1. Introduction

In recent decades, VSAs have emerged as a significant technological advancement in robotic engineering and advanced mechanical systems that operate in dynamic and unstructured environments [

1,

2]. In contrast to traditional rigid stiffness actuators, VSAs can modulate their rigidity in real-time response to external stimuli or designated tasks [

3,

4]. This capability improves the flexibility and adaptability of systems, providing significant benefits in terms of safety, energy efficiency, and precision. VSAs have many applications, including soft robotics, industrial manipulation, and medical rehabilitation. These fields are characterized by continuously varying operational conditions that require innovative technical solutions [

3].

Stiffness is a mechanical property that indicates how much a system resists deformation when subjected to external forces. In traditional applications, constant stiffness actuators effectively perform tasks under relatively stable conditions [

5]. However, fixed stiffness can significantly limit the ability to adapt to changing conditions in dynamic or unpredictable environments. This can lead to potential device damage, structural failures, or risks to human operators. VSAs address this problem by using mechanisms that adjust their stiffness, allowing them to increase or decrease resistance based on specific requirements [

3,

5]. This adaptability makes VSAs essential when safety and flexibility are critical, such as handling delicate materials or reducing impact forces in collaborative robotic systems [

6,

7].

The operation of VSAs is based on mechanical principles and materials designed to facilitate the active modulation of their stiffness. One prominent approach is particle jamming, in which granular materials are used within flexible membranes. The particles are compacted by applying vacuum or pneumatic pressure, significantly increasing stiffness [

8,

9,

10]. This method is popular in soft robotics for its mechanical simplicity and the ability to offer a wide range of stiffness with rapid response times [

8,

9,

11]. It combines flexibility and structural support in a unique design, which is ideal for manipulation tasks. Another approach involves magnetorheological materials consisting of metal particles suspended in a fluid and adjusting their mechanical properties in a magnetic field. The particles align under the magnetic field conditions, increasing stiffness, which is particularly useful in applications requiring fast and precise adjustments, such as medical devices and smart suspension systems [

3,

12]. Additionally, some VSA designs opt for variable geometry, using mechanical structures whose stiffness can be modulated through changes in their geometric configuration. Mechanisms such as adjustable springs or laminar structures allow for a smooth transition between different stiffness states, which proves to be effective in robotic systems for dynamic tasks such as adaptive walking or handling heavy objects [

3,

12].

The integration of textiles into VSAs is an exciting and innovative area of research, especially within wearable robotics and soft exoskeletons [

13,

14,

15]. These advances in variable stiffness technology, particularly those that use the principle of layer jamming, have shown great promise in being incorporated into fabric-based systems. This integration balances conflicting requirements for strength, comfort, and safety in various applications [

3,

9,

16]. A prime example of this technology is a modular band designed with variable stiffness capabilities that employs a mechanism known as layer locking. This mechanism enables the significant modulation of stiffness by applying negative pressure. The band is constructed from layers that are adhered to and encapsulated in a composite fabric composed of elastane, a stretchable material, and silicone, providing durability and flexibility [

13].

In the context of anticipated advances, materials characterized by variable stiffness are projected to achieve significant progress in addressing the dilemma of maintaining an optimal balance between adequate compliance and maximum load-bearing capacity [

17]. Such breakthroughs possess the potential to reveal novel perspectives within the sectors of aerospace engineering, portable electronic devices, and various industrial applications [

3].

Several recent studies have explored the integration of chain mail structures into jamming-based devices. Shah et al. [

9] demonstrated “jamming skins” composed of 3D-printed chain links, enabling controllable surface stiffness in soft systems. Wang et al. [

10] introduced chain mail-based textiles with tunable stiffness properties for adaptive clothing and protective gear. Hu et al. [

18] implemented chain mail jamming in a soft robotic finger, demonstrating effective grasping and shape adaptation in unstructured manipulation tasks. In particular, their work validated the feasibility of chain mail-based jamming systems in robotic actuators but focused on a single link geometry and fixed configuration, leaving questions regarding topological influence. Xu et al. [

19,

20] conducted an in-depth experimental and numerical investigation of vacuum-confined chain mail sheets, demonstrating up to a 20-fold increase in bending stiffness. However, their study did not explore integration into soft robotic actuators, nor did it evaluate stiffness modulation in segmented or multichamber architectures.

Yang et al. [

11] and Narang et al. [

16] expanded the design space by proposing hybrid systems that combine granular and structural jamming, further demonstrating the versatility of jamming-based mechanisms.

Despite these advances, the current literature reveals important gaps. Most studies use a single chain mail topology, typically square or hexagonal, without analyzing how geometric variation affects stiffness. Moreover, there is a lack of systematic comparative evaluations of multiple patterns under controlled conditions, and very few efforts attempt to establish predictive models linking link geometry to mechanical performance. Furthermore, many existing systems are not designed to isolate the effect of chain mail properties due to overlapping actuation modalities or complex integration, which limits their adaptability and versatility [

3].

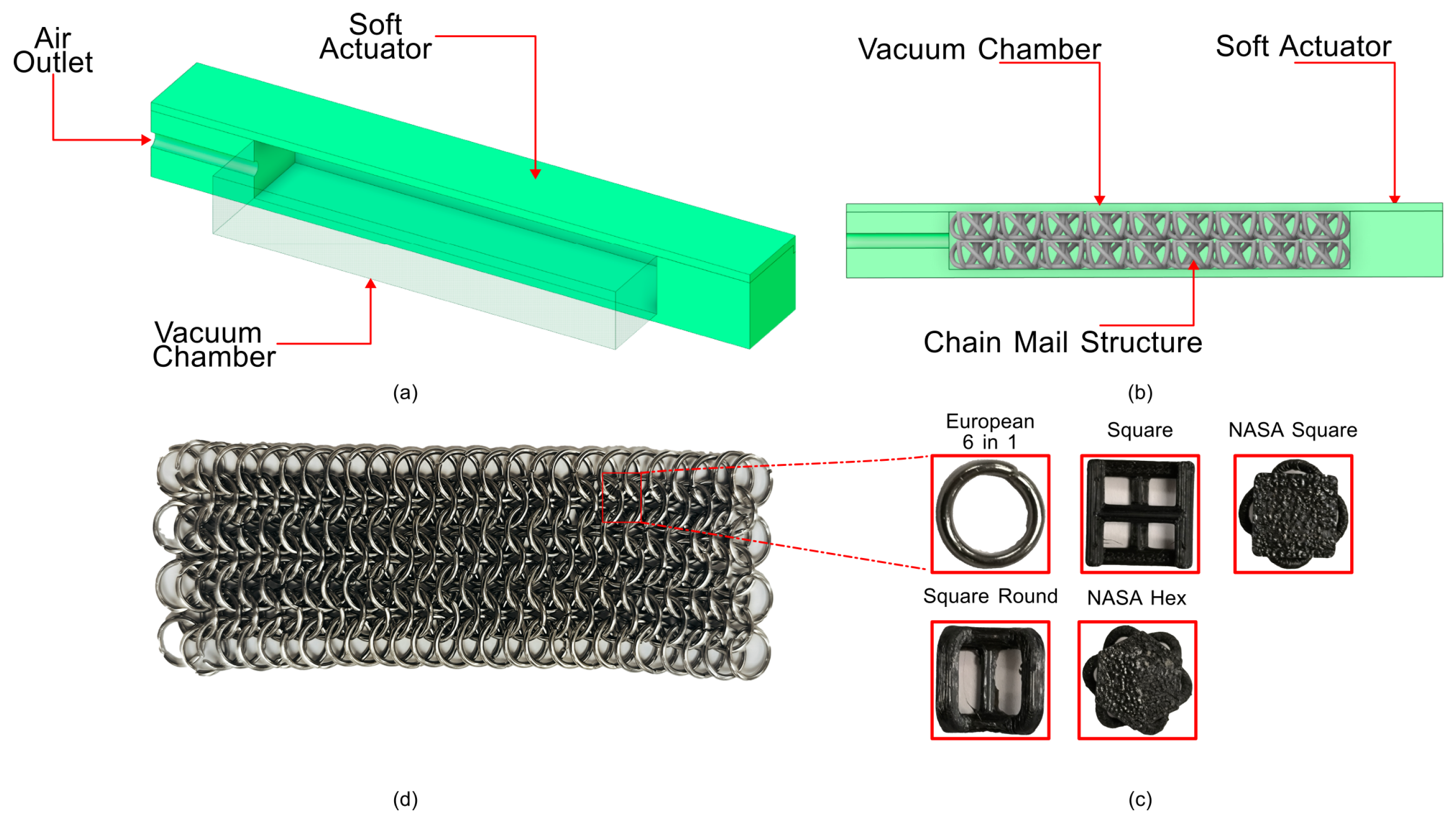

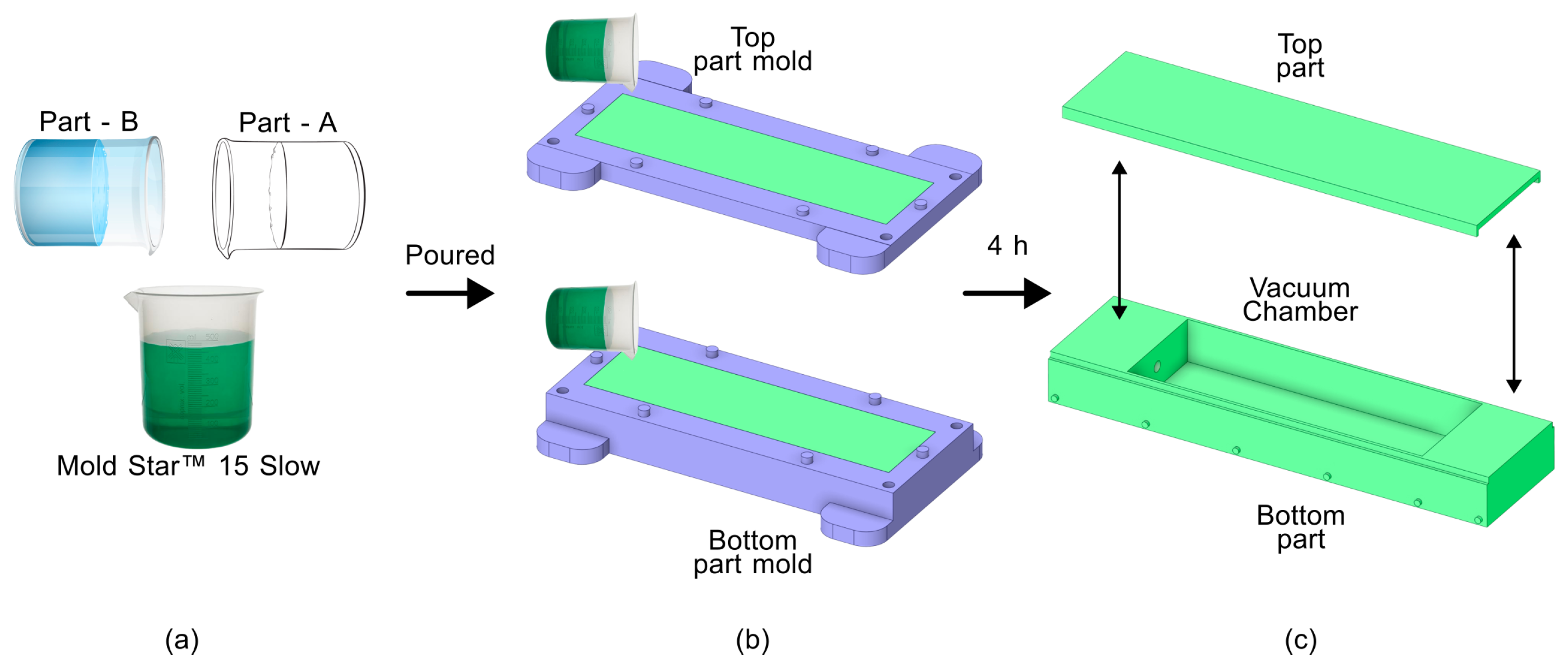

In this study, we illustrate how using a chain mail structure with various link topologies can adjust the stiffness of a VSA by applying a vacuum. We present a design for a VSA that utilizes the interlocking of the chain mail fabric link structure to enable changes in stiffness and deformation modes. Elastomeric VSAs were created using a vacuum system, which allowed us to increase or decrease the number of interlockings and, consequently, the variation in stiffness. We explored five different chain mail pattern topologies: European 6-in-1, square, NASA square, NASA hexagonal, rounded square, and a version without the chain mail structure as a proof of concept.

Our work introduces a method for incorporating a chain mail structure into VSAs that allows for rapid variation in stiffness

Figure 1. A chain mail structure can be quickly manufactured using additive manufacturing (AM) technologies to meet design requirements, highlighting the potential for greater exploration at the intersection of soft robotics and materials engineering.

This work contributes to understanding stiffness modulation in soft systems by experimentally exploring how different topologies of chain mail structures respond to varying vacuum levels. It presents a comparative analysis of five geometries under uniform test conditions and offers a quantitative framework for evaluating the influence of topology and vacuum pressure on mechanical behavior. In addition, the study outlines design recommendations for integrating these structures into soft actuators and wearable robotic systems. By connecting soft robotic actuation with structured mesh mechanics, the findings demonstrate the potential of rapidly manufacturable, mechanically tunable structures for applications in exoskeletons, orthoses, and portable assistive devices.

3. Results

3.1. Experimental Evaluation of the Stiffness Actuator

The versatility of the proposed chain mails allows the exploration of a wide variety of designs, which opens up the possibility of optimizing the mechanical response of the actuator. The following section will present the different chain mail configurations used in the analysis and evaluate their stiffness under controlled conditions. Based on these results, the most suitable model was selected for future developments, considering its structural performance and its response to the application of external loads.

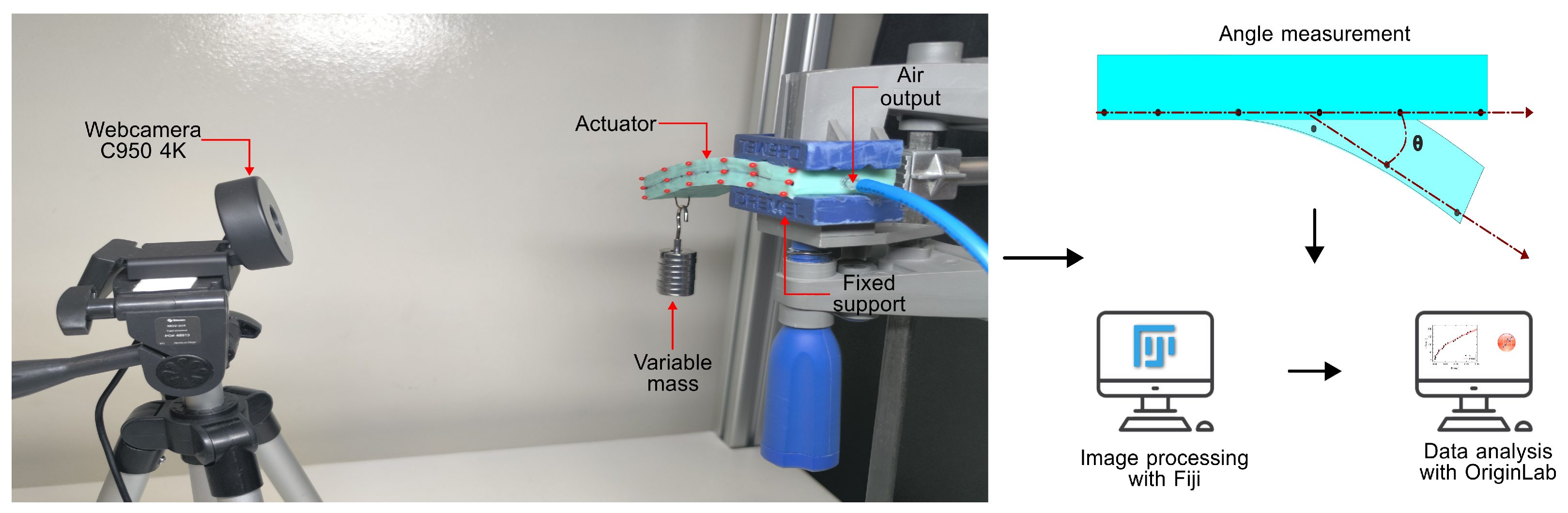

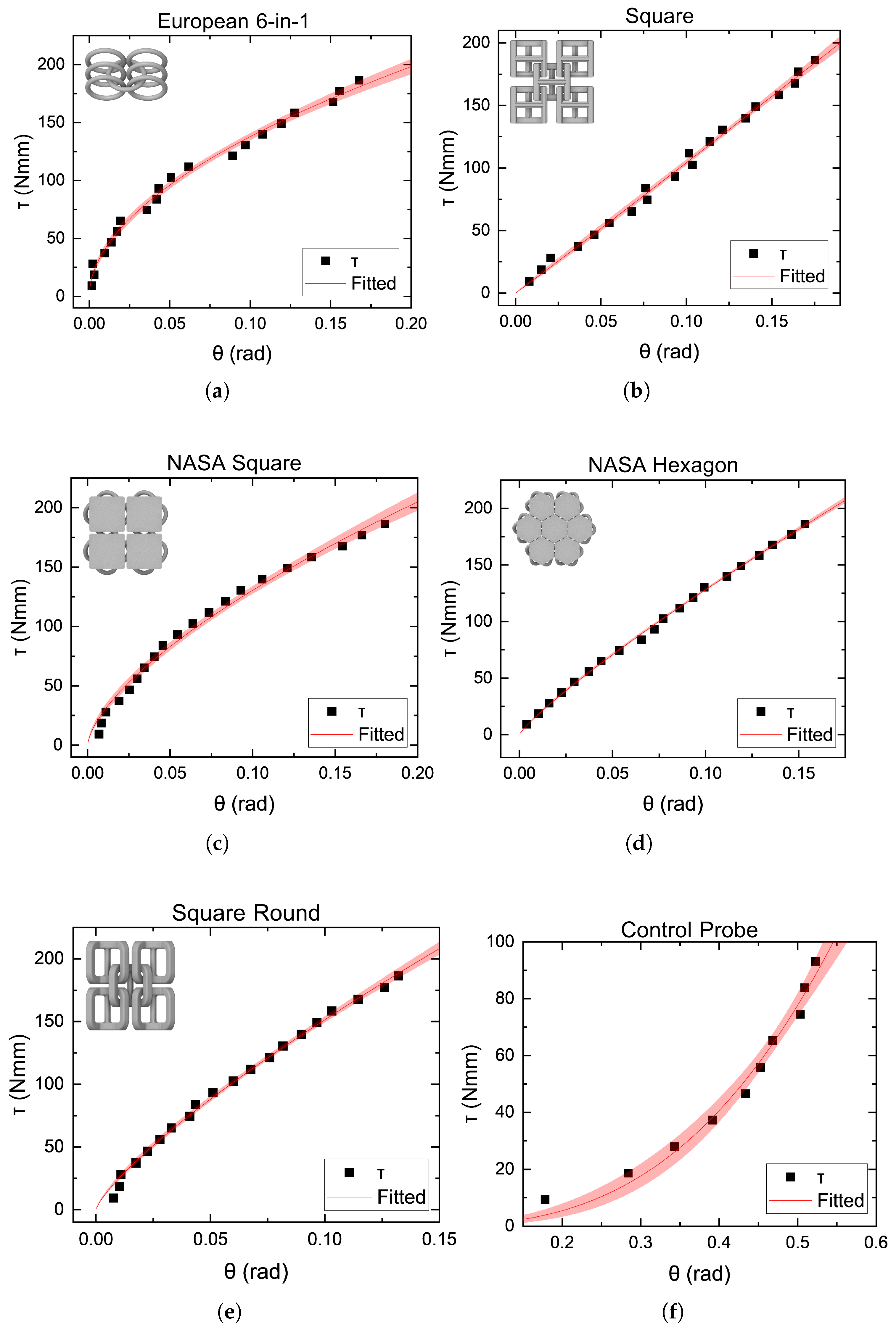

During the development of the experimental tests, the deflection angles of the samples were determined by applying a bending load to each sample. The results for each sample are presented below, including the stiffness value corresponding to the pressure level supplied by the vacuum pump. To characterize the behavior of the manufactured actuators, a model was generated that describes the mechanical response of the samples subjected to vacuum pressure and external load. As a result, six behavior curves were determined for each sample studied, allowing a comparative analysis of their performance and validating the influence of the chain mail configuration on the final stiffness of the system.

Figure 6 summarizes the curves determined. The Y-axis corresponds to the applied torque (

, in N mm), while the X-axis represents the measured relative angle (rad). This representation allows for the visualization of the relationship between the stiffness of the actuator and the chain mail configuration, facilitating comparison among the evaluated models.

All configurations that include chain mail were observed to show an increase in deformation resistance compared to the control test, confirming the influence of interconnected links on actuator load capacity. In contrast, the configuration without chain mail exhibited a more flexible response and behaved similarly to an elastomeric material without structural reinforcement. To mathematically model the relationship between torque and the angle of deformation, the experimental data were fitted to an allometric model expressed as:

where

is the applied torque,

is the deformation angle, and

k and

n are the fitting parameters determined by non-linear regression. Origin performed the fitting using the Levenberg–Marquardt algorithm, which iteratively minimizes the residuals between experimental and model values. This power-law relationship captures the nonlinear stiffening behavior observed in chain mail-reinforced configurations, highlighting the contribution of mechanical interlocking to torque resistance. From this model, the effective stiffness of the system was derived as:

For a more accurate comparison between configurations, the effective stiffness was calculated, taking the average value of the data obtained in the final phase of the tests, that is, when the actuator reached a stable deformation state. This criterion allowed for the evaluation of the mechanical response under prolonged loading conditions, which more realistically represented the performance of the actuator in practical applications.

3.2. Comparison of Stiffness for Different Configurations

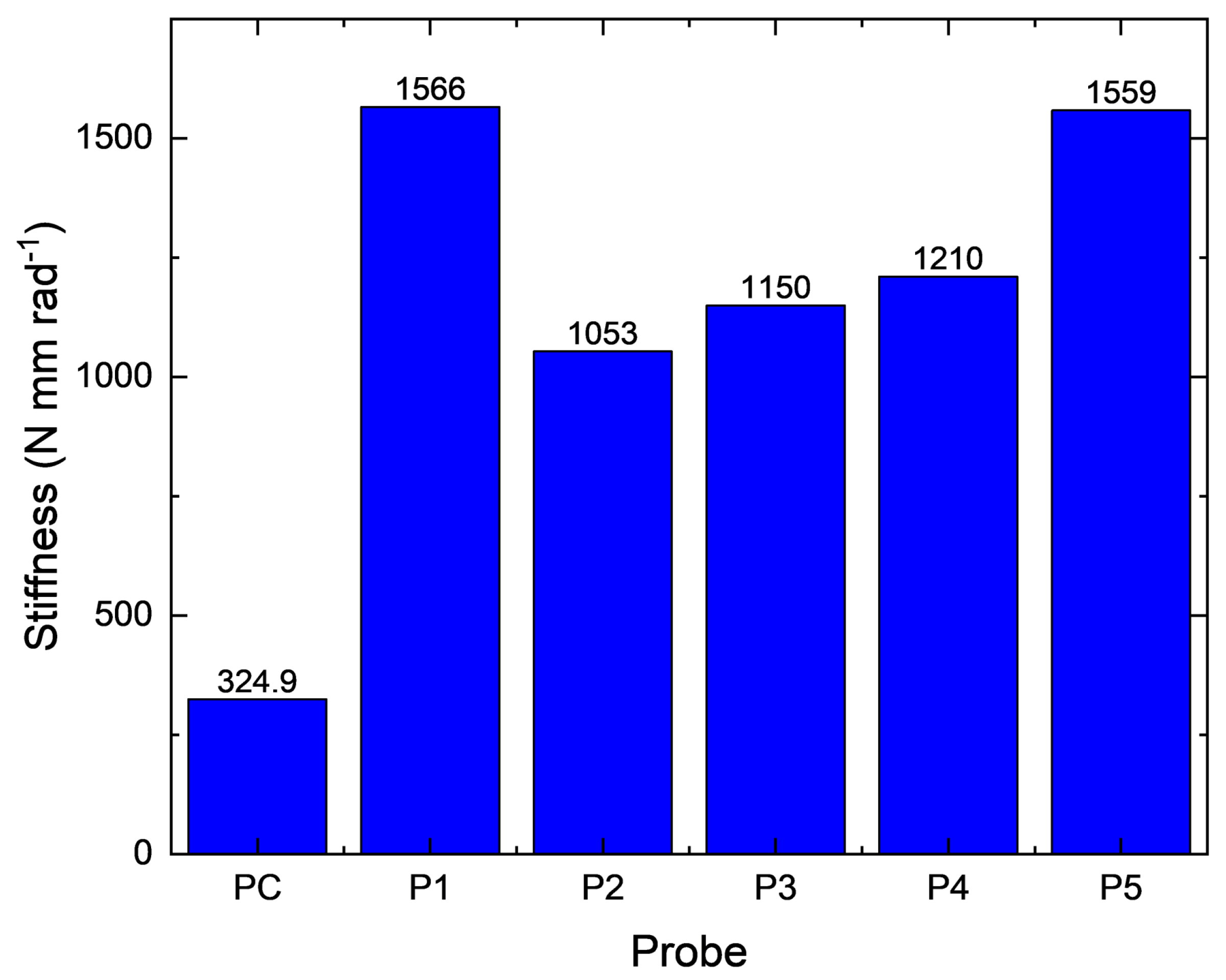

Table 2 presents the effective stiffness values obtained for each of the six evaluated configurations, which were differentiated according to the type of chain mail used. The control test (PC) corresponded to the actuator without chain mail. In contrast, chain mail configurations were classified as P1 (European 6-in-1), P2 (square), P3 (NASA square), P4 (NASA hexagon) and P5 (rounded square).

The experimental results show that the P1 configuration exhibited the highest effective stiffness, reaching a value of 1566 N mm rad−1. This behavior can be attributed to the highly interconnected nature of this chain mail, where each link connects to six neighbors, forming a dense structure that effectively restricts deformation under load conditions. The P5 configuration showed similar stiffness, with 1559 N mm rad−1, indicating that including rounded links in a square arrangement significantly improves stiffness.

The P2, P3, and P4 configurations exhibited intermediate stiffness values in 1053, 1150, and 1210 N mm rad−1, respectively. Although these values did not reach the stiffness levels observed in P1 and P5, they improved significantly compared to the control test. The variation in the response of these configurations suggests that the degree of interconnection of the links and the chain mail density play a crucial role in modulating the stiffness of the actuator.

However, the control test configuration (PC) showed the lowest effective stiffness, with 324.9 N mm rad−1. This result was anticipated because, in the absence of a structural chain mail, the actuator stiffness depends solely on the mechanical properties of the elastomer used in its manufacturing. Material selection significantly impacts actuator performance. The European 6-in-1 configuration is stainless steel, offering high stiffness and wear resistance but adding weight and assembly complexity. Others use PLA, which is lightweight and 3D printable, facilitating prototyping but with lower strength and durability. These factors are crucial in the interpretation of the results and the evaluation of practical applications.

Figure 7 presents the same results in a bar diagram, allowing for a clear visualization of the differences in stiffness between configurations. The stiffness is observed to increase significantly in all configurations that incorporate chain mail, with variations depending on the design of the links and their geometric distribution.

The stiffness values obtained in this study significantly exceed those reported in previous research on VSAs that utilize analogous physical principles for stiffness modulation. For example, in the work of Singh et al. (2022) [

22] on modular cellular robots, various mesh topologies were analyzed to assess their passive stiffness. Although the authors concluded that stretching-dominated configurations exhibited greater stiffness than bending-dominated ones, the specific values were not detailed, limiting direct quantitative comparison. In the study by Allen et al. (2020) [

23], variable stiffness structures were proposed that incorporate smart materials and geometric patterns, but no specific numerical stiffness values were provided, making it difficult to evaluate their performance in relation to our work. Likewise, Wolf et al. (2016) [

24] conducted a comprehensive review of VSAs and their modulation mechanisms, highlighting their potential in efficiency and adaptability but without reporting applicable quantitative data for direct comparison.

Since our stiffness values presented were measured experimentally, it can be stated that the P1 configuration (European 6-in-1) and P5 (rounded square), with values of up to 1566 N mm rad−1, represent a significant contribution to the design of actuators with lattice structures. This shows that including structural lattices within flexible actuators effectively increases their load-bearing capacity, providing a clear framework for future developments in VSAs.

4. Conclusions

The results obtained in this study confirm that the use of chain mail structures within a VSA significantly improves its ability to resist deformations. The P1 and P5 configurations were shown to be the most effective, achieving an increase in stiffness of up to 382% compared to the chain mail-free configuration, highlighting the positive impact of these structural designs.

When comparing these values with previous works, the results obtained in this study far exceed those reported in similar research. In studies such as that of Singh et al. (2022) [

22] on modular cellular robots, different mesh topologies were explored, concluding that configurations dominated by stretching exhibit greater rigidity. However, this study did not include concrete experimental values, making a quantitative comparison difficult. Other works, such as those of Allen (2020) [

23] and Wolf et al. (2016) [

24], have addressed the design of VSAs from a conceptual and numerical perspective, highlighting the advantages of these devices for adaptability. However, their research did not present a detailed experimental characterization of the stiffness achieved, which reinforces the relevance of the present study by providing concrete measurements obtained under controlled conditions.

Despite the favorable results, this study presents some limitations that must be addressed in future research. First, the characterization was performed under static conditions, without considering the effect of dynamic loads or repetitive deformation cycles. For a more comprehensive assessment, it is recommended to perform additional tests that include mechanical fatigue analysis and transient actuator behavior. While this study emphasized static stiffness, dynamic performance is crucial for practical use. Future research should explore the actuator response to cyclic loads, including fatigue resistance and recovery. Preliminary tests indicate that chain mail interlinking might cause hysteresis, affecting long-term responsiveness and control in repetitive tasks.

Furthermore, it would be important to complement these findings with finite element analysis (FEA), allowing for a more detailed modeling of the internal stress distribution and the interaction between the chain mail and the elastomeric matrix. This would contribute to optimizing the structural design of the actuator, enabling the better prediction of its behavior under different operating conditions. Furthermore, FEA could provide more insight into the internal stress distribution within the elastomer and the localized contact forces between chain mail elements. This modeling approach would allow the better prediction of stiffness behavior, optimization of link geometries, and identification of failure points under dynamic conditions.

It is also necessary to consider the implementation of these actuators in practical applications, such as exoskeletons and robotic manipulation systems. Their integration into real devices would allow for their performance in interaction with external forces to be evaluated, validating their effectiveness in dynamic environments. Future work should integrate this actuator design into wearable systems such as soft exoskeletons or adaptive orthoses. The variable stiffness of chain mail structures can enhance human motion, improving comfort and adaptability in joint support, rehabilitation, and industrial lifting tasks. Additionally, exploring new chain mail configurations, combining different geometric patterns and materials with anisotropic properties, could further enhance the ability of the actuator to adapt to various load conditions.