Disturbance-Resilient Flatness-Based Control for End-Effector Rehabilitation Robotics

Abstract

1. Introduction

- Development of a flatness-based control strategy specifically tailored to the iTbot platform, enabling precise and robust trajectory tracking.

- Derivation of a 0-flat canonical form of the system dynamics using differential geometric tools.

- Integration of a derivative-free Kalman filter for real-time estimation and rejection of external disturbances and unmeasured dynamics, without the need for derivative computations.

- Demonstration—through both simulations and real-time experiments—that the proposed method offers improved tracking performance and robustness under a variety of disturbance conditions, all with reduced computational load.

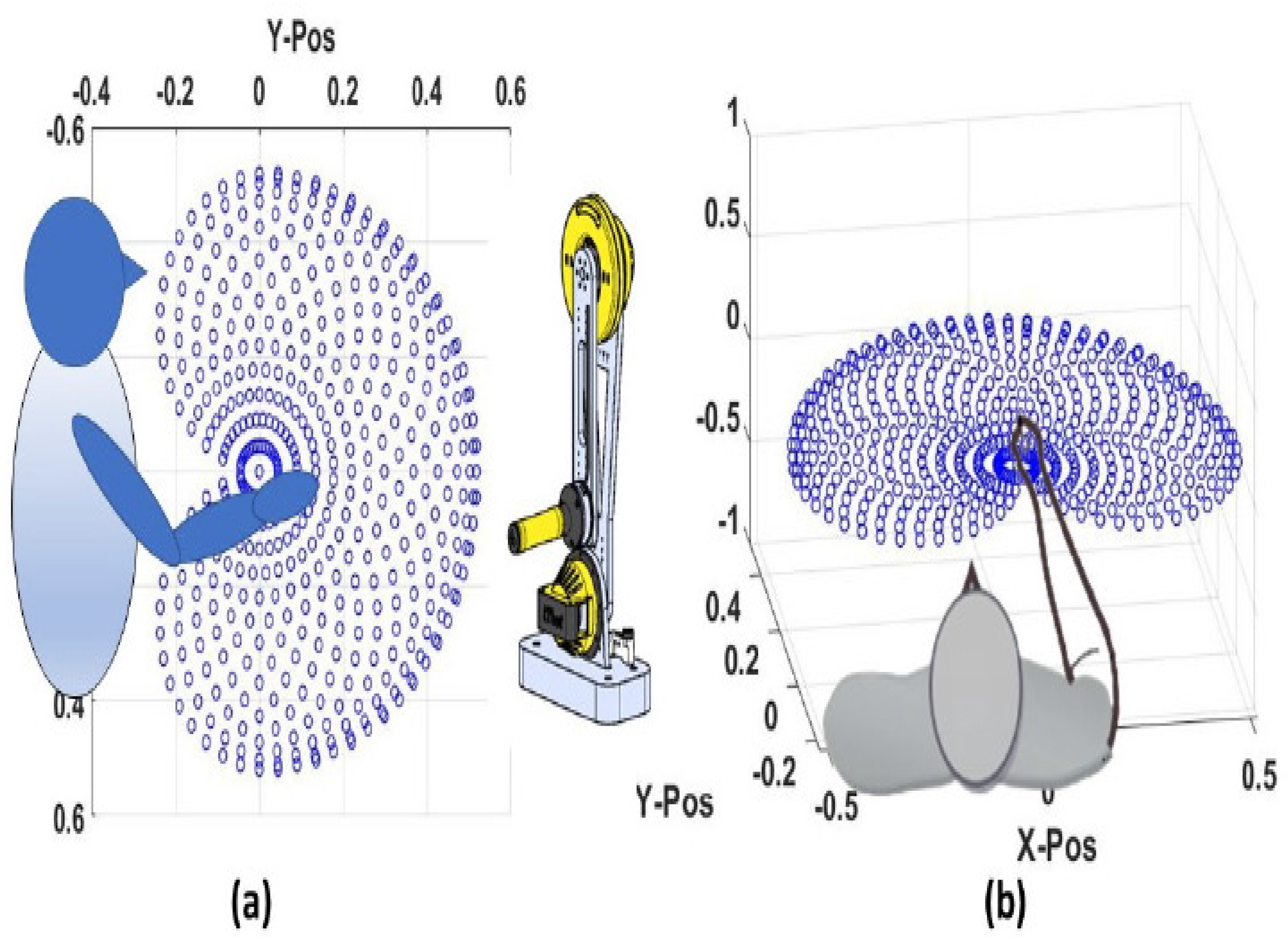

2. Mechanical Design of iTbot

Specification of the iTbot

| Joint Parameters | ||

|---|---|---|

| Item | Joint-1 | Joint-2 |

| Joint range of motion (degrees) | ±85° | ±180° |

| Link Parameters | ||

| Mass (Kg) | 1.79 | 0.65 |

| Location of the center of gravity in link frame (m) | Center of gravity of link 1 in frame {1}, see Figure 3 = 0.26, = 0.00, = 0.00 | Center of gravity of link 2 in frame {2}, see Figure 3 = 0.15, = 0.00, = 0.02 |

| Robot Properties | ||

| Mass (Kg) | 6.67 (3.2 without base) | |

| Maximum Horizontal reach (m) | ±0.55 | |

| Maximum Vertical reach (m) | +0.1 to +0.55 | |

3. Kinematics and Mathematical Model of iTbot

Dynamics of the iTbot

- is the control input (torque),

- is the inverse of the inertia matrix,

- represents the system dynamics including nonlinearities and disturbances.

4. Control Design

4.1. Notation

4.2. The Differential Geometric Approach

- 1.

- γ is written as function of the state vector x, the control input vector u and its time derivatives : .

- 2.

- The components of the state vector x can be expressed from the flat output γ and its time derivatives: .

- 3.

- The components of the input vector u can be expressed from the flat output and its time derivatives: , where and y are smooth functions.

4.3. 0-Flat Form for Co-Dimension 2 System

4.4. Geometrical Background

4.5. Design of a Flatness Based Controller for iTbot’s Robot System

4.6. Filtering Kalman for Dynamical Systems

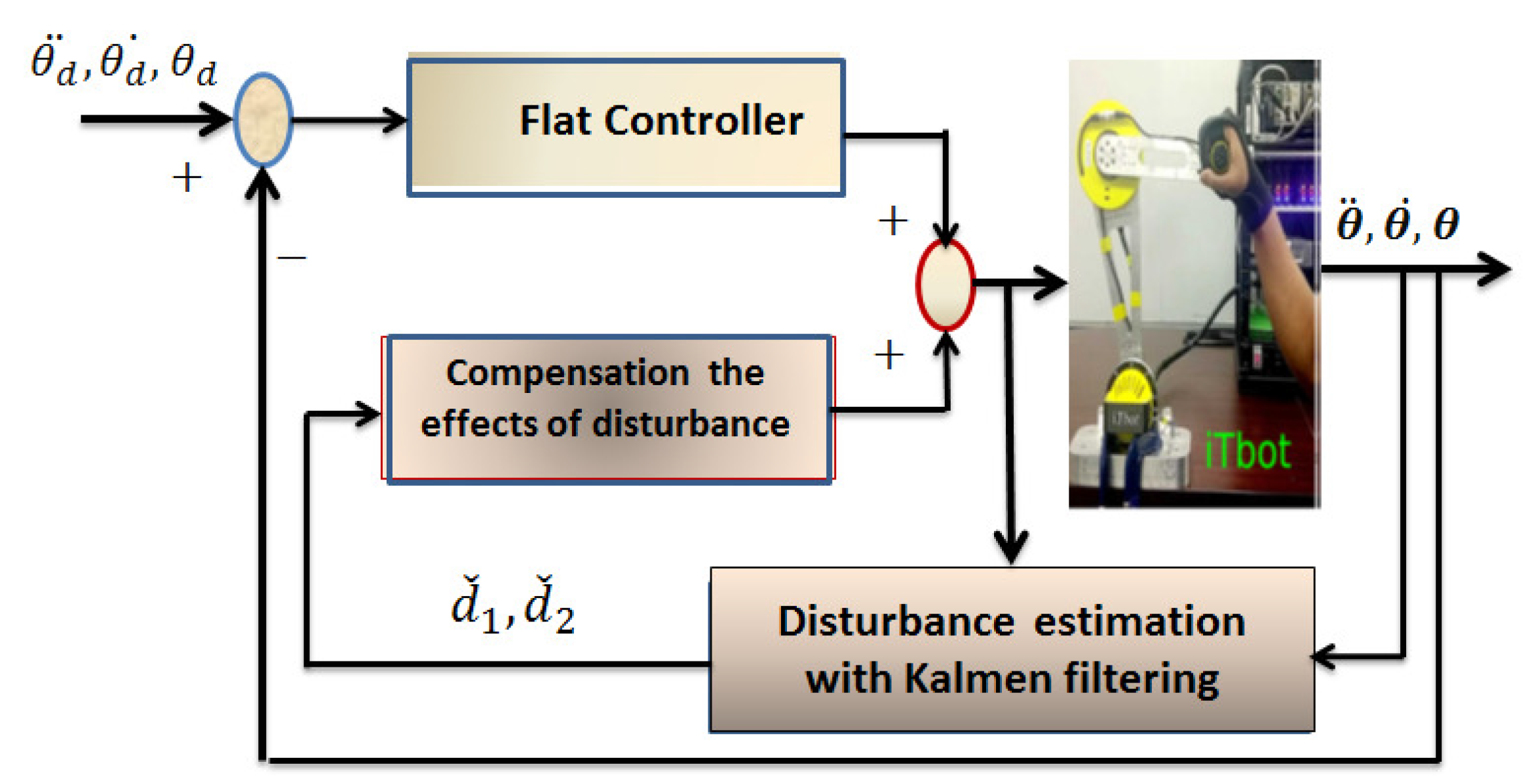

4.7. Disturbances Compensation Using (DFK) Derivative-Free Kalman Filtering

- First step (measurement update):

- Second step (time update):and are defined as the discrete-time equivalents of the previous matrices and

4.8. Stability Studies

5. Simulation Setup and Performance Evaluation

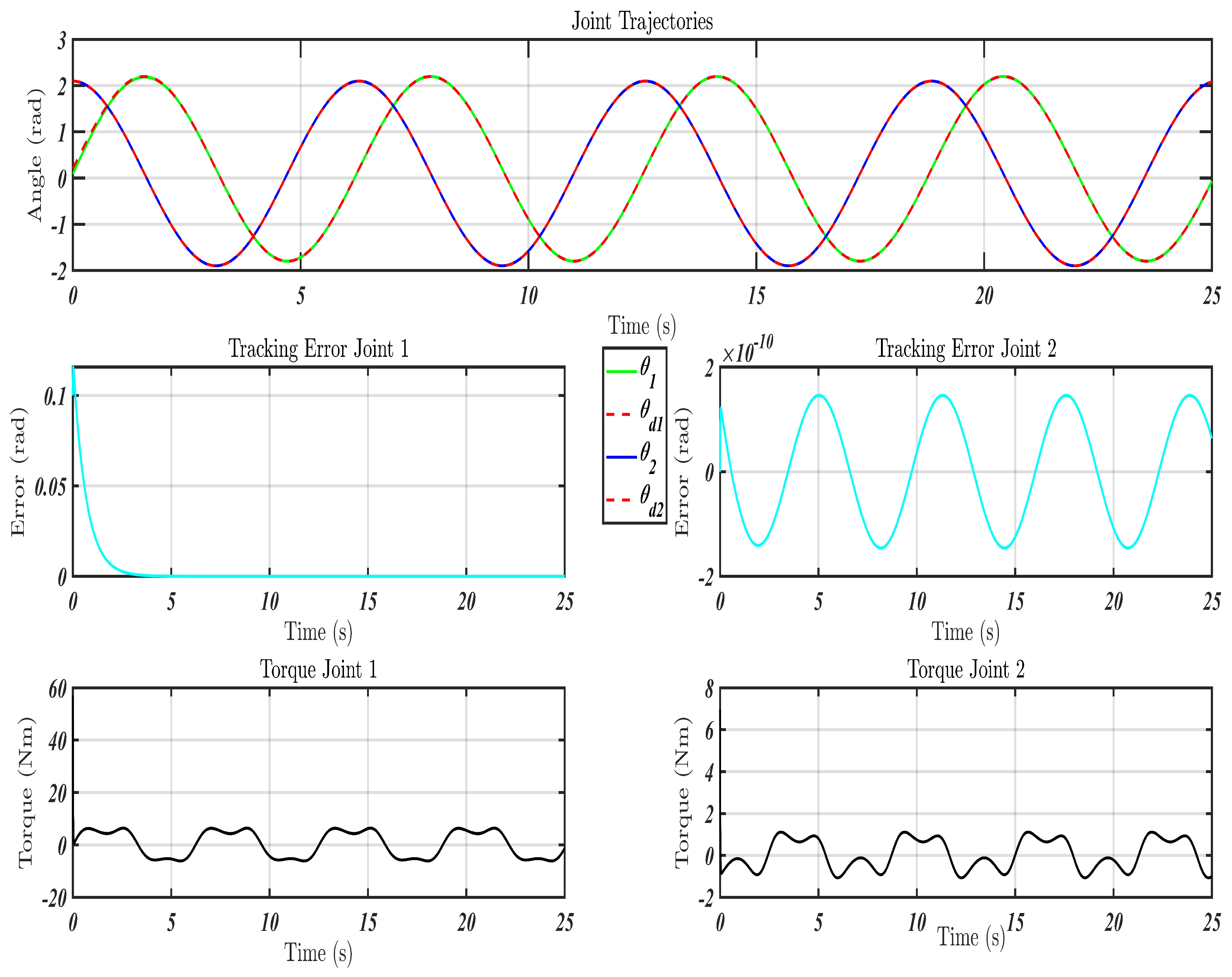

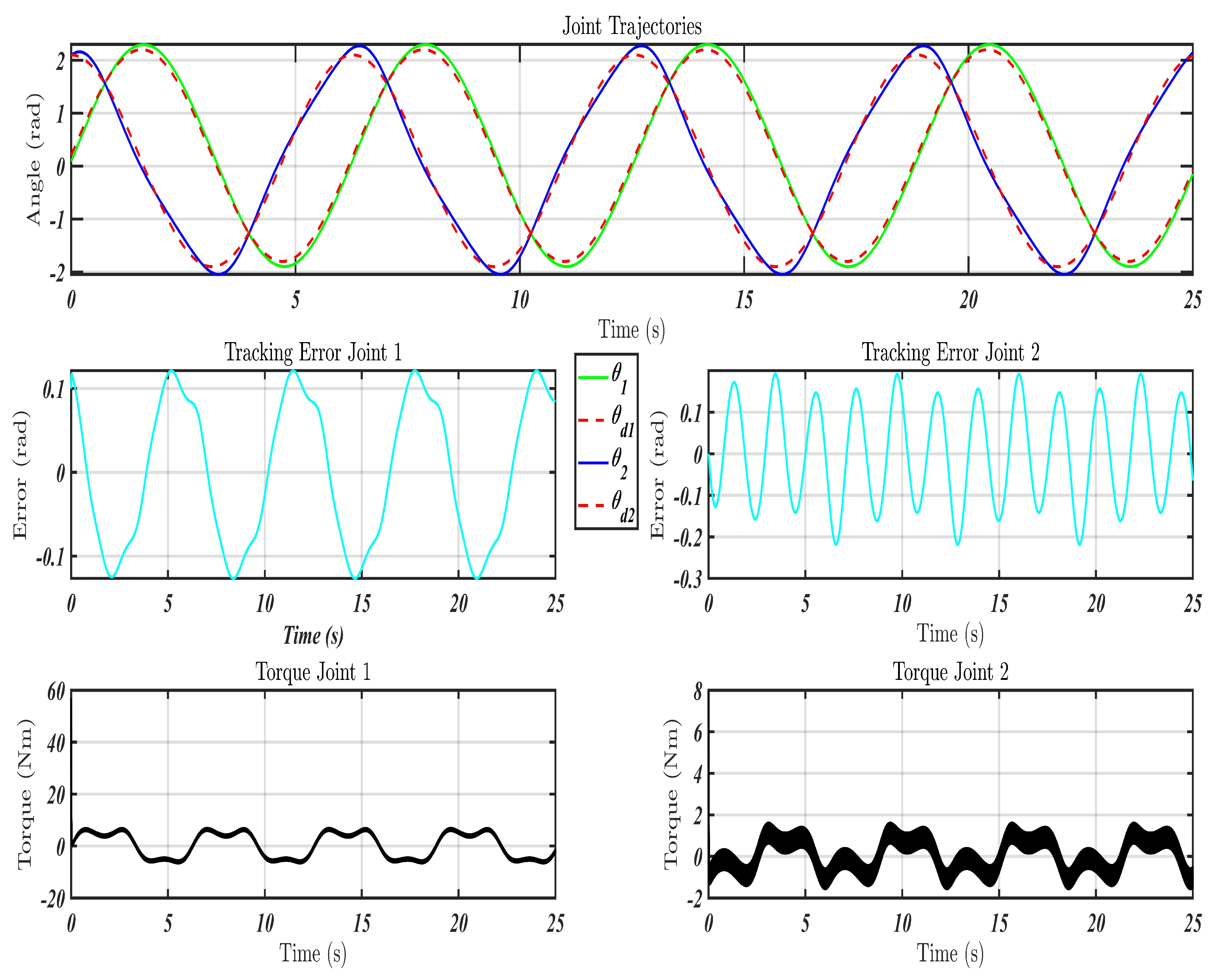

- Scenario 1: Nominal Conditions

- Scenario 2: External Disturbance

- Scenario 3: Proposed Control Strategy

5.1. Trajectory and Control Parameters

5.2. Performance Metrics

5.3. Simulation Results

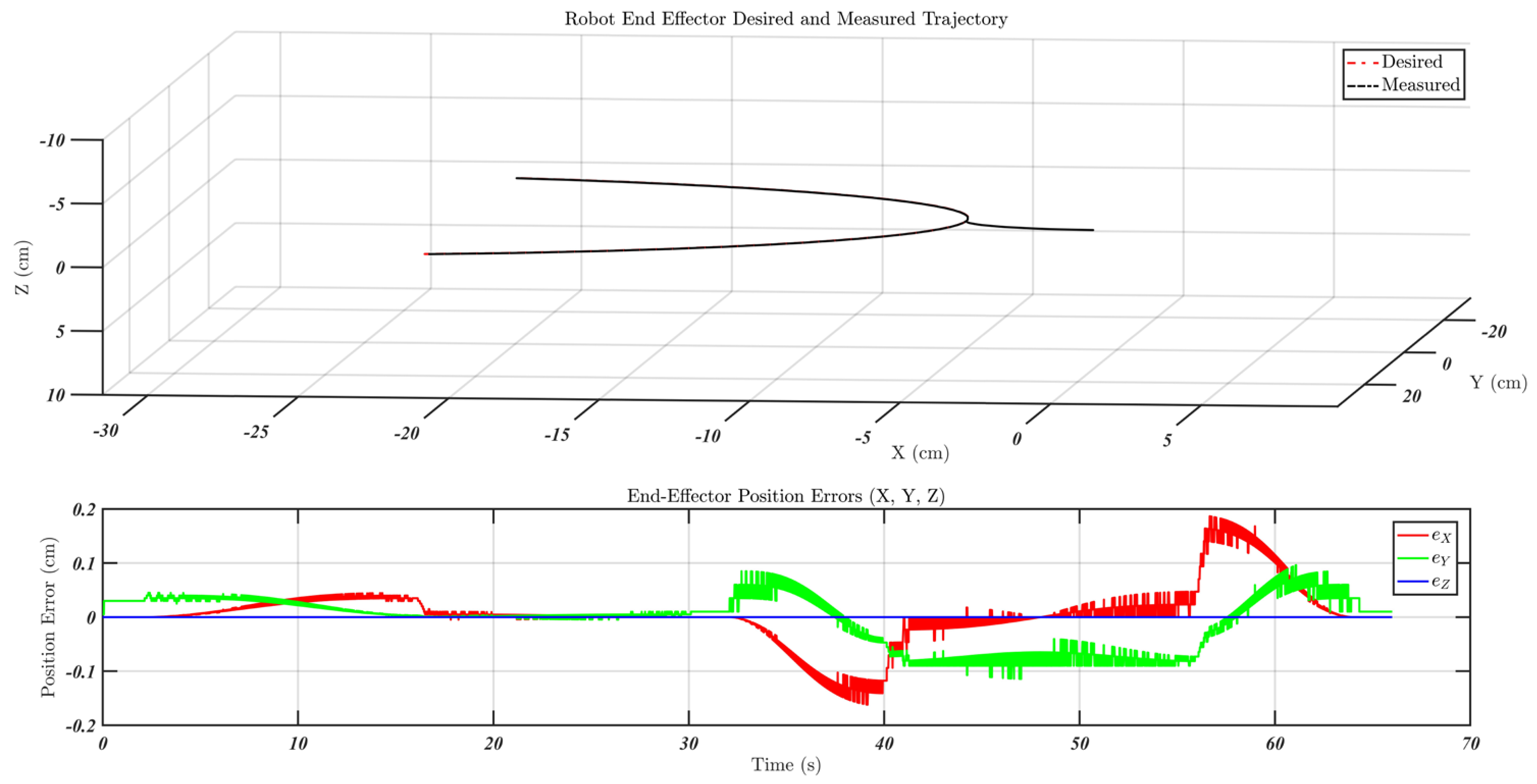

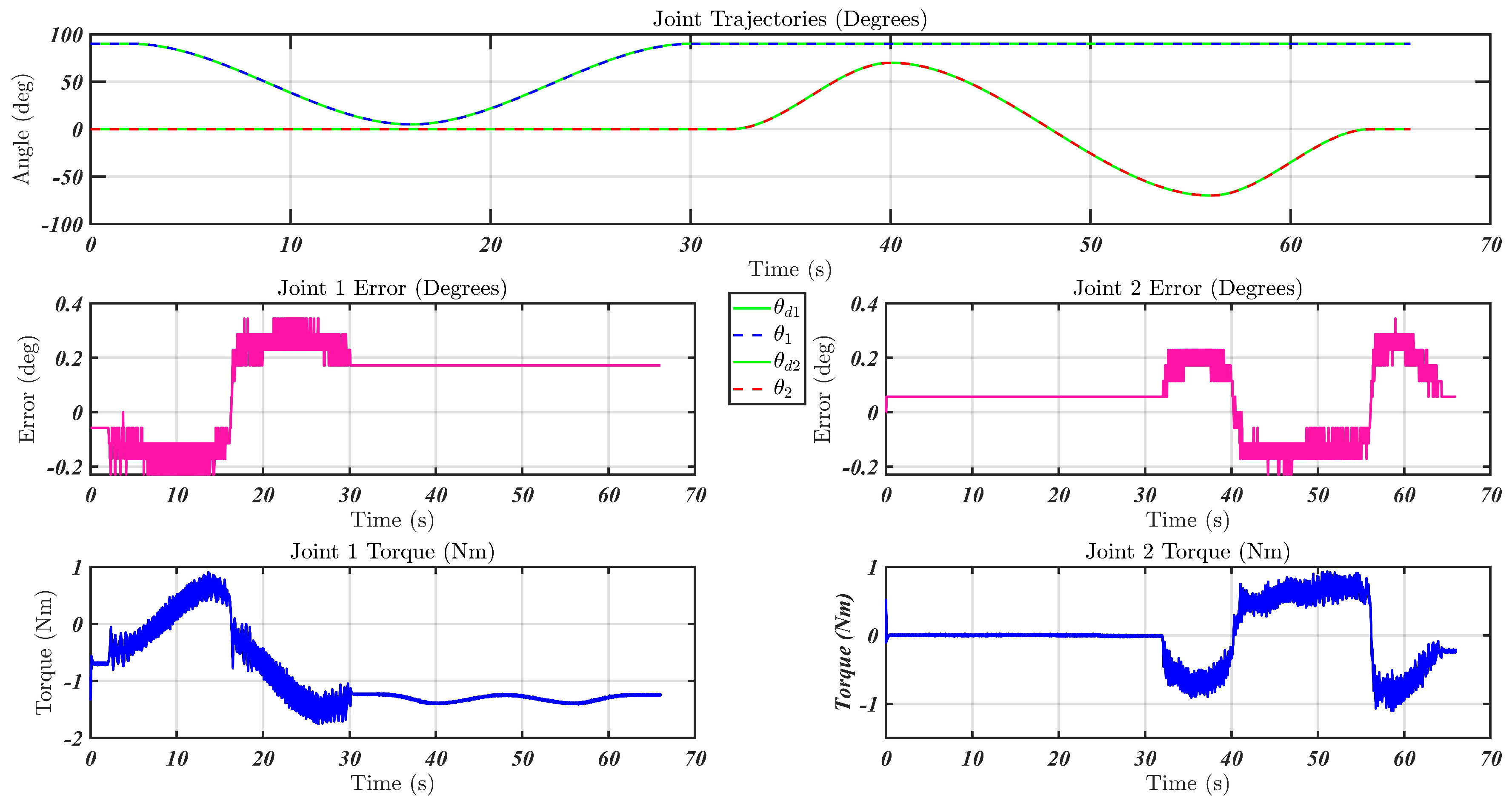

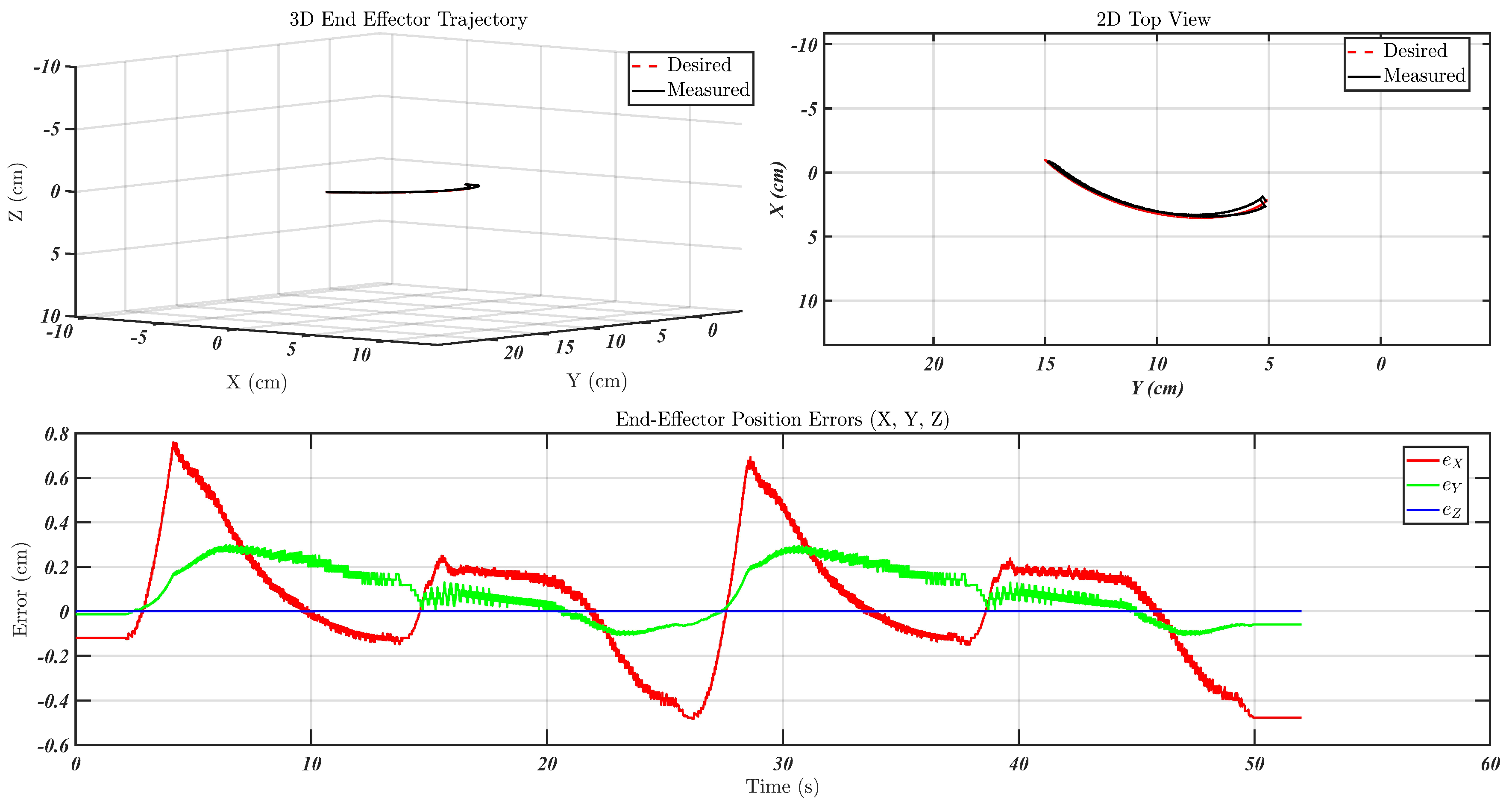

6. Experimental Results

Experimental Evaluation

- Scenario 1: simple motion

- Scenario 2: repetitive motion

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, S.; Huang, T.H.; Yang, X.; Jiao, C.; Yang, J.; Chen, Y.; Yi, J.; Su, H. Quasi-Direct Drive Actuation for a Lightweight Hip Exoskeleton with High Backdrivability and High Bandwidth. IEEE/ASME Trans. Mechatron. 2020, 25, 1794–1802. [Google Scholar] [CrossRef] [PubMed]

- Teng, L.; Gull, M.A.; Bai, S. PD Based Fuzzy Sliding Mode Control of A Wheelchair Exoskeleton Robot. IEEE/ASME Trans. Mechatron. 2020, 25, 2546–2555. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Wei, R.; Perez, M.; Shepard, B.; Koeneman, E.; Koeneman, J.; He, J. RUPERT: An exoskeleton robot for assisting rehabilitation of arm functions. In Proceedings of the 2008 Virtual Rehabilitation, Vancouver, BC, Canada, 25–27 August 2008; pp. 163–167. [Google Scholar]

- Xiao, F.; Gao, Y.; Wang, Y.; Zhu, Y.; Zhao, J. Design of a wearable cable-driven upper limb exoskeleton based on epicyclic gear trains structure. Technol. Health Care 2017, 25, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.M.R.; Ahmed, T.; Pallares, J.R.H.; Islam, M.R.; Brahmi, B.; Rahman, M.H. Development of A Desktop-mounted Rehabilitation Robot For Upper Extremities. In Proceedings of the International Conference on Industrial Mechanical Engineering and Operations Management, Dhaka, Bangladesh, 26–27 December 2021. [Google Scholar]

- Cao, W.; Chen, C.; Hu, H.; Fang, K.; Wu, X. Effect of hip assistance modes on metabolic cost of walking with a soft exoskeleton. IEEE Trans. Autom. Sci. Eng. 2020, 18, 426–436. [Google Scholar] [CrossRef]

- Loureiro, R.C.; Harwin, W.S.; Nagai, K.; Johnson, M. Advances in upper limb stroke rehabilitation: A technology push. Med. Biol. Eng. Comput. 2011, 49, 1103–1118. [Google Scholar] [CrossRef]

- Nef, T.; Guidali, M.; Riener, R. ARMin III–arm therapy exoskeleton with an ergonomic shoulder actuation. Appl. Bionics Biomech. 2009, 6, 127–142. [Google Scholar] [CrossRef]

- Kim, B.; Deshpande, A.D. An upper-body rehabilitation exoskeleton Harmony with an anatomical shoulder mechanism: Design, modeling, control, and performance evaluation. Int. J. Robot. Res. 2017, 36, 414–435. [Google Scholar] [CrossRef]

- Liu, L.; Shi, Y.Y.; Xie, L. A novel multi-dof exoskeleton robot for upper limb rehabilitation. J. Mech. Med. Biol. 2016, 16, 1640023. [Google Scholar] [CrossRef]

- Pignolo, L.; Dolce, G.; Basta, G.; Lucca, L.; Serra, S.; Sannita, W. Upper limb rehabilitation after stroke: ARAMIS a “robo-mechatronic” innovative approach and prototype. In Proceedings of the 2012 4th IEEE RAS-EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; pp. 1410–1414. [Google Scholar]

- Bououden, S.; Boutat, D.; Zheng, G.; Barbot, J.P.; Kratz, F. A triangular canonical form for a class of 0-flat nonlinear systems. Int. J. Control 2011, 84, 261–269. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, S.; Sun, Q. Development and assist-as-needed control of an end-effector upper limb rehabilitation robot. Appl. Sci. 2020, 10, 6684. [Google Scholar] [CrossRef]

- Brahmi, B.; Saad, M.; Rahman, M.H.; Ochoa-Luna, C. Cartesian trajectory tracking of a 7-DOF exoskeleton robot based on human inverse kinematics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 600–611. [Google Scholar] [CrossRef]

- Chen, W.; Ge, S.S.; Wu, J.; Gong, M. Globally stable adaptive backstepping neural network control for uncertain strict-feedback systems with tracking accuracy known a priori. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 1842–1854. [Google Scholar] [CrossRef] [PubMed]

- Yoo, B.K.; Ham, W.C. Adaptive control of robot manipulator using fuzzy compensator. IEEE Trans. Fuzzy Syst. 2000, 8, 186–199. [Google Scholar]

- Craig, J.J. Introduction to Robotics: Mechanics and Control (Pearson Prentice Hall Upper Saddle River, 2005). Available online: https://marsuniversity.github.io/ece387/Introduction-to-Robotics-Craig.pdf (accessed on 25 May 2025).

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Kinematics; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Ferrer, S.; Ochoa-Luna, C.; Rahman, M.; Saad, M.; Archambault, P. HELIOS: The Human Machine Interface forMARSERobot. In Proceedings of the 6th International Conference on Human System Interaction (HSI), Sopot, Poland, 6–8 June 2013; pp. 117–122. [Google Scholar]

- Luna, C.O.; Rahman, M.H.; Saad, M.; Archambault, P.; Zhu, W.-H. Virtual decomposition control of an exoskeleton robot arm. Robotica 2016, 34, 1587–1609. [Google Scholar] [CrossRef]

- Rahman, M.H.; Kittel-Ouimet, T.; Saad, M.; Kenné, J.P.; Archambault, P.S. Dynamic modeling and evaluation of a robotic exoskeleton for upper-limb rehabilitation. Int. J. Inform. Acquis. 2011, 8, 83–102. [Google Scholar] [CrossRef]

- Chen, P.; Chen, C.-W.; Chiang, W.-L. GA-based modified adaptive fuzzy sliding mode controller for nonlinear systems. Expert Syst. Appl. 2009, 36, 5872–5879. [Google Scholar] [CrossRef]

- Brahmi, B.; Saad, M.; Luna, C.O.; Archambault, P.S.; Rahman, M.H. Passive and active rehabilitation control of human upper-limb exoskeleton robot with dynamic uncertainties. Robotica 2018, 36, 1757–1779. [Google Scholar] [CrossRef]

- Rigatos, G.G. Extended Kalman and particle Filtering for sensor fusion in motion control of mobile robots. Math. Comput. Simul. 2010, 81, 590–607. [Google Scholar] [CrossRef]

- Rigatos, G.; Zhang, Q. Fuzzy Model Validation Using the Local Statistical Approach; IRISA No 1417; Publication Interne: Rennes, France, 2001. [Google Scholar]

- Fliess, M.; Levine, J.; Martin, P.; Rouchon, P. Flatness and Defect of Non-Linear Systems: Introductory Theory and Examples. Int. J. Control 1995, 61, 1327–1361. [Google Scholar] [CrossRef]

- Fliess, M.; Levine, J.; Martin, P.; Rouchon, P. On differentially flat nonlinear systems. In Proceedings of the 2nd IFAC-Symposium on Nonlinear Control Systems, Bordeaux, France, 24–26 June 1992; pp. 159–163. [Google Scholar]

- Murray, M.P.M.; Rouchon, P. Flat systems. In Advances in the Control of Nonlinear Systems, Plenary Lectures and Mini-Courses, Proceedings of the 4th European Control Conference ECC 97, Brussels Belgium, 1–4 July 1997; Gevers, M., Bastin, G., Eds.; Springer: London, UK, 1997; pp. 211–264. [Google Scholar]

- Ramirez, H.S.; Agrawal, S.K. Differentially Flat Systems; Marcel Dekker: New York, NY, USA, 2004. [Google Scholar]

- Brahmi, B.; Ahmed, T.; El Bojairami, I.; Swapnil, A.A.Z.; Assad-Uz-Zaman, M.; Schultz, K.; McGonigle, E.; Rahman, M.H. Flatness based control of a novel smart exoskeleton robot. IEEE/ASME Trans. Mechatronics 2021, 27, 974–984. [Google Scholar] [CrossRef]

- Khan, M.M.R.; Swapnil, A.A.Z.; Ahmed, T.; Rahman, M.M.; Islam, M.R.; Brahmi, B.; Fareh, R.; Rahman, M.H. Development of an end-effector type therapeutic robot with sliding mode control for upper-limb rehabilitation. Robotics 2022, 11, 98. [Google Scholar] [CrossRef]

- Chen, Y.; Fan, J.; Zhu, Y.; Zhao, J.; Cai, H. A passively safe cable driven upper limb rehabilitation exoskeleton. Technol. Health Care 2015, 23, S197–S202. [Google Scholar] [CrossRef] [PubMed]

- Luh, J.Y.; Walker, M.W.; Paul, R.P. On-line computational scheme for mechanical manipulators. J. Dyn. Syst. Meas. Control 1980, 102, 69–76. [Google Scholar] [CrossRef]

- Pereira da Silva, P.S. Flatness of nonlinear control systems: A Cartan-Kähler approach. In Proceedings of the Mathematical Theory of Networks et Systems, MTNS 2000, Perpignan, France, 19–23 June 2000; pp. 1–10. [Google Scholar]

- Isidori, A. Nonlinear Control Systems, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Rigatos, G.G.; Tzafestas, S.G. Extended Kalman filtering for fuzzy modelling and multisensor fusion. Math. Comput. Model. Dyn. Syst. 2007, 13, 251–266. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Zervos, N. Derivative-free nonlinear Kalman filtering for PMSG sensorless control. In Mechatronics Engineering: Research Development and Education; Habib, M., Ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Rigatos, G.; Siano, P. A derivative-free extended information filtering approach for sensorless control of nonlinear systems. In Proceedings of the MASCOT 2010, IMACS Workshop on Scientific Computation; Italian Institute for Calculus Applications: Gran Canaria, Spain, 2010. [Google Scholar]

- Chen, W.H.; Ballance, D.J.; Gawthrop, P.J.; Reilly, J.O. A nonlinear disturbance observer for robotic manipulators. IEEE Trans. Industr. Electron. 2000, 47, 932–938. [Google Scholar] [CrossRef]

- Cortesao, R. On Kalman active observers. J. Intell. Robot. Syst. 2006, 48, 131–155. [Google Scholar] [CrossRef]

- Slotine, J.J.E.; Li, W. Applied Nonlinear Control; Prentia Hall: Englewood Cliffs, NJ, USA, 1991. [Google Scholar]

| Joint (i) | ||||

|---|---|---|---|---|

| 1 | 0 | 0 | 0 | |

| 2 | 0 | 0 | ||

| 3 | 0 | 0 | 0 |

| Performance | Scenario 1 | Scenario 2 | Scenario 3 | |||

|---|---|---|---|---|---|---|

| Joint 1 | Joint 2 | Joint 1 | Joint 2 | Joint 1 | Joint 2 | |

| MAE (rad) | 0.0032 | 0.0010 | 0.0789 | 0.1055 | 0.0561 | 0.0559 |

| SDE (rad) | 0.0136 | 0.0015 | 0.0345 | 0.0545 | 0.0254 | 0.0298 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bououden, S.; Brahmi, B.; Iqbal, N.; Fareh, R.; Rahman, M.H. Disturbance-Resilient Flatness-Based Control for End-Effector Rehabilitation Robotics. Actuators 2025, 14, 341. https://doi.org/10.3390/act14070341

Bououden S, Brahmi B, Iqbal N, Fareh R, Rahman MH. Disturbance-Resilient Flatness-Based Control for End-Effector Rehabilitation Robotics. Actuators. 2025; 14(7):341. https://doi.org/10.3390/act14070341

Chicago/Turabian StyleBououden, Soraya, Brahim Brahmi, Naveed Iqbal, Raouf Fareh, and Mohammad Habibur Rahman. 2025. "Disturbance-Resilient Flatness-Based Control for End-Effector Rehabilitation Robotics" Actuators 14, no. 7: 341. https://doi.org/10.3390/act14070341

APA StyleBououden, S., Brahmi, B., Iqbal, N., Fareh, R., & Rahman, M. H. (2025). Disturbance-Resilient Flatness-Based Control for End-Effector Rehabilitation Robotics. Actuators, 14(7), 341. https://doi.org/10.3390/act14070341