Study on the Vibration Characteristics of Separated Armature Assembly in an Electro-Hydraulic Servo Valve Under Interference Fit

Abstract

1. Introduction

2. Armature Assembly

2.1. Geometry Model of Armature Assembly

2.2. Dynamic Model of Armature Assembly Under Prestressed Condition

3. Modal Analysis of Interference Connected Assembly

3.1. Scheme A: Setting of Bonded Contact

3.2. Scheme B: Setting of Friction Contact

3.3. Scheme C: Setting of Bonded Contacts with the Condition of Node Coupling

- (1)

- Modeling: The model is created using NX10.0 software and imported into HyperMesh software 2021 in stp format.

- (2)

- Unit type and material properties definition: The unit type is set as solid186, and the material properties are set according to Table 1.

- (3)

- Operation of armature assembly geometry model: Boolean operations are performed between the armature and spring tube, the spring tube and flapper, as well as the flapper and feedback spring. These operations serve a similar purpose as the shared topology function in Workbench.

- (4)

- Tetrahedral mesh division is used throughout the component. The mesh size for the armature is set as 0.4 mm; spring tube mesh size is 0.3 mm with thin wall encryption applied; flapper mesh size is 0.2 mm; feedback spring mesh size is also 0.2 mm.

- (5)

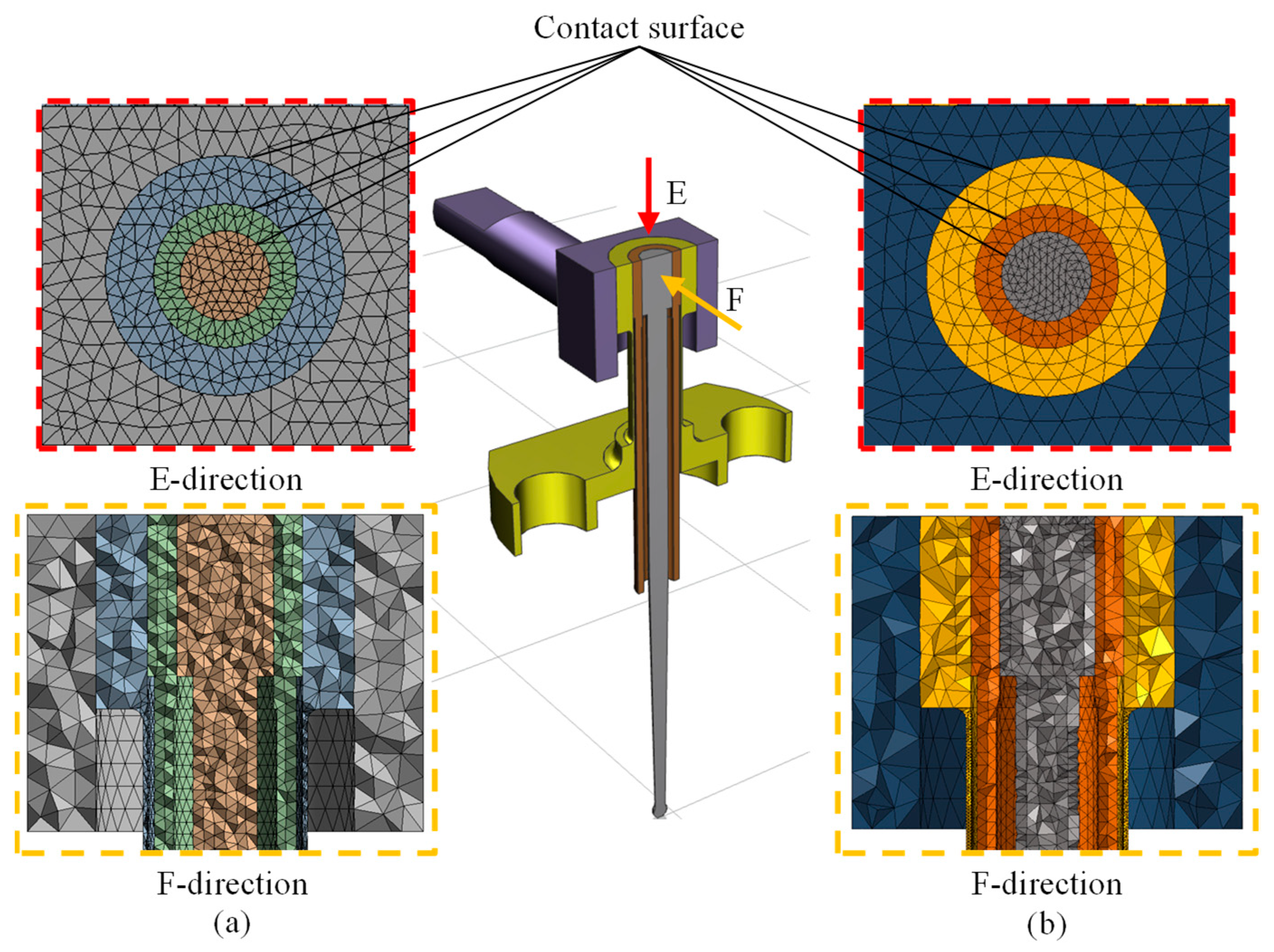

- Shared nodes separation: Using the detach function, boolean parts are separated into two so that shared nodes belong to two different parts while maintaining their original positions. This allows for node sharing while keeping both parts independent. If the contact surface nodes are not separated, they default to being part of a whole entity which prevents proper contact setting from being achieved, the meshed result is shown in Figure 2b.

- (6)

- Format conversion: Mesh generated by HyperMesh software 2021 is exported then converted into Mechanical APDL Product format before importing it back into Workbench software 2021R1.

- (7)

- The solver continues to utilize the Workbench software 2021R1. Bonded contact is employed for the interaction between the armature, spring tube, flapper, and feedback spring. A fixed constraint is applied to the bottom surface of the spring tube, and results of first-order mode to fourth-order mode are analyzed.

3.4. Scheme D: Frictional Contact Under Node Coupling Conditions

4. Modal Analysis Results and Comparative Analysis

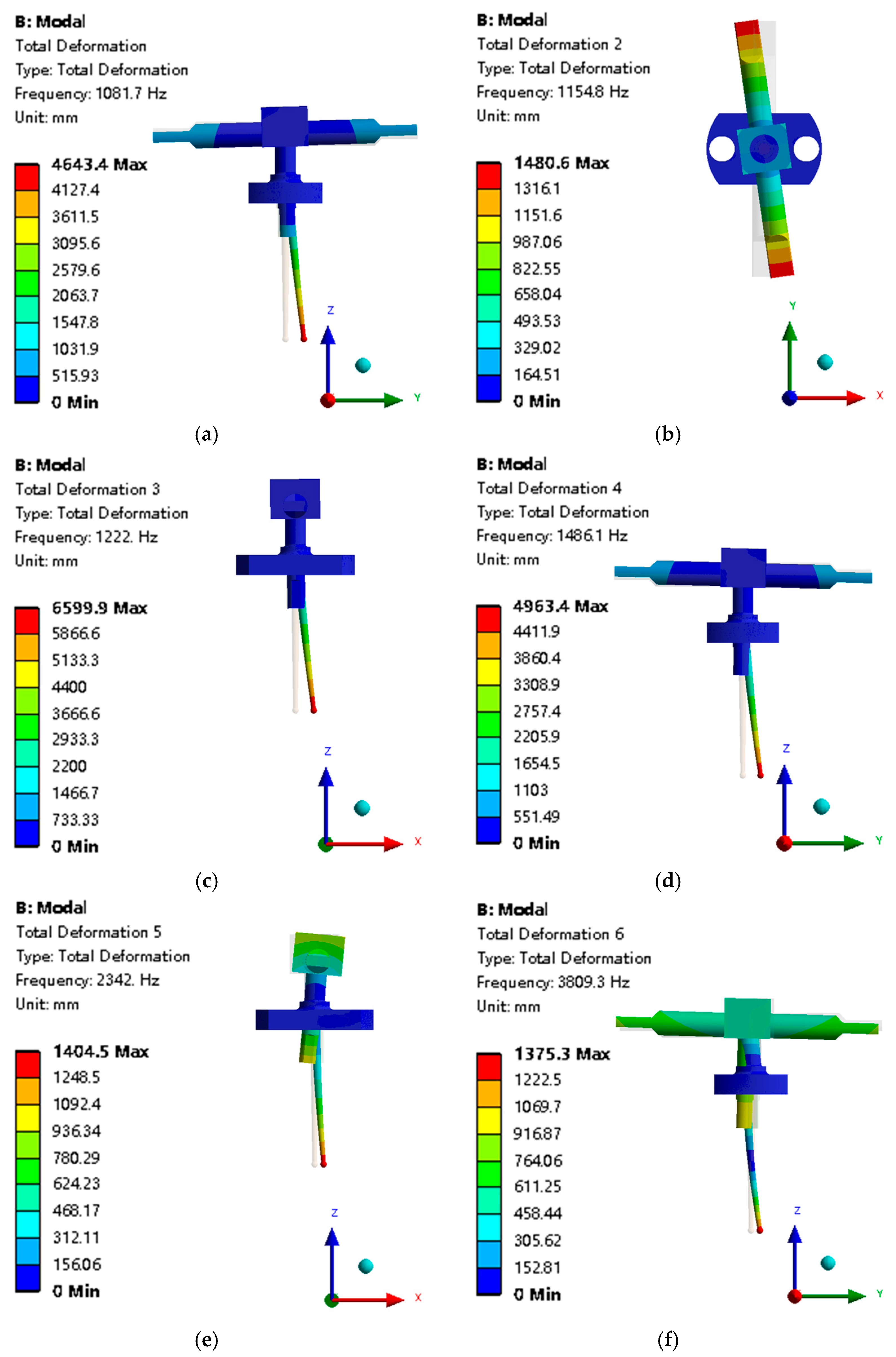

4.1. Modal Analysis Results of Different Schemes

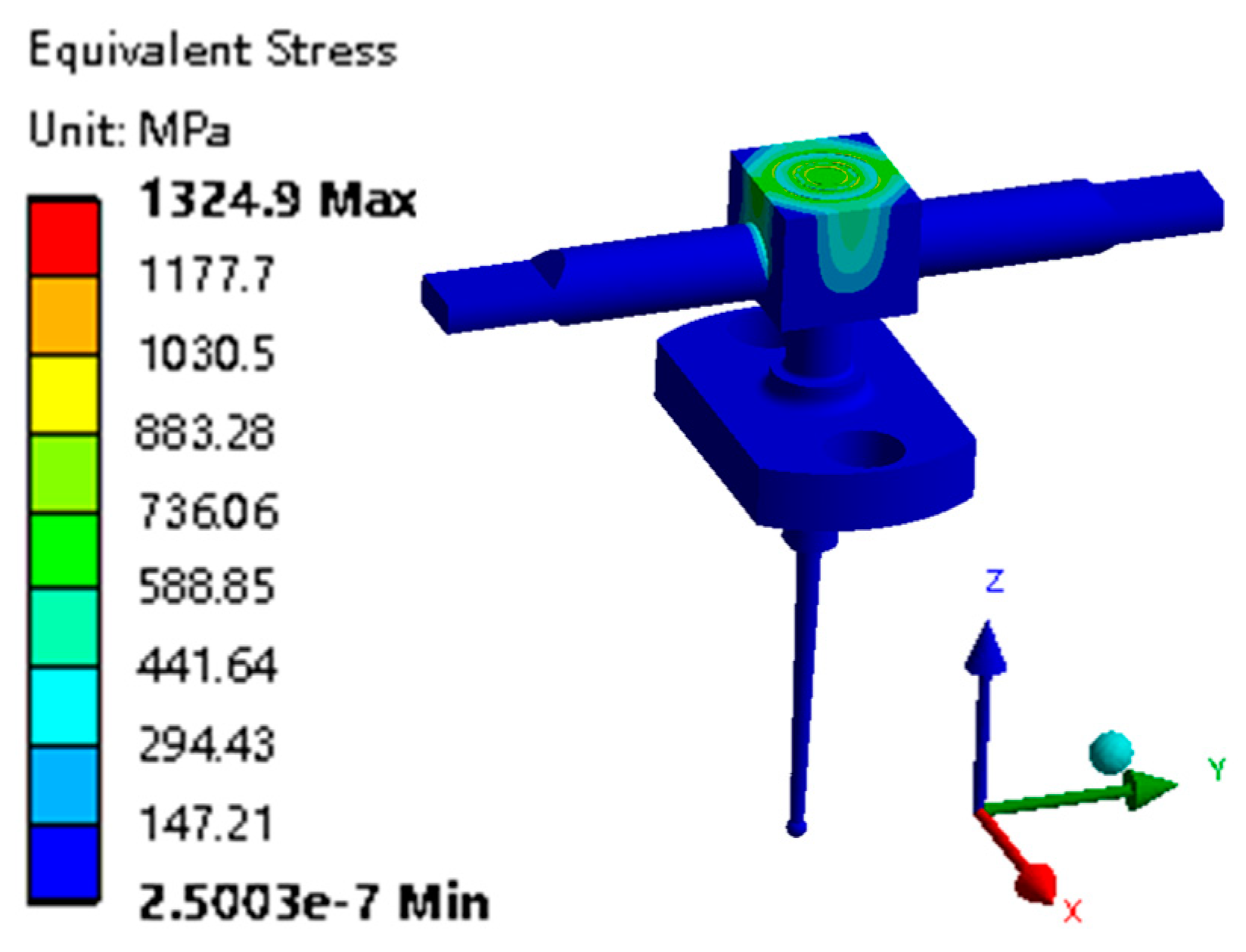

4.2. Static Structural Analysis of Armature Assembly

4.3. Modal Analysis of Armature Assembly

4.4. Verification of Modal Experiments

4.5. Influence of Interference on Modal Analysis Results

5. Precautions for the Design of Servo Valves

- (1)

- For a separated armature assembly, while ensuring compliance with the assembly’s stiffness requirements, the natural frequency of the armature assembly can be altered by modifying the structure or adjusting the interference fit.

- (2)

- While ensuring the fundamental functionality of the pilot stage of the servo valve, it is possible to modify the flow field structure to alter the frequency and amplitude of pressure pulsations. This adjustment helps to prevent the coupling of the pressure pulsation frequency with the natural frequency of the armature assembly, thereby reducing the likelihood of self-excited oscillations in the servo valve and enhancing its overall performance.

6. Conclusions

- (1)

- Due to the interference connection between the parts of the separated armature assembly, prestress is present and cannot be ignored. The method of bonded contact simplification in modal simulation analysis is unscientific. Whether the contact surface has common nodes or not has little influence on the modal simulation results.

- (2)

- The electric drive method is used to provide sweeping frequency signals to the armature assembly, and the natural frequencies of first-order and fourth-order modes of the armature assembly are obtained by the resonance principle, which verifies the feasibility of the simulation.

- (3)

- Interference has an effect on the modes of the armature assembly. With the increase in interference, the natural frequency corresponding to the first, third, and fourth modes of the armature assembly, all decrease with increasing interference, but the change is little, while the natural frequency corresponding to the second mode gradually decreases.

- (4)

- In the design of a servo valve with a separable armature assembly, while ensuring the fundamental functionality of the servo valve, it is possible to enhance its performance through two approaches. On the one hand, the natural frequency of the armature assembly can be modified by altering its structure or adjusting the interference fit. On the other hand, the frequency and amplitude of pressure pulsations can be changed by modifying the flow field structure. These adjustments help to prevent the coupling of the pressure pulsation frequency with the natural frequency of the armature assembly, thereby reducing the likelihood of self-excited oscillations in the servo valve and improving its overall performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aung, N.Z.; Li, S. A numerical study of cavitation phenomenon in a flapper-nozzle pilot stage of an electrohydraulic servo-valve with an innovative flapper shape. Energy Convers. Manag. 2014, 77, 31–39. [Google Scholar] [CrossRef]

- Zhang, S.; Aung, N.Z.; Li, S. Reduction of undesired lateral forces acting on the flapper of a flapper–nozzle pilot valve by using an innovative flapper shape. Energy Convers. Manag. 2015, 106, 835–848. [Google Scholar] [CrossRef]

- Glaun, A. Avoiding flow-induced Sympathetic vibration in control valves. Power 2012, 156, 80–83. [Google Scholar]

- Peng, J.; Li, S.; Han, H. Damping properties for vibration suppression in electrohydraulic servo-valve torque motor using magnetic fluid. Appl. Phys. Lett. 2014, 104, 171905. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, J.; Wen, T. A Modified Transfer Matrix Method for Modal Analysis of Stepped Rotor Assembly Applied in the Turbomolecular Pump. Shock. Vib. 2022, 2022, 3692081. [Google Scholar] [CrossRef]

- Kim, K.K.; Lee, Y.S. Modal characteristics according to the tip shape and assembly condition of the turbine blade. J. Mech. Sci. Technol. 2013, 27, 3409–3417. [Google Scholar] [CrossRef]

- Zhai, L.; Han, B.; Zhang, Y.; Ye, X.; Sun, M. A Modal Analysis Method for Turbomolecular Pump Rotor Assembly with Separable Thrust Disk. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Republic of Korea, 7–10 October 2018; pp. 2561–2564. [Google Scholar] [CrossRef]

- Daouk, S.; Louf, F.; Cluzel, C.; Dorival, O.; Champaney, L. Variability of a bolted assembly through an experimental modal analysis. In Model Validation and Uncertainty Quantification, Volume 3: Proceedings of the 33rd IMAC, A Conference and Exposition on Structural Dynamics, 2015; Springer International Publishing: Cham, Switzerland, 2015; pp. 171–178. [Google Scholar] [CrossRef]

- Yang, B.; Li, D.; Yang, H.; Hu, Y.; Yang, P. Vibrational fatigue and reliability of package-on-package stacked chip assembly. Microelectron. J. 2019, 92, 104609. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, D.W.; Shi, Y.G.; Sun, Z.H. Research on the Effect of Pre-Stress on Bending Stiffness of the Ball Screw Based on ANSYS. Adv. Mater. Res. 2013, 690–693, 1784–1787. [Google Scholar] [CrossRef]

- Feron, J.; Latteur, P. Implementation and propagation of prestress forces in pin-jointed and tensegrity structures. Eng. Struct. 2023, 289, 116152. [Google Scholar] [CrossRef]

- Yang, H.; Xu, J.; Wang, G.; Yang, Z.; Li, Q. Prestress Modal Analysis and Optimization of Cantilever Supported Rotor under the Unbalanced Axis Force and Moving Mass. Appl. Sci. 2022, 12, 4940. [Google Scholar] [CrossRef]

- Orlowska, A.; Graczykowski, C.; Galezia, A. The effect of prestress force magnitude on the natural bending frequencies of the eccentrically prestressed glass fibre reinforced polymer composite beams. J. Compos. Mater. 2018, 52, 2115–2128. [Google Scholar] [CrossRef]

- Hu, Y.; Xie, Y.; Peng, R.; Zhang, S. Modal Analysis of Rail Transit Gearbox. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 267, p. 042055. [Google Scholar] [CrossRef]

- Wang, Y. Lightweight steering equipment based on prestressed modal analysis. J. Vibroeng. 2024, 26, 370–382. [Google Scholar] [CrossRef]

- Li, T.; Li, M.; Zhou, L.; Wang, H.; Hu, W.; Zhang, X. Mechanical Property and Sealing Performance Analysis of the Diaphragm Compressor Cylinder Head for the Hydrogen Refueling Station Under the Mutation Impact Load; Tech Science Press: Henderson, NV, USA, 2023. [Google Scholar] [CrossRef]

- Liu, F.; Gong, R.; Duan, Z.; Wang, Z.; Zhou, J. Research on vibration reliability of solder joint based on modal experiment of PCBA. J. Mater. Sci. Mater. Electron. 2025, 36, 43. [Google Scholar] [CrossRef]

- Huang, Z.; Fang, J.; Wang, K. Dynamics of flexible rotor-shaft assembly with consideration of contact behaviors. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 859–868. [Google Scholar] [CrossRef]

- Liu, G.; Hong, J.; Wu, W.; Sun, Y. Investigation on the influence of interference fit on the static and dynamic characteristics of spindle system. Int. J. Adv. Manuf. Technol. 2018, 99, 1953–1966. [Google Scholar] [CrossRef]

- Fan, Y.; Ding, H.; Li, M.; Li, J. Modal Analysis of a Thick-Disk Rotor with Interference Fit Using Finite Element Method. Math. Probl. Eng. 2018, 2018, 5021245. [Google Scholar] [CrossRef]

- Ce, R.; He, Z.; Li, D.; Yang, Z.; Xue, G. Dynamic Modeling and Analysis of Stack Giant Magnetostrictive Actuator. Sens. Actuators A Phys. 2018, 276, 205–218. [Google Scholar] [CrossRef]

- Peng, J.; Fan, Y.; Li, S. Modeling of armature-flapper assembly in a hydraulic servo valve by finite element analysis and acoustic excitation measurements. In Proceedings of the 2015 International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015; pp. 301–306. [Google Scholar] [CrossRef]

- Peng, J.; Zhang, Y.; Li, S.; Bao, W.; Tanaka, Y. Identification Algorithm and Improvement of Modal Damping Ratios for Armature Assembly in a Hydraulic Servo-Valve with Magnetic Fluid. Energies 2023, 16, 3419. [Google Scholar] [CrossRef]

| Part | Armature | Spring Tube | Flapper | Feedback Spring |

|---|---|---|---|---|

| Materials | 1J50 | QBe1.9 | 3J1 | 3J1 |

| Density (kg/m3) | 8200 | 8230 | 8000 | 8000 |

| Young’s Modulus (GPa) | 157 | 125 | 190 | 190 |

| Poisson’s Ratio | 0.3 | 0.35 | 0.3 | 0.3 |

| Yield strength (MPa) | 685 | 1035 | 882 | 882 |

| Simulation Plan | Plan A | Plan B | Plan C | Plan D |

|---|---|---|---|---|

| Calculated f1 (Hz) | 1093.8 | 1081.7 | 1104.7 | 1090.4 |

| Measured f1 (Hz) | 991 | 991 | 991 | 991 |

| Error (%) | 10.37% | 9.15% | 11.47% | 10.03% |

| Simulation Plan | Plan A | Plan B | Plan C | Plan D |

|---|---|---|---|---|

| Calculated f4 (Hz) | 1479.2 | 1486.1 | 1483.6 | 1489.4 |

| Measured f4 (Hz) | 1572.4 | 1572.4 | 1572.4 | 1572.4 |

| Error (%) | 5.93% | 5.49% | 5.65% | 5.28% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Peng, J.; Li, S.; Zhang, J.; Zhang, A. Study on the Vibration Characteristics of Separated Armature Assembly in an Electro-Hydraulic Servo Valve Under Interference Fit. Actuators 2025, 14, 98. https://doi.org/10.3390/act14020098

Li T, Peng J, Li S, Zhang J, Zhang A. Study on the Vibration Characteristics of Separated Armature Assembly in an Electro-Hydraulic Servo Valve Under Interference Fit. Actuators. 2025; 14(2):98. https://doi.org/10.3390/act14020098

Chicago/Turabian StyleLi, Tong, Jinghui Peng, Songjing Li, Juan Zhang, and Aiying Zhang. 2025. "Study on the Vibration Characteristics of Separated Armature Assembly in an Electro-Hydraulic Servo Valve Under Interference Fit" Actuators 14, no. 2: 98. https://doi.org/10.3390/act14020098

APA StyleLi, T., Peng, J., Li, S., Zhang, J., & Zhang, A. (2025). Study on the Vibration Characteristics of Separated Armature Assembly in an Electro-Hydraulic Servo Valve Under Interference Fit. Actuators, 14(2), 98. https://doi.org/10.3390/act14020098