Study on Trajectory Planning for Polishing Free-Form Surfaces of XY-3-RPS Hybrid Robot

Abstract

1. Introduction

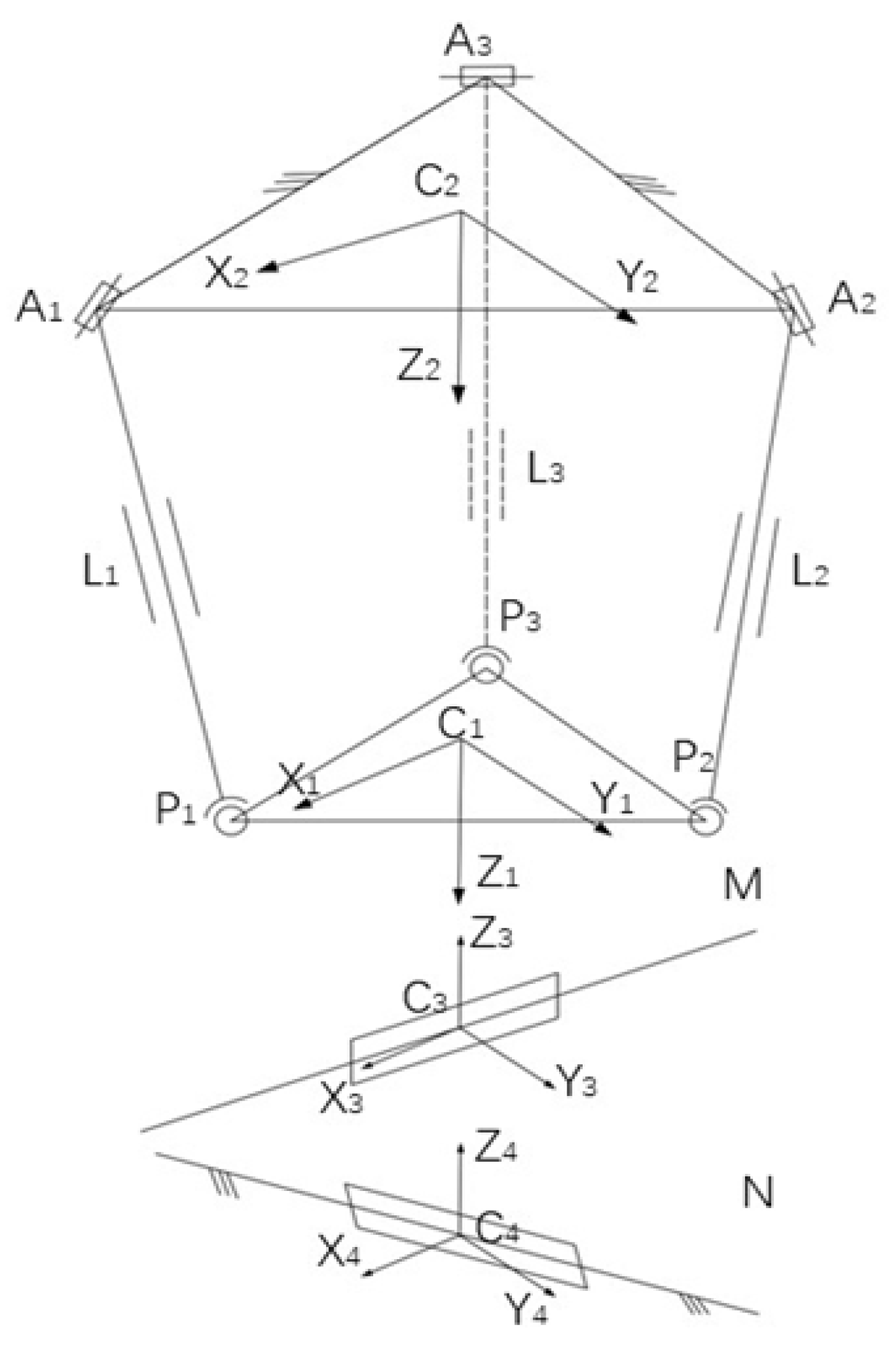

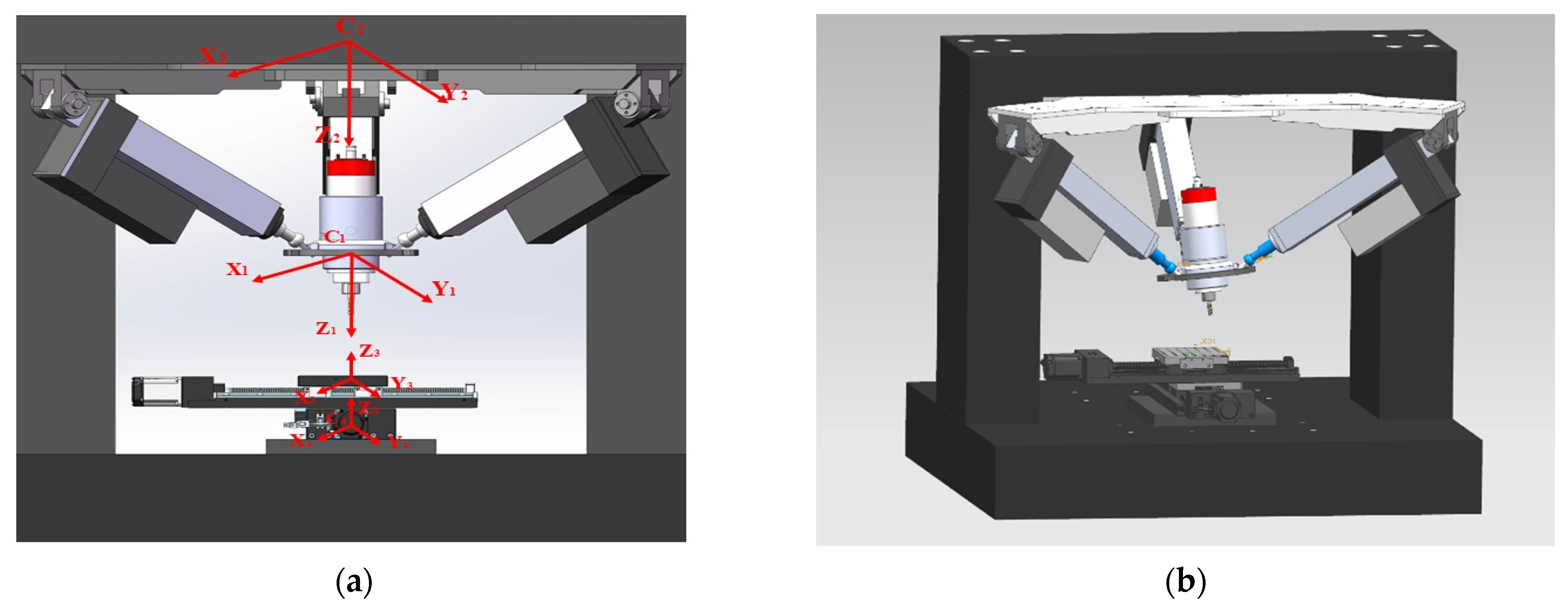

2. Kinematic Modeling of XY-3-RPS Hybrid Robots

2.1. Structure and Principle of Motion

2.2. Kinematic Inverse Solution

3. Free-Form Surface Representation

4. Automatic Partitioned Trajectory Planning Based on Improved Curvature Properties

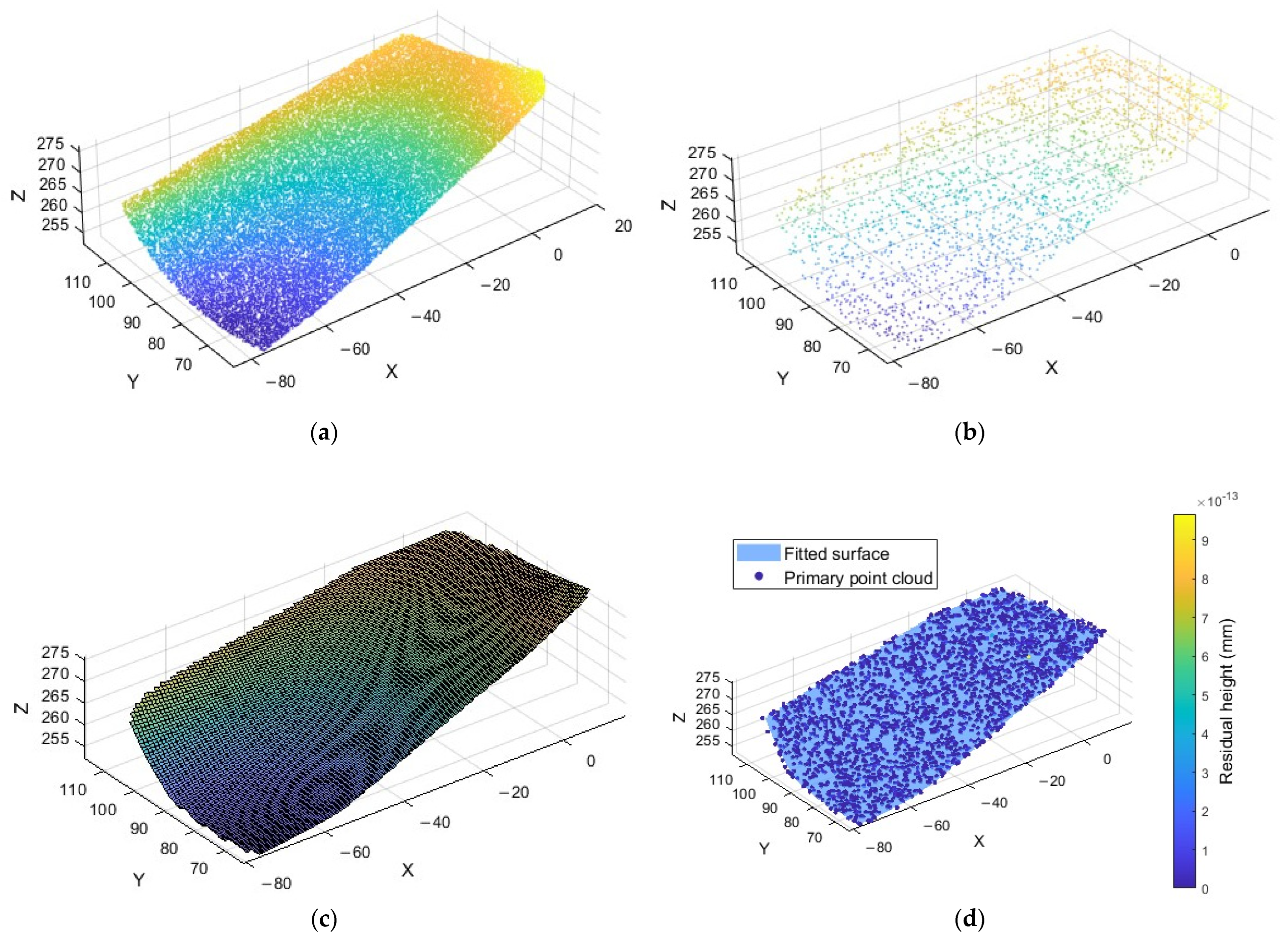

4.1. Free-Form Surface Generation

4.1.1. Free-Form Surface Data Acquisition and Processing

4.1.2. Surface Fitting

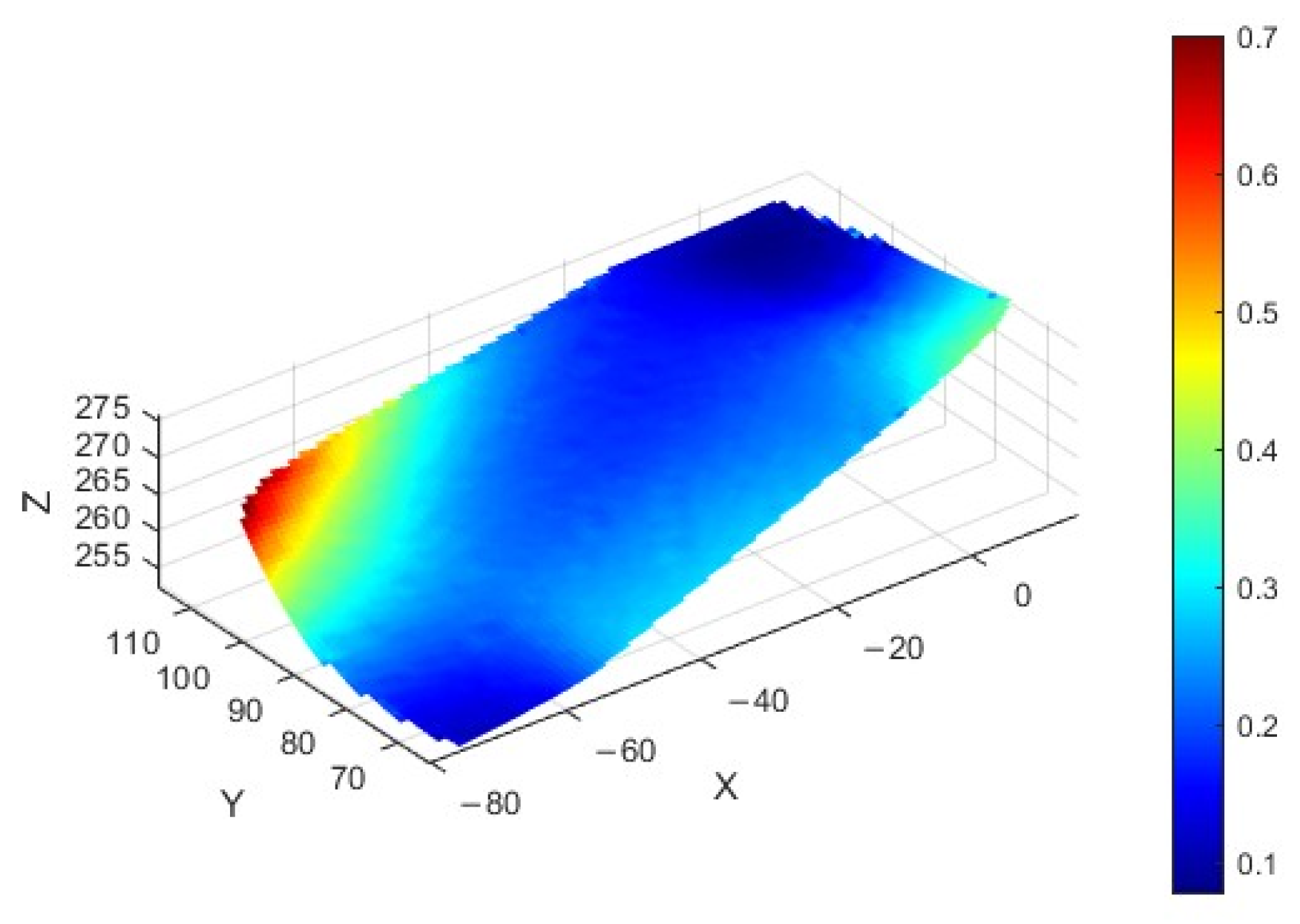

4.2. Curvature Calculation

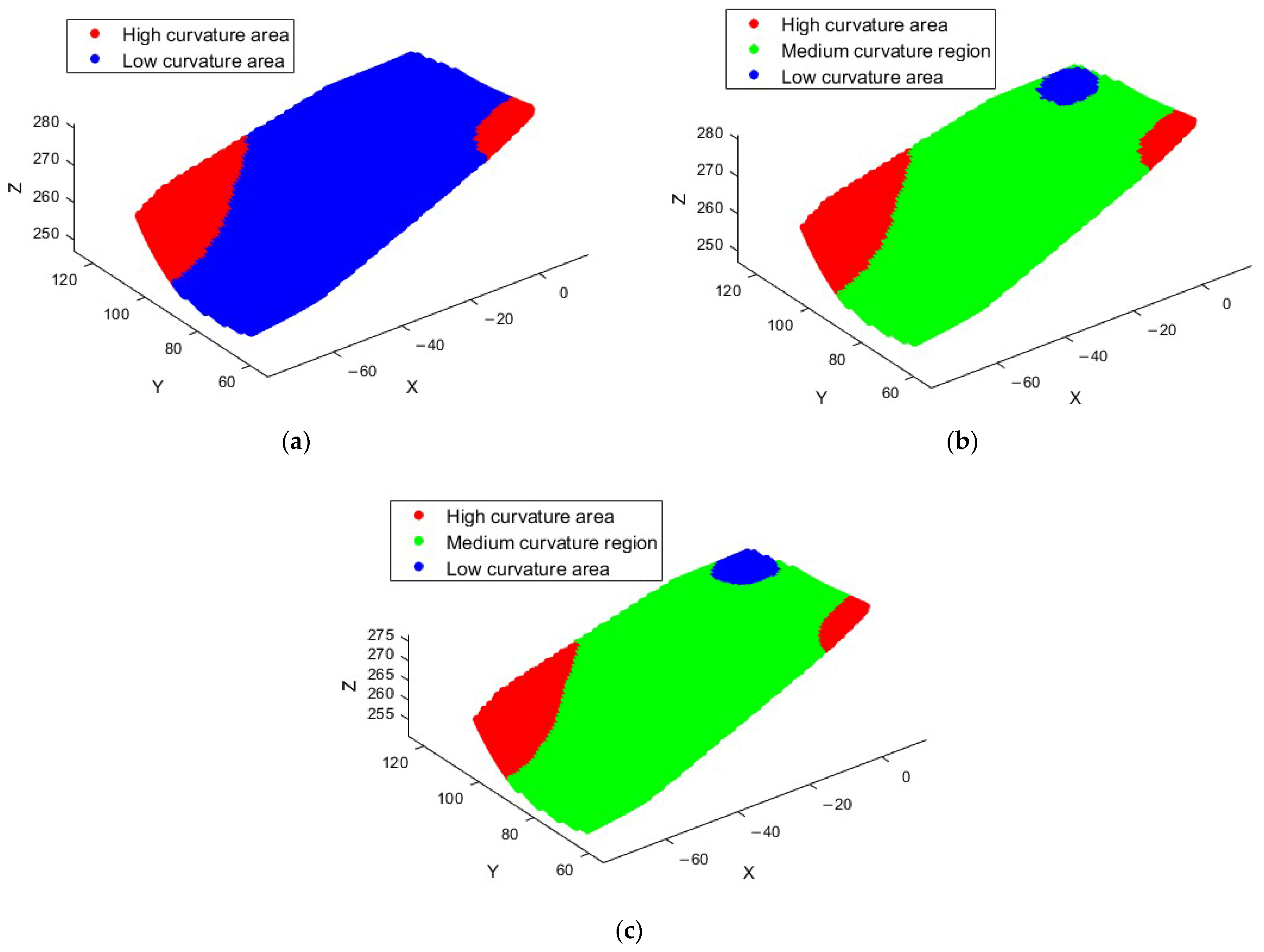

4.3. Automatic Partitioning Based on Improved Curvature Properties

- (1)

- Curvature-based automatic partitioning

- (2)

- Dynamic Partitioning Algorithm

- (3)

- Partition Boundary Smoothing

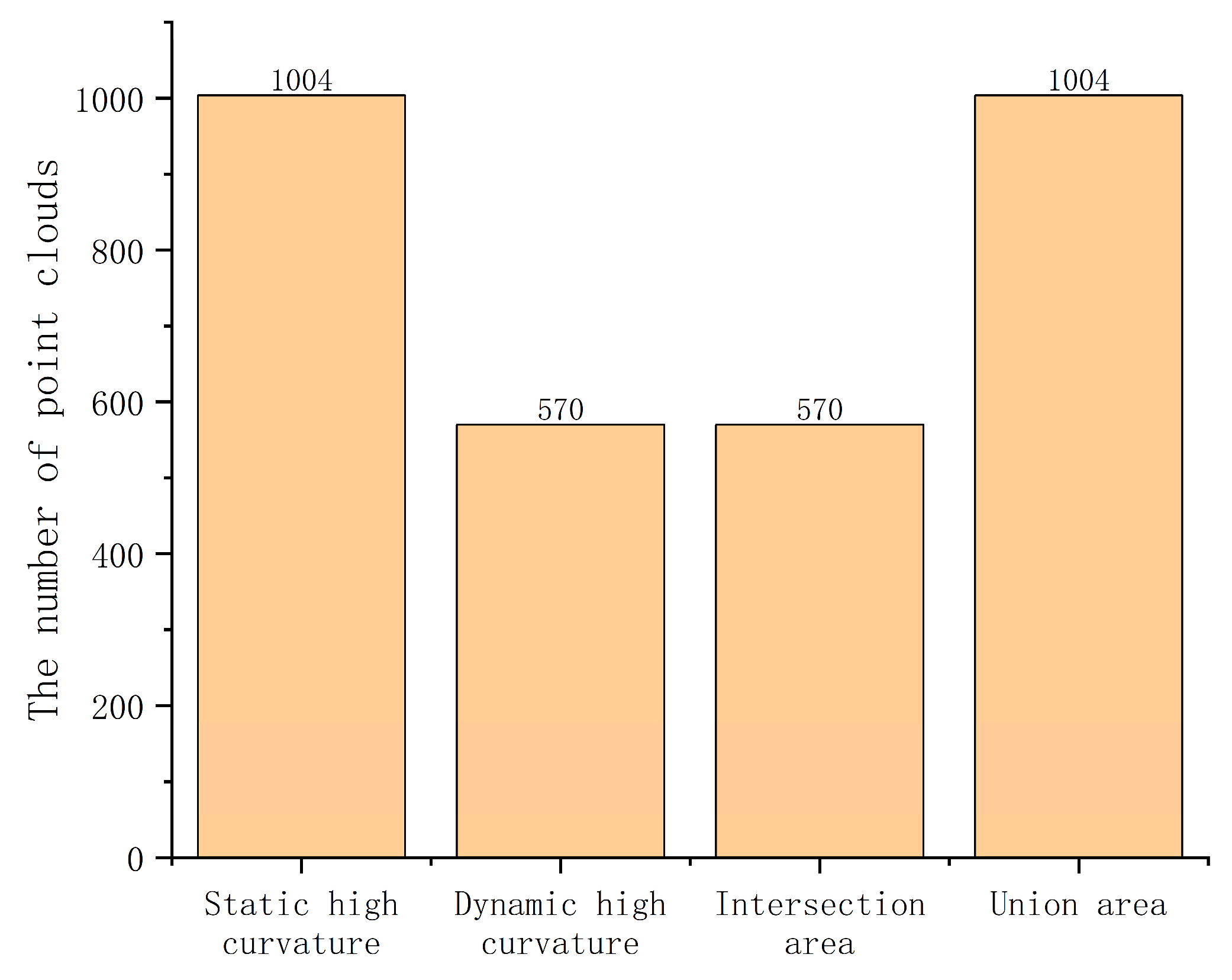

4.4. Extraction of Effective Polishing Areas

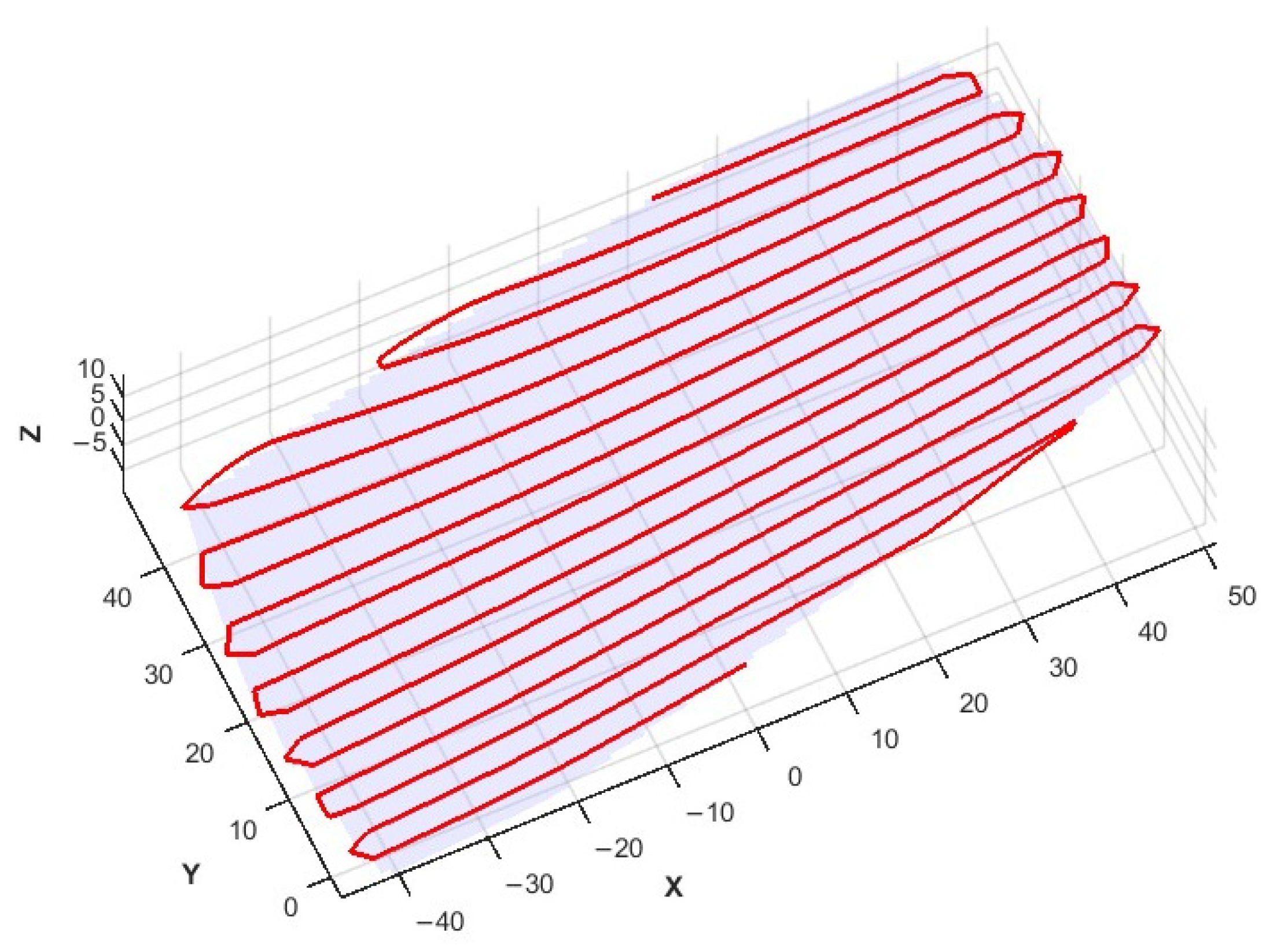

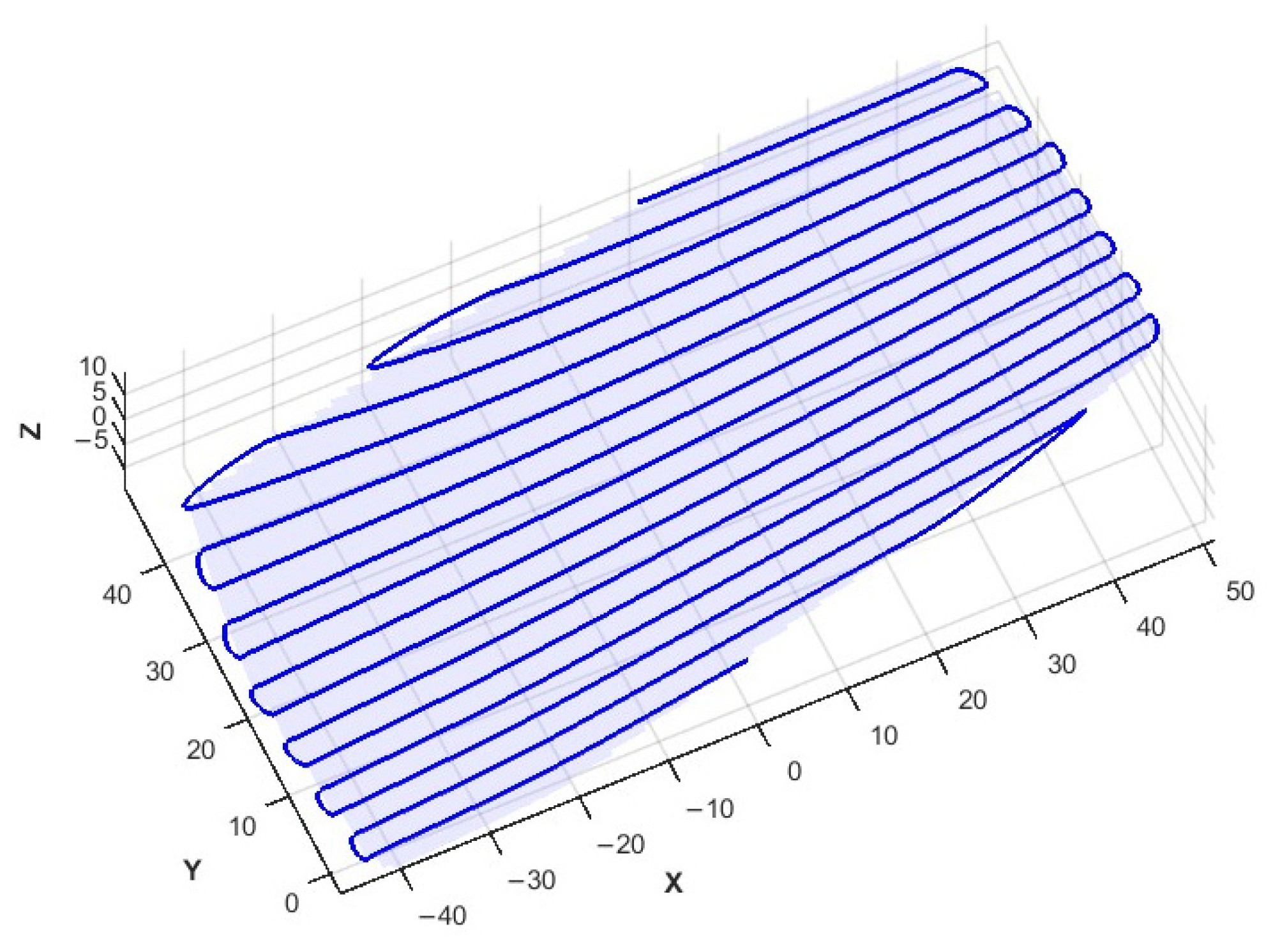

4.5. Trajectory Generation

4.6. Tool Site Generation

5. Trajectory Optimization

5.1. Trajectory Optimization Objectives and Strategies

5.1.1. Trajectory Optimization Objective Definition

- (1)

- Trajectory Smoothness

- (2)

- Total trajectory length

- (3)

- Machining error

5.1.2. Optimization Objective Function Definition

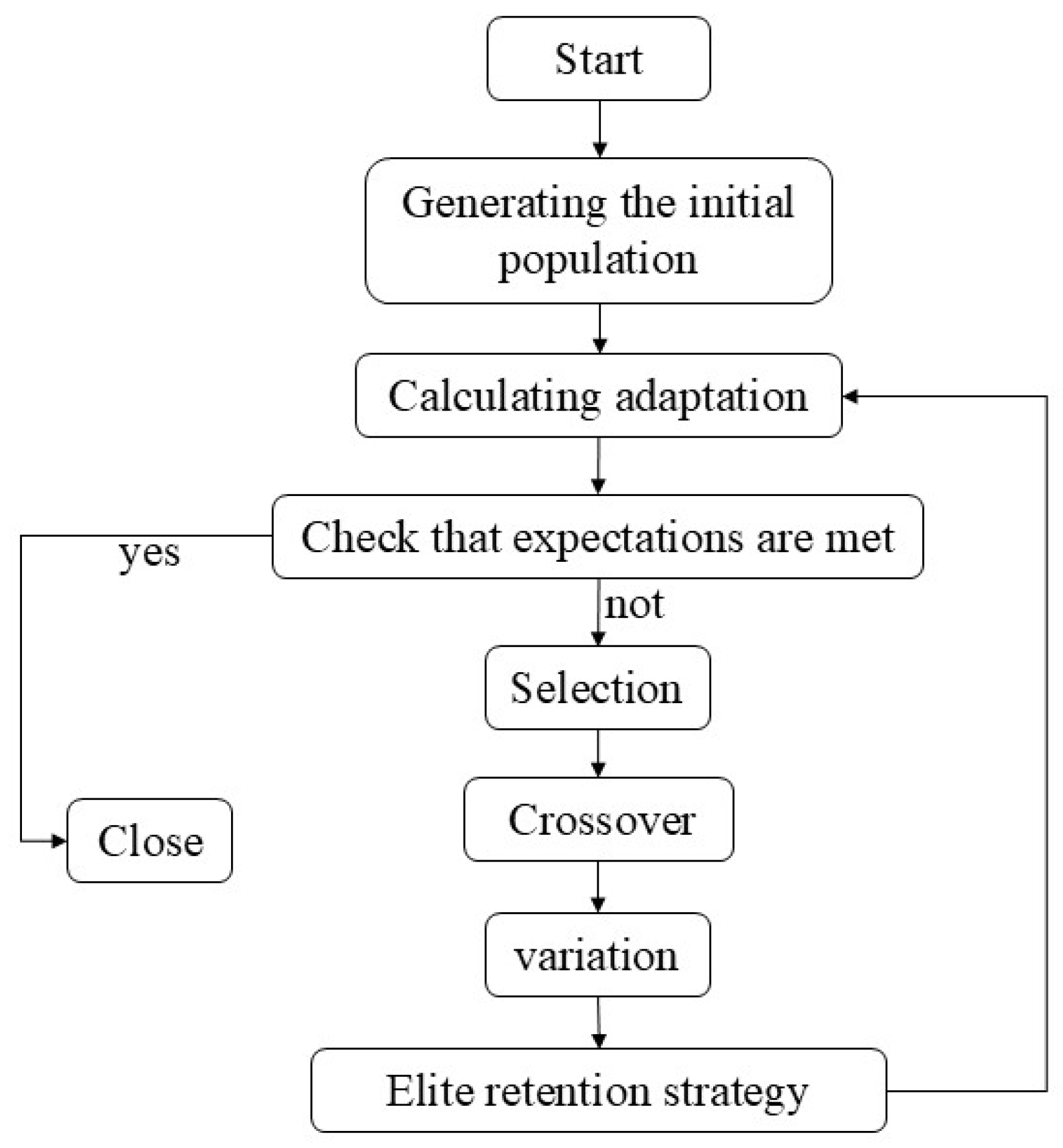

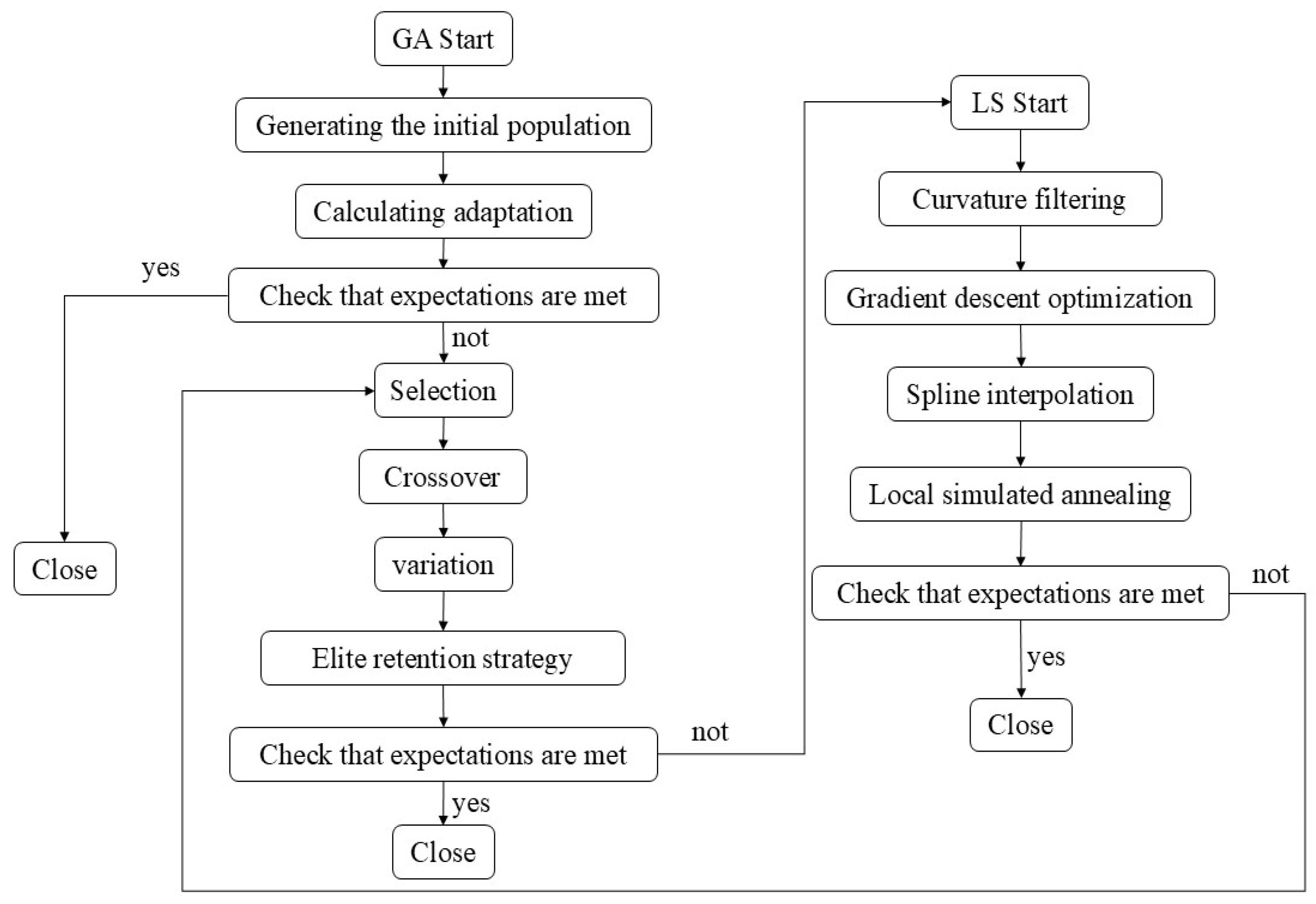

5.2. Genetic Algorithm (GA) Optimization

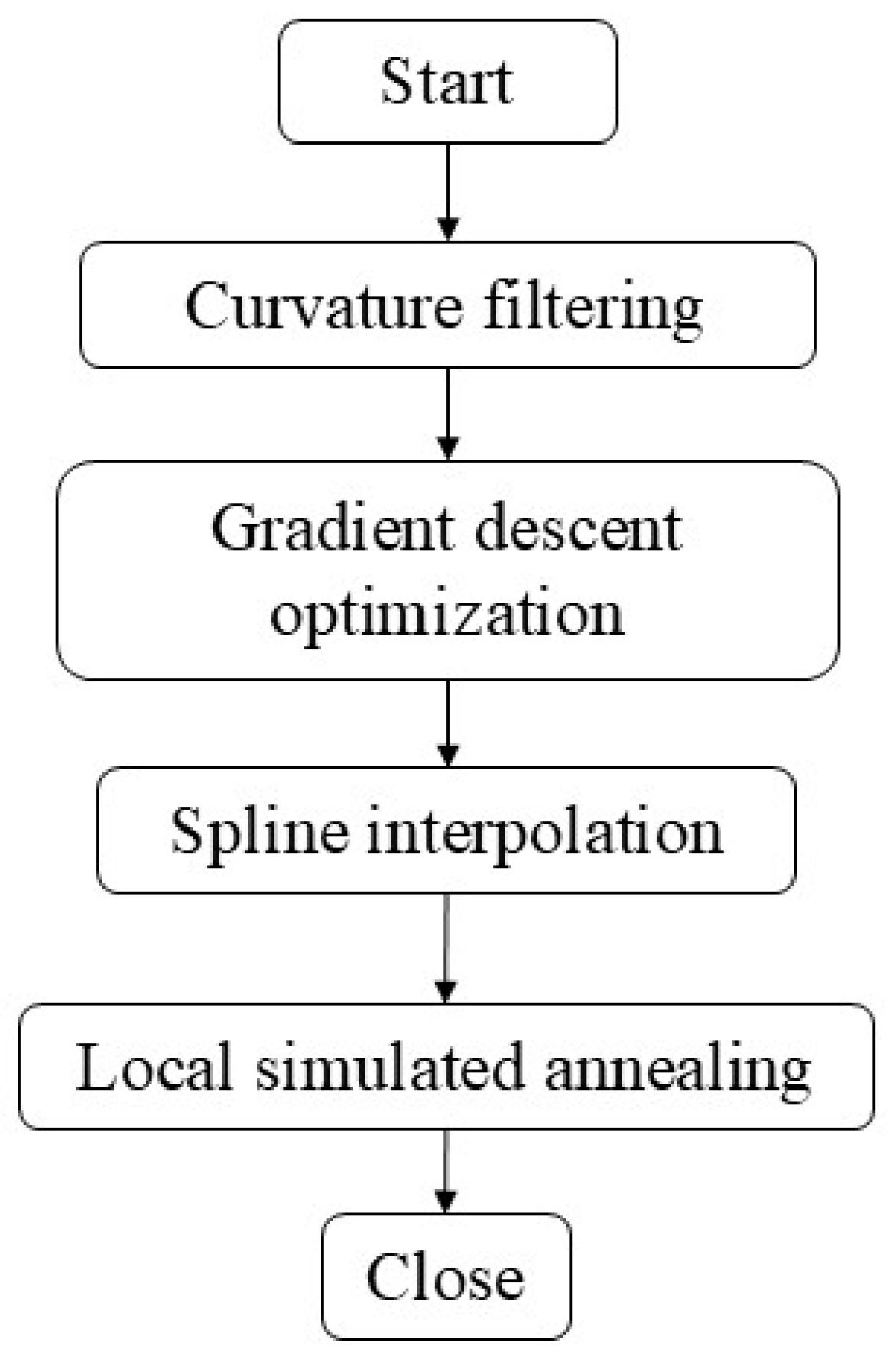

5.3. Local Search (LS) Optimization

5.4. GA + LS Combined Strategy

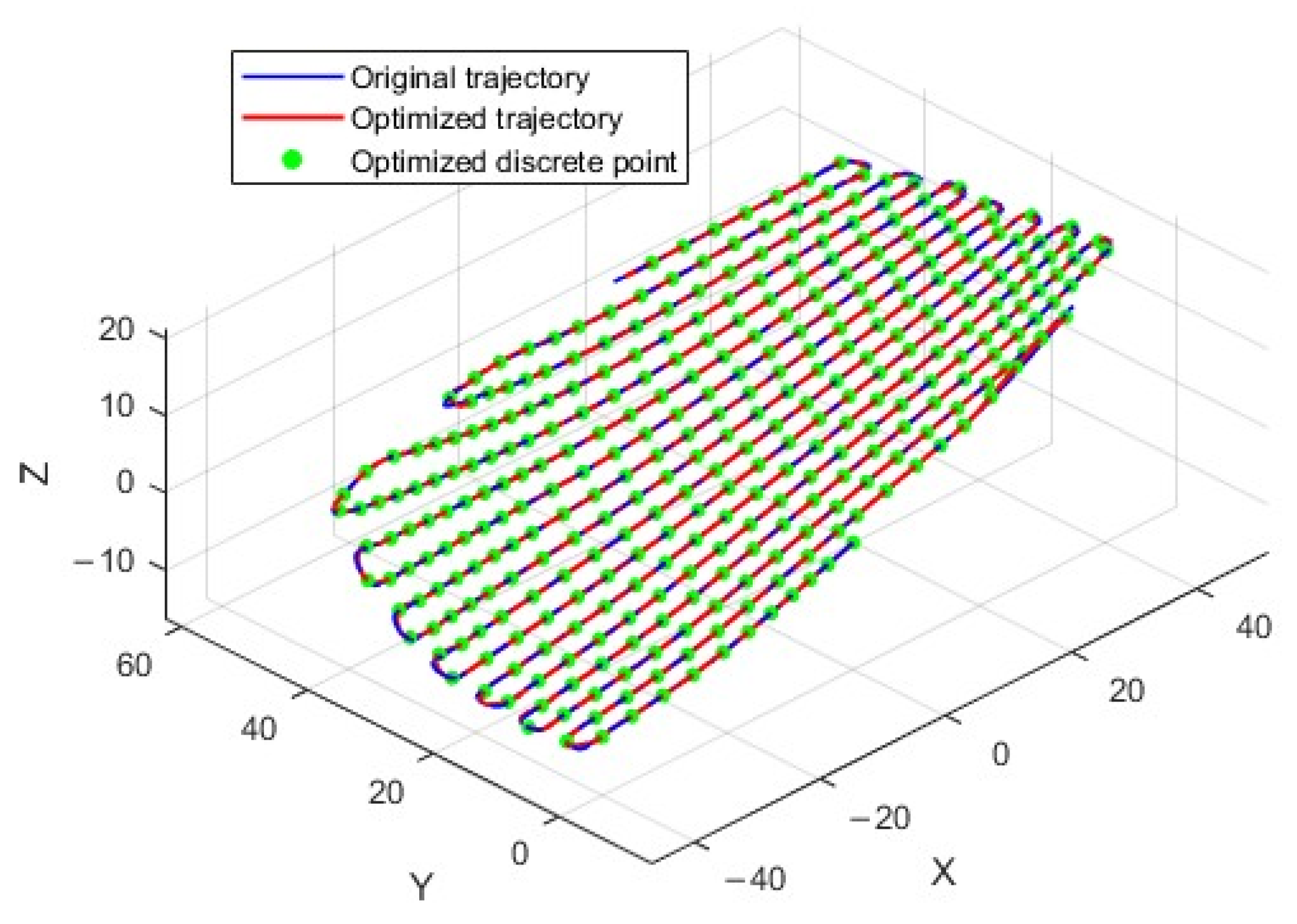

5.5. Trajectory Comparison and Optimization Effect Analysis

6. XY-3-RPS Hybrid Robot Construction and Simulation

6.1. XY-3-RPS Hybrid Robot Construction

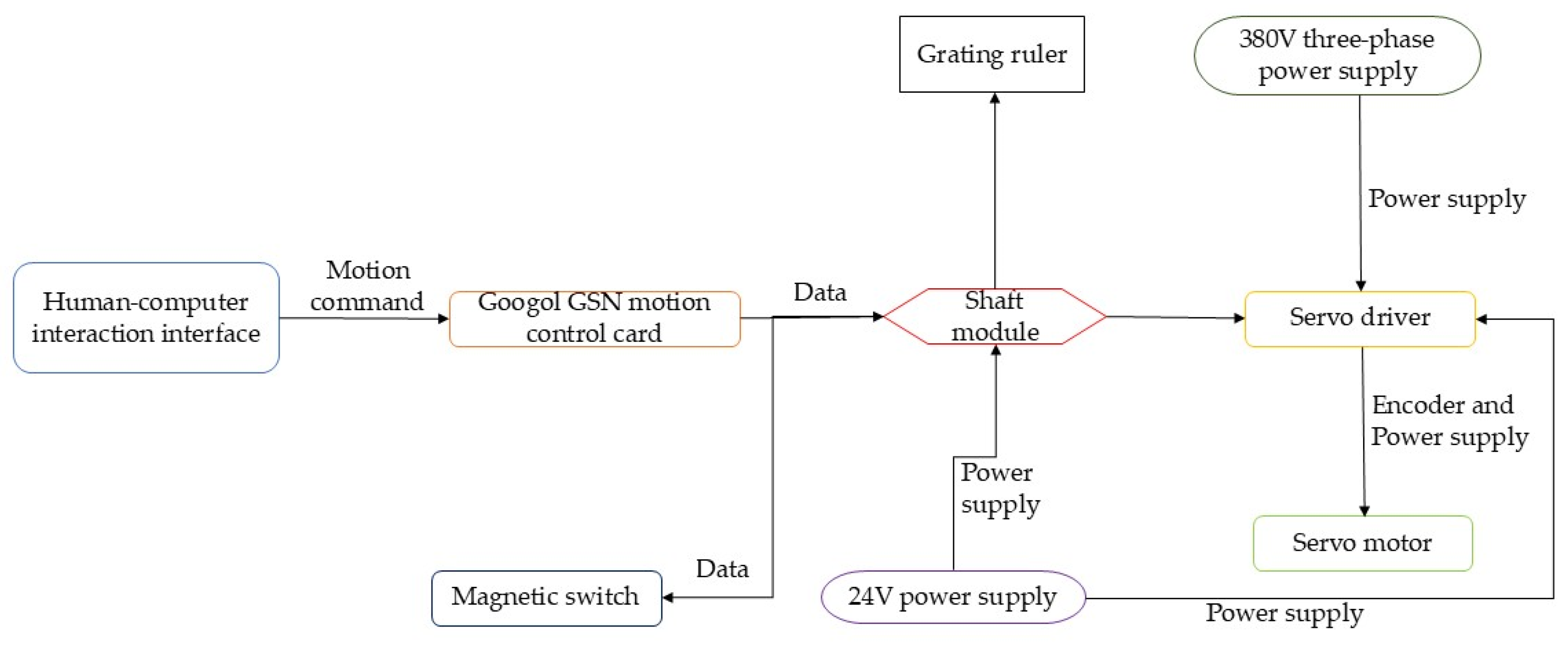

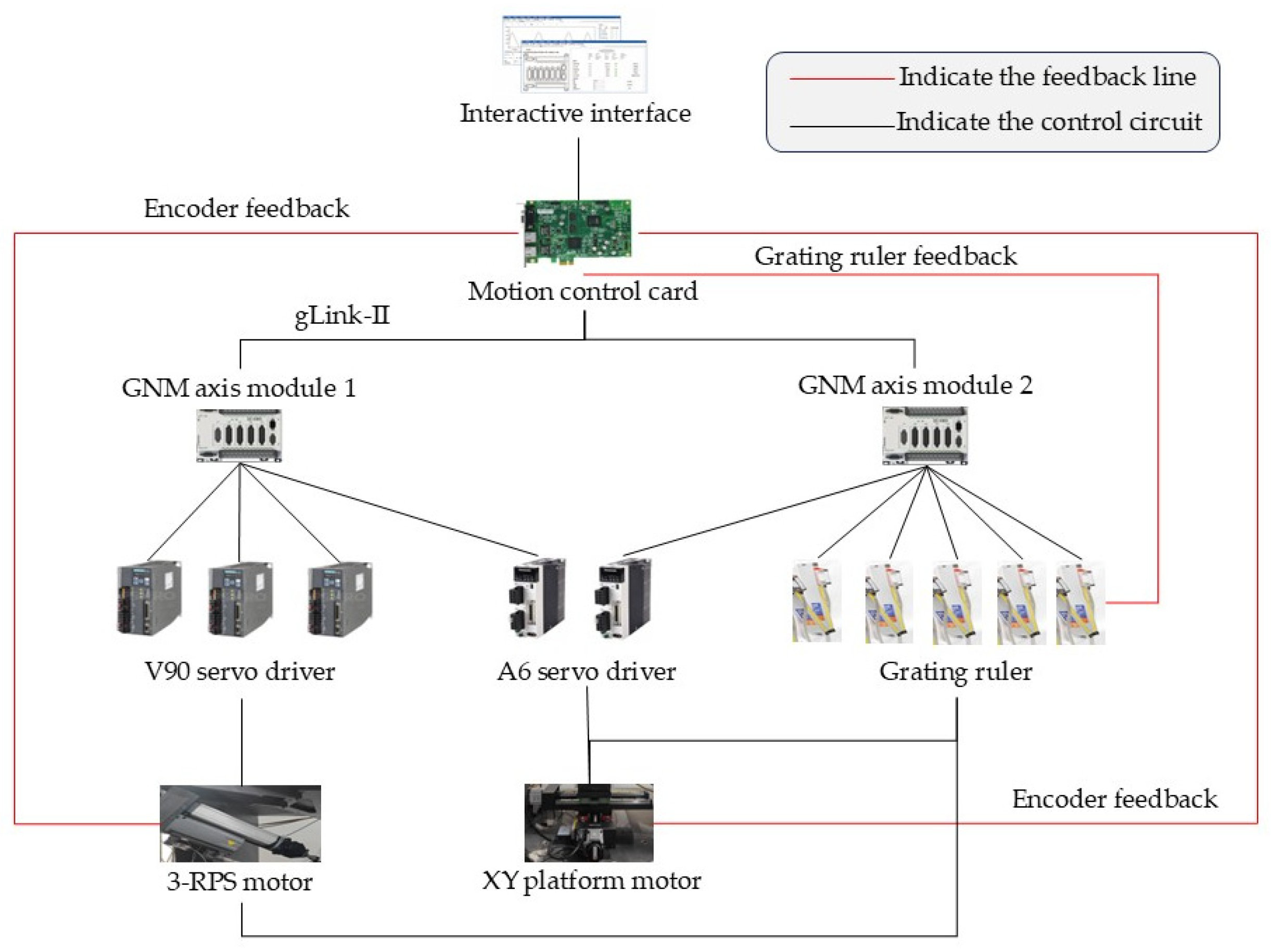

6.1.1. XY-3-RPS Hybrid Robot Control System Design

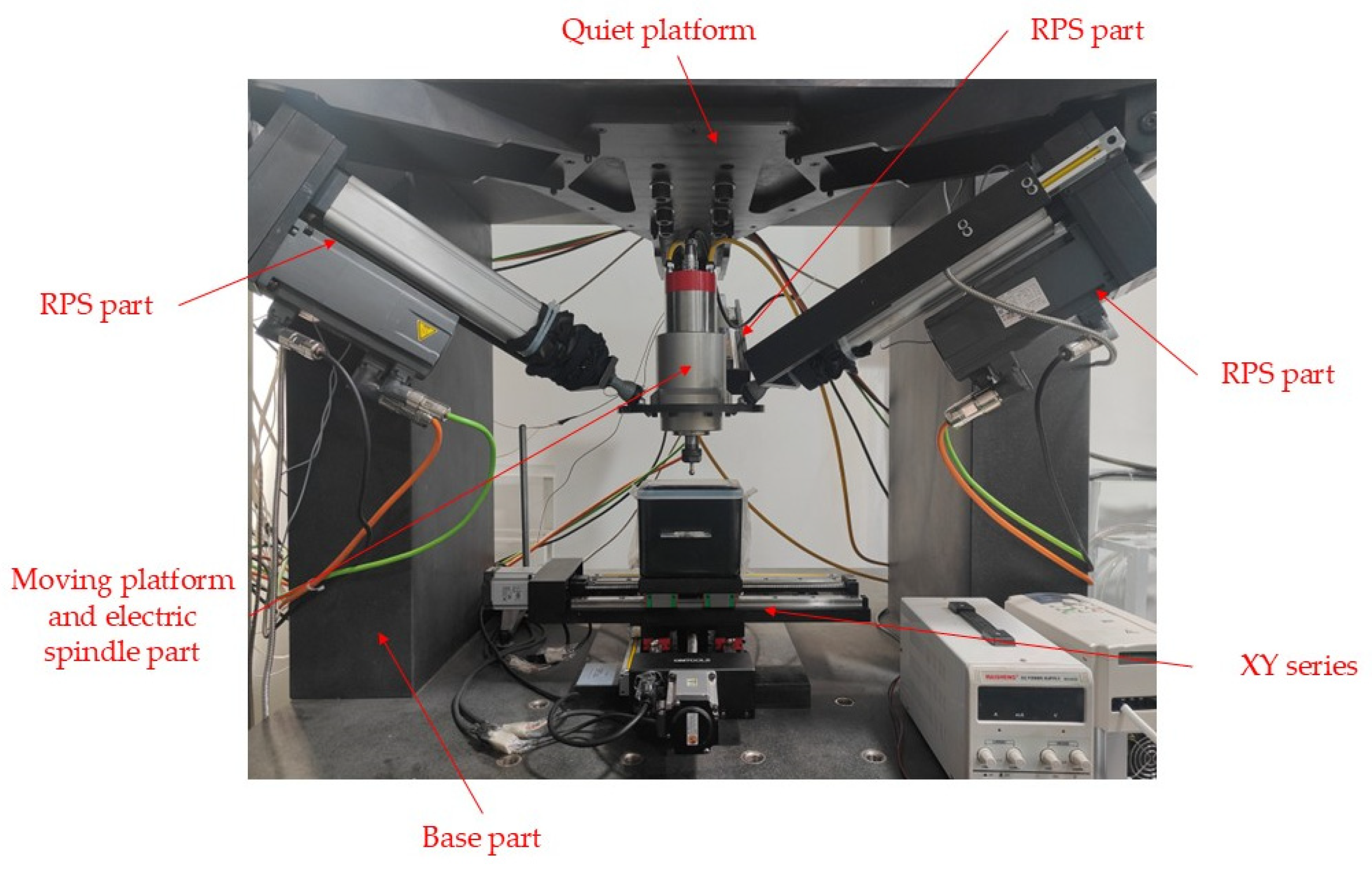

6.1.2. XY-3-RPS Mixed-Link Robot Installation

6.2. Polishing Simulation Design

7. Discussion

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Werner, A.; Poniatowska, M. Planning the Coordinate Measurements of a Freeform Surface after Milling based on a CAD Model Simulating the Surface after Machining. Acta Mech. Autom. 2024, 18, 730–736. [Google Scholar] [CrossRef]

- Deng, X.; Hu, P.; Li, Z.; Zhang, W.; He, D.; Chen, Y. Reinforcement Learning-based five-axis continuous inspection method for complex freeform surface. Robot. Comput.-Integr. Manuf. 2025, 94, 102990. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, E.; Zhang, W.; Hu, J.; Guo, J.; Li, X. Simulation and experimental verification of the precision finishing method for optical free-form surface segmentation. PLoS ONE 2025, 20, e0314489. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Wang, X.; Wang, J.; Fu, H. Design and Analysis of an Inverted XY-3RPS Hybrid Mechanism for Polishing of Complex Surface. Recent Pat. Mech. Eng. 2022, 15, 422–437. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Wen, Y.; Song, X. Design and kinematic simulation of the XY-3-RPS hybrid robot. Light Ind. Mach. 2020, 38, 5–10. [Google Scholar]

- Dimitrov, D.; Karachorova, V.; Szecsi, T. System for controlling the accuracy and reliability of machining operations on machining centres. Procedia Eng. 2013, 63, 108–114. [Google Scholar] [CrossRef]

- Li, W.; Fan, B.; Shi, C.; Wang, J.; Zhuo, B. A path planning method used in fluid jet polishing eliminating lightweight mirror imprinting effect. In Proceedings of the 7th International Symposium on Advanced Optical Manufacturing and Testing Technologies (AOMATT 2014), Harbin, China, 26–29 April 2014; Volume 9281. 92811H-92811H-8. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, X.; Yang, W.; Lei, M.; Zhang, C.; Wan, J. Ant colony optimization-based method for energy-efficient cutting trajectory planning in axial robotic roadheader. Appl. Soft Comput. 2024, 163, 111965. [Google Scholar] [CrossRef]

- Myasoedova, M.T.; Panchuk, L.K. Geometric model of generation of family of contour-parallel trajectories (equidistant family) of a machine tool. J. Phys. Conf. Ser. 2019, 1210, 012104. [Google Scholar] [CrossRef]

- Chen, M.; Zhu, Z.; Zhu, Y.; Han, T. A New Method for spherical tool polishing Trajectory Planning considering material removal Characteristics. Comput. Integr. Manuf. Syst. 2023, 29, 864–873. [Google Scholar] [CrossRef]

- Zheng, Y.X. Multi-Directional Trajectory Planning for Surface Polishing. Master’s Thesis, South China University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Amersdorfer, M.; Kappey, J.; Meurer, T. Real-time freeform surface and path tracking for force controlled robotic tooling applications. Robot. Comput.-Integr. Manuf. 2020, 65, 101955. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Shuai, K.; Zhu, W.; Chen, B.; Chen, K. Multi-objective trajectory planning method based on the improved elitist non-dominated sorting genetic algorithm. Chin. J. Mech. Eng. 2022, 35, 7. [Google Scholar] [CrossRef]

- Baghli, Z.F.; Bakkali, E.L.; Lakhal, Y. Optimization of arm manipulator trajectory planning in the presence of obstacles by ant colony algorithm. Procedia Eng. 2017, 181, 560–567. [Google Scholar] [CrossRef]

- Zhu, A.; Wang, Z. Trajectory planning of rotor welding manipulator based on an improved particle swarm optimization algorithm. Adv. Comput. Signals Syst. 2024, 8, 122–129. [Google Scholar] [CrossRef]

- Gui, H. Research on trajectory optimization of robot polishing freeform surfaces. Sci. Technol. Consult. Her. 2007, 11, 3–4. [Google Scholar] [CrossRef]

- Liu, Q. Research on Polishing Trajectory and Material Removal Optimization Based on CCOS. Master’s Thesis, Jilin University, Changchun, China, 2022. [Google Scholar]

- Kazim, M.; Hong, J.; Kim, G.M.; Kim, K.-K.K. Recent advances in path integral control for trajectory optimization: An overview in theoretical and algorithmic perspectives. Annu. Rev. Control 2024, 57, 100931. [Google Scholar] [CrossRef]

- Grubler, A.; Kutzbach, H. The synthesis of planar mechanisms. J. Appl. Mech. 1963, 30, 10–17. [Google Scholar]

- Luo, S.; Sun, Y.; Zhai, J.; Zhang, Q.; Chang, X. Optimization of free form surface in bulge formed joint based on isogeometric analysis. Iran. J. Sci. Technol. Trans. Mech. Eng. 2024, 49, 1069–1083. [Google Scholar] [CrossRef]

- Zhao, P.; Gao, F.; Guo, K.; Zhang, E.; Li, S. Trajectory optimization of B-splines interpolation based on dynamic error adjustment. J. Phys. Conf. Ser. 2024, 2760, 012038. [Google Scholar] [CrossRef]

- Zhaohui, G.; Arman, S.; Bopaya, B. A framework of tolerance specification for freeform point clouds and capability analysis for reverse engineering processes. Int. J. Prod. Res. 2022, 60, 7475–7491. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, H.; Weihong, W.; Yehua, S.; Xin, J. Processing of multitemporal 3D point cloud data for use in reconstructing historical geographic scenarios. Sens. Mater. 2022, 34, 4551. [Google Scholar] [CrossRef]

- Harmening, C.; Butzer, R. Improving the approximation quality of tensor product B-spline surfaces by local parameterization. J. Appl. Geod. 2024, 18, 575–596. [Google Scholar] [CrossRef]

- Hao, J.; He, D.; Li, Z.; Hu, P.; Chen, Y.; Tang, K. Efficient cutting path planning for a non-spherical tool based on an iso-scallop height distance field. Chin. J. Aeronaut. 2024, 37, 496–510. [Google Scholar] [CrossRef]

- Cervone, A.; Manservisi, S.; Scardovelli, R.; Sirotti, L. Computing interface curvature from height functions using machine learning with a symmetry-preserving approach for two-phase simulations. Energies 2024, 17, 3674. [Google Scholar] [CrossRef]

- Gao, X.; Li, R.; Wang, B.; Li, W.; Zhao, Z. Automatic partitioning algorithm for profile feature processing of aircraft structural components. J. Aeronaut. 2021, 42, 32–42. [Google Scholar]

- Duan, P. Research on Robot Trajectory Optimization for Polishing Small-Curvature Freeform Surfaces. Master’s Thesis, Anhui University of Engineering, Wuhu, China, 2023. [Google Scholar]

- Jia, R.; Li, H.; Wei, F.; Xu, Y.; Zhou, Y. Polar weld seam recognition and robot trajectory generation technology based on 3D point cloud. Trans. China Weld. Inst. 2024, 45, 50–54. [Google Scholar]

- Yang, H.L. Adaptive robotic trajectory generation and control strategy for complex curved surface welding. Off. Autom. 2024, 29, 62–64. [Google Scholar]

- Duan, H.Y.X.; Zhang, Y.; Chen, H.R.; Zhang, Q.Y. Review on trajectory planning and optimization of industrial robots. Agric. Equip. Veh. Eng. 2023, 61, 54–57. [Google Scholar]

| Norm | Original Value | Optimal Value | Improvement Rate |

|---|---|---|---|

| Total length of path (mm) | 1514.60 | 1495.61 | 1.3% |

| Average curvature (1/mm) | 0.06 | 0.05 | 18.1% |

| Maximum curvature (1/mm) | 26.00 | 6.81 | 73.8% |

| Number of angle overruns | 400.00 | 126.00 | 68.5% |

| Track point | 15,858.00 | 500.00 | 96.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, X.; An, J.; Ma, X. Study on Trajectory Planning for Polishing Free-Form Surfaces of XY-3-RPS Hybrid Robot. Actuators 2025, 14, 269. https://doi.org/10.3390/act14060269

Song X, An J, Ma X. Study on Trajectory Planning for Polishing Free-Form Surfaces of XY-3-RPS Hybrid Robot. Actuators. 2025; 14(6):269. https://doi.org/10.3390/act14060269

Chicago/Turabian StyleSong, Xiaozong, Junfeng An, and Xingwu Ma. 2025. "Study on Trajectory Planning for Polishing Free-Form Surfaces of XY-3-RPS Hybrid Robot" Actuators 14, no. 6: 269. https://doi.org/10.3390/act14060269

APA StyleSong, X., An, J., & Ma, X. (2025). Study on Trajectory Planning for Polishing Free-Form Surfaces of XY-3-RPS Hybrid Robot. Actuators, 14(6), 269. https://doi.org/10.3390/act14060269