Hybrid Fault-Tolerant Control in Cooperative Robotics: Advances in Resilience and Scalability

Abstract

1. Introduction

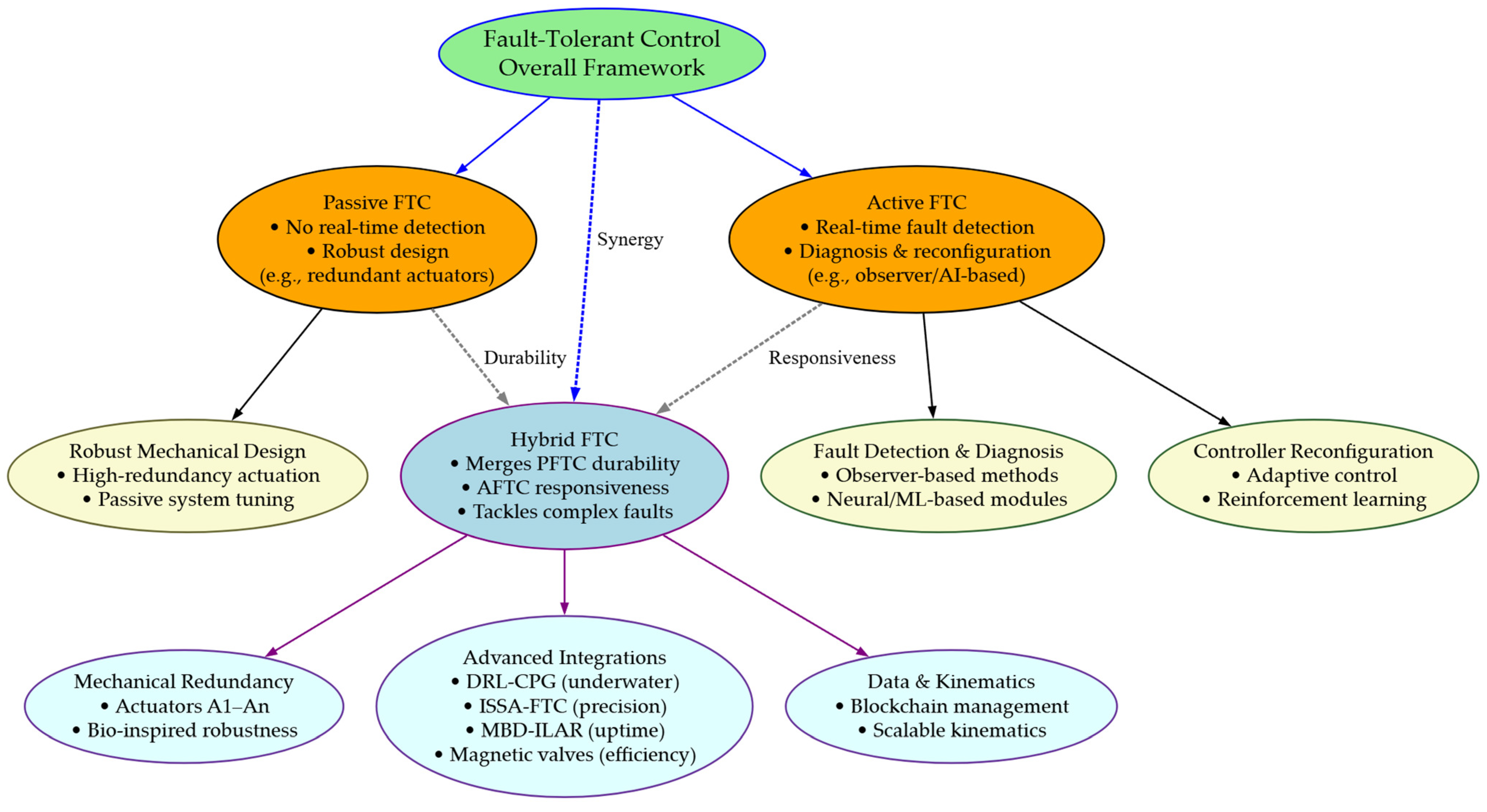

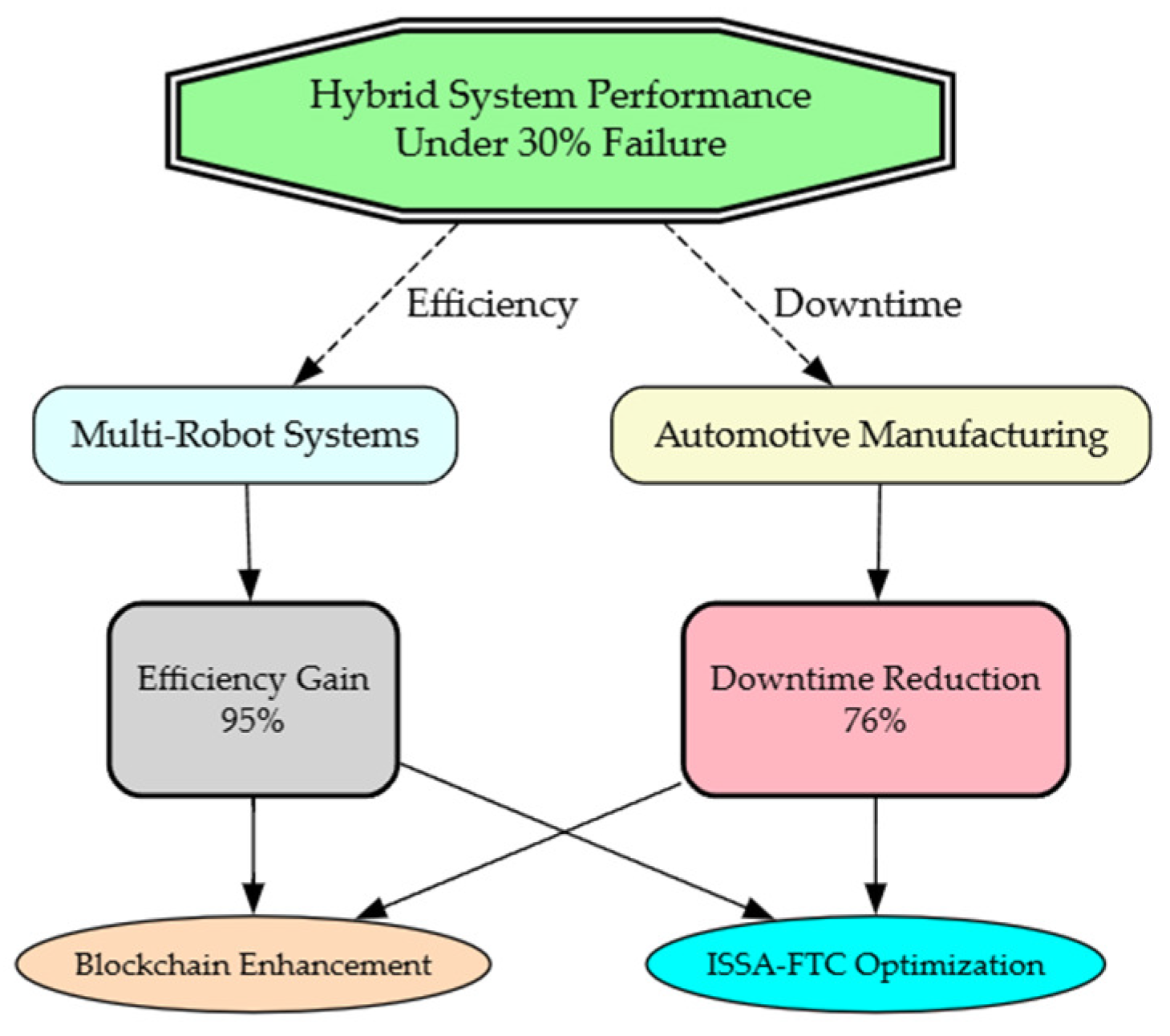

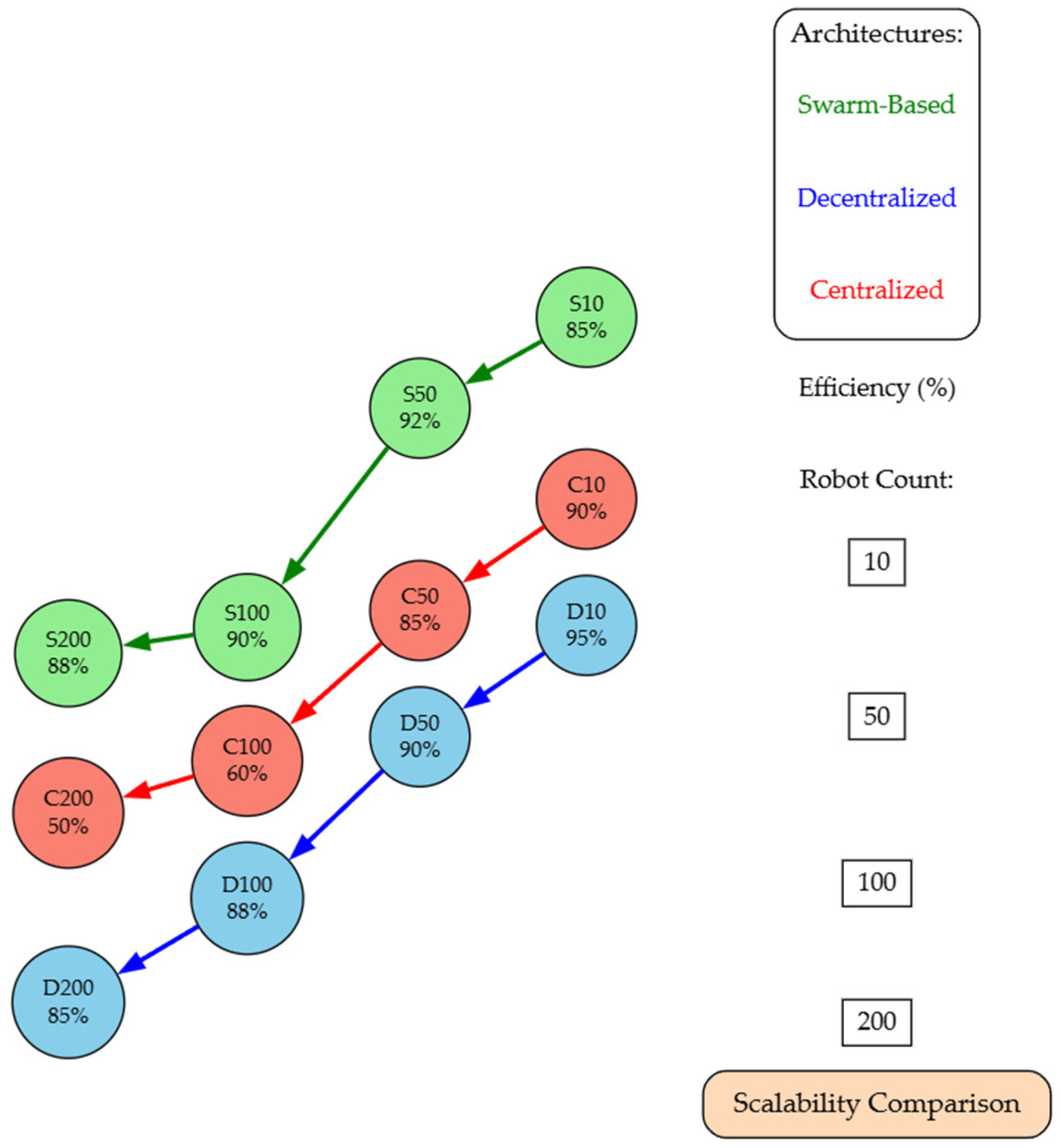

2. Fault-Tolerant Control: State of the Art

Key Technical Methods in Hybrid FTC

3. Redundancy Strategies in Cooperative Robotic Systems

4. Innovations in Learning-Based Fault Tolerance

5. Hybrid Mechanical-Electronic Systems

6. Challenges and Future Directions

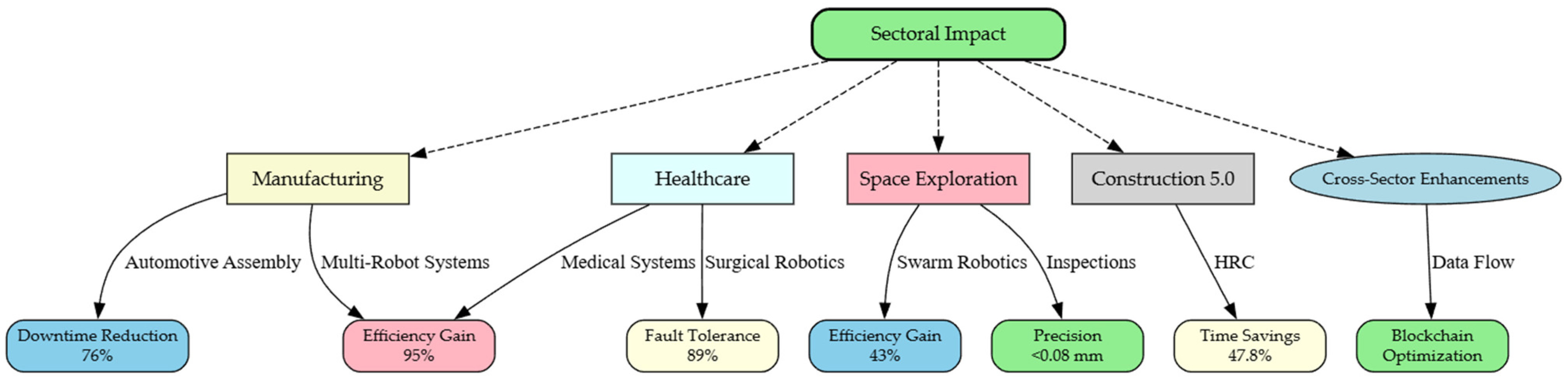

7. Discussion

Safety and Ethical Considerations

8. Conclusions and Future Perspectives

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFTC | Active Fault-Tolerant Control |

| AI | Artificial Intelligence |

| CNN | Convolutional Neural Network |

| CPG | Central Pattern Generators |

| DoF | Degrees of Freedom |

| DRL | Deep Reinforcement Learning |

| DRL-CPG | Deep Reinforcement Learning with Central Pattern Generators |

| DTs | Digital Twins |

| FDD | Fault Detection and Diagnosis |

| FPGAs | Field Programmable Gate Arrays |

| FTC | Fault-Tolerant Control |

| FT-NCBFs | Fault-Tolerant Neural Control Barrier Functions |

| GPU | Graphics Processing Unit |

| HRA | High-Redundancy Actuation |

| HRC | Human–Robot Collaboration |

| IJSS | International Journal of Systems Science |

| ILAR | Inching-Locomotion Adaptive Robustness |

| IMUs | Inertial Measurement Units |

| ISSA | Improved Sparrow Search Algorithm |

| LiDAR | Light Detection and Ranging |

| MBD-ILAR | Multibody Dynamics-Inching Locomotion Adaptive Robustness |

| MLP | Multi-Layer Perceptron |

| MPC | Model Predictive Control |

| NABAS | Non-linear Activated Beetle Antennae Search |

| PDQ | Probabilistic Differential Quadrature |

| PFTC | Passive Fault-Tolerant Control |

| RBF | Radial Basis Function |

| RL | Reinforcement Learning |

| ReLU | Rectified Linear Unit |

| RNN | Recurrent Neural Network |

| UAV | Unmanned Aerial Vehicle |

| VSAs | Variable Stiffness Actuators |

References

- Milecki, A.; Nowak, P. Review of Fault-Tolerant Control Systems Used in Robotic Manipulators. Appl. Sci. 2023, 13, 2675. [Google Scholar] [CrossRef]

- Lei, Y.; Liu, H.; Li, N.; Cao, J.; Qiao, Y.; Wang, H. Condition Monitoring and Fault Diagnosis of Industrial Robots: A Review. Sci. China Technol. Sci. 2025, 68, 1110301. [Google Scholar] [CrossRef]

- Iriarte, I.; Gorostiza, J.; Iglesias, I.; Lasa, J.; Calvo-Soraluze, H.; Sierra, B. An Overactuated Aerial Robot Based on Cooperative Quadrotors Attached Through Passive Universal Joints: Modeling, Control and 6-DoF Trajectory Tracking. Robot. Auton. Syst. 2024, 180, 104761. [Google Scholar] [CrossRef]

- Cai, W.; Chen, H.; Zhang, M. A Survey on Collaborative Hunting with Robotic Swarm: Key Technologies and Application Scenarios. Neurocomputing 2024, 598, 128008. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, L.; Zhao, D.; Sun, Y.; Lei, J.; Wang, Q. A dual-robot cooperative arc welding path planning algorithm based on multi-objective cross-entropy optimization. Robot. Comput. Integr. Manuf. 2024, 89, 102760. [Google Scholar] [CrossRef]

- Barth, A.; Ma, O. Cooperative Behavior of a Heterogeneous Robot Team for Planetary Exploration Using Deep Reinforcement Learning. Acta Astronaut. 2024, 214, 689–700. [Google Scholar] [CrossRef]

- Dhanda, M.; Rogers, B.A.; Hall, S.; Dekoninck, E.; Dhokia, V. Reviewing Human-Robot Collaboration in Manufacturing: Opportunities and Challenges in the Context of Industry 5.0. Robot. Comput. Integr. Manuf. 2025, 93, 102937. [Google Scholar] [CrossRef]

- Gong, J.; Ma, Y.; Jiang, B.; Zhang, Y.; Guo, L. An Adaptive Fault-Tolerant Control Scheme for Heterogeneous Multiagent Systems. IEEE Trans. Syst. Man Cybern. Syst. 2025, 55, 1264–1276. [Google Scholar] [CrossRef]

- Tian, Z.; Guo, X.; Ma, W.; Xue, X. Research on Kiwifruit Harvesting Robot Worldwide: A Solution for Sustainable Development of Kiwifruit Industry. Smart Agric. Technol. 2025, 10, 100792. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Chen, Z.; Han, Q.-L. A Fault Diagnosis Method for Quadruped Robot Based on Hybrid Deep Neural Networks. IEEE Trans. Ind. Inform. 2024, 20, 1–10. [Google Scholar] [CrossRef]

- Le, Q.D.; Yang, E. Adaptive Fault-Tolerant Tracking Control for Multi-Joint Robot Manipulators via Neural Network-Based Synchronization. Sensors 2024, 24, 6837. [Google Scholar] [CrossRef]

- Zhao, R.; Tao, S.; Li, P. Safety-Efficiency Integrated Assembly: The Next-Stage Adaptive Task Allocation and Planning Framework for Human–Robot Collaboration. Robot. Comput. Integr. Manuf. 2025, 94, 102942. [Google Scholar] [CrossRef]

- Du, W.; Yi, G.; Omisore, O.M.; Duan, W.; Akinyemi, T.O.; Chen, X.; Liu, J.; Lee, B.-G.; Wang, L. Analyzing Surgeon–Robot Cooperative Performance in Robot-Assisted Intravascular Catheterization. IEEE Trans. Hum. Mach. Syst. 2024, 54, 698–710. [Google Scholar] [CrossRef]

- Moshayedi, A.J.; Khan, A.S.; Geng, K.; Hu, J.; Kolahdooz, A. Advancing Agricultural Practices: Analyzing the Role of Robotics in Corn Farming. Int. J. Eng. Trans. A Basics 2025, 38, 1517–1532. [Google Scholar] [CrossRef]

- Yoo, J.; Chung, G.; Park, Y. Bio-Inspired Miniaturized Magnetic Heart Valve System for Superior Performance. Adv. Mater. 2025, 2419504, in press. [Google Scholar] [CrossRef]

- Wang, K.; Sang, G.-Y.; Huang, L.-Z.; Li, S.-H.; Guo, J.-W. The Effectiveness of Educational Robots in Improving Learning Outcomes: A Meta-Analysis. Sustainability 2023, 15, 4637. [Google Scholar] [CrossRef]

- Hameed, I.; Chao, X.; Navarro-Alarcon, D.; Jing, X. Deep Reinforcement Learning Enabling a BCFbot to Learn Various Undulatory Patterns. Ocean Eng. 2025, 320, 120322. [Google Scholar] [CrossRef]

- Zhang, R.; Choi, H.-S.; Jung, D.; Cho, H.; Anh, P.H.N.; Vu, M.T. Fixed-Time Control with an Improved Sparrow Search Algorithm for Robotic Arm Performance Optimization. Appl. Sci. 2024, 14, 10096. [Google Scholar] [CrossRef]

- Cornejo, J.; Sierra, J.E.; Gomez-Gil, F.J.; Gallego, J.A.; Biancardi, C.M.; Weitzenfeld, A. Multibody System Dynamics for Bio-Robotic Design and Simulation Based on Inching-Locomotion Caterpillar’s Gait: MBD-ILAR Method. Bioinspir. Biomim. 2025, 20, 016021. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, S. Cooperative Object Transport by Two Robots Connected with a Ball-String-Ball Structure. IEEE Robot. Autom. Lett. 2024, 9, 4313–4320. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, T.; Zhao, Y.; Yu, S.; Zhou, F. Adaptive Dynamic Programming-Based Multi-Fault Tolerant Control of Reconfigurable Manipulator with Input Constraint. Complex Intell. Syst. 2024, 10, 8341–8353. [Google Scholar] [CrossRef]

- Wei, J.; Pan, Y.; Sun, L.; Shang, H.; Chen, X. A Novel Redundant Cooperative Control Strategy for Robotic Pollination. Comput. Electron. Agric. 2024, 220, 108846. [Google Scholar] [CrossRef]

- Estrada, M.A.; Fridman, L.; Moreno, J.A. Passive Fault-Tolerant Control via Sliding-Mode-Based Lyapunov Redesign. IEEE Trans. Autom. Control 2024, 69, 6777–6788. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Q.; Xu, H.; Zhu, H.; Cao, Y.; Cao, Y.; Pan, G. Development and Three-Dimensional Modeling of a Bionic Robotic Fish with Pectoral Fins. Ocean Eng. 2025, 321, 120393. [Google Scholar] [CrossRef]

- Dong, Z.-Y.; Xinyi, Y.; Wei, Y.; Zhou, L.; Ou, L. A Novel Data-Driven-Based Anti-Disturbance Fault-Tolerant Control Method with Application to Franka-Panda Robot. IEEE Trans. Instrum. Meas. 2024, 73, 3540311. [Google Scholar] [CrossRef]

- Mazare, M.; Taghizadeh, M.; Ghaf-Ghanbari, P.; Davoodi, E. Robust Fault Detection and Adaptive Fixed-Time Fault-Tolerant Control for Quadrotor UAVs. Robot. Auton. Syst. 2024, 179, 104747. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Li, T.; Mao, Z. Distributed Observer-Based Close Formation Control for UAV Swarm under Outside Disturbances and Wake Interferences. J. Frankl. Inst. 2024, 361, 106651. [Google Scholar] [CrossRef]

- Wang, C.; Yang, L.; Chen, Y.; Lai, G. Adaptive Fault-Tolerant Control for Uncalibrated Camera–Robot System with Multiple Uncertainties. J. Frankl. Inst. 2024, 361, 107048. [Google Scholar] [CrossRef]

- Ma, T.; Hu, F.; Su, X.; Shen, C.; Ma, X. Adaptive Neural Cooperative Control of Multirobot Systems with Input Quantization. IEEE Trans. Cybern. 2024, 54, 5518–5528. [Google Scholar] [CrossRef]

- Xia, Y.; Liu, Y.; Sun, W. A New Fault Tolerant Strategy Using Adaptive Time Delay Estimation for Robot Manipulators with Actuator Faults. Nonlinear Dyn. 2025, 113, 123–145. [Google Scholar] [CrossRef]

- Yamamoto, T.; Fukuda, M.; Yakushigawa, T.; Okuchi, Y.; Taura, K.; Terajima, H. RoboLap Cooperative Technique for Lymphadenectomy in Robotic Surgery for Right-Sided Colon Cancer—A Video Vignette. Color. Dis. 2024, 26, 1779–1781. [Google Scholar] [CrossRef]

- Wild, S.; Zeng, T.; Mohammad, A.; Billingham, J.; Axinte, D.; Dong, X. Efficient and Scalable Inverse Kinematics for Continuum Robots. IEEE Robot. Autom. Lett. 2024, 9, 375–381. [Google Scholar] [CrossRef]

- Pan, Q.; Ma, B.; An, T.; Dong, B.; Zhu, M.; Li, Y. Design and Experimental Verification: Health Indicator-Based Decentralized Optimal Fault-Tolerant Control for Modular Robot Manipulators via Adjustable Event-Triggered Mechanism. Expert Syst. Appl. 2024, 243, 122944. [Google Scholar] [CrossRef]

- Lou, S.; Zhang, Y.; Tan, R.; Lv, C. A Human-Cyber-Physical System Enabled Sequential Disassembly Planning Approach for a Human-Robot Collaboration Cell in Industry 5.0. Robot. Comput. Integr. Manuf. 2024, 87, 102706. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, K.; Gong, Y.J.; Yang, S.Y.; Hwang, S.T.; Jung, H.S.; Moon, H.; Koo, J.C.; Rodrigue, H.; Choi, H.R. Cooperative Antagonistic Mechanism Driven by Bidirectional Pneumatic Artificial Muscles for Soft Robotic Joints. Mechatronics 2024, 97, 103099. [Google Scholar] [CrossRef]

- Xi, Q.; Chen, Z.; Yin, K.; Liu, X.; Gao, F. Fault-Tolerant Gait for Hexapod Robots with Partial Active Joints Locked. Mech. Mach. Theory 2025, 205, 105895. [Google Scholar] [CrossRef]

- Bai, R.; Yang, N.; Qiu, Z.; Johnson, S.; Wu, K.; Li, B.; Chen, G. Achieving High-Quality and Large-Stroke Constant Torque by Axial Force Release. Mech. Mach. Theory 2025, 205, 105869. [Google Scholar] [CrossRef]

- Liu, X.; Li, G.; Xiang, F.; Tao, B.; Jiang, G. Blockchain-Based Cloud-Edge Collaborative Data Management for Human-Robot Collaboration Digital Twin System. J. Manuf. Syst. 2024, 77, 228–245. [Google Scholar] [CrossRef]

- Guo, J.; Li, Y.; Du, B.; Sun, X.; Wang, K. A Multi-Population Cooperative Coevolution Artificial Bee Colony Algorithm for Partial Multi-Robotic Disassembly Line Balancing Problem Considering Preventive Maintenance Scenarios. Adv. Eng. Inform. 2024, 62, 102750. [Google Scholar] [CrossRef]

- Mahmud, K.R.; Wang, L.; Hassan, S.; Zhang, Z. A Knowledge-Driven Framework for Robotic Odor Source Localization Using Large Language Models. Robot. Auton. Syst. 2025, 186, 104915. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, W.; Ge, S.S. Adaptive Fuzzy Fault-Tolerant Control via Integral Terminal Sliding Mode of Robotic Systems with Prescribed Performance. Asian J. Control 2025, 1–11, in press. [Google Scholar] [CrossRef]

- Sandini, G.; Sciutti, A.; Morasso, P. Collaborative Robots with Cognitive Capabilities for Industry 4.0 and Beyond. AI 2024, 5, 1858–1869. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, Q.; Hu, Y. Fault-Tolerant Trajectory Tracking Control of Underwater Salvage Robots Based on Super-Twisting Sliding Mode. Ocean Eng. 2024, 312, 119340. [Google Scholar] [CrossRef]

- Ai, X.; Chen, Y.-Y.; Yu, H. Adaptive Fault-Tolerant Formation Tracking Control of Networked Mobile Robots with Input Delays. J. Frankl. Inst. 2024, 361, 248–264. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Gedeon, T.; Valaskova, K.; Vrbka, J.; Šuleř, P.; Zvarikova, K.; Kramarova, K.; Rowland, Z.; Stehel, V.; Gajanova, L.; et al. Cognitive Digital Twin-Based Internet of Robotic Things, Multi-Sensory Extended Reality and Simulation Modeling Technologies, and Generative Artificial Intelligence and Cyber-Physical Manufacturing Systems in the Immersive Industrial Metaverse. Equilibrium. Q. J. Econ. Econ. Policy 2024, 19, 719–748. [Google Scholar] [CrossRef]

- Dalla Gasperina, S.; Ferrari, F.; Gandolla, M.; Pedrocchi, A.; Ambrosini, E. Hybrid Cooperative Control of Functional Electrical Stimulation and Robot Assistance for Upper Extremity Rehabilitation. IEEE Trans. Biomed. Eng. 2024, 71, 2642–2650. [Google Scholar] [CrossRef] [PubMed]

- Bofill, J.; Abisado, M.; Villaverde, J.; Sampedro, G.A. Exploring Digital Twin-Based Fault Monitoring: Challenges and Opportunities. Sensors 2023, 23, 7087. [Google Scholar] [CrossRef] [PubMed]

- Acvi, F. Effects of robotic module-supported experimental activities with the cooperative learning method on student achievement, 21st-century skills, and students’ opinions. J. Comput. Assist. Learn. 2024, 40, 2325–2338. [Google Scholar] [CrossRef]

- Song, Z.; Shi, H.; Bai, X.; Li, G. Digital Twin-Assisted Fault Diagnosis System for Robot Joints with Insufficient Data. J. Field Robot. 2023, 40, 258–271. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, D.; Ma, L.; Liu, X.; Li, Y. Adaptive Neural Fault-Tolerant Prescribed Performance Control of a Rehabilitation Exoskeleton for Lower Limb Passive Training. ISA Trans. 2024, 151, 143–152. [Google Scholar] [CrossRef]

- Carnevale, G.; Mimmo, N.; Notarstefano, G. Nonconvex Distributed Feedback Optimization for Aggregative Cooperative Robotics. Automatica 2024, 167, 111767. [Google Scholar] [CrossRef]

- Ebel, H.; Rosenfelder, M.; Eberhard, P. Cooperative Object Transportation with Differential-Drive Mobile Robots: Control and Experimentation. Robot. Auton. Syst. 2024, 173, 104612. [Google Scholar] [CrossRef]

- Khan, A.T.; Cao, X.; Li, S.; Hu, B.; Katsikis, V.N. Quantum Beetle Antennae Search: A Novel Technique for the Constrained Portfolio Optimization Problem. Sci. China Inf. Sci. 2021, 64, 152204. [Google Scholar] [CrossRef]

- Liu, C.; Filaretov, V.; Zuev, A.; Protsenko, A.; Zhirabok, A. Fault Tolerant Control in Underwater Vehicles. J. Mar. Sci. Eng. 2024, 12, 1836. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, J.; Yao, X. Event-Triggered Adaptive Fault-Tolerant Boundary Control for Flexible Bionic Fish Tail with Output Constraint. IEEE Robot. Autom. Lett. 2024, 9, 6384–6391. [Google Scholar] [CrossRef]

- Fang, X.; Cheng, R.; Cheng, S.; Fan, Y. Nonsingular Fixed-Time Fault-Tolerant Sliding Mode Control of Robot Manipulator with Disturbance Observer. Int. J. Control Autom. Syst. 2024, 22, 2182–2192. [Google Scholar] [CrossRef]

- Khan, A.T.; Cao, X.; Brajevic, I.; Stanimirovic, P.S.; Katsikis, V.N.; Li, S. Non-Linear Activated Beetle Antennae Search: A Novel Technique for Non-Convex Tax-Aware Portfolio Optimization Problem. Expert Syst. Appl. 2022, 197, 116631. [Google Scholar] [CrossRef]

| Feature | PFTC | AFTC |

|---|---|---|

| Complexity | Low computational load | High demands due to real-time adaptation |

| Adaptability | Limited to predefined faults | Dynamic response to unforeseen faults |

| Implementation Cost | Lower (simpler design) | Higher (sensors, algorithms) |

| Response Time | Immediate, static | Sub-0.1 s [27] |

| Validation | 85% uptime [19], underwater resilience [24] | 95% efficiency [32] |

| Method | Accuracy | Response Time | Computational Load | Validation |

|---|---|---|---|---|

| Neural-Adaptive | ~94% | <50 ms [11], sub-0.017 s [18] | High (GPU-accelerated) | 98% resilience [17] |

| Gain Scheduling | ≥90% | <100 ms [33], sub-0.1 s [27] | Moderate (Field Programmable Gate Arrays (FPGAs)-based) | 98% resilience [8], 95% efficiency [15] |

| Strategy | Advantages | Limitations |

|---|---|---|

| Dual Actuators | 92% capacity [35] | Weight, cost, scalability issues [3] |

| HRA (Tensegrity) | 70–80% capacity [3], 85% uptime [14] | Complex fabrication, energy needs [14] |

| Modular Structures | 85% tolerance [21], sub-0.08 mm precision [32] | Integration complexity [38] |

| Approach | Advantages | Drawbacks |

|---|---|---|

| Model Predictive Control | 94% accuracy [43] | GPU-dependent [29] |

| Fuzzy Logic | 91% drop reduction [30], 85% uptime [14] | Scalability limits [39] |

| Neural Adaptive | 94% accuracy [11] | High GPU needs [27] |

| Reinforcement Learning | 90% recovery [28], 98% resilience [17] | Safety risks [13] |

| Hybrid AI | 95% efficiency [41], 98% resilience [8] | 20–30% overhead [42] |

| Approach | Advantages | Drawbacks | Applications |

|---|---|---|---|

| Neural-Adaptive | 94% accuracy [11] | GPU-intensive [27] | Surgery [13], HRC [40] |

| Reinforcement Learning | 90% recovery [28], high resilience [17] | Exploration risks [13] | Swarms [8], agriculture [9] |

| Aspect | Advantages | Challenges |

|---|---|---|

| Mechanical | High uptime [14], 92% capacity [35] | High costs, 20% weight [3] |

| Electronic | High detection accuracy [40] | Computational spikes [10] |

| Coordination | Improved resilience [8] | 15% latency [44] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urrea, C. Hybrid Fault-Tolerant Control in Cooperative Robotics: Advances in Resilience and Scalability. Actuators 2025, 14, 177. https://doi.org/10.3390/act14040177

Urrea C. Hybrid Fault-Tolerant Control in Cooperative Robotics: Advances in Resilience and Scalability. Actuators. 2025; 14(4):177. https://doi.org/10.3390/act14040177

Chicago/Turabian StyleUrrea, Claudio. 2025. "Hybrid Fault-Tolerant Control in Cooperative Robotics: Advances in Resilience and Scalability" Actuators 14, no. 4: 177. https://doi.org/10.3390/act14040177

APA StyleUrrea, C. (2025). Hybrid Fault-Tolerant Control in Cooperative Robotics: Advances in Resilience and Scalability. Actuators, 14(4), 177. https://doi.org/10.3390/act14040177