Recent Progress on BaTiO3-Based Piezoelectric Ceramics for Actuator Applications

Abstract

:1. Introduction

2. Undoped BaTiO3

2.1. BaTiO3 Ceramics and Single Crystal

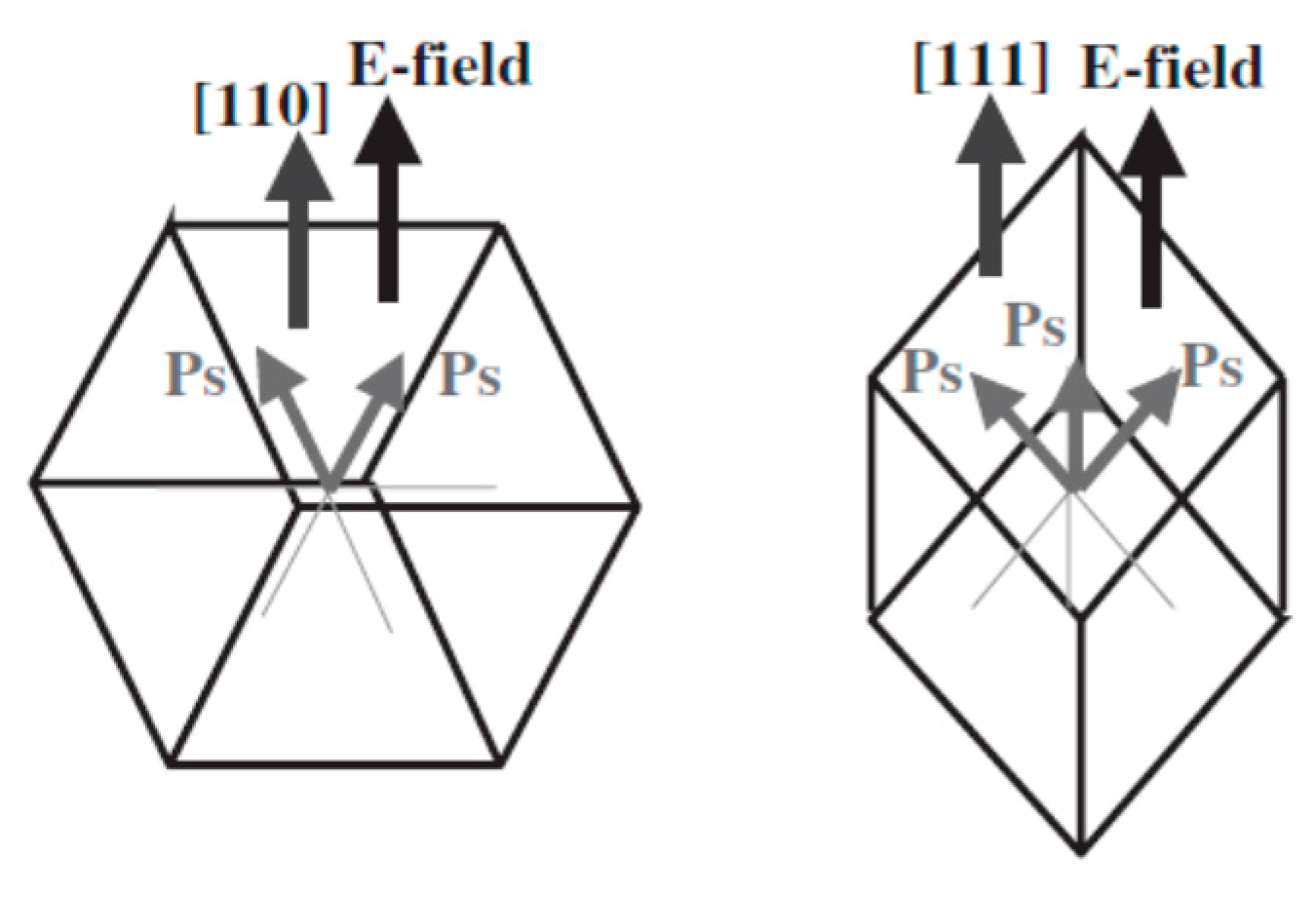

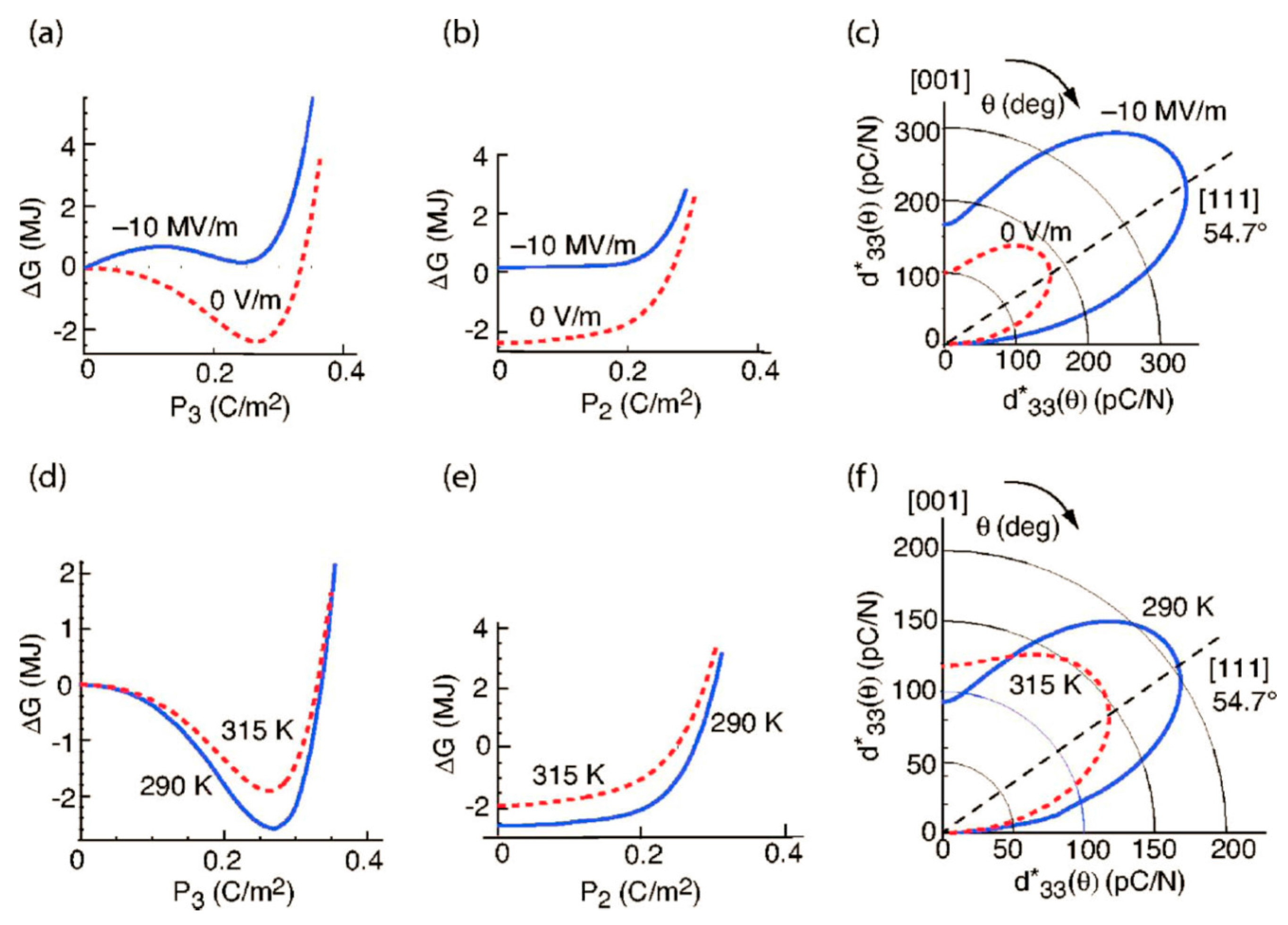

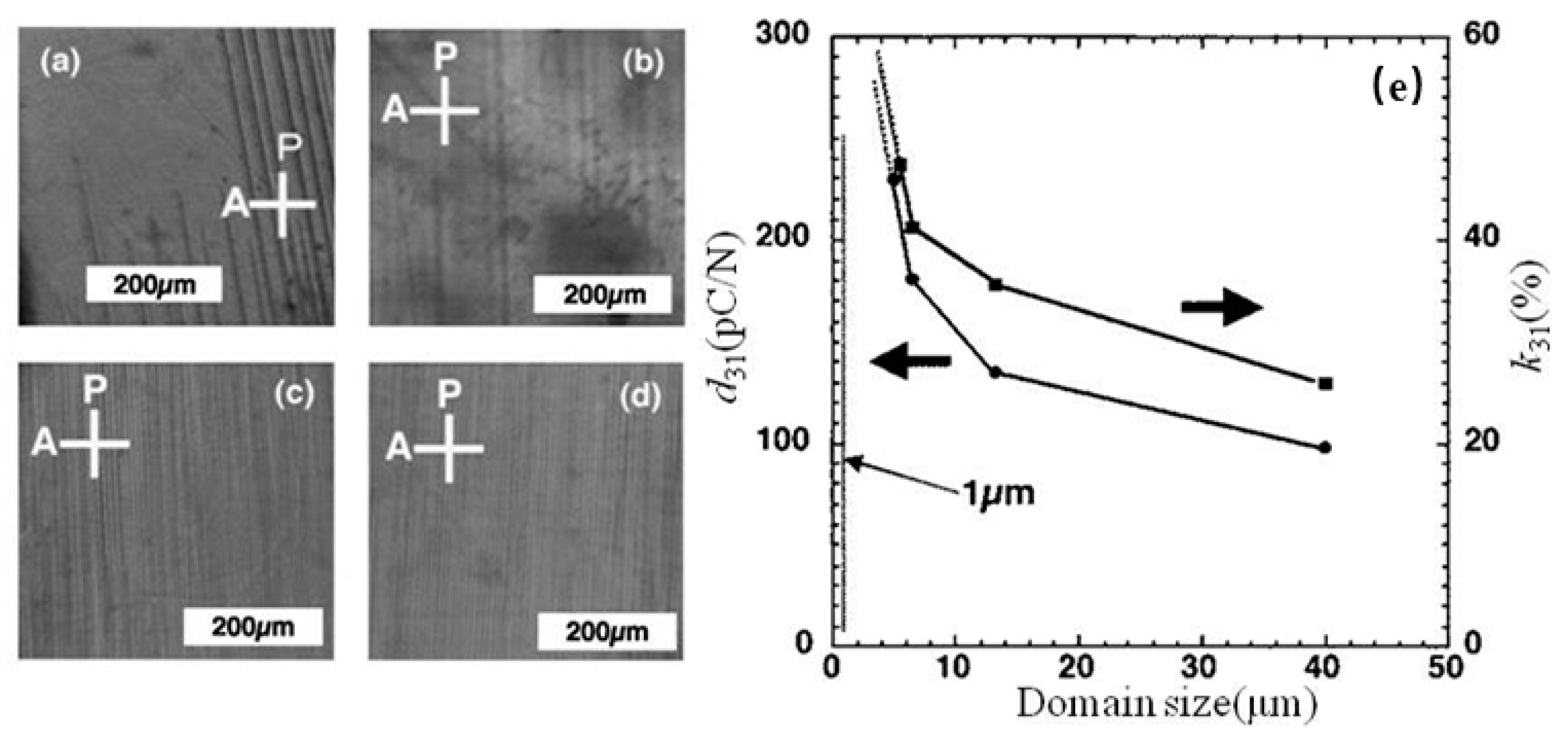

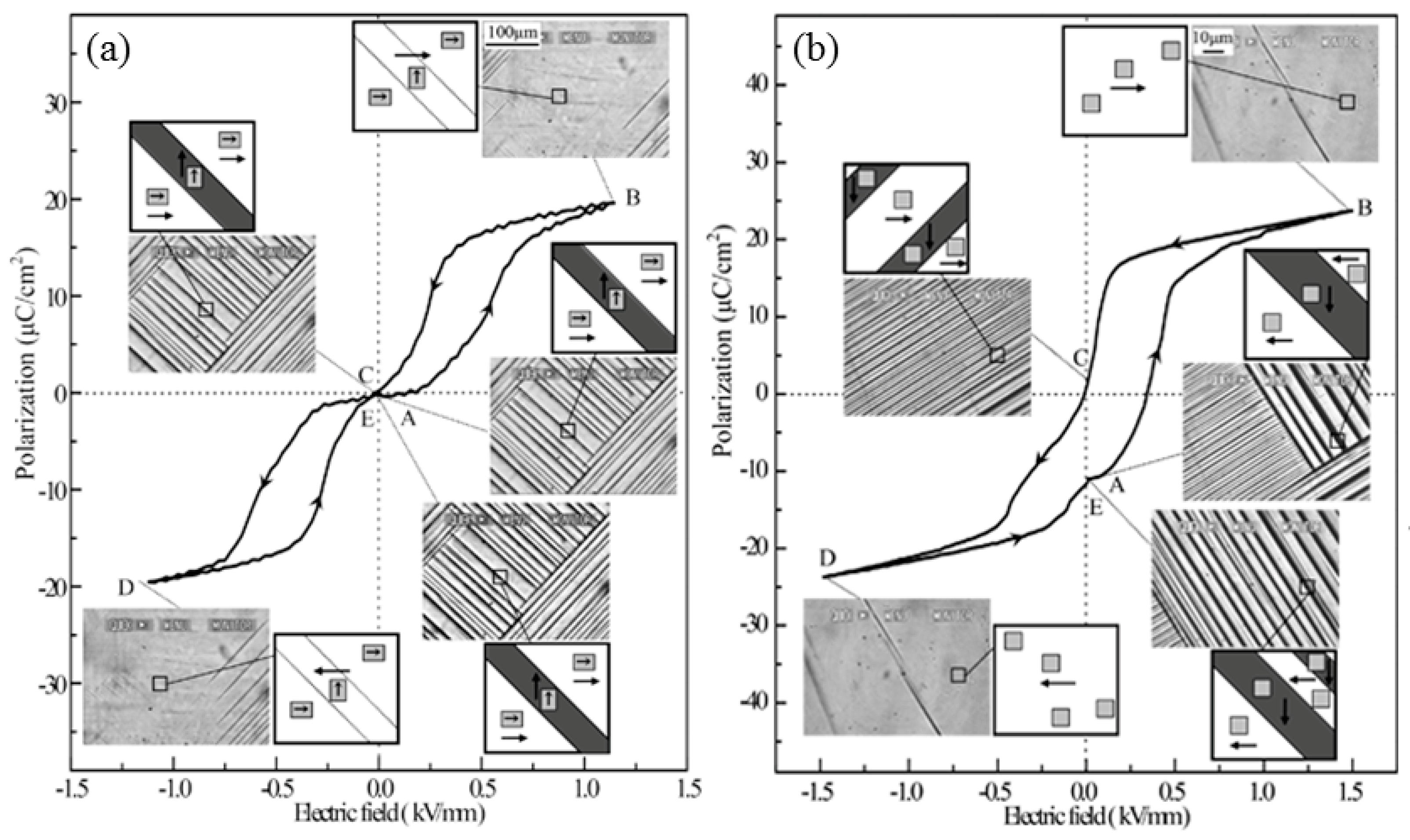

2.2. Domain-Engineered BaTiO3

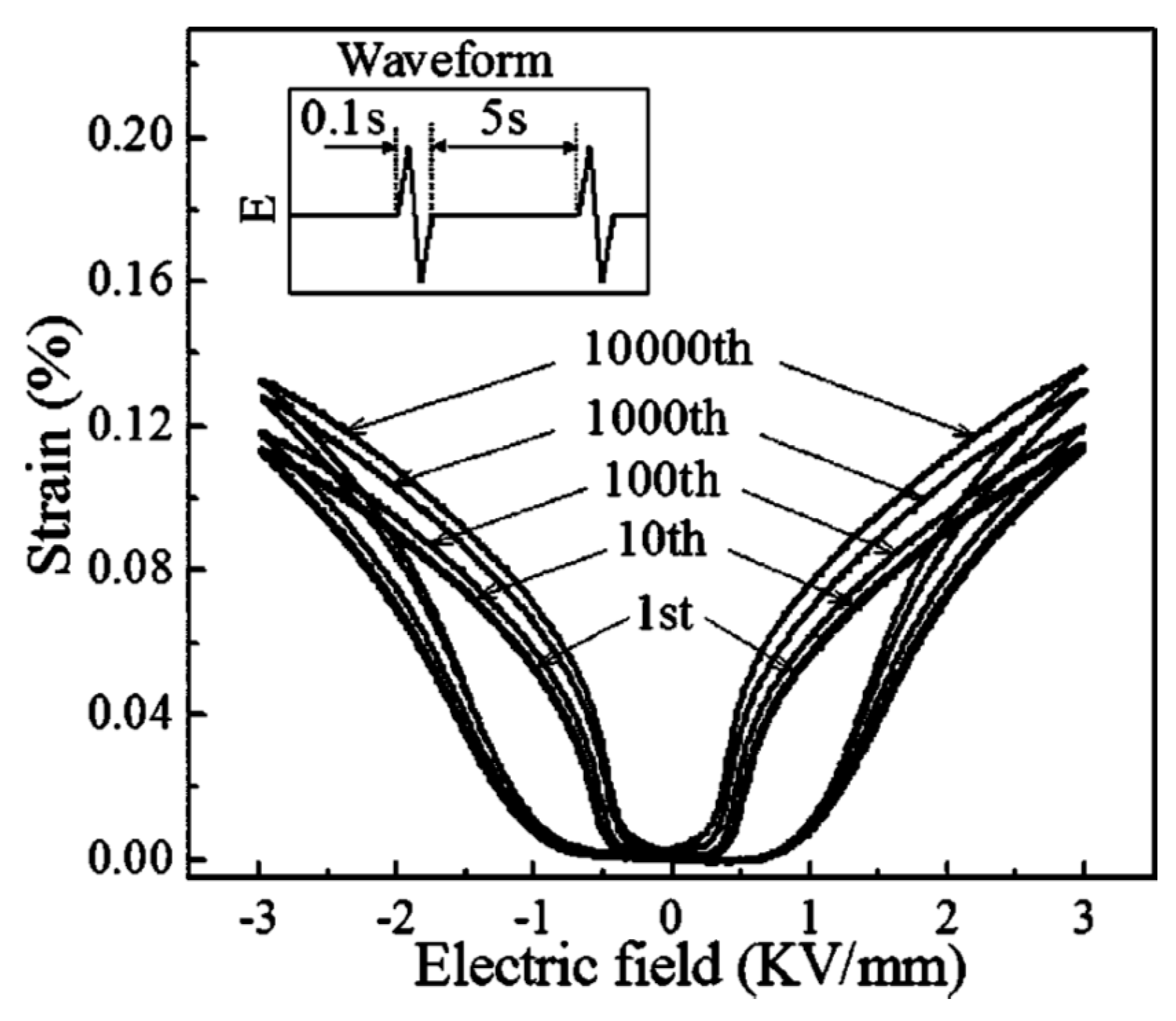

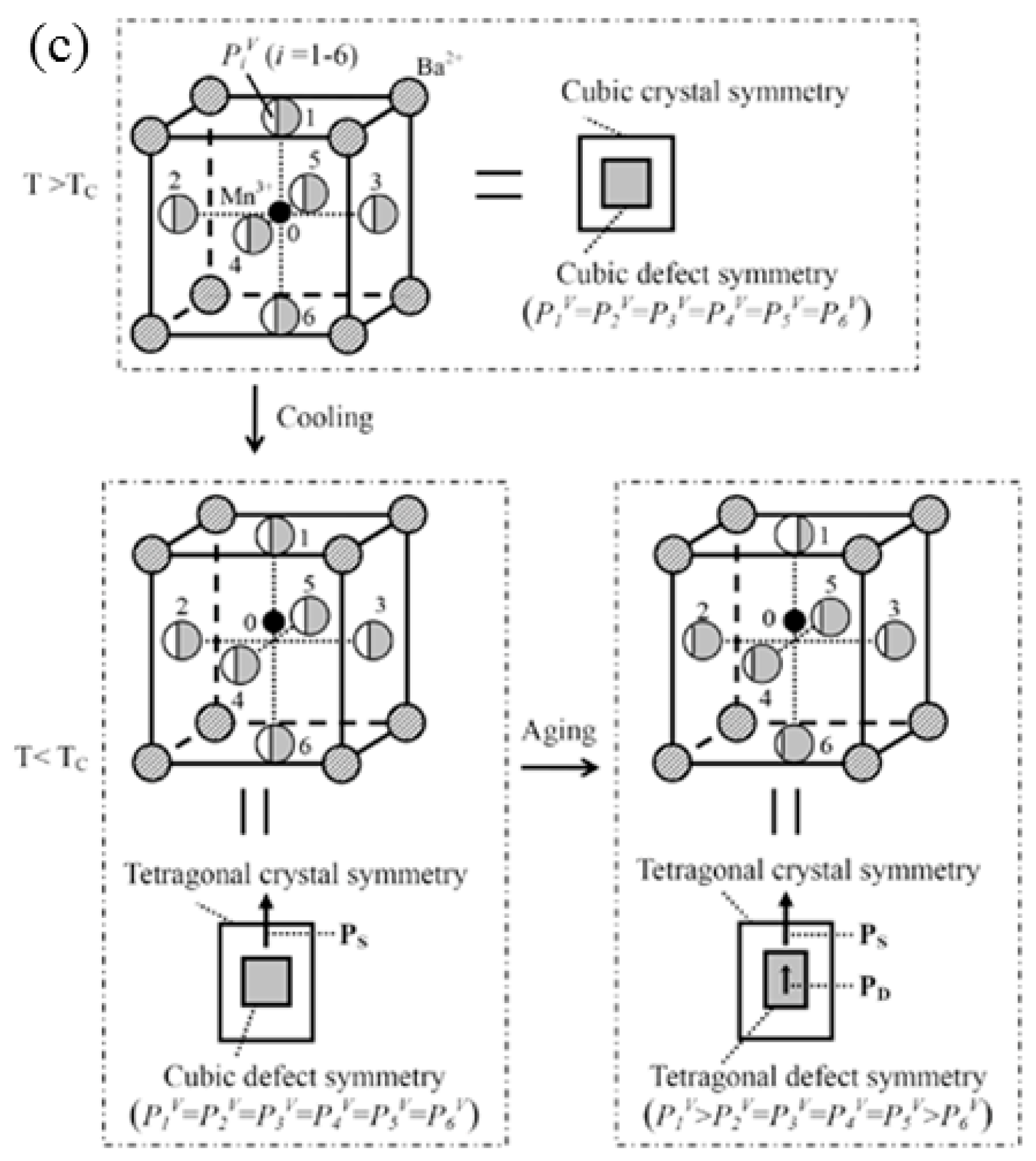

3. Large Non-Linear Electrostrain in Aging Point-Defect-Doped BaTiO3

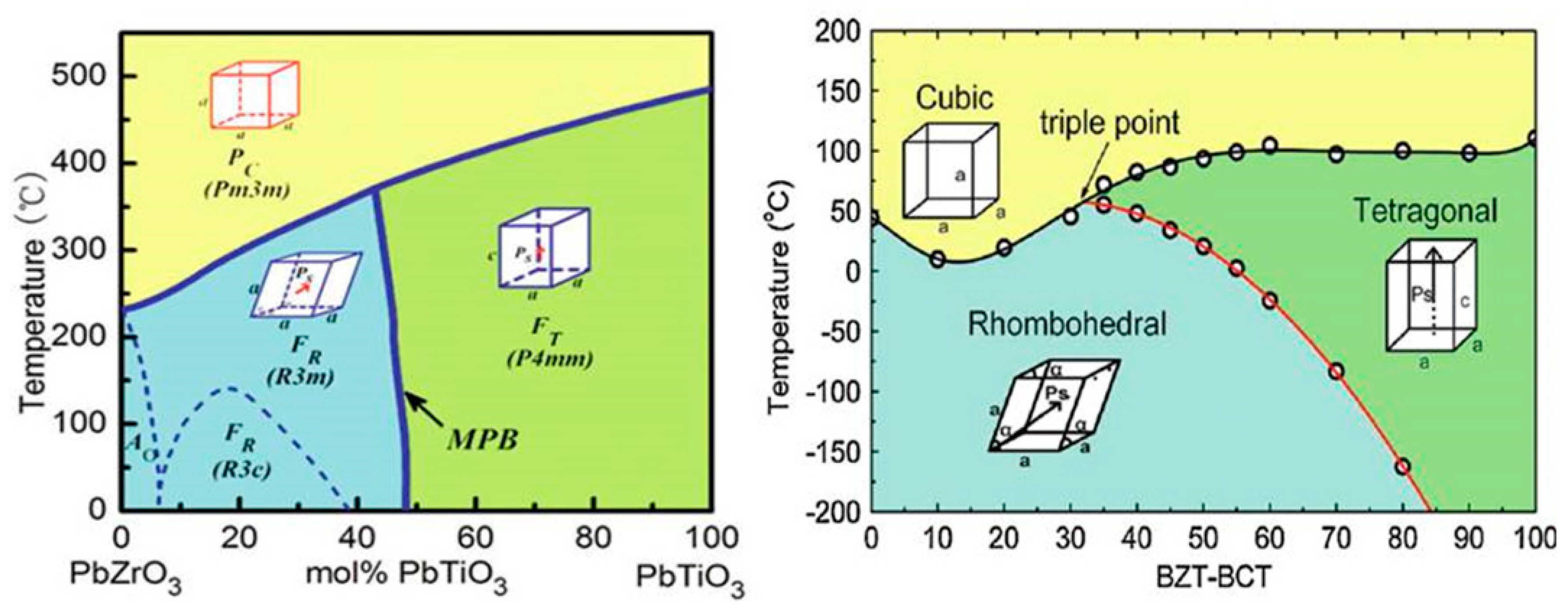

4. Large Piezoelectric Response Caused by Morphotropic Phase Boundary in BaTiO3

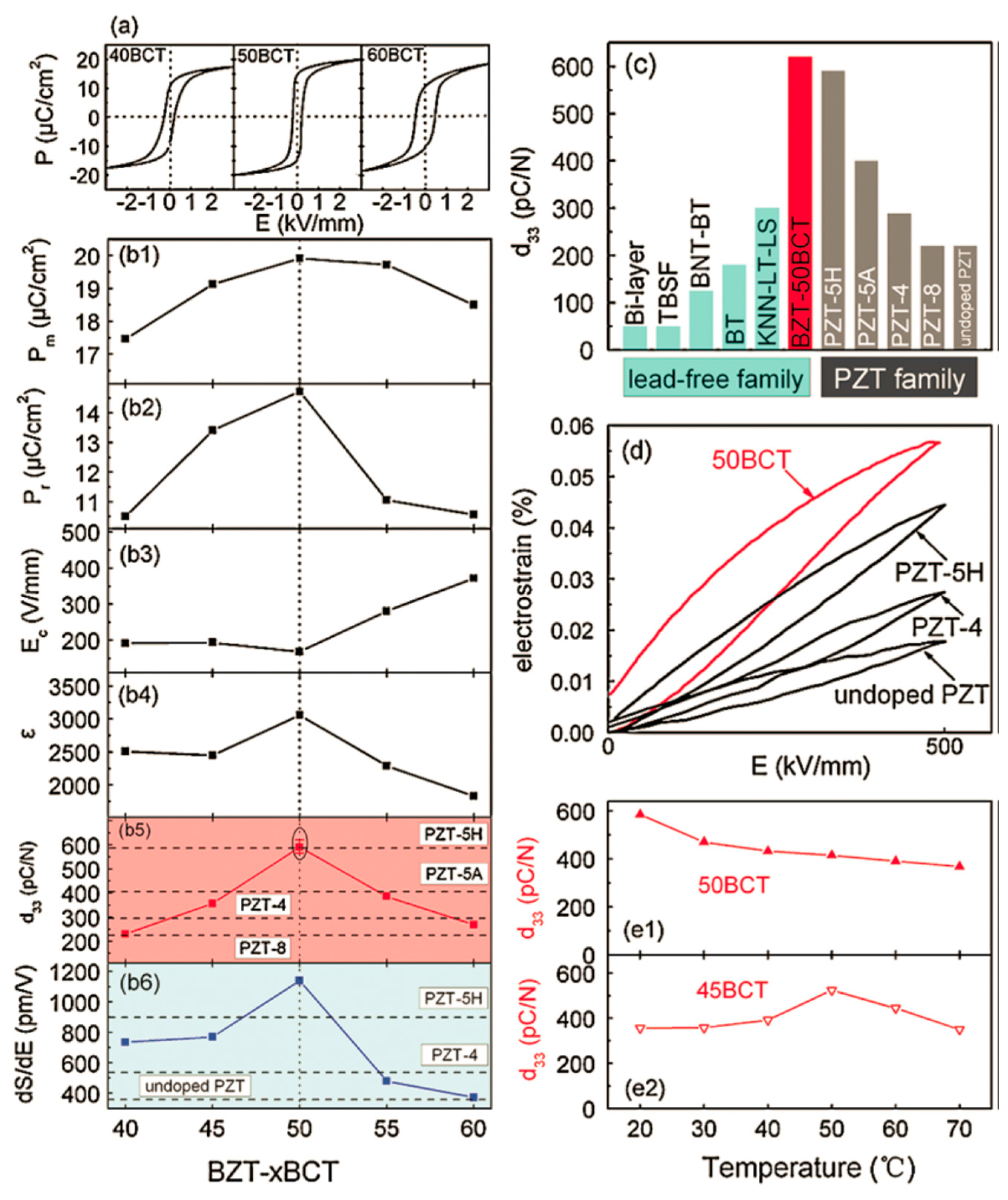

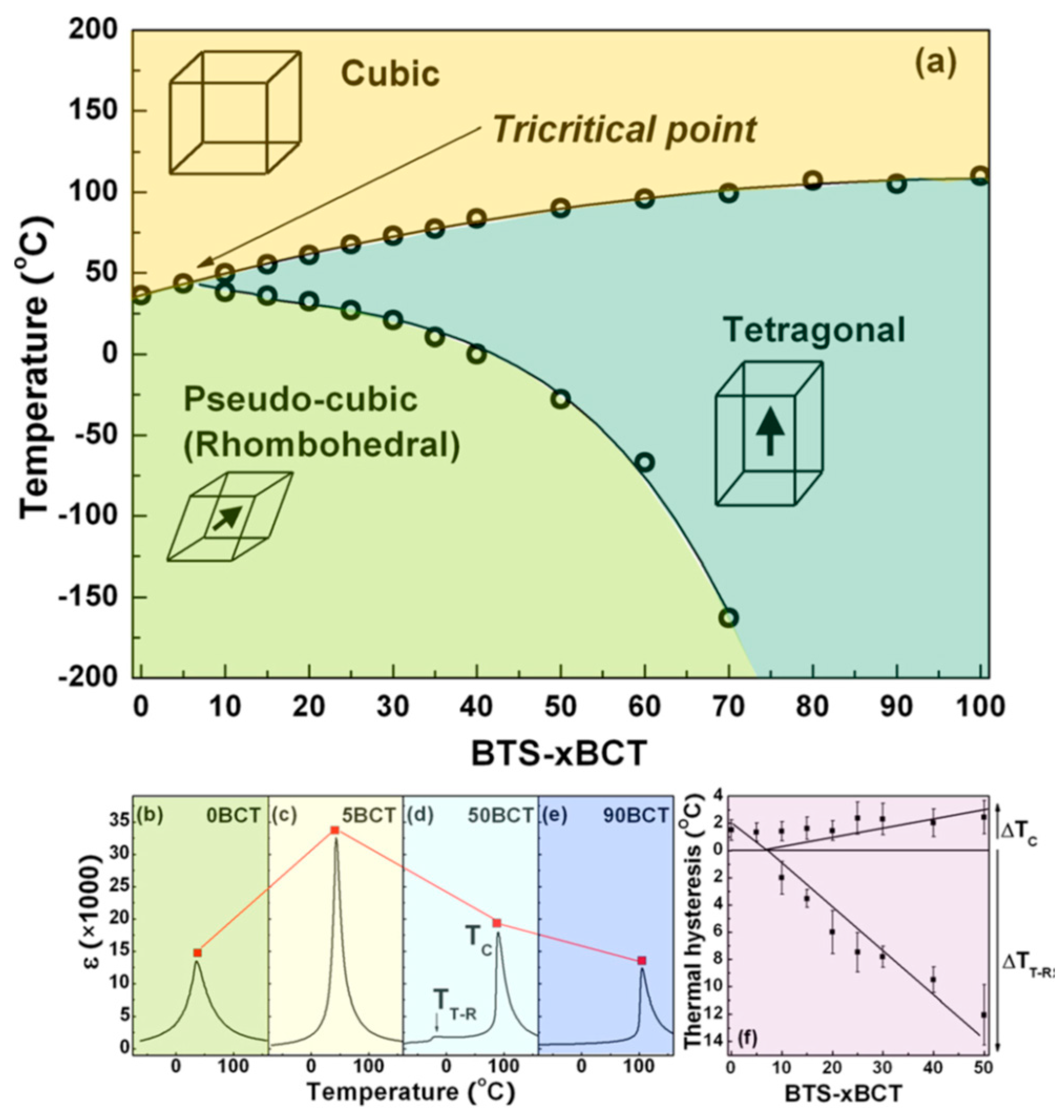

4.1. Ba(Zr0.2Ti0.8)O3–(Ba0.7Ca0.3)TiO3

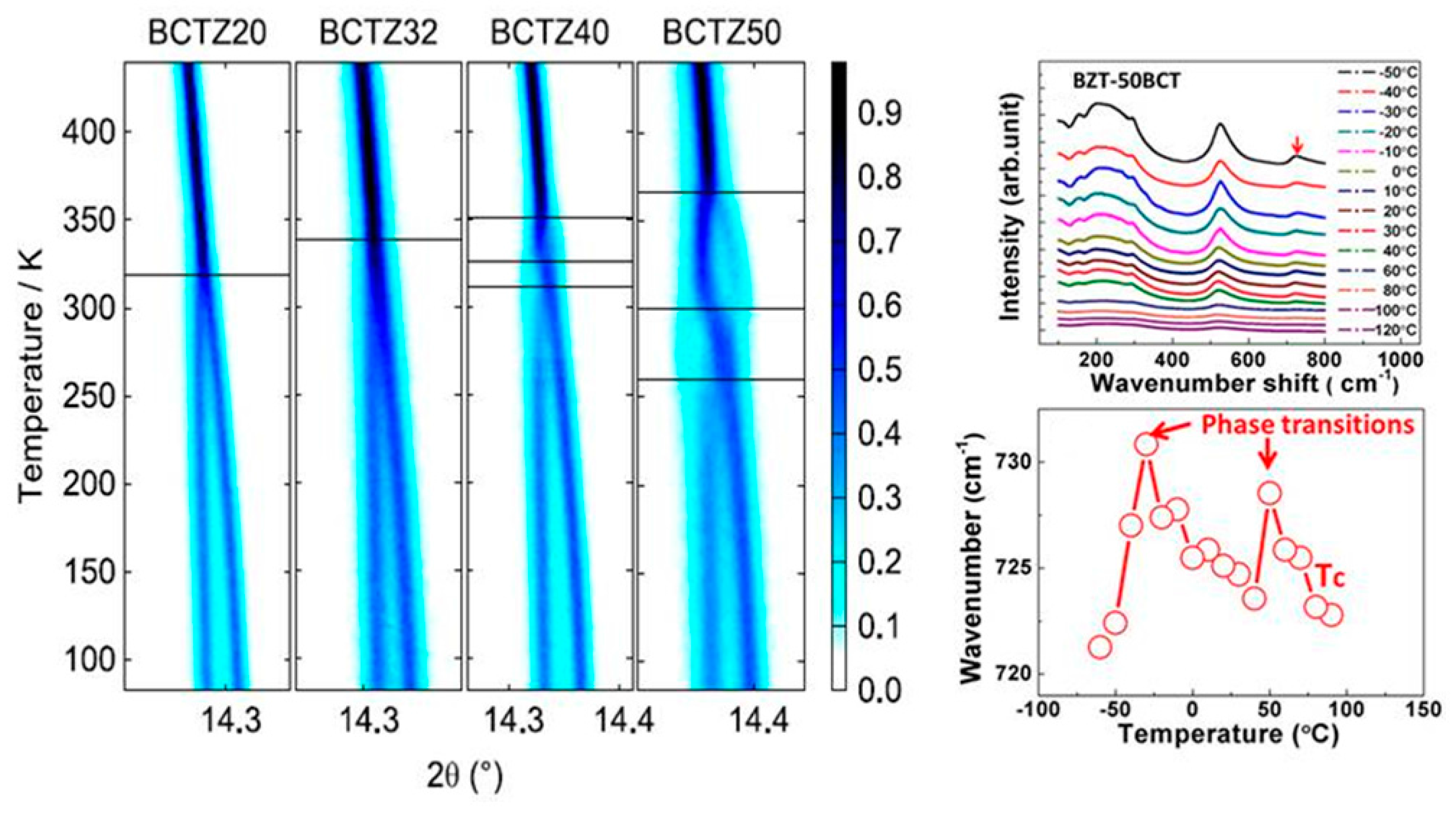

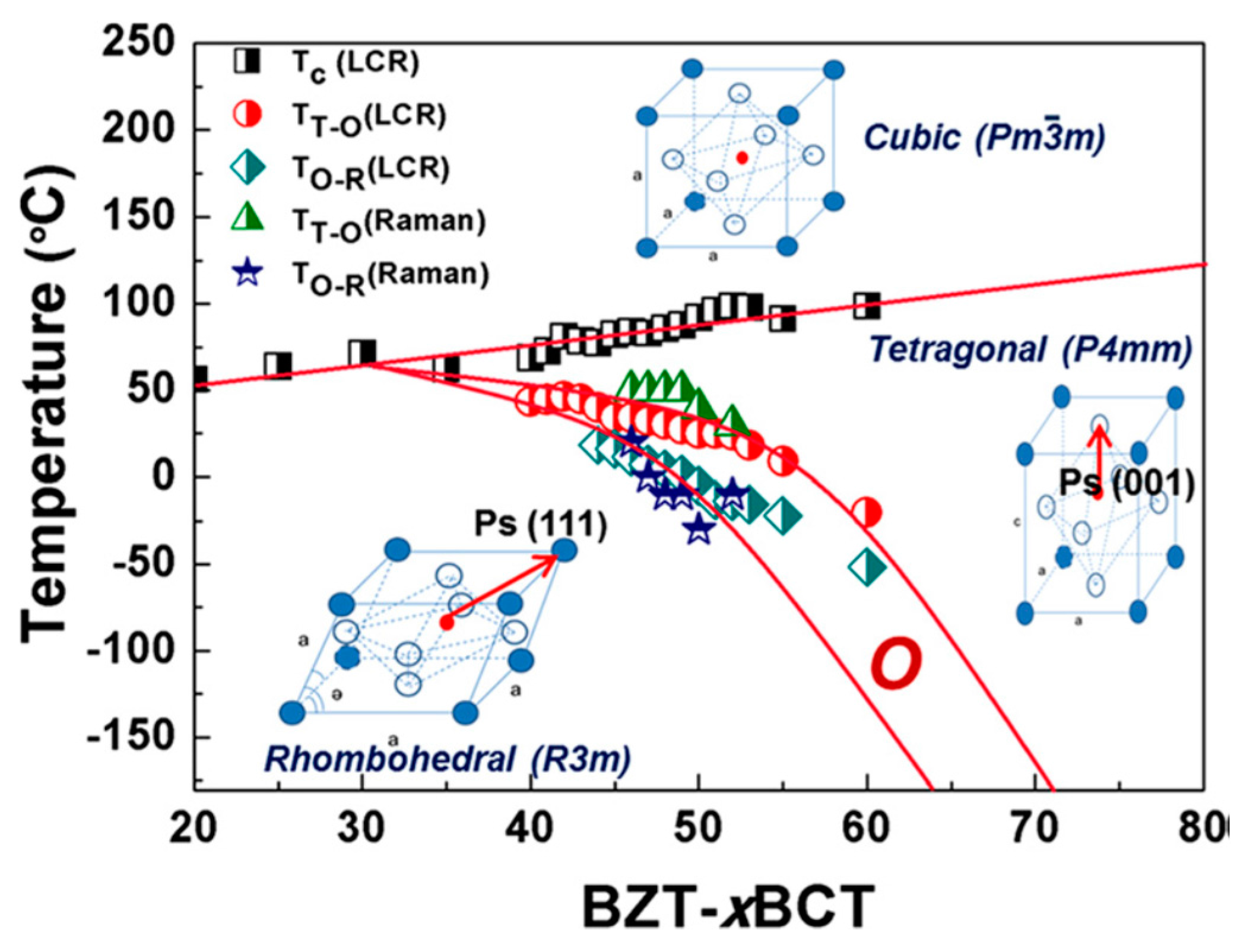

4.2. Crystal Structure

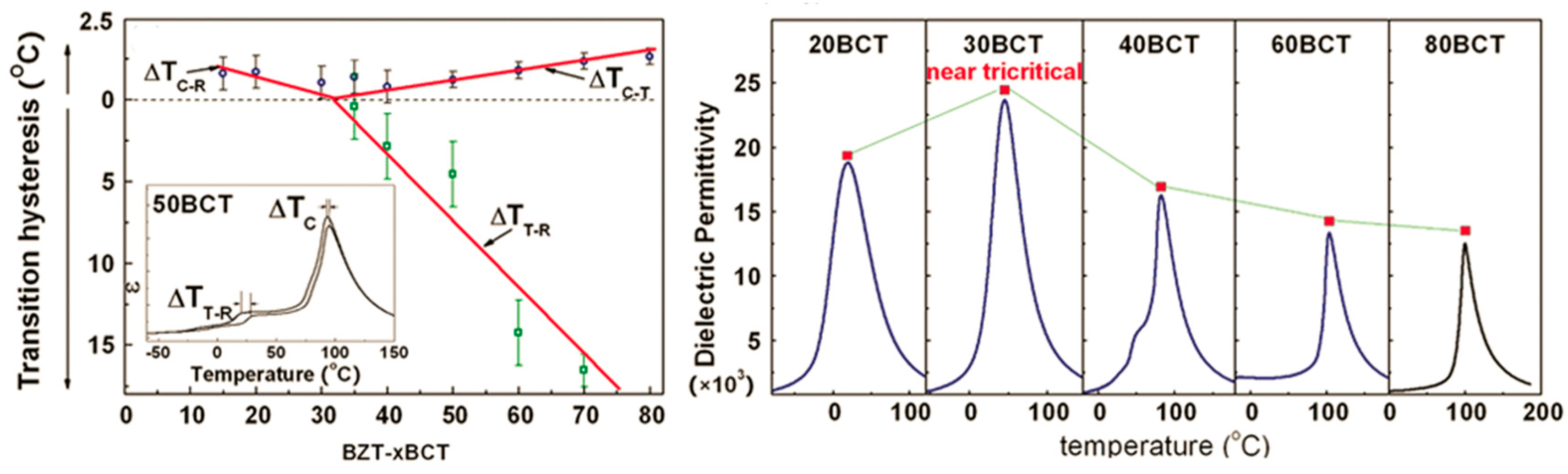

4.3. Tricritical Phenomenon

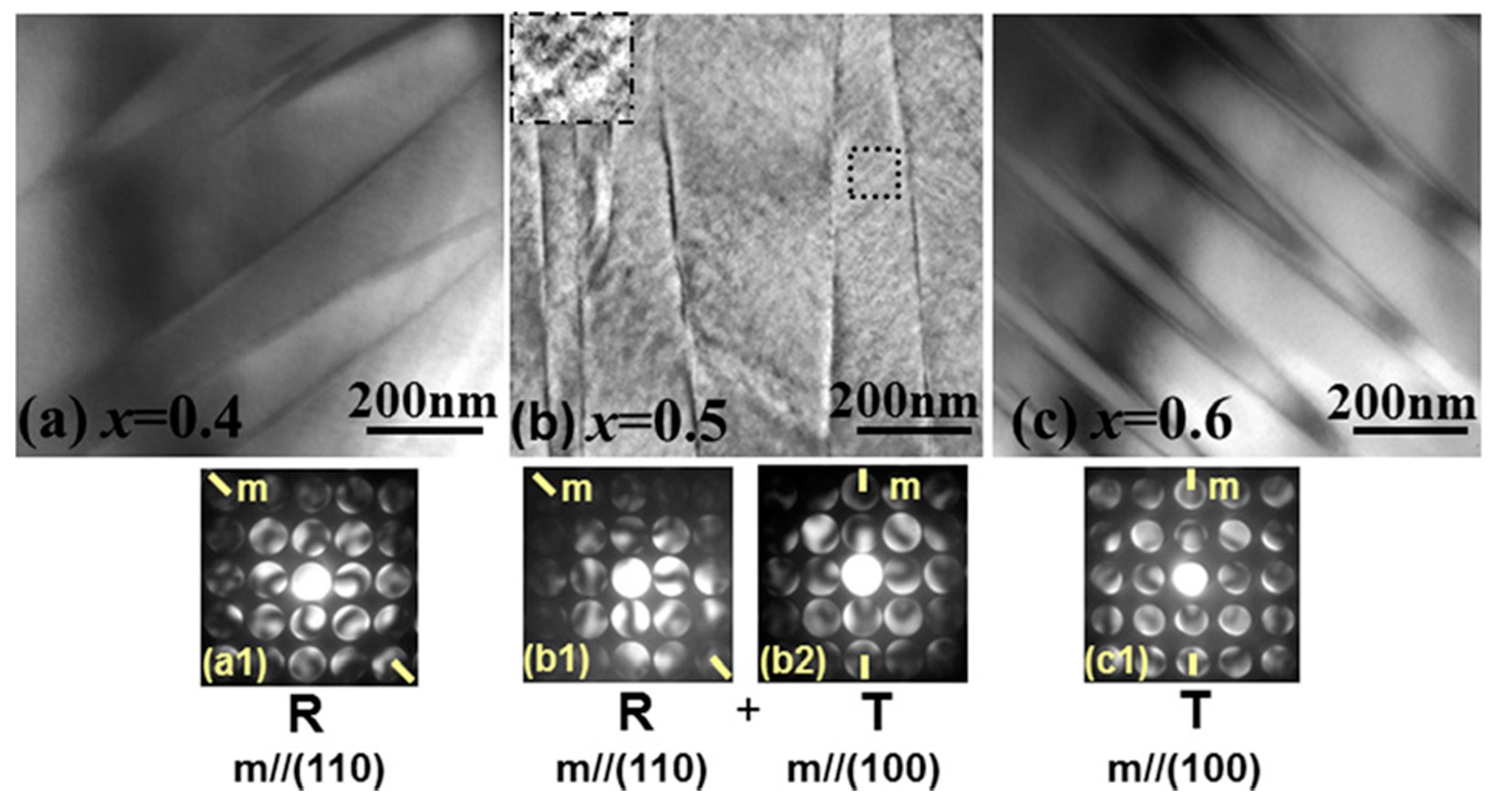

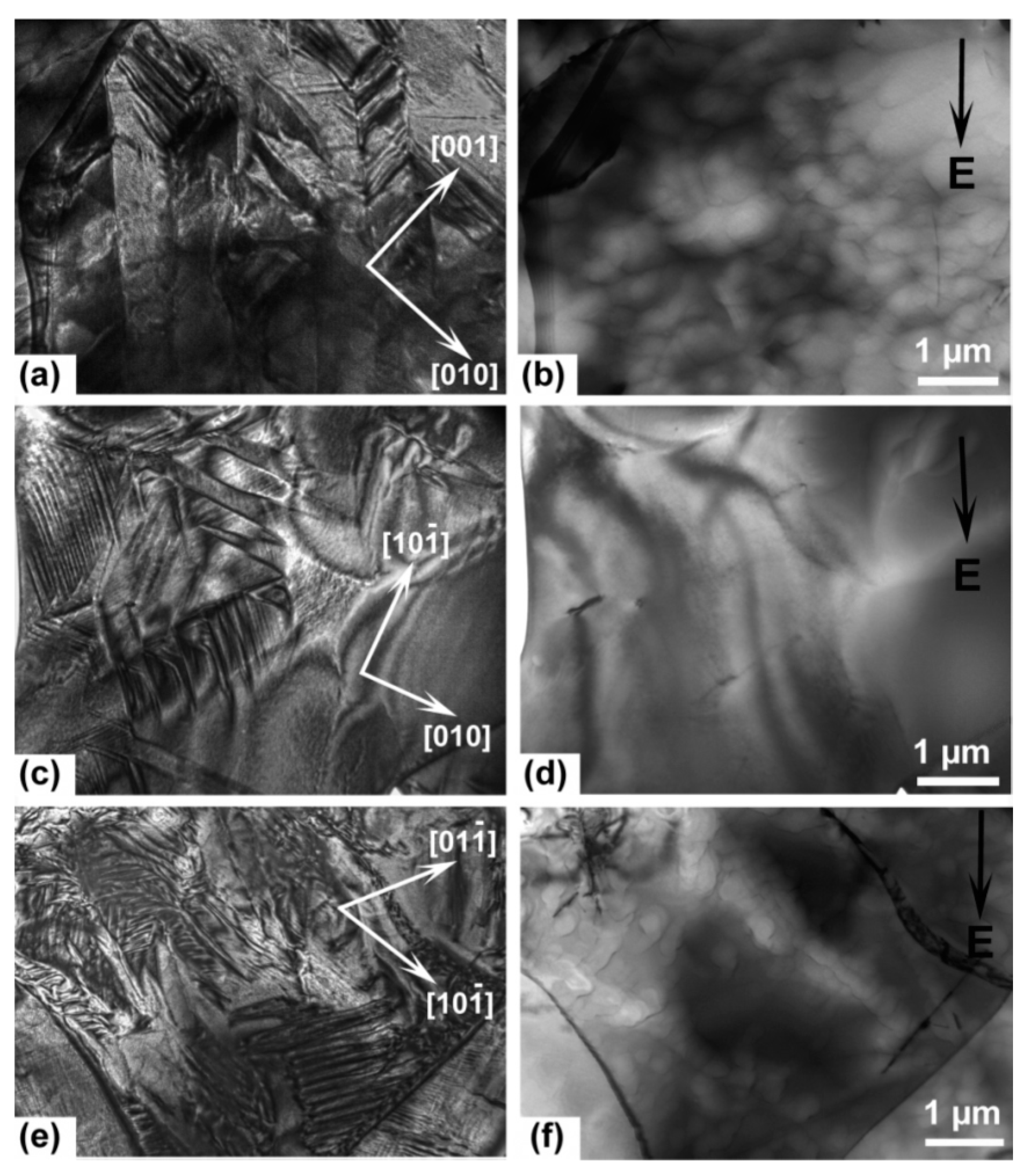

4.4. Microstructure of Ferroelectric Domains

4.5. General Systems

5. Applications and Outline

6. Summary

Acknowledgments

Conflicts of Interest

References

- Uchino, K. Ferroelectric Devices; Marcel Dekker: New York, NY, USA, 2000. [Google Scholar]

- Malek, C.K.; Saile, V. Applications of LIGA technology to precision manufacturing of high-aspect-ratio micro-components and -systems: A review. Microelectron. J. 2004, 35, 131–143. [Google Scholar] [CrossRef]

- Fennimore, A.M.; Yuzvinsky, T.D.; Han, W.Q.; Fuhrer, M.S.; Cumings, J.; Zettl, A. Rotational actuators based on carbon nanotubes. Nature 2003, 424, 408–410. [Google Scholar] [CrossRef] [PubMed]

- Tadaki, T.; Otsuka, K.; Shimizu, K. Shape memory alloys. Annu. Rev. Mater. Sci. 1988, 18, 25–45. [Google Scholar] [CrossRef]

- Setter, N.; Damjanovic, D.; Eng, L.; Fox, G.; Gevorgian, S.; Hong, S.; Kingon, A.; Kohlstedt, H.; Park, N.Y.; Stephenson, G.B.; et al. Ferroelectric thin films: Review of materials, properties, and applications. J. Appl. Phys. 2006, 100, 051606. [Google Scholar] [CrossRef]

- Haertling, G.H. Ferroelectric ceramics: History and technology. J. Am. Ceram. Soc. 1999, 82, 797–818. [Google Scholar] [CrossRef]

- Park, S.-E.; Shrout, T.R. Ultrahigh strain and piezoelectric behavior in relaxor based ferroelectric single crystals. J. Appl. Phys. 1997, 82, 1804–1811. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F. High performance ferroelectric relaxor-PbTiO3 single crystals: Status and perspective. J. Appl. Phys. 2012, 111, 031301. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Jiang, X.; Kim, J.; Luo, J.; Geng, X. Advantages and challenges of relaxor-PbTiO3 ferroelectric crystals for electroacoustic transducers—A review. Prog. Mater. Sci. 2015, 68, 1–66. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Jin, L.; Xu, Z.; Zhang, S. Electrostrictive effect in ferroelectrics: An alternative approach to improve piezoelectricity. Appl. Phys. Rev. 2014, 1, 011103. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Yang, T.; Xu, Z.; Zhang, N.; Liu, G.; Wang, J.; Wang, J.; Cheng, Z.; Ye, Z.-G.; et al. The origin of ultrahigh piezoelectricity in relaxor-ferroelectric solid solution crystals. Nat. Commun. 2016, 7, 13807. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.M.; Zhang, J. Electromechanical properties of lead zirconate titanate piezoceramics under the influence of mechanical stresses. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1999, 46, 1518–1526. [Google Scholar] [CrossRef] [PubMed]

- Shrout, T.R.; Park, S.E.E.; Lopath, P.D.; Meyer, J.R.J.; Ritter, T.A.; Shung, K.K. Innovations in piezoelectric materials for ultrasound transducers. Proc. SPIE 1998, 3341, 174–183. [Google Scholar]

- Liu, W.; Ren, X. Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef] [PubMed]

- Xue, D.; Zhou, Y.; Bao, H.; Gao, J.; Zhou, C.; Ren, X. Large piezoelectric effect in Pb-free Ba(Ti,Sn)O3–x(Ba,Ca)TiO3 ceramics. Appl. Phys. Lett. 2011, 99, 122901. [Google Scholar] [CrossRef]

- Directive 2002/95/EC: Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS). Available online: https://ec.europa.eu/growth/single-market/european-standards/harmonised-standards/restriction-of-hazardous-substances_en (accessed on 23 July 2017).

- Wu, J.; Xiao, D.; Zhu, J. Potassium–sodium niobate lead-free piezoelectric materials: Past, present, and future of phase boundaries. Chem. Rev. 2015, 115, 2559–2595. [Google Scholar] [CrossRef] [PubMed]

- Zheng, T.; Yuan, Y.; Lv, X.; Li, Q.; Men, T.; Zhao, C.; Xiao, D.; Wu, J.; Wang, K.; Li, J.-F. The structural origin of enhanced piezoelectric performance and stability in lead free ceramics. Energy Environ. Sci. 2017, 10, 528–537. [Google Scholar] [CrossRef]

- Wang, K.; Yao, F.Z.; Jo, W.; Gobeljic, D.; Shvartsman, V.V.; Lupascu, D.C.; Li, J.F.; Rödel, J. Temperature-insensitive (K,Na)NbO3-based lead-free piezoactuator ceramics. Adv. Funct. Mater. 2013, 23, 4079–4086. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, R.; Shrout, T.R.; Zang, G.; Wang, J. Piezoelectric properties in perovskite 0.948(K0.5Na0.5)NbO3–0.052LiSbO3 lead-free ceramics. J. Appl. Phys. 2006, 100, 104108. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, R.; Shrout, T.R.; Zang, G.; Wang, J. Characterization of lead free (K0.5Na0.5)NbO3–LiSbO3 piezoceramic. Solid State Commun. 2007, 141, 675–679. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Xiao, D.; Zhu, J.; Cheng, X.; Zheng, T.; Zhang, B.; Lou, X.; Wang, X. Giant piezoelectricity in potassium–sodium niobate lead-free ceramics. J. Am. Chem. Soc. 2014, 136, 2905–2910. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Xu, P.; Patterson, E.; Zang, J.; Jiang, S.; Rödel, J. Preparation and enhanced electrical properties of grain-oriented (Bi1/2Na1/2)TiO3-based lead-free incipient piezoceramics. J. Eur. Ceram. Soc. 2015, 35, 2501–2512. [Google Scholar] [CrossRef]

- Shrout, T.R.; Zhang, S.J. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Rödel, J.; Jo, W.; Seifert, K.T.P.; Anton, E.M.; Granzow, T.; Damjanovic, D. Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Takenaka, T.; Nagata, H. Current status and prospects of lead-free piezoelectric ceramics. J. Eur. Ceram. Soc. 2005, 25, 2693–2700. [Google Scholar] [CrossRef]

- Li, J.-F.; Wang, K.; Zhu, F.-Y.; Cheng, L.-Q.; Yao, F.-Z. (K,Na)NbO3-based lead-free piezoceramics: Fundamental aspects, processing technologies, and remaining challenges. J. Am. Ceram. Soc. 2013, 96, 3677–3696. [Google Scholar] [CrossRef]

- Berlincourt, D.; Jaffe, H. Elastic and piezoelectric coefficients of single-crystal barium titanate. Phys. Rev. 1958, 111, 143–148. [Google Scholar] [CrossRef]

- Takenaka, T.; Nagata, H.; Hiruma, Y.; Yoshii, Y.; Matumoto, K. Lead-free piezoelectric ceramics based on perovskite structures. J. Electroceram. 2007, 19, 259–265. [Google Scholar] [CrossRef]

- Budimir, M.; Damjanovic, D.; Setter, N. Piezoelectric response and free-energy instability in the perovskite crystals BaTiO3, PbTiO3, and Pb(Zr,Ti)O3. Phys. Rev. B 2006, 73, 174106. [Google Scholar] [CrossRef]

- Budimir, M.; Damjanovic, D.; Setter, N. Enhancement of the piezoelectric response of tetragonal perovskite single crystals by uniaxial stress applied along the polar axis: A free-energy approach. Phys. Rev. B 2005, 72, 064107. [Google Scholar] [CrossRef]

- Damjanovic, D. Contributions to the piezoelectric effect in ferroelectric single crystals and ceramics. J. Am. Ceram. Soc. 2005, 88, 2663–2676. [Google Scholar] [CrossRef]

- Wada, S.; Kakemoto, H.; Tsurumi, T. Enhanced piezoeletric properties of piezoelectric single crystals by domain engineering. Mater. Trans. 2004, 45, 178–187. [Google Scholar] [CrossRef]

- Wada, S.; Yako, K.; Kakemoto, H.; Tsurumi, T.; Kiguchi, T. Enhanced piezoelectric properties of barium titanate single crystals with different engineered-domain sizes. J. Appl. Phys. 2005, 98, 014109. [Google Scholar] [CrossRef]

- Takahashi, H.; Numamoto, Y.; Tani, J.; Tsurekawa, S. Piezoelectric properties of BaTiO3 ceramics with high performance fabricated by microwave sintering. Jpn. J. Appl. Phys. 2006, 45, 7405–7408. [Google Scholar] [CrossRef]

- Karaki, T.; Yan, K.; Miyamoto, T.; Adachi, M. Lead-free piezoelectric ceramics with large dielectric and piezoelectric constants manufactured from BaTiO3 nano-powder. Jpn. J. Appl. Phys. 2007, 46, L97–L98. [Google Scholar]

- Satoshi, W.; Kotaro, T.; Tomomitsu, M.; Hirofumi, K.; Takaaki, T.; Toshio, K. Preparation of [110] grain oriented barium titanate ceramics by templated grain growth method and their piezoelectric properties. Jpn. J. Appl. Phys. 2007, 46, 7039. [Google Scholar]

- Yin, J.; Cao, W. Domain configurations in domain engineered 0.955Pb(Zn1/3Nb2/3)O3–0.045PbTiO3 single crystals. J. Appl. Phys. 2000, 87, 7438–7441. [Google Scholar] [CrossRef]

- Shen, Z.-Y.; Li, J.-F. Enhancement of piezoelectric constant d33 in BaTiO3 ceramics due to nano-domain structure. J. Ceram. Soc. Jpn. 2010, 118, 940–943. [Google Scholar] [CrossRef]

- Ren, X. Large electric-field-induced strain in ferroelectric crystals by point-defect-mediated reversible domain switching. Nat. Mater. 2004, 3, 91–94. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.X.; Chen, W.; Ren, X. Large recoverable electrostrain in Mn-doped (Ba,Sr)TiO3 ceramics. Appl. Phys. Lett. 2004, 85, 5658–5660. [Google Scholar] [CrossRef]

- Zhang, L.X.; Ren, X. In situ observation of reversible domain switching in aged Mn-doped BaTiO3 single crystals. Phys. Rev. B 2005, 71, 174108. [Google Scholar] [CrossRef]

- Kiyoshi, O.; Hiroshi, M. Space charge effects on ferroelectric ceramic particle surfaces. Jpn. J. Appl. Phys. 1992, 31, 3113. [Google Scholar]

- Carl, K.; Hardtl, K.H. Electrical after-effects in Pb(Ti,Zr)O3 ceramics. Ferroelectrics 1977, 17, 473–486. [Google Scholar] [CrossRef]

- Postnikov, V.S.; Pavlov, V.S.; Turkov, S.K. Internal friction in ferroelectrics due to interaction of domain boundaries and point defects. J. Phys. Chem. Solids 1970, 31, 1785–1791. [Google Scholar] [CrossRef]

- Yang, T.J.; Gopalan, V.; Swart, P.J.; Mohideen, U. Direct observation of pinning and bowing of a single ferroelectric domain wall. Phys. Rev. Lett. 1999, 82, 4106–4109. [Google Scholar] [CrossRef]

- Lambeck, P.V.; Jonker, G.H. The nature of domain stabilization in ferroelectric perovskites. J. Phys. Chem. Solids 1986, 47, 453–461. [Google Scholar] [CrossRef]

- Robels, U.; Arlt, G. Domain wall clamping in ferroelectrics by orientation of defects. J. Appl. Phys. 1993, 73, 3454–3460. [Google Scholar] [CrossRef]

- Lambeck, P.V.; Jonker, G.H. Ferroelectric domain stabilization in BaTiO3 by bulk ordering of defects. Ferroelectrics 1978, 22, 729–731. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, X. Aging behavior in single-domain Mn-doped BaTiO3 crystals: Implication for a unified microscopic explanation of ferroelectric aging. Phys. Rev. B 2006, 73, 094121. [Google Scholar] [CrossRef]

- Gao, J.; Xue, D.; Zhang, L.; Wang, Y.; Bao, H.; Zhou, C.; Liu, W.; Chen, W.; Ren, X. Aging-induced domain memory in acceptor-doped perovskite ferroelectrics associated with ferroelectric-ferroelectric transition cycle. EPL 2011, 96, 37001. [Google Scholar] [CrossRef]

- Gao, J.; Xue, D.; Bao, H.; Zhang, L.; Zhou, C.; Liu, W.; Chen, W.; Ren, X. Aging-induced two-step ferroelectric-to-paraelectric transition in acceptor-doped ferroelectrics. Appl. Phys. Lett. 2010, 96, 082906. [Google Scholar] [CrossRef]

- Gao, J.; Xue, D.; Bao, H.; Zhang, L.; Zhou, C.; Liu, W.; Chen, W.; Ren, X. Two-step ferroelectric to paraelectric transition caused by peak aging. Ferroelectrics 2010, 401, 24–29. [Google Scholar] [CrossRef]

- Sun, D.; Ren, X.; Otsuka, K. Stabilization effect in ferroelectric materials during aging in ferroelectric state. Appl. Phys. Lett. 2005, 87, 142903. [Google Scholar] [CrossRef]

- Jaffe, B.; Roth, R.S.; Marzullo, S. Properties of piezoelectric ceramics in the solid-solution series lead titanate-lead zirconate-lead oxide-tin oxide and lead titanate-lead hafnate. J. Res. Natl. Bur. Stand. 1955, 55, 239–254. [Google Scholar] [CrossRef]

- Jaffe, B.; Roth, R.S.; Marzullo, S. Piezoelectric properties of lead zirconate-lead titanate solid-solution ceramics. J. Appl. Phys. 1954, 25, 809–810. [Google Scholar] [CrossRef]

- Wu, B.; Wu, H.; Wu, J.; Xiao, D.; Zhu, J.; Stephen, J.P. Giant piezoelectricity and high Curie temperature in nanostructured alkali niobate lead-free piezoceramics through phase coexistence. J. Am. Chem. Soc. 2016, 138, 15459–15464. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Xiao, D.; Wu, W.; Chen, Q.; Zhu, J.; Yang, Z.; Wang, J. Role of room-temperature phase transition in the electrical properties of (Ba,Ca)(Ti,Zr)O3 ceramics. Scr. Mater. 2011, 65, 771–774. [Google Scholar] [CrossRef]

- Li, B.; Blendell, J.E.; Bowman, K.J. Temperature-dependent poling behavior of lead-free BZT–BCT piezoelectrics. J. Am. Ceram. Soc. 2011, 94, 3192–3194. [Google Scholar] [CrossRef]

- Ehmke, M.C.; Glaum, J.; Hoffman, M.; Blendell, J.E.; Bowman, K.J. The effect of electric poling on the performance of lead-free (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 piezoceramics. J. Am. Ceram. Soc. 2013, 96, 3805–3811. [Google Scholar] [CrossRef]

- Li, B.; Ehmke, M.C.; Blendell, J.E.; Bowman, K.J. Optimizing electrical poling for tetragonal, lead-free BZT–BCT piezoceramic alloys. J. Eur. Ceram. Soc. 2013, 33, 3037–3044. [Google Scholar] [CrossRef]

- Jin, L.; Huo, R.; Guo, R.; Li, F.; Wang, D.; Tian, Y.; Hu, Q.; Wei, X.; He, Z.; Yan, Y.; et al. Diffuse phase transitions and giant electrostrictive coefficients in lead-free Fe3+-doped 0.5Ba(Zr0.2Ti0.8)O3–0.5(Ba0.7Ca0.3)TiO3 ferroelectric ceramics. ACS Appl. Mater. Interfaces 2016, 8, 31109–31119. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Jin, L.; Guo, R. High electrostrictive coefficient Q33 in lead-free Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 piezoelectric ceramics. Appl. Phys. Lett. 2014, 105, 232903. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Wu, W.; Chen, Q.; Zhu, J.; Yang, Z.; Wang, J. Composition and poling condition-induced electrical behavior of (Ba0.85Ca0.15)(Ti1 − xZrx)O3 lead-free piezoelectric ceramics. J. Eur. Ceram. Soc. 2012, 32, 891–898. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Wu, B.; Wu, W.; Zhu, J.; Yang, Z.; Wang, J. Sintering temperature-induced electrical properties of (Ba0.90Ca0.10)(Ti0.85Zr0.15)O3 lead-free ceramics. Mater. Res. Bull. 2012, 47, 1281–1284. [Google Scholar] [CrossRef]

- Xue, D.; Zhou, Y.; Bao, H.; Zhou, C.; Gao, J.; Ren, X. Elastic, piezoelectric, and dielectric properties of Ba(Zr0.2Ti0.8)O3–50(Ba0.7Ca0.3)TiO3 Pb-free ceramic at the morphotropic phase boundary. J. Appl. Phys. 2011, 109, 054110. [Google Scholar] [CrossRef]

- Ehmke, M.C.; Ehrlich, S.N.; Blendell, J.E.; Bowman, K.J. Phase coexistence and ferroelastic texture in high strain (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 piezoceramics. J. Appl. Phys. 2012, 111, 124110. [Google Scholar] [CrossRef]

- Haugen, A.B.; Forrester, J.S.; Damjanovic, D.; Li, B.; Bowman, K.J.; Jones, J.L. Structure and phase transitions in 0.5(Ba0.7Ca0.3TiO3)–0.5(BaZr0.2Ti0.8O3) from −100 °C to 150 °C. J. Appl. Phys. 2013, 113, 014103. [Google Scholar] [CrossRef]

- Gao, J.; Xue, D.; Wang, Y.; Wang, D.; Zhang, L.; Wu, H.; Guo, S.; Bao, H.; Zhou, C.; Liu, W.; et al. Microstructure basis for strong piezoelectricity in Pb-free Ba(Zr0.2Ti0.8)O3–(Ba0.7Ca0.3)TiO3 ceramics. Appl. Phys. Lett. 2011, 99, 092901. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, L.; Xue, D.; Kimoto, T.; Song, M.; Zhong, L.; Ren, X. Symmetry determination on Pb-free piezoceramic 0.5Ba(Zr0.2Ti0.8)O3–0.5(Ba0.7Ca0.3)TiO3 using convergent beam electron diffraction method. J. Appl. Phys. 2014, 115, 054108. [Google Scholar] [CrossRef]

- Keeble, D.S.; Benabdallah, F.; Thomas, P.A.; Maglione, M.; Kreisel, J. Revised structural phase diagram of (Ba0.7Ca0.3TiO3)–(BaZr0.2Ti0.8O3). Appl. Phys. Lett. 2013, 102, 092903. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Wang, L.; Zhou, C.; Zhang, Z.; Yao, Y.; Zhang, L.; Xue, D.; Lou, X.; Ren, X. Phase transitions and the piezoelectricity around morphotropic phase boundary in Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 lead-free solid solution. Appl. Phys. Lett. 2014, 105, 162908. [Google Scholar] [CrossRef]

- Damjanovic, D.; Biancoli, A.; Batooli, L.; Vahabzadeh, A.; Trodahl, J. Elastic, dielectric, and piezoelectric anomalies and Raman spectroscopy of 0.5Ba(Ti0.8Zr0.2)O3–0.5(Ba0.7Ca0.3)TiO3. Appl. Phys. Lett. 2012, 100, 192907. [Google Scholar] [CrossRef]

- Acosta, M.; Novak, N.; Rossetti, G.A., Jr.; Rödel, J. Mechanisms of electromechanical response in (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 ceramics. Appl. Phys. Lett. 2015, 107, 142906. [Google Scholar] [CrossRef]

- Acosta, M.; Novak, N.; Jo, W.; Rödel, J. Relationship between electromechanical properties and phase diagram in the Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 lead-free piezoceramic. Acta Mater. 2014, 80, 48–55. [Google Scholar] [CrossRef]

- Acosta, M.; Khakpash, N.; Someya, T.; Novak, N.; Jo, W.; Nagata, H.; Rossetti, G.A.; Rödel, J. Origin of the large piezoelectric activity in (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 ceramics. Phys. Rev. B 2015, 91, 104108. [Google Scholar] [CrossRef]

- Gao, J.; Ye, D.; Xinghao, H.; Xiaoqin, K.; Lisheng, Z.; Shengtao, L.; Lixue, Z.; Yu, W.; Dong, W.; Yan, W.; et al. Phase transition behaviours near the triple point for Pb-free (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 piezoceramics. EPL 2016, 115, 37001. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Y.; Liu, Y.; Hu, X.; Ke, X.; Zhong, L.; He, Y.; Ren, X. Enhancing dielectric permittivity for energy-storage devices through tricritical phenomenon. Sci. Rep. 2017, 7, 40916. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.H.; Hu, X.H.; Wang, Y.; Liu, Y.B.; Zhang, L.X.; Ke, X.Q.; Zhong, L.S.; Zhao, H.; Ren, X.B. Understanding the mechanism of large dielectric response in Pb-free (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 ferroelectric ceramics. Acta Mater. 2017, 125, 177–186. [Google Scholar] [CrossRef]

- Gao, J.; Liu, Y.; Wang, Y.; Hu, X.; Yan, W.; Ke, X.; Zhong, L.; He, Y.; Ren, X. Designing high dielectric permittivity material in barium titanate. J. Phys. Chem. C 2017, 121, 13106–13113. [Google Scholar] [CrossRef]

- Gao, J.; Ren, S.; Zhang, L.; Hao, Y.; Fang, M.; Zhang, M.; Dai, Y.; Hu, X.; Wang, D.; Zhong, L.; et al. Phase transition sequence in Pb-free 0.96(K0.5Na0.5)0.95Li0.05Nb0.93Sb0.07O3–0.04BaZrO3 ceramic with large piezoelectric response. Appl. Phys. Lett. 2015, 107, 032902. [Google Scholar] [CrossRef]

- Gao, J.; Hao, Y.; Ren, S.; Takayoshi, K.; Fang, M.; Li, H.; Wang, Y.; Zhong, L.; Li, S.; Ren, X. Large piezoelectricity in Pb-free 0.96(K0.5Na0.5)0.95Li0.05Nb0.93Sb0.07O3–0.04BaZrO3 ceramic: A perspective from microstructure. Appl. Phys. Lett. 2015, 117, 084106. [Google Scholar] [CrossRef]

- Guo, H.; Voas, B.K.; Zhang, S.; Zhou, C.; Ren, X.; Beckman, S.P.; Tan, X. Polarization alignment, phase transition, and piezoelectricity development in polycrystalline 0.5Ba(Zr0.2Ti0.8)O3–0.5(Ba0.7Ca0.3)TiO3. Phys. Rev. B 2014, 90, 014103. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, C.; Ren, X.; Tan, X. Unique single-domain state in a polycrystalline ferroelectric ceramic. Phys. Rev. B 2014, 89, 100104. [Google Scholar] [CrossRef]

- Zakhozheva, M.; Schmitt, L.A.; Acosta, M.; Jo, W.; Rödel, J.; Kleebe, H.-J. In situ electric field induced domain evolution in Ba(Zr0.2Ti0.8)O3–0.3(Ba0.7Ca0.3)TiO3 ferroelectrics. Appl. Phys. Lett. 2014, 105, 112904. [Google Scholar] [CrossRef]

- Tutuncu, G.; Li, B.; Bowman, K.; Jones, J.L. Domain wall motion and electromechanical strain in lead-free piezoelectrics: Insight from the model system (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 using in situ high-energy X-ray diffraction during application of electric fields. J. Appl. Phys. 2014, 115, 144104. [Google Scholar] [CrossRef]

- Gao, J.; Hu, X.; Zhang, L.; Li, F.; Zhang, L.; Wang, Y.; Hao, Y.; Zhong, L.; Ren, X. Major contributor to the large piezoelectric response in (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 ceramics: Domain wall motion. Appl. Phys. Lett. 2014, 104, 252909. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, W.; Xue, D.; Ren, X.; Bao, H.; Gao, J.; Zhang, L. Triple-point-type morphotropic phase boundary based large piezoelectric Pb-free material—Ba(Ti0.8Hf0.2)O3–(Ba0.7Ca0.3)TiO3. Appl. Phys. Lett. 2012, 100, 222910. [Google Scholar] [CrossRef]

- Yao, Y.; Zhou, C.; Lv, D.; Wang, D.; Wu, H.; Yang, Y.; Ren, X. Large piezoelectricity and dielectric permittivity in BaTiO3–xBaSnO3 system: The role of phase coexisting. EPL 2012, 98, 27008. [Google Scholar] [CrossRef]

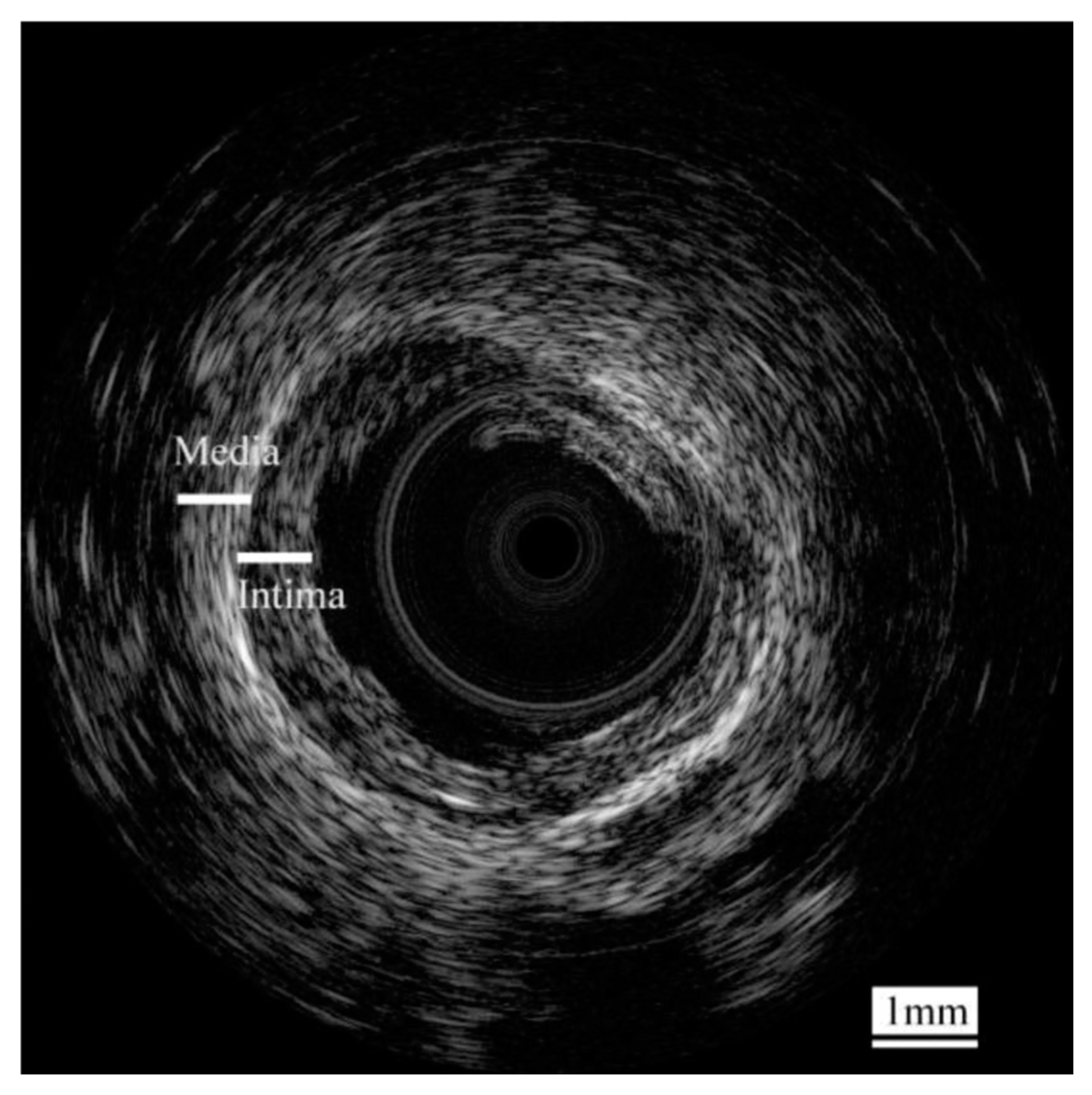

- Yan, X.; Lam, K.H.; Li, X.; Chen, R.; Ren, W.; Ren, X.; Zhou, Q.; Shung, K.K. Correspondence: Lead-free intravascular ultrasound transducer using 0.5BZT–0.5BCT ceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1272–1276. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Li, J.; Lv, X.; Wu, J.; Zhang, X.; Xiao, D.; Zhu, J. Superior piezoelectric properties in potassium-sodium niobate lead-free ceramics. Adv. Mater. 2016, 28, 8519–8523. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Liu, Y.; Wang, Y.; Wang, D.; Zhong, L.; Ren, X. High temperature-stability of (Pb0.9La0.1)(Zr0.65Ti0.35)O3 ceramic for energy-storage applications at finite electric field strength. Scr. Mater. 2017, 137, 114–118. [Google Scholar] [CrossRef]

| Materials | Poly/Single Crystal | d33 (pC/N) | k33 | Reference |

|---|---|---|---|---|

| PZT–5A (soft) | Polycrystalline | 374 | 0.71 | [6] |

| PZT–8 (hard) | Polycrystalline | 225 | 0.64 | [12] |

| PMN–70PT | Single crystal | 1500 | >0.9 | [7] |

| 92%PZN–8%PT | Single crystal | 2200 | >0.9 | [13] |

| 0.5BZT–0.5BCT | Polycrystalline | 620 | 0.65 | [14] |

| 0.7BTS–0.3BCT | Polycrystalline | 530 | 0.57 | [15] |

| Crystal | Ceramic | |

|---|---|---|

| d15 | 392 | 270 |

| d31 | −34.5 | −79 |

| d33 | 85.6 | 191 |

| g15 | 15.2 | 18.8 |

| g31 | −23.0 | −4.7 |

| g33 | 57.5 | 11.4 |

| k31 | 0.315 | 0.208 |

| k33 | 0.560 | 0.494 |

| k15 | 0.570 | 0.466 |

| ε11T/ε0 | 2920 | 1436 |

| ε33T/ε0 | 168 | 1680 |

| ε11S/ε0 | 1970 | 1123 |

| ε33S/ε0 | 109 | 1256 |

| S11E | 8.05 | 8.55 |

| S33E | 15.7 | 8.93 |

| S12E | −2.35 | −2.61 |

| S13E | −5.24 | 2.85 |

| S44E | 18.4 | 23.3 |

| S66 | 8.84 | 22.3 |

| S11D | 7.25 | 8.18 |

| S33D | 10.8 | 6.76 |

| S12D | −3.15 | −2.98 |

| S13D | −3.26 | −1.95 |

| S44D | 12.4 | 18.3 |

| Piezoelectric Coefficients | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| dij (10−12 N/C) | eij (C/m2) | gij (10−3 Vm/N) | hij (108 V/m) | ||||||||||||

| Material | d33 | d31 | d15 | e33 | e31 | e15 | g33 | g31 | g15 | h33 | h31 | h15 | |||

| BZT–50BCT | 546 | −231 | 453 | 22.4 | −5.7 | 12.1 | 15.3 | −6.5 | 31.0 | 8.6 | −2.1 | 8.3 | |||

| BaTiO3 | 191 | −79 | 270 | 11.6 | −4.4 | 18.6 | 11.4 | −4.7 | 18.8 | 9.2 | −3.5 | 16.6 | |||

| PZT5A | 374 | −171 | 584 | 15.8 | −5.4 | 12.3 | 24.9 | −11.4 | 38.0 | 21.4 | −7.3 | 15.0 | |||

| Dielectric Constants | Electromechanical Coupling Factors | ||||||||||||||

| (ε0) | (10−4/ε0) | ||||||||||||||

| a | a | a | a | k33 | k31 | k15 | kt | kp | |||||||

| BZT-50BCT | 4050 | 2732 | 2930 | 1652 | 2.47 | 3.66 | 3.41 | 6.05 | 0.65 | 0.31 | 0.48 | 0.42 | 0.53 | ||

| BaTiO3 | 1898 | 1622 | 1419 | 1269 | 5.3 | 6.2 | 7.0 | 7.9 | 0.49 | 0.21 | 0.48 | … | 0.35 | ||

| PZT5A | 1700 | 1730 | 830 | 916 | 5.9 | 5.8 | 12.0 | 10.9 | 0.70 | 0.34 | 0.68 | 0.49 | 0.60 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Xue, D.; Liu, W.; Zhou, C.; Ren, X. Recent Progress on BaTiO3-Based Piezoelectric Ceramics for Actuator Applications. Actuators 2017, 6, 24. https://doi.org/10.3390/act6030024

Gao J, Xue D, Liu W, Zhou C, Ren X. Recent Progress on BaTiO3-Based Piezoelectric Ceramics for Actuator Applications. Actuators. 2017; 6(3):24. https://doi.org/10.3390/act6030024

Chicago/Turabian StyleGao, Jinghui, Dezhen Xue, Wenfeng Liu, Chao Zhou, and Xiaobing Ren. 2017. "Recent Progress on BaTiO3-Based Piezoelectric Ceramics for Actuator Applications" Actuators 6, no. 3: 24. https://doi.org/10.3390/act6030024

APA StyleGao, J., Xue, D., Liu, W., Zhou, C., & Ren, X. (2017). Recent Progress on BaTiO3-Based Piezoelectric Ceramics for Actuator Applications. Actuators, 6(3), 24. https://doi.org/10.3390/act6030024