1. Introduction

Over the last decade polymer-based actuation technologies with electrical, thermal or chemical stimuli have driven the development of a variety of novel, multi-modal devices [

1,

2,

3]. One of the most promising types of polymer actuator are dielectric elastomers due to their high active strains and energy densities (>1 J/g) and capacity for self-sensing [

4,

5]. The inherently compliant nature of dielectric elastomer actuators (DEAs) is particularly advantageous in comparison to conventional “stiff” actuation technologies for applications that involve inhomogeneous and unstructured environments or multi-axis loading e.g., human-robot interaction. Furthermore, compliance determines the level of intrinsic mechanical constraint of an actuation device, which in turn determines the number of kinematically-free degrees of freedom (DOF) that the actuator can control. Hence, in contrast to conventional multiple DOF actuation technologies, which typically consist of serial or parallel mechanisms with rigid links and several 1-DOF actuators, DEAs can effectively unify numerous discrete components into a single contiguous membrane through their inherent elasticity. Previous multiple DOF DEAs have included 2-DOF membranes [

6,

7], 3-DOF spring rolls [

8], 3-DOF and 5-DOF cone actuators [

9,

10,

11], and 5-DOF membrane motors [

1].

In this work, a new compact DEA configuration is presented which is capable of non-holonomic 6-DOF actuation. This cube DEA design incorporates four DEA membranes in a cubic polymer structure that are coupled via a cross-shaped end effector (the actuator can be inverted so that the cubic body becomes the end effector and vice versa). Each DEA membrane can independently produce a 2-DOF output through electrode segmentation, where the elastomer membrane provides continuous elastic coupling between each active segment [

6,

7]. A rigid cross-shaped link couples each membrane via bushings and enables 6-DOF actuation via a single protruding end effector. The simplicity of the cube DEA relative to its functionality is most evident when it is compared to an existing large displacement 6-DOF actuator such as the Stewart platform [

12], which typically consists of 13 mobile parts (6 × 2-component legs and top plate/end effector) and 18 articulated joints (6 × universal, 6 × spherical and 6 × prismatic) that are driven by six linear actuators. In contrast, the cube DEA can be constructed from as few as two rigid parts (cubic frame and cross rod) and four DEA membranes. However, it should be noted that the Stewart platform can be designed to produce much larger displacements.

6-DOF actuation from a readily scalable and compact structure enables the cube DEA to potentially be developed for several applications. It can be utilised as a compact haptic device with 6-DOF force,

F, and moment,

M, output by fitting a thin shell onto the outside of the cross-rod end effector, as shown in

Figure 1a. The capacity for each DEA membrane to self-sense strain [

5] to enable user input could be exploited in this haptic device without any additional mechanical complexity. Multi-layered DEA membranes would likely be required to maximize the output values of

F and

M, but this would not limit the number of kinematically free DOF due the inherent membrane compliance.

The actuation output of the cube DEA can also be applied for active vibration stability, which can be required to stabilise cameras or other optic devices. An example of this is shown in

Figure 1b, where the cube DEA is fixed to the body of an autonomous air vehicle and the camera is connected to the centre of the cross-rod end effector. This design could be equally applied to terrestrial or aquatic mobile robots that rely on optical sensory input or any camera mount that might experience multi-axis vibrational disturbances. As with the proposed haptic device application in

Figure 1a the DEA membranes could be multi-layered to increase passive stiffness and active output of

F and

M.

A robotic application of the cube DEA is shown in

Figure 1c. Here it is proposed that a 1-DOF gripper mechanism (actuated independently of the cube DEA) is mounted inside the cube frame and attached to the centre of the cross rod, which allows the gripper to be displaced linearly,

δ, and rotationally,

θ, in 6-DOF. This has a specific benefit over traditional, larger multiple DOF robotic manipulators with applications where there is a significant limitation on the available workspace e.g., machine and pipe inspection/maintenance. However, it should be noted that while the use of monolithic DEA membranes provides notable compactness and inherent compliance, the maximum

δ range will be limited compared to conventional multi-component parallel robotic manipulators. In addition, the cube DEA in this work can be fabricated entirely from polymers and non-ferromagnetic electrodes (such as the gel electrode in [

13]) so it can potentially be compatible with MRI scanners to facilitate invasive manipulation.

Figure 1.

Example applications for the cube dielectric elastomer actuator (DEA) with six degrees of freedom (6-DOF) output: (a) lightweight haptic device; (b) active vibration stabilisation of camera on a mobile quadrotor robot; (c) 6-DOF manipulator (where grasping mechanism is driven by separate 1-DOF actuator inside cube DEA).

Figure 1.

Example applications for the cube dielectric elastomer actuator (DEA) with six degrees of freedom (6-DOF) output: (a) lightweight haptic device; (b) active vibration stabilisation of camera on a mobile quadrotor robot; (c) 6-DOF manipulator (where grasping mechanism is driven by separate 1-DOF actuator inside cube DEA).

2. Principle of Operation

DEA membranes are elastic capacitors that produce a shape change response when a high electric field (>10 V/μm) is applied. The electrostatic Maxwell pressure,

P, produces planar expansion and transverse thickness reduction of the DE membrane. The magnitude of

P is proportional to the applied electric field squared [

4]:

where

E is the applied electric field (V/m),

ε0 is the permittivity of free space (8.85 × 10

−12 F/m) and

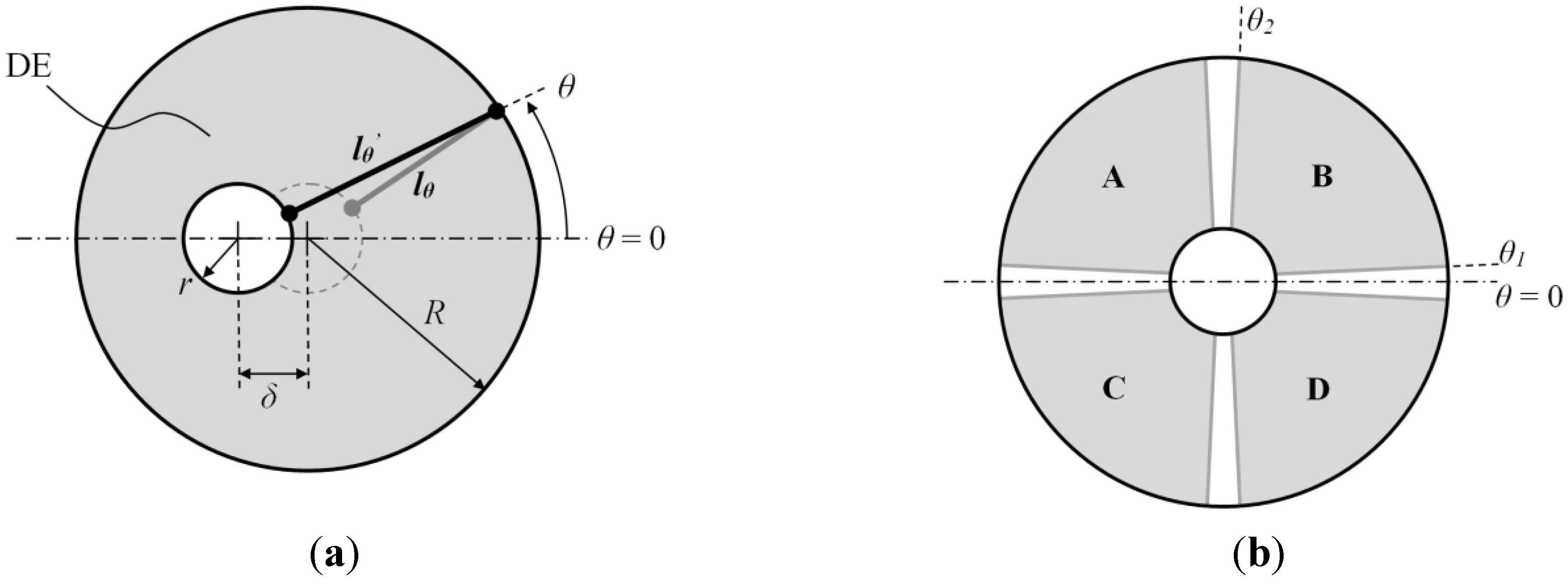

εr is the relative dielectric constant of the elastomer. An unconstrained DEA membrane produces biaxial actuation strain, so in order to produce a usable output in a specific DOF it is necessary to introduce some form of constraint. This can be achieved by attaching a single membrane to a rigid ring, so that all active strain is directed inwards towards a rigid central inclusion (

Figure 2a). Circumferential strain is largely constrained so applying an electric field results in a radial strain that pushes the central effector. By segmenting the electrodes, so that different regions of the membrane can be selectively actuated, 2-DOF actuation is produced by the single membrane (

Figure 2b). The actuator concept presented here combines four of these DEA membranes into a cubic frame, with a central cross rod to couple the output of each membrane to an external load (

Figure 2c). By independently controlling the response of each electrode quadrant, the cube DEA is capable of producing full 6-DOF actuation.

Figure 2.

Schematic of a single DEA membrane with four electrodes (shaded) in: (a) passive state; and (b) active state with two electrodes actuated producing output displacement, δ. (c) Cube DEA design with the output of four membranes coupled using a cross rod. The characteristic dimension, L, of the cube DEA is the distance between each pair of parallel membranes.

Figure 2.

Schematic of a single DEA membrane with four electrodes (shaded) in: (a) passive state; and (b) active state with two electrodes actuated producing output displacement, δ. (c) Cube DEA design with the output of four membranes coupled using a cross rod. The characteristic dimension, L, of the cube DEA is the distance between each pair of parallel membranes.

Translational (prismatic) actuation along the

x-axis is achieved by activating two membranes that are parallel to the

x-z plane as shown in

Figure 3a. Similarly, lateral actuation along

y-axis is attained by activating two membranes that are parallel to the

y-z plane as shown in

Figure 3b. Actuation along the

z-axis is produced by actuating two electrode quadrants in all four membranes as shown in

Figure 3c. Engaging the additional two membranes for

z-axis actuation generates twice the force, but does not effect the output displacement since the membranes act in parallel (assuming each membrane has the same thickness and pre-stretch). Equal force output in all three DOF can be achieved by adding an additional two DEA membranes to complete the cube (and modifying the cross rod accordingly). Rotational outputs about each axis are achieved by activating diametrically opposing pairs of electrode segments, as shown in

Figure 3d,e,f. As with actuation along the

z-axis, rotation about the

z-axis incorporates all four membranes being activated (

Figure 3f), which will produce twice the torque generated by the other two rotational actuation modes.

An advantage of the cube DEA design is that it produces antagonistic actuation in all 6-DOF (the inherent elasticity of the membrane will provide a return force in any case). By modulating the applied voltage to each electrode quadrant the response magnitude is controlled, as determined by Equation (1). Furthermore, the actuation modes shown in

Figure 3 can be combined to produce non-orthogonal outputs.

It should be noted that 6-DOF actuation can be achieved using other electrode configurations than those in

Figure 3. Specifically, the orientation of the four electrode quadrants on each membrane can be rotated by 45° (so that only one quadrant per membrane needs to be activated for the outputs in

Figure 3) or, alternatively, the number of electrode segments per membrane can be reduced to three (120° circular sectors). The latter configuration represents the most efficient version of the cube DEA in terms of control inputs, since only 12 inputs are required to produce antagonistic actuation in 6-DOF.

Figure 3.

Translational (a,b,c) and rotational (d,e,f) displacement generated by selective activation of electrodes. Active quadrants are highlighted and passive quadrants are black. Note that actuation along and about the x and y axes requires two active DEA membranes (m = 2), while actuation along and about the z axis requires four active DEA membranes (m = 4).

Figure 3.

Translational (a,b,c) and rotational (d,e,f) displacement generated by selective activation of electrodes. Active quadrants are highlighted and passive quadrants are black. Note that actuation along and about the x and y axes requires two active DEA membranes (m = 2), while actuation along and about the z axis requires four active DEA membranes (m = 4).

4. Materials and Methods

The DEA membranes were fabricated using VHB 4905 polyacrylate tape (3 M) with carbon grease electrodes (MG Chemicals) bonded to a laser cut acrylic frame. The cube frame has a length of 60 mm and the DEA membrane diameter is 50 mm. Four compliant electrode quadrants are applied to each side of the membrane with a passive gap of 3 mm between each electrode segment. Each circular membrane was 3 × 3 biaxially pre-stretched (

λr,pre =

λθ,pre = 3) prior to being attached to the frame, which resulted in the nominal thickness,

T, being reduced from 500 µm to a pre-stretched thickness,

λ3T, of 55.6 µm. The maximum applied biaxial stretch before mechanical failure for VHB 4905/4910 has been experimentally determined to be

λr,pre =

λθ,pre = 36 [

29,

30]. Therefore, by selecting

λr,pre =

λθ,pre = 3, and considering that

λr ≤ 2

λr,pre, the cube DEA should be fail-safe in its passive state.

High voltage drive signals were generated by a Biomimetics Laboratory EAP controller (Auckland Bioengineering Institute, Auckland, New Zealand). Angular displacement was recorded by high resolution camera (Powershot G9, Canon, Tokyo, Japan) and then analysed frame by frame using software (ImageJ) to obtain the maximum displacement. Linear displacement measurements were taken by a laser sensor (LK-G152 and LK-GD500, Keyence) focussed on a flat plastic marker measuring 19 × 11 mm2 fixed to one end of the connecting cross rod, with a sampling rate of 200 Hz. Force measurements were taken using a load cell (LMA-A-10N, Kyowa, Japan) aligned with the flat plastic marker and a signal amplifier (DPM-712B, Kyowa, Japan).

5. Results and Discussion

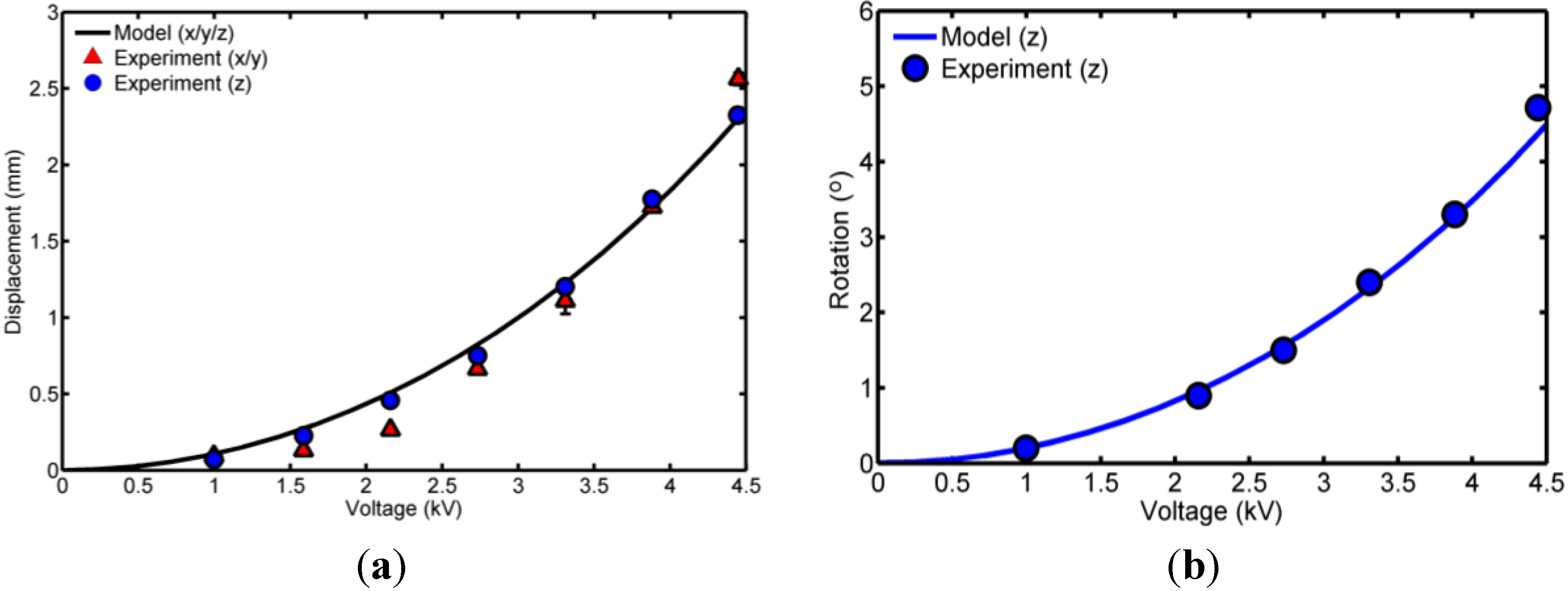

Actuation of a single membrane on the cube DEA (without the cross rod connected) is shown in

Figure 5b,c for both single electrode quadrant activation and double electrode quadrant activation. The performance of the cube DEA was then characterised experimentally for the double electrode activation, as described in

Section 2 and

Section 3. The linear and rotational displacement responses for varying supply voltages are plotted in

Figure 6. The dielectric breakdown voltage was found to be around 5.5 kV so 4.5 kV was determined to be a safe working limit for robust actuation and displacement measurements were recorded for supply voltages up to 4.4 kV. The maximum linear displacement in

z-axis equalled 2.4 mm and the maximum linear displacement in

x-axis equalled 2.6 mm. Note that measurement in the

y-axis was not taken as it can be assumed to be identical to the

x-axis. As expected, the displacement along the

x and

y-axes is approximately equal to that of the

z-axis, despite the latter utilising twice the number of active electrode quadrants, since the DEA membranes operate in parallel. The results from the analytical model derived in

Section 3 are plotted alongside the experimental data in

Figure 6. For the rotational displacement the model predicts the response of the non-linear elasticity and electric field-dependent Maxwell stress of the DEA membranes. However, the model does not capture a higher order trend evident in the linear

x and

y-axis displacement response. The model exhibits an error of 0.24 mm at 2.16 kV and an error of −0.20 mm at 4.45 kV which indicates it is not sufficiently accurate to precisely predict this response along these two DOF. This error is likely attributable to the assumption of homogenous strain along radial lines and hence future work will neglect this assumption by considering finite deformations.

Figure 5.

(a) Cube DEA prototype with 50 mm diameter membranes capable of 6-DOF actuation. Activated membranes shown with single active electrode (b); and with two active electrodes (c).

Figure 5.

(a) Cube DEA prototype with 50 mm diameter membranes capable of 6-DOF actuation. Activated membranes shown with single active electrode (b); and with two active electrodes (c).

Figure 6.

(a) Lateral displacement in x, y and z-axes; and (b) rotational output about z-axis against voltage.

Figure 6.

(a) Lateral displacement in x, y and z-axes; and (b) rotational output about z-axis against voltage.

Although measurements were only taken for positive displacements along each axis, the symmetrical design of the cube DEA means that each output can be antagonistic. Hence the maximum displacements are actually ±2.6 mm for

x and

y-axis displacement and ±2.4 mm for

z-axis displacement at 4.4 kV. These maximum displacement values can be converted to strains relative to the characteristic cube dimension of 60 mm, giving maximum actuation strains of ±4.3% along the

x and

y-axis and ±4.0% along the

z-axis.

Figure 6b shows that the maximum rotational displacement measured about

z-axis was ±4.8° at 4.44 kV.

The blocking moment is considered here to be the moment produced with zero output displacement measured about the

x and

z-axes (again it is assumed that actuation along/about the

x and

y-axes are identical) with the results are plotted in

Figure 7. The maximum blocking moment about the

z-axis was ±75.5 mNm at 4.4 kV and the maximum blocking moment about the

x-axis was ±34.8 mNm (also at 4.4 kV). As expected, the blocking moment about the

z-axis is approximately double that about

x and

y-axes, since the former utilises twice the number of active electrode quadrants operating in parallel. Also, approximate linear blocking force values can be estimated from the blocking moment measurements since both outputs relate to the sum of forces generated by each DEA membrane at zero displacement and hence the activated DEA membrane equilibrium states are equivalent. Using the experimental moment arm value of 30 mm this gives an estimated linear blocking force along the

x axis of 1.16 N and along the

z axis of 2.51 N.

It should be noted that because the blocking moment was measured using a load cell pressing against a single arm from the cross rod, the centre of rotation shifted slightly during actuation (two load cells, if available, aligned against two opposing arms from the cross rod would correct this issue). Analysis of video capture suggested that this created a maximum error of 3.7%.

The predicted blocking moment from the analytical model derived in

Section 3 is plotted alongside the experimental data in

Figure 7 and correlates to the measured blocking moment. However, there is a discrepancy with the numerical and experimental blocking moment about the

z-axis at a voltage of over 3 kV. This is likely due to the onset of membrane wrinkling and resulting increase in localized circumferential stretch,

λθ. Any increase of

λθ will concomitantly increase the electric field and hence

P, which will generate a greater blocking moment. Electromechanical membrane wrinkling and increased

λ2 is not captured in the current analytical model so is the likely sources of error. In summary the model has been shown to predict the general response but more computationally involved methods such as finite element modelling are required for detailed design.

Figure 7.

Blocking moment generated about each axis against voltage.

Figure 7.

Blocking moment generated about each axis against voltage.

The simple structure of the cube DEA means that it is readily scalable. Assuming that

r/

R and

L/

R can be maintained at all scales and

V and

T are constant then as the cube dimensions are reduced (

R→0) the actuation will be affected as listed in

Table 1. In summary, these scaling relationships show that the displacements and forces in the three linear DOF will both scale proportionally, meaning that performance is likely to scale with the anticipated load. In contrast, the angular displacements and moments in the three rotational DOF scale differently, so the relative displacement/moment performance will change considerably at different scales.

Table 1.

Scaling of cube DEA output assuming r/R and L/R are constant.

Table 1.

Scaling of cube DEA output assuming r/R and L/R are constant.

| Output | Scaling Relationship |

|---|

| linear displacement, δx,y,z | δx,y,z ∝ 1/R | actuation stretch is dimensionless |

| rotational displacement, φx,y,z | independent of independent of R | actuation stretch is dimensionless |

| blocking force, Fb | Fb ∝ 1/R | Equation (8): dF’ ∝ r and r ∝ R |

| blocking moment, Mb | Mb ∝ 1/R2 | Equation (8): dF’ ∝ r and r ∝ R

Equation (10) dF’ ∝ L and L ∝ R |

It is anticipated that future development of the cube DEA will involve utilizing improved DEA materials and increased automation of fabrication. Switching the elastomer material from VHB 4905 to a silicone elastomer will greatly reduce the viscoelasticity and creep behaviour of the membrane [

3,

31]. This is particularly important for active vibration damping applications, where a large viscous component will inhibit high frequency response. However, silicone elastomer DEAs described in literature to date have not generated actuation strains equal to VHB 4905/4910. In addition, silicone elastomer films are more readily fabricated as multi-layered stacks using techniques such as spin coating [

32] or spray deposition [

33]. Such fabrication methods can enable the development of heterogeneous DE microstructures, which have been numerically demonstrated to significantly amplify the electromechanical coupling [

22]. The polymeric composition of the cube DEA means that it could ultimately be fabricated using 3D printing techniques (as demonstrated by [

34]). The potential 3D printed devices would open the possibility for a network of inter-connected cube DEAs to be embedded within a structure for novel morphing capabilities or active vibration damping. An important consideration for the cube DEA to be developed for practical applications where the external loading may be unpredictable are instabilities such as pull-in failure that are associated across various configurations of DEAs [

35,

36,

37].