1. Introduction

Conventional applications in the robotics and transportation industries have gravitated towards electric motors due to their high operating efficiency (often above 90%) and their ubiquitous, low-cost and miniaturized embedded motion controllers. While these benefits often outweigh the shortcomings of electric motors compared to other actuation technologies, new applications in robotics and related fields require improvement over the current state-of-the-art. Life-sized autonomous humanoid robots [

1], rehabilitation exoskeletons [

2] and electric vehicles [

3] are just a few examples of current technology development that can directly benefit from electric motors that are less expensive, yet more torque- and power-dense.

Consider an example of current actuation technology limitations. The maximum continuous torque per unit mass for electric motors is currently limited to around 6 Nm/kg given current rare-earth magnets [

4]. As a point of comparison, hydraulic actuators achieve torque densities of 90+ Nm/kg, depending on operating conditions [

4]. By a torque-density metric, hydraulics performs very well. However, compared to the aforementioned 90% efficiency of electric motors, hydraulic actuation systems perform rather poorly, achieving 14% in one study [

5]. Given such limitations, the demands on modern actuators require improvements beyond the current state of the art [

6]. Envisioned robotic applications, such as the helpful humanoid house assistant or the disaster robotic first-responder, provide contradicting requirements: torque/mass, power/mass and efficiency are simultaneously required.

While an ambitious goal, incremental steps towards this vision may be realized leveraging existing technology. Liquid cooling of electric motors is one such technology that is commonly used today in a wide range of electric vehicles. These motors span the range from small in-wheel motors for automobiles [

3,

7,

8], to massive megawatt motors for ocean-going ships [

9] and everything in between [

10,

11,

12]. The primary benefit of liquid cooling is that heat generated from Ohmic loss can be quickly removed from the system with convection, thus allowing larger continuous current, torque and power output. Additionally, designers of these vehicles are afforded flexibility in the location of the cooling components. In automobiles, for example, this advantage is leveraged in placing the radiator at the front of the vehicle, where it is most likely to encounter cool, pressurized air.

Phase-changing cooling methods, such as heat pipes, capillary-pumped loops and two-phase mechanically-pumped loops provide another option for heat dissipation. Their primary advantage, relative to single-phase liquid cooling, is improved mass effectiveness due to the latent heat of most fluids being at least an order of magnitude greater than their sensible heat [

13]. General disadvantages include increased complexity and cost compared to single-phase systems, inflexibility in system layout, potential dependence on gravity and the common use of toxic working fluids, such as ammonia, ethanol and methanol [

13]. For these reasons, there has been little work in applying phase changing cooling to electric motors, although a small number of disclosures on such technology have been recently submitted and may prove a viable option in the future [

14].

Compared to the transportation industry, single-phase liquid cooling applied to robotic applications is less explored. Existing work can be largely grouped into two distinct categories, each benefiting from the increased continuous torque production. The first category applies liquid cooling to direct drive robotic joints [

15,

16,

17,

18]. Drivetrains introduce cost, complexity, additional points of failure and can significantly reduce system efficiency (beyond 50% in some cases [

19]). Additional drawbacks include backlash, compliance, and several forms of friction. These factors negatively affect the mechanical durability, energetics and controllability of the robotic system. By removing the drivetrain and directly driving a robotic joint with a motor, most of these issues are reduced or removed completely. At the same time, direct drive robots are much more sensitive to motor torque ripple and possess greatly reduced torque/mass compared to highly geared motors [

4]. By liquid cooling a direct drive motor, this torque/mass drawback is reduced. In one study, the continuous torque improved by a factor of six when liquid cooling was applied, resulting in a overall torque/mass of 15 Nm/kg [

4,

18]. Unfortunately, such motors require a completely custom design and many years of iterative development to obtain a reliable device. This development cycle sets an unrealistically high bar for new adopters of the technology.

The second existing category in robotics uses the combined effects of liquid cooling and a highly geared drivetrain to sustain large continuous joint torques with minimal system mass [

20,

21,

22]. Unlike the large and expensive motors used in the transportation industry or the complex and custom-made direct drive motors, motors intended for geared applications are commercially-available off-the-shelf (COTS), making them ubiquitous and relatively inexpensive. While this type of motor is rarely designed for use with liquid cooling, it is often designed to minimize thermal resistance to surrounding air. By applying liquid cooling, its continuous current can be increased, but rarely to the levels of more expensive or customized liquid-cooled motors. So far, this class of liquid-cooled COTS motors most directly benefits humanoid robots, whose leg joints must support their weight along with the weight of the upper torso and any additional payload [

20,

21,

22]. While demonstrably effective [

23], this actuation approach is relatively new and has not been extensively studied or characterized in prior work. For example, in [

20], theoretically-expected improvement factors for continuous current are derived, but are never validated empirically.

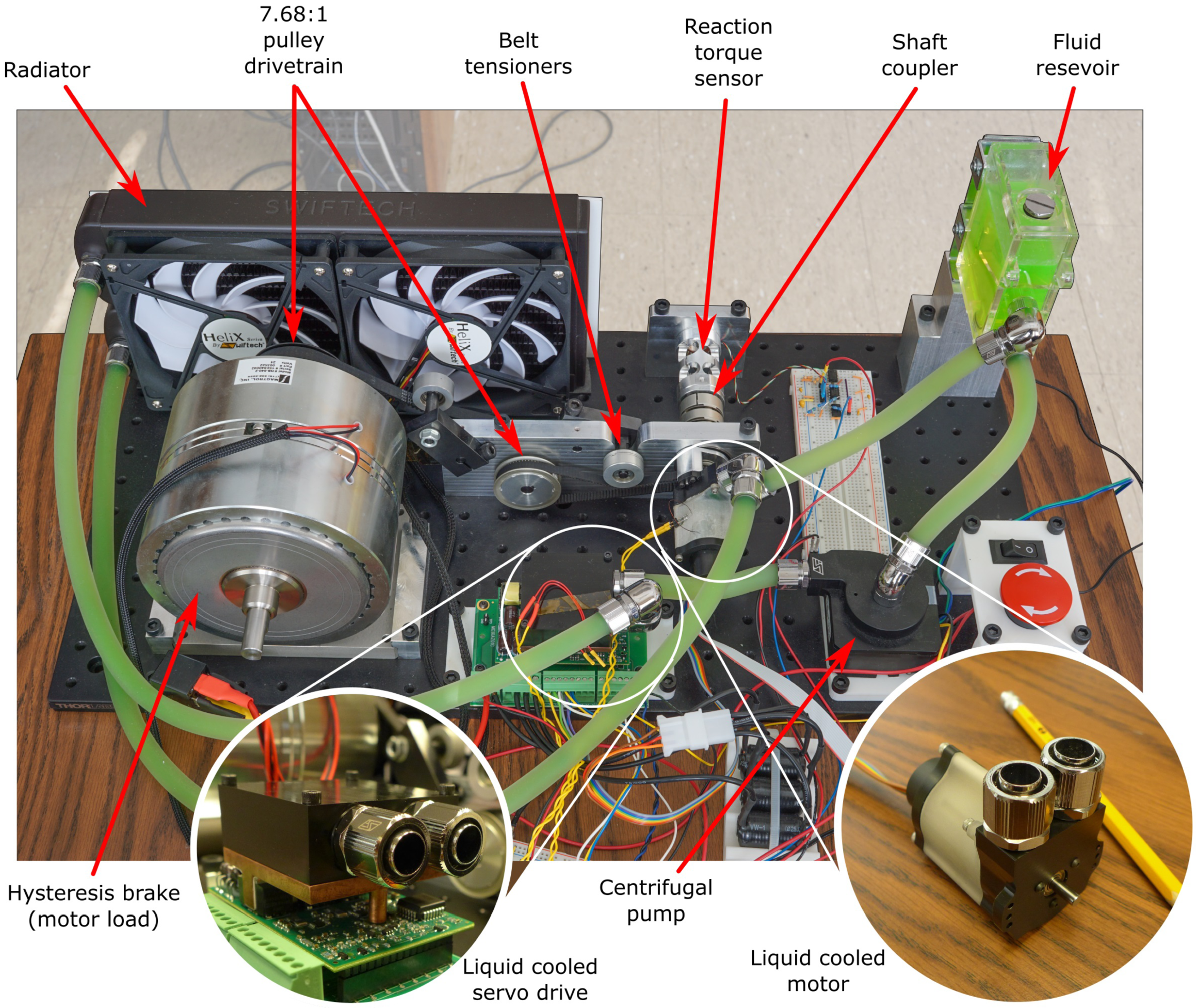

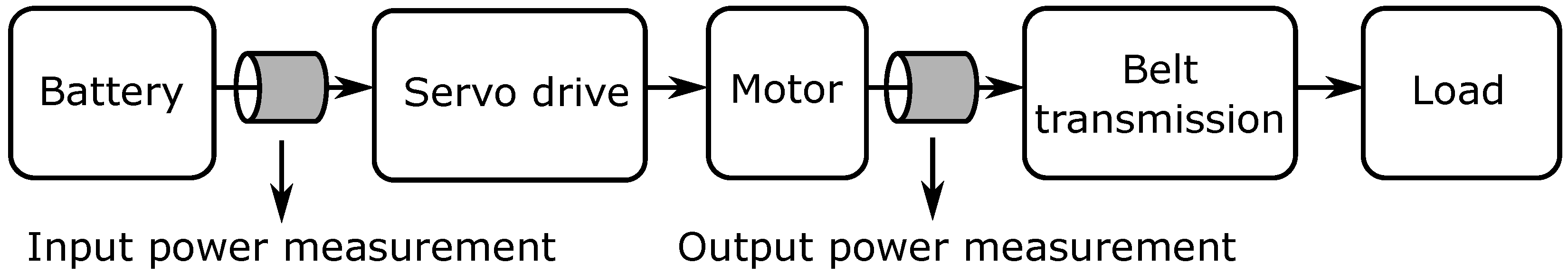

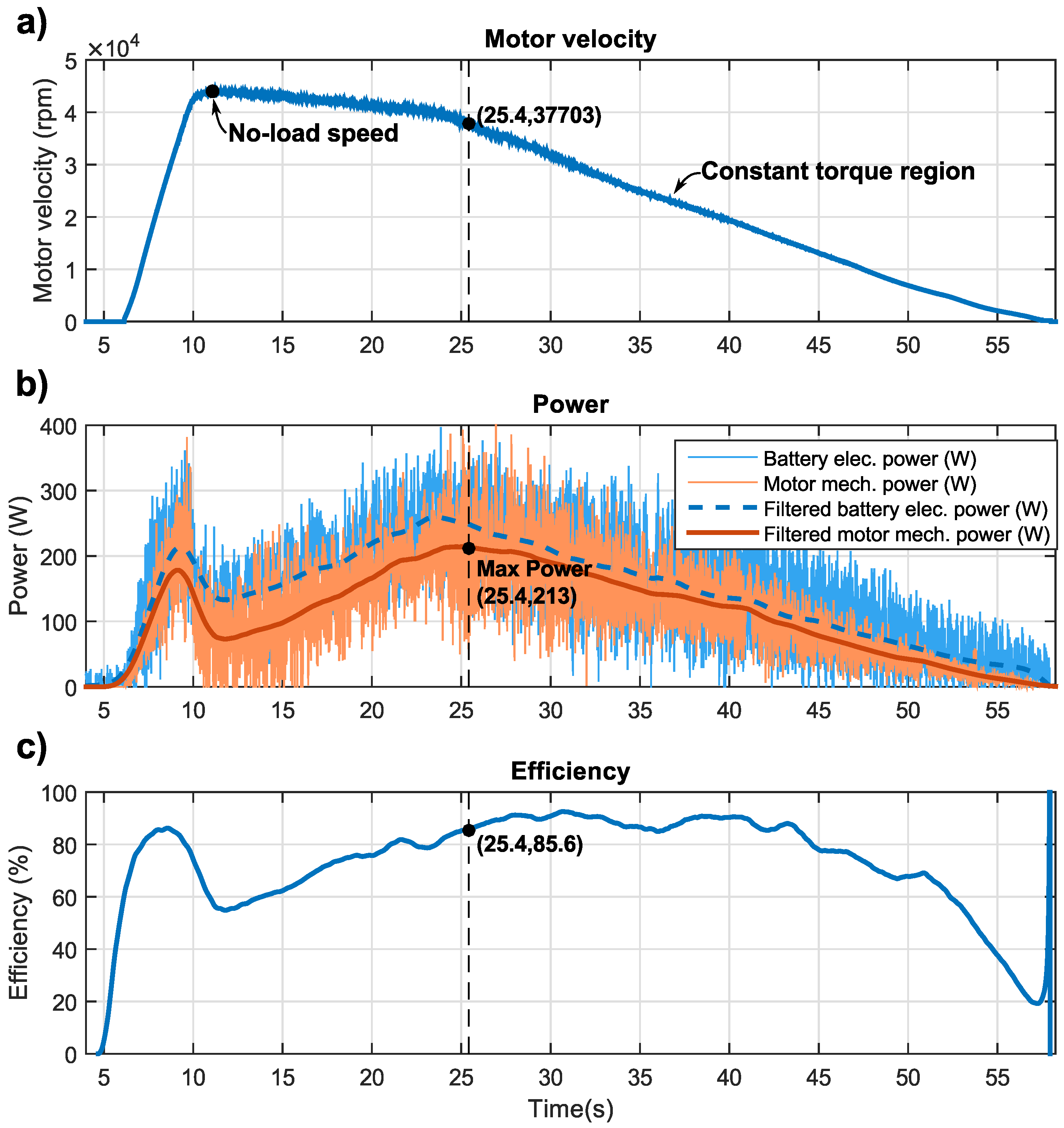

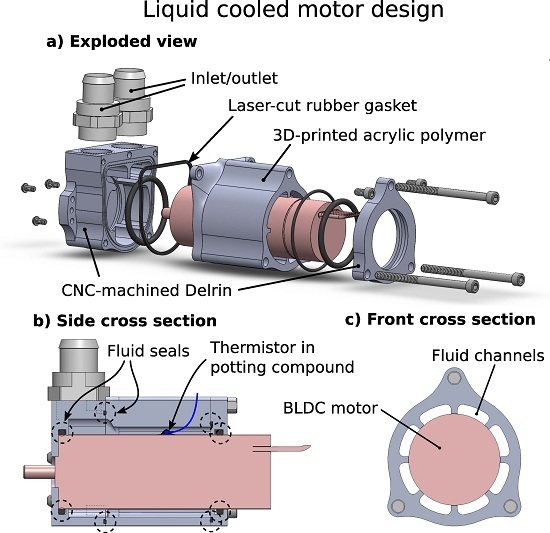

The work presented here aims to help solidify the understanding of liquid cooling as applied to COTS electric motors. Specifically, empirically-measured factors of improvement are provided not only for continuous current, but also for continuous power output. These results are gathered on a specially-designed and heavily-instrumented testbed that also measures actuation efficiency versus load. An abundance of temperature sensors enables direct measurement and comparison of the motor’s thermal resistance in air- and liquid-cooled scenarios. In addition to this performance study, an effective design for a retrofitted liquid-cooled motor housing is proposed. The design improves upon existing work in that it is non-permanent and removable. This feature facilitates periodic maintenance and component reuse, key features for a well-designed machine. Overall, the results obtained in this work benefit future designers, providing insight towards expected performance improvements based on simple motor datasheet parameters. The presented approach extends the reach of liquid-cooled motor applications beyond their current high-cost/custom-designed niche and thus brings their performance benefits to a wider community.

The remainder of this paper is structured as follows.

Section 2 introduces simple models for the thermal behavior of electric motors. These models are then analyzed to establish the rules that govern maximum continuous motor torque as a function of a motor’s thermal properties. A motor core temperature estimation technique is also described, which offers protection from motor core burnout.

Section 3 presents a new design for retrofitted liquid-cooled motors and motor drivers. It also discusses issues pertinent to the selection of COTS motors for liquid cooling applications. Comparative experimental results between air-cooled and liquid-cooled motors are then shown and analyzed in

Section 4.

Section 5 then concludes the paper after a brief discussion.

2. Thermal Modeling of Electric Motors

This section gives a brief overview of the models and underlying concepts used in the experimental portion of the paper. It focuses on simple models for the thermal behavior of electric motors and establishes rules that govern maximum continuous torque and the effects of heat dissipation. For a supplemental discussion, refer to [

4,

20,

24].

As energy transducers, electric motors convert electric energy into mechanical energy. However, loss is incurred in the process and manifests itself as heat generated by the motor. Two main sources of loss contribute to this heating: mechanical friction and Ohmic loss (also referred to as Joule heating or resistive loss). Ohmic loss (

) depends on instantaneous motor current (

I) and on the winding resistance (

):

At a small motor load, mechanical friction is the largest source of loss, while Ohmic loss dominates at larger loads [

24]. For the remainder of this discussion, we focus on the second case and neglect the relatively small losses due to mechanical friction.

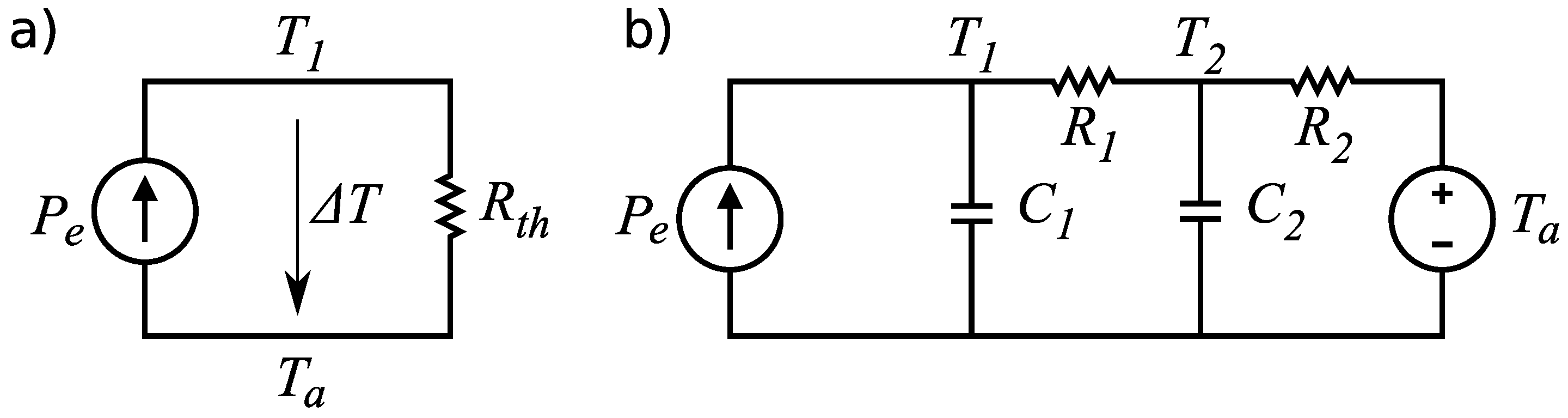

A simple circuit model, shown in

Figure 1a, describes the steady-state thermal behavior of an electric motor subject to Ohmic losses. Heat current (

) is injected into the system and is dissipated to the surrounding environment through a lumped thermal resistance (

) representing the combined effects of conduction, convection and radiation. A temperature difference (

) is produced between the motor’s core temperature (

) and the ambient air temperature (

). At steady state, the motor core temperature can be calculated using Ohm’s law,

Figure 1.

Two models of motor thermal behavior. (a) A simple steady-state model. Given the thermal resistance , Ohmic losses and ambient temperature , the motor core temperature can be calculated. (b) A more accurate thermal model. Given winding-to-housing thermal resistance and capacitance and housing-to-ambient thermal resistance and capacitance , the motor’s thermal transient response can also be modeled.

Figure 1.

Two models of motor thermal behavior. (a) A simple steady-state model. Given the thermal resistance , Ohmic losses and ambient temperature , the motor core temperature can be calculated. (b) A more accurate thermal model. Given winding-to-housing thermal resistance and capacitance and housing-to-ambient thermal resistance and capacitance , the motor’s thermal transient response can also be modeled.

Given the maximum permissible motor winding temperature (

), we can combine Equations (

1) and (

2) to calculate the maximum thermally-permissible continuous current,

noting that

is a thermal resistance, while

is an electrical resistance.

Equation (

3) depends on

, which is itself a function of temperature. This relationship is defined by the resistor temperature coefficient equation [

25],

where

is the nominal resistance at the nominal temperature (

) and

α is the winding material’s temperature coefficient (copper has an

α of around 0.0039

).

From Equation (

3), we can see how

plays a critical role in determining maximum continuous current. The other parameters,

,

and

, cannot be significantly altered from nominal values. Alternatively,

is very sensitive to design and environmental factors.

To further this analysis, consider the thermal model illustrated in

Figure 1b. Here, additional elements are included:

to represent the thermal resistance between the motor core and the motor housing,

to represent the thermal capacitance of the motor’s core,

to represent the thermal resistance between the motor housing and the environment,

to represent the thermal capacitance of the motor’s housing and

to represent ambient temperature. Several motor manufacturers provide these parameters in motor datasheets. This model improves over

Figure 1a in that it more accurately captures the transient response of the motor to a thermal load and also breaks down the lumped thermal resistance into two distinct components.

From Equation (

3), it is clear that

must be minimized to maximize a motor’s torque to mass ratio. This is a central consideration for any high-performance motor design and is often addressed either by using forced convective air cooling [

1] or by adopting liquid cooling [

10,

12,

18].

Table 1 demonstrates the benefits of liquid cooling with water, where water exhibits up to a 50× improvement in convective heat transfer compared to air.

Table 1 gives a range for each situation due to a number of factors affecting convective heat transfer, such as the rate of fluid flow and surface shape.

Table 1.

Typical values for mean convective heat transfer coefficient [

26].

Table 1.

Typical values for mean convective heat transfer coefficient [26].

| Flow Situation and Fluid | Mean Heat Transfer Coefficient [W/(mK)] |

|---|

| Free convection in air | 3 to 20 |

| Forced convection in air | 10 to 200 |

| Free convection in water | 20 to 200 |

| Forced convection in water | 40 to 10,000 |

2.1. Thermal Ratio

In the case of liquid cooling, custom motor designs typically pass cooling fluid as close to the heat-generating windings as possible in order to reduce

. However, custom motor designs are not always possible, either for cost, time or complexity reasons. An alternative design is to apply liquid cooling to COTS motors to improve their performance [

20,

21,

22]. In this case, the fundamental design of the motor cannot be altered. This consideration implies that

must stay fixed while

may be reduced using liquid cooling. Taking this constraint into consideration, we can define the thermal ratio (

ρ) of a motor to be the maximum achievable improvement of continuous current (Equation (

3)) assuming

must remains fixed and

can be made close to zero using liquid cooling. The thermal ratio is derived by taking the ratio of two continuous currents, one with with

, (

) and the second with

, (

):

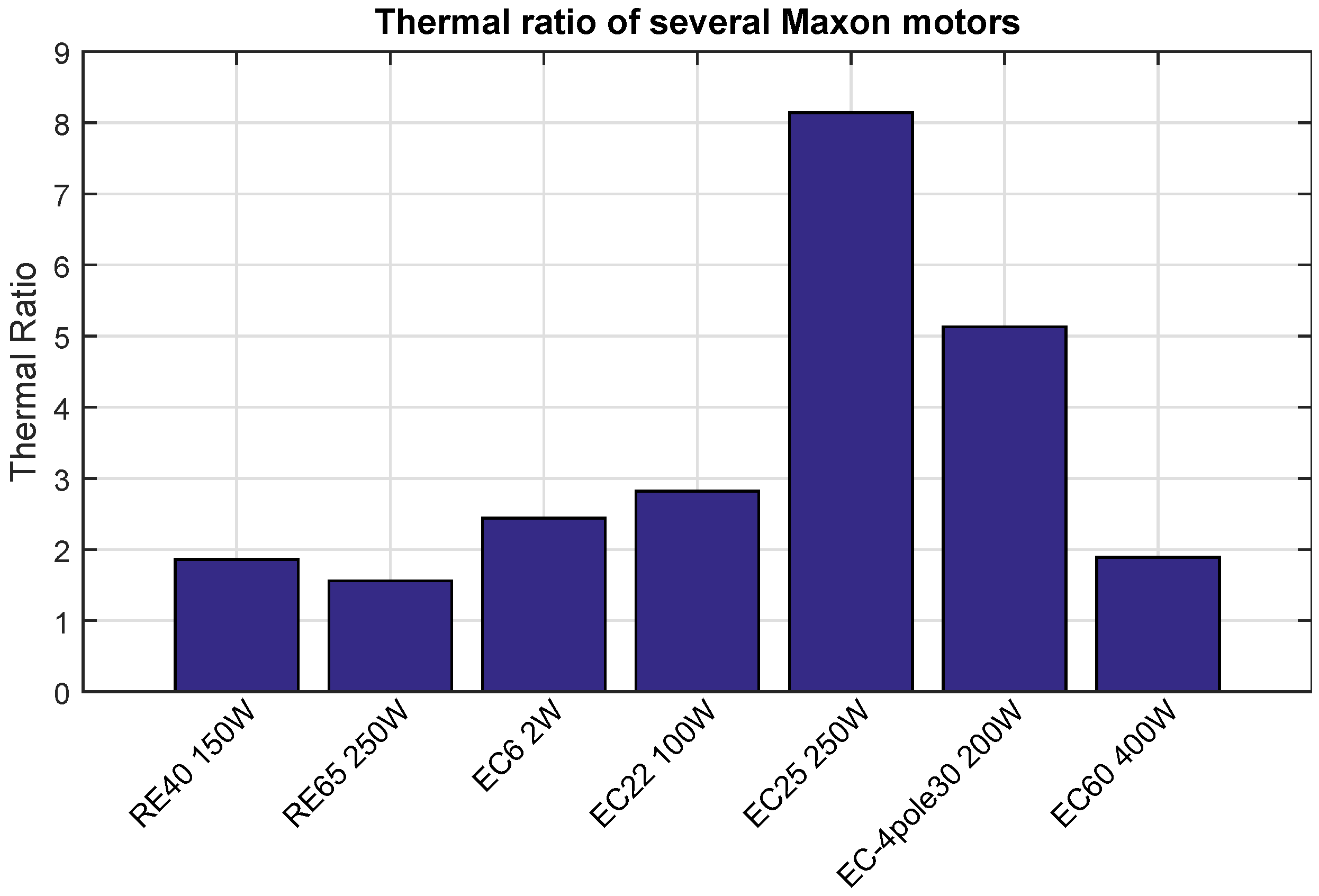

Figure 2 shows the thermal ratio for several Maxon motors. As the figure shows, the type of motor and its design significantly affect the potential benefit of adding liquid cooling. Assuming the added heat can be adequately dissipated, a central issue that will be discussed further in

Section 5, the EC25 250 W Maxon motor should be able to tolerate over 8× the continuous current of air cooling when liquid cooling is applied, while the RE65 250 W motor’s continuous current is only increased by 1.56×.

Figure 2.

Thermal ratios of several Maxon motors. The thermal ratio is the theoretical improvement factor in continuous current of liquid cooling versus air cooling. Part numbers beginning with `RE’ are brushed DC motors, while part numbers beginning with `EC’ are brushless DC motors.

Figure 2.

Thermal ratios of several Maxon motors. The thermal ratio is the theoretical improvement factor in continuous current of liquid cooling versus air cooling. Part numbers beginning with `RE’ are brushed DC motors, while part numbers beginning with `EC’ are brushless DC motors.

2.2. Core Temperature Estimation

While liquid cooling may significantly improve continuous current output of electric motors, it does not have the same effect on short-term current output. To gain insight into the maximum permissible short-term current output, [

20] introduced the thermal control concept, which is a method to estimate the core motor temperature based on current and previous state measurements. This method is more effective than placing a temperature sensor directly on the motor’s windings due to the temperature difference between the winding core and its surface and the winding’s associated thermodynamics. Here, the thermal control approach is briefly described and is applied later in

Section 4.

Two differential equations fully describe the thermal circuit model shown in

Figure 1b:

Given accurate initial conditions and measurements of

(by measuring motor current) and

, these equations can be integrated in real time using, for example, Euler integration, to estimate the values of

and

. If

is directly measured, as it is in our experimental testbed, then

can be calculated from Equation (

6a) alone.

5. Conclusion and Discussion

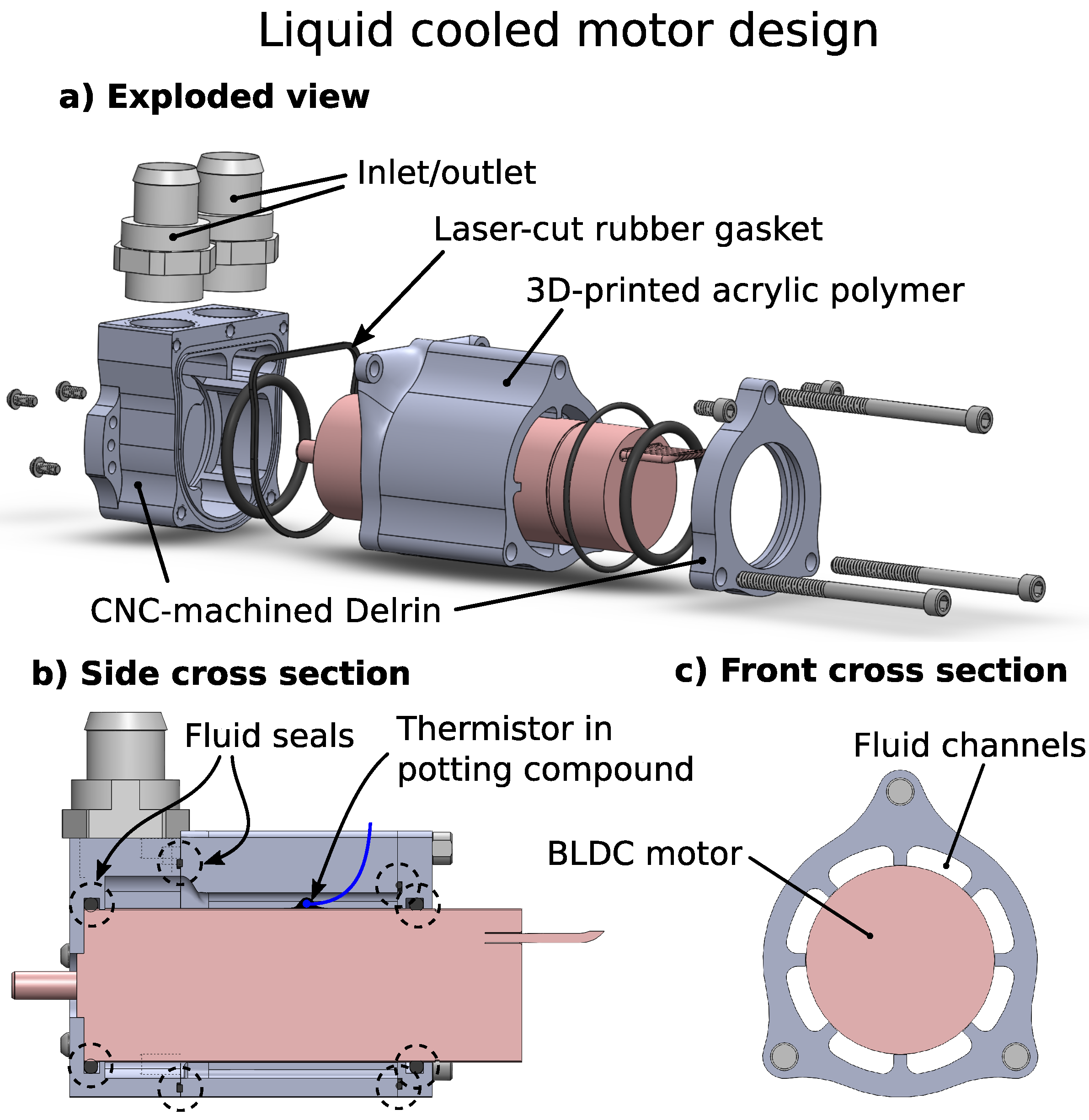

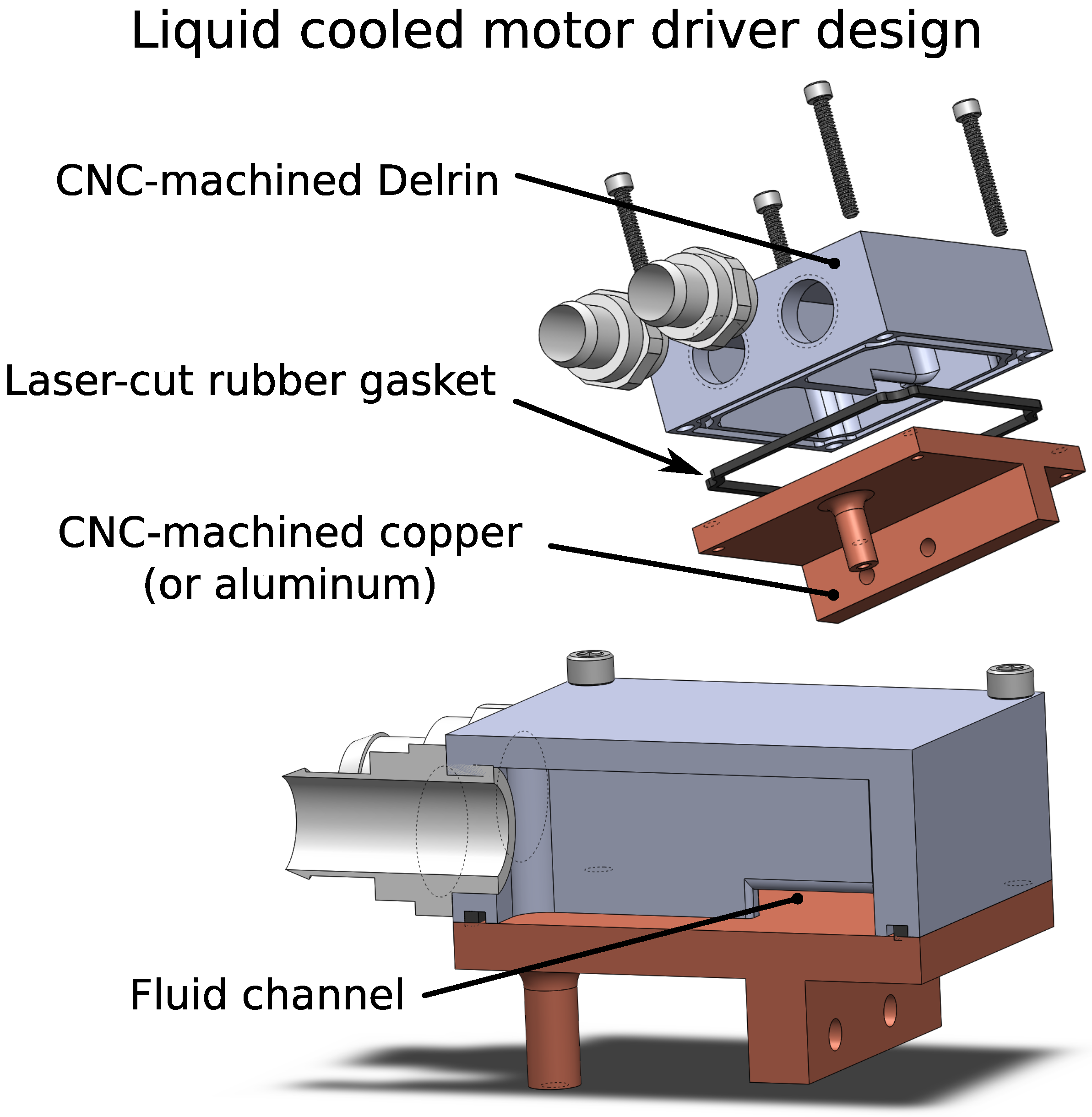

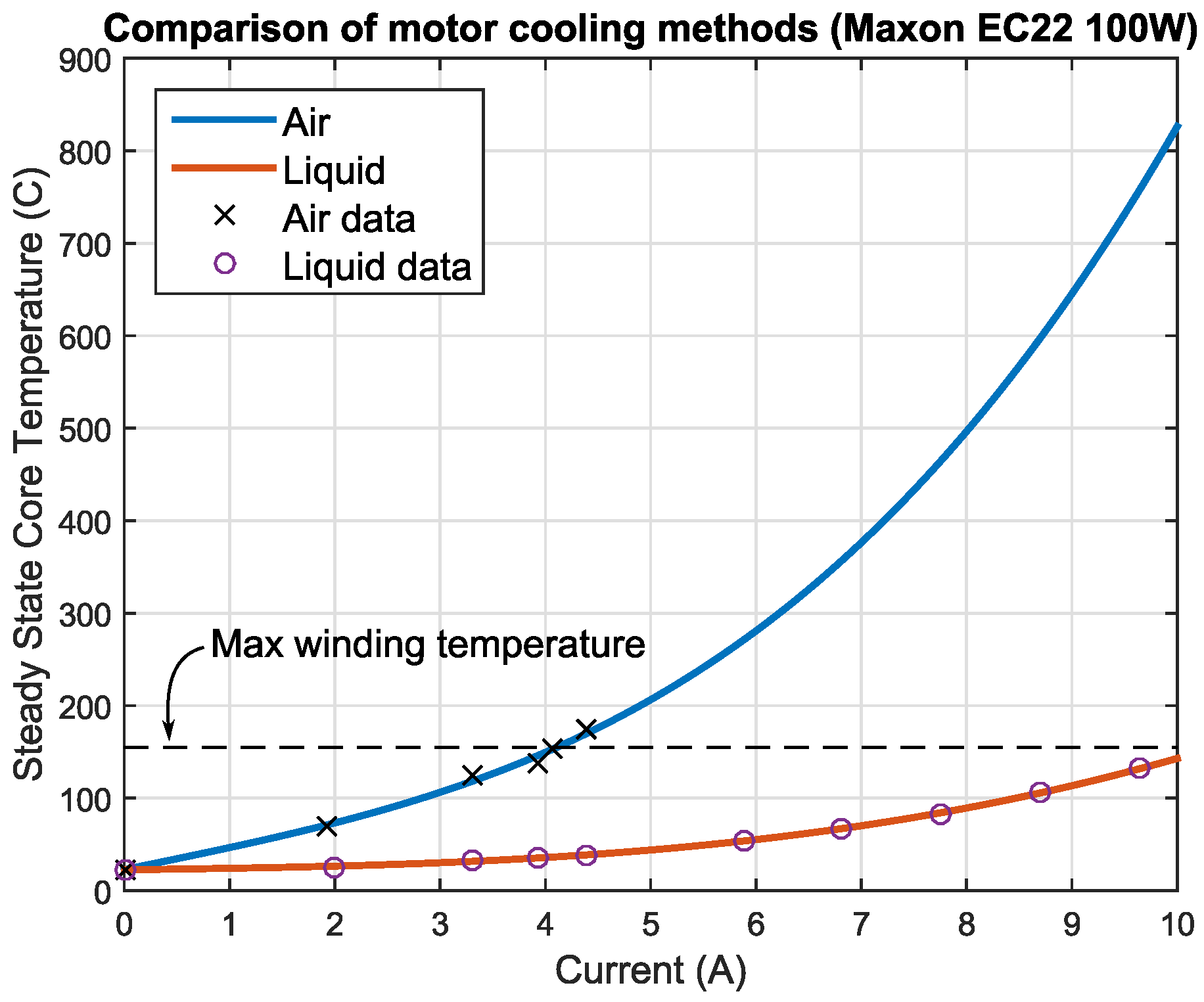

This paper directly compared the achievable torque and power improvements yielded by constructing a retrofitted liquid cooling system for a COTS electric motor. It was found that, for the Maxon EC22 100 W motor, 2.58-times higher current and torque output could be safely obtained with the liquid-cooled motor compared to the same motor with air cooling. This improvement factor closely matched the motor’s thermal ratio, a theoretical value that can be directly calculated from datasheet motor parameters. This empirical validation is the main contribution of the paper and enables future designers to place confidence in and have intuition towards active cooling performance for COTS motors. An increase in continuous power output by a factor of two between the two cooling methods was also measured, and importantly, this increase fostered a mere 2.2% decrease in operating efficiency. This observation suggests that liquid cooling may also serve roles in actuators with strict energy consumption requirements, yet that are required to produce high energy output periodically.

We presented a new design for a retrofitted liquid cooling housing, which features high cooling performance (reaching a thermal resistance of = 0.035 K/W), but that is based on a non-permanent O-ring-sealed structure. This improves over existing designs in that the cooling structure can be disassembled and cleaned periodically. The empirical measurement of the parameter is also useful in that it provides a data point for the performance of the heat convection in liquid-cooled COTS motors. Comparing the value of with liquid cooling (0.035 K/W) against its air-cooled counterpart (5.2 K/W) resulted in a reduction of thermal resistance by a factor of 160. This yields a data point of for the thermal ratio of a “thermally-optimized” motor, where , meaning cooling fluid is passed directly over the windings. This value is, of course, related to the many factors associated with our particular liquid-cooled system, such as the outside surface area of the Maxon EC22 100-W motor, the size of the radiator, the number of cooling fans used, etc., and therefore is not a hard theoretical limit, only a single, empirically-derived data point.

An additional question to ask is “how may these methods be applied to motors without pre-specified thermal properties?” In this case, a more thorough system identification process must be used where all four parameters, are empirically identified. In this paper, was identified by commanding a constant current, letting the system reach a steady-state temperature and then measuring the difference between and . With identified, was found based on the system’s transient response. Accurately identifying and is more difficult. Approaches for measuring these values could leverage the fact that winding resistance is a function of temperature thus enabling its use as a temperature sensor.

Future work remains in the best sizing of liquid cooling components, such as the radiator, pump and tubing diameter for optimal system-wide power/torque per unit mass. Additionally, limited attempts were made in this work to optimize pressure versus flow characteristics of the motor and driver water blocks. Improvements here may improve cooling performance further, leading to improved empirically-measured thermal ratios.