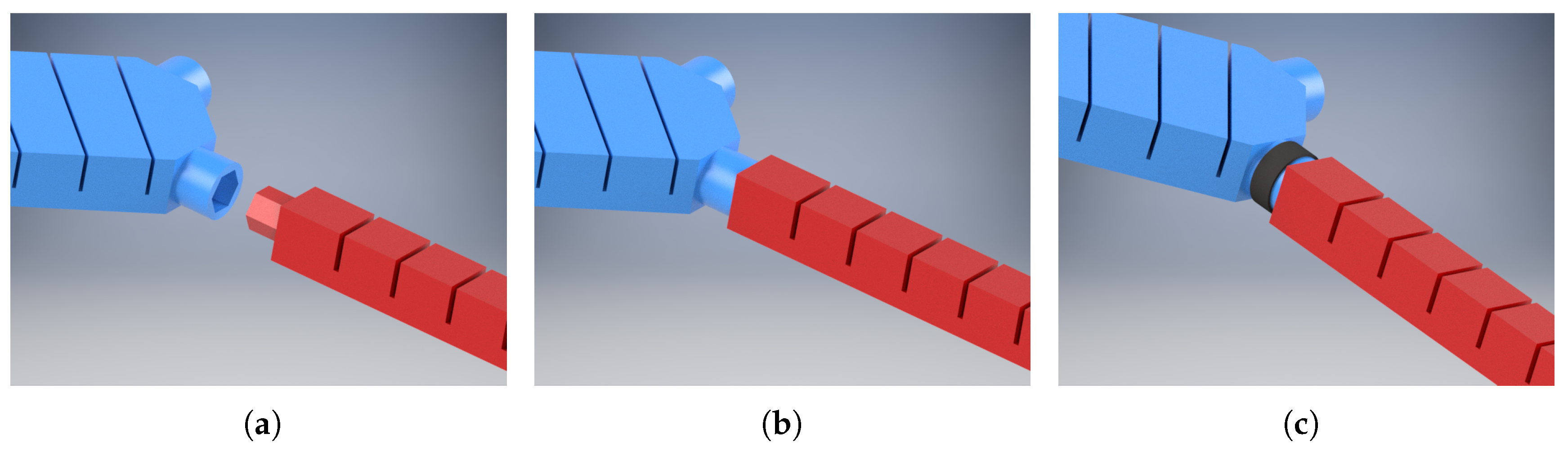

4.2.1. Force Connections

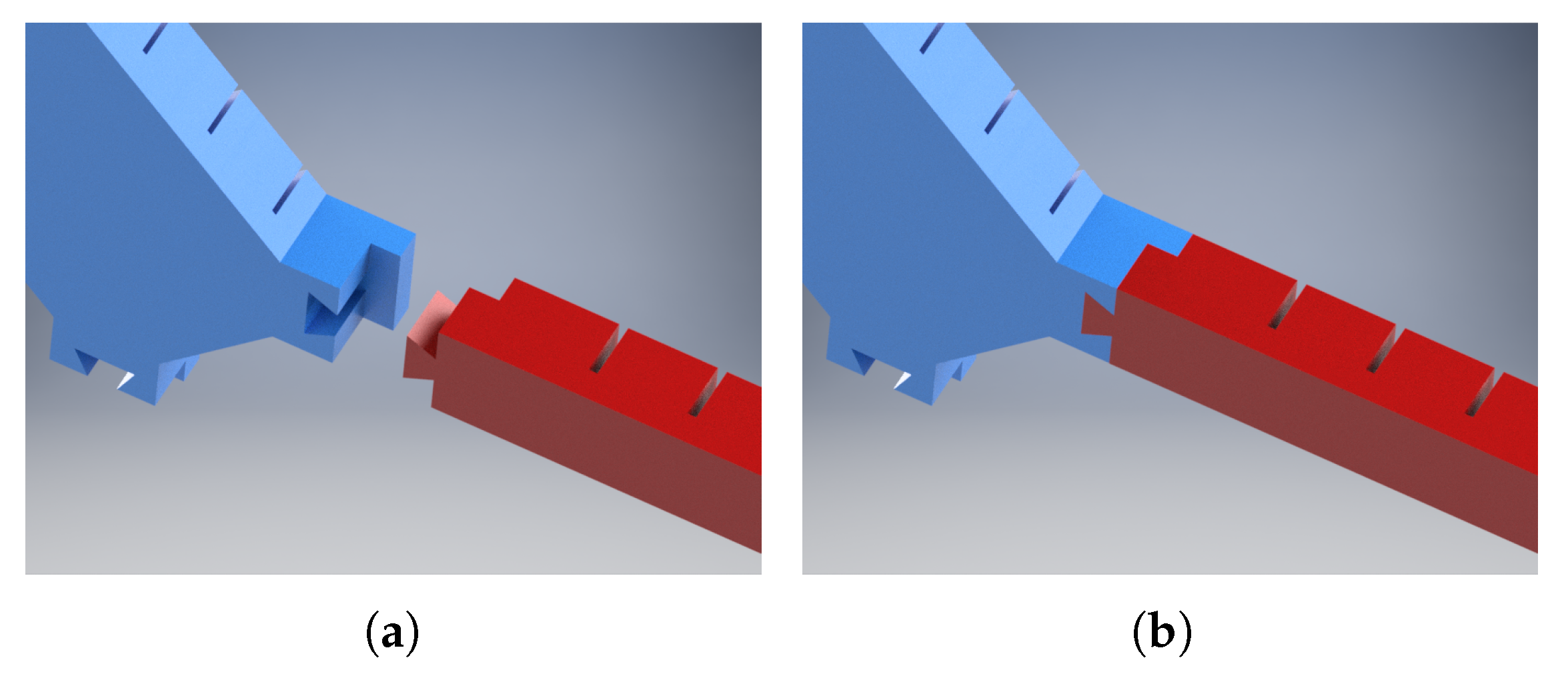

4.2.2. Form Connections

5. Actions in the Tertiary Cycle

5.1. Material

5.1.1. Elastomer Body

5.1.2. Strain-Limiting Layer

5.2. Design for Disassembly

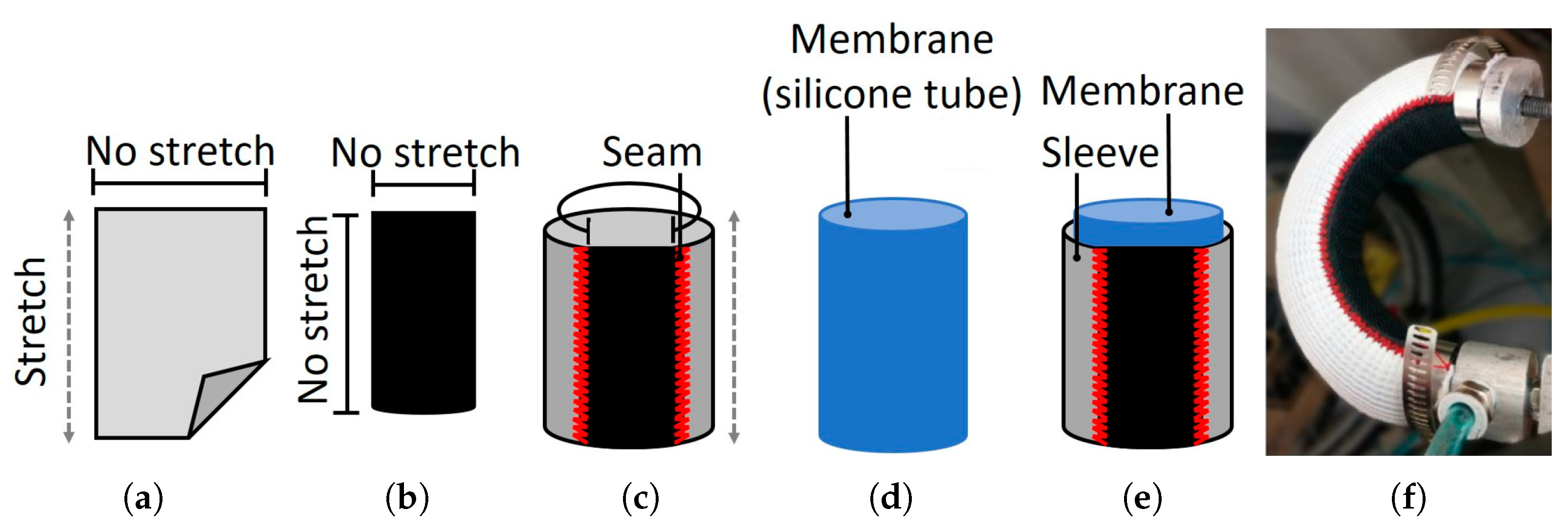

5.2.1. Strain-Limiting Layer

5.2.2. Fiber-Reinforced FEAs

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Craig, J.J. Introduction to Robotics: Mechanics and Control; Pearson: Essex, UK, 2014. [Google Scholar]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Laschi, C.; Cianchetti, M. Soft robotics: New perspectives for robot bodyware and control. Front. Bioeng. Biotechnol. 2014, 2, 3. [Google Scholar] [CrossRef] [PubMed]

- Iida, F.; Laschi, C. Soft robotics: Challenges and perspectives. Procedia Comput. Sci. 2011, 7, 99–102. [Google Scholar] [CrossRef]

- Whitesides, G.M. Bioinspiration: Something for everyone. Interface Focus 2015, 5, 20150031. [Google Scholar] [CrossRef] [PubMed]

- Calisti, M.; Picardi, G.; Laschi, C. Fundamentals of soft robot locomotion. J. R. Soc. Interface 2017, 14, 20170101. [Google Scholar] [CrossRef] [PubMed]

- Seok, S.; Onal, C.D.; Wood, R.; Rus, D.; Kim, S. Peristaltic locomotion with antagonistic actuators in soft robotics. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Anchorage, AK, USA, 3–8 May 2010; pp. 1228–1233. [Google Scholar]

- Marchese, A.D.; Onal, C.D.; Rus, D. Autonomous soft robotic fish capable of escape maneuvers using fluidic elastomer actuators. Soft Robot. 2014, 1, 75–87. [Google Scholar] [CrossRef]

- Deimel, R.; Brock, O. A novel type of compliant and underactuated robotic hand for dexterous grasping. Int. J. Robot. Res. 2016, 35, 161–185. [Google Scholar] [CrossRef]

- Fras, J.; Althoefer, K. Soft biomimetic prosthetic hand: Design, manufacturing and preliminary examination. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 1–6. [Google Scholar]

- Laschi, C.; Cianchetti, M.; Mazzolai, B.; Margheri, L.; Follador, M.; Dario, P. Soft robot arm inspired by the octopus. Adv. Robot. 2012, 26, 709–727. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Polygerinos, P.; Correll, N.; Morin, S.A.; Mosadegh, B.; Onal, C.D.; Petersen, K.; Cianchetti, M.; Tolley, M.T.; Shepherd, R.F. Soft robotics: Review of fluid-driven intrinsically soft devices; manufacturing, sensing, control, and applications in human-robot interaction. Adv. Eng. Mater. 2017, 19, 1700016. [Google Scholar] [CrossRef]

- Jorden, W. Recycling Conform Design. In Materials Substitution and Recycling. AGARD Conference Proceedings No. 356; AGARD: Neuilly sur Seine, France, 1984; p. 23. [Google Scholar]

- Jorden, W. Designing of products in view of recycling. In Environmental Technology; Martinus Nijhoff Publishers: Dordrecht, The Netherlands, 1987; pp. 367–376. [Google Scholar]

- Marchese, A.D.; Katzschmann, R.K.; Rus, D. A recipe for soft fluidic elastomer robots. Soft Robot. 2015, 2, 7–25. [Google Scholar] [CrossRef]

- Wallin, T.J.; Pikul, J.; Shepherd, R.F. 3D printing of soft robotic systems. Nat. Rev. Mater. 2018, 3, 84–100. [Google Scholar] [CrossRef]

- Ilievski, F.; Mazzeo, A.D.; Shepherd, R.F.; Chen, X.; Whitesides, G.M. Soft robotics for chemists. Angew. Chem. Int. Ed. 2011, 50, 1890–1895. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic networks for soft robotics that actuate rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Galloway, K.C.; Polygerinos, P.; Walsh, C.J.; Wood, R.J. Mechanically programmable bend radius for fiber-reinforced soft actuators. In Proceedings of the International Conference on Advanced Robotics (ICAR), Montevideo, Uruguay, 25–29 November 2013. [Google Scholar]

- Tolley, M.T.; Shepherd, R.F.; Mosadegh, B.; Galloway, K.C.; Wehner, M.; Karpelson, M.; Wood, R.J.; Whitesides, G.M. A resilient, untethered soft robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Filastruder. Available online: https://www.filastruder.com/collections/filastruders-accessories/products/ filastruder-kit (accessed on 10 August 2019).

- Protocycler. Available online: https://redetec.com/pages/protocycler (accessed on 10 August 2019).

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal robotic gripper based on the jamming of granular material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Amend, J.R.; Brown, E.; Rodenberg, N.; Jaeger, H.M.; Lipson, H. A positive pressure universal gripper based on the jamming of granular material. IEEE Trans. Robot. 2012, 28, 341–350. [Google Scholar] [CrossRef]

- Scharff, R.B.N.; Doubrovski, E.L.; Poelman, W.A.; Jonker, P.P.; Wang, C.C.L.; Geraedts, J.M.P. Towards behavior design of a 3D-printed soft robotic hand. In Soft Robotics: Trends, Applications and Challenges; Springer: Cham, Switzerland, 2017; pp. 23–29. [Google Scholar]

- Peele, B.N.; Wallin, T.J.; Zhao, H.; Shepherd, R.F. 3D printing antagonistic systems of artificial muscle using projection stereolithography. Bioinspir. Biomim. 2015, 10, 055003. [Google Scholar] [CrossRef]

- Patel, D.K.; Sakhaei, A.H.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly stretchable and UV curable elastomers for digital light processing based 3D printing. Adv. Mater. 2017, 29, 1606000. [Google Scholar] [CrossRef]

- Yap, H.K.; Ng, H.Y.; Yeow, C.H. High-force soft printable pneumatics for soft robotic applications. Soft Robot. 2016, 3, 144–158. [Google Scholar] [CrossRef]

- Yirmibesoglu, O.D.; Morrow, J.; Walker, S.; Gosrich, W.; Canizares, R.; Kim, H.; Daalkhaijav, U.; Fleming, C.; Branyan, C.; Menguc, Y. Direct 3D printing of silicone elastomer soft robots and their performance comparison with molded counterparts. In Proceedings of the IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018. [Google Scholar]

- Byrne, O.; Coulter, F.; Glynn, M.; Jones, J.F.X.; Annaidh, A.N.; O’Cearbhaill, E.D.; Holland, D.P. Additive manufacture of composite soft pneumatic actuators. Soft Robot. 2018, 5, 726–736. [Google Scholar] [CrossRef]

- Drotman, D.; Jadhav, S.; Karimi, M.; Dezonia, P.; Tolley, M.T. 3D printed soft actuators for a legged robot capable of navigating unstructured terrain. Proceeding of the IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 5532–5538. [Google Scholar]

- Terryn, S.; Brancart, J.; Lefeber, D.; van Assche, G.; Vanderborght, B. Self-healing soft pneumatic robots. Sci. Robot. 2017, 2, eaan4268. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Stokes, A.A.; Nunes, R.M.D.; Whitesides, G.M. Soft machines that are resistant to puncture and that self seal. Adv. Mater. 2013, 25, 6709–6713. [Google Scholar] [CrossRef]

- Bartlett, N.D.; Dickey, M.D.; Majidi, C. Self-healing materials for soft-matter machines and electronics. NPG Asia Mater. 2019, 11, 21. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef]

- Onal, C.D.; Rus, D. A modular approach to soft robots. In Proceedings of the IEEE RAS/EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; pp. 1038–1045. [Google Scholar]

- Seibel, A.; Schiller, L. Systematic engineering design helps creating new soft machines. Robot. Biomim. 2018, 5, 5. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design. A Systematic Approach, 3rd ed.; Springer: London, UK, 2007. [Google Scholar]

- Morin, S.A.; Shevchenko, Y.; Lessing, J.; Kwok, S.W.; Shepherd, R.F.; Stokes, A.A.; Whitesides, G.M. Using ‘click-e-bricks’ to make 3D elastomeric structures. Adv. Mater. 2014, 26, 5991–5999. [Google Scholar] [CrossRef]

- Kwok, S.W.; Morin, S.A.; Mosadegh, B.; So, J.H.; Shepherd, R.F.; Martinez, R.V.; Smith, B.; Simeone, F.C.; Stokes, A.A.; Whitesides, G.M. Magnetic assembly of soft robots with hard components. Adv. Funct. Mater. 2014, 24, 2180–2187. [Google Scholar] [CrossRef]

- Morin, S.A.; Kwok, S.W.; Lessing, J.; Ting, J.; Shepherd, R.F.; Stokes, A.A.; Whitesides, G.M. Elastomeric tiles for the fabrication of inflatable structures. Adv. Funct. Mater. 2014, 24, 5541–5549. [Google Scholar] [CrossRef]

- ECO U.S.A. Available online: https://siliconerecycling.com (accessed on 10 August 2019).

- N.C. Siamenergy Co., Ltd. Available online: http://www.nc-silicone.com (accessed on 10 August 2019).

- De, D.; Das, A.; De, D.; Dey, B.; Debnath, S.C.; Roy, B.C. Reclaiming of ground rubber tire (GRT) by a novel reclaiming agent. Eur. Polym. J. 2006, 42, 917–927. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Kumnuantip, C. Comparison of physical and mechanical properties of NR/carbon black/reclaimed rubber blends vulcanized by conventional thermal and microwave irradiation methods. J. Appl. Polym. Sci. 2006, 100, 5039–5048. [Google Scholar] [CrossRef]

- Sun, X.; Isayev, A.I. Ultrasound devulcanization: Comparison of synthetic isoprene and natural rubbers. J. Mater. Sci. 2007, 42, 7520–7529. [Google Scholar] [CrossRef]

- Chambers, L.D.; Winfield, J.; Ieropoulos, I.; Rossiter, J. Biodegradable and edible gelatine actuators for use as artificial muscles. In Proceedings of the SPIE Conference on Electroactive Polymer Actuators and Devices (EAPAD), San Diego, CA, USA, 9–13 March 2014. [Google Scholar]

- Rossiter, J.; Winfield, J.; Ieropoulos, I. Here today, gone tomorrow: Biodegradable soft robots. In Proceedings of the SPIE Conference on Electroactive Polymer Actuators and Devices (EAPAD), Las Vegas, NV, USA, 20–24 March 2016. [Google Scholar]

- Shintake, J.; Sonar, H.; Piskarev, E.; Paik, J.; Floreano, D. Soft pneumatic gelatin actuator for edible robotics. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 6221–6226. [Google Scholar]

- Zolfagharian, A.; Kaynak, A.; Khoo, S.Y.; Kouzani, A.Z. Polyelectrolyte soft actuators: 3D printed chitosan and cast gelatin. 3D Print. Addit. Manuf. 2018, 5, 138–150. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kouzani, A.Z.; Maheepala, M.; Khoo, S.Y.; Kaynak, A. Bending control of a 3D printed polyelectrolyte soft actuator with uncertain model. Sens. Actuators A Phys. 2019, 288, 134–143. [Google Scholar] [CrossRef]

- Stalin, T.; Thanigaivel, N.K.; Joseph, V.S.; Valdivia y Alvarado, P. Automated fiber embedding for tailoring mechanical and functional properties of soft robot components. In Proceedings of the IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 762–767. [Google Scholar]

- Miron, G.; Bédard, B.; Plante, J.S. Sleeved bending actuators for soft grippers: A durable solution for high force-to-weight applications. Actuators 2018, 7, 40. [Google Scholar] [CrossRef]

- Li, S.; Zhao, H.; Shepherd, R.F. Flexible and stretchable sensors for fluidic elastomer actuated soft robots. MRS Bull. 2017, 42, 138–142. [Google Scholar] [CrossRef]

- Wehner, M.; Tolley, M.T.; Mengüç, Y.; Park, Y.L.; Mozeika, A.; Ding, Y.; Onal, C.; Shepherd, R.F.; Whitesides, G.M.; Wood, R.J. Pneumatic energy sources for autonomous and wearable soft robotics. Soft Robot. 2014, 1, 263–274. [Google Scholar] [CrossRef]

- Adami, M.; Seibel, A. On-board pneumatic pressure generation methods for soft robotics applications. Actuators 2019, 8, 2. [Google Scholar] [CrossRef]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef]

- Lu, N.; Kim, D.H. Flexible and stretchable electronics paving the way for soft robotics. Soft Robot. 2014, 1, 53–62. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, A.M.; Seibel, A. Recycling-Oriented Design in Soft Robotics. Actuators 2019, 8, 62. https://doi.org/10.3390/act8030062

Nguyen AM, Seibel A. Recycling-Oriented Design in Soft Robotics. Actuators. 2019; 8(3):62. https://doi.org/10.3390/act8030062

Chicago/Turabian StyleNguyen, Anh Minh, and Arthur Seibel. 2019. "Recycling-Oriented Design in Soft Robotics" Actuators 8, no. 3: 62. https://doi.org/10.3390/act8030062

APA StyleNguyen, A. M., & Seibel, A. (2019). Recycling-Oriented Design in Soft Robotics. Actuators, 8(3), 62. https://doi.org/10.3390/act8030062